Page 1

C

EXPERIEN

•

GLOBAL

•

Projected Capacitive Near

Field Imaging

SOLUTIONS

Integration Guide

INNOVATIVE

•

EXPERIENCE DEPENDABLE

•

TM

(“NFI”)

GLOBAL

•

INNOVATIVE

•

DEPENDABLE

touch

3M Touch Systems Proprietary Information

Page 2

Copyright

This manual is © 3M 2003. All rights reserved.

Reproduction of the contents of this copyrighted manual in whole or in part, by

any means, electronic or mechanical, for any purpose, without written permission

of 3M Touch Systems, a subsidiary of 3M, is prohibited.

Notice

Important notice to

purchaser

Given the variety of factors that can affect the use and performance of a 3M

Touch Systems Product (the “Product”), including that solid state equipment has

operation characteristics different from electromechanical equipment, some of

which factors are uniquely within User’s knowledge and control, it is essential

that User evaluate the 3M Touch Systems Product and software to determine

whether it is suitable for User’s particular purpose and suitable fo r User’s method

of application. 3M Touch Systems’ statements, engineering/technical

information, and recommendations are provided for User’s convenience, but

their accuracy or completeness is not warran ted. 3M Touch Systems products and

software are not specifically designed for use in medical devices as defined by

United States federal law. 3M Touch Systems products and software should not

be used in such applications without 3M Touch Systems’ express written

consent. User should contact its sales representative if User’s opportunity

involves a medical device application.

Specifications are subject to change without notice. These 3M Touch Systems’

Products and software are warranted to meet their published specifications from

the date of shipment and for the period stated in the specification. 3M Touch

Systems makes no additional warranties, express or implied, including but

not limited to any implied warranties of merchantability or fitness for a

particular purpose.

User is responsible for determining whether the 3M Touch Systems Products and

software are fit for User’s particular purpose and suitable for its method of

production, including intellectual property liability for User's application. If the

Product, software or software media is proven not to have met 3M Touch

Systems’ warranty, then 3M Touch Systems’ sole obligation and User’s and

Purchaser’s exclusive remedy, will be, at 3M Touch Systems’ option, to repair

or replace that Product quantity or software media or to refund its purchase price.

3M Touch Systems has no obligation under 3M Touch Systems’ warranty for any

Product, software or software media that has been modified or damaged through

misuse, accident, neglect, or subsequent manufacturing operations or assemblies

by anyone other than 3M Touch Systems. 3M Touch Systems shall not be liable

in any action against it in any way related to the Products or software for any

loss or damages, whether non-specified direct, indirect, special, incidental or

consequential (including downtime, loss of profits or goodwill) regardless of

the legal theory asserted.

Edition

July 2003. Document Number: 14116 (Rev. 3.0)

Trademarks MicroTouch, Near Field Imaging, and TouchSurround are trademarks of 3M.

Microsoft, Windows, MS-DOS, Windows NT, Windows 2000,

Windows XP, and/or other Microsoft products referenced herein are

either trademarks or registered trademarks of Microsoft Corporation in

the United States and/or other countries. JST is a registered trademark of

J.S.T. Mfg. Co., Ltd.

3M Touch Systems Proprietary Information

Page 3

Intended use

Safety notices

Product Safety Information

The Near Field ImagingTM (NFI) touch screen system is composed of components

for incorporation in electrical or electronic apparatus, equipment or installations.

The NFI touch screen system has been tested to the standards that are cited in the

Appendix of this integration guide to show compatibility for use in products

requiring CE marking under the following directives: the EMC Directive

89/336/EEC, the Low Voltage Directive 73/23/EEC, and the Machinery Directive

89/392/EEC. Caution: Changes or modifications to this equipment not expressly

approved by the manufacturer could void the user’s authority to operate this

equipment.

The manufacturer of the end apparatus will, under their responsibility, comply

with the applicable Directives in design and construction.

WARNING

To reduce the risks associated with electrical shock or mechanical function which,

if not avoided, could result in death or serious injury and/or property damage:

Do not use a power cable that is damaged or frayed or a power plug that is damaged.

Do not use a damaged power supply.

Handle the power supply with care.

Do not service the NFI touch screen system. There no user serviceable parts. Refer all

servicing to qualified service personnel.

Safety labels

CAUTION

To reduce the risks associated with glass breakable which, if not avoided, may result

in minor or moderate cut-related injury:

Handle a touch screen with care to avoid breaking the glass. Be aware of cracked or

broken sensors with sharp edges.

CAUTION

To reduce the risks associated with environmental contamination which, if not

avoided, may result in minor or moderate injury and/or cause property damage:

Dispose of components in accordance with local, state, and federal regulations.

The following safety symbols appear on your NFI touch screen system or

packaging materials:

Symbol Meaning

Warning: Hazardous voltage

Caution: Item is susceptible to electrostatic discharge

(ESD) damage if proper precautions are not taken.

3M Touch Systems Proprietary Information

iii

Page 4

Page 5

Contents

Chapter 1 Overview.......................................................................... 1

Components............................................................................................ 1

Cleaning the touch screen ...................................................................... 2

Chapter 2 Mounting the touch screen............................................ 5

Critical information..................................................... ........................... 5

Steps for mounting an NFI touch screen ................................................ 7

TouchSurround

Chapter 3 Mounting the controller.................................................. 9

Critical information..................................................... ........................... 9

Materials required ................................................................................ 10

Steps for mounting an NFI controller .................................................. 11

Chapter 4 Making connections and resetting the baseline........ 13

Critical information: Connecting the tail .............................................13

Steps for connecting tail to controller.................................................. 14

Critical information: Connecting communications and power ............ 16

Steps for attaching power/communications cable................................17

Critical information: Resetting the baseline.........................................18

Steps for resetting baseline................................................................... 18

Chapter 5 Outdoor applications.................................................... 21

Critical information: Integrating with a metal bezel............................ 21

Critical information: Integrating with a plastic bezel........................... 25

Chapter 6 Troubleshooting............................................................ 27

Strategies..............................................................................................27

Interpreting the controller’s status lights..............................................29

Appendix Standards and certifications........................................ 31

TM

underlay (optional).................................................... 8

3M Touch Systems Proprietary Information

v

Page 6

Page 7

Components

CHAPTER 1

Overview

This chapter provides:

Description of the components of a typical MicroTouch

Capacitive Near Field Imaging

Guidelines for cleaning the touch screen

Terms used in the manual

3M contact information

TM

(“NFI”) touch screen system

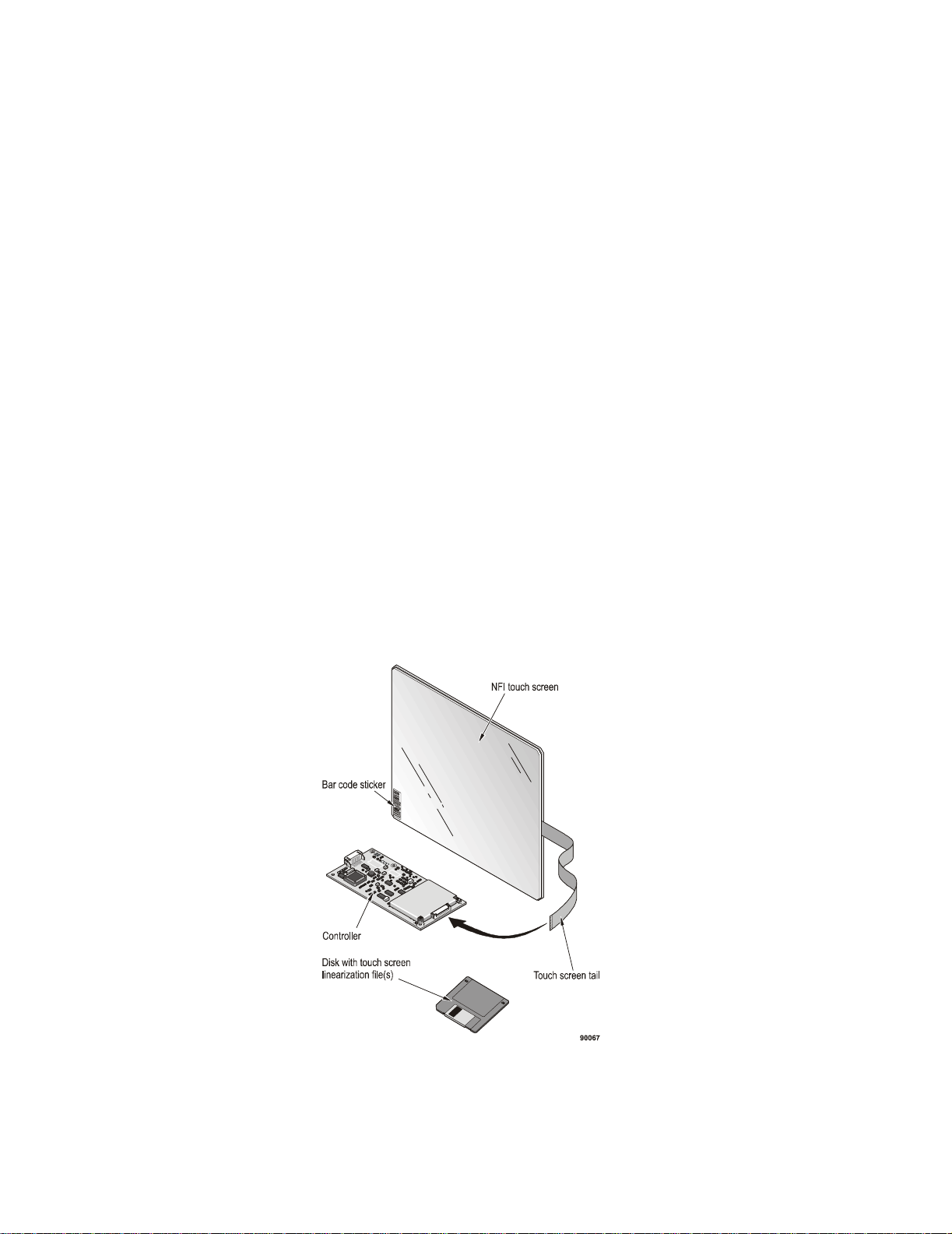

The NFI touch screen system includes the following components:

NFI touch screen and tail. The touch screen is available in different sizes

and can be used with most flat panel displays or adapted to fit flat cathode ray

tube displays. The tail connects the touch screen to the controller.

TM

Projected

3M Touch Systems Proprietary Information

1

Page 8

MicroTouch

TM

Near Field Imaging (NFI)TM Integration Guide

Touch screen controller. The controller decodes signals on the touch

screen. It has connectors for the touch screen tail and for communications/

power.

Floppy disk with linearization file (does not accompany 8.4-inch

screens). Linearization increases the accuracy of an NFI touch screen and

is required for screens larger than 8.4 inches. For details on linearizing, see

“Steps for resetting baseline”, starting on page 18.

Bar code sticker on the touch screen. The serial number provided on

the bar code stickers correspond to the linearization file that is installed (from

the floppy disk) when setting up the touch screen system.

The bar code sticker on the touch screen helps you to recognize which side

of the touch screen is the front side and which is the back side. If you are

looking at the printed side of the bar code sticker, you are looking at the front

of the touch screen.

You will need the serial number if it is ever necessary to:

Re-install the linearization file.

Contact 3M Touch Systems customer service.

Cleaning the touch screen

Follow these guidelines for cleaning the NFI touch screen:

To clean the touch screen’s back side, blow away dust with pressurized air.

To clean the front of the touch screen, use cleaning solutions and cloths

designed for cleaning coated optical glass (e.g., isopropyl alcohol and water

50:50 solution). Do not use any chemical that corrodes glass. Follow cleaner

manufacturer’s material safety data sheet (MSDS) and follow all instructions

and recommendations on product label.

Apply the cleaner with a soft, lint-free cloth. Avoid using gritty cloths.

Apply the cleaning liquid to the cloth, not directly to the screen.

Terms

These terms appear in this manual and may be unfamiliar.

This term Refers to

Baseline An electronic ‘picture’ of the touch screen and its immediate

Display area The part of the touch screen that is positioned over the product’s

Continuous frame Gasket material that has no ends.

Metallized bezel Plastic bezel with conductive material applied to its interior.

Near Field Imaging

(NFI)

Opaque area A narrow border around the perimeter of the touch screen

Touch sensitive area Part of touch screen’s viewing area that will register a touch.

Viewing area The part of the touch screen that is within the opaque area.

3M Touch Systems Proprietary Information

surroundings. Baseline must be reset after any physical or

mechanical change is made to the NFI touch screen integration

or system. With an up-to-date baseline, the touch screen system

performs more accurately and efficiently.

display. Touches in the display area emulate the movements

and actions of a mouse.

A touch screen that uses a proprietary imaging technique to

generate a precise profile of a touch from changes in the

electrostatic field near to the point of contact.

(usually silver-grey or black) that does not register touches.

Sometimes called “the guard”.

2

Page 9

3M Touch Systems support services

3M Touch Systems provides extensive support services through our website and

technical support organization. Visit the 3M Touch Systems website at

www.3Mtouch.com

obtain regularly updated technical documentation on 3M Touch Systems

products, and learn more about our company.

Whenever you contact Technical Support, please provide the following

information:

Part number and serial number

Current driver version

Operating system used

Information on additional peripherals

Technical Support is available Monday through Friday 8:00 a.m. to 8:00 p.m.

US Eastern Standard Time, 9:00 a.m. to 5:00 p.m. throug hout Europe. There is

limited service on Saturdays and Sundays.

You can contact 3M Touch Systems Technical Support (US only — Eastern

Standard Time) by calling the hot line or sending a fax:

Technical Support Hot Line: 978-659-9200

Technical Support Fax: 978-659-9400

Toll Free: 1-866-407-6666

Email: US-TS-techsupport@mmm.com

, where you can download touch screen software and drivers,

Overview

3M Touch Systems worldwide offices

All offices can be reached through the website: www.3Mtouch.com.

Country Telephone

United States 978-659-9000

Australia 61-3-9582-4799

Canada 604-521-3962

France 33-(1)-30-31-68-32

Germany 49-(0)-2131-14-4003

Hong Kong/China 852-2333-6138

Italy 39-(0)-39-230-2230

Japan 81-(4)-4811-1133

Korea 822-552-3198

Singapore 65-6450-8851

Spain 34-934-15-6285

Taiwan 886-2-2704-9011

3M Touch Systems Proprietary Information

3

Page 10

Page 11

CHAPTER 2

Mounting the touch screen

This chapter outlines:

Critical information to help you mount the touch screen successfully.

Step-by-step mounting instructions.

Basic information on the TouchSurround

If you are integrating the touch screen in an outdoor application:

Using a metal bezel, see additional instructions starting on page 21.

Using a plastic bezel, see additional instructions on page 25.

Critical information

Prevent interference

Mount the touch screen as far away as possible from:

Components (such as radios) that generate a signal in the 50 kHz to 60 kHz

AC sources and backlight inverters (unless there is intervening grounded

TM

range (unless they are adequately shielded).

metal work or shielding).

underlay.

Observe minimum mounting clearances

Minimum mounting clearances are shown in Table A to help in tegrators make

mounting decisions that will minimize capacitive loading on the touch screen and

tail. Read Table A while referring to Figure 1 or Figure 2 (whichever figure

applies to your mounting materials).

