Page 1

Instructions for the following series products:

Sayine™ Multi-Span Wire Rope

Horizontal Lifeline

(See inside back page for specic model numbers.)

User Instruction Manual

Sayine™ Multi-span Wire Rope Horizontal Lifeline

This manual is intended to meet the Manufacturer’s Instructions requirement of applicable standards dened in

Section 1.2 and should be used as part of an employee training program as required by the identied agencies.

WARNING: This product is part of a fall protection system. The users must read and follow the

manufacturer’s instructions for each component of the system. These instructions must be provided to the

users of this equipment. The users must read and understand these instructions before using this equipment.

Manufacturer’s instructions must be followed for proper use and maintenance of this product. Alterations or

misuse of this product, or failure to follow instructions, may result in serious injury or death.

IMPORTANT: If you have questions on the use, care, or suitability of this equipment for your application,

contact 3M Fall Protection.

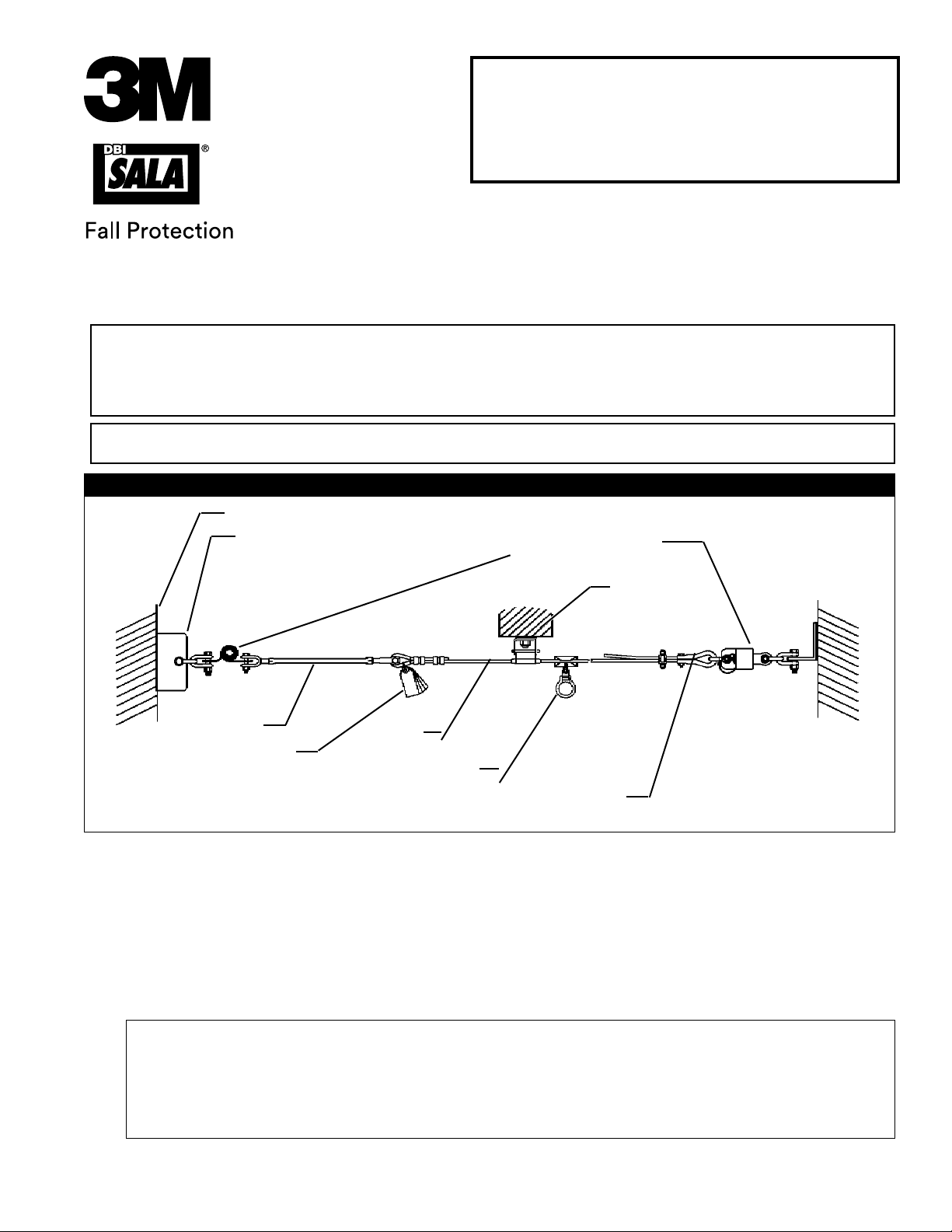

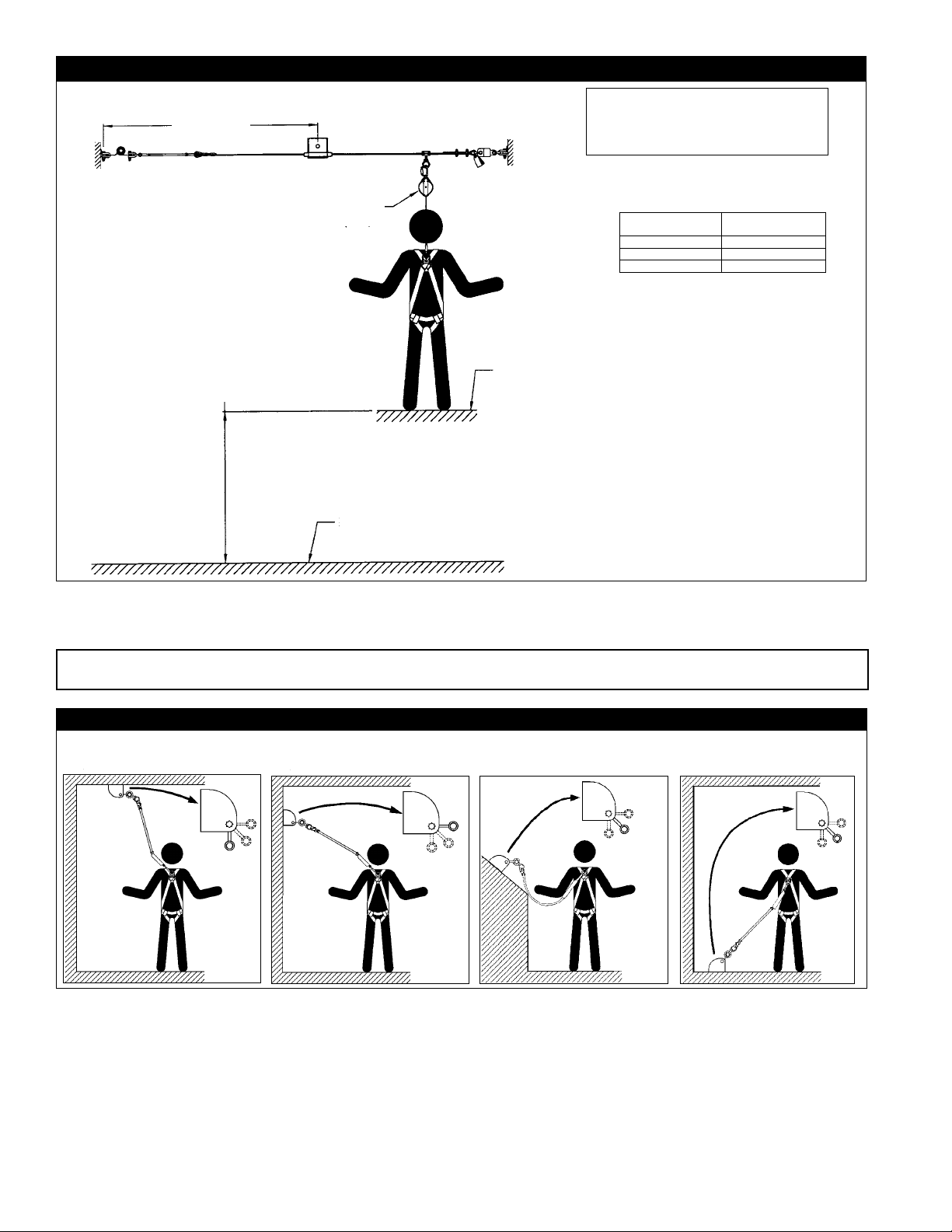

Figure 1 - Typical Sayine™ Multi-span Wire Rope Horizontal Lifeline System

Anchorage

Anchorage Connector

(Supplied by customer)

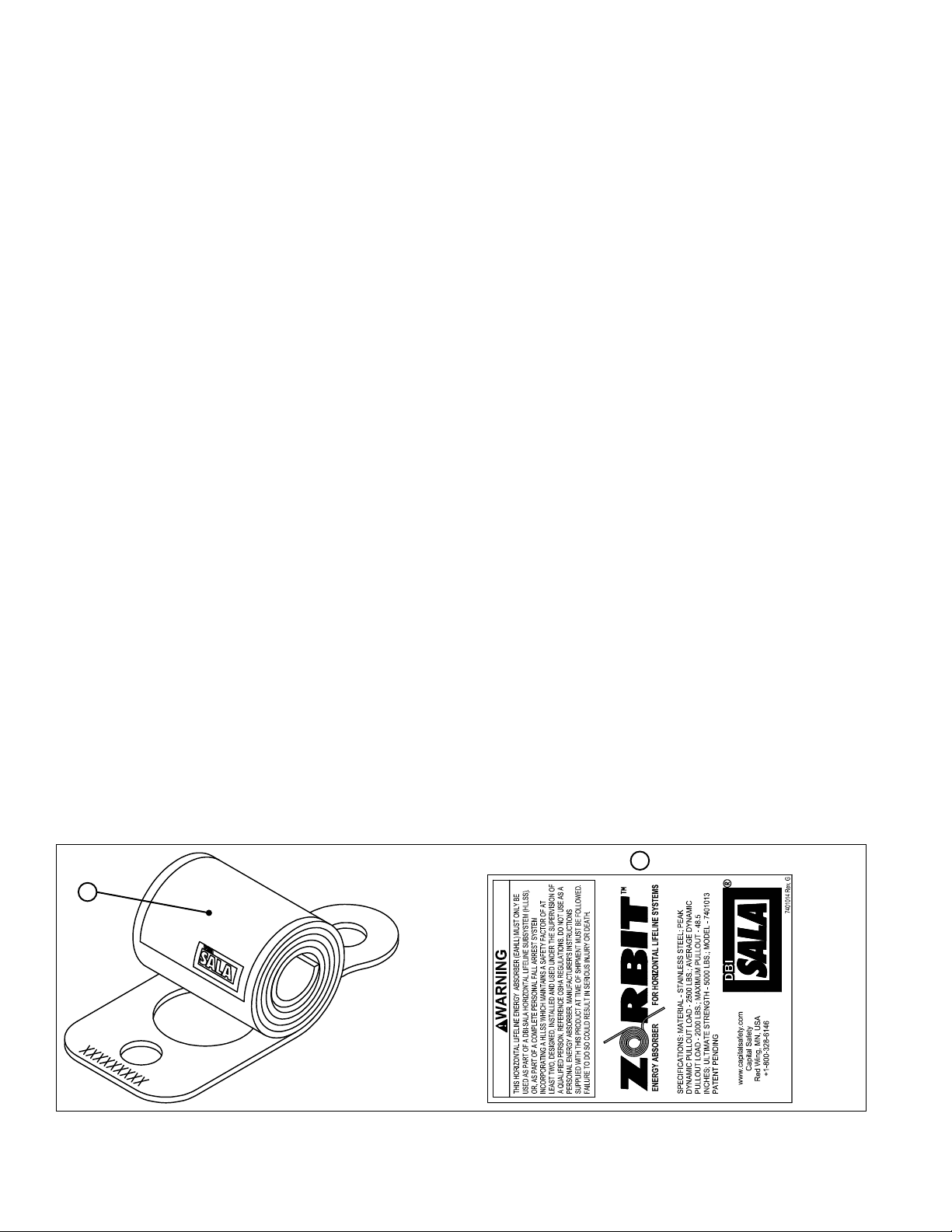

Zorbit HLL Energy

Absorber

Intermediate

Bracket

Turnbuckle

Labels

Cable

Sayink Sleeve

Thimble/Cable Clip

End Termination

1.0 APPLICATION

1.1 PURPOSE: The Sayine Multi-span Wire Rope Horizontal Lifeline System is designed for use as an anchoring

means for one or two personal fall arrest system (PFAS) or fall restraint system. Use the Sayine Horizontal

Lifeline (HLL) where horizontal mobility and fall protection is required. The Sayine Horizontal Lifeline may

not be used for fall protection of material or equipment.

