Page 1

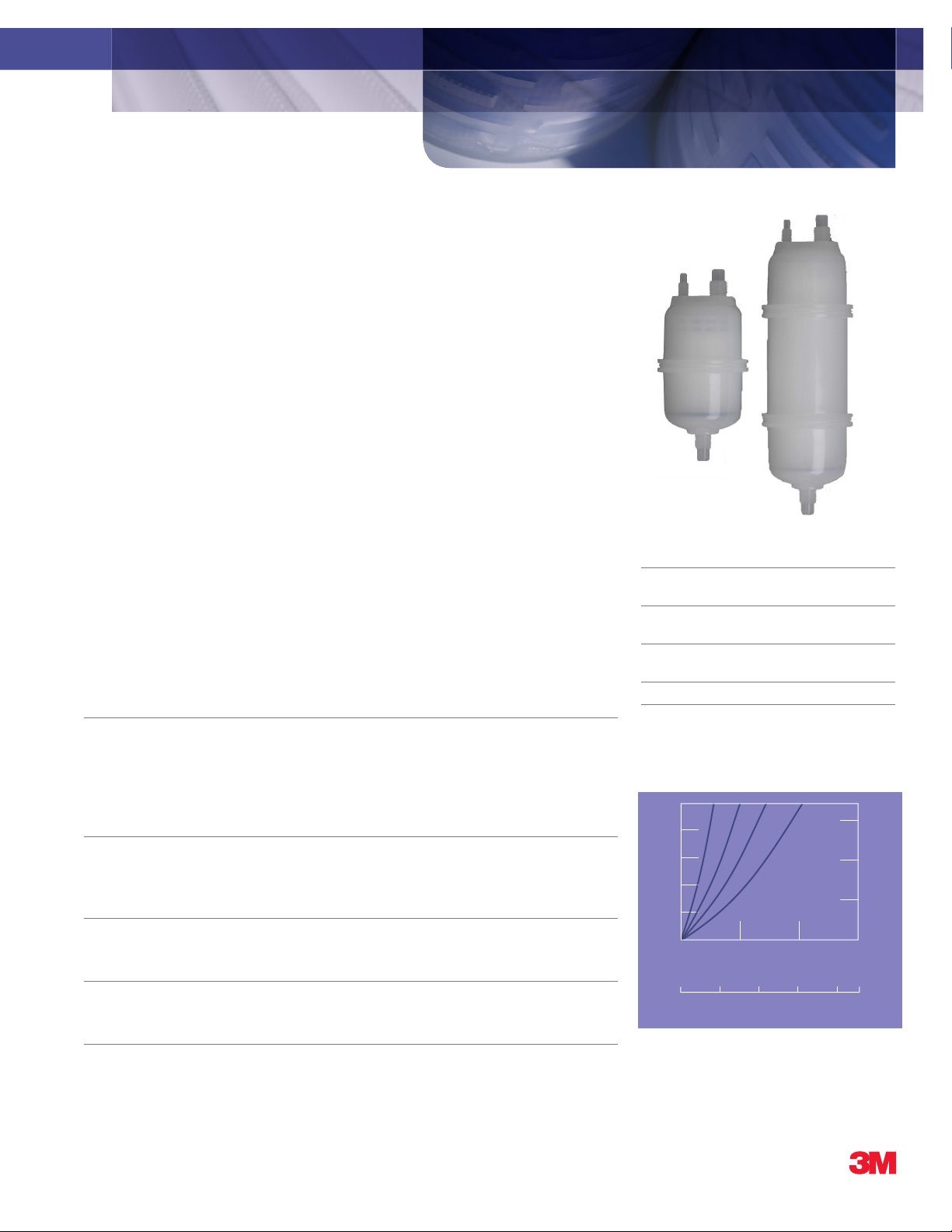

Graph 1: 5” LDC Capsule Flow vs.

26

NanoSHIELD™ Hollow

Fiber Series LDC

Filter Capsules

Superior Defect Reduction from Advanced Photoresists and Chemicals

NanoSHIELD™ hollow fiber series LDC filter capsules have been specially designed

tocombine the highest level of particle retention with superior flow rates and minimal

pressure drop for demanding high viscosity chemical applications. Utilizing Hollow Fiber

Technology (HFT), NanoSHIELD hollow fiber series filters are able to deliver superior

flow with minimal pressure drop, while maintaining the highest level of filter efficiency

in a small disposable design.

All filters are critically cleaned, integrity tested, and rinsed with high purity water to

provide fast start-up times and low extractables right out of the box. The small compact

design of NanoSHIELD hollow fiber series LDC filter capsules make them ideally suited

for critical applications requiring low hold-up volume with superior f low rates and high

particle retention at 0.01, 0.02, 0.05, and 0.1 µm.

NanoSHIELD™ Hollow Fiber Series Capsule Construction

The filter’s polypropylene and polyethylene materials of construction combined with

quality manufacturing ensure that ionic, organic, and metallic contaminants are not being

added back into the process f luid. Ionic, organic, and metallic contaminants can extract

from surface modified and or improperly manufactured filters, which may reduce shelf

life and or change the photo-speed, viscosity, or molecular weight of the photo-chemical.

