3M Cylinder Spray Adhesives Technical Manual

Technical Manual July 2017

Cylinder Spray Adhesive - User’s Guide

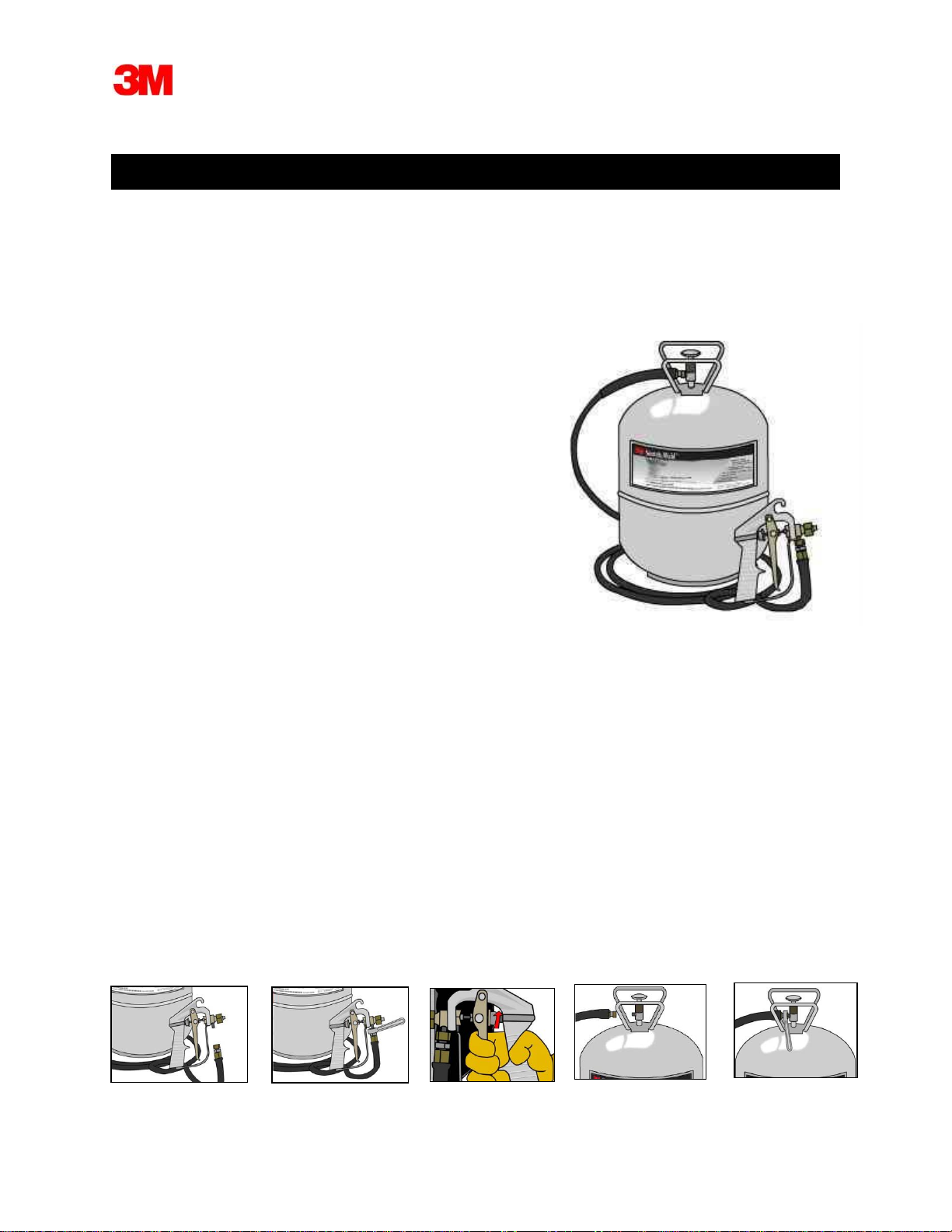

3M™ Cylinder Spray Adhesives

3M has a full line of industrial-grade bulk spray adhesives, prepackaged in convenient,

portable, and no-maintenance aerosol cylinders.