1.2 LIMITATIONS: The following limits apply to the installation and use of Sayine Multi-span Wire Rope

Horizontal Lifeline System. Other limitations may apply:

IMPORTANT: The employer must ensure that each horizontal lifeline is designed, installed, and used under the

supervision of a qualied person; and is part of a complete personal fall arrest system that maintains a safety factor of

at least two. Reference OSHA 1010.140 (c) (11). See also OSHA 1926.502 (d)(8).

QUALIFIED PERSON: Qualied describes a person who, by possession of a recognized degree, certicate, or

professional standing, or who by extensive knowledge, training, and experience has successfully demonstrated the

ability to solve or resolve problems relating to the subject matter, the work, or the project. Reference OSHA 1910.140

(b). See also OSHA 1926.32 (m).

FORM NO: 5902167

REV: F

© 3M 2018

1

Page 2

A. HORIZONTAL LIFELINE SPAN: The maximum horizontal lifeline total length is 180 ft. (55 m) with a

Zorbit HLL energy absorber installed on each end of the system. See Figure 1. Systems that are more

than 30 ft. (9 m) in length must include an intermediate bracket for every 30 ft. span (9 m). The span

length must be reduced when clearance is limited. See section 3.3 for clearance information.

B. ANCHORAGES: The Sayine horizontal lifeline must be installed on anchorages that meet the

requirements specied in section 2.5.

C. SYSTEM CAPACITY: The maximum capacity of the Sayine horizontal lifeline is two persons. The

maximum weight of each person, including tools and clothing, is 310 lbs (141 kg).

D. CONNECTING SUBSYSTEM: Each person’s connecting subsystem must limit fall arrest forces to 900

lbs. (4 kN) or less. See section 2.6.

E. FREE FALL: Rig and use the personal fall arrest system such that the maximum potential free fall does

not exceed government regulatory and subsystem manufacturer’s requirements. The personal fall arrest

system must be rigged to limit free falls to six feet or less when using an energy absorbing lanyard, or

such that the SRL is overhead and without slack, according to OSHA requirements. See section 3.0 and

subsystem manufacturer’s instructions for more information.

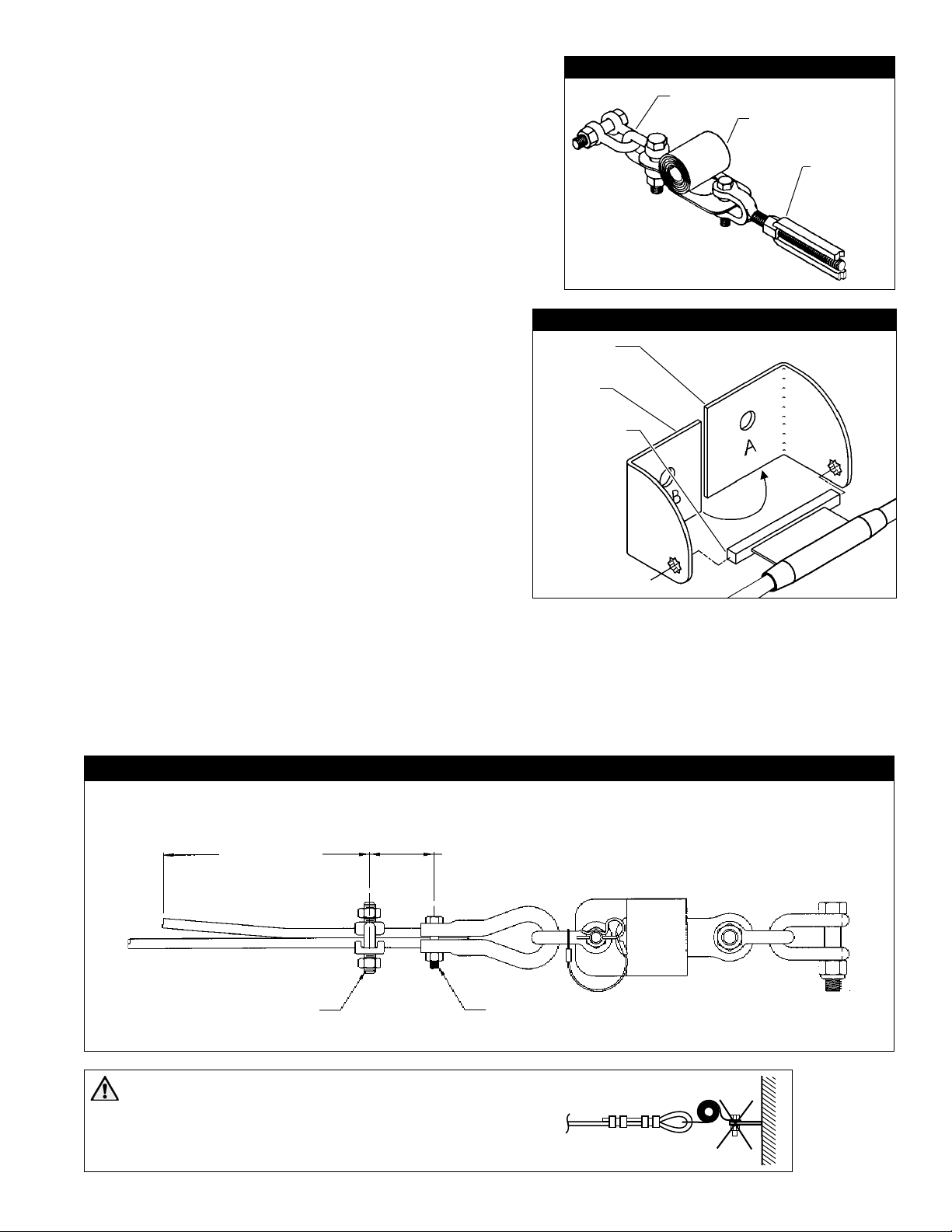

F. SWING FALLS: See Figure 2. Swing falls occur when the

anchorage point is not directly overhead. The force of striking an

object in a swing fall may cause serious injury or death. Minimize

swing falls by working as directly below the anchorage point as

possible. Do not permit a swing fall if injury could occur. Swing

falls will signicantly increase the clearance required when a self

retracting lifeline or other variable length connecting subsystem

is used. If a swing fall situation exists in your application, contact

3M Fall Protection before proceeding.

G. FALL CLEARANCE: There must be sufcient clearance below

the worker to arrest a fall before striking the lower level or

obstruction. See section 3.3 for required clearance information.

H. BODY SUPPORT: Sayine Multi-span Wire Rope Horizontal

Lifelines must only be used with personal fall arrest systems

incorporating a full body harness.

I. PHYSICAL AND ENVIRONMENTAL HAZARDS: Use of this equipment in areas with physical or

environmental hazards may require additional precautions to reduce the possibility of injury to the user

or damage to the equipment. Hazards may include, but are not limited to; heat, chemicals, corrosive

environments, high voltage power lines, gases, moving machinery, and sharp edges. Contact 3M Fall

Protection if you have questions about using this equipment where physical or environmental hazards

exist.

J. TRAINING: This equipment must be installed and used by persons trained in the correct application

and use of this equipment. See section 5.0.

Figure 2 - Swing Falls

1.3 APPLICABLE STANDARDS: Refer to national standards, including ANSI Z359.1-1992, and local, state, and

federal (OSHA 1910.66 and 1926.502) requirements for more information on personal fall arrest systems

and associated components.

2.0 SYSTEM REQUIREMENTS

2.0YSTEM REQUIREMENTS

2.1 PERSONAL FALL ARREST SYSTEM COMPONENTS: The Sayine horizontal lifeline must be used with 3M

Fall Protection approved components and subsystems. Non-approved components may be incompatible, and

could affect the safety and reliability of the complete system. Personal fall arrest components used with this

system must meet all applicable OSHA and ANSI requirements. A full body harness must be used with this

system. The connecting subsystem between the harness and horizontal lifeline must limit fall arrest forces to

900 lbs. or less.

2.2 COMPATIBILITY OF CONNECTORS: Connectors are considered to be compatible with connecting

elements when they have been designed to work together in such a way that their sizes and shapes do not

cause their gate mechanisms to inadvertently open regardless of how they become oriented. Contact 3M Fall

Protection if you have any questions about compatibility.

2

Page 3

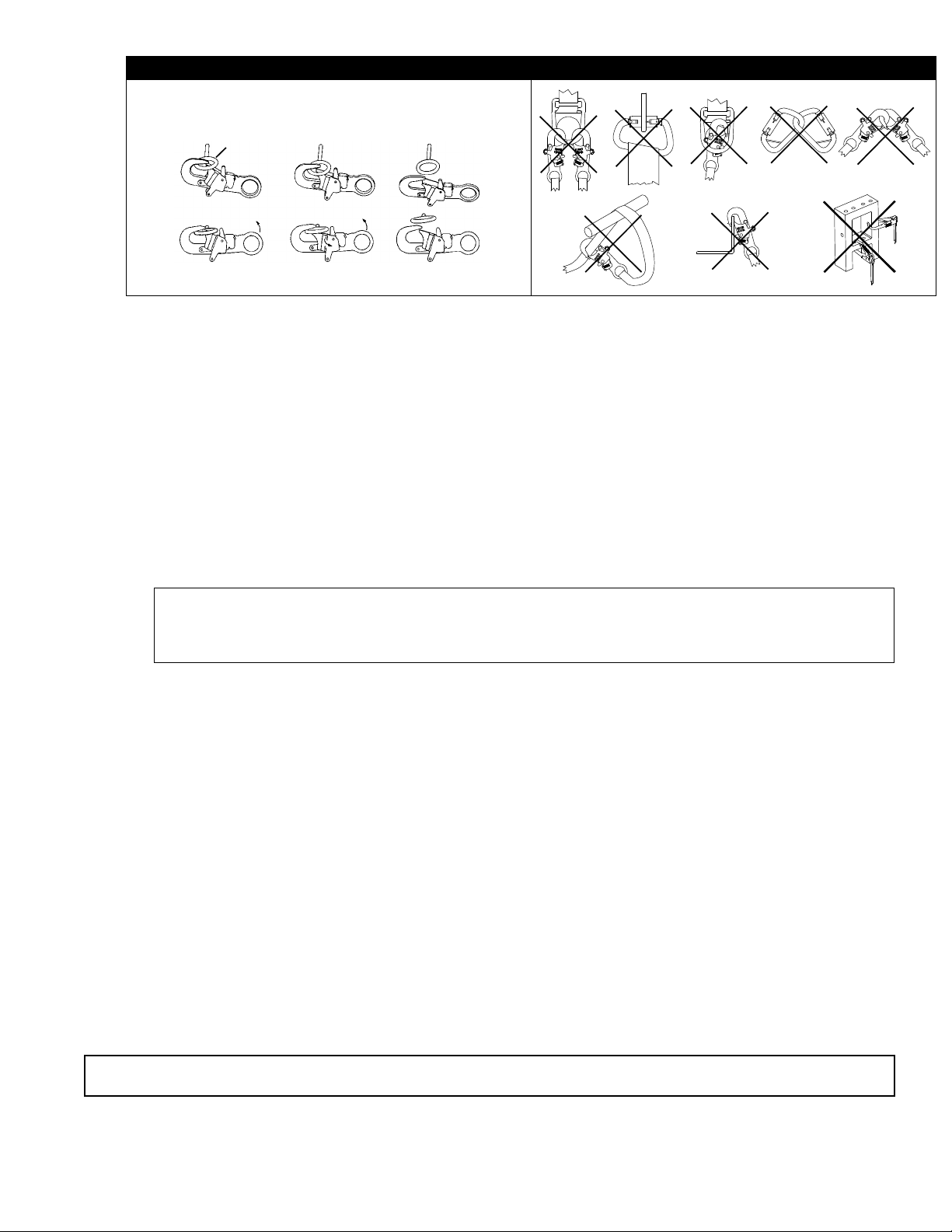

Figure 3 - Unintentional Disengagement Figure 4 - Inappropriate Connections

If the connecting element to which a snap hook (shown) or carabiner attaches

is undersized or irregular in shape, a situation could occur where the connecting

element applies a force to the gate of the snap hook or carabiner. This force may

cause the gate (of either a self-locking or a non-locking snap hook) to open,

allowing the snap hook or carabiner to disengage from the connecting point.

Small ring or other

non-compatibly

shaped element

A. B. C. D.

E. F. G.

Force is applied to the

Snap Hook.

The Gate presses against

the Connecting Ring.

The Gate opens allowing

the Snap Hook to slip off.

Connectors (hooks, carabiners, and D-rings) must be capable of supporting at least 5,000 lbs. (22kN).

Connectors must be compatible with the anchorage or other system components. Do not use equipment

that is not compatible. Non-compatible connectors may unintentionally disengage. See Figure 3. Connectors

must be compatible in size, shape, and strength. Self locking snap hooks and carabiners are required by

ANSI Z359.1 and OSHA.

