Page 1

INSTALLATION AND OPERATING

INSTRUCTIONS

CFSM1254 WATER SOFTENER

Installer: Please leave this manual with owner/operator.

Owner/Operator: Please retain for operation and future

maintenance instructions.

Page 2

SAFETY INFORMATION

WARNING

CAUTION

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the CFSM1254 Water

Softener. Retain these instructions for future reference. Failure to follow installation, operation and maintenance instructions may result

in property damage and will void warranty.

Intended use:

The CFSM1254 Water Softener is intended for use in softening water and has not been evaluated for other uses. The system must be

installed indoors near the point of entry of a water line, and be installed by qualifi ed professional installers according to these installation

instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

W

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

To reduce the risk of physical injury:

• Shut off inlet water supply and depressurize system as shown in manual prior to service.

To reduce the risk associated with a hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across

the fi lter installation piping — refer installation to qualifi ed personnel.

• Do not use the system if the power cord is damaged — contact qualifi ed service personnel for repair.

To reduce the risk associated with back strain due to the heavy weight of the various system components:

• Follow safe lifting procedures.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install systems in areas where ambient temperatures may go above 110°F (43.3°C) or below 40°F (4.4°C).

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing

professional if you are uncertain how to check for this condition.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

• Do not install in direct sunlight or outdoors.

• Mount system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure all tubing and fi ttings are secure and free of leaks.

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

• Do not apply heat to any fi tting connected to Bypass or Control Valve as damage may result to internal parts or connecting adapters.

• Install on a fl at/level surface. It is also advisable to sweep the fl oor to eliminate objects that could pierce the brine tank.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

Page 3

IMPORTANT NOTES

• The system should be installed on cold water lines only.

• Failure to follow instructions will void warranty.

SECTION DESCRIPTION

TABLE OF CONTENTS

1 BEFORE INSTALLATION

2 INSTALLATION

3 CONTROL VALVE PROGRAMMING AND REGENERATION

4 MAINTENANCE

5 TROUBLESHOOTING AND SERVICE INSTRUCTIONS

6 SPECIFICATIONS & OPERATING DATA

7 PARTS

LIMITED WARRANTY

SECTION 1: BEFORE INSTALLATION

When properly installed, operated, and maintained, your new softener will provide many years of dependable service. Before starting the installation please

read this manual all the way through for an overview, and then follow the installation in proper sequence. Failure to follow instructions will void warranty.

Inspecting And Handling Your Softener:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection.

Handle the equipment with care. Damage can result if dropped or if the brine tank is set on sharp, uneven projections on the fl oor. When handling, do not

turn the water softener unit upside down.

Make Sure Your Water Has Been Thoroughly Tested:

An analysis of your water should be made prior to the selection of your water conditioning equipment. Your dealer will generally perform this service for you,

and may send a sample to the factory for analysis and recommendations. Enter your analysis below for your permanent record.

Analysis of Your Water:

Hardness gpg Tannins (Humic Acid) ppm

Iron (Fe) ppm Hydrogen Sulfi de (H2S) ppm

Manganese (Mn) ppm Other ppm

pH ppm

Other ppm

IMPORTANT NOTES

Hydrogen sulfi de (H

S) must be tested for at the well site. For accuracy, the sample must be drawn with the

2

pump RUNNING, and the test be completed within ONE minute after the sample is drawn.

Softeners are designed to reduce hardness but can handle reasonable amounts of soluble iron if consideration

is given to content when selecting model and regeneration settings. To treat sulfur (hydrogen sulfi de), bacterial iron, precipitated iron or very high levels of soluble iron requires special equipment in addition to a water

softener. For best results, a Chem-Free Iron Reduction System is recommended for use on waters containing

more than 2 ppm of iron.

1-1

Page 4

Check Your Pumping Rate and Water Pressure:

Two water system conditions must be checked carefully to avoid unsatisfactory operation or equipment damage:

1) MINIMUM water pressure required at the water softener inlet is 20 psi (1.4 bar). IF WATER PRESSURE IS OVER 80 psi (552 kPa), A PRESSURE REDUCING VALVE MUST BE INSTALLED IN THE WATER SUPPLY LINE AHEAD OF THE WATER SOFTENER.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing professional if you are uncertain how to check your water pressure.

NOTE: If you have a municipal or a community water supply and daytime water pressure is 85 psi or more, nighttime pressure may exceed 100

psi. Call your local water department or plant operator to obtain pressure readings. If you have a private well, the gauge on the pressure tank will

indicate the high and low system pressure. Record your water pressure data below:

Water Pressure:

Low psi High psi

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

The installer should take appropriate measures if there is the possibility a vacuum may occur. This would include the installation of an appropriate

device in the supply line to the system, i.e., a vacuum breaker or backfl ow prevention device. Vacuum damage voids the factory warranty.

2) The pumping rate of your well must be suffi cient for satisfactory operation and BACKWASHING of the water softener. (See SPECIFICATIONS AND

OPERATING DATA, Section 6)

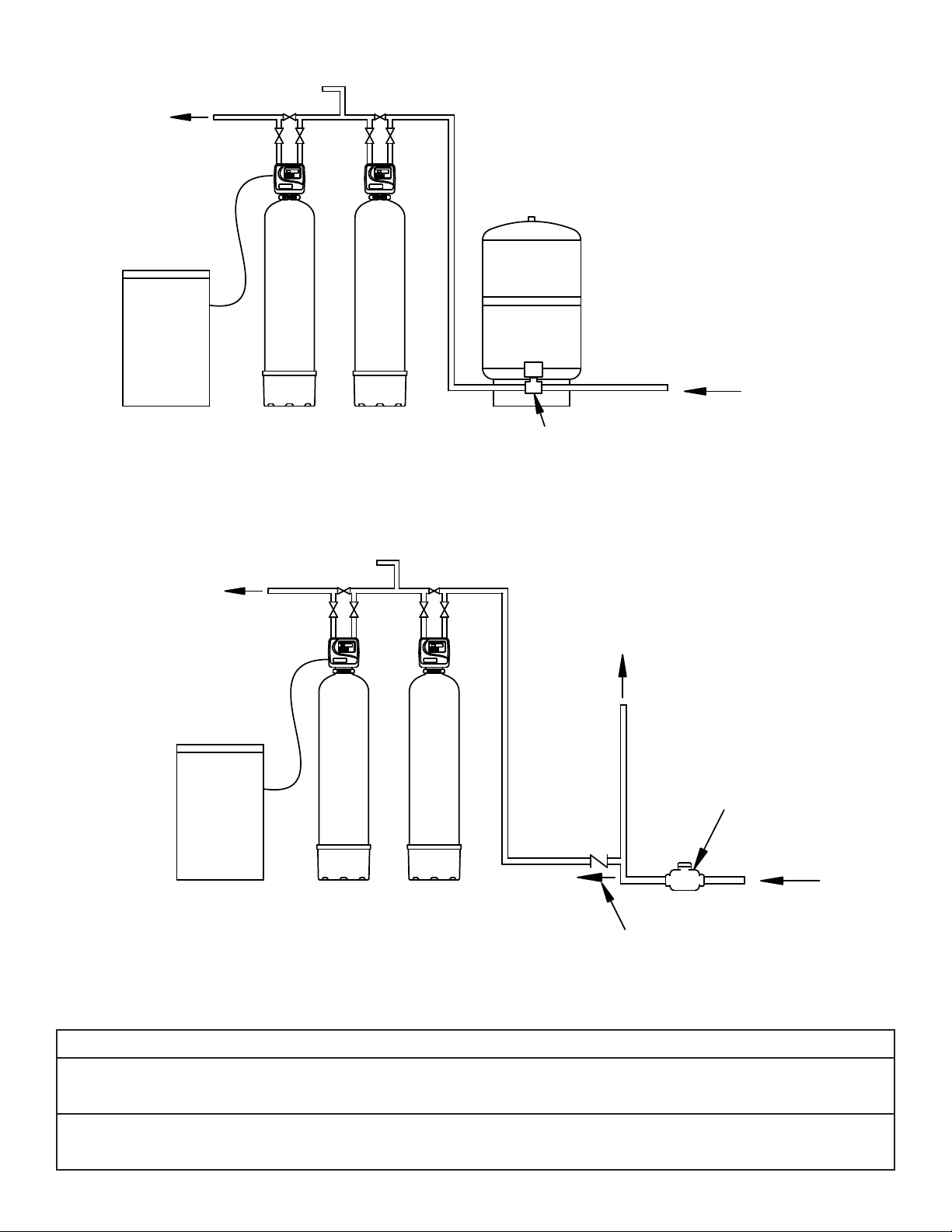

Locate Water Conditioning Equipment Correctly:

Select the location of your water softener with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a drain.

