Page 1

Betapure™

CMP Series

CMP Filter Cartridges

Superior Reduction Of Large Particle

Counts For Improved Yields

Betapure™ CMP filter cartridges are high capacity depth filters optimized for oxide and metal

slurries used in chemical mechanical planarization (CMP) applications. Betapure CMP filters are

composed of all-polypropylene components and features a multi-zone "graded-porosity" design

for the optimum level of particle classification. This novel construction provides enhanced flow

characteristics, including low pressure drop, to minimize shearing of the slurry while providing

superior service life.

The objective of a slurry lter is for the majority of particles to pass through it unchanged,

while only removing the undesired or “oversized” particles. The oversized particle population

is commonly referred to as large particle counts (LPC) and they typically form over time when

the suspended particles in the slurry settle forming aggregates, agglomerates, and gels. Large

particles can also be the result of ad verse shipping conditions, shearing, slurry drying, and

interaction with other distribution loop components such as ttings, tanks, piping, valves, and

pumps. These large particles can scratch metal and inter-level dielectrics potentially causing

wafer defects. The Betapure CMP lter reduces large particle counts that can potentially

reduce yields while maintaining the polishing characteristics of the slurry.

Applications

Semiconductor Oxide/Low-k Dielectrics, Shallow Trench

Features & Benefits

Graded Porosity Design

Superior removal of hard and soft gel contaminants, for reduced defectivity

and improved yields

High contaminant holding capacity reduces downtime and increases overall

equipment effectiveness

The filters are "matched" to the slurry providing the optimum level of

performance needed to dramatically reduce defect causing particles

Provides a low pressure drop reducing the potential for fluid shear of the slurry

100% Polypropylene

Low cartridge extractables, free of adhesives, binders, and surfactants

Excellent chemical compatibility with low and high pH slurries

Quality Manufacturing

ISO certified quality management system

Non-contact welding reduces a potential source for contamination

Manufactured and double-bagged in a clean environment to provide superior downstream cleanliness out of the package

Built to Exacting Specifications

Provides a consistent quality of slurry enabling repeatability of the planarization process

Data Storage Magnetic Heads, Nickel and Glass

Data Transmission Optical Fiber

Compound Semiconductor Light Emitting Diodes (LED)

Isolation (STI), Inter-level Dielectric (ILD),

Polysilicon, Tungsten, and Copper

Substrates

1

Page 2

Particle Size Distribution

The filtration of CMP slurries is a unique and challenging process as compared to the filtration of high purity chemicals used in electronics

manufacturing. High purity chemical filtration is typically performed using 0.2 micron or tighter membrane filters that have a sharp particle

removal cut-off at the rated pore size. The majority of CMP slurries contain a de sired mean particle size that ranges from 0.03 - 0.2 microns.

Consequently, the filter that was specifically designed for particle clarification of high purity chemicals would strip out the de sired particles and

adversely affect the polishing characteristics of the CMP slurry. Over sized particles in the slurry typically greater than 0.5 micron are undesired

and represent the “tail” (Figure 1) of the particle size distribution (PSD). Betapure™ CMP filters remove the PSD tail while allowing the majority

of desired or “target” size particles to pass through it unchanged

.

Particle Removal Efficiency is the Best Measure of Filter Performance

Figure 1 com pares the PSD of colloidal-silica slurry and a lab oratory test dust which is typically used by filter suppliers to establish depth filter

ratings. The data shows that test dust has a broader PSD above 0.5 micron proving that it is not a true representation of the types of particles in

