Page 1

a 3M company

®

®

PolyKLEAN

All-Polypropylene Rigid Thermal Bonded Filters

Featuring:

Consistentfiltration

throughout the life of

the filter for superior

quality effluent

Up to ten or more times

the service life of

competitivefilters

Lowoperatingpressure

drop achievesthe

required flowusing

fewerfilterelements

Applications

Include:

Industrial Processes

Coatings

Food&Beverages

Oil & GasProcessFluids

Chemicals

Electronics

Pharmaceuticals

Page 2

PolyKLEAN®Filter Cartridges

Advancing depth filtration through technological innovation

PolyKLEAN filters, manufactured using CUNO's rigid extrusion bonded technology, are

all-polypropylene depth filter cartridges offering premium features including:

consistent particle removal efficiencies throughout the filter's life,

6

increased surface area for extended filter life,

6

low initial pressure drop for enhanced flow, and

6

high particle removal efficiencies at high flow rates (flux).

6

The filter's extended service life results in fewer filter change-outs while its enhanced

flow characteristics can typically reduce the number of filters required to achieve a given

flow rate. These combined features of PolyKLEAN filters can

.

PolyKLEAN Filter Construction

The unique PolyKLEAN filter manufacturing process combines the superior process

control with the quality assurance enabled by an ISO 9001 certified quality system to

provide consistent product performance. The CUNO exclusive manufacturing process

provides a high degree of fiber-to-fiber thermal bonding, without the use of binders, to

produce a rigid, core-less, filter structure with the following properties:

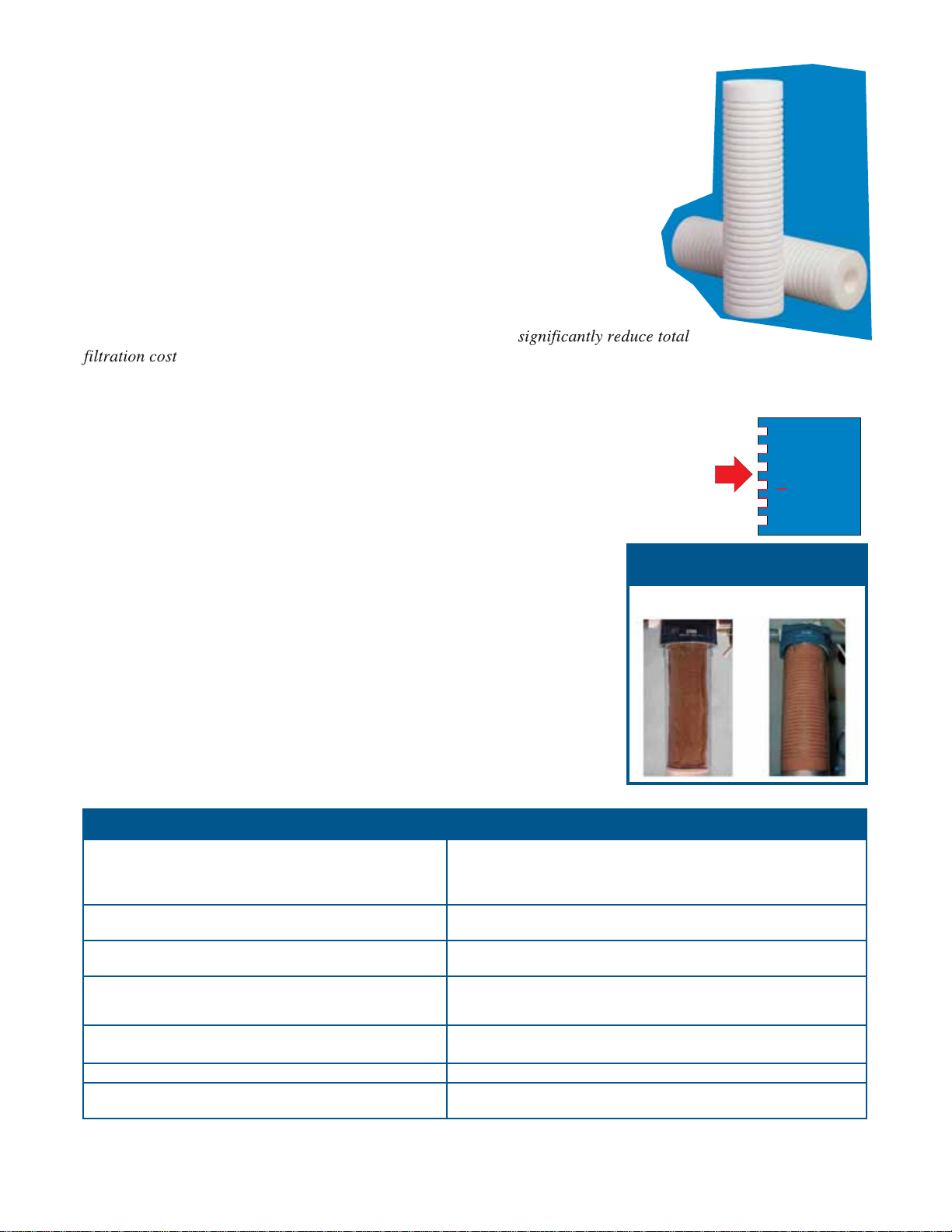

FLOW

GROOVED

SURFACE

INCREASE IN

SURFACE AREA

does not unload contaminants with increasing differential pressure like

6

typical meltblown filters,

allows grooves to be machined into the upstream surface, without

6

tearing or melting the filter structure, providing more than double the

effective surface area, and

6

exhibits exceptionally low differential pressure for a given filter rating.

Consistent filtration throughout the service life of a depth-style filter depends

on how well the filter’s structure tolerates fluctuations in operating

conditions - including contaminant loading and differential pressure.

Flexible structures, such as those found in typical meltblown and

string-wound filters, tend to compress and change porosity with increased

pressure, while rigid structures do not (Photo 1). Media compression can

result in short filter life because the pores collapse and ultimately close.

Feature Benefit

6

Eliminates unloading at high differential pressure

6

6

Rigid depth filter construction

6

Enhanced contaminant holding capacity

6

Grooved cartridge with extended surface area

6

All polypropylene construction

6

Materials of construction listed in FDA 21CFR and

ANSI / NSF Standard 42 and 61 certified

6

Core-less filter structure

6

Continuous integral length filter element (up to 40")

Efficient removal of deformable materials

6

Consistently superior particle removal throughout filter life

and at high flow rates (flux).

6

Fewer filter change outs

6

Long filter life

6

Promotes fuller utilization of the depth-matrix

6

Long filter life

6

Compatibility in a wide range of applications and operating

conditions

6

No adhesives, binders, surfactants, lubricants

6

Complies with regulations for food and beverage contact

6

Approved for use in potable water applications

6

Ease of disposal via incineration or shredding

6

No bond joints to break

6

Easy to install

Photo 1. - Compressible vs Rigid

Compressible

structures @ 35 psid

Rigid

2

Page 3

Media compression can also cause the filter to release already held particles. The robust PolyKLEAN

r

filter captures and retains contaminant within its rigid filter matrix, even under increasing differential

pressure. In addition, the unique depth filter structure of the PolyKLEAN filter provides a significant

increase in contaminant holding capacity and provides greater flow capacity at a given pressure.

Unlike soft meltblown and string-wound filters that require core support, the PolyKLEAN filter is

self-supporting and is grooved to provide greater than twice the surface area. The increase in surface

area prevents premature blinding of the outer surface by large particles and gels and promotes fuller

utilization of the depth-matrix. The result is significantly longer life than competitive cartridges.

PolyKLEAN Filter Performance

PolyKLEAN filters exhibit superior filtration characteristics. The rigid construction allows for

enhanced performance compared to other filter structures with equivalent removal ratings.

