Page 1

MODELS:

CFS101BWF

CFS201BWF

CFS151BWF

INSTALLATION AND OPERATING

INSTRUCTIONS

CFSBWF SERIES

BACKWASH FILTRATION SYSTEMS

Installer: Please leave this manual with owner/operator.

Owner/Operator: Please retain for operation and future

maintenance instructions.

Page 2

Page 3

SAFETY INFORMATION

CAUTION

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the CFSBWF Series Backwashing

Filtration Systems. Retain these instructions for future reference.

Intended use:

The CFSBWF Series Backwashing Filtration Systems are intended for use in reducing undesirable aesthetics in water in commercial establishments

and have not been evaluated for other uses. The system is intended for indoor installations near the entry point of a water line, and must be installed by

qualifi ed professional installers according to these installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or

property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury and/or

property damage.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

To reduce the risk of physical injury:

• Shut off inlet water supply and depressurize system as shown in manual prior to service.

To reduce the risk associated with a hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection

across the fi lter installation piping — refer installation to qualifi ed personnel.

• Do not use the system if the power cord is damaged — contact qualifi ed service personnel for repair.

To reduce the risk associated with back strain due to the heavy weight of the various system components:

• Follow safe lifting procedures.

CAUTION

To reduce the risk associated with skin, eye, and respiratory tract irritation from dust from fi lter media during installation:

• Gravel and several types of fi lter media may be used in this product, depending upon the application. During installation, dust may cause irritation to skin,

eyes, and respiratory tract, and may affect lungs.

• Utilize a NIOSH-approved dust fi lter mask and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product, call 203-238-8965 or visit the web at http://solutions.3m.com/wps/portal/3M/en_US/MSDS (click MSDS

search). For emergencies, call 800-364-3577 or 651-737-6501 (24 hours).

Page 4

CAUTION

IMPORTANT NOTES

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install systems in areas where ambient temperatures may go above 110°F (43.3°C) or below 40°F (4.4°C).

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a

plumbing professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing professional if you are uncertain how to check for this condition.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

• Do not install in direct sunlight or outdoors.

• Mount system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure all tubing and fi ttings are secure and free of leaks.

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

• Do not apply heat to any fi tting connected to Bypass or Control Valve as damage may result to internal parts or connecting adapters.

• Install on a fl at/level surface. It is also advisable to sweep the fl oor to eliminate objects that could pierce the brine tank.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

IMPORTANT NOTES

• Failure to follow instructions may result in leakage and will void warranty.

• Since some media dissolves as it elevates pH level, it will increase the hardness. If your dwelling is equipped with a tankless water heater, the

installation of a water softener may be necessary to prevent the heater coil from plugging.

Page 5

Page 6

IMPORTANT NOTE:

IMPORTANT NOTE

TABLE OF CONTENTS

SECTION DESCRIPTION

1 BEFORE INSTALLATION

2 INSTALLATION

3 MAINTENANCE

4 TROUBLESHOOTING

5 SPECIFICATION AND OPERATING DATA

WARRANTY

SECTION 1: BEFORE INSTALLATION

Inspecting And Handling Your Filter:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection.

Handle the fi lter with care. Damage can occur if dropped or set on sharp, uneven projections on the fl oor. Do not turn the fi lter upside down.

Make Sure Your Water Has Been Thoroughly Tested:

An analysis of your water should be made prior to the selection of your water conditioning equipment. Your dealer will generally perform this service for you,

and may send a sample to the factory for analysis and recommendations. Enter your below for a permanent record.

IMPORTANT NOTE:

Hydrogen sulfi de (H2S) must be tested for at the well site. For accuracy, the sample must be drawn with the pump RUNNING and the test be completed

within ONE minute after the sample is drawn.

Analysis Of Your Water

Hardness _____gpg

Iron (Fe) _____gpg

Manganese (Mn) _____ppm

pH _____

Tannins (Humic Acid) _____ppm

Hydrogen Sulfi de (H2S) _____ppm

Other_______________ _____

Other_______________ _____

There are several different fi lter media which can be used in this fi lter. Each is designed to improve a particular aesthetic problem. NONE OF THEM SHOULD

BE USED TO MAKE NON-POTABLE WATER SAFE TO DRINK. The following descriptions indicate not only what the media is designed to do, but also points out

their limitations.

