Page 1

Zeta Plus™

PRK

The Zeta Plus™ PRK (Press Retrofit Kit) kit economically adapts Sparkler® presses for

use with Zeta Plus filter cartridges. This 3 piece kit is easy to install and eliminates the

inefficiencies associated with Sparkler press filters. Presses are noted for operating problems such as bypass, leaking, extensive labor, recirculation of product to achieve quality

specification, media disposal, product waste, and operator safety. Zeta Plus cartridges will

dramatically improve product quality and reduce operating costs, while retrofitting existing hardware provides capital savings by eliminating new hardware.

Zeta Plus PRK Kit Performance Benefits

The Zeta Plus PRK kit has established new quality standards and eliminated product

rejection and rework. Conversion from a Sparkler Press to Zeta Plus PRK kit eliminated shipping delays, increased productivity, and reduced overall operating costs. A

typical comparison of the two systems, as shown in “The Zeta Plus PRK Advantage”

below, demonstrates how the Zeta Plus PRK conversion dramatically reduced operating costs.

Zeta Plus PRK Kit Materials of Construction

Press Retrofit Kit

Part Description Material

Nut Polypropylene & 316 Stainless Steel

Post 316 Stainless Steel

Adapter Plate 316 Stainless Steel

The Zeta Plus PRK Advantage

Condition Zeta Plus PRK Sparkler Press

Bypass Gasket Knife Edge Seal Eliminates

Bypass

Change-Out Simple Cartridge Design (15 minutes) Difficult - Requires a Hoist (2 Hours) 87

Quality Single Pass Quality Continual Recirculation & Redundant

Disposal Simple, Easy, Convenient Cartridge

Design

Product Minimal Loss Typical Loss 7 Times Greater than

Safety User Friendly Change-Out:

Reduced Exposure, Eliminate Leakage, Reduce Accidents

No Positive Sealing System Available N/A

Quality Checks Required

Messy Inconvenient Handling and

Disposal of Filter Paper and Precoat

with Zeta Plus Filter Cartridges

Change-Out of Filter Media is Cumbersome with Significant Leakage and

Operator Exposure

Savings*

Percent

75

84

86

N/A

Applications

Resins

Carbonated Bottling Plants

Pharmaceutical Chemicals

Breweries and Wineries

Fine Chemicals

Turbine and diesel engine recirculation

Bulk Carbon Removal

Tank car and truck tanker filling lines

Cosmetics

Photoresist Chemicals

Distilleries

Fuel Oil and Distillate Lines

3M Purification Inc. offers a complete line of Zeta

Plus filter media and cartridges. Consult your

local distributor for more information.

* Savings based on typical installations of Sparkler presses and a re a direct result of increased eff iciencies