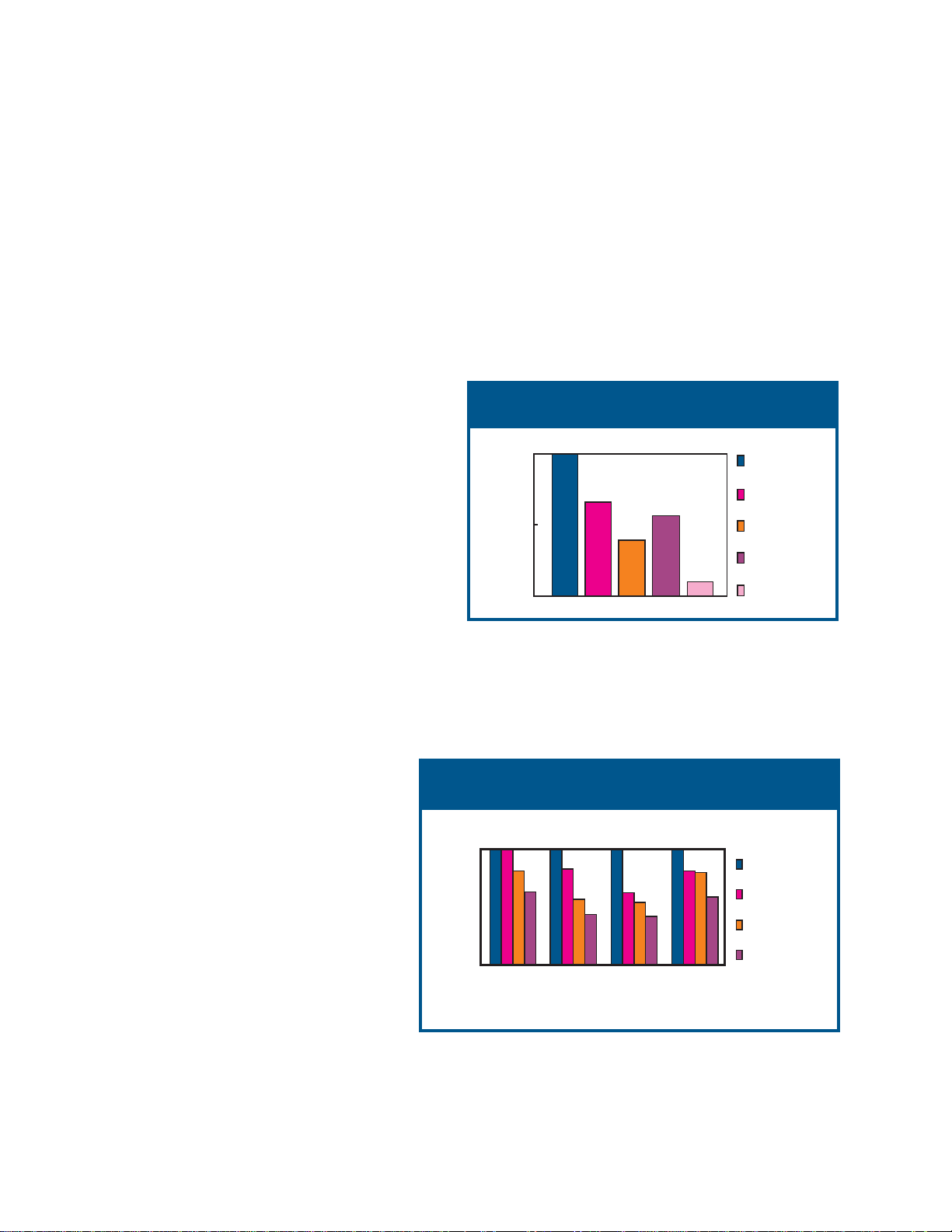

Superior Service Life

Extensive testing of PolyKLEAN filters has

demonstrated an appreciable advantage in service

Graph1.-Life Comparison of Filters Exhibiting

Similar Efficiency

life. Graph 1 compares rigid PolyKLEAN filters

to typical meltblown and string-wound filters of

equivalent efficiency. All filters were challenged

under identical conditions. Comparison of test

results, when test filters are subjected to the same

contaminant load up to 20 psid, shows the

relative life of the test filters. As depicted,

PolyKLEAN filters typically provide nearly twice

the life of its closest competitor, and up to10

Percent (%) of

PolyKLEAN Filter Life

100

50

PolyKLEAN

Meltblown 1

Meltblown 2

Wound Filte

0

Meltblown 3

times or more the life of some competitive filters.

