Page 1

Kill germs including

SARS-CoV-2

3M™ Chemical Management Solutions

Keep your facility clean. And open.

Our world has changed — cleaning and disinfecting have never been more

important. Make sure your chemical management solutions are up to the task.

1 3M Chemical Management Solutions

Page 2

Take the guesswork out of

System

Consequences of inaccuracy.

mixing chemicals.

Accuracy is more important than ever. Over-diluted chemicals

can result in decreased ecacy, and with today’s cleaning

challenges you need to know your surfaces are clean. With the

added complication of eliminating viruses from surfaces —

including SARS-CoV-2 — you can’t aord to guess.

3M™ Chemical Management Solutions control the ow of water

by adjusting to changing water pressures, providing an accurate

ready-to-use (RTU) solution.

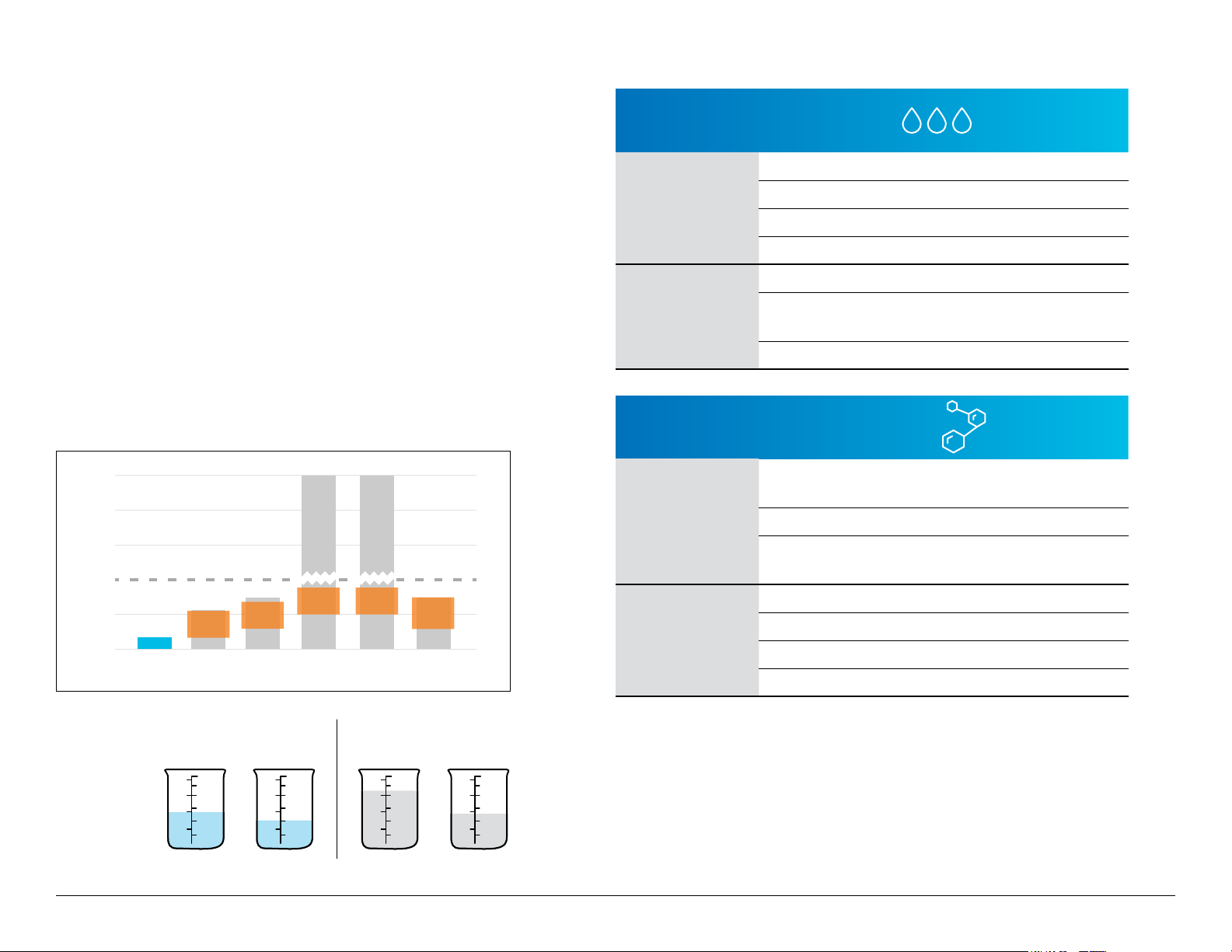

3M outperforms the competition.