Neutralizer

NEUTRALIZATION (C or N Media) helps prevent corrosion of copper pipes and plumbing fi xtures by correcting low pH (acidic) water conditions. This process

is similar to adding lime to acidic soil or to taking an antacid. C Media is used for moderate pH correction (pH 6.0 - 6.8). N Media, which dissolves more

rapidly, is used for more extreme conditions (pH 5.5 - 6.0 and as low as 5.0 under certain conditions). Both types of media are consumed during neutraliza-

tion and must be replenished periodically.

IMPORTANT NOTE

Since neutralizer media dissolves as it raises pH, it will increase the hardness. To help protect your water heater from the "scaling effect" of hard water,

a Scale Inhibitor Filter or Water Softener should be installed after the neutralizer.

1-1

Page 7

Activated Carbon

IMPORTANT NOTE

ACTIVATED CARBON ADSORPTION (A Media) is used to reduce chlorine, many impurities that give water an unpleasant taste or odor, and a wide variety of

organic chemicals, including most pesticides, herbicides, and solvents (consult with manufacturer when attempting to reduce specifi c chemical contaminants). Carbon contains millions of microscopic pores which chemically bond with these impurities to reduce them from the water. The capacity for adsorption is quite large but eventually the carbon must be replaced (the interval depends on the total quantity of impurities and amount of water used.)

Filtration Media

Filtration (F Media) is used when particle reduction is the only process required. The media is inert and does not react chemically with the water. GradedDensity media can be backwashed very effi ciently and is particularly effective for the reduction of precipitated iron.

Activated Carbon

Activated carbon is generally used to reduce objectionable tastes and odors from water, chlorine being the most common. Activated carbon works primarily on the concept of adsorption. Each particle of carbon has numerous pores through which the water passes. It is in these pores that the reduction of

unwanted constituents occurs. During backwash, these “collected” contaminants are knocked off and fl ushed away to drain. Since the pores in the carbon

are very important, the presence of sediment in the water — which can plug these pores — will greatly shorten the run time and life span of the carbon.

The chlorine is reduced by a chemical reaction on the surface of the activated carbon, where the chlorine ions in the water are reduced to chloride ions,

lessening the taste and odor issues associated with chlorine in the water.

The useful life of activated carbon will vary greatly depending on the water contaminants and amount of water fi ltered per day. Rarely will the carbon last

more than three (3) years.

Check Your Water Pressure And Pumping Rate:

Two water system conditions must be checked carefully to avoid unsatisfactory operation or equipment damage:

1) Minimum water pressure required at the fi lter tank inlet is 20 psi (138 kPa).

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a

plumbing professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing

professional if you are uncertain how to check for this condition.

IMPORTANT NOTE

If you have a municipal or a community water supply and daytime water pressure is 85 psi (586 kPa) or more, nighttime pressure may exceed 100 psi (689 kPa).

Call your local water department or plant operator to obtain pressure readings. If you have a private well, the gauge on the pressure tank will indicate high and

low system pressure. Record your water pressure data below:

Water Pressure

Low _________psi High _________psi

2) The pumping rate of your well pump must be suffi cient for satisfactory BACKWASH. Although the density of a media normally determines the backwash

rate, all the media discussed earlier will require the same fl ow rate. These models require a 5 gpm rate (refer to SPECIFICATIONS AND OPERATING DATA

for the backwash requirement for other models). To measure the pumping rate of your pump, follow these instructions:

a. Make certain no water is being drawn. Open spigot nearest pressure tank. When pump starts, close spigot and measure time (in seconds) to refi ll

pressure tank (when pump shuts off). This fi gure represents CYCLE TIME.

b. With the pressure tank full, draw water into a container of known volume, measure the number of gallons drawn until the pump starts again. This

is DRAW-DOWN. Divide this fi gure by CYCLE TIME and multiply by 60 to arrive at the PUMPING RATE in gallons per minute (gpm). To aid in you

calculation, insert the data in the following formula:

DRAW-DOWN ______ ÷ CYCLE TIME ______ x 60 = PUMPING RATE ______

(gals.) (secs.) (gpm)

EXAMPLE: CYCLE TIME is 63 secs.; DRAWDOWN is 8 gals.; then PUMPING RATE equals:

8 gals. ÷ 63 secs. x 60 = 7.6 gpm

1-2

Page 8

Locate Water Conditioning Equipment Correctly:

Select the location of your backwash system with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a drain.