3) Locate in correct relationship to other water conditioning equipment (Figure 1).

4) Locate the softener in the supply line BEFORE the water heater. Temperatures above 100°F (38°C) will damage the softener and void the factory

warranty.

5) DO NOT install the softener in a location where freezing temperatures occur. Freezing may cause permanent damage and will also void the factory

warranty.

6) Allow suffi cient space around the installation for easy servicing.

7) Provide a non-switched 110V, 60Hz (220V, 50Hz for specifi ed systems) power source for the control valve.

WARNING

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install systems in areas where ambient temperatures may go above 110°F (43.3°C) or below 40°F (4.4°C).

1-2

Page 5

Facts to Remember While Planning Your Installation:

1) All installation procedures MUST conform to local and state plumbing codes.

2) Remember that the water softener INLET is attached to the pipe that supplies water (i.e. runs to the pump) and the OUTLET is the line that runs

toward the water heater.

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

3) Before commencing the installation it is advisable to study the existing piping system and to determine the size, number and type of fi ttings required.

WARNING

To reduce the risk associated with a hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across

the fi lter installation piping — refer installation to qualifi ed personnel.

4) It is also advisable to sweep the fl oor to eliminate objects that could pierce the brine tank.

IMPORTANT NOTE

Sodium Information: Water softeners utilizing sodium chloride for regeneration add sodium to the water softened water. Persons who are on sodium restricted diets should consider the added sodium as part of their overall sodium intake. As a reference as to how much sodium is added to softened water

consider the following. For each grain per gallon of water hardness that is exchanged from the water supply, 7.5 milligrams per liter of sodium will be added

to the softened water. e.g. 10 grains per gallon (gpg) exchanged will add 75 milligrams of sodium to the softened water.

1-3

Page 6

FILTERED

SOFT WATER

BRINE

MAKER

FILTERED WATER

SOFTENER

SECTION 2: INSTALLATION

PRESSURE

TANK

FILTER

PRESSURE

SWITCH.

STANDARD WELL INSTALLATION

RAW

WELL

WATER

FILTERED

SOFT WATER

BRINE

MAKER

FILTERED WATER

WATER FOR

LAWN SPRINKLERS

HIGH DEMAND

SOFTENER

FILTER

PUBLIC WATER SUPPLY INSTALLATION

Figure 1. Typical Installation

OR OTHER

METER

RAW

WATER

CHECK VALVE

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

2-1

Page 7

SECTION 2: INSTALLATION

Step 1) Remove the unit from the shipping box and remove all packaging. Ensure no freight damage has occurred since shipment from our manufacturing

facility. Locate the parts package and install the bypass and adapter fi ttings on the control valve to facilitate the connection to the customer’s

water supply.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic;

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

Step 2) Verify all packaging materials have been removed from the brine tank. On all units, legs rest on bottom of the brine tank.

Step 3) Shut off all water at main supply valve. On a private well system, turn off power to the pump and drain pressure tank. Make certain pressure is relieved

from complete system by opening nearest faucet to drain system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

Step 4) Cut main supply line as required to fi t plumbing to INLET and OUTLET of unit.

Step 5) Attach plumbing. DO NOT apply heat to any fi tting connected to BYPASS or CONTROL VALVE as damage may result to internal parts or connecting

adapters. MAKE CERTAIN WATER FLOW ENTERS THROUGH INLET AND DISCHARGES THROUGH OUTLET.

WARNING

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient

ground connection across the fi lter installation piping — refer installation to qualifi ed personnel.

Step 6) The controls allow for either a 3/4” NPT connection or 5/8” poly tubing for use as a drain line connection.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic;

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

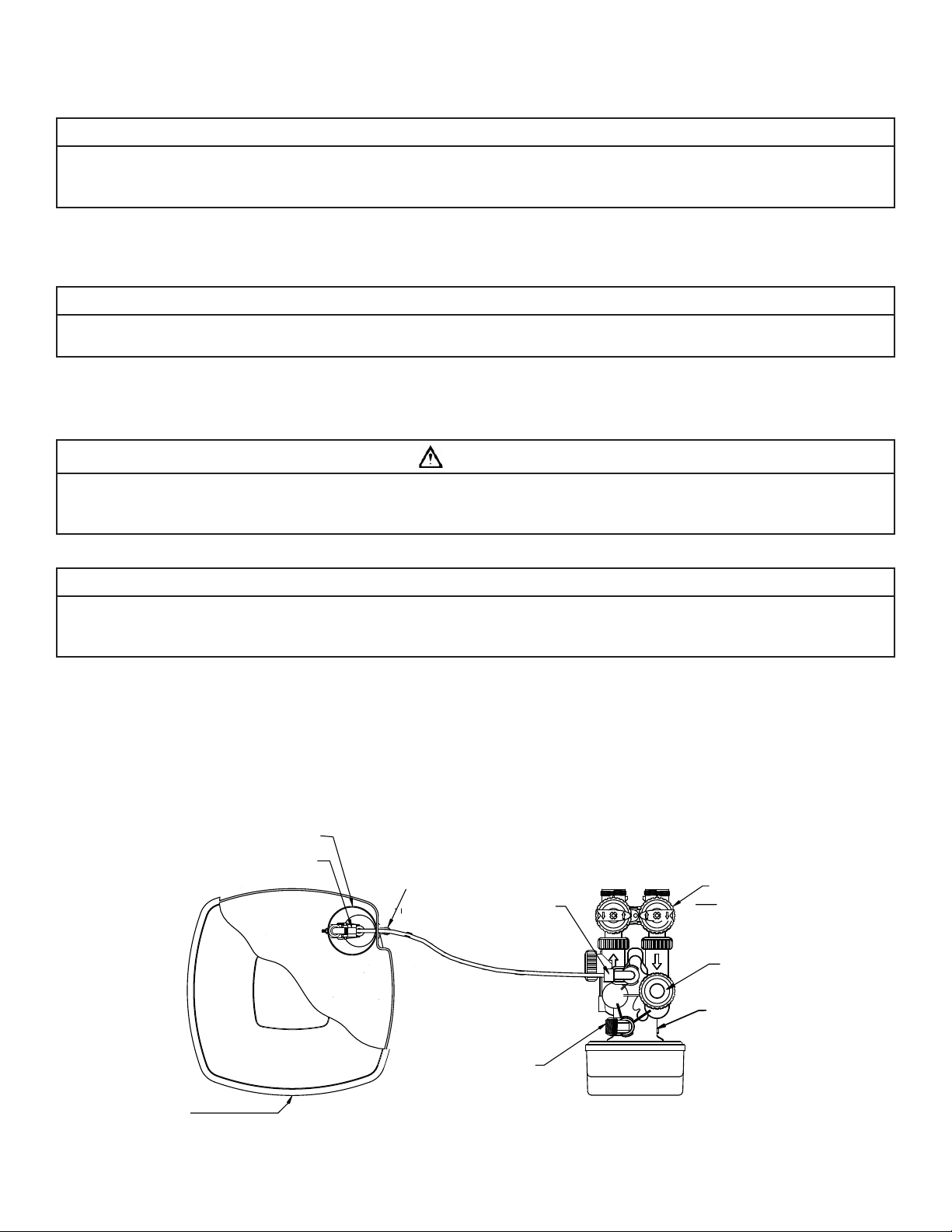

BRINE WELL

SAFETY BRINE

VALVE ASSEMBLY

OVERFLOW

FITTING

BRINE LINE

ELBOW

INOUT

OFF

OFF

OFF

OFF

BYPASS VALVE

INJECTOR COVER

BRINE TANK

DRAIN LINE FLOW

CONTROL ASSEMBLY

Figure 2. SOFTENER AND BRINE TANK ASSEMBLY, TOP VIEW

2-2

CONTROL VALVE BODY

Page 8

Step 7) Attach DRAIN LINE to DRAIN LINE FITTING. To prevent back pressure from reducing fl ow

rate below minimum required for backwash, DRAIN LINE MUST be sized according to run

length and relative height. Be careful not to bend fl exible drain tubing sharply enough to

cause “kinking” (if kinking occurs DRAIN LINE MUST BE REPLACED). Typical examples of

proper DRAIN LINE diameters are:

1) 1/2” ID up to 15 ft. when discharge is lower than INLET.