2.3 MAKING CONNECTIONS: Only use self-locking snap hooks and carabiners with this equipment. Only use

connectors that are suitable to each application. Ensure all connections are compatible in size, shape and

strength. Do not use equipment that is not compatible. Ensure all connectors are fully closed and locked.

3M Fall Protection connectors (snap hooks and carabiners) are designed to be used only as specied in each

product’s user’s instructions. See Figure 4 for inappropriate connections. 3M Fall Protection snap hooks and

carabiners should not be connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

NOTE: Large throat opening snap hooks should not be connected to standard size D-rings or similar

objects which will result in a load on the gate if the hook or D-ring twists or rotates. Large throat snap

hooks are designed for use on xed structural elements such as rebar or cross members that are not

shaped in a way that can capture the gate of the hook.

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the

anchor and without visual conrmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the

lanyard and connector specically allow such a connection).

F. To any object which is shaped or dimensioned such that the snap hook or carabiner will not close and

lock, or that roll-out could occur.

G. n a manner that does not allow the connector to align properly while under load.

2.4 ANCHORAGE CONNECTORS: 3M Fall Protection does not supply anchorage fasteners. Connectors used to

attach the horizontal lifeline to end anchors must be compatible with the connection point. The connection

must be positive; and, with connecting elements, capable of sustaining a 5,000 lb. (22 kN) load without

failure.

The intermediate brackets require a 1/2-13 UNC bolt meeting SAE Grade 5 strength minimum. A at washer,

lock washer and a nut are also required. A locking nut may be used in place of the lock washer and plain

nut.

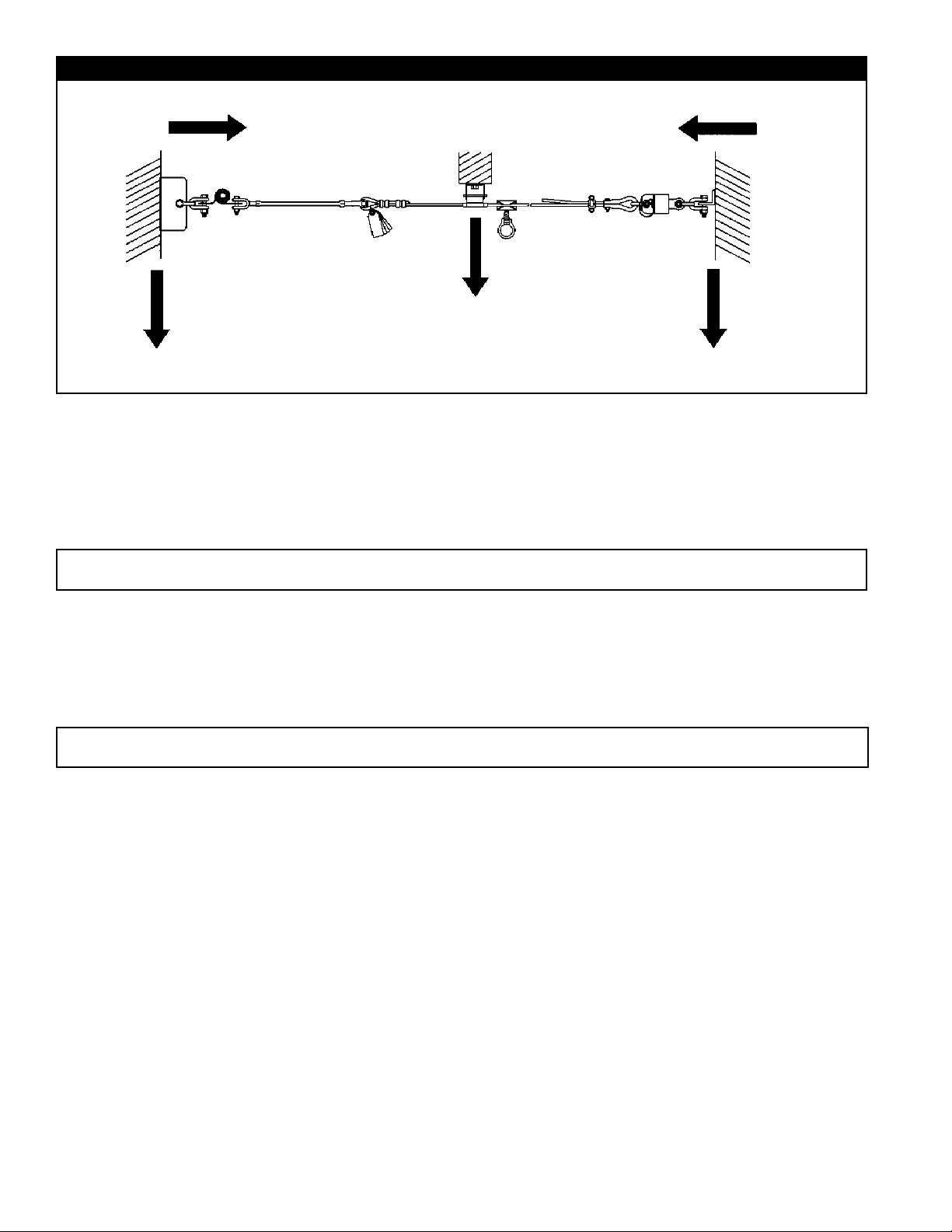

2.5 STRUCTURE LOAD: Structural anchorage points must be rigid, and capable of supporting at least 5,000

lbs. (22 kN) along the axis of the horizontal lifeline. Anchorages, including the intermediate brackets, must

also support at least 3,600 lbs. (16 kN) applied in all potential directions of fall arrest that are perpendicular

to the axis of the horizontal lifeline. See Figure 5.

WARNING: Anchorages must be rigid. Large deformations of the anchorage will affect system performance, and

may increase the required fall clearance below the system, which could result in serious injury or death.

2.6 CONNECTING SUBSYSTEM: The connecting subsystem is the portion of the personal fall arrest system

that is used to connect between the horizontal lifeline subsystem and harness fall arrest attachment

element. The connecting subsystem must limit forces applied to the horizontal lifeline to 900 lbs. (4 kN) or

less.

3

Page 4

Figure 5 - Anchorage Strength

5,000 lbs Minimum

(22 kN Minimum)

3,600 lbs Minimum

(16 kN Minimum)

3,600 lbs (16 kN) Minimum

(in all potential direction of fall arrest applied loading)

5,000 lbs Minimum

(22 kN Minimum)

3,600 lbs Minimum

(16 kN Minimum)

3.0 INSTALLATION

3.1 Inspection

Upon receipt of the Sayine Horizontal Lifeline System, inspect all components and user equipment for

defects and/or damage. If any Sayine components or 3M Fall Protection equipment are found to be

damaged, defective, or missing, contact 3M Fall Protection immediately for replacements. Do not use any

defective or damaged parts in a Sayine Horizontal Lifeline System installation.

WARNING: Use of defective or damaged parts will hinder the performance of the Sayine system, potentially

causing serious injury or death in the event of a fall.

3.2 Safety

A separate means of fall protection must be utilized during the installation of a Sayine System. A separate

means of fall protection must be used when inspecting or servicing a Sayine System following a fall.

3M Fall Protection recommends the use of certied eye protection, steel toe boots and gloves be worn during

the installation of the horizontal lifeline system.

WARNING: Do not alter or intentionally misuse this equipment. Use caution when using this equipment around

moving machinery, electrical and chemical hazards, and sharp edges.

4

Page 5

3.3 SYSTEM INSTALLATION:

Figure 1 shows a typical horizontal lifeline system installation. When using an energy absorbing lanyard to connect

to the system, the anchorages must be located at a height above the working level which will limit the free fall to six feet. The

length of the lanyard must be considered when determining the height of the anchorages.

When using a self retracting lifeline (SRL) to connect to the system, the end anchorages must be located

above the user. The SRL, when fully retracted, must be above the harness attachment level. The horizontal

lifeline system should be positioned at a level that will minimize free fall while allowing ease of use.

The horizontal lifeline should be positioned near the work location to minimize swing fall hazards. The

connecting subsystem length should be kept as short as possible to reduce the potential free fall and

required clearance distance.

Both anchorages must be installed at approximately the same elevation, so that the horizontal lifeline

system is not sloped more than a 1:12 pitch (1 inch [3 cm] rise over a 12 inch [30 cm] run). The cable must

be in a straight line; no curves or turns are allowed in a Sayine Multi-span Lifeline installation.

The installation process consists of the following steps:

1. Determine the location of end anchors and intermediate brackets.

2. Determine the orientation of the intermediate brackets

3. Attach one end to its anchor point.

4. Install cable guides and Sayink sleeves onto the cable.

5. Assemble intermediate brackets into their anchor points.

6. Unthread turnbuckle(s)

7. Attach the other cable end to its anchor point and tension the cable

The steps are described in detail below:

Step 1. Determine the locations of the end anchorages and evaluate their strengths in accordance with

section 2.4. Determine the number of intermediate brackets necessary for your application. There

must be one intermediate bracket for every 30 feet (9 m) of cable for systems over 30 feet (9 m)

in length. Additional intermediate brackets (Part No. 7608001) may be purchased from 3M Fall

Protection. Use Figures 6 and 7 to determine the span length and evaluate the required clearance.

Figures 6 and 7 apply to one or two users connected to the system.

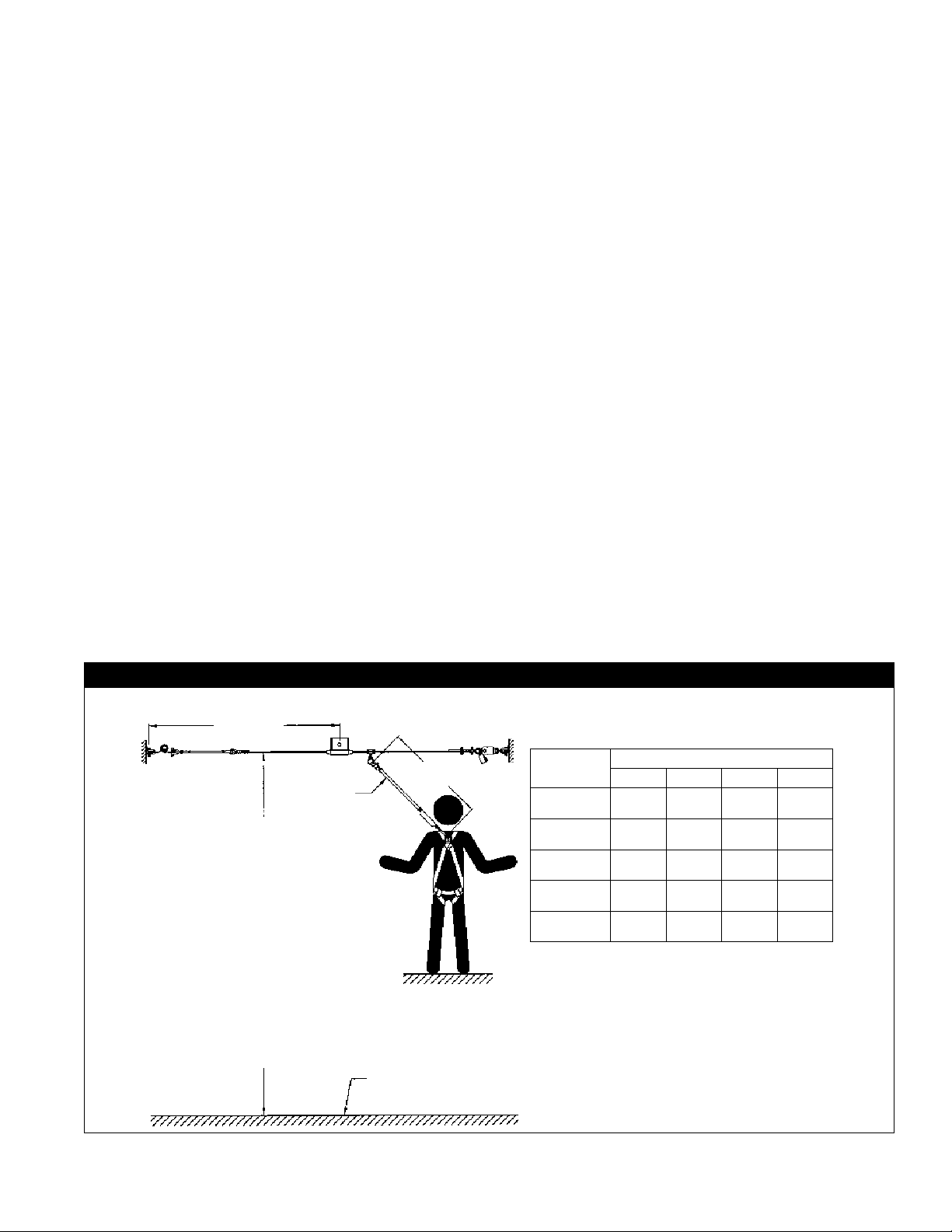

Figure 6 - Energy Absorbing Lanyard Clearance Requirements

Span Length

Energy Absorbing

Lanyard

Required Clearance from nearest lower

level or obstruction to HLL system height:

1. Find your Longest Span Length row

in the Clearance Table.