3) Locate in correct relationship to other water conditioning equipment (Figure 1).

4) Locate the backwash system in the supply line BEFORE the water heater. Temperatures above 110°F (43.3°C) will damage the backwash system

and void the factory warranty.

5) DO NOT install the backwash system in a location where freezing temperatures occur. Freezing may cause permanent damage and will also void

the factory warranty.

6) Allow suffi cient space around the installation for easy servicing.

7) Provide a non-switched 110V, 60Hz (220V, 50Hz for specifi ed systems) power source for the control valve.

WARNING

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install systems in areas where ambient temperatures may go above 110°F (43.3°C) or below 40°F (4.4°C).

The Importance Of Your Pressure Tank:

A properly sized pressure tank will require a minimum pump cycle of 60 seconds to refi ll from pump on-to-off pressure settings.

NOTE: If your pressure tank (or any part of your water system) is not functioning properly, corrective action MUST be taken before installation of your fi lter.

Facts to Remember While Planning Your Installation:

1) All installation procedures MUST conform to local and state plumbing codes.

2) If lawn sprinkling, a swimming pool, or geothermal heating/cooling or water for other devices/activities are to be treated by the backwash system,

a larger model MUST be selected to accommodate the higher fl ow rate plus the backwashing requirements of the backwash system. Consult your

dealer for alternative instructions if the pumping rate is insuffi cient.

3) Remember that the backwash system INLET is attached to the pipe that supplies water (i.e. runs to the pump) and the OUTLET is the line that runs

toward the water heater.

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

4) Before commencing the installation it is advisable to study the existing piping system and to determine the size, number and type of fi ttings

required.

WARNING

To reduce the risk associated with a hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across

the fi lter installation piping — refer installation to qualifi ed personnel.

5) It is also advisable to sweep the fl oor to eliminate objects that could pierce the brine tank.