2) 5/8” ID up to 15 ft. when discharge is slightly higher than the INLET.

3) 3/4” ID when drain is 25 ft. away and/or drain is installed overhead.

Some areas prohibit the use of fl exible drain lines. Check with local code offi cials prior to

installation.

Step 8) Position DRAIN LINE over drain and secure fi rmly. To prevent backsiphoning of sewer

water, provide an air-gap of at least 2” or 2 pipe diameters between end of drain hose and

drain (Figure 3). DO NOT raise DRAIN LINE more than 10 ft. above fl oor.

Step 9) Connect one end of the 3/8” black Polyethylene tubing to the brine

fi tting located on the left side of the CONTROL VALVE. Connect the

other end to the SAFETY BRINE VALVE ELBOW inside of the brine

well in the brine tank. To do so remove the retaining clip from the

brine line fi tting on the control valve. The retaining clip is holding

BRINE LINE

ELBOW

a plastic insert sleeve and needs to be inserted into the polyethylene tubing before installing the tubing into the fi tting elbow and

hand tighten only. CAUTION: Do not use pliers or wrenches to

tighten as damage may occur and will void the manufacturer’s

warranty.

Figure 3

INOUT

OFF

OFF

OFF

OFF

BYPASS VALVE

INJECTOR COVER

Step 10) Install OVERFLOW LINE to brine tank OVERFLOW FITTING (Figure 2).

Discharge of line must be lower than OVERFLOW FITTING. DO NOT

INTERCONNECT OVERFLOW LINE WITH VALVE DRAIN LINE.

Step 11) Make certain BYPASS VALVE INLET and OUTLET KNOBS ARE IN

DRAIN LINE FLOW

CONTROL ASSEMBLY

“BYPASS” position. After all plumbing connections have been

completed, open main water shut-off valve or restore power to

well pump. Check for leaks and correct as necessary.

Step 12)Plug CONTROL VALVE POWER CORD into 120v/60Hz, non-switched power

source. Manually stage control to BACKWASH POSITION and then

unplug power cord to prevent the unit from advancing automatically.

NORMAL OPERATION BYPASS OPERATION

Treated Water

Exits

OFF

OFF

Supply Water

Enters

OFF

OFF

Step 13) Partially open INLET knob on bypass valve (Figure 4). This will

allow the unit to fi ll slowly from the bottom up, reducing air entrapment. Allow unit to fi ll slowly, failure to do so could result in

loss of resin to the drain. Once a steady stream of water, no air,

is fl owing to drain the inlet and outlet knobs on the bypass can be

Figure 4. BYPASS VALVE

fully opened.

Step 14) Plug the power cord back into the power source. Press the REGEN button and wait for the valve to advance to the

next regeneration position. Repeat the process until the valve is in Service Position (Time will be on the display).

Step 15) Refer to Section 3: Regeneration Instructions, on how to set control valve for proper set up and regeneration

settings.

NOTE: Regeneration settings for the control valve are factory preset. The control valve design permits adjustment

of the salt setting. This adjustment may be necessary when unusual operating conditions exist, such as high

concentrations of iron, manganese or hardness and/or high fl ow rates or daily water consumption.

Supply (Untreated)

Water Exits

CONTROL VALVE BODY

Supply Water

Enters

OFF

OFF

OFF

OFF

SPECIAL SERVICE INSTRUCTIONS:

Under normal circumstances removal of valve should not be required. However, if it must be removed, it

can be done by disassembling the quick release clamp, and latch. Pressure should be relieved before attempting any

disassembly. Upon reassembly, all o-rings should be lubricated with silicone grease. Reassemble clamp as shown in

Figure 5. MAKE SURE ARROWS ON LATCH SIDE OF CLAMP ARE ALIGNED.

Figure 5.

2-3

Clamp Assembly

Page 9

SECTION 3: CONTROL VALVE PROGRAMMING AND REGENERATION

Grains Capacity/lb NaCl 6,000 to 3,000

2

Lbs NaCl/cu ft resin

Cycle Time

in Minutes

Backwash Normal 8

Regenerate 60

Backwash Normal 10

Rinse 8

Total

Less than 7.5

3

86

Step 1

Step 2

Step 3

WS1 & WS 1.25 Downfl ow

Regenerant Refi ll After Rinse

1st Cycle Backwash

2nd Cycle Regenerate

3rd Cycle Backwash

4th Cycle Rinse

5th Cycle Fill Dissolve

6th Cycle Service

Installer Display Settings

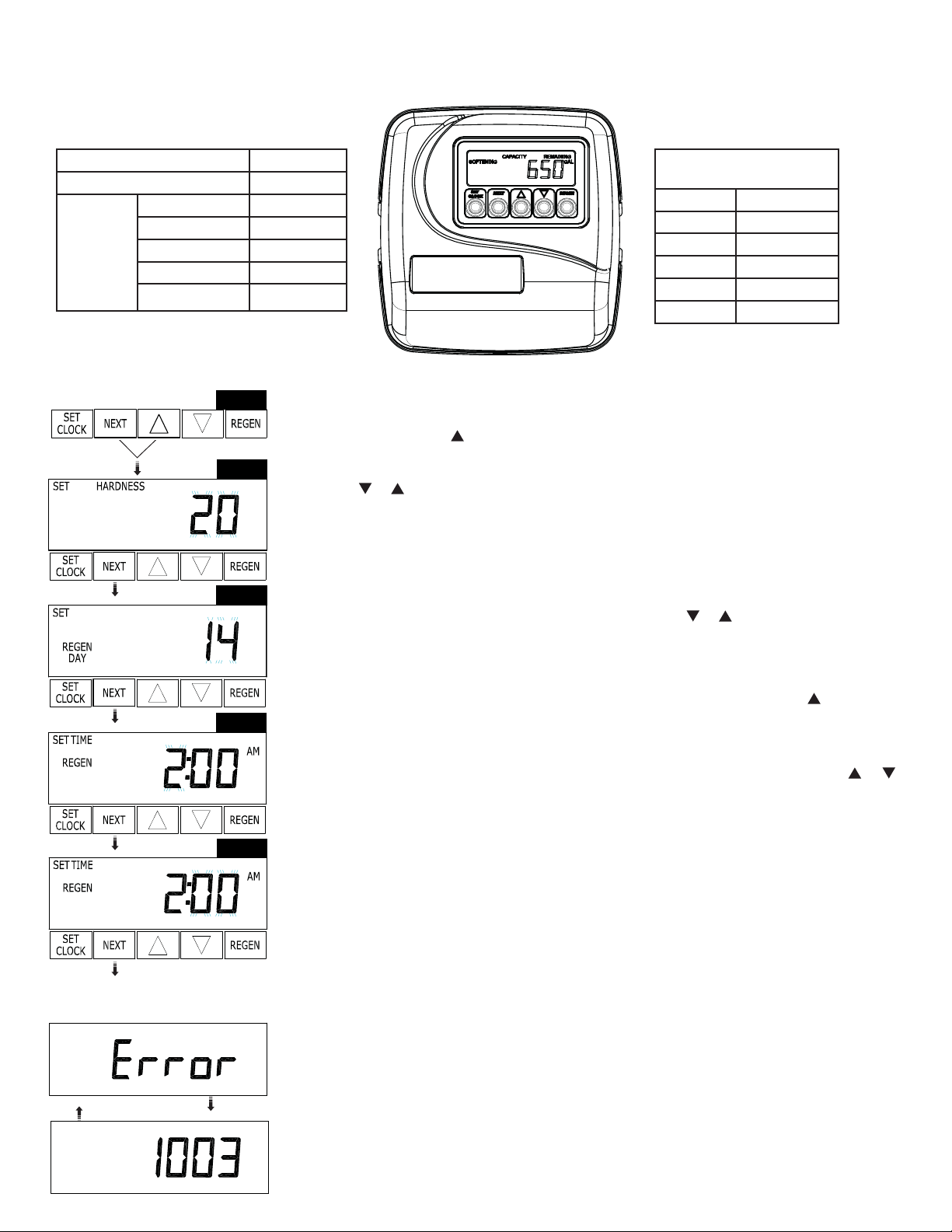

(Step 1) Press NEXT and simultaneously for 3 seconds.

(Step 2) Hardness: Set the amount of hardness in grains of hardness as calcium carbonate per gallon

using the or buttons. The default is 20 with value ranging from 1 to 150 in 1 grain increments.