3M Touch Systems Proprietary Information

5

Page 12

MicroTouchTM Near Field Imaging (NFI)

TM

Integration Guide

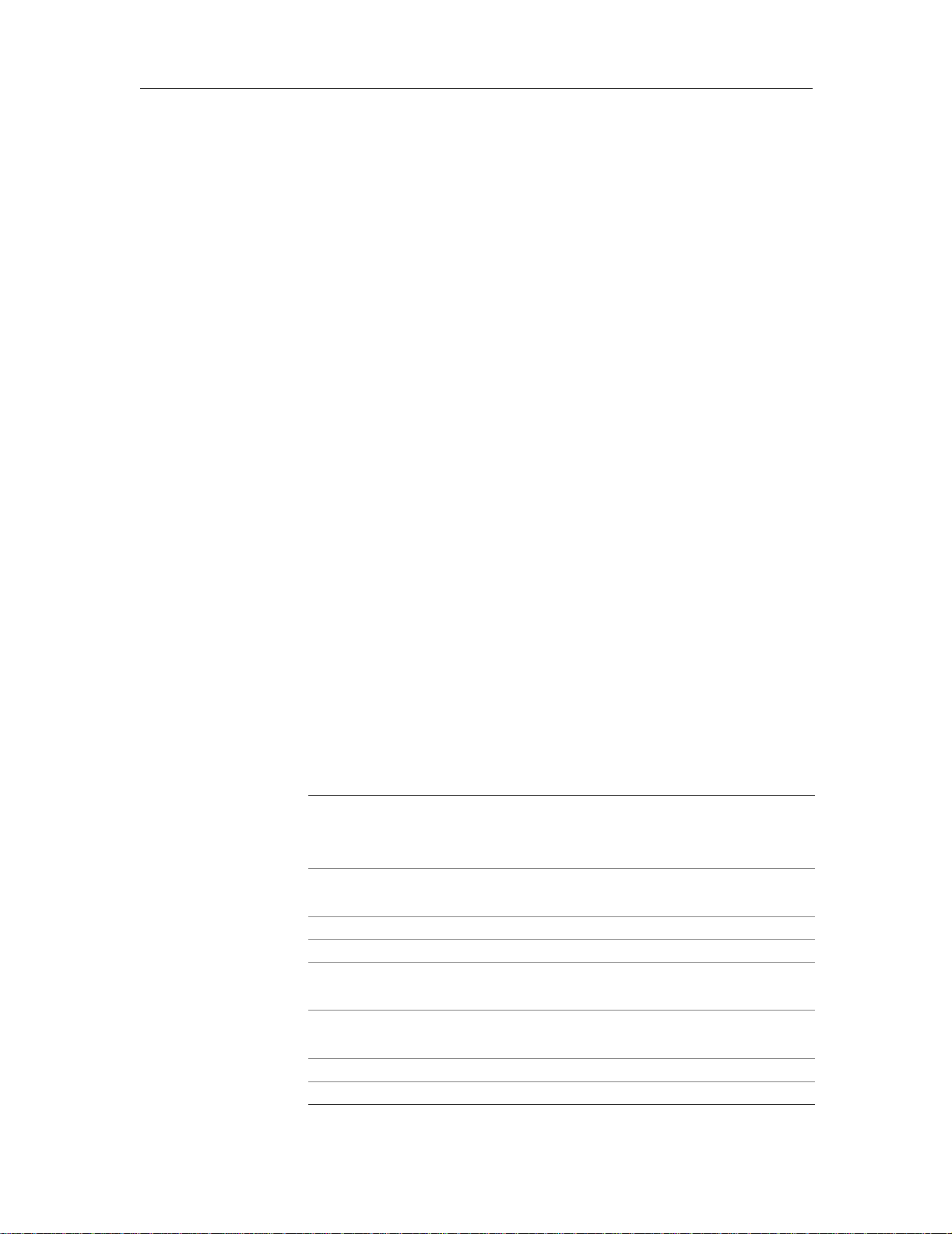

Display

Metal bezel

Metal clamp

Spacer (Non-

NFI touch

screen

C

conductive)

B

A

Front

Gasket (Non-

conductive)

Figure 1: Mounting (using metal bezel) with metal clamp (Top View)

Metal bezel

D

NFI touch

screen

Display

C

A

Front

Adhesive

Figure 2: Mounting (using metal bezel) with adhesive (Top View)

T able A: Minimum mounting clearances (Use this table with Figure 1

Screen size

8.4" 10.4" 12.1" 15.0" 18.1"

A

— Front of touch screen to

inside lip of bezel

B

— Front of clamp to back of

touch screen

C

— Display to back of touch

screen

D

— Side of bezel to edge of

touch screen

Viewing area & bezel opening: See NFI touch screen drawings on 3M Touch Systems website: www.3Mtouch.com

0.020"

(0.5 mm)

0.020"

(0.5 mm)

0.060"

(1.5 mm)

0.030"

(0.8 mm)

0.020"

(0.5 mm)

0.030"

(0.8 mm)

0.070"

(1.8 mm)

0.030"

(0.8 mm)

0.020"

(0.5 mm)

0.035"

(0.9 mm)

0.080"

(2.0 mm)

0.030"

(0.8 mm)

or Figure 2)

0.020”

(0.5 mm)

0.045"

(1.1 mm)

0.100"

(2.5 mm)

0.030"

(0.8 mm)

0.030"

(0.8 mm)

0.060"

(1.5 mm)

0.120"

(3.1 mm)

0.030"

(0.8 mm)

3M Touch Systems Proprietary Information

6

Page 13

Mounting the touch screen

Observe best practices for different mounting methods

The touch screen can be integrated with either clamps or adhesive:

If mounting with a clamp

Use gaskets between the sensor and clamp and between the sensor and bezel.

Choose gaskets with the following properties:

Non-conductive (with little or, preferably, no carbon content) to seal

gap A in Table A.

Low compression set.

If foam gaskets are required, they should be water resistant (closed-cell and

non-porous). Many neoprene and silicone gaskets have these properties.

Choose non-conductive spacers to achieve the minimum clearances for gap B

(see Table A), or use an air gap.

If you are mounting the NFI touch screen outdoors, refer to Chapter 5.

If mounting with adhesive

Choose adhesives with the following properties:

Non-acidic, neutral pH adhesive such as room temperature vulcanizing

(RTV) adhesives.

You can also integrate the NFI touch screen with closed cell foam with

adhesive on both sides.

Warranty note: If you use an adhesive to mount an NFI touch screen into a bezel,

the touch screen must be detached from the bezel and adhesive to be returned to

3M Touch Systems under warranty.

If your application requires an exceptional seal to prevent moisture or dust

entering the bezel, please see instructions for outdoor applications in Chapter 5.

Steps for mounting an NFI touch screen

For specific information on mounting a touch screen outdoors, refer to Chapter 5.

1. On a protected surface, line up the gasketing or adhesive with the bezel.

Do not allow the bezel and gasket to encroach on any side of the touch

screen’s viewing area by more than 0.020 inches (0.5 mm). Encroaching by

more than that amount may adversely affect the performance of the touch

screen.

2. Check that the minimum clearances have been met for gap A (Tabl e A on

page 6).

3. Position the NFI touch screen on top of the gasketing or adhesive.

4. If you use clamps to integrate the touch screen, then spacers are required to

push the touch screen against the gasket. Align the spacers and install the

clamps and screws according to the instructions provided by the bezel

manufacturer.

5. If the NFI touch screen is integrated with adhesive, follow the instructions

provided by the manufacturer to ensure that the bonding is set correctly.