2. Find your Lanyard Length column in

the Clearance Table.

3. The required clearance is where the

Longest Span Length row intersects

the Lanyard Length column.

Example: Span is 24 ft (7 m); Lanyard

Length is 5 ft (1.5 m). Your Required

Clearance is 18 ft - 11 in (5.8 m).

Use this distance to determine if adequate

clearance exists in the event of a fall. If

clearance is inadequate, add intermediate

brackets to reduce span length, or reduce

your lanyard length and reevaluate

required clearance.

Energy Absorbing

Lanyard Length

Lower Level

or Obstruction

3M Fall Protection Energy Absorbing Lanyards

Longest Span

Lenght: ft (m)

>0 but ≤10

(>0 but ≤3)

10 - 15

(3 - 4.5)

15 - 20

(4.5 - 6)

20 - 25

(6 - 7.6)

25 - 30

(7.6 - 9)

> Greater Than

≤ Less Than or Equal To

Clearance Table

Energy Absorbing Lanyard Length: ft-in (m)

3 4 5 6

14’-11”

(4.5 m)

15’-7”

(4.7 m)

16’-2”

(4.9 m)

16’-11”

(5.2 m)

17’-6”

(5.3 m)

15’-11”

(4.9 m)

16’-7”

(5.1 m)

17’-2”

(5.2 m)

17’-11”

(5.5 m)

18’-6”

(5.6 m)

16’-11”

(5.2 m)

17’-7”

(5.4 m)

18’-2”

(5.5 m)

18’-11”

(5.8 m)

19’-6”

(5.9 m)

17’-11”

(5.5 m)

18’-7”

5.7 m)

19’-2”

(5.8 m)

19’-11”

(6.1 m)

20’-6”

(6.2 m)

5

Page 6

Figure 7 - Self Retracting Lifeline Clearance Requirements

Span Length

WARNING: This information only applies

when the HLL and SRL are located

overhead and above the level of the

harness attachment point, and the user is

standing.

Required Clearance from nearest

lower level or obstruction to working

level:

4. Find your longest span length

row in the clearance table.

5. Read the required clearance

distance from the distance

column to determine if adequate

clearance exists in the event

of a fall. If there is inadequate

clearance, add intermediate

brackets to reduce the span

length and reevaluate your

required clearance.

Example: Span is 16 ft (5 m), Clearance required

is 8 ft (2.5 m).

Self Retracting

Lifeline (SRL)

Lower Level or

Obstruction

Working

Level

>0 (0) but ≤10 (3) 6’-11” (2.1)

> Greater Than

≤ Less Than or Equal To

Clearance Table

3M Fall Protection Self Retracting

Longest Span

Length: ft (m)

10 (3) - 20 (6) 8’-0” (2.4)

20 (6) - 30 (90) 9’-1” (2.8)

Lifelines

Required Distance:

ft-in (m)

Step 2. Determine the correct orientation of the intermediate brackets. Depending on the positioning of

the cable, the intermediate brackets may be installed in one of three orientations. See Figure 8 for

the bracket orientations.

Note: A maximum free fall distance of 6 ft. must be maintained in all bracket positions; a system with brackets

mounted below the user should only be used for fall restraint applications.

Figure 8 - Bracket Orientations

Overhead

To the side

At an angle

Below

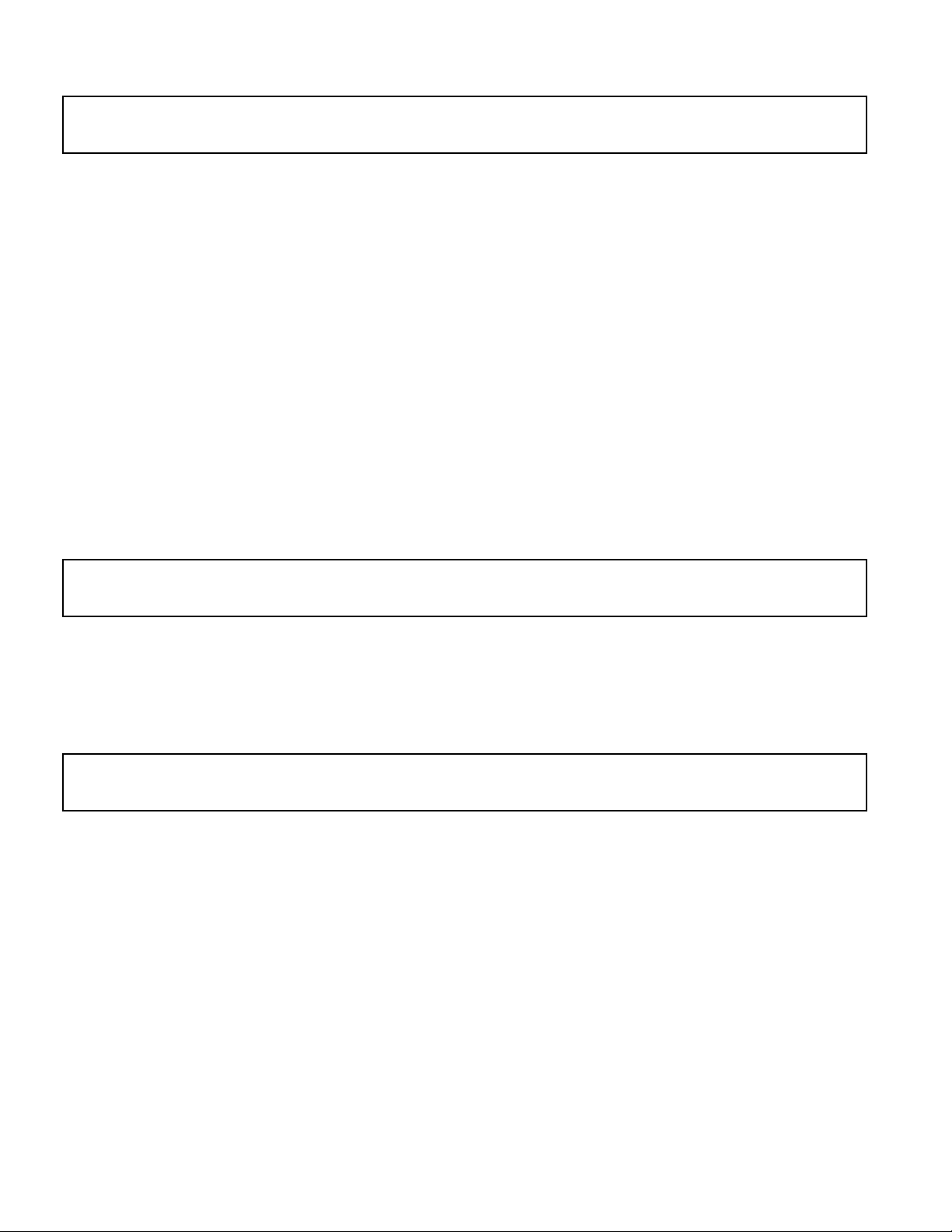

Step 3. To attach the cable to the rst anchor point, link one pair of shackles together, then connect

one side of the linked shackles to the anchor using the included nut and bolt. Connect the

other side of the shackles to the Zorbit that’s connected to the turnbuckle. See Figure 9. The

horizontal lifeline system may be secured directly to the anchorage if the anchorage incorporates

a connecting element that meets the requirements specied in section 2.4. The user must supply

the anchorage hardware. Tighten bolts and nuts used to connect the system to the anchorage

connectors. Slide the Sayink sleeve(s) onto the lifeline before terminating the other end of the

cable to the anchor.

6

Page 7

Step 4. If additional intermediate brackets are purchased,

slide all of the cable guides from the brackets onto

the cable before installing the cable.

Step 5. The intermediate brackets are composed of three

parts: two side plates and a cable guide. Each of

the plates is stamped with the letter “A” or “B”.

See Figure 10. To assemble a bracket, start by

placing a cable guide into Part A at the appropriate

angle as determined in Step 2. Then slide Part

B onto the cable guide at the same angle and

nestle Part B into Part A. Place the assembled

bracket at its designated anchor point and anchor

it by placing the user supplied bolt through a at

washer and then though the mated holes in the

bracket and into the anchor point. The bolt

may be installed through the anchor and

into the bracket if preferred, but the washer

must remain inside the bracket, between the

bracket and the bolt head or nut. Torque the

anchor hardware to 55 ft./lbs (75 nM).

Figure 9 - Cable Termination

Shackles

Zorbit Shock

Absorber

Turnbuckle

Figure 10 - Bracket Assembly

Part A

Part B

Step 6. Before terminating the second end of the

horizontal lifeline, unthread the turnbuckle

on the rst end so that only four threads are

visible inside the turnbuckle body. This will

allow for maximum tensioning of the system

after anchoring the second end. Install all of

the Sayink sleeves onto the cable before

terminating the second end.

Step 7. To terminate the second end of the cable

to its anchor, attach the shackles to the

anchor and Zorbit as described in Step 3. Then attach the thimble and connecting hardware to

the Zorbit. See Figure 11. Slide the lifeline through the thimble. Remove excess slack by pulling

the wire rope through the thimble and cable clip. Maintain tension while torquing the cable clip

nut and the thimble clip nut to the values specied in Figure 11. Tension the wire rope by turning

the turnbuckle at the other end of the installation. The unrestrained turnbuckle jaw end must be

prevented from turning to prevent twisting the wire rope. The wire rope must be tensioned until

the sag on the system at mid-span, between intermediate brackets, is two inches or less, with no

weight on the wire rope.

Figure 11 - Thimble/Cable Clip End Termination

Sayine Wire Rope HLL System End Termination

8” (20 cm) Min.

2 1./2” ± 1/2”

(6.35 cm ± 1.25 cm)

Cable Guide

Cable Clip

Torque to 45 ft/lbs

Thimble/Cable Clip

Torque to 40 ft/lbs (54 Nm)

(61 Nm)

CAUTION: Do not rigidly mount Zorbit to structure or

stanchion. May cause failure due to bending. Mount so Zorbit

can pivot and move freely as shown in Figures 9 and 11.

7

Page 8

4.0 OPERATION AND USE

WARNING: Consult your doctor if there is reason to doubt your tness to absorb the impact from a fall arrest.

Age and tness can affect your ability to withstand fall arrest forces. Pregnant women and minors must not use

the Sayine Multi-span Wire Rope Horizontal Lifeline System.

4.1 BEFORE EACH USE inspect this equipment according to steps listed in section 6.4. Do not use this

equipment if inspection reveals an unsafe or defective condition. Plan your use of the fall protection

system prior to exposing workers to dangerous situations. Consider all factors affecting your safety

before using this system.

A. Read and understand all manufacturer’s instructions for each component of the personal fall arrest

system. All 3M Fall Protection harnesses and connecting subsystems are supplied with separate user

instructions. Keep all instructions for future reference.

B. Review sections 1.0 and 2.0 to ensure system limitations and other requirements have been adhered to.

Review applicable information regarding system clearance criteria, and ensure changes have not been

made to the system installation (i.e. length), or occurred at the job site, that could affect the required

fall clearance. Do not use the system if changes are required.

4.2 USE OF THE SYSTEM:

A. PERSONAL FALL ARREST SYSTEM COMPONENTS: Inspect and don the full body harness according

to manufacturer’s instructions. Attach the connecting subsystem (energy absorbing lanyard or self

retracting lifeline) to the dorsal connection on the harness. If a self retracting lifeline (SRL) is used, 3M

Fall Protection recommends using SRLs that are 20 feet (6 m) long or shorter. The weight of longer SRLs

may cause the Sayink sleeve to catch on intermediate brackets, causing the lifeline to extend which may result in an

unexpected swing fall.

WARNING: If the Sayink sleeve catches on an intermediate bracket, the SRL lifeline may extend while the

worker moves along the HLL. This will increase fall distance and create a swing fall hazard which may result in

serious injury or death.

B. CONNECTING TO THE HLL SYSTEM: Approach the work area using the appropriate access equipment.

Connect the personal fall arrest system to one of the D-rings on a Sayink sleeve on the HLL.

Connectors must meet all compatibility and strength requirements.