Note: The grains per gallon can be increased if soluble iron needs to be reduced. Press NEXT to go

to Step 3. Press REGEN to exit Installer Display Settings.

(Step 3) Day Override: Day Override sets the number of days between regenerations and sets the

maximum number of days between regenerations. If value is set as a number (allowable range from

1 to 28) a regeneration initiation will be called for on that day even if suffi cient number of gallons

were not used to call for a regeneration. Set Day Override using or buttons.

• number of days between regeneration (1 to 28); or “OFF”.

Press NEXT to go to Step 4. Press REGEN to return to previous step.

RETURN TO

NORMAL MODE

Step 4

Step 5

(Step 4) Next Regeneration Time (hour): Set the hour of day for regeneration using or buttons.

AM/PM toggles after 12. The default time is 2:00 a.m. Press NEXT to go to Step 5. Press REGEN to

return to previous step.

(Step 5) Next Regeneration Time (minutes): Set the minutes of day for regeneration using or

buttons. Press NEXT to exit Installer Display Settings. Press REGEN to return to previous step.

To initiate a manual regeneration immediately, press and hold the “REGEN” button for three seconds.

The system will begin to regeneration immediately. The control valve may be stepped through the

various regeneration cycles by pressing the “REGEN” button.

Power Lost

If power goes out for less than two hours, the system will automatically reset itself. If an extended

power outage occurs, the time of day will fl ash on and off which indicated the time of day should be

reset. The system will remember the rest.

Error Message

If the word “error” and a number are alternately fl ashing on the display contact the “Technical

Support Services Department” at CUNO Incorporated, phone number 1-866-693-2543 for help. This

indicates that the valve was not able to function properly.

3-1

Page 10

Step 1

Step 2

Diagnostics

(Step 1) Press or simultaneously for 3 seconds. If screen in step does not appear in 5 seconds the

lock on the valve is activated. To unlock press, , NEXT, , and SET CLOCK in sequence, then press

NEXT and simultaneously for 3 seconds.

(Step 2) Days, since last regeneration: This display shows the days since the last regeneration occurred.

Press the NEXT button. Press REGEN to exit Diagnostics.

Step 3

Step 4

Step 5

Step 6

Step 7

(Step 3) Gallons, since last regeneration: This display shows the number of gallons that have been

treated since the last regeneration. This display will equal zero if a water meter is not installed. Press

the NEXT button. Press REGEN to return to previous step.

(Step 4) Gallons, reserve capacity used for last 7 days: This display shows 0 day (for today) and fl ashes

the reserve capacity. Pressing the

button show day 1 (which would be yesterday) and fl ashes the

reserve capacity used. Pressing the button again will show day

2 (the day before yesterday) and reserve capacity. Keep press-

ing the button to show the gallons for days 3, 4, 5 and 6. The

button can be pressed to move backwards in the day series.

Press the NEXT button at any time. Press REGEN to return to

previous step.

(Step 5) Gallons, 63 day usage history: This display shows day 1 (for yesterday) and fl ashes

the number of gallons treated yesterday. Pressing the

button will show day 2 (which would be the day before yesterday) and fl ashes the number of gallons treated on that day.

Continue to press the button to show the

maximum number of gallons treated for the last 63 days. This display will show dashes if a water meter

is not installed. Press the NEXT button at any time. Press REGEN to return to previous step.

(Step 6) Flow rate, current: Turn the water on at one or more taps in the building. The fl ow rate in gallons

per minute will be displayed. If fl ow stops the value will fall to zero in a few seconds. This display will

equal zero if a water meter is not installed. Press the NEXT button. Press REGEN to return to previous

step.

RETURN TO

NORMAL MODE

Step 8

Step 9

Step 10

(Step 7) Flow rate, maximum last seven days: The maximum fl ow rate in gallons per minute that occurred

in the last seven days will be displayed. This display will equal zero if a water meter is not installed.

Press the NEXT button. Press REGEN to return to previous step.

(Step 8) Gallons, total used since last reset: The total number of gallons used since last reset will be

displayed. This display will equal zero if a water meter is not installed. Press the NEXT button. Press

REGEN to return to previous step.

(Step 9) Days, total number since last reset: The total number of days the control valve has been in service since last reset will be displayed. Press the NEXT button. Press REGEN to return to previous step.

(Step 10) Regenerations, total number since last reset: The total number of regenerations that have

occurred since last reset will be displayed. Press the NEXT button to exit Diagnostics. Press REGEN to

return to previous step. To lock settings press , NEXT, , and SET CLOCK in sequence.

3-2

Page 11

Step 1

Step 1

Step 2

Step 3

Step 4

Valve History

(Step 1) Press or simultaneously for 3 seconds and release. Then press and simultaneously

and release. If screen, to the left, does not appear is 5 seconds the lock on the valve is activated. To

unlock press , NEXT, and SET CLOCK in sequence, then press and . Then press and

simultaneously and release.

(Step 2) Software Version: This display shows the software version of the valve. Press the NEXT but-

ton to go to the next step or press REGEN to exit Valve History.

(Step 3) Flow rate, maximum since startup: This display shows the maximum fl ow rate in gallons per

minute that has occurred since startup. This display will equal zero if a water meter is not functioning. Press the NEXT button to go to the next step. Press REGEN to return to previous step.

(Step 4) Gallons, total used since start-up: This display shows the total gallons. This display shows

the total days since start-up. Press the NEXT button to go to the next step. Press REGEN to return to

previous step.

(Step 5) Days, total since start-up: This display shows the total days since start-up. Press the NEXT

button to go to the next step. Press REGEN to return to previous step.

(Step 6) Regenerations, total number since start-up: This display shows the total number of regenerations that have occurred since start-up. Press the NEXT button to go to the next step. Press

REGEN to return previous step.

Step 5

Step 6

Step 7

(Step 7) Error, number of occurrences since start-up: This display shows E and the total number of

errors that have occurred since start-up. Press the NEXT button to exit Valve History. Press REGEN to

return to previous step. To lock settings press

, NEXT, and SET CLOCK in sequence.

RETURN T

NORMAL MOD

3-3

Page 12

User Display Settings

General Operation

OR

When the system is operating, one of two displays will be

shown. Pressing NEXT will alternate between the displays.

One of the displays is always the current time of day. The second display is one of the following: days remaining or gallons

remaining. Days remaining is the number of days left before

the system goes through a regeneration cycle. Capacity remaining is the number of gallons that will be treated before the

system goes through a regeneration cycle. The user can scroll

between the displays as desired.

REGEN TODAY will be

displayed if a regeneration

is expected “Tonight.”

If the system has called for a regeneration that will occur at the preset time of regeneration, the words “REGEN TODAY” will appear on the

display.

When water is being treated (i.e. water is fl owing through the system) the word “SOFTENING” fl ashes on the display if a water meter is installed.

Regeneration Mode

Typically a system is set to regenerate at a time of low water usage. An example of a time with low

water usage is when members of a household are asleep. If there is a demand for water when the

system is regenerating, untreated water will be used.

When the system begins to regenerate, the display will change to include information about the step of the regeneration process and the time

remaining for that step to be completed. The system runs through the steps automatically and will reset itself to help provide treated water

when the regeneration has been completed.

Manual Regeneration

Sometimes there is a need to regenerate the system sooner than

when the system calls for it, usually referred to as manual regen-

REGEN TODAY will

Flash if a regeneration

is expected “Tonight.”

eration. There may be a period of heavy water usage because of

guests or a heavy laundry day.

To initiate a manual regeneration at the present delayed regeneration time, press and release “REGEN”. The words “REGEN TODAY” will fl ash

on the display to indicate that the system will regenerate at the preset delayed regeneration time.

NOTE: If you pressed the “REGEN” button in error, pressing the button again will cancel the request.

To initiate a manual regeneration immediately, press and hold the “REGEN” button for 3 seconds. The system will begin to regenerate immediately. The request cannot be cancelled.

NOTE: For softeners, if brine tank does not contain salt, fi ll with salt and wait at least two hours before regenerating.

Set Time of Day

The user can also set the time of day. Time should only need to be set after extended

power outages or when daylight saving time begins or ends. If an extended power out-

ages or when daylight saving time begins or ends. If an extended power outage occurs,

the time of day will fl ash on and off which indicates the time of day should be reset.

Step 1 - Press SET CLOCK.

Step 2 - Current Time (hour): Set the hour of the day using or button. AM/PM

toggles after 12. Press NEXT to go to Step 3.