3M Touch Systems Proprietary Information

7

Page 14

MicroTouchTM Near Field Imaging (NFI)

TM

Integration Guide

TouchSurroundTM underlay (optional)

A TouchSurround underlay can be fitted behind an NFI touch screen (when the

touch screen is larger than the display) to allow part of the touch screen to be used

to define keys such as the ones on a keyboard (Figure 3).

Figure 3: TouchSurround underlay

3M Touch Systems Proprietary Information

8

Page 15

CHAPTER 3

Mounting the controller

This chapter provides the following information:

Critical information about mounting the controller. Following the

Materials required

Step-by-step instructions

Critical information

Ground properly

There is only one correct grounding location on the controller (see

Extend the grounded metal surface (to which the controller is mounted) by

If the controller is above a grounded continuous metal surface, place it

recommendations in this section will help ensure you are successful in

mounting the controller

“Grounding Hole” in Figure 4 on page 10) and it must be connected for the

controller to operate correctly.

at least 0.25 inches (6.4 mm) beyond the outli ne of the controller.

no less than 0.10 inches (2.5 mm) and no more than 0.30 inches (7.6 mm)

from that surface.

Avoid contact with shields

Make sure that nothing touches the top or bottom shields (Figure 5 on

page 11).

Prevent interference

Minimize electromagnetic interference. Specifically, make sure that the

controller is:

Away from sources of noise (e.g., transformers, AC sources, backlight

inverters, and high-voltage switching noise).

As far away as possible from components that generate a signal in the

50 kHz to 60 kHz range (unless th ey are adequately shielded).

(For guidelines on electrically connecting portable applications, contact “3M

Touch Systems support services” on page 3.)

3M Touch Systems Proprietary Information

9

Page 16

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

Materials required

To mount the NFI controller, the following materials are required:

Screwdriver appropriate for No.4 Phillips or M3 screws

4 No. 4 Phillips (or M3) pan-head screws

Make sure the screw heads are small enough that they do not touch the

circuitry surrounding them (see Figure 5 on page 11 and Figure 6 on

page 11).

4 No. 4 (or M3) compression washers

If compression washers are unavailable, star washers, single coil washers or

shakeproof washers may be substituted. Make sure the washers are small

enough that they do not touch the circuitry surrounding them (see Figure 5

on page 11 and Figure 6 on page 11).

1 grounding wrist strap

Shield

5.50" (139.7 mm)

0.2" (5.1 mm)0.2" (5.1 mm)

0.2"

(5.1 mm)

2.75"

(69.9 mm)

0.2" (5.1 mm)

0.2"

(5.1 mm)

Do not touch shields with grounding wire.

They are not grounded. If shields touch grounded

metal work, the controller will malfunction.

Shield

Shield

0.125" (3.2 mm) Dia.

all holes

3.77" (95.8 mm)

5.10" (129.5 mm)

Plan view

Side view

0.24"

(6.1 mm)

1.53" (38.9 mm)

Overall height

0.32" (8.1 mm)

Figure 4: Dimensions of controller

Critical

There is only one grounding location and it must be connected for the controller to operate

correctly (See Figure 5 on page 11).

0.2"

(5.1 mm)

2.35"

(59.7 mm)

Grounding

hole

3M Touch Systems Proprietary Information

10

Page 17

Steps for mounting an NFI controller

1. The components on the NFI controller are sensitive to damage from

electrostatic discharge (ESD). To prevent damage from ESD, put on a

grounding strap, connect to ground, and touch a grounded object to

discharge any built-up static.

2. Locate the mounting holes on the NFI controller (Figure 5).

Mounting the controller

Figure 5: Controller’s mounting holes, grounding/mounting hole

3. Insert the screws and washers into the mounting holes. T ake care to not short

out the surrounding circuitry with either the screws or washers. Tighten the

screws so that the controller is firmly in place and the washers will not

move.

Do not use metal fasteners that could touch and

short out the surrounding circuitry or plated holes.

Figure 6: Mounting controller

3M Touch Systems Proprietary Information

11

90075_2003

Page 18

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

4. Ground the controller. 3M Touch Systems recommends grounding the

controller using a ground screw through a metal stand off (Figure 7). If the

stand off is not grounded, attach a grounding cable (Figure 8).

Metal grounding

To achieve grounding, useonly

grounding screw hole.

Grounding screw hole

Grounded stand off

screw

Metal compression

washer

Controller

90076_2003_a

Figure 7: Grounding controller using stand off

Metal grounding

screw

Metal compression

washer

Grounding cable

To achieve grounding, useonly

the grounding screw hole.

Grounding screw hole

Controller

Figure 8: Grounding controller using cable

5.

Make sure that the grounding cable, compression washer and metal

grounding screw do not touch or short out the surrounding circuitry.

90077_2003

3M Touch Systems Proprietary Information

12

Page 19

CHAPTER 4

Making connections and resetting the

baseline

This chapter provides the following information:

Critical information and steps for connecting the NFI touch screen tail.

Critical information and steps for connecting power/communications.

Critical information and steps for resetting the baseline.

Critical information: Connecting the tail

The touch screen tail connects the touch screen to the controller. The following

tail connection practices are essential for achieving a successful integration.

Prevent interference

Position the tail and controller away from:

Components that gene rate a signal in the 50 kHz to 60 kHz range (unless

components are adequately shielded).

AC sources (such as backlight inverters) and high-voltage switching

noise. If this is not possible, make sure the AC or noise source is

appropriately shielded and grounded.

Conductive surfaces — at least 0.10 inches (2.5 mm) away.

If the tail must run along a large conductive metal surface, keep it at least

0.10 inches (2.5 mm) from the surface and make sure that it cannot move

(e.g., by using an adhesive foam spacer).

Bending and position the tail properly

Do not bend the tail past a radius of 0.100 inches (2.5 mm). The tail can be

damaged and the touch screen may not operate correctly if it is severely

creased.

To provide extra protection for the touch screen tail, consider wrapping the

entire tail in an insulator (i.e. foam or nylon).

If the tail wraps around a sharp edge in your product, use an insulator on

the edge of the surface to prevent chafing.

3M Touch Systems Proprietary Information

13

Page 20

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

At least 0.100" (2.5 mm)

between tail and a surface

that is conductive

Use insulator to protect tail

wrapped around sharp edge

Figure 9: Using an insulator if tail wraps around a sharp edge

Steps for connecting tail to controller

To connect the touch screen tail to the controller:

1. Put on a grounding strap, connect to ground, and touch a grounded object to

discharge any built-up static on your body.

2. Place the touch screen on a non-conductive surface (e.g., cardboard). Make

sure the side of the touch screen with the bar code visible is face up.

3. Remove the controller from its ESD-protected plastic envelope. Make sure

that the major electronic components are face up.

4. Use two fingers to gently pull out the retaining clip so that it protrudes

slightly from the controller’s connector. To protect the retaining clip from

damage, do not remove it completely (Figure 10).

Touch screen tail

Bend radius 0.100"

(2.5 mm)

90085

Pull out clip just enough so it

protrudes slightly from connector

90010_2003

Figure 10: Pulling out retaining clip from touch sc ree n co nn e cto r on

controller

3M Touch Systems Proprietary Information

14

Page 21

Making connections and resetting the baseline

5. Orient the end of the touch screen tail so that the shiny (conductive) side

faces you (Figure 11).

Conductive side

Figure 11: Orientin g tail

6. Attach the tail by inserting it gently — with the shiny side up — between the

retaining clip and the connector on the controller. Make sure that the tail is

seated straight and fully inserted in the connector (Figure 12).

Touch screen

tail

Connector

Retaining

clip

Conductive side

90079_2003

Figure 12: Attach in g tail

With a finger on each side of the retaining clip, push it until the retaining clip

7.

fits snugly inside the connector (Figur e 13).