CMP slurry. A wide variation in performance also exists from one filter supplier to the next because there is no industry accepted standard for

rating retention of depth filters. Furthermore, Absolute and Nominal filter ratings are both used to specify particle removal efficiency which

only serves to confuse the situation while not providing the application specific information needed. In Figure 2, particle removal efficiency is

compared for the same grade of CMP filters from 3M Purification. The filters were challenged using both a lab oratory test dust and colloidal

silica slurry. There is a significant difference in particle removal efficiency, which is a direct result of the contaminant PSD distribution. The

broad PSD of the test dust yields significantly higher particle removal efficiency than achieved when tested with slurry. Therefore, test dust is not

representative of slurry and ratings based on test dust will likely be over stated and meaningless for CMP slurry applications. In Figure 3, particle

removal efficiency is compared for equivalent rated CMP filters from 3M Purification Inc., Competitor P, and Competitor M in colloidal silica

slurry. The data clearly shows that equivalent rated filters from different manufacturers does not deliver equivalent performance and reinforces

the fact that the “rating” generated in a lab using test dust is not meaningful in predicting actual performance. Based on this information particle

removal efficiency generated in slurry is the best measure of filter performance. Other important factors in selecting the appropriate slurry filter

include particle classification, pressure drop, and filter lifetime..

Number of Particles per ml

Figure 1. - Particle Size Distribution > 0.5 micron - Colloidal Silica Slurry & ISO Test Dust

200000

Colloidal Silica Slurry

150000

100000

ISO Test Dust

50000

0

0.5 1 2 105

Particle Diameter (microns)

2

Page 3

Betapure™ CMP Series

CMP Filter Cartridges

Particle Removal Efficiency

Colloidal Silica vs. ISO Test Dust

Betapure CMP560 - Colloidal Silica

Betapure CMP560 - ISO Test Dust

100

80

60

40

20

0

Particle Removal Efficiency (%)

Figure 2. - Particle Removal Efficiency Figure 3. - Comparative Particle Removal Efficiency in Colloidal Silica

Particle Size > 0.54 micron

Superior Particle Retention through

Graded Porosity Design

Betapure™ CMP filter media was specifically engineered to provide a low

porosity, downstream section with a sharp retention cut-off that closely aligns

to the size distribution of undesired particles to be removed. This sharp removal

cut-off will not alter per cent solids (Figure 4) or re move de sired or “target” size

particles thus preserving the polishing characteristics of the slurry. In contrast,

competitive point-of-use filters (Figure 4) that have a broad removal range can in

fact retain particles smaller than the PSD. Re moving these “target” size particles

can alter the per cent solids of the slurry which in turn reduces filter lifetime

because more particles are being re moved than required in the application.

The multiple higher porosity layers on the upstream section (Figure 5) provide

effective pre-filtration of over sized particles resulting in higher contaminant

removal capacity and increased filter life-time. This novel graded porosity

(Figure 5) design also provides a tortuous downstream path and low pressure

drop which is ideal for gel capture and reduced shear effect on the slurry.

Particle Removal Efficiency

for Equivalent Rated Filter Cartridges

Betapure CMP

Competitor P

Competitor M

100

80

60

40

20

0

Particle Removal Efficiency (%)

> 0.54 micron > 1.01 micron

Percent Solids - Colloidal Silica

Influent

Effluent

0.5

0.4

0.3

0.2

0.1

Percent Solids (%)

0

Competitor P Betapure CMP

Figure 4. - Percent Solids Comparison

TM

Superior Particle Retention through

Graded Porosity Design

Large particles, greater than 0.5 micron, can scratch metal and interlevel dielectrics

potentially causing wafer defects. Variations in particle size distribution and

particle counts in the slurry can affect re peat ability of the planarization process.

In both cases, major reductions in large particle counts can be associated to proper

filtration, resulting in reduced defectivity (Figure 6) and an increase to yields. Proper

filtration also provides a consistent quality of slurry which enables repeatability

of the planarization process. The ideal slurry filter will have a retention curve that

closely aligns to the PSD of “undesired” particles to be removed. By matching that

characteristic, Betapure CMP filters are able to maintain the polishing characteristics

of the slurry, maximize contaminant holding capacity, and increase filter lifetime.

