3M CFS5400N Installation Manual

INSTR4096 0909

Installation and

Operating Instructions

For 3M Water Filtration Products CFS5400/CFS5400N Softening Systems

Safety Instructions

• The filter system must be installed with the inlet

and outlet as labeled. Make sure not to reverse

the connections. (See markings on top of the

filter head.)

• Do not install on the hot water line. Maximum

temperature allowed is 100°F (38°C).

• Do not install on line pressure above 100 psi

(690 kPa).

• Do not use a torch or other high temperature

sources near the filter or plastic cartridge.

• Do not install near electrical wires or water

pipes which will be in the path of the drill when

selecting the position to mount the bracket.

• Do not install in direct sunlight.

• The filter system may be used with metal or

non-metallic piping systems. Any non-metallic

fittings used in the installation must be of

adequate rating for the line pressure.

• Protect from freezing. Drain the filter when

room temperature drops below 40°F (4.4°C).

• Allow minimum of 2” (5 cm) clear space

under the filter system to facilitate cartridge

changes.

• Mount the filter system in such a position as

to prevent it from being struck by other items.

• Installation must comply with existing state

and local plumbing codes.

• Do not use with water that is microbiologically

unsafe or of unknown quality without

adequate disinfection before or after the

system.

The CFS5400 system with blending capability is designed to reduce hardness caused by calcium and

magnesium minerals in point of use beverage applications such as brewed tea machines. The

CFS5400N system is designed to provide complete hardness reduction when required.

The CFS5400 & CFS5400N systems will require an external shut-off valve installed before the system. A

drain valve should be installed after the system for routine maintenance. A flush kit can be purchased

separately if a drain valve is not desired. See the 3M Water Filtration Products price list for part number

and price. The housing comes with a pressure relief valve and 1” inlet/outlet ports. 3/8” reducer

bushings, mounting bracket and wrench are supplied.

Installation Procedure

Note: Read instructions all the way through before attempting to install the filter system. Observe

all installation precautions.

The filter systems can be adapted to various pipe sizes by using reducing bushings at either end. The

filter system has 1” NPT ports. 3/8” NPT reducer bushings are supplied if needed.

Filter System Assembly:

1. Turn off incoming water line.

2. Mount bracket onto filter head. Use mounting holes provided to mount the system to a wall or

support structure.

3. Install a shut-off valve on the incoming cold water supply line.

4. Connect the incoming cold water supply to the filter system’s inlet water connection.

5. Connect the outlet port of the system to the outlet water line.

6. Install drain valve on the outlet water line.

for assembly.

7. After all connections are complete, unscrew sump from filter head and remove o-ring (Gasket)

from bottom of sump and place on top of sump. If unit comes with cartridge installed, o-ring

(Gasket) should already be installed. Install cartridge, referring to the cartridge replacement

instructions, if necessary.

8. Turn on incoming water to the system.

9. Pressurize system. Check for leaks. Retighten connections if necessary.

gallon of water through new cartridge to remove entrapped air.

10. System is now ready for service.

Note: If flush kit is used, follow instructions supplied

Flush a minimum of 1

Cartridge Replacement Instructions

The CFS5400/CFS5400N Systems are designed to use only the 3M Water Filtration Products CFS5400C

replacement cartridge. Use of housings and replacement cartridges other than those specified below

may seriously compromise water quality and/or cartridge life.

Note: The CFS5400C cartridge has a grain capacity of 4,200 grains. When used in the CFS5400

system, gallon throughput will increase by 25% or better, dependent upon incoming

hardness levels. When used in the CFS5400N system, the system will provide complete

softening for 4,200 grains.

1. Turn off incoming water supply.

2. Depress pressure relief button on top of filter head to relieve pressure in filter.

3. Unscrew sump from filter head. Empty water from sump and dispose of spent cartridge.

4. Clean and inspect all components including the o-ring seal. Lubricate o-ring seals with a light

coating of food grade lubricant. Replace o-ring seal if there is visible damage.

5. Install new cartridge into sump.

6. Place lubricated o-ring onto sump groove. Screw sump into head. Tighten with the wrench

provided (p/n 68900-33). After approximately 1 turn, additional resistance will be felt as gasket

engages with head. Continue turning until sump becomes snug and cartridge is sealed.

7. Turn on incoming water supply.

8. Depress pressure relief button on filter head until air is purged from system. Flush a minimum of 1

gallon of water through new cartridge prior to service to remove entrapped air.