1-3

Page 9

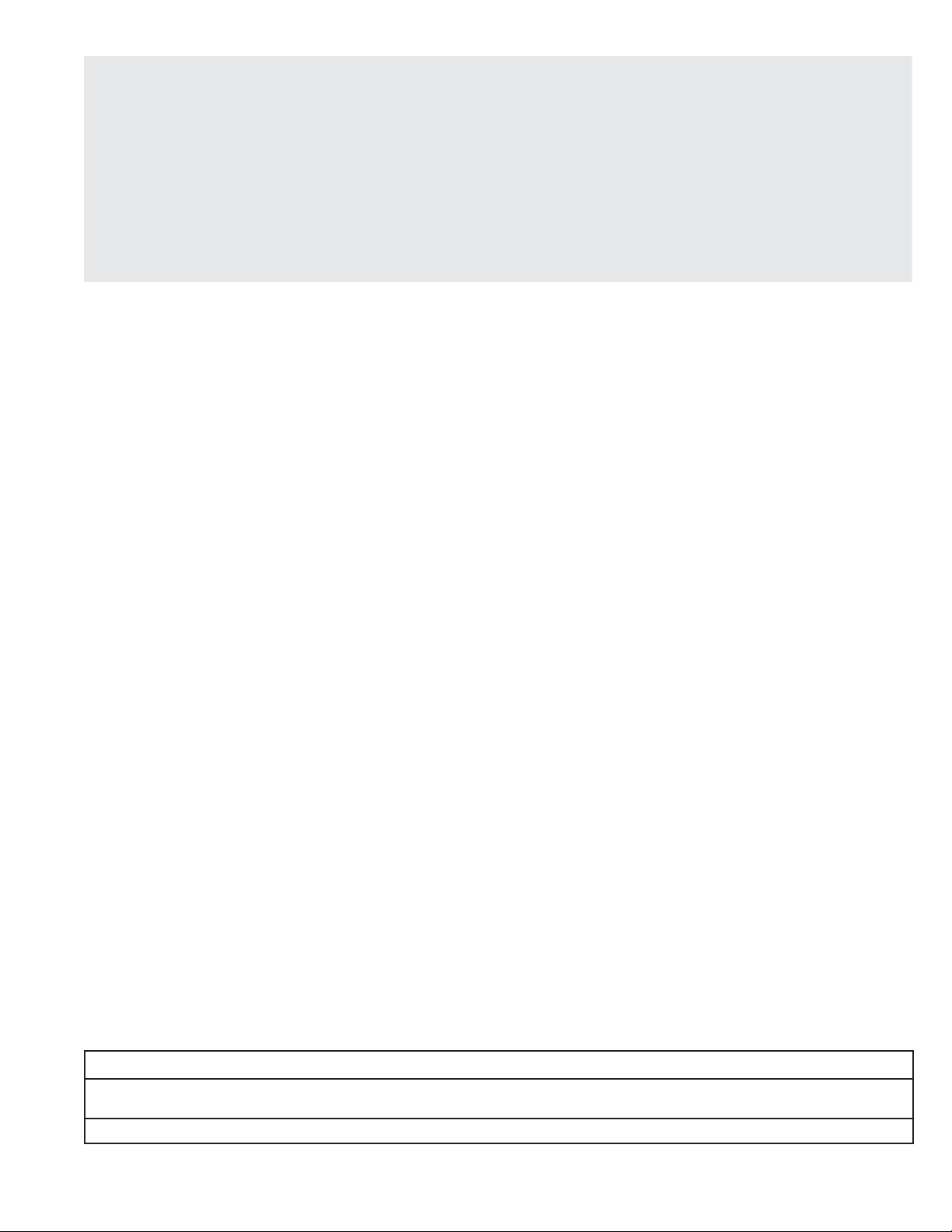

SECTION 2: INSTALLATION

CAUTION

Proper installation sequence of Filter System is very important. Refer to the diagram following for your particular supply.

FILTERED WATER

FILTERED

SOFT WATER

WATER FOR

LAWN SPRINKLERS

OR OTHER

HIGH DEMAND

BRINE

MAKER

SOFTENER

PUBLIC WATER SUPPLY INSTALLATION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

FILTER

Figure 1 Installation Sequence

CAUTION

CHECK VALVE

METER

RAW

WATER

2-1

Page 10

Step 1

IMPORTANT NOTE

CAUTION

CAUTION

CAUTION

(a) Remove the control valve by removing the latch and clamp and pulling the valve up and out of the tank. Before loading

the media into the tank, the distributor must be all the way to the bottom of the tank. It is therefore recommended that the

distributor be removed and the gravel dumped out and saved. The distributor tube should then be replaced in the empty

tank making sure it rests on the bottom. Use the plastic cap provided to plug the distributor tube and prevent media from

entering the distributor. Material lodge in the distributor tube can enter the control valve, thus damaging it. First, pour the

gravel removed earlier back into the media tank and then add the media. Utilize the centering tool to help keep the distributor tube centered in the mineral tank opening to aid in mounting the control over the distributor tube. Never add media to

a level above the line on the side of the tank. Additional media may have been shipped for future replenishment.

(b) Fill the tank with water. Lubricate o-ring on tank adapter with silicone grease and reinstall the CONTROL VALVE. Make sure

the distributor tube fi ts into the valve body tube adapter protruding from the bottom of the valve body.

(c) Reinstall clamp. Align the "LATCH" arrows on the clamp body (see FIGURE 2).

(d) If the BYPASS VALVE/YOKE ASSEMBLY is not factory pre-installed, attach to back of CONTROL VALVE using ADAPTER COU-

PLINGS, CLIPS and SCREWS.

IMPORTANT NOTE

Never add media above line indicated on side of tank. You may have received more media than required for the initial

fi ll, save extra media for future replenishment.

CAUTION

To reduce the risk associated with skin, eye, and respiratory tract irritation from dust from fi lter media during installation:

• Gravel and several types of fi lter media may be used in this product, depending upon the application. During installation, dust may cause irritation to

skin, eyes, and respiratory tract, and may affect lungs.

• Utilize a NIOSH-approved dust fi lter mask and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product, call 203-238-8965 or visit the web at http://solutions.3m.com/wps/portal/3M/en_US/MSDS (click MSDS

search). For emergencies, call 800-364-3577 or 651-737-6501 (24 hours).

Figure 2. LATCH

Step 2

Shut off water at main supply. On a private well systems, turn off power to pump and drain pressure tank. Make certain pressure is relieved from complete system

by opening nearest faucet to drain system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

Step 3

Cut main supply line as required to fi t plumbing to Inlet and Outlet of Bypass Valve Assembly.