C. WALKING ALONG THE SYSTEM: Once attached to the Sayine System, the Sayink Sleeve will follow

the user along the lifeline and will automatically pass over each intermediate support bracket.

WARNING: Movement along the Sayine System must be done manually by the user of the system. Never

allow moving stock (such as railcars) to move the user along the Sayine System. This could cause serious

injury or death.

D. HAZARDOUS SITUATIONS: Do not take unnecessary risks, such as jumping or reaching too far from

the edge of the working surface. Do not allow the connecting subsystem to pass under arms or between

feet. To avoid inadequate fall clearance, do not climb above the HLL. To avoid swing fall hazards, do not

work too far from either side of the HLL.

E. TWO PERSONS CONNECTED TO THE HLL: When a person falls while connected to the HLL, the

system will deect. If two persons are connected to the same HLL, and one person falls, the second

person may be pulled off the working surface due to deection. The potential for the second person

falling increases as the HLL span length increases. The use of independent HLL systems for each person,

or shorter span length, is recommended to minimize the potential of the second person falling.

F. FREE FALL: The personal fall arrest system must be rigged to limit free falls to 6 ft. (1.8 m) or less

when using an energy absorbing lanyard, or such that the SRL is overhead and without slack, according

to OSHA requirements.

G. SHARP EDGES: Avoid working where the connecting subsystem or other system components will be in

contact with, or abrade against, unprotected sharp edges. If working around sharp edges is unavoidable,

provide protection by securing a heavy pad or other means over the exposed edge.

H. IN THE EVENT OF A FALL: The responsible party must have a rescue plan and the ability to implement

a rescue. Tolerable suspension time in a full body harness is limited, so a prompt rescue is critical.

8

Page 9

IMPORTANT: Use care when handling an expended Zorbit energy absorber. The tearing of the energy absorber

material produces extremely sharp edges.

I. RESCUE: With the number of potential scenarios for a worker requiring rescue, an on site rescue team

is benecial. The rescue team is given the tools, both in equipment and techniques, so it can perform a

successful rescue. Training should be provided on a periodic basis to ensure rescuers’ prociency.

4.3 SYSTEM REMOVAL: When no longer required, the HLL system should be removed from the job site. To

slacken the HLL, loosen the turnbuckle until tension is removed from the wire rope. Disconnect the HLL

system from the anchorages. Ensure there are no knots or kinks in the wire rope before storage.

5.0 TRAINING

5.1 It is the responsibility of all users of this equipment to understand these instructions, and to be trained in

the correct installation, use, and maintenance of this equipment. These individuals must be aware of the

consequences of improper installation or use of this equipment. This user manual is not a substitute for a

comprehensive training program. Training must be provided on a periodic basis to ensure prociency of the

users.

6.0 INSPECTION

6.1 BEFORE EACH INSTALLATION: Inspect the Zorbit HLL energy absorbers, kit components, and other

system components according to these or other manufacturer’s instructions. System components must be

formally inspected by a Competent1 person (other than the user). Formal inspections should concentrate

on visible signs of deterioration or damage to the system components. Items found to be defective must be

replaced. Do not use components if inspection reveals an unsafe or defective condition. Record results of

each inspection in the inspection and maintenance log in section 11.0 of this manual.

6.2 INSTALLED SYSTEMS: An inspection of the HLL system by a Competent person must be completed after

the system is installed. The system must be periodically inspected by a Competent person when left installed

for an extended period. Periodic inspections should be performed at least monthly, or more frequently when

site conditions and use warrant. Inspections of installed systems should include the inspection steps listed in

section 6.4.

6.3 Annually: A Competent Person shall inspect the entire system including the anchorage points. Inspect for

deterioration or damage. Items found to be defective must be replaced. Do not use components if inspection

reveals an unsafe or defective condition. Record the results of each inspection in the Inspection and

Maintenance Log in section 11.0 of this manual.

6.4 BEFORE SYSTEM USE:

Step 1. Inspect the turnbuckle for damage. Ensure at least four threads are visible inside the turnbuckle

body. Look for any cracks or deformities in the metal. Inspect metal components for rust or corrosion that

may affect their strength or operation.

Step 2. Inspect the wire rope for rust, corrosion, broken wires, or other obvious faults. Inspect the HLL

for proper tension. Inspect all hardware (fasteners, shackles, wire rope cable clips, etc.) securing the HLL

assembly to ensure they are present and properly installed.

Step 3. Inspect the Sayink Sleeve for excessive wear, damage, or corrosion.

Step 4. Inspect the Zorbit HLL energy absorber for extension or deformities. There should be no tearing

of the metal between holes in the Zorbit coiled section. Increase inspection frequency if the Zorbit is

exposed to prolonged vibration. Extended Zorbit HLL energy absorbers must be removed from service and

destroyed, or marked for training only. Inspect securing hardware for strength and function.

Step 5. Inspect the intermediate brackets for wear or damage. Check brackets to make certain they are

securely attached. Make certain all installed Sayink sleeves pass freely through the intermediate brackets

when moving along the system during normal use.

Step 6. Inspect system labels. The labels must be present and fully legible. See section 9.0. Replace labels

if missing or illegible.

IMPORTANT: If this equipment is subjected to the forces of a fall arrest, it must be removed from

service and destroyed, or returned to 3M Fall Protection for inspection or repair.

6.5 If inspection reveals an unsafe or defective condition, remove unit from service and destroy, or contact 3M

Fall Protection for possible repair.

1 Competent Person: One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are

unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

9

Page 10

6.6 USER EQUIPMENT: Inspect harnesses and energy absorbing lanyards or SRL’s used with the HLL system

according to manufacturer’s instructions.

7.0 MAINTENANCE, SERVICE, STORAGE

7.1 MAINTENANCE: The Sayine components require no scheduled maintenance, other than repair or

replacement of items found defective during inspection. See section 6.0.

7.2 CLEANING: If components become heavily soiled with grease, paint, or other substances, clean with

appropriate cleaning solutions.

Remove dirt from the cable using a ber brush. Do not use a wire brush and do not apply any solvents or

lubricants without prior approval from 3M Fall Protection.

Clean all other Sayine components using a nonabrasive cloth and hot water/mild detergent mix. Dry with

a clean cloth. Do not use solvents to clean any Sayine Component. Do not use caustic chemicals that could

damage system components.

7.3 USER EQUIPMENT: Maintain, service, and store system components according to manufacturer’s

instructions for each component.

8.0 SPECIFICATIONS

8.1 MATERIALS: 8.2 ENERGY ABSORBER PERFORMANCE:

Zorbit Energy Absorber: Stainless steel Peak Dynamic Pullout Load: 2,500 lbs. (11 kN)

Wire Rope: 3/8 inch diameter, 7x19

galvanized steel

Bolts: Grade 5 or Grade 8 zinc plated steel Maximum Pullout: 48.5 inches (123 cm)

Nuts: Zinc plated steel Minimum Tensile Strength: 5,000 lbs. (22 kN)

Intermediate Brackets: 11 ga. hot rolled

steel, zinc plated

Sayink Sleeve Assembly: alloy steel

Shackles: Galvanized steel, 5,000 lbs.

(22 kN) minimum tensile strength

Thimbles: Galvanized steel

Turnbuckle: Galvanized steel, 5,000 lbs.

(22 kN)minimum tensile strength

Cable Clips: Galvanized steel

Average Dynamic Pullout Load: 2,000 lbs. (9 kN)

Patents Pending

9.0 LABELING

9.1 The following labels must be present and fully legible:

A

10

A

Page 11

A

E

B

D

F

C

B C

D D

A

WARNING

E E

F

F

11

Page 12

Page 13

Page 14

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 15

7603000

7603020

7603040

7603060

This instruction applies to the following product models:

7603070

7603071

7603072

7603073

Additional Model Numbers may appear on the next printing of this instruction.

7603074

7603075

7603076

7603079

7603080

7603100

7603120

7603140

7603160

7603180

7603200

7603220

7603240

7603260

7603299

7608001

Page 16

ISO

USA

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

3Mfallprotection@mmm.com

Brazil

Rua Anne Frank, 2621

Boqueirão Curitiba PR

81650-020

Brazil

Phone: 0800-942-2300

falecoma3m@mmm.com

Mexico

Calle Norte 35, 895-E

Col. Industrial Vallejo

C.P. 02300 Azcapotzalco

Mexico D.F.

Phone: (55) 57194820

3msaludocupacional@mmm.com

Colombia

Compañía Latinoamericana de Seguridad S.A.S.

Carrera 106 #15-25 Interior 105 Manzana 15

Zona Franca - Bogotá, Colombia

Phone: 57 1 6014777

fallprotection-co@mmm.com

U.S. PRODUCT WARRANTY, LIMITED REMEDY

AND LIMITATION OF LIABILITY

WARRANTY: THE FOLLOWING IS MADE IN LIEU OF ALL WARRANTIES OR CONDITIONS, EXPRESS

OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Unless otherwise provided by applicable law, 3M fall protection products are warranted against factory

defects in workmanship and materials for a period of one year from the date of installation or fi rst use

by the original owner.

LIMITED REMEDY: Upon written notice to 3M, 3M will repair or replace any product determined by

3M to have a factory defect in workmanship or materials. 3M reserves the right to require product be

returned to its facility for evaluation of warranty claims. This warranty does not cover product damage

due to wear, abuse, misuse, damage in transit, failure to maintain the product or other damage beyond

3M’s control. 3M will be the sole judge of product condition and warranty options.

This warranty applies only to the original purchaser and is the only warranty applicable to 3M’s fall

protection products. Please contact 3M’s customer service department at 800-328-6146 or via email at

3MFallProtection@mmm.com for assistance.

LIMITATION OF LIABILITY: TO THE EXTENT PERMITTED BY APPLICABLE LAW, 3M IS NOT

LIABLE FOR ANY INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING,

BUT NOT LIMITED TO LOSS OF PROFITS, IN ANY WAY RELATED TO THE PRODUCTS REGARDLESS

OF THE LEGAL THEORY ASSERTED.

Canada

260 Export Boulevard

Mississauga, ON L5S 1Y9

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

3Mfallprotection-ca@mmm.com

EME A (Europe, Middle East, Africa)

EMEA Headquarters:

5a Merse Road

North Moons Moat

Redditch, Worcestershire

B98 9HL UK

Phone: + 44 (0)1527 548 000

Fax: + 44 (0)1527 591 000

informationfallprotection@mmm.com

France:

Le Broc Center

Z.I. 1re Avenue - BP15

06511 Carros Le Broc Cedex

France

Phone: + 33 04 97 10 00 10

Fax: + 33 04 93 08 79 70

informationfallprotection@mmm.com

Australia & New Zealand

95 Derby Street

Silverwater

Sydney NSW 2128

Australia

Phone: +(61) 2 8753 7600

Toll-Free : 1800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

Fax: +(61) 2 8753 7603

anzfallprotectionsales@mmm.com

3M.com/FallProtection

Asia

Singapore:

1 Yishun Avenue 7

Singapore 768923

Phone: +65-6450 8888

Fax: +65-6552 2113

TotalFallProtection@mmm.com

Shanghai:

19/F, L’Avenue, No.99 Xian Xia Rd

Shanghai 200051, P R China

Phone: +86 21 62539050

Fax: +86 21 62539060

3MFallProtecton-CN@mmm.com

Korea:

3M Koread Ltd

20F, 82, Uisadang-daero,

Yeongdeungpo-gu, Seoul

Phone: +82-80-033-4114

Fax: +82-2-3771-4271

TotalFallProtection@mmm.com

Japan:

3M Japan Ltd

6-7-29, Kitashinagawa, Shinagawa-ku, Tokyo

Phone: +81-570-011-321

Fax: +81-3-6409-5818

psd.jp@mmm.com

9001

Page 17

psd.jp@mmm.com

Fax: +81-3-6409-5818

Phone: +81-570-011-321

6-7-29, Kitashinagawa, Shinagawa-ku, Tokyo

3M Japan Ltd

Japan:

TotalFallProtection@mmm.com

Fax: +82-2-3771-4271

Phone: +82-80-033-4114

Yeongdeungpo-gu, Seoul

20F, 82, Uisadang-daero,

3M Koread Ltd

Korea:

3MFallProtecton-CN@mmm.com

Fax: +86 21 62539060

Phone: +86 21 62539050

Shanghai 200051, P R China

19/F, L’Avenue, No.99 Xian Xia Rd

Shanghai:

TotalFallProtection@mmm.com

Fax: +65-6552 2113

Phone: +65-6450 8888

Singapore 768923

1 Yishun Avenue 7

Singapore:

Asia

9001

ISO

3M.com/FallProtection

anzfallprotectionsales@mmm.com

Fax: +(61) 2 8753 7603

Toll-Free : 0800 212 505 (NZ)

Toll-Free : 1800 245 002 (AUS)

Phone: +(61) 2 8753 7600

Australia

Sydney NSW 2128

Silverwater

95 Derby Street

Australia & New Zealand

informationfallprotection@mmm.com

Fax: + 33 04 93 08 79 70

Phone: + 33 04 97 10 00 10

France

06511 Carros Le Broc Cedex

Z.I. 1re Avenue - BP15

Le Broc Center

France:

informationfallprotection@mmm.com

Fax: + 44 (0)1527 591 000

Phone: + 44 (0)1527 548 000

B98 9HL UK

Redditch, Worcestershire

North Moons Moat

5a Merse Road

EMEA Headquarters:

EMEA (Europe, Middle East, Africa)

3Mfallprotection-ca@mmm.com

Fax: 888.387.7484

Toll-Free: 800.387.7484

Phone: 905.795.9333

Mississauga, ON L5S 1Y9

260 Export Boulevard

Canada

fallprotection-co@mmm.com

Phone: 57 1 6014777

Zona Franca - Bogotá, Colombia

Carrera 106 #15-25 Interior 105 Manzana 15

Compañía Latinoamericana de Seguridad S.A.S.