Consistent Removal Efficiency

The rigid PolyKLEAN structure resists deformation, filter by-pass, compression, and particle unloading.

This allows PolyKLEAN filters to achieve excellent filtration efficiency up to its recommended

change-out pressure (35 psid), while typical melt blown and wound structures exhibit significant drops in

removal efficiency at much lower differential pressures (£ 10 psid).

To demonstrate the PolyKLEAN filter’s

removal consistency, efficiency at four

sampling points (initial, 0.5 psid, 1 psid,

and 10 psid) was measured on

PolyKLEAN filters and typical melt blown

and wound structures. All equivalently

rated filters were tested under the same

conditions to enable direct comparison.

As shown in Graph 2, PolyKLEAN filters

display a stable, consistently higher

contaminant removal throughout the

duration of the test. Note that the other

melt blown and string wound structures

yield erratic removal and as such can not

provide predictable performance even

under controlled conditions of uniform

contaminant loading and pressure.

Graph 2. - Efficiency Comparison of Filter Cartridges

Rated at 5 Microns

100

80

60

40

20

Percent (%) of

0

PolyKLEAN Efficiency

Initial

Differential Pressure (psid)

0.5

1

10

PolyKLEAN

Meltblown 1

Meltblown 2

Wound Filter

3

Page 4

PolyKLEAN filters are also capable of

(

)

Graph 3. - Particle Removal Efficiency at increased flux

delivering consistent particle removal

efficiencies at high fluid flux (flow rate per

surface area). This capability is

demonstrated in Graph 3 which shows both

removal efficiency and differential

pressure results from tests conducted with

25u PolyKLEAN cartridges at a fluid flux

of 18 gpm per 10-inch length - six times

higher than typical design flux for

cartridge filters. Because of its rigid

structure and high contaminant holding

capability, PolyKLEAN cartridges are able

to maintain high particle removal

efficiencies throughout the life of the filter

at this high flux.

Particle Removal Efficiency (%)

100

100

90

80

70

60

50

40

30

20

10

0

10

0

20

Particle Removal

Differential Pressure

30

40

Percent ofFilter Life

50

60

80

70

90

80

70

60

50

40

30

Differential Pressure (psid)

20

10

0

100

90

This consistent performance capability at high fluid flux makes PolyKLEAN an effective solution for

systems where smaller housing size is desirable because of physical limitations or budgetary constraints.

Utilizing PolyKLEAN cartridges at higher flux can also be beneficial for low contaminant load systems.

Lower Initial Differential Pressure

The unique design and construction of the PolyKLEAN element allows for significantly lower pressure

drop when compared to competitive elements. Graph 4 clearly demonstrates the PolyKLEAN flow

advantage when compared to other 5mm rated competitive meltblown and wound cartridges. For a given

differential pressure, PolyKLEAN filters yield flows up to ten times that of competitive filters. When

sizing a system for a given process flow rate, this is a significant advantage and translates into lower

capital investment for filter housings and fewer cartridges to purchase. For example, as shown in Table

1, in a process with a water flow rate of 180 gpm and a maximum clean pressure drop of 0.5 psid, a

PolyKLEAN filter system requires significantly fewer cartridges and smaller filter vessels (compared to

competitive filters) for greatly reduced capital costs.