Step 4

Solder or solvent weld plumbing. Do not apply heat to any fi tting connected to bypass or control

valve as damage may result to internal parts or connecting adapters. Make certain water fl ow

enters through inlet and discharges through outlet.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not use a torch or other high temperature sources near fi lter system, cartridges,

plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe

dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may

occur if over tightening occurs.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment equipment products will

vary depending on the control valve brand used.

ADAPTER YOKE

ADAPTER COUPLING

CLIP &

SCREW

SERVICE

Figure 3 . INLET/OUTLET CONNECTIONS

OUT IN

BYPASS

ROTATE

KNOBS

BYPASS VALVE

DRAIN LINE

BYPASS

FITTING

BYPASS

2-2

Page 11

Step 5

CAUTION

IMPORTANT NOTE

IMPORTANT NOTE

IMPORTANT NOTE

Attach Drain Line to Drain Line Fitting. To prevent back pressure from reducing the fl ow rate below minimum required for backwash, Drain Line MUST be sized

according to run length and relative height. Be careful not to bend fl exible drain tubing sharply enough to cause “kinking” (if kinking occurs Drain Line MUST be

replaced). Typical examples of proper Drain Line diameters are:

a. 1/2” ID lengths up to 15 feet and heights lower or slightly higher than the control valve.

b. 5/8” ID length up to 25 feet in length and up to 4 feet above the control valve.

c. For distances higher or longer than previously stated, relocate the fi lter closer to the desired discharge point or consult

factory for advice. Avoid overhead drain lines as it may prevent desirable performance.

Avoid installing drain overhead or using fl exible vinyl tubing, either may result in failure.

Some areas prohibit the use of fl exible drain lines. Check with local code offi cials prior to installation.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Installation must comply with existing state or local plumbing codes..

Figure 4. DRAIN

Step 6

Position Drain Line over drain and secure fi rmly. To prevent back-siphoning of sewer water, provide an air-gap of at least 2 inches or 2 pipe diameters between

end of drain hose and drain (See Figure 4). Do not raise Drain Line more than 10 feet above fl oor.

Step 7

Make certain both inlet and outlet knobs of bypass valve are in "bypass" position. Turn on power to well pump or completely open main supply valve. Check for

leaks and correct as necessary.

Step 8

a) Manually stage control to Backwash Position (See “How To Manually Backwash Your Filter At Any Time”, Page 2-4). Open Bypass Valve approximately 1/4 of

the way to full open (“Service” Position), allowing unit to fi ll slowly. This will purge entrapped air in the bed.

b) Once a steady stream of water is fl owing to drain, open Bypass Valve completely. Leave unit in backwash for at least 10 minutes OR until drain line water

runs clear, whichever is longer.

IMPORTANT NOTE

Filters containing activated carbon or F media must be saturated for at least 2 hours prior to subjecting the unit to full backwash fl ow rates. Failure to do this

may result in loss of mineral during initial backwash procedure.

Step 9

After this preliminary backwash, manually advance Control Valve to “Service” position and plug valve into a 110V, 60Hz properly grounded non-switched power

source.

Step 10

Set time of day (See How To Set Time Control) and set Backwash Frequency (See Determining Backwash Frequency). Installation is now complete.

IMPORTANT NOTE

During the initial backwashings, a small amount of media may be observed in drain water. This is normal and benefi cial for effi cient operation of your fi lter

system.

Step 11

Manually initiate a complete “regeneration” process, allowing the unit to automatically proceed through a backwash and rapid rinse. See “How to Manually Backwash Your Filter At Any Time.” Check drain water at end of rapid rinse cycle. If water is cloudy, repeat the backwash process.

IMPORTANT NOTE

Restore Fuel Supply or power to Water Heater.

Determining Backwash Frequency

The exact backwash frequency depends on the quality of the raw water, but it is recommended that fi lters containing Activated Carbon, Birm, Filter Ag or Filter Sand be

programmed to backwash at least once every six days. If pressure drop becomes excessive or contaminant reappears in the treated water before six days, increase

the frequency. Filters containing Neutralizer should be backwashed every other day to prevent the media particles from “cementing” together. See “How to Set Time

Control” for procedure.