Colombia

3msaludocupacional@mmm.com

Phone: (55) 57194820

Mexico D.F.

C.P. 02300 Azcapotzalco

Col. Industrial Vallejo

Calle Norte 35, 895-E

Mexico

falecoma3m@mmm.com

Phone: 0800-942-2300

Brazil

81650-020

Boqueirão Curitiba PR

Rua Anne Frank, 2621

Brazil

3Mfallprotection@mmm.com

Fax: 651.388.5065

Phone: 651.388.8282

Toll Free: 800.328.6146

Red Wing, MN 55066-5005

3833 SALA Way

USA

QUE SOIT LA THÉORIE LÉGALE INVOQUÉE.

INCLUANT , SANS S’Y LIMITER, LA PERTE DE PROFIT, LIÉS DE QUELQUE MANIÈRE AUX PRODUITS, QUELLE

TENU POUR RESPONSABLE DE TOUT DOMMAGE INDIRECT, ACCESSOIRE, SPÉCIFIQUE OU CONSÉCUTIF

LIMITATION DE RESPONSABILITÉ : DANS LES LIMITES PRÉVUES PAR LES LOIS LOCALES, 3M NE SERA

obtenir de l’aide.

protection antichute de 3M. Veuillez communiquer avec le service à la clientèle de 3M de votre région pour

Cette garantie s’applique uniquement à l’acheteur initial et est la seule garantie applicable aux produits de

de 3M. 3M jugera seul de l’état du produit et des options de garantie.

subis pendant l’expédition, le manque d’entretien du produit ou d’autres dommages en dehors du contrôle

pas les dommages au produit résultant de l’usure, d’un abus ou d’une mauvaise utilisation, les dommages

retour du produit dans ses installations afi n d’évaluer la réclamation de garantie. Cette garantie ne couvre

défaut de fabrication en usine ou de matériaux, tel que déterminé par 3M. 3M se réserve le droit d’exiger le

RECOURS LIMITÉ : Moyennant un avis écrit à 3M, 3M réparera ou remplacera tout produit présentant un

de la première utilisation par le propriétaire initial.

de fabrication en usine et de matériaux pour une période d’un (1) an à compter de la date d’installation ou

Sauf disposition contraire de la loi, les produits de protection antichute 3M sont garantis contre tout défaut

MARCHANDE ET À L’ADAPTATION À UN USAGE PARTICULIER.

IMPLICITES, Y COMPRIS LES GARANTIES OU LES CONDITIONS IMPLICITES RELATIVES À LA QUALITÉ

ET LIMITATION DE RESPONSABILITÉ

GARANTIE INTERNATIONALE DU PRODUIT, RECOURS LIMITÉ

GARANTIE : CE QUI SUIT REMPLACE TOUTES LES GARANTIES OU CONDITIONS, EXPRESSES OU

LEGAL THEORY ASSERTED.

LIMITED TO LOSS OF PROFITS, IN ANY WAY RELATED TO THE PRODUCTS REGARDLESS OF THE

FOR ANY INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT

LIMITATION OF LIABILITY: TO THE EXTENT PERMITTED BY LOCAL LAWS, 3M IS NOT LIABLE

protection products. Please contact 3M’s customer service department in your region for assistance.

This warranty applies only to the original purchaser and is the only warranty applicable to 3M’s fall

3M’s control. 3M will be the sole judge of product condition and warranty options.

due to wear, abuse, misuse, damage in transit, failure to maintain the product or other damage beyond

returned to its facility for evaluation of warranty claims. This warranty does not cover product damage

3M to have a factory defect in workmanship or materials. 3M reserves the right to require product be

LIMITED REMEDY: Upon written notice to 3M, 3M will repair or replace any product determined by

by the original owner.

defects in workmanship and materials for a period of one year from the date of installation or fi rst use

Unless otherwise provided by local laws, 3M fall protection products are warranted against factory

FITNESS FOR A PARTICULAR PURPOSE.

OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY OR

AND LIMITATION OF LIABILITY

GLOBAL PRODUCT WARRANTY, LIMITED REMEDY

WARRANTY: THE FOLLOWING IS MADE IN LIEU OF ALL WARRANTIES OR CONDITIONS, EXPRESS

Page 18

De nouveaux numéros de modèles peuvent apparaître lors de la prochaine impression de ces instructions.

7608001

7603299

7603260

7603240

7603220

7603200

7603180

7603160

7603140

7603120

7603100

7603080

7603079

7603076

7603075

7603074

7603073

7603072

7603071

7603070

Ces directives se rapportent aux modèles des produits suivants :

7603060

7603040

7603020

7603000

Page 19

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

EFFECTUÉ

ENTRETIEN

CORRECTIVES

MESURES

D’INSPECTION NOTÉS

ÉLÉMENTS

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

Approuvé par :

DATE D’INSPECTION

DATE D’ACHAT : DATE DE PREMIÈRE UTILISATION :

NUMÉRO DE MODÈLE

NUMÉRO DE SÉRIE :

JOURNAL D’INSPECTION ET D’ENTRETIEN

Page 20

Page 21

Page 22

11

WARNING

F

F

E E

D D

B C

C

F

D

B

E

A

A

Page 23

10

A

A

9.1 Les étiquettes suivantes doivent être présentes et entièrement lisibles :

9.0 ÉTIQUETAGE

Serre-câbles : acier galvanisé

traction minimale de 5 000 lb (22 kN).

Tendeur : acier galvanisé, résistance à la

Cosses : Acier galvanisé

à la traction minimale 5 000 lb (22 kN).

Maillons d’attache : acier galvanisé, résistance

Ensemble manchon Sayfl ink : alliage d'acier

chaud, plaqué au zinc 11 ga.

Brevets en instance

2 000 lb (9 kN)

Charge de résistance dynamique moyenne :

2 500 lb (11 kN)

D’ÉNERGIE :

Supports intermédiaires : acier laminé à

Écrous : acier zingué Résistance à la traction minimale : 5 000 lb (22 kN)

Boulons : acier zingué de classe 5 ou 8 Résistance maximale : 48,5 po (116 cm)

(0,95 cm), acier galvanisé 7 x 19

Câble métallique : diamètre de 3/8 po

Absorbeur d’énergie Zorbit : acier inoxydable Charge de résistance dynamique maximale :

8.1 MATÉRIAUX : 8.2 PERFORMANCES DE L’ABSORBEUR

8.0 SPÉCIFICATIONS

directives du fabricant.

7.3 ÉQUIPEMENT DE L’UTILISATEUR : nettoyez, réparez et entreposez les composants du système selon les

Sayfl ine. N’utilisez pas de produits chimiques caustiques pouvant endommager les composants du système.

détergent doux. Séchez avec un chiffon propre. N'utilisez pas de solvants pour nettoyer les composants

Nettoyez tous les autres composants Sayfl ine à l'aide d'un chiffon doux et un mélange d'eau chaude et de

A

aucun solvant ou lubrifi ant sans approbation antérieure de DBI/SALA.

Enlevez les saletés sur le câble avec une brosse de fi bres. N'utilisez pas de brosse métallique et n'appliquez

nettoyés avec les produits de nettoyage appropriés.

7.2 NETTOYAGE : les composants souillés de graisse, de peinture ou de toute autre substance doivent être

le remplacement des éléments jugés défectueux lors d'une inspection. Voir Section 6.0.

7.1 ENTRETIEN: les composants Sayfl ine ne nécessitent aucun entretien périodique autre que la réparation ou

7.0 ENTRETIEN, RÉPARATION ET ENTREPOSAGE

de vie auto-rétractable utilisés avec le système de ligne de vie horizontale selon les instructions du fabricant.

6.6 ÉQUIPEMENT DE L’UTILISATEUR : inspectez les harnais et les longes absorbeuses d'énergie ou la ligne

l’équipement du service et détruisez-le, ou communiquez avec DBI/SALA pour une éventuelle réparation.

6.5 Si l’inspection révèle l’existence d’un défaut ou d’une condition non sécuritaire, retirez immédiatement

immédiatement du service et détruit, ou retourné à DBI/SALA pour inspection ou réparation.

IMPORTANT : si l’équipement a été soumis à des forces résultant d’un arrêt de chute, il doit être retiré

Page 24

9

insalubres, peligrosas o peligrosas para los empleados, y que tiene autorización para tomar medidas correctivas inmediatas para eliminarlos.

1- Persona competente: alguien que es capaz de identifi car peligros existentes y predecibles en el entorno o condiciones de trabajo que son

Voir Section 9.0. Remplacez les étiquettes illisibles ou manquantes.

Étape 6. Vérifi ez les étiquettes du système. Les étiquettes doivent être présentes et entièrement lisibles.

normale.

encombre dans les supports intermédiaires lors de déplacements le long du système pendant une utilisation

vous qu'ils sont solidement attachés. Assurez-vous que tous les manchons Sayfl ink installés passent sans

Étape 5. Vérifi ez si les supports intermédiaires sont usés ou endommagés. Vérifi ez les supports et assurez-

Vérifi ez la résistance et le bon fonctionnement du matériel de fi xation.

étirés, ou marquez-les pour qu’ils soient utilisés uniquement dans le cadre d’un programme de formation.

une vibration prolongée. Retirez et détruisez les absorbeurs d’énergie pour lignes de vie horizontales Zorbit

extensible du système Zorbit. Augmentez la fréquence des inspections si le système Zorbit est exposé à

extension ou déformation. Le système ne doit présenter aucun bris de métal entre les trous de la section

Étape 4. Vérifi ez si l’absorbeur d’énergie pour ligne de vie horizontale Zorbit ne présente aucune

Étape 3. Vérifi ez si le manchon Sayfl ink n'est pas excessivement usé, endommagé ou corrodé.

vie horizontale pour s’assurer qu’il ne manque aucun accessoire et qu’ils sont bien installés.

fi xation, maillons d’attache, serre-câbles pour câbles métalliques, etc.) en fi xant l’ensemble de la ligne de

nu. Vérifi ez si la ligne de vie horizontale a une tension appropriée. Vérifi ez tout le matériel (dispositifs de

Étape 2. Vérifi ez si le câble métallique est rouillé, corrodé, brisé ou tout autrement défectueux à l’œil

rouillés ou corrodés car cela pourrait nuire à leur solidité ou à leur fonctionnement.

du tendeur. Identifi ez toute fi ssure ou déformation du métal. Vérifi ez si les composants métalliques sont

Étape 1. Vérifi ez si le tendeur est endommagé. Assurez-vous que quatre fi ls sont visibles dans le corps

6.4 AVANT L’UTILISATION DU SYSTÈME :

section 11.0 de ce manuel.

équipement. Consignez les résultats de chaque inspection dans le journal d’inspection et d’entretien de la

doivent être remplacés. Si une inspection révèle un état non sécuritaire ou douteux, n’utilisez pas cet

d’ancrage. Inspectez en vue de déceler toute détérioration ou tout dommage. Les éléments défectueux

6.3 Une fois par an : une personne qualifi ée doit inspecter l’ensemble du système, y compris les points

section 6.4.

site les justifi ent. Les inspections des systèmes installés doivent comprendre les étapes d’inspection de la

devraient être faites au moins chaque mois ou plus fréquemment lorsque les conditions et l'utilisation du

personne competente lorsqu’on le laisse installé pour une période prolongée. Des inspections périodiques

personne competente après l’installation du système. Le système doit être inspecté périodiquement par une

6.2 SYSTÈMES INSTALLÉS : une inspection du système de ligne de vie horizontale doit être menée par une

d’entretien de ce manuel.