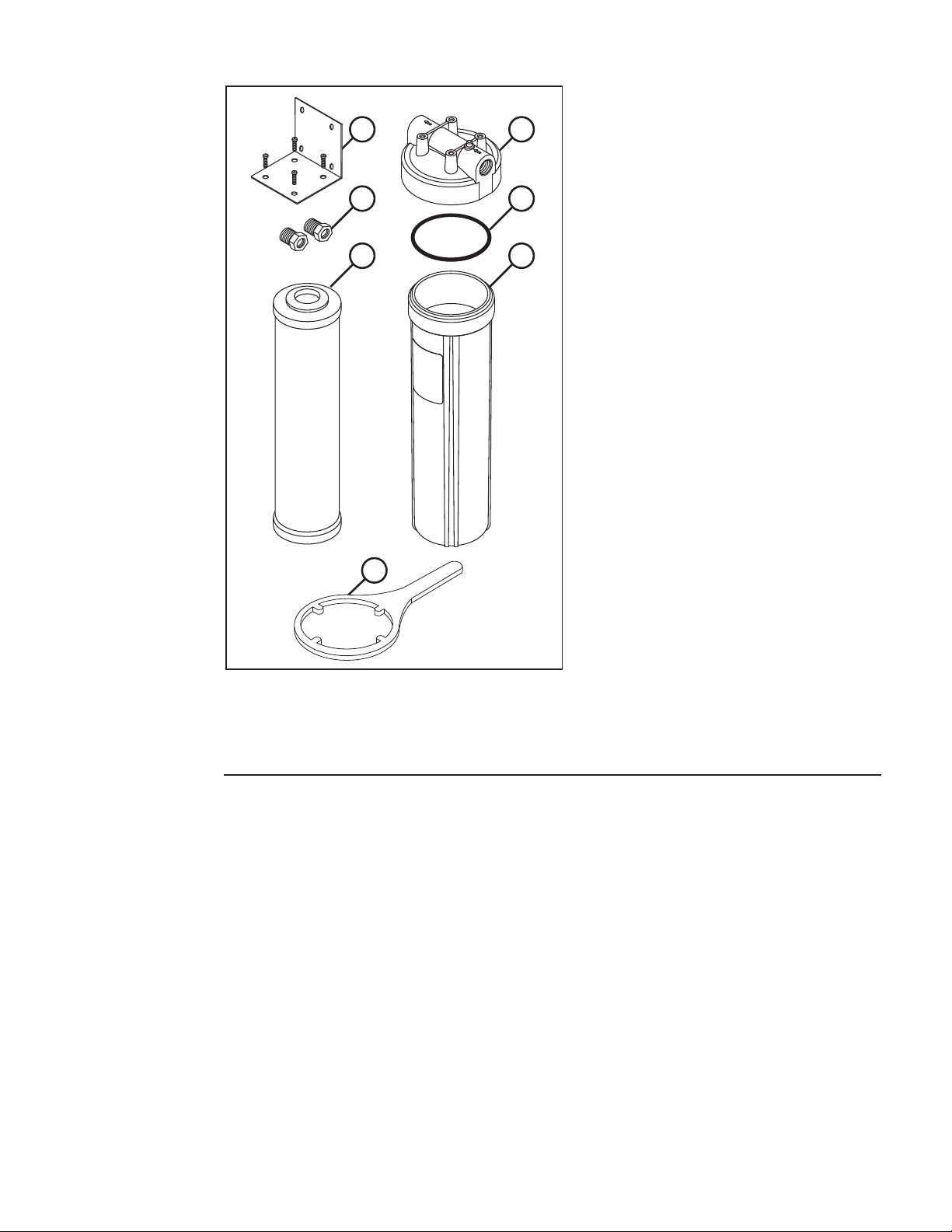

Part Numbers

5

1

1. Head Assembly with bypass

(CFS5400) - 62009-04

6

2

1. Head Assembly without bypass

(CFS5400N)- 62009-01

2. O-ring - 68898-32

4

3

3. Sump - 62010-32

4. CFS5400C Cartridge - 56066-01

5. Bracket Kit - 68901-31

6. Reducer Bushing - 72-811606

7. Wrench - 68900-33

Optional Flush Kit (not shown) - 56065-01

7

Limited Warranty

CUNO Incorporated warrants this Product (excluding disposable filter cartridge(s)) to be free from defects in material and workmanship for two (2) years from the date

of purchase. The disposable filter cartridge is warranted from defects in material and workmanship for a period of one (1) year from the date of purchase. This

warranty does not cover failures resulting from abuse, misuse, alteration or damage not caused by CUNO or failure to follow installation and use instructions. If the

Product is defective CUNO will replace the Product or refund your Product purchase price. CUNO will not be liable for any indirect, special, incidental, or con-sequential

damages arising from the use of this Product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation may

not apply to you. To obtain warranty service, mail your request to Warranty Claims, CUNO Incorporated, 400 Research Parkway, Meriden, CT 06450. Proof of purchase

(original sales receipt) must accompany the warranty claim, along with a complete description of the Product, model number and alleged defect. This warranty gives

you specific legal rights and you may have other rights which vary from state to state, or country to country.

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450, USA

Toll Free: 1-888-218-CUNO

Worldwide: 203-237-5541

Fax: 203-238-8701

www.cunofoodservice.com • www.cuno.com

3M is a trademark of 3M Company.

© 2009 3M Company. All rights reserved.

Loading...

Loading...