2-3

Page 12

HOW TO SET TIME CONTROL

IMPORTANT NOTE

IMPORTANT NOTE

RED TIME-SET

BUTTON

TO SET TIME OF DAY - PRESS RED

BUTTON AND TURN LARGE GEAR UNTIL

PRESENT TIME APPEARS ABOVE ARROW.

FOR MANUAL REGENERATION TURN KNOB

CLOCKWISE TO REGEN. POSITION.

MANUAL REGENERATION

KNOB

SERVICE

12

DAY

TIME OF

TIME OF DAY

ARROW

How To Set Time Of Day

12 HOUR GEAR

6

5

RED POINTER

SKIPPER WHEEL

(SHOWS EVERY DAY

REGENERATION)

2

3

4

1) Press and hold the red button in to disengage the drive gear.

2) Turn the large gear until the actual time of day shows in the time of day window. Unit will now be set to backwash at 1:00 a.m. (See note below to adjust

the time).

3) Release the red button to again engage the drive wheel.

How To Set The Skipper Wheel

If you are setting the Time Control after Midnight but before Noon, the red pointer on the Skipper Wheel must be between two numbers (as shown). If you are

setting the Time Control after Noon, but before Midnight, the red pointer must be covering one of the numbers. Setting the Skipper Wheel in this manner will

provide a 1:00 a.m. Backwashing time.

IMPORTANT NOTE

If directions above on How To Set The Skipper Wheel are not followed, Backwashing will not take place at the appropriate time of day.

How To Set Days On Which Filter Is To Backwash

Set the days that backwash is to occur by sliding tabs on the skipper wheel outward to expose trip fi ngers. Each tab is one day. Extend or retract fi ngers to obtain the desired backwashing schedule. Typically, these units are backwashed every third day. Consult your dealer for their recommendations for your water.

How To Manually Backwash Your Filter At Any Time

Turn the manual backwash knob clockwise until the knob engages the program wheel. This slight movement of the knob will start the backwash program.

The backwash knob will make one revolution in approximately 1 1/2 hours and stop in the position shown in the drawing. Even though it takes 1 1/2 hours for

the knob to complete one revolution, the backwash cycle of your unit might be about 20 minutes in duration.

In any event, fi ltered water may be drawn after rinse water stops fl owing from the fi lter drain line.

IMPORTANT NOTE

Should it be necessary to change the time of day which backwash is to start, the time on 12 hour gear must be altered. For example, if 2:00 a.m. is desired

instead of 1:00 a.m., set the 12 hour gear one hour earlier than actual time.

2-

Page 13

CAUTION

SECTION 3: MAINTENANCE

1) At least every six months you should check the time of day setting. Power outages will cause the unit to lose time.

2) If your unit contains Activated Carbon, you must replace the carbon and gravel underbed at least every three (3) years. Replacement may be required

sooner if the taste and odor being reduced reappears in the treated water or pressure drop due to fouling of the media becomes excessive.

3) Filtration media will last an indefi nite period of time. It may be necessary to replace it, if the pressure drop across the fi lter becomes too great or fi ltration

results drop.

4) Neutralizer media, (C or N) must be replenished at least annually. Measure down from the top of the tank, comparing the current level with the mark. If

the level is down by more than three (3) inches, add media

To Replenish (Rebed) Media

Pressure must be relieved on system by turning both Inlet and Outlet knobs of Bypass Valve to “Bypass” position and manually rotating Control Valve to “Backwash” position.

(a) Remove the control valve by removing the latch and clamp and pulling the valve up and out of the tank. Before loading the media into the tank, the dis-

tributor must be all the way to the bottom of the tank. It is therefore recommended that the distributor be removed and the gravel dumped out and saved.

The distributor tube should then be replaced in the empty tank making sure it rests on the bottom. Use the plastic cap provided to plug the distributor

tube and prevent media from entering the distributor. Material lodge in the distributor tube can enter the control valve, thus damaging it. First, pour the

gravel removed earlier back into the media tank and then add the media. Utilize the centering tool to help keep the distributor tube centered in the mineral

tank opening to aid in mounting the control over the distributor tube. Never add media to a level above the line on the side of the tank. Additional media

may have been shipped for future replenishment.