Enregistrez les résultats de toutes les inspections formelles dans la section 11.0 du journal d’inspection et

être remplacés. Si une inspection révèle un état non sécuritaire ou douteux, n’utilisez pas cet équipement.

visibles de détérioration ou de dommages aux éléments du système. Les éléments défectueux doivent

(autre que l’utilisateur). Les inspections formelles doivent être centrées sur les signes

1

personne competente

aux autres instructions du fabricant. Les éléments du système doivent être formellement inspectés par une

les composants de la trousse et les autres composants du système, conformément à ces instructions et

6.1 AVANT CHAQUE INSTALLATION : inspectez les absorbeurs d’énergie pour ligne de vie horizontale Zorbit,

6.0 INSPECTION

réguliers afi n de garantir la compétence des utilisateurs.

ne peut se substituer à un programme de formation complet. Cette formation doit être menée à intervalles

été sensibilisés sur les conséquences d'une mauvaise installation de cet équipement. Ce guide d'utilisation

formation pour installer, utiliser et entretenir correctement cet équipement. Les utilisateurs doivent avoir

5.1 Tous les utilisateurs de cet équipement sont tenus de comprendre les instructions et de suivre une

5.0 FORMATION

Assurez-vous qu’il n’y a pas de nœuds ou de plis dans le câble métallique avant de l’entreposer.

ait plus de tension dans le câble métallique. Décrochez le système de ligne de vie horizontale des ancrages.

lorsqu’il n’est plus utile. Pour relâcher la ligne de vie horizontale, desserrez le tendeur jusqu’à ce qu’il n’y

4.3 DÉSASSEMBLAGE DU SYSTÈME : le système de ligne de vie horizontale doit être retiré du chantier

périodique afi n d'assurer l'effi cacité des sauveteurs.

équipement qu’en techniques, pour réussir le sauvetage. La formation devrait être fournie sur une base

utile d’avoir une équipe de sauvetage sur place. L’équipe de sauvetage doit avoir les outils, autant en

I. SAUVETAGE : avec le nombre de scénarios possibles lors du sauvetage d’un ouvrier, il peut être

absorbeur d’énergie peut former des rebords extrêmement tranchants.

IMPORTANT : manipulez toujours avec précaution un absorbeur d’énergie Zorbit tendu. Le bris de matériel d’un

Page 25

8

limité, le sauvetage doit se faire au plus vite.

mettre en œuvre. Comme le temps de suspension acceptable dans le harnais de sécurité complet est

H. EN CAS DE CHUTE : la personne responsable doit avoir un plan de sauvetage et la capacité de le

épais ou d'autres moyens placés sur l'arête tranchante exposée.

devez utiliser cet équipement près d'arêtes tranchantes, prévoyez une protection comme un coussin

du système seront en contact avec ou s’useront contre des rebords tranchants non protégés. Si vous

G. ARÊTES TRANCHANTES : évitez de travailler où le sous-système de connexion ou d’autres composants

auto-rétractable soit au-dessus de la tête sans relâchement, conformément aux exigences de l’OSHA.

chutes libres lorsque vous utilisez une longe absorbeuse d'énergie, ou de telle sorte que la ligne de vie

F. CHUTE LIBRE : le dispositif antichute personnel doit être fi xé à 6 pi (1,8 m) ou moins afi n de limiter les

minimiser le risque de chute de la deuxième personne.

indépendants pour chaque personne, ou une longueur de portée plus courte est recommandée afi n de

avec la portée de la ligne de vie horizontale. L’utilisation de systèmes de ligne de vie horizontale

de la surface de travail à cause de la fl exion Le risque de chute pour la deuxième personne augmente

la même ligne de vie horizontale et qu’une personne tombe, la deuxième personne peut être tirée hors

qu’elle est fi xée à la ligne de vie horizontale, cela fait fl échir le système. Si deux personnes sont fi xées à

E. DEUX PERSONNES FIXÉES À LA LIGNE DE VIE HORIZONTALE : lorsqu’une personne tombe alors

chaque côté de la ligne de vie horizontale.

de vie horizontale. Pour éviter tout risque de chute avec effet pendulaire, ne travaillez pas trop loin de

ou entre les pieds. Afi n d’éviter une distance d'arrêt inadéquate, ne grimpez pas au-dessus de la ligne

du bord de la surface de travail. Ne laissez pas le sous-système de connexion vous passer sous les bras

D. SITUATIONS DANGEREUSES : ne prenez pas de risques inutiles, tels que sauter ou s’étirer trop loin

l'utilisateur le long du système Sayfl ine. Cela pourrait entraîner des blessures graves ou la mort.

l'utilisateur du système. Ne laissez pas des wagons en déplacement (tels que des wagonnets) déplacer

AVERTISSEMENT : les déplacements le long du système Sayfl ine doivent être effectués manuellement par

l'utilisateur le long de la ligne de vie et passera automatiquement au-dessus de chaque support intermédiaire.

C. DÉPLACEMENT AVEC LE SYSTÈME : une fois attaché au système Sayfl ine, le manchon Sayfl ine suivra

répondre à toutes les exigences de compatibilité et de résistance.

D d'accrochage sur le manchon Sayfl ink sur la ligne de vie horizontale. Les connecteurs doivent

utilisant l’équipement approprié pour y accéder. Attachez le dispositif antichute personnel à un

B. CONNEXION À LA LIGNE DE VIE HORIZONTALE : rendez-vous à l’emplacement de travail en

danger de chute avec effet pendulaire pouvant entraîner des blessures graves ou la mort.

que l'ouvrier se déplace le long de la ligne de vie horizontale. Cela augmentera la distance de chute et créera un

AVERTISSEMENT : si le manchon Sayfl ink se coince sur un support intermédiaire, la SRL peut s'étendre pendant

une extension de la ligne de vie, et pouvant entraîner un effet pendulaire inopiné.

Le manchon Sayfl ink peut se coincer sur les supports intermédiaires avec des SRL plus longues et plus lourdes, créant

rétractable (SRL) est utilisée, DBI/SALA recommande l'utilisation d'une SRL de 20 pi (6 m) ou plus courte.

d'énergie ou ligne de vie auto-rétractable) à la connexion dorsale du harnais. Si une ligne de vie autosécurité complet selon les instructions du fabricant. Fixez le sous-système de connexion (longe absorbeuse

A. COMPOSANTS DU DISPOSITIF ANTICHUTE PERSONNEL : veuillez inspecter et revêtir le harnais de

4.2 UTILISATION DU SYSTÈME :

distance d'arrêt nécessaire. N’utilisez pas le système si des changements sont nécessaires.

système (c.-à-d. la longueur) ou autre changement sur le chantier de travail, qui pourrait affecter

dégagement du système, et assurez-vous qu’aucun changement n’a été apporté à l’installation du

prérequis ont été respectés. Révisez les renseignements applicables au sujet des critères de

B. Révisez les sections 1.0 et 2.0 afi n de vous assurer que toutes les limitations du système et autres

utilisation ultérieure.

accompagnés de leurs propres instructions d’utilisation. Veuillez conserver ces instructions pour une

du dispositif antichute. Tous les harnais de DBI/SALA ainsi que leurs sous-systèmes de connexion sont

A. Prenez connaissance de toutes les instructions émises par le fabricant au sujet de chaque composant

tous les facteurs pouvant affecter la sécurité avant l’utilisation de ce système.

un dispositif antichute avant d’exposer vos ouvriers à des conditions de travail dangereuses. Tenez compte de

Si une inspection révèle un état non sécuritaire ou douteux, n’utilisez pas cet équipement. Prévoyez d’utiliser

4.1 AVANT CHAQUE UTILISATION, veuillez inspecter cet équipement selon les étapes qui fi gurent à la section 6.4.

métallique à longueur réglable Sayfl ine.

forces d'arrêt de chute. Les femmes enceintes et les mineurs ne doivent pas utiliser la ligne de vie horizontale

choc d’arrêt de chute. L’âge et le niveau de forme physique peuvent affecter votre capacité à endurer les

AVERTISSEMENT : consultez votre médecin en cas de doute quant à votre capacité physique à amortir le

4.0 FONCTIONNEMENT ET UTILISATION

Page 26

7

Couple de 40 lb-pi (54 Nm)

Cosse/Serre-câble

Figures 9 et 11.

et se déplacer librement, comme il est indiqué à dans les

Fixez le système Zorbit de telle sorte que celui-ci puisse pivoter

pourrait entraîner une défaillance en raison d’une courbure.

manière rigide à la structure ou à un poteau métallique. Cela

MISE EN GARDE : ne fi xez pas le système Zorbit de

(61 Nm)

Couple de 45 lb-pi

Serre-câble

Tendeur

Zorbit

Absorbeur de choc

Maillons d’attache

(6,35 cm ± 1,25 cm)

2 1./2 po ± 1/2 po

Guide-câble

Pièce B

Pièce A

Figure 10 - Ensemble support

Figure 9 - Raccord de câble

8 po (20 cm) min.

Raccord de l'extrémité de la ligne de vie horizontale métallique Sayfl ine

Figure 11 - Raccord de l'extrémité à la cosse/au serre-câble

supports intermédiaires, soit à 2 pouces (5 cm) ou moins, sans poids exercé sur le câble.

Le câble métallique doit être tendu jusqu'à ce que la fl èche sur le système à mi-portée, entre les

Empêchez la mâchoire non attachée du tendeur de tourner afi n d'éviter de tordre le câble métallique.

la Figure 11. Serrez le câble métallique en tournant le tendeur à l'autre extrémité de l'installation.

la tension en serrant l'écrou du serre-câble et l'écrou de la cosse au couple de valeurs précisées dans

Éliminez le jeu excédentaire en tirant le câble métallique à travers la cosse et le serre-câble. Maintenez

le matériel de connexion au Zorbit. Voir Figure 11. Faites glisser la ligne de vie à travers la cosse.

dans l'Étape 3. Ensuite, attachez la cosse et

d'attache sur l'ancrage et le Zorbit tel que décrit

câble à son ancrage, attachez les maillons

Étape 7. Pour raccorder la deuxième extrémité du

deuxième extrémité.

Sayfl ink sur le câble avant de raccorder la

extrémité. Installez tous les manchons

du système après avoir ancré la deuxième

tendeur. Cela permettra une tension maximale

4 fi ls soient visible à l'intérieur du corps du

tendeur à l'autre extrémité afi n que seulement

de la ligne de vie horizontale, desserrez le

Étape 6. Avant de raccorder la deuxième extrémité

d'ancrage au couple de 55 pi/lb (75 nM).

tête de boulon ou d'écrou. Serrez le matériel

à l'intérieur du support, entre celui-ci et la

vous le préférez, mais la rondelle doit rester

à travers l'ancrage et dans le support si

point d'ancrage. Le boulon peut être installé

trous superposés dans le support et dans le

à travers la rondelle plate et ensuite à travers les

ancrez-le en plaçant le boulon d'utilisateur fourni

assemblé sur son point d'ancrage désigné et

la pièce B dans la pièce A. Placez le support ainsi

le guide-câble selon le même angle et emboîtez

dans l'Étape 2. Ensuite, faites glisser la pièce B sur

sur la pièce A selon un angle approprié déterminé

support, commencez par placer un guide-câble

« A » ou « B ». Voir Figure 10. Pour assembler un

Chacune des plaques est estampillée de la lettre

parties : deux plaques latérales et un guide-câble.

Étape 5. Les supports intermédiaires sont composés de trois

supports sur le câble avant d'installer celui-ci.

été achetés, faites glisser tous les guide-câbles des

Étape 4. Si des supports intermédiaires supplémentaires ont

Page 27

6

ligne de vie avant de raccorder l'autre extrémité du câble à l'ancrage.

connecter le système aux connecteurs d'ancrage. Faites glisser le(s) manchon(s) Sayfl ink sur la

2.4. L'utilisateur doit fournir le matériel d'ancrage. Serrez les boulons et les écrous utilisés pour

si celui-ci comprend un élément de fi xation qui répond aux exigences spécifi ées dans la section

Figure 9. La ligne de vie horizontale peut être directement rattachée en toute sécurité à l'ancrage

boulon fournis. Connectez l'autre côté des maillons d'attache au Zorbit connecté au tendeur. Voir

entre eux, puis, connectez un côté des maillons connectés à l'ancrage à l'aide de l'écrou et du

Étape 3. Pour attacher un câble au premier point d'ancrage, connectez une paire de maillons d'attache

En dessous

6 pi-11 po (2,1)

pi-po (m)

Distance requise :

SALA

≤ Moins que ou égal à

> Plus que

20 (6) - 30 (90) 9 pi-1 po (2,8)

10 (3) - 20 (6) 8 pi-0 po (2,4)

(3)

>0 (0) mais ≤10

pi (m)

Plus longue portée :

dégagement

Lignes de vie auto-rétractables DBI-

Tableau des hauteurs de

À un angle

Travail

Niveau de

Sur le côté

Figure 8 - Sens des supports

des supports.

supports intermédiaires peuvent être installés dans un des trois sens. Voir Figure 8 pour les sens

ou obstacle

Niveau inférieur

(SRL)

rétractable

vie autoLigne de

Au-dessus

des applications de dispositif de sécurité antichute.

positions du support ; un système avec supports montés en dessous de l'utilisateur ne doit être utilisé que dans

Remarque : Une distance maximale de chute libre de 6 pi (1,80 m) doit être maintenue dans toutes les

Étape 2. Déterminez le bon sens des supports intermédiaires. En fonction du positionnement du câble, les

de dégagement requise est 8 pi (2,5 m).