3

Flow Direction

Inner

Outer

Medium

Figure 5. - Graded Porosity Design

Medium

Page 4

Cartridge Removal Efficiencies

Depending on the location in the slurry distribution system a filter with a sharp particle removal cut-off and a filter with a broad particle removal

cut-off will be needed to re duce defectivity and increase yields. For example, in single pass applications at point-of-use the filter should have

a sharp cut-off which is slightly larger than the de sired PSD. Figure 7 shows that Betapure™ CMP510, CMP520, CMP530, and CMP540

contain that sharp cut-off making it ideal for particle classification at point-of-use. However, in the distribution loop, the filter should have a

broad removal range that closely aligns to the un de sired PSD tail to be removed like that exhibited by Betapure CMP550, CMP560, CMP570,

CMP580 and CMP590. Betapure CMP filters for distribution loop applications contain a higher porosity media as compared to Betapure CMP

filters at point-of-use. The higher porosity media increases flow while reducing pressure drop and f luid shear on the slurry. Increasing flow

while maintaining particle removal efficiency results in particle specifications being achieved in less time. Figure 8, shows the particle removal

efficiency of an Betapure CMP560 filter in re-circulation mode over specific time intervals.

“Matching” the slurry to the proper Betapure CMP filter provides the peak level of performance needed to dramatically reduce defect causing

large particle counts. The porosity of the media layers can also be customized to meet the specific requirements of CMP slurry manufacturers.

Figure 6. - Benefits of Proper Filtration -

Horizon Capture of Copper Wafer Surface

Figure 7. - Betapure™ CMP Particle Removal Efficiency

100

90

No Filtration - High Level of Defectivity

80

70

60

50

40

30

Particle Removal Efficiency (%)

20

10

0

0

0.4

0.2

Particle Size (microns)