(b) Fill the tank with water. Lubricate o-ring on tank adapter with silicone grease and reinstall the CONTROL VALVE. Make sure the distributor tube fi ts into

the valve body tube adapter protruding from the bottom of the valve body.

(c) Reinstall clamp. Align the "LATCH" arrows on the clamp body (see FIGURE 2).

(d) If the BYPASS VALVE/YOKE ASSEMBLY is not factory pre-installed, attach to back of CONTROL VALVE using ADAPTER COUPLINGS, CLIPS and SCREWS.

CAUTION

To reduce the risk associated with skin, eye, and respiratory tract irritation from dust from fi lter media during installation:

• Gravel and several types of fi lter media may be used in this product, depending upon the application. During installation, dust may cause irritation to

skin, eyes, and respiratory tract, and may affect lungs.

• Utilize a NIOSH-approved dust fi lter mask and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product, call 203-238-8965 or visit the web at http://solutions.3m.com/wps/portal/3M/en_US/MSDS (click MSDS

search). For emergencies, call 800-364-3577 or 651-737-6501 (24 hours).

3-1

Page 14

PROBLEM CAUSE SOLUTION

1 Excessive pressure drop

through fi lter

2 Contaminant not being

properly reduced.

3 Filter raises pH too high

(Neutralizer)

4 Filter fails to raise pH

(Neutralizer)

SECTION 4: TROUBLESHOOTING

A Filter not backwashing 1 Check motor by manually initiating a regeneration, re-

place as necessary

2 Check for uninterrupted power supply.

3 Check backwash frequency. Change program if neces-

sary.

B Filter bed loaded with sand. 1 Verify sediment being reduced is less dense than the

fi lter media.

C “Cementing” or “Channeling” of media. 1 Probe bed for this condition. Verify adequate pumping

rate for backwashing.

2 Check for frozen, plugged or restricted drain line.

3 Check for adequate backwash frequency.

D Top Screen Fouled 1 Remove screen and clean as necessary.

A Leaking bypass valve. 1 Check bypass valve in “SERVICE” position. Repair or re-

place if necessary.

B Internal valve leak. 1 Check piston and spacers and seals. Replace as neces-

sary.

C Distributor not properly seated in control valve. 1 Make sure distributor is in tube adaptor protruding from

bottom of control valve.

2 Check distributor tube o-ring. Replace as necessary.

D Flow rate too high for fi lter. 1 Check demand requirements against fi lter recommend-

ed fl ow rates.

A Filter is brand new. 1 Crack the bypass valve allowing some water to bypass

the unit.

B Wrong media used. 1 Rebed unit.

A Flow rates too high. 1 Verify demand rate does not exceed fi lter rating.

B Filter bed cemented or channeled. 1 Verify adequate pumping rate for backwashing unit.

2 Check drain line for freezing, plugging or restrictions.

4-1

Page 15

SECTION 5: SPECIFICATION & OPERATING DATA

ITEM CFS101BWF CFS151BWF CFS201BWF

Filter Media Volume, cu.ft. (cu.mtr.) 1.0 (0.03) 1.5 (0.05) 2.0 (0.06)

Gravel Underbed, lbs. (kg.) 18 (8.2) 18 (8.2) 22 (10.0)

Operating Flow Rate, gpm (lpm) (Note 1):

Continuous (no duration limit) 3 (11) 3 (11) 4 (15)

Service (10 mins. or less) 5 (19) 6 (23) 7 (26)

Backwash Flow Rate, gpm (lpm) (Note 2) 5 (19) 5 (19) 7 (26)

Service Pipe Size, in. (cm.) 1 (2.54) 1 (2.54) 1 (2.54)

Tank Diameter x Height, in. (cm.) 10 x 44

(25 x 112)

Minimum Space Required, in. (cm.):

Width 12 (31) 12 (31) 12 (31)

Depth 18 (46) 18 (46) 18 (46)

Height 56 (142) 66 (168) 66 (168)

Approximate Shipping Weight, lbs. (kg.) l/media 45 (20) 51 (23) 57 (26)

10 x 54

(25 x 137)

12 x 54

(31 x 137)

Maximum operating temperature 110º F (43.3º C)

Electrical requirements 110V/60Hz

Operating pressure 20-100 psi.

Specifi cations are subject to change without notice.