Graph 4. - Flow vs. Differential Pressure

(see note * in table 1)

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Differential Pressure (psid)

1.0

0.5

0

GE Osmonics Hytrex filters

Parker Fulflo HoneycombWound

PolyPropylenefilters

Pall Claris filters

PolyKLEAN filters

012345678910

Water Flow (gpm)

10

Water Flow (lpm)

20

30

0.3

0.2

0.1

Table 1. - Comparison of 5 Micron Filters in

a Water System

bar

PolyKLEAN Filters

Parker Fulflo®

Honeycomb™ Wound

Polypropylene Filters

Differential Pressure

Osmonics Hytrex®

Pall Claris® Filters

Filters

*Based on the manufacturers literature piece specifications

12 12

29 20

60 30

24 16

Fulflo and Honeycomb are trademarks of Parker Hannifin Corporation, Hytrex is a trademark of GE Osmonics , and Claris is a trademark of Pall

Corporation

4

Page 5

PolyKLEAN Filter System Sizing

(

(

To size a system of PolyKLEAN filters, flow vs. differential pressure data is provided in Table 2.

Table 2. - PolyKLEAN Filter Specific Pressure Drop (SPD)

m

1 0.073 1.330

5 0.042 0.765

10 0.025 0.455

25 0.015 0.273

50 0.010 0.182

75 0.006 0.109

To calculate filter’s clean pressure drop for Newtonian fluids, use the following formula in conjunction

with the Specific Pressure Drop Values. The Specific Pressure Drop values may be effectively used

when three of the four variables (Viscosity, Flow, Differential Pressure, and Cartridge Grade) are set.

Care must be taken when sizing PolyKLEAN filtration systems. Select a filter housing that will accept at

least the required number of 10 inch filter elements, and ensure that the total

system flow does not exceed the maximum housing flow rating.

psid [mbar]

clean

=

Total system

gpm [lpm]

(

Viscosity in

(

(

Equivalent number of 10 inch

Cartridges in housing

Cp

SPD Value

(

(

from Table 2

(

PolyKLEAN Filter Applications

6 Plating 6 Process cooling water

6

De-salination plants

6

Pulp & paper

6

Additives

6

Resin manufacturers (water & solvent)

6

Trade, architectural paint

6

Bottled water

6

Ready-To-Drink Beverages

6

Amine & glycol

6

Prefiltration in waterflood

6

PE-PP

6

Intermediate grade chemicals

6

Printed Circuit Boards

6

CMP slurries

6

Electronic Capacitors

6

Parts washing

6

Peroxide

6

Mechanical seals

6

Ink

6

Soft drinks

6

Juice

6

Process cooling water

6

Completion fluid

6

PVC-VCM

6

Herbicides, pesticides

6

Video Dispalys

6

Pre-RO

6

CD/DVD

6

Pre-RO

6

Bulk pharmaceutical chemicals

6

Particle control in WFI

6

Rinse water

6

Active pharmaceutical ingredients

5

Page 6

PolyKLEAN Filter Cartridge Specifications

Table 3. - PolyKLEAN Filter Specifications

Construction

Filter Media, End Connector

Gaskets & O-ring Options (see ordering guide)

Silicone, Fluorocarbon, EPR, Nitrile, and Polyethylene

Operating Conditions

Maximum Operating Temperature

15 psid @ 176°F (1.0 bar @ 80°C)

Maximum Differential Pressure

Recommended Change-out Differential Pressure 35 psid @ 68°F ( 2.4 bar @ 20°C)

25 psid @ 140°F (1.7 bar @ 60°C)

Cartridge Dimensions

Inside Diameter (nominal) 1.1" (28 mm)

Outside Diameter (nominal) 2.6" (66 mm)

Length (nominal) see ordering guide 9

Regulatory

PolyKLEAN filters meet the requirements of USP for the Biological Test for Plastics, Class VI-70°C.