Figure 13: Pushing retaining clip into connector

3M Touch Systems Proprietary Information

15

Page 22

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

Critical information: Connecting communications and power

Check power supply

Before connecting the NFI controller to the host computer’s COM port and power

source, make sure that:

The NFI controller has a regulated DC power supply of 5V ±5 percent,

capable of providing at least 300 mA.

There is at least 4.75 VDC measured on the NFI controller (otherwise it will

remain in reset mode).

For the NFI controller, 3M Touch Systems reco mm ends using a Class 2

power source according to the standards set by the U.S. National Electrical

Code or the Canadian Electrical Code. Using a power source other than

Class 2 may require additional safety certifications for your product.

If the power supply is noisy, it may be necessary to isolate the power and other

cables by using a ferrite core.

Use an RS-232 power/communications cable

To connect the controller, a standard RS-232 power/communications cable is

required:

An NFI RS-232 power/communications cable (which comes with stripped

flying leads) is available from 3M Touch Systems. This cable can then be

completed to fit the power supply and communications requirements of your

application. To purchase this cable contact “3M Touch Systems support

services” on page 3.

Alternatively, you may choose to make a cable using the information located

in Table B and Table C.

Making an RS-232 power/communications cable

Table B provides information on recommended components for the cable.

Table B: Components for RS-232 power/communications cable

Component Manufacturer Part number

Power and communications connector on the

controller

Recommended mating connector housing JST* PHR–8

Recommended mating connector contacts JST* SPH–002T–P0.5S

*For information on JST products, refer to www.jst.com

JST* S08B–PH–SM3–TB

.

3M Touch Systems Proprietary Information

16

Page 23

Making connections and resetting the baseline

Table C provides information on the pin out for the controller and cable.

Table C: Pin out for RS-232 power/communications cable

Controller

Pin

1 Unused Unused Unused -2 SGND RS-232 signal ground -- 5 - DB9 female

3 RXD RS-232 receive IN 3 - DB9 female

4 TXD RS-232 transmit OUT 2 - DB9 female

5 _RST Reset— active low TTL

6 Gnd Common -- User-provided

7 Gnd Common -- User-provided

8 +5VDC + 5V DC IN User-provided

Controller Function Controller

In/Out

IN If needed, user

logic level (leave

unconnected if not used)

Steps for attaching power/communications cable

To attach the RS-232 power/communications cable to the controller:

1. Locate the power/communications connector (Figure 14).

Connector Pin

Connector

Connector

Connector

defined control

power supply

power supply

power supply

Power/communications

connector

90009

Figure 14: Power/communications connec to r on controller

3M Touch Systems Proprietary Information

17

Page 24

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

2. Orient the end of the cable so that it is aligned with the connector on the

controller. Pin 1 of the RS-232 power/communications cable lines up with

Pin 1 of the connector on the controller (Figure 15).

Pin 1

Pin 8

Figure 15: Attach ing power/communications ca ble

3. Insert the cable fully into the connector. Secure the cable so that it cannot

move.

4. Attach the remainder of the cable as appropriate for the specifications of

your application.

Critical information: Resetting the baseline

The baseline must be reset after any physical or mechanical change is made to the

NFI touch screen system (e.g., after integrating in a bezel or display assembly,

adding or replacing gaskets, mounting or re-mounting the unit).

When you reset the baseline, an electronic ‘picture’ is taken of the touch screen

and its immediate surroundings. To ensure that the baseline is reset successfully,

make sure that nothing is touching the screen, bezel, or controller during the

baselining process.

Steps for resetting baseline

There are different procedures for resetting the baseline, depending on which NFI

touch screen driver you are using. Follow the instructions below that are

appropriate for your touch screen driver. After the NFI touch screen is fully

integrated see the Near Field Imaging

information on setting up and installing the NFI software.

TM

(NFI) Software User’s Guide for

90015_2003

Critical

If a message appears indicating that baselining was not successful, check to make sure

that nothing is touching the touch screen, bezel, or controller and that nothing conductive

is touching the tail, then try resetting the baseline again.

3M Touch Systems Proprietary Information

18

Page 25

Making connections and resetting the baseline

Windows XP/2000 drivers

1. From the Windows desktop, select Start » Programs » Touch » NFI Setup

Utility.

2. Select NFI Setup Wizard.

3. Select Continue.

4. Select Start to begin resetting the baseline. Do not touch or allow other

things to touch the touch screen, bezel, or controller during baselining.

5. Select OK to acknowledge that baselining was successful.

6. Select Skip (linearization data is not required to reset the baseline).

7. Select Start to begin re-aligning the touch screen (the touch screen must be

re-aligned after the baseline is reset).

When aligning, be sure you are directly in front of the touch screen. Use a

finger or alignment tool to align the touch screen. An alignment tool

produces a more accurate alignment.

8. Select OK if you are satisfied with the new touch screen alignment.

9. Select Exit when the NFI Setup Utility dialog box reappears.

10. Power cycle the controller.

Windows NT/9X drivers

1. From the Windows desktop, select Start » Programs » Touch Screen

Utilities » NFI Setup Wizard.

2. Select Next to start the Wizard.

3. Select Next and then select Start to begin setting the baseline.

4. Select Next if baselining was successful.

5. Select Next.

6. Select Cancel (linearization data is not required to reset the baseline).

7. Select No to confirm that you do not want to download linearization data but

that you want linearization to continue to function on the NFI touch screen

system.

8. Select Next to proceed with touch screen alignment (the touch screen must

be re-aligned after the baseline is reset).

9. Select OK and then follow the on-screen instructions to align the touch

screen.

Note: If your touch screen has defined TouchSurround

that the Align TouchSurround check box is selected before selecting OK.

T o cancel alignment without changes, press ESC at any time. When aligning,

be sure you are directly in front of the touch screen. Use a finger or

alignment tool to align the touch screen. An alignment tool produces a more

accurate alignment.

TM

buttons, be sure

10. Select Done when alignment is finished and you are satisfied with the

alignment.

11. Power cycle the controller.

3M Touch Systems Proprietary Information

19

Page 26

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

For Windows 3.1 and MS-DOS drivers

If you are using Windows 3.1, exit to MS-DOS.

1. At the MS-DOS prompt type CD \TOUCH (note that there is a space

after CD).

2. Type NSD to start the NFI Setup and Diagnostic utility.

3. Type 1 and then press Enter.

4. If you are using a COM port other than COM 1, follow the on-screen

instructions to change the COM setting.

5. Select Y and press Enter to skip downloading linearization data

(linearization data is not required to reset the baseline).

6. Select Y and then press Enter to begin resetting the baseline. A message will

appear on the screen after the baseline has been successfully reset.

7. The touch screen must be re-aligned after the baseline is reset.

8. At the MS-DOS prompt, type ECAL and then press Enter.

Follow the on-screen instructions to re-align the touch screen.

When aligning, be sure you are directly in front of the touch screen. Use a

finger or alignment tool to align the touch screen. An alignment tool

produces a more accurate alignment.

9. After the touch screen is re-aligned, if your touch screen has defined

TM

TouchSurround

buttons, you must also re-align the TouchSurround

underlay . To do so, follow these steps:

At the MS-DOS prompt, type ECAL /S (note that there is a space

after ECAL) and then press Enter.

Follow the on-screen instructions to complete the TouchSurround underlay

alignment.

10. Power cycle the controller.

3M Touch Systems Proprietary Information

20

Page 27

CHAPTER 5

Outdoor applications

This chapter provides:

Critical information on how to integrate the NFI touch screen system

outdoors using a metal bezel. Information in the first section of this chapter

(“Critical information: Integrating with a metal bezel” ) assumes that your

bezel is metal.

Critical information for metalizing a plastic bezel. Although most of this

chapter assumes that a metal bezel is being used, 3M Touch Systems

recommends that, for outdoor applications, a metalized plastic bezel be used

whenever possible.