Step 3 - Current Time (minutes): Set the minutes of the day using or buttons.

Press NEXT to exit Set Clock. Press “REGEN” to return to previous step.

3-4

Page 13

SECTION 4: MAINTENANCE

Replenishment of Salt Supply:

The salt storage capacity of the brine tank is approximately 135 lbs. (61 kg). During each regeneration a specifi c amount of salt is consumed, thus requiring its

periodic replenishment (the frequency and salt dosage level is dependent on the regeneration schedule). Always replenish salt before the supply is exhausted

for a continuous supply of softened water.

Type of Salt to Use:

Any type of water softener salt may be used. There are advantages and disadvantages to every type of salt. Please ask your local dealer for his advice. Your

unit is designed to compensate for the disadvantages. However the use of block salt is not encouraged due to its possible problems in making enough brine

for regeneration purposes.

Brine Tank Clean-Out:

To prevent service problems the brine tank should be emptied and fl ushed out with a garden hose when dirt and other insolubles accumulate.

Steps to follow:

(1) Disconnect brine line at either end.

(2) Turn brine tank upside down and discard old salt.

(3) Rinse out with a garden hose.

(4) Reconnect brine line.

(5) Before loading salt, using a pail or garden hose, add enough water to the brine tank to cover the salt grid lower shelf on 15” x 15” x 34” brine tank at least

one (1) inch in depth. Then add initial salt to brine tank and add one (1) cup of unscented laundry bleach to the brine well.

(6) Perform approximately once a year if rock salt is used; with other types of salt, approximately once every other year.

Preventing Iron-Fouling of Mineral Bed:

If iron is present in the water supply, the softener mineral bed will eventually become iron-fouled, resulting in reduced softening capacity and rust-stained

fi xtures. Mixing one to two ounces of IRON-X Mineral Cleaner with every 80 lbs. of salt added to brine tank will help minimize these problems from occurring.

IRON-X is available from your dealer.

Periodically Check Time of Day Setting:

Power outages will cause “TIME OF DAY” setting to become incorrect. To correct, refer to Section 4.

Malfunction of Unit:

Your water softener, under normal conditions, should provide years of virtually trouble-free service; however, since it is a mechanical device, it can malfunction.

(Refer to Section 5, SERVICE INSTRUCTIONS, if necessary).

Change of Operating Conditions:

Should your family size, your water usage habits, or your water quality change, the regeneration program settings may have to be adjusted. Consult your

dealer if any of the above occur.

Special Service Instructions:

Under normal circumstances removal of valve should not be required. However, if it must be removed, it can be done by disassembling the quick release clamp, and

latch. Pressure should be relieved before attempting any disassembly. Upon reassembly, all o-rings should be lubricated with silicone grease. Reassemble clamp

as shown in Figure 5. MAKE SURE ARROWS ON LATCH SIDE OF CLAMP ARE ALIGNED.

4-1

Figure 6. CLAMP ASSEMBLY

Page 14

SECTION 5: CONTROL VALVE TROUBLESHOOTING GUIDE

Problem Possible Cause Solution

1. Timer does not display time of day

2. Timer does not display correct time

of day

3. No softening/fi ltering display when

water is fl owing

4. Control Valve regenerates at wrong

time of day

5. ERROR followed by code number

Error Code 1001 - Unable to recognize start of

regeneration

Error Code 1002 - Unexpected stall

Error Code 1003 - Motor ran too long, timed out

trying to reach next cycle position

Error Code 1004 - Motor ran too long, timed out

trying to reach home position

If other Error Codes display, contact the factory

6. Control valve stalled in regeneration

7. Control valve does not regenerate

automatically when “REGEN” button

is depressed and held

8. Control valve does not regenerate

automatically but does when “REGEN”

button is depressed

9. Time of day fl ashes on and off

A. AC Adapter unplugged A. Connect power

B. No electric power at outlet B. Repair outlet or use working outlet

C. Problem with AC Adapter C. Replace AC Adapter

D. Problem with PC Board D. Replace PC Board

A. Switched outlet A. Use uninterrupted outlet

B. Power outage B. Reset time of day

C. Problem with PC board C. Replace PC board

A. Bypass valve in bypass position A. Put bypass valve in service position

B. Meter connection disconnected B. Connect meter to PC board

C. Restricted/stalled meter turbine C. Remove meter and check for rotation or foreign material

D. Problem with meter D. Replace meter

E. Problem with PC board E. Replace PC board

A. Power outages A. Reset control valve to correct time of day

B. Time of day not set correctly B. Reset to correct time of day

C. Time of regeneration incorrect C. Reset regeneration time

A. Control valve has just been serviced or unplug power

source jack (black wire) and plug back in to reset control

valve.

B. Foreign matter is lodged in control valve B. Check piston and spacer stack assembly

C. High drive forces on piston C. Replace piston(s) and spacer stack assembly

D. Control valve piston not in home position seconds D. Press NEXT and REGEN for 3 seconds or unplug power source jack

E. Motor not inserted fully to engage pinion, motor wires

broken or disconnected, motor failure

F. Drive gear label dirty or damaged, missing or broken

gear

G. Drive bracket incorrectly aligned to back plate G. Reseat drive bracket properly

H. PC board is damaged or problematic H. Replace PC board

I. PC board incorrectly aligned to drive bracket I. Ensure PC board is correctly snapped on to drive bracket

A. Motor not operating A. Replace motor

B. No electric power at outlet B. Repair outlet or use working outlet

C. Problem with AC Adapter C. Replace AC Adapter

D. Problem with PC board D. Replace PC board

E. Broken drive gear or drive cap assembly E. Replace drive gear or drive cap assembly

F. Broken piston retainer F. Replace drive cap assembly

G. Broken main or regenerant piston G. Replace main or regenerant piston

A. AC Adapter unplugged A. Connect AC Adapter

B. No electric power at outlet B. Repair outlet or use working outlet

C. Broken drive gear or drive cap assembly C. Replace drive gear or drive cap assembly

D. Problem with PC board D. Replace PC board

A. Bypass valve in bypass position A. Put bypass valve in normal operating position

B. Meter connection disconnected B. Connect meter to PC board

C. Restricted/stalled meter turbine C. Remove meter and check for rotation or foreign matter

D. Problem with meter D. Replace meter

E. Problem with PC board E. Replace PC board

F. Set-up error F. Check control valve set-up procedure

A. Power has been out more than two hours, the AC

Adapter was unplugged and then plugged back into the

wall outlet, the AC Adapter plug was unplugged and then

plugged back into the board or the NEXT and REGEN buttons were pressed to reset the valve

A. Press NEXT and REGEN for 3 seconds

(black wire) and plug back in to reset control valve

E. Check motor and wiring. Replace motor if necessary

F. Replace or clean drive gear

A. Reset the time of day

5-1

Page 15

SECTION 5: CONTROL VALVE SERVICE INSTRUCTIONS

Drive Assembly:

Remove the valve cover to access the drive assembly.

IMPORTANT NOTE: Disconnect the power source plug (black wire) from the PC board prior to disconnecting the motor or water meter plugs from the PC board. The

power source plug connects to the four-pin jack. The motor plug connects to the two-pin jack on the left-hand side of the PC board. The water meter plug (grey

wire) connects to the three-pin jack on the far right-hand side of the PC board.

The PC board can be removed separately from the drive bracket but it is not recommended. Do not attempt to remove the display panel from the PC board. Handle

the board by the edges. To remove the PC board from the drive bracket, unplug the power, water meter and motor plugs from the PC board. Lift the middle latch

along the top of the drive bracket while pulling outward on the top of the PC board. The drive bracket has two plastic pins that fi t into the holes on the lower edges

of the PC board. Once the PC board is tilted about 45° from the drive bracket it can be lifted off of these pins. To reinstall the PC board, position the lower edge of

the PC board so that the holes in the PC board line up with the plastic pins. Push the top of the PC board towards the valve until it snaps under the middle latch,

weave the power and water meter wires into the holders and reconnect the motor, water meter and power plugs.

The drive bracket must be removed to access the drive cap assembly and pistons or the drive cap gear cover. It is not necessary to remove the PC board from the

drive bracket to remove the drive bracket. To remove the drive bracket, start by removing the plugs for the power source and the water meter. Unweave the wires

from the side holders. Two tabs on the top of the drive back plate hold the drive bracket in place. Simultaneously lift the two tabs and gently ease the top of the

drive bracket forward. The lower edge of the drive bracket has two notches that rest on the back plate. Lift up and outward on the drive bracket to disengage the

notches.