Features & Benefits

Hollow Fiber Technology.

n Up to 3 times more surface area as compared to equivalent sized capsules.

n Provides both lower operating and differential pressure across the filter to minimize outgassing

and micro-bubble formation.

n Reduces hold-up volume and “dead space” by eliminating the filter core.

n Increased lifetime, throughput, and overall equipment effectiveness (OEE).

Polypropylene and Polyethylene Construction.

n

Excellent chemical resistance to photoresists and ancillary chemicals.

n No IPA pre-wetting and system flushing required – eliminates a potential source of contamina-

tion and chemical interaction, while reducing downtime.

0.01 µm and 0.02 µm Retention Ratings.

n Superior removal of particles, gels, and micro-bubbles.

n Reduced micro-bridge and wafer level defects for 193 nm photoresists.

Superior Flow Rates.

n Flow rates 3 - 8 times higher as compared to competitive pleated capsules while not sacrificing

particle removal efficiency.

Quality Manufacturing.

n Manufactured in a cleanroom to reduce particle adders and extractables.

n All filters are critically cleaned and integrity tested to ensure process repeatability.

Applications

193 nm

Photoresists

ARC, BARC,

TARC

Etchants/

Strippers

Polyimide Solvents

Differential Pressure (1cps @ 25°C)

10

8

6

4

2

Differential Pressure (psid)

0

0

01051520

Alcohols

Bases

Developers

NSP005

NSP010

NSP001

NSP002

Fluid Flow Rate (GPM)

Fluid Flow Rate (LPM)

4

0.6

0.4

0.2

Differential Pressure (bar)

Page 2

NanoSHIELD™ Hollow Fiber Series LDC Filter Capsules

O

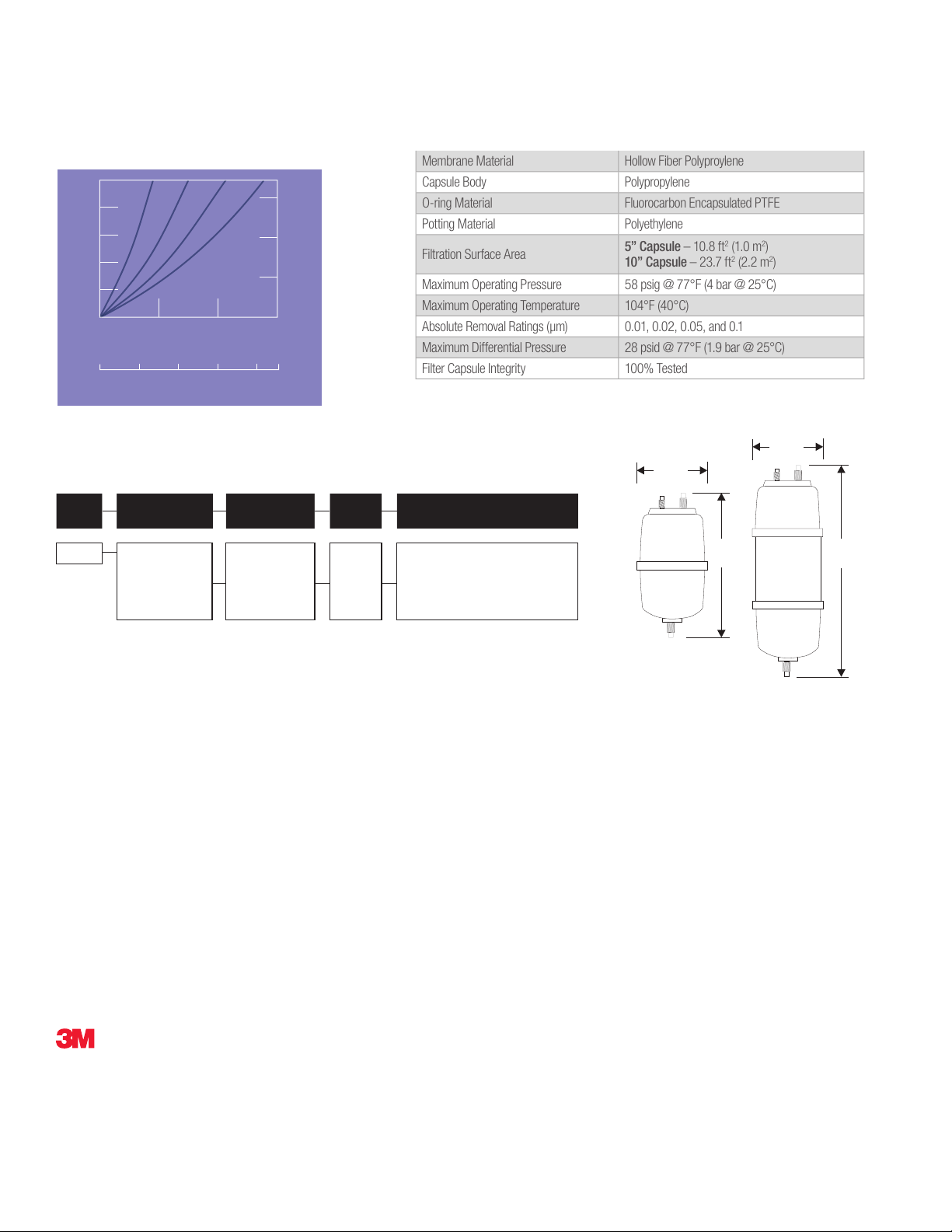

Graph 1: 10” LDC Capsule Flow vs.