This chapter assumes that you have already read information on mounting the

touch screen (Chapter 2), mounting the controller (Chapter 3), and making

connections and resetting the baseline (Chapter 4).

If you are integrating outdoors and information in this chapter conflicts with

information elsewhere in this manual, this chapter takes precedence.

Critical information: Integrating with a metal bezel

Prevent electrical shorts

The top priority when integrating an NFI touch screen into an outdoor

application, is to prevent water from shorting the 55khz signal on the touch screen

to the grounded bezel. This is especially important when using a metal bezel to

integrate outdoors (as is assumed in this section of the chapter).

If water is allowed to pool in the area between the bezel edge and the sensor, it can

become an electrical bridge and electrically short the touch screen system and/or

generate false touches. Salt water has an even greater potential to cause this sort

of problem.

To help prevent electrical shorts:

Observe minimum mounting clearances. Minimum mounting clearances

for metal bezels are shown in Table D to help integrators make mounting

decisions that will minimize capacitive loading on the touch screen and tail.

Read Table D while referring to Figure 16 or Figure 17 (whichever figure

applies to your mounting materials).

3M Touch Systems Proprietary Information

21

Page 28

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

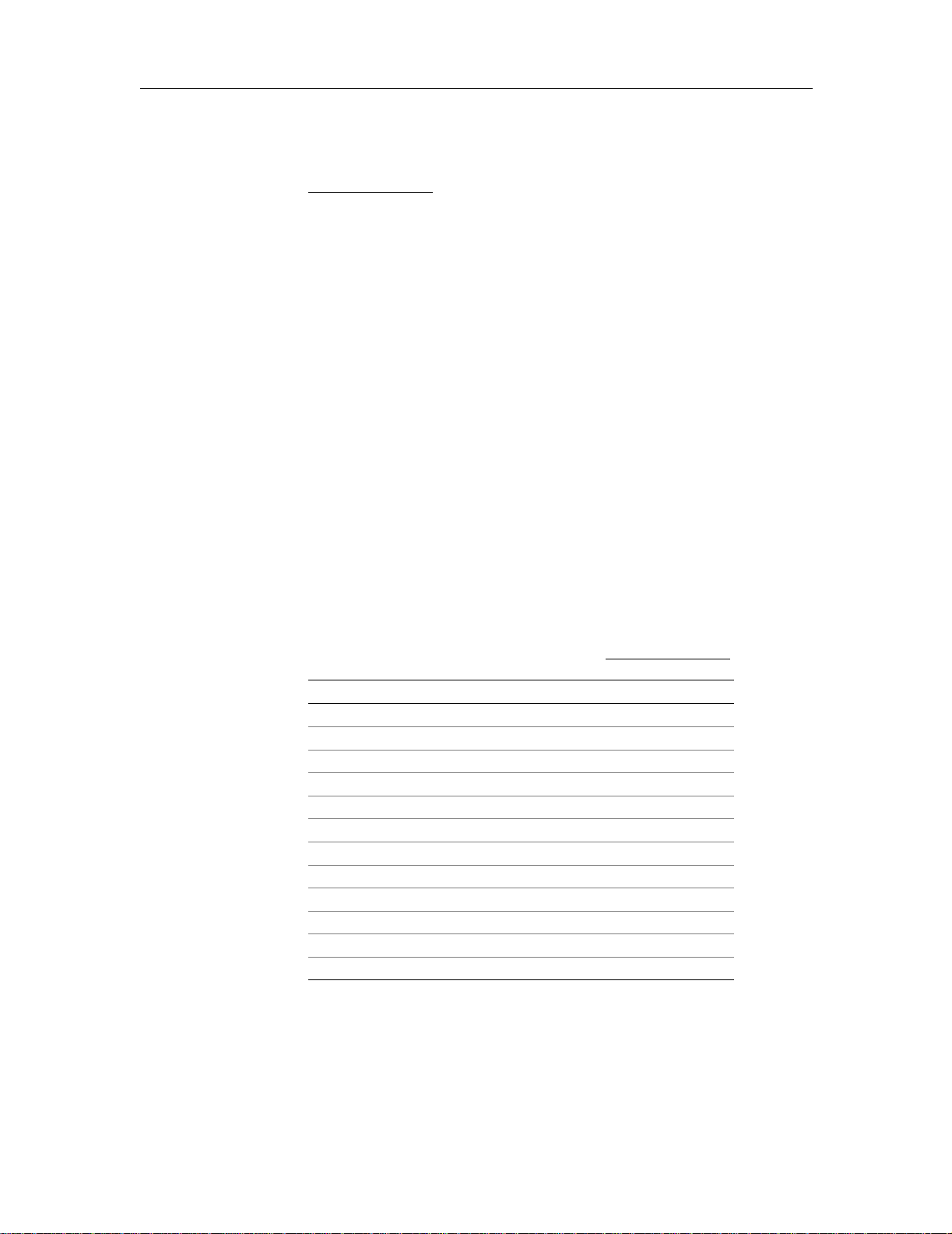

Metal bezel

D

Adhesive

NFI touch

screen

Display

C

A

Front

Figure 16: Mounting (using metal bezel) with metal clamp (Top View)

Display

Metal bezel

D

NFI touch

screen

C

A

Front

Figure 17: Mounting (using metal bezel) with adhesive (Top View)

T able D: Minimum mounting clearances

Screen size

8.4" 10.4" 12.1" 15.0" 18.1"

A

— Front of touch screen to

inside lip of bezel

B

— Front of clamp to back of

touch screen

C

— Display to back of touch

screen

D

— Side of bezel to edge of

touch screen

Viewing area & bezel opening: See NFI touch screen drawings on 3M Touch Systems website: www.3Mtouch.com

0.020"

(0.5 mm)

0.020"

(0.5 mm)

0.060"

(1.5 mm)

0.030"

(0.8 mm)

0.020"

(0.5 mm)

0.030"

(0.8 mm)

0.070"

(1.8 mm)

0.030"

(0.8 mm)

0.020"

(0.5 mm)

0.035"

(0.9 mm)

0.080"

(2.0 mm)

0.030"

(0.8 mm)

0.020”

(0.5 mm)

0.045"

(1.1 mm)

0.100"

(2.5 mm)

0.030"

(0.8 mm)

0.030"

(0.8 mm)

0.060"

(1.5 mm)

0.120"

(3.1 mm)

0.030"

(0.8 mm)

3M Touch Systems Proprietary Information

22

Page 29

Outdoor applications

If mounting outdoors with a clamp:

Use only foam closed-cell gaskets that do not absorb moisture and that

have a low compression set.

Use spacers to push the touch screen against the gasket. Align the spacers

and install the clamps and screws according to the instructions provided

by the manufacturer.

If mounting outdoors with adhesive, follow the instructions provided by the

adhesive manufacturer to ensure that the bonding is set correctly. 3M

Touch Systems recommends:

Use a non-acidic variety of RTV (room temperature vulcanizing) or

silicone adhesives. Using a non-acidic adhesive helps prevent corrosion.

If you choose to use foam adhesive, it is preferab le to purchase it in a

large square and then cut it to create a continuous frame that fits your

touch screen and bezel. This method is the best way of creating a

moisture-resistant seal when using this type of adhesive.

Do not use PSAs (pressure-sensitive adhesives) for outdoor applications.

PSAs will eventually deteriorate and admit water between the touch

screen and bezel (and potentially short out the touch screen).

Design and position the NFI touch screen as described below:

For best results, design the bezel ledge so that it slopes away from the

touch screen exposing the gasket and opaque area of the touch screen

(Figure 18). By recessing the bezel from the touch screen, water will be

shed easier.