To reassemble, seat the bottom of the drive bracket so the notches are engaged at the bottom of the drive back plate. Push the top of the drive bracket toward the

two latches. The drive bracket may have to be lifted slightly to let the threaded piston rod pass through the hole in the drive bracket. Maintain a slight engaging

force on top of the drive bracket while defl ecting the bracket slightly to the left by pressing on the side of the upper right corner. This helps the drive gears mesh

with the drive cap assembly. The drive bracket is properly seated when it snaps under the latches on the drive back plate. If resistance is felt before latching, then

notches are not fully engaged, the piston rod is not in the hole, the wires are jammed between the drive bracket and drive back plate, or the gear is not engaging

the drive cap assembly. To inspect the drive gears, the drive gear cover needs to be removed. Before trying to remove the gear cover, the drive bracket must be

removed from the drive back plate. (Refer to the proceeding instructions regarding removing the drive bracket from the drive back plate. The drive gear cover can

be removed from the drive bracket without removing the motor or the PC board.) The drive gear cover is held in place on the drive bracket by three clips. The largest

of the three clips is always orientated to the bottom of the drive bracket. With the PC board facing up, push in and down on the large clip on the drive gear cover.

Handle the cover and the gears carefully so that the gears do not fall off of the pegs in the cover.

Replace broken or damaged drive gears. Do not lubricate any of the gears. Avoid getting any foreign matter on the refl ective coating because dirt or oils may

interfere with pulse counting.

The drive gear cover only fi ts on one way, with the large clip orientated towards the bottom. If all three clips are outside of the gear shroud on the drive bracket

and the drive gear cover slips easily into place.

The drive bracket does not need to be removed from the drive plate if the motor needs to be removed. To remove the motor, disconnect the power and motor plugs

from the jacks on the PC board. Move the spring clip loop to the right and hold. Rotate the motor at least a 1/4 turn in either direction so the wires are vertical

(up & down) before gently pulling on the wire connectors to remove the motor. Pulling directly on the wires without rotating the motor may break the wires off the

motor.

Replace the motor if necessary. Do not lubricate the motor or the gears. To reinstall the motor, move the spring clip loop to the right and hold. Gently turn the motor

while inserting so that the gear on the motor meshes with the gears under the drive gear cover. Release the spring clip loop and continue to rotate the motor until

the wires are horizontal and the motor housing engages the small plastic bulge inside the drive bracket motor retainer. Reconnect the motor plug to the two-pronged

jack on the lower left hand side of the PC board. If the motor will not easily engage with the drive gears when reinstalling, lift and slightly rotate the motor before

reinserting. Reconnect the power.

Replace the valve cover. After completing any valve maintenance, press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (black wire)

and plug back in. This resets the electronics and establishes the service piston position. The display should fl ash all wording, then fl ash the software version (e.g.

181) and then reset the valve to the service position.

Drive Cap Assembly, Main Piston and Regenerant Piston:

The drive assembly must be removed to access the drive cap assembly. The drive cap assembly must be removed access the piston(s). The drive cap assembly

is threaded into the control valve body and seals with an o-ring. To remove the drive cap assembly use the special plastic wrench or insert a ¼” to ½” fl at blade

screwdriver into one of the slots around the top 2” of the drive cap assembly so it engages the notches molded into the drive back plate around 2” or the piston

cavity. See Figure 7. The notches are visible through the holes. Lever the screwdriver so the drive cap assembly turns to the left. Once loosened, unscrew the drive

cap assembly by hand and pull straight out. The drive cap assembly contains the drive cap, the main drive gear, drive cap spline, piston rod and various other parts

that should not be dissembled in the fi eld. The only replaceable part on the drive cap assembly is the o-ring. Attached to the drive cap assembly is the main piston

and a regenerant piston.

The regenerant piston (the small diameter one behind the main piston) is removed form the main piston by pressing sideways and unsnapping if from its latch.

Chemically clean in dilute sodium or vinegar, or replace the regenerant piston if needed. To remove the main piston fully extend the piston rod and then unsnap the

main piston from its latch by pressing on the side with the number. Chemically clean in dilute sodium bisulfi te or vinegar, or replace the main piston.

5-2

Page 16

Reattach the main piston to the drive cap assembly. Reattach the regenerant piston (if needed)

to the main piston. Do not lubricate the piston rod, main piston or regenerant piston. Lubricant

will adversely affect the clear lip seals. Reinsert the drive cap assembly and piston into the

spacer stack assembly and hand tighten the drive cap assembly. Continue to tighten the drive

cap assembly using a screwdriver as a ratchet until the black o-ring on the spacer stack assembly is no longer visible through the drain port. Excessive force can break the notches molded

into the dive back plate. Make certain that the main drive gear still turns freely.

The exact position is not important as long as the main drive gear turns freely. Reattach the drive

assembly to the control valve and connect all plugs. After completing any valve maintenance,

press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (black wire)

and plug back in. This resets the electronics and establishes the service piston position. The

display should fl ash all wording, then fl ash the software version (e.g. 181) and then reset the

valve to the service position.

Figure 7

Spacer Stack Assembly:

To access the spacer stack assembly remove the drive assembly, drive cap assembly and piston. The spacer stack assembly can be removed easily

without tools by using thumb and forefi nger. Inspect the black o-rings and clear lip seals for wear or damage. Replace the entire stack if necessary.

Do not disassemble.

The spacer stack assembly may be chemically cleaned (dilute sodium bisulfi te or vinegar) or wiped with a soft cloth.

The spacer stack assembly can be pushed in to the control valve body bore by hand. Since the spacer stack assembly can be compressed it is

easier to use a blunt object (5/8” to 1-1/8” in diameter) to push the center of the assembly into the control valve body. The assembly is properly

seated with at least four threads are exposed (approximately 5/8’). Do not force the spacer stack assembly in. The control valve body bore interior

can be lubricated with silicone to allow for easy insertion of the entire stack. Do not use silicone or any other type of lubricant on the clear lip seals

or the piston.

Reattach the drive cap assembly and piston(s) and the drive assembly.

After completing any valve maintenance, press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (black wire) and plug

back in. This resets the electronics and establishes the service piston position. The display should fl ash all wording, then fl ash the software version

(e.g. 181) and then reset the valve to the service position.

Injector Cap, Screen, Injector Plug and Injector:

Unscrew the injector cap and lift off. Loosen cap with special plastic wrench or pliers if necessary. Attached to the injector cap is a screen. Remove the screen and

clean if fouled. The plug and/or injector can be pried out with a small screwdriver. The plug can be wiped clean. If the plug leaks replace the entire plug. The injector consists of a throat and a nozzle. Chemically clean the injector with vinegar or sodium bisulfi te. The holes can be blown out with air. Both pieces have a small

diameter holes that control the fl ow rates of water to insure that the proper concentration of regenerant is used. Sharp objects, which can score the plastic, should

not be used to clean the injector. Scoring the injector or increasing the diameter of the hole could change the operating parameters of the injector. Push the plug(s)

and/or injectors fi rmly in place, replace the screen and hand tighten the injector cap.

Refi ll Flow Control Assembly or Refi ll Port Plug:

To clean or replace the refi ll fl ow control, pull out the elbow-locking clip and then pull straight up on the elbow. Replace the elbow locking clip in the

slot so that it is not misplaced. Twist to remove the white fl ow control retainer. The fl ow control can be removed by prying upward through the side

slots of the retainer with a small fl at blade screwdriver.

Clean the fl ow control or the white fl ow control retainer using dilute sodium bisulfi te or vinegar. Do not use a wire brush. If necessary, replace the

fl ow control, o-ring on the fl ow control retainer, or the o-ring on the elbow.

Reseat the fl ow control so the rounded end is visible in the fl ow control. Reseat the white fl ow control retainer by pushing the retainer into the

elbow until the o-ring seats. Remove locking clip, push down on elbow to reseat and insert locking clip. Do not use petroleum jellies, oils, or other

unacceptable on o-rings. A silicone lubricant may be used on the o-ring on the elbow or the white retainer.