When six leading competitive dispensers were tested over a dynamic

water pressure range of 20–120 psi, 3M had the lowest dilution error.

100

80

60

40

20

Average % Dilution Error

0

™

3M

Control

22%

Flow

Comp A Comp B Comp C Comp D Comp E

29%

326% 127%

35% 113%

30%

Over-Dilution (too much water)

Decreasedecacyofover-dilutedchemicals

Ineective

disinfectant

PotentialHAIandoutbreakrisk

Higherpotentialforincreasedinfection/absenteerates

Non-compliancewithEPAlabel

Re-cleaningofsurfaces

Ineective

cleaning

Increasedlabortocounterperformanceissues

ofincorrectlymixedconcentrates,overallcosts

ability

Tamperingandsafetyrisks

Under-Dilution (toomuchchemical)

Over-budgeting/increasedcostduetoinconsistent

Increased

exposure

and costs

Excess

residue

chemicaldispensing

Potentialforharmfulexposureandworkersafetyhazards

Surfacedegradationcausedbyoverlyacidicorbasic

chemicalmixes,increasingreplacementcosts

Higherfrequencyofstickyoors/surfaces

Re-cleaningofsurfaces

Additionallabor/eort,increasinglaborandproductcosts

Tamperingandsafetyrisks

73% less

variation

in volume

dispensed

57% less

variation

in dilution

accuracy

3M™ Flow Control System Competitor

80 psi 80 psi30 psi 30 psi

22qt.

20L

15L

10L

5L

20qt.

16qt.

12qt.

8qt.

4qt.

20L

15L

10L

5L

2 3M Chemical Management Solutions

22qt.

20qt.

16qt.

12qt.

8qt.

4qt.

20L

15L

10L

5L

22qt.

20qt.

16qt.

12qt.

8qt.

4qt.

20L

15L

10L

5L

22qt.

20qt.

16qt.

12qt.

8qt.

4qt.

Page 3

Fighting a new foe:

SARS-CoV-2.

You and your sta have an even harder

job to do with the arrival of SARS-CoV-2,

the virus that causes COVID-19. The right

disinfectant matched with best practices

can help you keep your facility safe

without signicant impact on your

process, productivity or cost.

Follow these best practices for proper

disinfection:

• Ensure accurate dilution. Accuracy is

more important now than ever. Choose

a chemical management solution that’s

proven to maximize accuracy.

• Keep high-touch surfaces clean.

Frequent disinfection of high-touch

areas can help stop the spread of germs.

• Adhere to dwell times. Without proper

dwell times, you may leave germs

on surfaces. Minimize the impact on

productivity by choosing a disinfectant

with a short dwell time, like 3M™ Quat

Disinfectant Cleaner Concentrate #5

or 3M™ Disinfectant Cleaner RCT

Concentrate #40, that kills SARS-CoV-2

on hard, nonporous surfaces in just three

minutes.

1

3 3M Chemical Management Solutions

Page 4

Accuracy and

sustainability

go hand in hand.

You don’t need to sacrice your sustainability

goals for eective cleaning and disinfection.

The correct combination of chemical

concentrate and water prevents excess

depletion of valuable disinfectants to eliminate

product waste and reduce water usage.

Improved dilution accuracy reduces

waste and minimizes chemical use.

As many as seven 3M™ Cleaning

Concentrates are Green Seal™ Certied,

and all are concentrated to maximize

value and cut packaging waste.

4 3M Chemical Management Solutions

Many 3M Cleaning Concentrates are

packaged in bottles made with 25%

post-consumer recycled content.

Using 3M™ Chemical Management

Solutions can help contribute to

LEED certication.

Page 5

The right solution for your cleaning challenges.

3M™ Flow Control Wall Mount System.