in time, labor and materials

Page 2

Zeta Plus™ PRK (Press Retrofit Kit) Ordering Guide

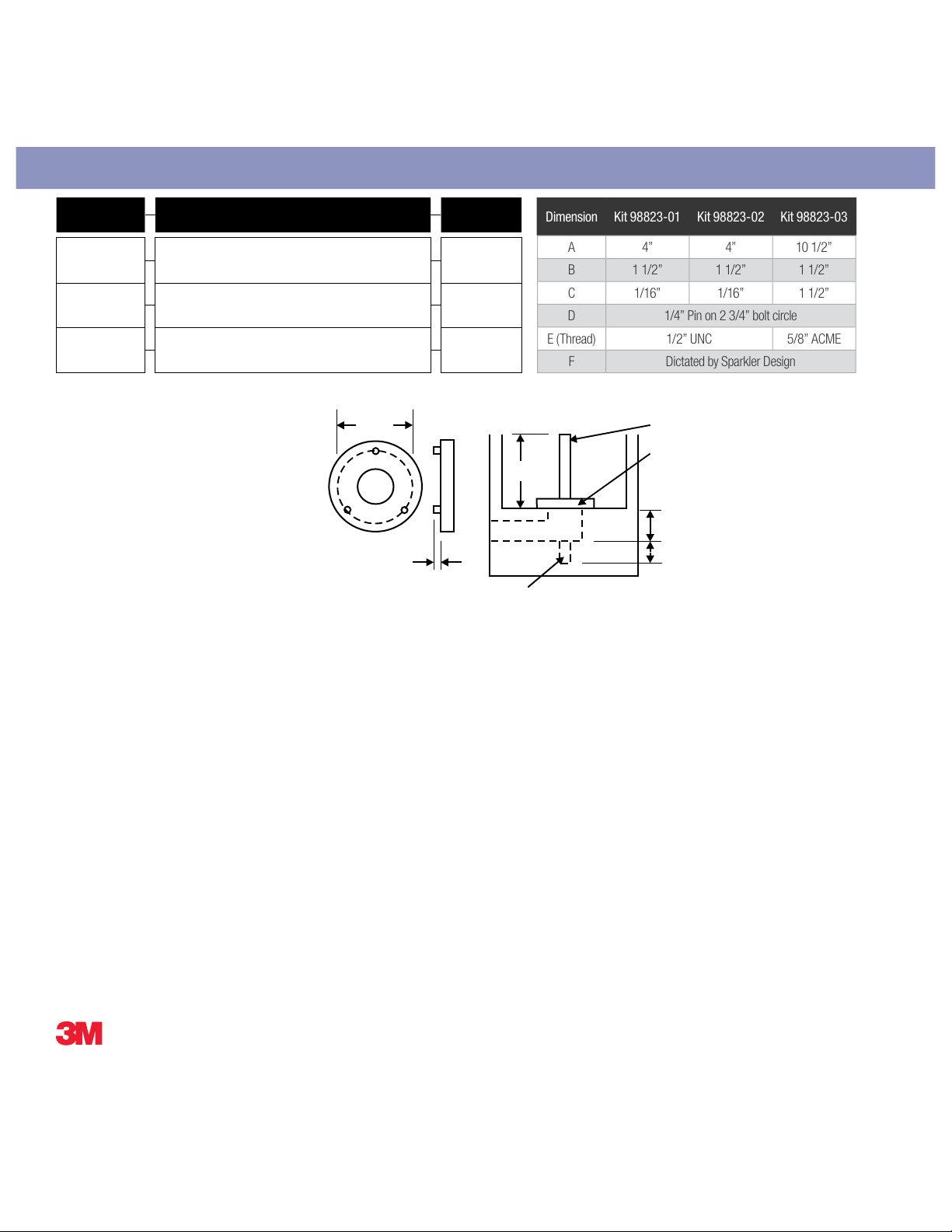

Dimension Kit 98823-01 Kit 98823-02 Kit 98823-03

A 4” 4” 10 1/2”

B 1 1/2” 1 1/2” 1 1/2”

C 1/16” 1/16” 1 1/2”

D 1/4” Pin on 2 3/4” bolt circle

E (Thread) 1/2” UNC 5/8” ACME

F Dictated by Sparkler Design

Part Number Description

98823-01 2 Zeta Plus Cartridges 10 3/4” Long x 12” Diameter 18- S-23

98823-02 3 Zeta Plus Cartridges 7 11/16” Long x 12” Diameter —

98822-03* 3 Zeta Plus Cartridges 7 11/16” Long x 12” Diameter 33- D -17

* Adapter Seal Plate is note required.

Numerous Sparkler press models other

D

than those listed above are currently in

service. Check the dimensions of the

unit before ordering. If the dimensions

are other than those shown in the table,

consult the factory for conversion

information.

C

Kit Seal Plate Sparkler Housing

Sparkler

Press Model

Outlet

Post

Seal Plate

F

A = Top of sealing

surface to top of

A

B

threaded post hole

B = Depth of threaded

post hole

E

F = Height of sparkler

post

Operating Parameters

Please refer to the individual Zeta Plus cartridge product brochure for the recommended operating parameters.

Impor tant Notice: T he information described in this literature is accurate to the best of our knowledge. A variety of factors, however, can affect the per formance of the Product(s) in a particular application, some of which

are uniquely within your k nowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE SAME WILL MAKE THEIR OWN DETERMINATION AS TO ITS SUITABIL-

ITY F OR THE IR USE . IN NO EVENT W ILL 3M PURIFICAT ION INC. BE RE SPON SIBLE FOR DA MAGES OF AN Y NATURE WHATSOE VER RESULTI NG FROM THE USE OF OR RELIA NCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if this product is fit for a particular purpose and suitable in your specific application.

3M PURIFIC ATION INC. MAKE S NO REP RESENTATIONS OR WAR RA NTIES, EITHER E XPRESS OR IMPLIED INCLUDING WITHOUT LIMITATION ANY WARR ANTIES OF MERCH ANTABILI TY, FITNESS FOR A

PARTICULAR PURPOSE OR OF ANY OTHER NATURE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH INFORMATION REFERS

Limitation of Liability: 3M Purification Inc. will not be liable for any loss or damage arising from the use of the Product(s), whether direct, indirect, special, incidental, or consequential, regardless of the legal theory as -

serted, including warranty, contract, negligence or strict liabilit y. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation may not apply to you.

3M Purification Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

(800) 243-6894

(203) 237-5541

Fax (230) 630-4530

www.3Mpurification.com

3M is a trademark of 3M Company.

Zeta Plus is a trademark of 3M Company used under license.

All other trademarks are the property of their respective owners.

© 2010 3M Company. All rights reserved.

70-0201-8867-1

Rev1010pt

Your Local 3M Purification Inc. Distributor:

Loading...

Loading...