Touch screen

Bezel

Gasket (stands proud of bezel)

Expose opaque area

as much as possible

Figure 18: Recess bezel to expose gasket

3M Touch Systems Proprietary Information

23

Page 30

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

Do not allow the bezel and gasket to encroach into the touch screen’s

viewing area. It is critical to expose the opaque area on the perimeter of

the touch screen by enlarging the bezel opening as much as possible —

especially along the bottom and sides of the touch screen — so that the

bezel is as far as possible from the touch screen’s viewing area

(Figure 18).

A good rule of thumb is to expose the opaque area by at least the height

of the water that you anticipate might collect on the ledge of the bezel.

You will need to strike a balance between exposing the opaque area

and ensuring an adequate seal for your application. If the bezel opening

is to large, the gasket may be to thin and the seal might be compromised.

Mount the touch screen system (bezel and touch screen) as vertically as

possible.

To give the touch screen extra protection from precipitation and direct

sunlight design and install a canopy over the touch screen. Direct sunlight

can cause the display to become very hot and may reduce the display's life

expectancy.

To help prevent moisture from collecting on the unit, you may want to

consider designing and creating a durable plastic "lip" to adhere to the

opaque area of the touch screen (see Figure 19 for an example). Note

Although adding a durable plastic lip may help prevent water from

pooling on the bezel ledge, incorporating a plastic part is not appropriate

for all applications (e.g., environmental conditions may cause the plastic

to crack or melt).

Example of a durable

plastic "lip"

Figure 19: Possible setup of plastic “lip”

Warranty note

: If you use an adhesive to mount an NFI touch screen into a bezel,

the touch screen must be detached from the bezel and adhesive to be returned to

3M Touch Systems under warranty.

3M Touch Systems Proprietary Information

24

Page 31

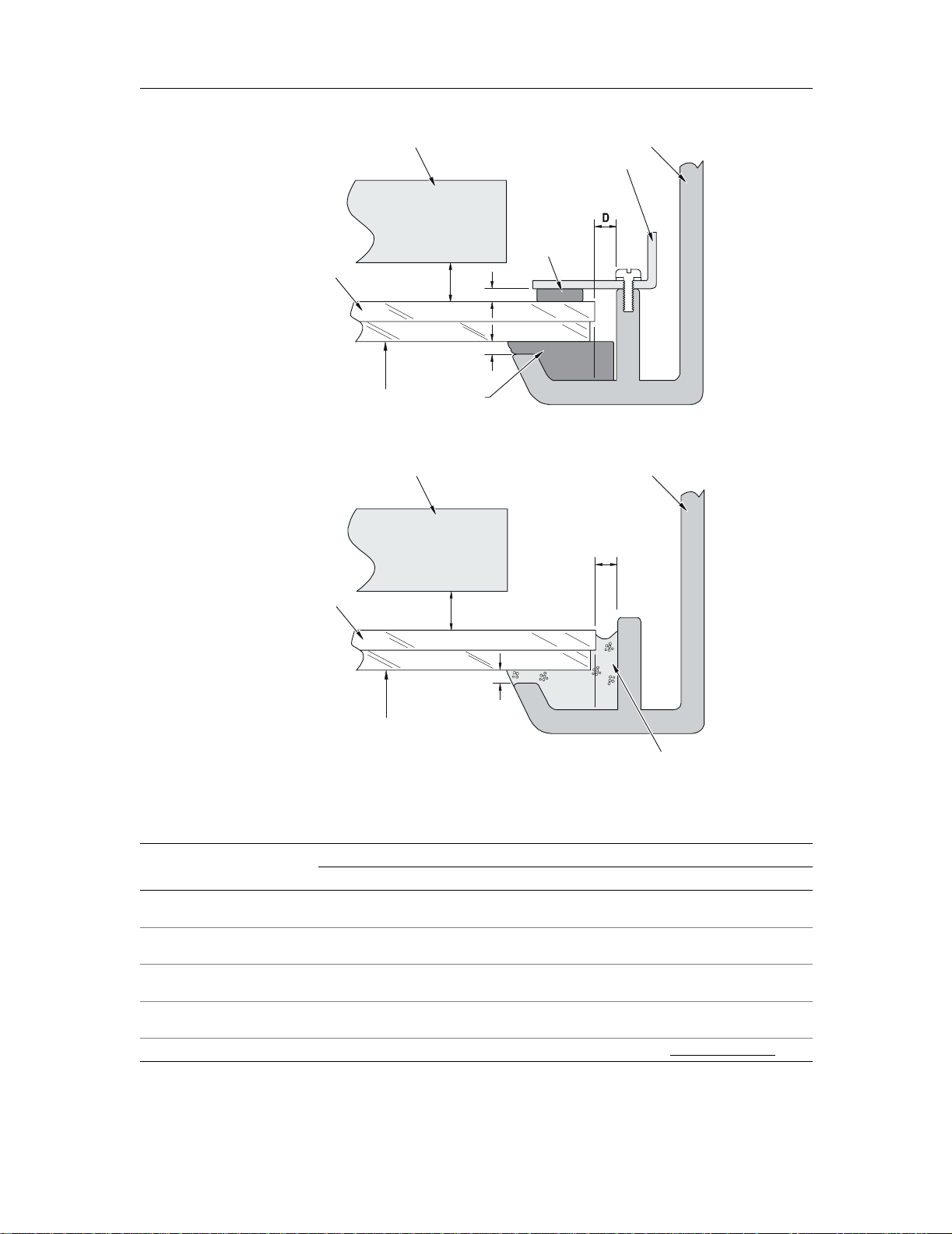

Critical information: Integrating with a plastic bezel

Before mounting an NFI touch screen in a plastic bezel, metalize the bezel using

conductive paint with conductivity of 10 ohms/square or less.

Leave an unpainted strip that is about 1/8-inch wide between the edge of

the bezel and the conductive paint. This helps prevent water from reaching the

metallized (painted) area (Figure 20, Figure 21, and Figure 22).

Apply the grounded metallization past the edge of the touch screen. This

prevents interference with the touch screen from objects near or touching the

bezel.

Touch screen

Gasket

Outdoor applications

Grounded metallization

Bezel

Front

Figure 20: Metallizing a plastic bezel

Ground the metallized area through screws that attach to the bezel.

Observe minimum mounting clearances (Table E on page 26). Note: The

Conductive paint on bezel

(for grounded metallization)

must extend past the edge

of touch screen

mounting clearances in Table E apply whether integrating into a plastic or

metal bezel.

3M Touch Systems Proprietary Information

25

Page 32

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

Plastic bezel

D

Adhesive

Grounded metallization

NFI touch

screen

Display

Metallization extends

beyond touch screen

C

A

Front

Recess metallization from

edge of plastic bezel

Figure 21: Mounting (using plastic bezel) with metal clamp (Top View)

Plastic bezel

D

NFI touch

screen

Display

Metallization extends

beyond touch screen

C

A

Front

Recess metallization from

edge of plastic bezel

Grounded metallization

Adhesive

Figure 22: Mounting (using plastic bezel) wit h ad he si v e (Top View)

Table E: Minimum mounting clearances

Screen size

8.4" 10.4" 12.1" 15.0" 18.1"

A

— Front of touch screen to

inside lip of bezel

B

— Front of clamp to back of

touch screen

C

— Display to back of touch

screen

D

— Side of bezel to edge of

touch screen

Viewing area & bezel opening: See NFI touch screen drawings on 3M Touch Systems website: www.3Mtouch.com

0.020"

(0.5 mm)

0.020"

(0.5 mm)

0.060"

(1.5 mm)

0.030"

(0.8 mm)

0.020"

(0.5 mm)

0.030"

(0.8 mm)

0.070"

(1.8 mm)

0.030"

(0.8 mm)

0.020"

(0.5 mm)

0.035"

(0.9 mm)

0.080"

(2.0 mm)

0.030"

(0.8 mm)

0.020”

(0.5 mm)

0.045"

(1.1 mm)

0.100"

(2.5 mm)

0.030"

(0.8 mm)

0.030"

(0.8 mm)

0.060"

(1.5 mm)

0.120"

(3.1 mm)

0.030"

(0.8 mm)

3M Touch Systems Proprietary Information

26

Page 33

Strategies

CHAPTER 6

Troubleshooting

This chapter provides:

Strategies to assist you in troubleshooting the NFI touch screen system.