________________________________________________________________________________________________________

Manual Content:

1. Equipment Set Up

2. Application Temperature

3. Surface Preparation

4. Handling/Application Information

Directions for Use

Spraying Adhesive

o Spray Distance

o Spray Angle

o Application Speed

Adjusting Spray Pattern

Changing Nozzles

Coverage

Dry Time

Open Time – Bonding Range

Bonding

5. Shut Down

6. Storage

7. Cylinder Changeover

8. Cylinder Disposal/Return

9. Cylinder Sizes

10. Equipment List (Part Numbers & UPC Numbers)

______________________________________________________________________________

1. Equipment Set Up

1

Attach the larger flare fitting end of the hose to the spray applicator and 2tighten the nut

securely. 3Check to see that the applicator gun trigger stop/adjusting nut is fully locked

against the trigger. 4Attach the other end of the hose, the smaller flare fitting, to the cylinder

valve and 5tighten securely.

Figures 1-5: Proper set up procedure for a cylinder adhesive.

2. Application Temperature

For best results the temperature of the adhesive and the surfaces being bonded should be

between 60o-80oF (16o-27oC). Temperatures outside this range may affect bonding range and

sprayability.

3. Surface Preparation

For best results all surfaces to be bonded must be clean, dry and free from dirt, dust, oil, loose

paint, wax or grease, etc.

4. Handling/Application Information

Directions for Use:

1. Slowly open the cylinder valve and inspect the connections for any leaks. Tighten if

needed.

2. Fully open the valve.

3. Unscrew the trigger stop/adjusting nut away from the trigger 3-4 turns and spray a

test pattern. For more adhesive output, continue to screw the nut away from the

trigger. For less adhesive output, screw the nut back towards the trigger.

4. Hold the applicator 3-10 inches away from the surfaces to be sprayed and apply a

uniform coat of adhesive. (The smaller the spray pattern chosen in step 3 the closer

the applicator gun will need to be to the surface and vice versa for larger patterns.)

5. Apply 1-3 even coats of adhesive. (This will depend on the needed coverage for the

bonding application.)

6. Allow adhesive to dry until tacky and then apply sufficient pressure to ensure complete

contact.

Note: Test for tackiness by gently touching the adhesive with your knuckle. If the adhesive

transfers to your skin it is too wet. If the adhesive is aggressively tacky and does not transfer

to your skin, it is ready to bond. If the adhesive is dry or only has a very light tack it is too dry

and another coat of adhesive should be applied to at least one of the surfaces.