26

NanoSHIELD LDC Filter Capsules Specifications

Membrane Material Hollow Fiber Polyproylene

Capsule Body Polypropylene

O-ring Material Fluorocarbon Encapsulated PTFE

Potting Material Polyethylene

Filtration Surface Area

5” Capsule – 10.8 ft2 (1.0 m2)

10” Capsule – 23.7 ft2 (2.2 m2)

Maximum Operating Pressure 58 psig @ 77°F (4 bar @ 25°C)

Maximum Operating Temperature 104°F (40°C)

Absolute Removal Ratings (µm) 0.01, 0.02, 0.05, and 0.1

Maximum Differential Pressure 28 psid @ 77°F (1.9 bar @ 25°C)

Filter Capsule Integrity 100% Tested

NanoSHIELD™ Hollow Fiber Series LDC Filter Capsules Specifications

Differential Pressure (1cps @ 25°C)

10

8

NSP005

NSP002

6

4

2

Differential Pressure (psid)

0

0

NSP001

Fluid Flow Rate (GPM)

NSP010

4

0.6

0.4

0.2

Differential Pressure (bar)

01051520

Fluid Flow Rate (LPM)

Ordering Guide

Media Removal Rating Configuration Length Fitting Connection

NSP

Important Notice

3M Purifi cation Inc. MA KES NO WAR RANTI ES, EXP RESS OR IM PLIED, INCLUDING , BUT NOT LIMIT ED TO, ANY IMPLIE D WARRA NTY OF ME RCHAN TABIL ITY OR FITN ESS FOR A PAR TICUL AR PURPOSE. Since a variet y

of factors can affect the use and performance of a 3M Purification Inc. product in a par ticular application, some of which are uniquely within the user’s knowledge and control, user is responsible for determining whether or

not the 3M Purification Inc. product is fit for a particular purpose and suitable for user’s method of application.

Limitation of Remedies and Liability

If the 3M Purification Inc. product is proved to be defective, TH E EXC LUS IVE R EMEDY, AT 3M Purification Inc.’S OP TION, SHALL B E TO REF UND THE PURCHASE PRIC E OR TO REPAIR O R REPLAC E THE D EFECTIVE

PROD UCT. 3M Purification Inc. shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the legal theor y asser ted, including, but not limited to, contract,

negligence, warranty or strict liability.

Warranty

Seller warrants its equipment against defects in work manship and material for a period of 12 months from date of shipment from the factor y under normal use and service and otherwise when such equipment is used in

accordance with instructions furnished by Seller and for purposes disclosed in writing at the time of purchase, if any. Any unauthorized alteration of modification of the equipment by Buyer will void this warranty. Seller’s

liability under this warranty shall be limited to the replacement or repair, F.O.B., point of manufacture, of any defective equipment or part which, having been returned to the factory, transportation charges prepaid, has

been inspected and determined by Seller to be defective. THI S WARRANTY IS IN LIEU OF A NY OTHER WA RRAN TY, EITHE R EXPRESSED OR IMP LIED, AS TO DE SCRIPT ION, QUALIT Y, MERC HANTABILITY, FIT NESS FOR ANY

PARTICULA R PURPOSE OR USE, OR AN Y OTHER MAT TER. Under no circumstances shall Seller be liable to Buyer or any third part y for any loss of profit s or other direct or indirect costs, expenses, losses or consequential

damages ar ising out of or as a result of a ny defects in or failure of i ts products or any p art or parts th ereof or arising out of or as a result of pa rts or componen ts incorporated in S eller’s equipment but n ot supplied by the Seller.

3M Purification Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

Phone (800) 243-6894

(2 03) 237-5541

Fax (203) 630-4530

www.3Mpurification.com

001 - 0.01 µm

002 - 0.02 µm

005 - 0.05 µm

S - LDC

010 - 0.1 µm

50 - 5”

01 - 10”

KH - 1/2” Flowell® 60 Inlet/Outlet Fittings

with 1/4” Flowell 60 Vent Fitting

Your Local Distributor:

Dimensions

5 inch LDC

3.97”

(101mm)

Inlet

Vent

Outlet

10 inch LDC

3.97”

(101mm)

Inlet

Vent

8.31”

(211mm)

utlet

Please recycle. Printed in U.S.A.

NanoSHIELD is a trademark of 3M Company.

© 3M 2011. All rights reserved.

70-0201-8779-8 REV 1011b

12.95”

(329mm)

Loading...

Loading...