Materials used in the manufacture of PolyKLEAN filters meet the requirements ofUSFDA 21 CFR for food and beverage contact

PolyKLEAN filters have been certified to ANSI/NSF Standard 42 and 61

Polypropylene

176° F (80°C)

60 psid @ 68°F (4.1 bar @ 20°C)

3

" - 40" (248 - 1016 mm)

4

Chemical Compatibility

The 100% polypropylene construction provides excellent chemical compatibility in many demanding process

fluid applications. Compatibility is influenced by process operating conditions. PolyKLEAN cartridges should

be tested under actual conditions to determine compatibility.

Table 4. - Fluid Compatibility

Chemical Temperature Chemical Temperature Chemical Temperature

Acetic Acid 20% 160°F (71°C) Hydrogen Peroxide 100°F (38°C) Sodium Carbonate 160°F (71°C)

Alkanolamines 140°F (60°C) Methyl Ethyl Ketone 70°F (21°C) Sodium Hydroxide 70% 160°F (71°C)

Ammonium Hydroxide 10% 160°F (71°C) Mineral Oil 70°F (21°C) Sulfuric Acid 20% 160°F (71°C)

Bleach 5.5% 120°F (49°C) Nitric Acid 20% 120°F (49°C) Sulfuric Acid 70% 160°F (71°C)

Ethylene Glycol 160°F (71°C) Potassium Hydroxide 140°F (60°C) Urea 160°F (71°C)

Scientific Applications Support Services (SASS)

Dedicated technical support teams comprised of CUNO scientists and

engineers are available to provide application specific recommendations for

the most effective and economical filtration system. In addition to

comprehensive testing and analyses conducted in advanced laboratories at

CUNO Incorporated, the SASS staff can also perform on site-testing at

customer’s facilities. Contact your CUNO Distributor for more information

Service Worldwide

CUNO is a U.S. based multinational company with distribution and manufacturing sites worldwide. Global

manufacturing sites together with trained stocking distributors and state-of-the-art laboratory facilities bring

quality solutions to challenging filtration applications.

6

Page 7

CUNO Filter Housings

CUNO manufactures a full line of industry standard filter housings to meet most application

requirements. Models are available for both gas and liquid service in a wide range of construction

materials, from plastics to ASME Code with 316L stainless steel, to suit a variety of application needs.

For more information about CUNO filter housings, consult your local CUNO distributor and ask for the

literature listed below.

(LITHSES1)

Maximum design flexibility

>

Available in a variety of sizes

>

Accepts both single and double

>

open end cartridges

Available in a variety

>

of sizes and materials

Mounting bracket

>

available

Rugged economical

>

design in cast iron and

steel

> Easy assembly

for a wide variety of system

requirements

ASME Code

>

Choice of carbon steel, 304L

>

or 316L stainless steel

Polyvinylchloride construction

>

Available for 2 or 3 high

>

cartridges

Features a removable cartridge

>

pack for rapid change-out and

easy cleaning

ASME Code

>

Available in a wide variety

>

of sizes

> 304 stainless steel

construction

> Available in cast iron and

> Enclosed System

> Uses disposable filter

pack

> Easy to use - housing

clean-up eliminated

6

>

Available in cast iron and

steel, or 304 stainless steel

>

Built-in valve for duplex

or single operation

>

Ideal for high pressure

applications

>

Durable steel

construction

>

Lightweight plastic

construction

>

Choice of 1 or 2 high

cartridge models

– the ES series filter housing is a durable high volume filter housing constructed from 316L

steel, or 304 stainless

steel

> Choice of 1 or 2 high

cartridge models

stainless steel or carbon steel. With a cartridge capacity from 12- to 480- 10 inch filter elements, the ES filter

housing can accommodate a wide range of flow requirements. For more information, ask your local CUNO

Distributor for brochure LITCHSES1

6

– AL and CT filter housings offer a wide range of sizes from one cartridge to

eighteen cartridges. For more information, ask your local CUNO Distributor for brochure LITHSAL1 and

LITHSCT3.

6

– DC and SD filter housings offer a low cost alternative for low volume filtration.