Water Meter or Meter Plug:

The water meter assembly is connected to the PC board by a wire. If the entire water meter assembly is to be replaced, remove the control valve cover and disconnect the power source and water meter plugs from the PC Board. Unlatch the drive assembly and lean if forward. Unthread the water meter wire from the side of the

drive assembly and through the drive back plate. To reinstall, rethread the water meter wire through the drive back plate and the side of the drive assembly. Reattach

the drive assembly and the water meter and power plugs. If no water meter wire is visible, then a plug is installed, not a water meter. The water meter wire does

not need to be removed from the PC board if the water meter is only being inspected and cleaned. To remove the water meter assembly, unscrew the meter cap on

5-3

Page 17

the left side of the control valve. Pliers may be used to unscrew the nut if necessary. With the nut removed, a slot at the top of the water meter is visible. Twist a fl at

blade screwdriver in the slot between the control valve body and the meter. When the meter is part way out it is easy to remove the water meter from the housing.

Once the water meter is removed from the control valve body, gently pull forward on the turbine to remove it from the shaft.

Do not use a wire brush to clean the turbine. Wipe with a clean cloth or clean in dilute sodium bisulfi te or vinegar. The turbine can be immersed in the chemical. Do

not immerse electronics. If the turbine is scored or damaged or the bearing on the turbine are worn, replace the turbine.

Do not lubricate the turbine shaft. The turbine shaft bearings are prelubricated. Do not use petroleum jellies, oils, or other unacceptable lubricants on the o-ring. A

silicone lubricant may be used on the black o-ring.

Snap the turbine on the shaft and reinsert the water meter into the side slot. Hand tighten the nut. Do not use a pipe wrench to tighten nut.

Bypass Valve:

The working parts of the bypass valve are the rotor assemblies that are contained under the bypass valve caps. Before working on the rotors, make sure the system

is depressurized. Turn the red arrow shaped handles towards the center of the bypass valve and back several times to ensure rotor is turning freely.

The nuts and caps are designed to be unscrewed or tightened by hand. If necessary a pliers can be used to unscrew the nut or cap. Do not use a pipe wrench to

tighten or loosen nuts or caps. Do not place screwdriver in slots on caps and/or tap with a hammer. To access the rotor, unscrew the cap and lift the cap, rotor and

handle out as one unit. Twisting the unit as you pull it out will help to remove it more easily. There are three o-rings: one under the rotor cap, one on the rotor stem

and the rotor seal. Replace worn o-rings. Clean rotor. Reinstall rotor.

When reinstalling the red arrow handles be sure that:

1. The handle pointers are lined up with the control valve body arrows, and the rotor seal o-ring and the retainer on both rotors face to the right when being

viewed from the front of the control valve; or

2. Arrows point toward each other in the bypass position.

Since the handles can be pulled off, they could be accidentally reinstalled 180° from their correct orientation. To install the red arrow handles correctly, keep the

handles pointed in the same direction as the arrows engraved on the control valve body while tightening the bypass valve caps. After completing and valve maintenance, press and hold NEXT and REGEN buttons for 3 seconds or unplug power source jack (black wire) and plug back in. The resets the electronics and establishes

the service piston position. The display should fl ash all wording, then fl ash the software version (e.g. 181) and then reset the valve to the service position.

5-4

Page 18

SECTION 5: SYSTEM TROUBLESHOOTING GUIDE

Problem Cause Solution

A. Electrical service to unit interrupted A. Assure permanent electrical service (check fuse, plug, pull chain,

B. Timer not working. B. Replace timer assembly.

1. Hard water (unit not using salt; liquid level in

brine tank NOT too high)

2. Hard water (unit using salt; liquid level in

brine tank NOT too high)

3. Liquid level in brine tank TOO high

4. System regenerates at wrong time

of day

5. Water continuously fl ows to drain

6. Water tastes salty

7. White spots on glassware and dark surfaces

8. Low water pressure (low fl ow rate)

9. “Rotten egg” smell (from hot water only) A. Magnesium rod in water heater A. Replace with aluminum rod or remove

10. “Rotten egg” smell (from both hot and cold

water

11 Loss of resin through drain

C. Timer improperly set C. Check programming function

D. Safety brine valve not opening D. Replace safety brine valve

E. Salt “bridged” in brine tank E. Breakup salt

F. Meter not functioning F. Clean or replace as necessary

A. Bypass open A. Close bypass (replace if necessary)

B. Timer improperly set B. Increase frequency of regeneration

C. No salt in brine tank C. Add salt; maintain above water level

D. Excessive water usage D. Increase frequency of regeneration and/or salt setting (See HOW TO

E. Unit installed backwards E. Reinstall unit

F. Unit undersized F. Replace with larger unit

A. Brine valve not closing A. Replace brine valve

B. Salt setting too high B. Reset timer

C. Injector or Injector screen plugged C. Clean injector and screen

D. Drain line frozen, plugged or restricted D. Free drain

E. Salt “mushed” or sand from salt plugging bottom of

brine tank

F. Incorrect brine line fl ow control (BLFC) F. Replace with correct fl ow control (see specifi cations)

A. Timer improperly set A. Reset timer

A. Foreign material in control valve A. Remove piston assembly and inspect bore: remove foreign material

B. Internal control leak B. Replace seals and/or piston assembly

C. Control valve jammed in brine or backwash position C. Replace piston, seals and spacers

A. Salt setting too high A. Reset program cycle

B. Cyclone distributor tube too short B. Replace

A. Sodium residual resulting from water having very high

hardness or total dissolved solids (TDS)

A. Iron build-up in line to water conditioner A. Clean line to water conditioner

B. Iron build-up in water conditioner B. Clean control and add Iron-X Mineral Cleaner to resin bed: increase

C. Well pumping sand C. Install sand trap

D. Pump losing capacity D. Contact pump repair service

A. Hydrogen sulfi de (“sulfur”) in water supply A. Install Sul-X Sulfur Reduction System

B. Bacterial iron in water supply B. Install Chem-Free Iron Reduction System

C. Algae in water supply C. Pour approximately 1/2 cup laundry bleach into brine well just

A. Air in water system A. Assure that well system has proper air eliminator control: check for

or switch)

SET TIMER)

E. Clean out brine tank (see instructions)

and check control in various regeneration positions

A. Installation of additional water treatment equipment such as

reverse osmosis or demineralization

frequency of regeneration

before regeneration as frequently as necessary

dry well condition

5-5

Page 19

SECTION 6: SPECIFICATIONS AND OPERATING DATA

ITEM CFSM1254

Nominal Media Vol.

Ft3 High Capacity Cation Exchange Media 2.5

Salt Dosage, Lbs.

Factory Setting 24

Softening Capacity, Grains

At Factory Salt Setting 62,200

Flow Rates

Continuous (no duration limit) 9

Service Flow Rate 10

At 15 psi Pressure Loss 11.9

Pressure Loss, psi

At Continuous Flow 10

Service Flow Rate 12

Regeneration Flow Rates, gpm

Backwash 3.2

Brine Draw 0.56

Slow Rinse 3.2

Rapid Rinse 3.2

Brine Refi ll 0.5

Approximate Water Used (at Factory Setting) 140

Regeneration Cycle Duration (approximate minutes)

Backwash 8

Brine Draw / Slow Rinse 60

Rapid Rinse 10

Settling Rinse 8

Brine Refi ll (At Factory Setting) 10

Regeneration Duration Complete (approximate hours) 3

Inlet/Outlet size

Inches 1”

Mineral Tank Size

Tank Dia. x Ht., In. 12 x 54

Overall D & H w/ Valve, Inches

Width (Including Brine Tank) 58

Depth (Including Meter and Bypass) 17

Height (Including Valve) 62

Brine Tank Size

W x D x H, Inches 15 x 15 x 34

Brine Tank Capacity

With Salt Grid Leg Extensions (required on salt settings above 18#) 135

Miscellaneous

Approximate Shipping Weight (lbs) 188

Maximum Operating Temperature 100°F (38°C)

Minimum Operating Temperature 34°F (1°C)

Operating Pressure 20-100 psi (138-689 kPa)

Electrical Requirements 110/120v, 60 Hz

NOTES:

1) The CFSM1254E softener conforms to NSF/ANSI Standard

44 for specifi c performance claims as verifi ed and substantiated by test data. Actual capacity may vary substantially

depending on water analysis and operating conditions.

2) For satisfactory performance listed fl ow rate and duration

should not be exceeded. Flow rates listed are adequate for

normal applications.

3) The CFSM1254E softener is not intended to be used for

treating water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after

the system.

4) All types of water softener salt may be used (see Maintenance.)

6-1

Page 20

Section 7: PARTS

COMPONENT PARTS LIST

REF

DESCRIPTION CFSM1254

No.