A guide to interpreting the LED status lights on the NFI controller.

The strategies listed below will resolve most problems.

If problems persist after working through this section and referring to other

relevant chapters in this manual, contact 3M Touch Systems technical support

(“3M Touch Systems support services” on page 3).

Check integration procedures

The information below regarding integration is not a substitute for the detailed

information in Chapters 2, Chapter 3, Chapter 4, and Chapter 5.

Check the way the touch screen is mounted to be sure that:

Touch screen and tail are mounted securely so they do not move when the

touch screen is used.

Tail is inserted correctly between the retaining clip and the connector on

the controller.

Controller is grounded to the product’s chassis with the grounding screw.

Controller is receiving the specified voltage (see “Check power supply”

below).

Touch screen, controller, and tail are mounted in accordance with

instructions in this manual.

3M Touch Systems Proprietary Information

27

Page 34

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

Check port settings and connections

Check that the COM port and COM port settings are correct (the system

communicates with the host computer using the RS-232 protocol).

Double-check all connections to be sure that:

The tail is properly connected to the controller.

Cable pin-outs are correct.

The power/communications cable is properly connected to the controller.

Check power supply

Check power to be sure that:

NFI controller has a regulated DC power supply of 5V ±5 percent, capable of

providing at least 300 mA.

At least 4.75 VDC is measured on the NFI controller (otherwise it will

remain in reset mode).

Prevent interference

If there is interference between the touch screen system and a radio or

television (which can be determined by turning the equipment off and on), try

the strategies below. (The NFI touch screen system can radiate radio

frequency energy. Some communication devices may also cause harmful

interference to the NFI touch screen system):

Re-orient or relocate the TV or radio antenna.

Increase the distance between the touch screen system and TV or radio.

Connect the touch screen system to a different outlet on a circuit different

from that of the TV or radio.

Consult the dealer or an experienced TV or radio technician for help.

The touch screen system may also experience interference when near:

Components that generate a signal in the 50 kHz to 60 kHz range (unless

they are adequately shielded).

AC sources and backlight invert ers (unless there is intervening grounded

metal work or shielding).

Reset the baseline

Always reset the baseline if the NFI components in the touch screen system

have moved.

Run the Setup Wizard to reset the touch screen’s baseline. Do not touch —

or allow other things to touch — the touch screen, bezel, or controller during

baselining. After baselining, power cycle the controller.

For details on resetting the baseline, see page 18.

3M Touch Systems Proprietary Information

28

Page 35

Interpreting the controller’s status lights

When you provide power to the touch screen controller, all four LED status lights

on the controller board (shown below) should illuminate briefly. The table below

recommends strategies for different status light characteristics.

LED Characteristics Strategies

DS1

Heartbeat/

Communication

DS2

Valid Touch

DS3

Unreadable Touch

DS4

Error Condition

Green, blinking light.

Should begin blinking within a couple of

seconds of powering up controller.

A dual purpose light:

Blinks about two times per second when

controller is idle.

Blinks faster rate when there is

communication between controller and

touch screen (e.g., when screen is

touched).

Green light.

Illuminates briefly with every readable

touch to the screen.

Red light.

Illuminates briefly when controller detects

an unreadable touch.

Red light.

Illuminates steadily when controller detects

that baseline needs resetting.

If DS1 is blinking and no other LEDs are

illuminated, no action is required.

If DS1 is not blinking, make sure power is

connected.

If DS2 does not illuminate when the screen is

touched and DS3 does illuminate, see

“Strategies” for DS3 below.

If DS2 is flashing rapidly (faster than one per

second), the baseline may need to be reset

(see “Reset the baseline” on page 28).

Occasional illumination of DS3 is not cause

for concern.

If DS3 is solidly lit the touch screen system

may be shorted out, improperly grounded or

have an inaccurate baseline. Rectify the

situation and reset the baseline.

If DS3 is illuminating often:

Make sure your hand is not resting on

screen or bezel.

If wearing gloves while touching the

screen, set sensitivity to higher setting.

Reset baseline, re-align the touch screen,

and power cycle the controller (see page 18

of this manual or the NFI software guide

applicable for your operating system).

Work through “Strategies” on page 27.

If problem persists and sensitivity is set at 1,

try changing sensitivity to a higher setting. If

that does not resolve the error, contact 3M

Touch Systems technical support.

Troubleshooting

3M Touch Systems Proprietary Information

29

Page 36

Page 37

Standards

APPENDIX

Product standards and certifications

The Near Field ImagingTM (NFI) touch screen system is composed of components

for incorporation in electrical or electronic apparatus, equipment or installations.

The NFI touch screen system is evaluated for use with a Class 2, Limited power

source. If integrated according to the guidelines in this manual, the NFI touch

screen allows certification to the following standards for the overall product:

Safety standards

Evaluated to:

UL/CSA 60950

EN 60950

UL Recognized Component (File E 217706)

Evaluated for use with a Class 2, limited power source

Dust and moisture resistance

CSA C22.2 No. 94–M91 Special Purpose Enclosures, enclosure 4X, enclosure 12

NEMA 250 Electrical Enclosures, Type 4X, Type 12

IEC 529 Degrees of Protection Provided by Enclosures, IP66

Electromagnetic emission standards

Tests were successfully conducted on a sample of the equipment for the purpose

of demonstrating EMC compliance with EN 50081-1992 Generic Emission

Standard, FCC CFR 47, Part 15, Subpart B, and ICES 003 (see “FCC compliance

note” below).

Standard Test

Radiated and conducted emissions FCC CFR 47, Part

Radiated and conducted emissions EN 55022, Class B

Power line harmonics EN 61000-3-2

Power line fluctuations and flicker EN 61000-3-3

15, Class B limits

limits

3M Touch Systems Proprietary Information

31

Page 38

MicroTouchTM Near Field Imaging (NFI)TM Integration Guide

FCC compliance note

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules and ICES 03. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one of more of the following measures:

Re-orient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Electromagnetic compatibility immunity standards

Tests were successfully conducted on a sample of the equipment for the purpose

of demonstrating EMI compliance with EN 61000-6-2 Generic Industrial

Immunity Standard and EN 55024 Information Technology Immunity Standard.

Certifications

Standard Test

Electrostatic discharge EN 61000-4-2

Radiated immunity, modulated EN 61000-4-3

Radiated immunity, keyed carrier ENV 50204

Electrical fast transient/burst EN 61000-4-4

Surge transient EN 61000-4-5

Conducted immunity EN 61000-4-6

Power frequency magnetic field EN 61000-4-8

Voltage dips and interruptions EN 61000-4-11

UL Recognized component (File E 217706).

CE Information Technology Equipment — Europe

The NFI touch screen system has been tested to the following standards to show

compatibility for use in products requiring CE marking under the following directives:

EMC Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

Machinery Directive 89/392/EEC

3M Touch Systems Proprietary Information

32

Page 39

Page 40

3M Touch Systems

3M Optical Systems Division

800 Carleton Court

Annacis Island

New Westminster, B.C.

Canada V3M 6L3

www.3Mtouch.com

© 3M 2003

MicroTouch, Near Field Imaging, and TouchSurround are trademarks of 3M.

Worldwide Manufacturing Plants:

Methuen, Massachusetts

Milwaukee, Wisconsin

Vancouver, BC Canada

Loading...

Loading...