Minimize worker interaction with chemicals and ensure you

have the right concentration to kill germs, including SARSCoV-2, on surfaces. With its unique ow control technology,

the 3M Flow Control Wall Mount System delivers accurate

cleaning solutions directly into your containers.

Whether you’re cleaning a hospital, classroom, oce

building or retail space, you know you’re getting the right

amount of chemicals to do the job.

• At least 55% more accurate dilution

2

• 17–49% more compact3 while holding

up to four half-gallon bottles

• Simple dispensing dial improves safety and productivity

• Three-point locking system limits chemical exposure and

helps prevent theft

• Compatible with 25 dierent 3M™ Cleaning Concentrates

• 3M Flow Control concentrate bottles are made with 25%

post-consumer recycled content and are BPA-free

• Compact size measurements: 12.25" w x 22.5" h x 6.3" d

The 3M™ Flow Control Portable

3M™ Flow Control Systems

Dispensing Reduction

Estimated pounds/year

reduced into drain

Quats

Detergents

Total estimated reduction

of disinfectant/detergent

substances

For context, the American Hospital directory lists 4,000 hospitals in the

U.S., with a total of 810,000 beds. An average healthcare facility in highly

populated states with a large number of hospitals (e.g., New York and

Massachusetts) has 250–350 beds; the largest hospitals in these state

have 1,000–2,500 beds. These estimates are based on sales data for

three cleaning solution products at three hospital facilities, averaged to

represent a 500-bed facility. ahd.com/state_statistics.html

3M™ Cleaning and Disinfecting

Solutions are a component of the

3M™ Clean & Protect Certied

Badge Program, which helps you

demonstrate your commitment to a

clean and safe environment to your

employees and guests. Contact a

3M representative for information

on how to participate.

Low End High End

55% 96%

263 460

197 345

461 806

5 3M Chemical Management Solutions

Dispensing System.

Reusable, portable dispensers are designed for

durability, comfort and the same accuracy as

the wall dispenser.

• Improved exibility, convenience and sta productivity

• Designed for half-gallon bottles of 3M Cleaning Concentrates

• Foaming adapter sold separately

Page 6

A simple twist mixes any

chemical you need.

3M™ Twist ’n Fill™ Chemical

Management System.

Using a single dispenser makes diluting

solutions easier and safer. The 3M™ Twist

’n Fill™ System accurately dilutes and

dispenses virtually any cleaning solution.

Just pick a 3M™ Twist ’n Fill™ System

chemical concentrate, insert your bottle, and

twist and ll. Simple. Ecient. Accurate.

• Fits almost any cleaning closet

• One dispenser mixes over 30 chemicals

• Change out chemicals in seconds

• Air gap prevents backow

With two ow rates,

3M™ Twist ’n Fill™ Chemical

Management System can easily

dilute solutions for mop bucket

and spray bottles.

Get your customized

3M™ Twist ’n Fill™ Chemical

Management System Reduction

Estimated pounds/year

reduced into drain

Quats

Detergents

Total estimated reduction

of disinfectant/detergent

substances

For context, the American Hospital directory lists 4,000 hospitals in the U.S.,

with a total of 810,000 beds. An average healthcare facility in highly populated

states with a large number of hospitals (e.g., New York and Massachusetts) has

250–350 beds; the largest hospitals in these state have 1,000–2,500 beds.

These estimates are based on sales data for three cleaning solution products

at three hospital facilities, averaged to represent a 500-bed facility. ahd.com/

state_statistics.html

Low End High End

36% 96%

172 460

130 345

302 806

Download the

3M™ COSMO App.

The 3M COmmercial Solutions

MObile (COSMO) app gives you

instant access to 3M Commercial Solutions product

information.

wall chart.

Help your sta determine what chemicals

to use. Choose from set templates and

customize the information for your specic

facility, or we can also help you create a

completely custom wall chart for your team.

For details, visit 3M.com/facility.

6 3M Chemical Management Solutions

Quickly access and view 3M products

and how-to videos.

Download and save content to your device in

custom folders so you can view it later without

internet access.

Easily share multiple pieces of literature and/or

videos to multiple email addresses at one time.