0.6

0.8

1.0

CMP 510

CMP 520

CMP 530

CMP 540

CMP 550

CMP 560

CMP 570

CMP 580

CMP 590

1.2

1.4

With Filtration - Relatively Defect Free

4

Page 5

200000

Betapure™ CMP Series

CMP Filter Cartridges

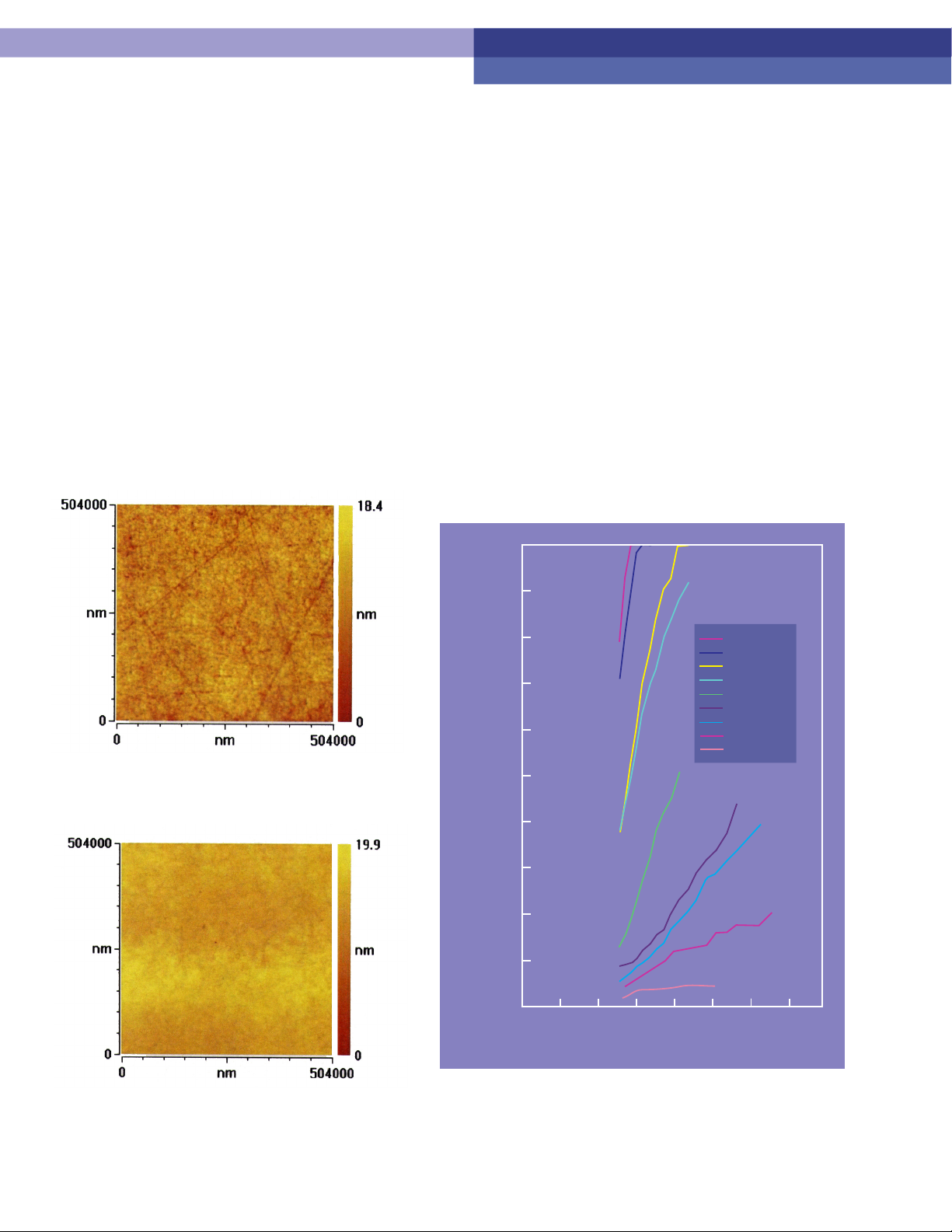

Figure 8. - Particle Removal Efficiency Over Time

Inlet

150000

10 minute Outlet

60 minute Outlet

100000

120 minute Outlet

180 minute Outlet

50000

Number of Particles per ml

0

0.5

1

2

Particle Diameter (microns)

Betapure™ CMP Cartridge Construction

Betapure™ CMP filter cartridges are constructed using all polypropylene components (see Table 1). Cartridges are manufactured using the most

advanced non-contact thermoplastic welding techniques - no adhesives, binders, or surfactants are used in the process - and are double-bagged in a

clean environment to ensure superior cleanliness out of the package. The Betapure CMP filter manufacturing site operates within an ISO certified

quality management system.

Table 1. - Product Specifications

Materials of Construction

Media

Media Support Layer

Core and End Caps

“O” Rings/Gaskets

Dimensions

Length

Outside Diameter

Operating Conditions

Maximum Forward Differential Pressure

Maximum Operating Temperature

Polypropylene

Polypropylene

Polypropylene

See ordering guide

See "Cartridge Configurations"

2.6” (6.6 cm)

60 psid @ 86°F (4.1 bar @30°C)

30 psid @ 140°F (2.0 bar @ 60°C)

140°F (60°C)

Betapure™ CMP Cartridge Flow Rates

Figure 9 depicts typical 10" cartridge f low rates for 1 cp fluids at 20°C.

Figure 9. - 10" Cartridge Flow Rate vs.

Pressure Drop for 1cp Fluids @ 20°C

10

CMP510

9

8

7

6

5

4

Pressure Drop (psid)

3

2

1

0

0

0

2

1

CMP520

3

10

CMP530

5

4

Flow Rate (GPM)

20 30

Flow Rate (LPM)

CMP540

CMP550

CMP560

CMP570

CMP590

6

7

CMP580

9

8

0.6

0.5

0.4

0.3

Pressure Drop (bar)

0.2

0.1

0

10

5

Page 6

SASS

3M Purification Electronics performs in-house and on-site filtration studies worldwide through its

Scientific Applications Support Services (SASS) group using the most advanced particle counting

technologies (PSS-780A) to optimize the CMP process at the customer facility. In addition, 3M

Purification Electronics works closely with the slurry manufacturers to characterize and customize

filtration solutions that meet current and future requirements.