NOTES:

1) For satisfactory performance, indicated durations should not be exceeded. Flow rates specifi ed are adequate for normal residential applications. Do not

use Service fl ow rates when sizing commercial applications or if treated water is to supply a geothermal heat pump, swimming pool, etc.

2) For system to operate properly, pumping rate of well pump MUST be suffi cient to backwash unit at rate specifi ed.

5-1

Page 16

COMPONENT PARTS LIST

Ref No. Description

1 Control Valve w/cover, l/Bypass N200500 N200500 N200700

2 Adapter Assy., Flange-Thrd (Incl. Ref. 3) 55640-130 55640-130 55640-130

3 O-ring ORG-234 ORG-234 ORG-234

4 Clamp Assy. 55640-131 55640-131 55640-131

9 Top Screen 13700 13700 13700

10 Media Tank w/Base MTP1044FB MTP1054FB MTP1252FB

11 Media (Various Types) (1.0 CF) (1.5 CF) (2.0 CF)

12 Distributor C37-16-41 C37-16-51 C37-16-51

13 Gravel Underbed 68696-37 68696-37 68686-38

NOTE: When ordering components, always specify model number.

NBW1001 NBW1501 NBW2001

10

1

12

9

2

4

3

11

13

5-2

Page 17

BACKWASH CONTROL

5-3

Page 18

ONLY THOSE PARTS CIRCLED IN DRAWING ON PREVIOUS PAGE AND/OR LISTED BELOW ARE STOCK ITEMS.

ALL OTHERS ARE SPECIAL ORDER, NON-RETURNABLE.

BACKWASH CONTROL PARTS LIST

REF PART NO> DESCRIPTION

60351-00 Power Head Assy., Complete, L/Cover, 110V,60Hz (Incl. Ref. Items 1-27)

A

60351-04 Power Head Assy., Complete, L/Cover, 220V,50Hz (Incl. Ref. Items 1-27)

B 19231X Skipper Wheel Assy. (incl. Ref. Items 4-9)

C 19235X 12-Hour Gear Assy. (Incl. Ref. Items 10-15)

D 14554X Control Valve Body Assy. (Incl. Ref. Items 30-36 E & G)

E 60102-52 Piston Assembly

F 60125 Seal Kit (incl. Ref. items 32& 33)

G 60384X Drain Line Flow Control Assy. (incl. Ref. Items 37-44)

H 10090X Adapter Coupling Assy. (incl. Ref. Items 45-48)

60049/18706X 1" NPT Bypass Valve Assy. (incl. Ref. Items 49-58)

J

60049/18706-10X 1" BSP Bypass Valve Assy. (incl. Ref. Items 49-58)

19170 Motor, 110V, 60 Hz

23

18825 Motor, 220V,50Hz

24 11384 Motor Mtg. & Ground Screw

19171 Main Drive Gear

27

28 13547 Strain Relief - Flat Cord

29 11842 Power Cord, 110V,60Hz, US Plug

12972 Power Cord, 220V,50Hz, European Plug

35 13304 Distributor Tube O-Ring 1"

36 12281 Tank O-Ring

37 13303 Injector Cover O-Ring

38 13301 Injector O-Ring

39 13163 Injector/Drain Housing

40 13166 Injector Cover

41 13315 Injector Mtg. Screw

Drain Line Flow Control Button:

42

12092 5.0 GPM

12408 7.0 GPM

43 13173 Drain Line Flow Control Button Retainer

44 12338 Drain Line Fitting

45 13305 Coupling O-Ring

46 13709 Adapter Coupling

47 13255 Adapter Clip

48 13314 Screw - Adapter Coupling

49 18660 O-ring

50 18661 O-ring (ORG-218)

18706 Adapter Yoke, 1" NPT

51

18706-10X Adapter Yoke, 1" BSP

5-4

Page 19

Page 20

LIMITED WARRANTY

For any warranty questions, please refer to the enclosed warranty card or call 1-800-222-7880 or mail your request to:

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450

© 2009 3M Company. All rights reserved.

3M is a trademark of 3M Company.

INSTR4333 0709

CUNO Incorporated

400 Research Parkway

Meriden, CT 06450, USA

Toll Free: 1.888.218.CUNO

Worldwide: 203.237.5541

Fax: 203.238.8701

www.cunofoodservice.com

Loading...

Loading...