Page 7

General Areas Restroom Areas

Most washable surfaces, including windows, glass, mirrors, carpets, oors and walls. Bathroom mirrors, tile, bowls, urinals and xtures.

1 5 12

2 8

14

13 17

20 24 26

23 25 34 41

40 42

1 5

4

13

12 14

19 23 34

15

17

25 40 42 51

20

41 5244

3M™ Cleaning Concentrates: A concentrated solution for almost any cleaning challenge, including SARS-CoV-2.

3M™ Glass Cleaner Concentrate

1

Non-streaking. For windows, glass and other

mirrored surfaces. RTU color: Light blue/purple.

TNF 30; FCS 35 gallons.

3M™ Heavy Duty Multi-Surface

2

Mark Remover Concentrate

Removes most spots, stains and grease from washable

surfaces. RTU color: Light purple. TNF 7; FCS 7.25 gallons.

3M™ Neutral Cleaner Concentrate

3

No-rinse, low-foaming formula. Use with mop

or automatic scrubber. Fresh scent. RTU color:

Light green/yellow. TNF 207; FCS 172 gallons.

3M™ Bathroom Disinfectant Cleaner Concentrate

4

EPA-registered disinfectant cleaner removes soap scum

and scale from bathroom surfaces. RTU color: Light forest

green. TNF 27; FCS 26 gallons.

3M™ Quat Disinfectant Cleaner Concentrate

5

EPA-registered, for use in hospitals. Kills SARS-CoV-2,

HIV-1, MRSA, VRE, herpes simplex I and II, and other

pathogens. Rinse-free, pleasant fragrance. RTU color:

Light green. TNF 127; FCS 107 gallons.

3M™ Food Service Degreaser Concentrate

7

Removes food and oily soils from hard

surfaces such as walls, oors, tables and vinyl.

RTU color: Light yellow. TNF 123; FCS 149 gallons.

3M™ General Purpose Cleaner Concentrate

8

All-purpose, everyday cleaner. Use on

oors, walls and other nonporous surfaces.

RTU color: Light pink. TNF 35; FCS 35 gallons.

Scotchgard™ Bonnet Cleaner Concentrate

11

For lightly soiled carpets. Helps maintain properties of carpets

treated with Scotchgard™ Protector. Neutral pH is safe for

cleaning nylon stain-resistant carpets. RTU color: Clear. TNF 26 gallons.

3M™ Deodorizer — Country Day

12

Scent Concentrate

Long-lasting deodorizer leaves a light, oral scent.

RTU color: Pink. TNF 36 gallons.

3M™ Deodorizer — Fresh Scent Concentrate

13

Long-lasting deodorizer leaves a fresh, clean scent.

RTU color: Blue. TNF 30; FCS 30 gallons.

3M™ Non-Acid Disinfectant Bathroom

15

Cleaner Concentrate

Daily use. EPA-registered for bowls, urinals and other hard

surfaces. RTU color: Clear to light green. TNF 61; FCS 61 gallons.

3M™ Sanitizer Concentrate

16

EPA-registered sanitizer for walls, oors and other hard,

nonporous surfaces. Safe for sanitizing food contact

surfaces. RTU color: Clear. TNF 135; FCS 75 gallons.

3M™ Glass Cleaner and Protector

17

Scotchgard™ Technology helps reduce fogging

on windows and mirrors after repeated use.

RTU color: Blue. TNF 42; FCS 40 gallons.

3M™ Non-Acid Bathroom Cleaner Concentrate

19

Daily use. For bowls, urinals and other hard surfaces, and

soap scum. RTU color: Light green. TNF 26 gallons.

3M™ Heavy Duty Glass Cleaner Concentrate

20

Non-streaking. For windows, glass and mirrors, and other

mirrored surfaces. RTU color: Light blue/purple.

TNF 12 gallons.

3M™ Speed Stripper Concentrate

6

Five-minute stripper. Removes sealers and oor nish

buildup and nishes hardened by frequent burnishing.

No unpleasant odor. RTU color: Light blue. TNF 8.2; FCS 10 gallons.

7 3M Chemical Management Solutions

3M™ Deodorizer — Mountain Spice Concentrate

14

Long-lasting deodorizer leaves a fragrant, spiced scent.