Slurry Type Post Blending (1) Distribution Loop (2) POU Dispense (3)

Fumed Silica Oxide*

Colloidal Silica Oxide

Silica Based Metal

Non - Silica Based Metal < 2% Solids

Non - Silica Based Metal > 2% Solids

* Shear sensitive

Concentrated

Slurry

Slurry Blending

Mixing Station

Betapure™ CMP Filter Recommendation Guide

Filtration Location (see Figure 10)

CMP560

CMP560

CMP560

CMP540 or CMP550

CMP560

CMP560, CMP570, or CMP580

CMP550, CMP560, or CMP570

CMP560 or CMP570

CMP540 or CMP550

CMP560 or CMP570

Figure 10. - CMP Filtration Locations

CMP

Tool

3

Day Tank

1

2

Distribution

Filter

CMP

Tool

3

Particle Sizing Instrumentation

CMP540, CMP550, or CMP560

CMP520, CMP530, or CMP540

CMP520, CMP530, or CMP540

CMP510 or CMP520

CMP530 or CMP540

CMP

Tool

3

3

CMP

Tool

Betapure™ CMP Filter to Pore Size Cross-Reference

Betapure™ CMP Filter Grade Typical Pore Size (Micron)

510

520

530

540

550

560

570

580

590

0.3

0.5

0.8

1

3

5

10

25

50

6

Page 7

Betapure™ CMP Series

CMP Filter Cartridges

Betapure™ CMP Filter Cartridge Ordering Guide

Cartridge

CMP

Filter Grade

510

520

530

540

550

560

570

580

590

Media

1 - Polypropylene

* F only; ** Replaces Mykrolis Code 0, 10" length only (see U Style below).

Betapure™ CMP Cartridge Configurations

C Style

2 5/8”

(6.6 cm)

C Style

Inches Centimeters

A

12.81 High

B

A

22.52 High

32.43 High

B

12.0

21.8

31.7

C

32.5

57. 2

82.3

Length (Inches)

4 - 4"*

10 - 10"

20 - 20"

30 - 30"

09 - 9

19 - 19

29 - 29

D

30.5

55.4

80.5

End Modification

C - 222 O-ring & Spear

F - 222 O-ring & Flat Cap

U - 222 O-ring & Flat Cap**

N Style

A

Gasket/O-ring Material

C - EPR

G - Polyethylene N - Double Open End

N Style

Inches Centimeters

A

9.81 High

19.62 High

29.43 High

B

24.9

49.8

74.7

1 3/4”

(4.4 cm)

F Style

2 5/8”

(6.6 cm)

F Style

U Style

2 5/8”

(6.6 cm)

Inches Centimeters

A

1/2 High

B

A

1 High

2 High

3 High

1 3/4”

(4.4 cm)

5.2

11.0

20.7

30.6

B

4.4

10.2

20.0

29.8

C

13. 2

27. 9

52.6

7 7. 7

D

11.2

25.9

50.8

75.7

10.4”

(26.4 cm)

9.6”

(24.4 cm)

1 3/4”

(4.4 cm)

7

Page 8

Important Notice

The information described in this literature is accurate to the best of our knowledge. A variety of factors, however, can affect the performance of the Product(s) in a particular

application, some of which are uniquely within your knowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE

SAME WILL MAKE THEIR OWN DETERMINATION AS TO ITS SUITABILITY FOR THEIR USE. IN NO EVENT WILL 3M PURIFICATION INC. BE RESPONSIBLE FOR DAMAGES

OF ANY NATURE WHATSOEVER RESULTING FROM THE USE OF OR RELIANCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if this product is fit for a particular purpose and suitable in your specific application.

3M PURIFICATION INC. MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OF ANY OTHER NATURE HEREUNDER WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH

INFORMATION REFERS.

Limitation of Liability

3M Purification Inc. will not be liable for any loss or damage arising from the use of the Product(s), whether direct, indirect, special, incidental, or consequential, regardless of

the legal theory asserted, including warranty, contract, negligence or strict liability. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation may not apply to you.

Your Local Distributor:

3M Purifi cation Inc.

400 Research Parkway

Meriden, CT 06450

U.S.A.

Phone (800) 243-6894

(2 03) 237- 5541

Fax (203) 630-4530

www.3Mpurifi cation.com

Betapure is a trademark of 3M Company used under license.

All other trademarks are the property of their respective owners.

Please recycle. Printed in U.S.A.

3M is a trademark of 3M Company.

© 3M 2011. All rights reserved.

70-0201-8697-2 REV 1011b

Loading...

Loading...