1 Control Valve W12M320-5B3-0M

2 Adapter Assembly, Flange-Thread (Incl. Ref 3) FA45TX

3 O-Ring ORG-234

4 Clamp Assembly (Incl. Ref 3) FC45XX

5 Media Tank (Incl. Ref 9) MTP1254FB

6 Media H-10P(x2) & H-050

7 CYCLONE Assembly C04N-54

8 Tank Base T06A-12P

9 Brine Line Tubing 13000X

10 Brine Tank, Complete, Black BT1534X-EXT-DLS

11 Overfl ow Fitting BT16

12 Brine Tank Shell, Black BT1534

13 Brine Well w/ Cap BT15BW

14 Grid Plate w/Extension Kit BT15GP-EXT

15 Safety Brine Valve, Complete BT15SBVA

16 Safety Brine Valve 60014

17 Float Assembly 60068X

18 Air Check Assembly 60002

19 Salt Monitor TPCB-TB30D

20 Brine Tank Lid BT15L

NOTE: When ordering replacement or repair components always specify by the unit or model number to ensure correct parts delivered.

Description of Item Part Number

Wrench V3193-01

Universal Elbow V3191-01

Retaining Clip H4615

1

OFF

OFF

OFF

3

6

7

OFF

5

8

9

2

10

13

12

14

11

15

16

17

Drain Line Insert PKP10TS8-BULK

Drain Line Elbow Nut V3192

Drain Line Elbow 3158-01

Plumbing Adapter Kits

1” Brass Sweat V3007-02

1” Plastic Male NPT V3007-04

1.25” Plastic Male NPT V3007-05

1” Plastic Male BSP V3007-06

18

19

Items Not Shown

7-1

Page 21

Section 7: PARTS

COMPONENT PARTS LIST

Front Cover and Drive Assembly

Drawing No. Order No. Description Quantity

1 V1375-01 WS1 Front Cover 1

2 V3107-01 WS1 Motor 1

3 V3106-01 WS-1 Drive Bracket & Spring Clip 1

4 V3108 WS1 PC Board 1

V3002 WS1 Drive Assy* 1

Not Shown V3168 WS1 AS Adapter 110V-12 V 1

Not Shown V3168-01 WS1 AC Adapter Cord Only 1

* Drawing number parts 2 through 6 may be purchased as a complete assembly, part V3002.

7-2

Page 22

Section 7: PARTS

4

COMPONENT PARTS LIST

Drive Cap Assembly, Downfl ow Piston, Regenerant Piston and Spacer Stack Assembly

Drawing No. Order No. Description Quantity

1 V3005 Spacer Stack Assembly 1

2 V3004 Drive Cap Assembly 1

3 V3178 Drive Back Plate 1

4 V3011 Piston Down Flow Assembly 1

5 V3174 Regenerant Piston 1

6 V3135 O-ring 228 1

7 V3180 O-ring 337 1

8 V3105 O-ring 215 (Distributor Tube) 1

Not Shown V3001 Body Assembly 1

3

1

2

5

4b

6

7

8

7-3

Page 23

Section 7: PARTS

COMPONENT PARTS LIST

Injector Cap, Injector Screen, Injector, Plug and O-Ring

Drawing No. Order No. Description Quantity

1 V3176 Injector Cap 1

2 V3152 O-ring 135 1

3 V3177 Injector Screen 1

4 V3010-1Z Injector Assy. Z Plug 1

5

Not Shown V3170 O-ring 011 *

Not Shown V3171 O-ring 013 *

V3010-1F INJECTOR ASSY H BLUE

* The injector plug and the injector each contain one 011 (lower and 013 (upper) o-ring

7-4

Page 24

Section 7: PARTS

COMPONENT PARTS LIST

Refi ll Flow Control Assembly

Drawing No. Order No. Description Quantity

1 H4615 Elbow Locking clip 1

2 JCP-P-6 Polytube insert 3/8” 1

3 JCPG-6PBLK Nut 3/8” 1

4 H4613 Elbow Cap 3/8” 1

5 V3163 O-ring 019 1

6 V3165-01* BLFC Retainer Assembly** 1

7 V3182 BLFC 1

Not Shown H4650 Elbow 1/2” with nut and insert Option

* Assembly includes V3182 BLFC.

** Includes drawing #7.

2

7

Water

Flow

Proper BLFC orientation

directs refill water flow

towards the washer face

with rounded edge and

text.

3

6

1

4

5

7-5

Page 25

Section 7: PARTS

COMPONENT PARTS LIST

Drain Line - 3/4”

Drawing No. Order No. Description Quantity

1 H4615 Elbow Locking Clip 1

2 PKP10TS8-BULK Polytube insert 5/8 1

3 V3192 Nut 3/4 Drain Elbow 1

4 V3158-01 Drain Elbow 3/4 Male 1

5 V3163 O-ring 019 1

6 V3159-01 DLFC Retainer Assembly 1

7 V3162-032 DLFC 3.2 gpm for 3/4”

One DLFC must be used if 3/4

fi tting is used

Water

Flow

Proper DLFC orientation

directs water flow towards

the washer face with

rounded edge.

7-6

Page 26

Section 7: PARTS

COMPONENT PARTS LIST

Water Meter and Meter Plug

Drawing No. Order No. Description Quantity

1 V3151 Nut 1” QC 1

2 V3003 Meter Assembly (includes drawing #3 & #4) 1

3 V3118-01 Turbine 1

4 V3105 O-ring 215 1

5 V3003-01 Meter Plug Assembly 1

4

5

3

2

1

7-7

Page 27

Section 7: PARTS

COMPONENT PARTS LIST

Description: Fitting 1” Brass Sweat Assembly

Order No: V3007-02

Drawing No. Order No. Description Quantity

1 V3151 Nut 1” Quick Connect 1

2 V3150 Split Ring 1

3 V3105 O-ring 215 1

4 V3188 Fitting 1” Brass Sweat

Assembly

1

4

3

1

2

Description: Fitting 3/4” Brass Sweat Assembly

Order No: V3007-03

Drawing No. Order No. Description Quantity

1 V3151 Nut 1” Quick Connect 1

2 V3150 Split Ring 1

3 V3105 O-ring 215 1

4 V3 Fitting 3/4” Brass Sweat

Assembly

1

4

3

1

2

Description: Fitting 1” Plastic Male NPT Assembly

Order No: V3007-04

Drawing No. Order No. Description Quantity

1 V3151 Nut 1” Quick Connect 1

2 V3150 Split Ring 1

3 V3105 O-ring 215 1

4 V3164 Fitting 1” Plastic Male

NPT

4

1

2

3

1

Description: Fitting 1-1/4” Plastic Male NPT Assembly

Order No: V3007-05

Drawing No. Order No. Description Quantity

1 V3151 Nut 1” Quick Connect 1

2 V3150 Split Ring 1

3 V3105 O-ring 215 1

4 V3317 Fitting 1-1/4” Plastic

Male NPT

4

1

2

3

1

7-8

Page 28

Section 7: PARTS

COMPONENT PARTS LIST

Bypass Valve

Drawing No. Order No. Description Quantity

1 V3151 Nut 1” Quick Connect 2

2 V3150 Split Ring 2

3 V3105 O-ring 215 2

4 V3145 Bypass 1” Rotor 2

5 V3146 Bypass Cap 2

6 V3147 Bypass Handle 2

7 V3148 Bypass Rotor Seal Retainer 2

8 V3152 O-ring 135 2

9 V3155 O-ring 112 2

10 V3156 O-ring 214 2

V3191-01 Vertical Adapter Assembly

Order No. Description Quantity

V3151 Nut 1” Quick Connect 2

V3150 Split Ring 2

V3105 O-ring 215 2

V3191 Vertical Adapter 2

6

5

6

5

4

1

1

2

4

1

3

1

2

3

7-9

Page 29

Section 7: PARTS

COMPONENT PARTS LIST

Wrench

(Order No. V3193-01)

Although no tools are necessary to assembly or disassemble the valve, the wrench (shown in various positions on the valve)

may be purchased to aid in assembly or disassembly.

7-10

Page 30

LIMITED WARRANTY

For any warranty questions, please refer to the enclosed warranty card or call 1-800-222-7880 or mail your request to:

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450

© 2009 3M Company. All rights reserved.

3M is a trademark of 3M Company.

INSTR4330 0709

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450, USA

Toll Free: 1.888.218.CUNO

Worldwide: 203.237.5541

Fax: 203.238.8701

www.cunofoodservice.com

Loading...

Loading...