RTU color: Yellow-green. TNF 36 gallons.

3M™ Floor Stripper LO Concentrate

22

Low-odor, low-foaming, ve-minute stripper for sealers,

oor-nish buildup and nishes hardened by frequent

burnishing. RTU color: Light green. TNF 11; FCS 11 gallons.

Page 8

Carpet Areas Hard Floor Maintenance Food Service Area

Prespray and extraction cleaning for

colorfast and nylon stain-resistant carpets.

40

2

5

23

24

25

26

28

11

34

27

3M™ Neutral Quat Disinfectant Cleaner Concentrate

For use in hospitals. EPA-registered disinfectant cleaner kills

HBV, HIV-1, MRSA, VRE, herpes simplex I and II, and other

pathogens. Rinse-free, low-foaming, neutral pH formula.

RTU color: Light green. TNF 120; FCS 100 gallons.

3M™ 3-in-1 Floor Cleaner Concentrate

Low-foaming. For use in automatic scrubbers. For

scrubbing before recoating, cleaning before

burnishing and daily cleaning. RTU color: Blue.

TNF 137;

FCS 132 gallons.

3M™ HB Quat Disinfectant Cleaner Concentrate

Rinse-free, EPA-registered disinfectant for cleaning

noncritical items. For use in hospitals. Kills hepatitis B virus

(HBV), HIV, MRSA, VRE, herpes simplex I and II, and other

pathogens. RTU color: Clear to light yellow. TNF 180; FCS 155 gallons.

3M™ Industrial Degreaser Concentrate

Removes petroleum-based grease and oil, animal fats,

and heavy dirt buildup. Can be used in industrial plants,

schools, hospitals and other facilities. RTU color: Red.

TNF 74; FCS 76 gallons.

Cleaning and stripping for hard oors. Cleaning and degreasing walls, oors, tables,

carpets and seating.

40 42

3

6

5

8

Scotchgard™ Pretreatment Cleaner Concentrate

28

For heavily soiled areas of colorfast carpet.

Use as a prespray prior to extraction or

shampooing. RTU color: Clear. TNF 24;

FCS 26 gallons.

3M™ Neutral Cleaner LO Concentrate

33

Specially formulated for minimal residue. Low odor.

RTU color: Light peach. TNF 207 gallons.

3M™ Peroxide Cleaner Concentrate

34

Daily use, no residue. For carpet and nonporous

surfaces such as oors, walls, tables, bathroom

xtures, tile, grout and more. Low odor. RTU color:

Clear. TNF 53; Green Seal certied only in TNF. FCS 50 gallons.

3M™ Clean & Shine Daily Floor Enhancer

35

Daily use. Repairs ne scratches while providing superior

cleaning eciency, requiring less burnishing to maintain

shine, thus extending life of protective oor coating. Usage of this

product reduces frequency of required oor restoration.

22

23 25

24 26

34

33 35

41

3

1

2

7 17 24 33

3M™ MBS Disinfectant Cleaner Fresh

41

Scent Concentrate

EPA-registered. For use in hospitals. Kills SARS-CoV-2, HIV-1,

Hepatitis B and C, Norovirus, MRSA, VRE, Acinetobacter

baumanii, Inuenza A Virus and other pathogens in ve minutes.

Fresh-scent fragrance. RTU color: Green. TNF 123; FCS 110 gallons.

™

3M

MBS Disinfectant Cleaner Concentrate

42

44

51

EPA-registered disinfectant cleaner for use in hospitals.

Kills SARS-CoV-2, HIV-1, Hepatitis B and C, Norovirus,

MRSA, VRE, Acinetobacter baumanii, Inuenza A Virus

and other pathogens in ve minutes. Low odor and

dye-free.RTU color: Clear. TNF 123; FCS 110 gallons.

3M™ Bathroom Cleaner Concentrate

Removes soap scum and scale from bathroom

surfaces. RTU color: Light forest green. TNF 27;

FCS 26 gallons.