Constructed from reliable 304Lstainless steel (Model DC) or 316L stainless steel (Model SD), these housings

are available for a wide range of flow rates and applications. For more information, ask your local CUNO

Distributor for brochure LITHSDC1 and LITHSSD1.

6

. This unique system design provides a

totally enclosed system using separate pressure vessel and filter pack to isolate process fluid from housing.

This system generally reduces the clean-up costs involved with filter change-out while protecting the work

environment and the operator from exposure to the process fluid. Ask your local CUNO distributor for

brochure LITCCK001.

7

Page 8

PolyKLEAN Filter Cartridge Ordering Guide

Ctg. Type Length Grade Material Surface Packaging Ring Support End Modification Gasket/O-Ring

3

- 9

"* - 1mm - Polypropylene - Grooved - Bulk - None - 226 O-Ring & Spear - Silicone

PolyKLEAN

* Available with N or P end modifications only ** Available with N, P, Q, or R end modifications only

4

- 10" - 5 mm - 222 O-Ring & Spear - Fluorocarbon

1

- 19

"* - 10 mm - 222 O-Ring & Flat Cap - EPR

2

- 20" - 25 mm - None - Nitrile

1

- 29

"* - 50mm -Polypropylene Core Extender - Polyethylene**

4

- 30" - 75 mm - Cap without Spring - Clear Silicone

- 39"* - Cap with Spring - None **

- 40"

B

Seller warrants its equipment against defects in workmanship and

material for a period of 12 months from date of shipment from the

factory under normal use and service and otherwise when such

equipment is used in accordance with instructions furnished by Seller

and for purposes disclosed in writing at the time of purchase, if any.

Anyunauthorized alterationof modificationof theequipment byBuyer

will void this warranty. Seller’s liability under this warranty shall be

limited to the replacement or repair, F.O.B., point of manufacture, of

any defective equipment or part which, having been returned to the

factory, transportation charges prepaid, has been inspected and

determined bySeller to be defective. THIS WARRANTY IS IN LIEU

OF ANY OTHER WARRANTY, EITHER EXPRESSED OR

IMPLIED, AS TO DESCRIPTION, QUALITY,

MERCHANTABILITY, FITNESS FOR ANY PARTICULAR

PURPOSE OR USE, OR ANY OTHER MATTER. Under no

circumstances shall Seller be liable to Buyer or any third party for any

loss of profits or other direct or indirect costs, expenses, losses or

consequential damages arising outof or as a result of any defects in or

failure of its productsor anypart orparts thereofor arisingout ofor asa

result of parts or components incorporated in Seller’s equipment but

not supplied bythe Seller.

C

F

P

N

This PolyKLEAN series filter is tested

and certified by NSF International

against NSF/ANSI Standard 42

For Material Requirements Only

Component

* For End Treatment "P" and O-ring "H" consult factory.

This PolyKLEAN series filter is tested

against NSF/ANSI Standard 61

*

For Material Requirements Only*

Q

and certified by WQA

R

a 3M company

CUNO Filtration Asia Pte Ltd

2A Tuas Avenue 12

Singapore 693023

Cuno Filtration Shanghai Co, Ltd

No.2 Xin Miao San Rd,

Xin Miao Town,

Song Jiang District,

Shanghai. China.201612

CUNO Pacific Pty Ltd

140 Sunnyholt Road

Blacktown, NSW 2148

Australia

CUNO K.K.

Hodogaya Station

Building 6F

1-7 Iwai-cho, Hodogaya-ku

Yokohama 240 Japan

CUNO Latina Ltda

Rua Amf Do Brasil 251

18120 Mairinque-Sp

Brazil

CUNO Ltd

21 Woking Business Park

Albert Drive

Woking, Surrey GU215JY

United Kingdom

CunoIncorporated

400 Research Parkway

Meriden, CT 06450, U.S.A.

Tel: (800) 243-6894

(203) 237-5541

Fax:(203) 630-4530

www.cuno.com

© CUNO Incorporated, 2005 - All Rights Reserved LITCPOLYKLN.1110p

Loading...

Loading...