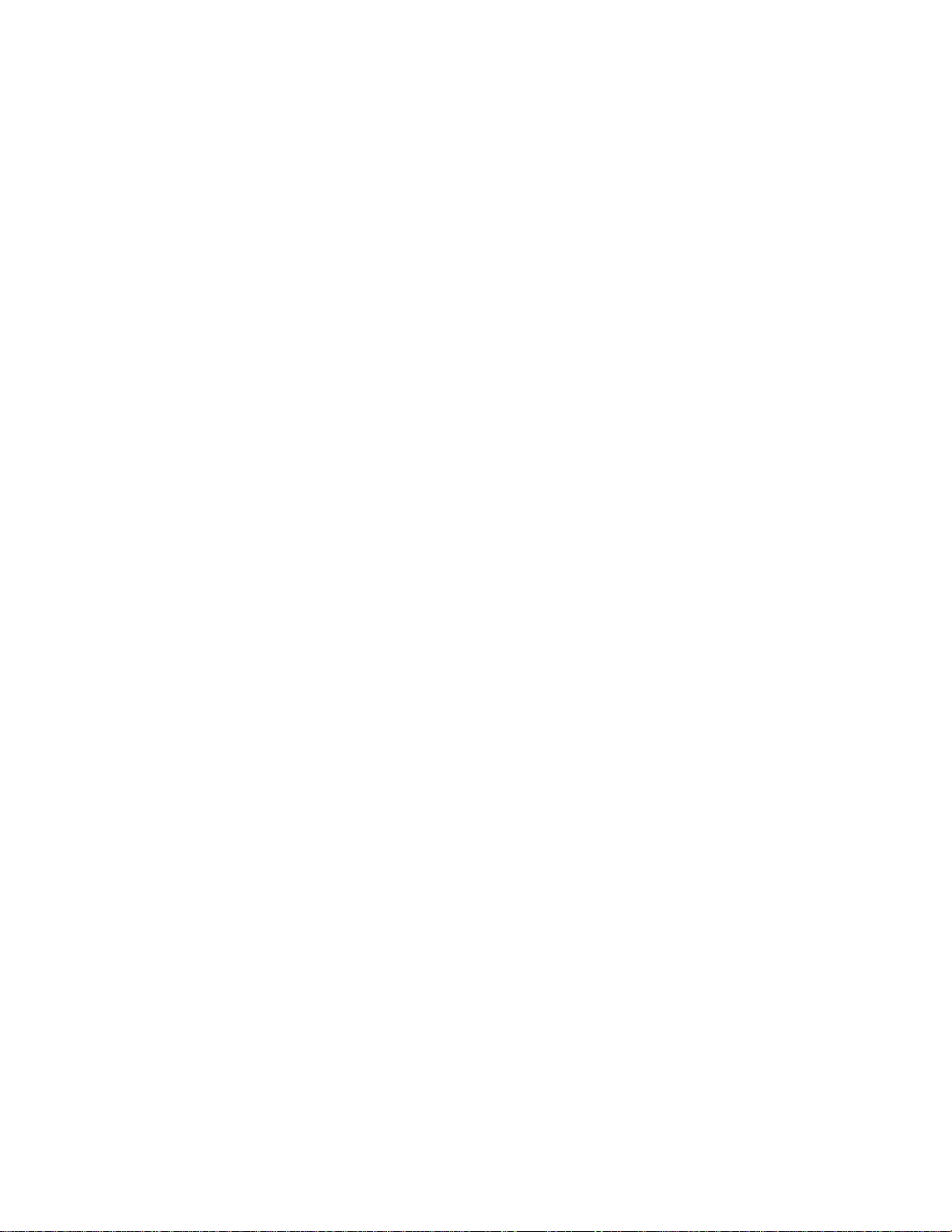

Spraying Adhesive

Spray patterns will vary depending on product due to variations in formulations and cylinder

pressure. Ambient temperatures may also have an effect. Higher temperatures may

increase solubility of the adhesive and create greater pressure in the cylinder causing an

increase in spray width. Colder temperatures will typically cause a decrease in the cylinders

pressure resulting in smaller spray widths. See figures 6-13 below for information on spray

technique.

Spray Distance: Unscrew the trigger stop/adjusting nut away from the trigger 3-4 turns

and spray a test pattern. The best distance is where the pattern is the widest. For more

adhesive output and a wider spray pattern, continue to unscrew the nut away from the

trigger. For less output and smaller spray pattern, screw the adjusting nut back towards

the trigger. Hold the applicator 3-10 inches away from the surfaces to be sprayed and

apply a uniform coat of adhesive. The smaller the spray pattern the closer the applicator

gun will need to be to the surface.

Lace Spray Adhesives form an elliptical pattern and should be sprayed at the patterns

6

widest point.

Pebble Spray Adhesives form more of a continuous triangular pattern that gets larger as

you continue to move the applicator from the surface being sprayed.

Mist Spray Adhesives also have the more triangular pattern, like the pebble, but will have

considerably more overspray.

7

Spraying from too close may cause an excess of adhesive to be deposited creating a

wet film or puddling. 8Spraying from too far away may cause a “cobwebbing” of the

adhesive and many open areas that have no adhesive coverage at all.

Figure 6-8: Determining proper distance from substrate when spraying with a cylinder spray adhesive.