3M™ Bathroom & Shower Cleaner Concentrate

For daily cleaning of surfaces such as ceramic tile, stainless

steel, xtures, oors and more. Can be used on shower walls,

oors and xtures. RTU color: Milky white. TNF 29; FCS 28 gallons.

16

20 26

34

Scotchgard™ Extraction Cleaner Concentrate

27

Low-foaming. For use on colorfast carpet.

Neutral pH safe for nylon stain-resistant

carpets. RTU color: Clear. TNF 53;

FCS 55 gallons.

The Carpet and Rug Insti tute (CRI) Seal of Approval

addresses cleaning e ectivenes s by testing and certif ying

only those products that meet high performance standards.

8 3M Chemical Management Solutions

3M™ Disinfectant Cleaner RCT Concentrate

40

EPA-registered. For use in hospitals. Kills SARS-CoV-2,

HIV-1, HBV, MRSA, VRE, KPC, Acinetobacter and other

pathogens in three minutes. Rinse-free, fragrance-free

and dye-free. RTU color: Clear. TNF 123; FCS 116 gallons.

Product No. 8, 34: Skin/eye damage met

requirements at the as-used dilution, as

specied for closed dilution systems.

Products No. 24, 44: Acute toxicity and skin/eye

damage met requirements at the as-used dilution,

as specied for closed dilution systems.

3M™ Tile, Grout & Bowl Cleaner Concentrate

52

For periodic cleaning. Removes both hard-water scale and

soap scum. RTU color: Milky white. TNF 2.6 gallons.

Products meet Green Seal™ Standard GS-37 based on eective performance,

concentrated volume, minimized/recycled packaging and protective limits

on: VOCs and human and environmental toxicity. Greenseal.org

Page 9

Ordering Information

Product Description

1

Glass Cleaner 23357 (L) 85843 (A)

2

HD Multi-Surface 19202 (L) 85827 (A)

3

Neutral Cleaner

4

Bathroom Disinfectant 19204 (L) 85806 (A)

5

Quat Disinfectant

6

Speed Stripper 19208 (H) 85872 (A)

7

Food Service Degreaser

8

General Purpose Cleaner

11

Scotchgard™ Bonnet Cleaner 25981 (L) n/a

12

Country Day Scent Deodorizer 20119 (L) n/a

13

Fresh Scent Deodorizer 20121 (L) 85829 (A)

14

Mountain Spice Scent Deodorizer 20120 (L) n/a

15

Non-Acid Disinfectant Bath† 20787 (L) 85830 (A)

16

Sanitizer 20112 (L) 85831 (A)

17

Glass Cleaner and Protector 59980 (L) 85790 (A)

19

Non-Acid Bath Cleaner 23207 (L) n/a

3M™ Twist ’n

Fill™ Gray Cap

20200 (H)

59167 (L)

23219 (H)

23218 (L)

23346 (H)

23347 (L)

19212 (H)

19211 (L)

3M™ Flow

*

Control System

85789 (A)

85926 (A)

85828 (A)

85871 (A)

Product Description

22

Floor Stripper LO 23555 (H) 85833 (A)

23

Neutral Quat Disinfectant†

24

3-in-1 Floor Cleaner 23553 (H) 85834 (A)

25

HB Quat Disinfectant

26

Industrial Degreaser Cleaner

27

Scotchgard™ Extraction Cleaner 34857 (H) 85928 (A)

28

Scotchgard

™

Pretreatment

Cleaner

33

Neutral Cleaner LO 59169 (H) n/a

34

Peroxide Cleaner

35

Clean & Shine Daily Floor Enhancer 84616 (H) 84615 (A)

40

Disinfectant Cleaner RCT 85783 (L) 85837 (A)

MBS Disinfectant Fresh

41

Scent Cleaner

42

MBS Disinfectant Cleaner

44

Bathroom Cleaner

51

Bath & Shower Cleaner

52

Tile, Grout and Bowl Cleaner 26323 (L) n/a

86047 (H)

3M™ Twist ’n

Fill™ Gray Cap

23552 (H)

26057 (L)

23550 (H)

23551 (L)

29664 (H)

29665 (L)

34858 (H) 85995 (A)

59288 (H)

59749 (L)

86045 (L)

86049 (H)

86050 (L)