Exemple : la portée est de 16 pi (5 m), la hauteur

hauteur de dégagement requise.

longueur de la portée et réévaluez votre

supports intermédiaires pour réduire la

dégagement est inadéquate, ajoutez des

en cas de chute. Si la hauteur de

une hauteur de dégagement adéquate

hauteurs afi n de déterminer s’il existe

requises présentées dans la colonne des

5. Consultez les hauteurs de dégagement

des hauteurs de dégagement.

système dans les rangées du Tableau

4. Trouvez la plus longue portée de votre

jusqu'au niveau de travail :

niveau inférieur ou de l'obstacle le plus près

Hauteur de dégagement requise à partir du

du harnais, et que l’utilisateur est debout.

situées au-dessus du niveau du point de fi xation

horizontale et la ligne de vie auto-rétractable sont

s’appliquent seulement lorsque la ligne de vie

AVERTISSEMENT : ces renseignements

Longueur de la portée

Figure 7 - Exigences en matière de dégagement de la ligne de vie auto-rétractable

Page 28

(6,2 m)

20 pi-6 po

(6,1 m)

11 po

19 pi-

(5,8 m)

19 pi-2 po

(5,7 m)

18 pi-7 po

(5,5 m)

11 po

17 pi-

(5,9 m)

19 pi-6 po

(5,8 m)

11 po

18 pi-

(5,5 m)

18 pi-2 po

(5,4 m)

17 pi-7 po

(5,2 m)

11 po

16 pi-

(5,6 m)

18 pi-6 po

(5,5 m)

11 po

17 pi-

(5,2 m)

17 pi-2 po

(5,1 m)

16 pi-7 po

(4,9 m)

11 po

15 pi-

5

≤ Moins que ou égal à

> Plus que

(5,3 m)

17 pi-6 po

(5,2 m)

11 po

16 pi-

(4,9 m)

16 pi-2 po

(4,7 m)

15 pi-7 po

(4,5 m)

11 po

14 pi-

3456

pi-po (m)

Longueur de la longe absorbeuse d'énergie :

(7,6 - 9)

25 - 30

(6 - 7,6)

20 - 25

(4,5 - 6)

15 - 20

(3 - 4,5)

10 - 15

(>0 mais ≤3)

>0 mais ≤10

portée : pi (m)

Plus longue

Longes absorbeuses d'énergie DBI-SALA

Tableau des hauteurs de dégagement

ou obstacle

Niveau inférieur

absorbeuse d’énergie

Longueur de la longe

d’énergie

Longe

absorbeuse

la longe.

portée et de la colonne de la longueur de

l'intersection de la rangée de plus longue

dégagement.

la colonne du Tableau des hauteurs de

hauteurs de dégagement.

système dans les rangées du Tableau des

la portée

Longueur de

votre hauteur de dégagement requise.

réduisez la longueur de votre longe et réévaluez

pour réduire la longueur de la portée, ou

inadéquate, ajoutez des supports intermédiaires

de chute. Si la hauteur de dégagement est

une hauteur de dégagement adéquate en cas

Utilisez cette distance pour déterminer s’il existe

dégagement requise est 18 pi-11 po (5,8 m).

de longe de 5 pi (1,5 m). La hauteur de

Exemple : portée de 24 pi (7 m) ; longueur

3. La hauteur de dégagement requise est à

2. Trouvez la longueur de votre longe dans

1. Trouvez la plus longue portée de votre

jusqu'à la hauteur de la ligne de vie horizontale :

niveau inférieur le plus près ou de l'obstacle

Hauteur de dégagement requise à partir du

Figure 6 - Exigences en matière de dégagement de la longe absorbeuse d'énergie

Figures 6 et 7 s’appliquent à un ou deux utilisateurs fi xés au système.

longueur de la portée et évaluez la hauteur de dégagement requise à l’aide des Figures 6 ou 7. Les

supplémentaires (Pièce n° 7608001) peuvent être achetés auprès de DBI/SALA. Déterminez la

les systèmes dont la longueur est supérieure à 30 pi (9 m). Des supports intermédiaires

vos applications. Il doit y avoir un support intermédiaire tous les 30 pi (9 m) de câble pour

selon la section 2.4. Déterminez le nombre de supports intermédiaires nécessaires pour

Étape 1. Déterminez les endroits où seront situés les points ancrages et évaluez leurs forces respectives

Les étapes sont décrites en détails ci-dessous :

7. Attachez l'autre extrémité du câble à son point d'ancrage et tendez le câble.

6. Dénouez le(s) tendeur(s).

5. Assemblez les supports intermédiaires sur leurs points d'ancrage.

4. Installez les guides-câbles et les manchons Sayfl ink sur le câble.

3. Attachez une extrémité à son point d'ancrage.

2. Déterminez l'orientation des supports intermédiaires.

1. Déterminez l'emplacement des points d'ancrage et des supports intermédiaires.

Le processus d'installation consiste des étapes suivantes :

Page 29

4

sont admis lors de l'installation d'une ligne de vie à portée multiple Sayfl ine.

dessus d'une longueur de 12 po [30 cm]). Le câble doit être une ligne droite, aucune courbe ou tournant ne

d'inclinaison de la ligne de vie ne dépasse pas un rapport de déclivité de 1:12 (1 po [3 cm] d'élévation au-

Les deux ancrages doivent être installés à une hauteur approximativement semblable afi n que le degré

possible afi n de réduire le risque de chute libre et la hauteur de dégagement nécessaire.

chute avec effet pendulaire. La longueur du sous-système de connexion doit être gardée la plus courte

La ligne de vie horizontale doit être positionnée près du lieu de travail afi n de minimiser les dangers de

facilitant l'utilisation.

horizontale doit être dans une position qui minimise le danger de chute tout en étant dans un endroit

une fois rétractée entièrement, doit se trouver au-dessus du point de fi xation du harnais. La ligne de vie

d'ancrages doivent être situés directement au-dessus de l'utilisateur. La ligne de vie auto-rétractable,

Lorsque vous utilisez ligne de vie auto-rétractable (SRL) pour vous connecter au système, les points

(6 pi). La longueur de la longe doit être prise en considération lorsque vous déterminez la hauteur des ancrages.

d'énergie pour vous connecter au système, les ancrages doivent être situés à une hauteur qui limitera la chute libre à 1,8 m

La Figure 1 montre une installation typique de ligne de vie horizontale. Lorsque vous utilisez une longe absorbeuse

3.3 INSTALLATION DU SYSTÈME :

chimiques et d'objets tranchants.

équipement avec précaution à proximité de machines en mouvement, de sources d'électricité, de substances

AVERTISSEMENT : veuillez ne pas modifi er cet équipement ni en faire sciemment un usage abusif. Utilisez cet

(16 kN minimum)

3 600 lb minimum

gants lors de l'installation de la ligne de vie horizontale.

DBI/SALA recommande l'utilisation et le port de protection oculaire agréée, de chaussures de sécurité et de

Sayfl ine suite à une chute.

moyen de protection antichute séparé doit être utilisé lors de l'inspection ou de l'entretien du système

Un moyen de protection antichute séparé doit être utilisé lors de l'installation du système Sayfl ine. Un

3.2 Sécurité

Sayfl ine, causant éventuellement des blessures graves ou la mort en cas de chute.

AVERTISSEMENT : l'utilisation de pièces endommagées ou défectueuses entravera le fonctionnement du système

ligne de vie horizontale.

obtenir un remplacement. N'utilisez pas des pièces endommagées ou défectueuses dans une installation de

DBI/SALA sont endommagés, défectueux ou manquants, communiquez immédiatement avec DBI/SALA pour

de l'utilisateur à la recherche de défauts et/ou de dommages. Si des composants Sayfl ine ou l'équipement

Lors de la réception de votre ligne de vie horizontale Sayfl ine, inspectez tous les composants et l'équipement

3.1 Inspection

3.0 INSTALLATION

charge appliquée sur le dispositif antichute)

3 600 lb (16 kN) minimum (dans toutes les directions possibles de

(16 kN minimum)

3 600 lb minimum

(22 kN minimum)

5 000 lb minimum

(22 kN minimum)

5 000 lb minimum

Figure 5 - Force de l'ancrage

Page 30

3

vie horizontale à 900 livres (4 kN) ou moins.

fi xation du harnais antichute. Le sous-système de connexion doit limiter les forces appliquées à la ligne de

personnel utilisée pour faire la connexion entre le sous-système de la ligne de vie horizontale et l'élément de

2.6 SOUS-SYSTÈME DE CONNEXION : le sous-système de connexion est la partie du dispositif antichute

entraîner de graves blessures, voire la mort.

rendement du système et pourraient faire augmenter la distance d'arrêt requise sous le système, ce qui pourrait

AVERTISSEMENT : les ancrages doivent être rigides. De grandes déformations de l'ancrage affecteront le

perpendiculaires à l'axe de la ligne de vie horizontale. Voir Figure 5.

un minimum de 3 600 livres (16 N) appliqué dans toutes les directions potentielles du dispositif antichute

horizontale. Les ancrages, y compris les supports intermédiaires, doivent également pouvoir supporter

la capacité de supporter une charge d'au moins 5 000 livres (22 kN) le long de l'axe de la ligne de vie

2.5 CHARGE SUR LA STRUCTURE : les points d'ancrage de la structure doivent être rigides, tout en ayant

peut être utilisé à la place de la rondelle de blocage et de l'écrou simple.

Une rondelle plate, une rondelle de blocage et un écrou sont également nécessaires. Un écrou de blocage

Les supports intermédiaires nécessitent un boulon UNC 1/2-13 répondant à une force de classe 5 minimum.

charge de 5 000 lb (22,2 kN) sans céder sous cette charge.

Cette connexion doit être positive; et, avec les éléments de connexion, doit être capable de supporter une

fi xer la ligne de vie horizontale aux points d'ancrage doivent être compatibles avec le point de connexion.

2.4 CONNECTEURS D’ANCRAGE : DBI/SALA ne fournit pas d'attaches d'ancrage. Les connecteurs utilisés pour

G. De manière ne permettant pas au connecteur de s’aligner correctement pendant qu’il est sous tension.

puisse pas se fermer et se verrouiller ou qu'un dégagement puisse se produire.

F. À un objet qui aurait une forme ou dimension de sorte que le crochet mousqueton ou le mousqueton ne

de la longe et du connecteur n'autorisent une connexion de ce type).

E. Directement à la sangle ou à la longe ou au tirant d'ancrage (à moins que les instructions du fabricant

D. Entre eux.

dans l’ancrage et, sans une confi rmation visuelle, semblent complètement attachés au point d’ancrage.

C. Dans un faux raccord où des éléments rattachés au crochet mousqueton ou au mousqueton s’accrochent

d'armature ou des traverses dont les formes ne peuvent pas accrocher le doigt du crochet.

ouverture large sont conçus pour être utilisés sur des éléments structuraux fi xes, tels que des barres

le doigt si le crochet ou le D d'accrochage venait à se tordre ou à pivoter. Les crochets mousquetons à

D d'accrochage de taille standard ou des objets semblables qui pourraient occasionner une charge sur

REMARQUE : les crochets mousquetons à ouverture large ne doivent pas être connectés à des

B. De façon à exercer une charge sur le doigt.

A. À un D d'accrochage auquel est fi xé un autre connecteur.

inappropriées. Les crochets mousquetons et les mousquetons DBI-SALA ne doivent pas être connectés :

uniquement selon les instructions de chacun des produits. Voir la Figure 4 pour les connexions

Les connecteurs DBI-SALA (crochets mousquetons et mousquetons) sont conçus pour être utilisés

non compatible. Assurez-vous que tous les connecteurs sont complètement fermés et verrouillés.

vous que tous les connecteurs sont compatibles en taille, forme et résistance. N'utilisez aucun équipement

mousquetons avec cet équipement. Utilisez uniquement des connecteurs adaptés à chaque usage. Assurez-