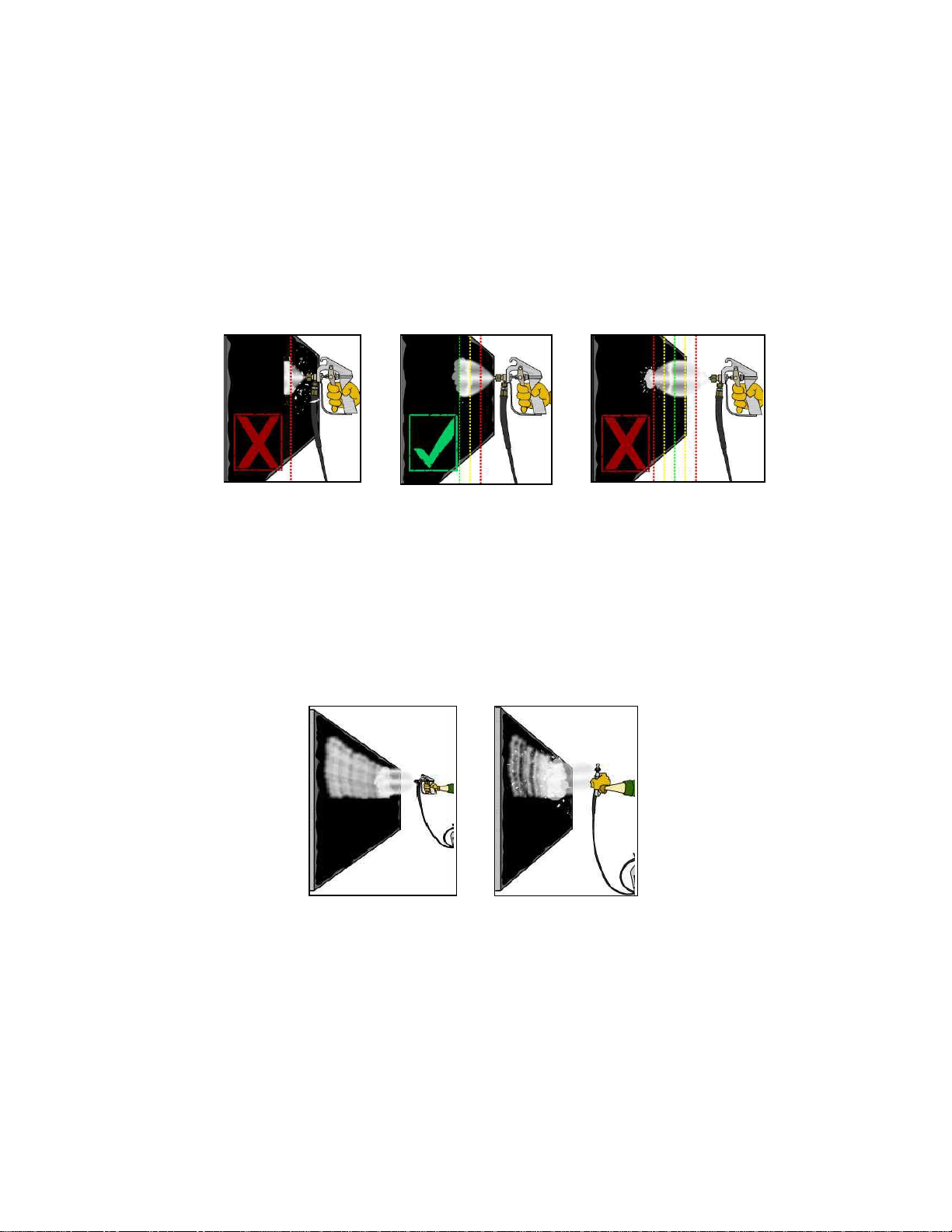

Spray Angle: For best results, 9maintain a 90o angle, between the surface and the

applicator gun. This is done by moving the applicator parallel to the spray surface and

keeping the wrist in a fixed position, moving at a constant rate. 10Poor coverage with

inconsistent bond strength may be seen if the wrist is turned, as the spray distance (see

notes above) will constantly be changing.

Figures 9-10: For best results when spraying, maintain a 90° angle between the surface and the applicator gun.

Loading...

Loading...