59164 (L) 85929 (A)

26321 (L) 85930 (A)

3M™ Flow

*

Control System

85927 (A)

85791 (A)

85835 (A)

85792 (A)

86044 (A)

86046 (A)

Dispensers 3M UPC

3M™ Twist ’n Fill™ System

3M™ Twist ’n Fill™ System Dispenser, Gray 23592

3M™ Twist ’n Fill™ System Dispenser,

Pressure Relief Fitting Gray Cap

25932

3M™ Flow Control System

3M™ Flow Control Portable Dispenser 85849

3M™ Flow Control Chemical Dispenser,

Action Gap

3M™ Flow Control Chemical Dispenser,

Action Gap, Pressure Relief Valve

3M™ Flow Control Chemical Dispenser,

Air Gap

3M™ Flow Control Chemical Dispenser,

Air Gap, Pressure Relief Valve

3M™ Flow Control System Spray/Foam

Applicator for Portable Dispenser

* (H) signies TNF High-Flow Bottle; (L) signies TNF Low-Flow Bottle.

Approved for the adoption of a SARS-CoV-2 ecacy claim.

† Meets the criteria dened in the U.S. EPA Emerging Pathogen Policy.

IMPORTANT NOTICE: To learn more, please refer to the 3M Technical Talk

“Coronavirus Disease 2019 (COVID-19) Tech Talk.”

85850

85851

85852

85853

85882

20

HD Glass Cleaner 23360 (L) n/a

3M, Scotchgard and Twist ’n Fill are trademarks of 3M

Company. Used under license in Canada. Green Seal and

the Green Seal Certied mark are trademarks of Green Seal,

Commercial Solutions

3M Center, Building 220-12E-04

St. Paul, MN 55144-1000 USA

Phone 1-800-852-9722

Web 3M.com/disinfection

Inc. The Carpet and Rug Institute’s Seal of Approval logo is a

trademark of the Carpet and Rug Institute. LEED and related

logo is a trademark owned by U.S. Green Building Council

and is used by permission.

© 3M 2021. All rights reserved. Printed in USA.

Please recycle. 78-8134-0831-3 January 2021

1. Reopening Guidance for Cleaning and Disinfecting Public Spaces, Workplaces, Businesses, Schools, and Homes. Centers for Disease Control (CDC). Accessed online 10/21/2020.

https://www.cdc.gov/coronavirus/2019-ncov/community/reopen-guidance.html.

2. The 3M™ Flow Control System (FCS) is 55% more accurate on average at diluting chemical concentrates than the nearest competitive system when used under laboratory conditions

at water pressures ranging from 20 to 120 psi.

3. The 3M™ Flow Control System is 17–49% smaller in cabinet size volume than the four competitive four-bottle dispenser systems tested.

Product Selection and Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can aect the use and performance of a 3M product in a particular

application. As a result, customer is solely responsible for evaluating the product and determining whether it is appropriate and suitable for customer’s application, including conducting

a workplace hazard assessment and reviewing all applicable regulations and standards (e.g., OSHA, ANSI, etc.). Failure to properly evaluate, select, and use a 3M product and

appropriate safety products, or to meet all applicable safety regulations, may result in injury, sickness, death, and/or harm to property.

Warranty, Limited Remedy, and Disclaimer: Unless a dierent warranty is specically stated on the applicable 3M product packaging or product literature (in which case such

warranty governs), 3M warrants that each 3M product meets the applicable 3M product specication at the time 3M ships the product. 3M MAKES NO OTHER WARRANTIES OR

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR ARISING OUT OF A COURSE OF DEALING, CUSTOM, OR USAGE OF TRADE. If a 3M product does not conform to this warranty, then the sole and exclusive remedy is,

at 3M’s option, replacement of the 3M product or refund of the purchase price. Limitation of Liability: Except for the limited remedy stated above, and except to the extent prohibited

by law, 3M will not be liable for any loss or damage arising from or related to the 3M product, whether direct, indirect, special, incidental, or consequential (including, but not limited to,

lost prots or business opportunity), regardless of the legal or equitable theory asserted, including, but not limited to, warranty, contract, negligence, or strict liability.

Loading...

Loading...