3M 7000124660 User Manual

Instructions and Parts List

Back

Important Safety

Information

™

3M-Matic

200a3 Type 40800

Adjustable

Case Sealer

with

BEFORE INSTALLING

OR OPERATING THIS

EQUIPMENT

Read, understand, and

follow all safety and

operating instructions.

Spare Parts

It is recommended you

AccuGlide 3

Taping Heads

Serial No.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

™

For reference, record machine serial number here.

immediately order the

spare parts listed in the

"Spare Parts/Service

Information" section.

These parts are expected

to wear through normal

use, and should be kept

on hand to minimize

production delays.

"3M-Matic"and "AccuGlide" are Trademarks of,

3M St. Paul, MN 55144-1000

Printed in U.S.A.

© 3M 2017 44-0009-2073-4 (D030817-NA)

This instruction manual covers safety aspects,

handling and transport, storage, unpacking,

preparation, installation, operation, adjustments,

maintenance, troubleshooting, repair work and

servicing plus parts list of the 3M-MaticTM 200a3

Adjustable case sealer.

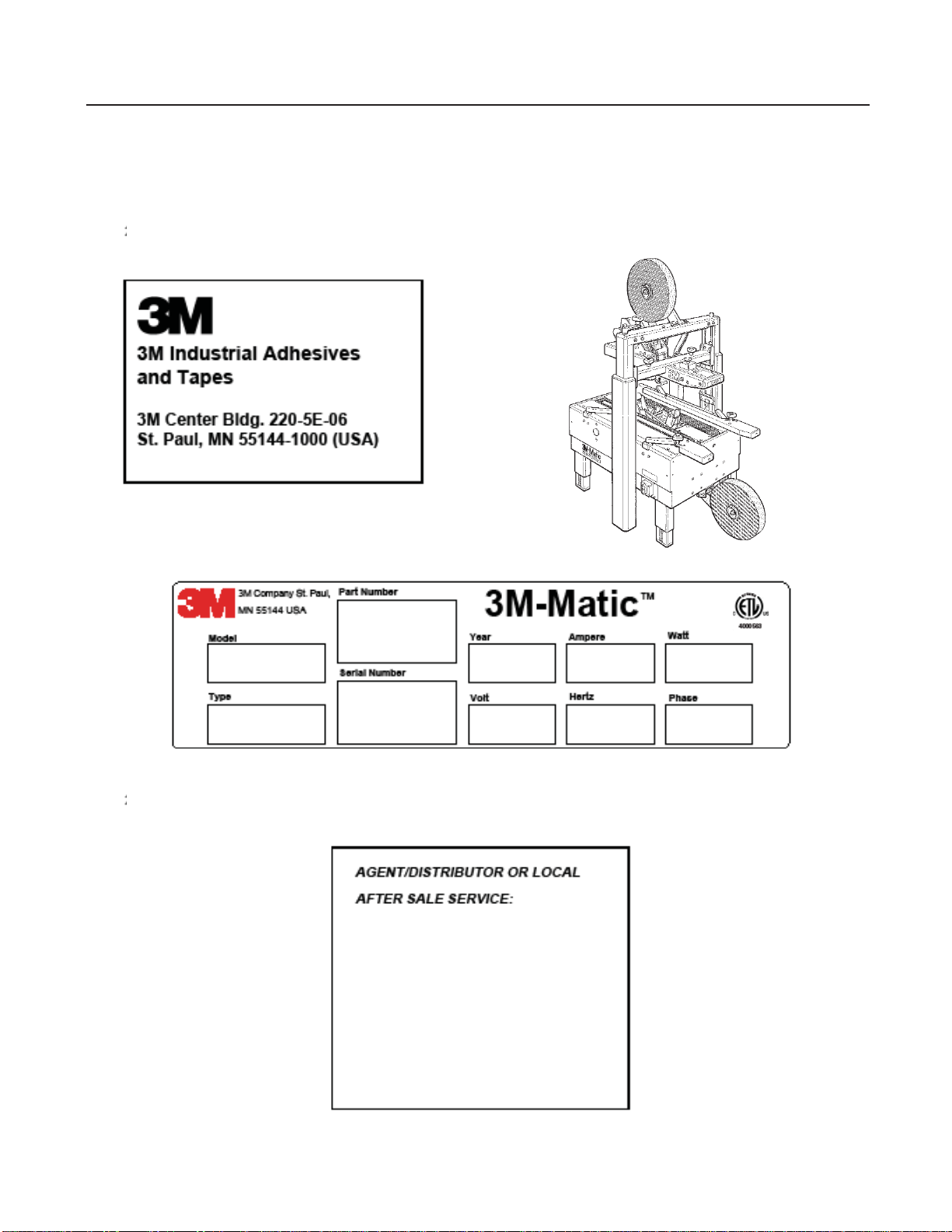

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

Edition June 2011

Copyright 3M 2011

All rights reserved

The manufacturer reserves the right to change

the product at any time without notice.

200a3-NA

2011 June

Replacement Parts and Service Information

To Our Customers:

®

This is the 3M-Matic™/AccuGlide™/Scotch

equipment you ordered. It has been set up and tested in

the factory with Scotch® tapes.

Included with each machine is an Instructions and Parts List manual.

Technical Assistance / Replacement Parts and Additional Manuals:

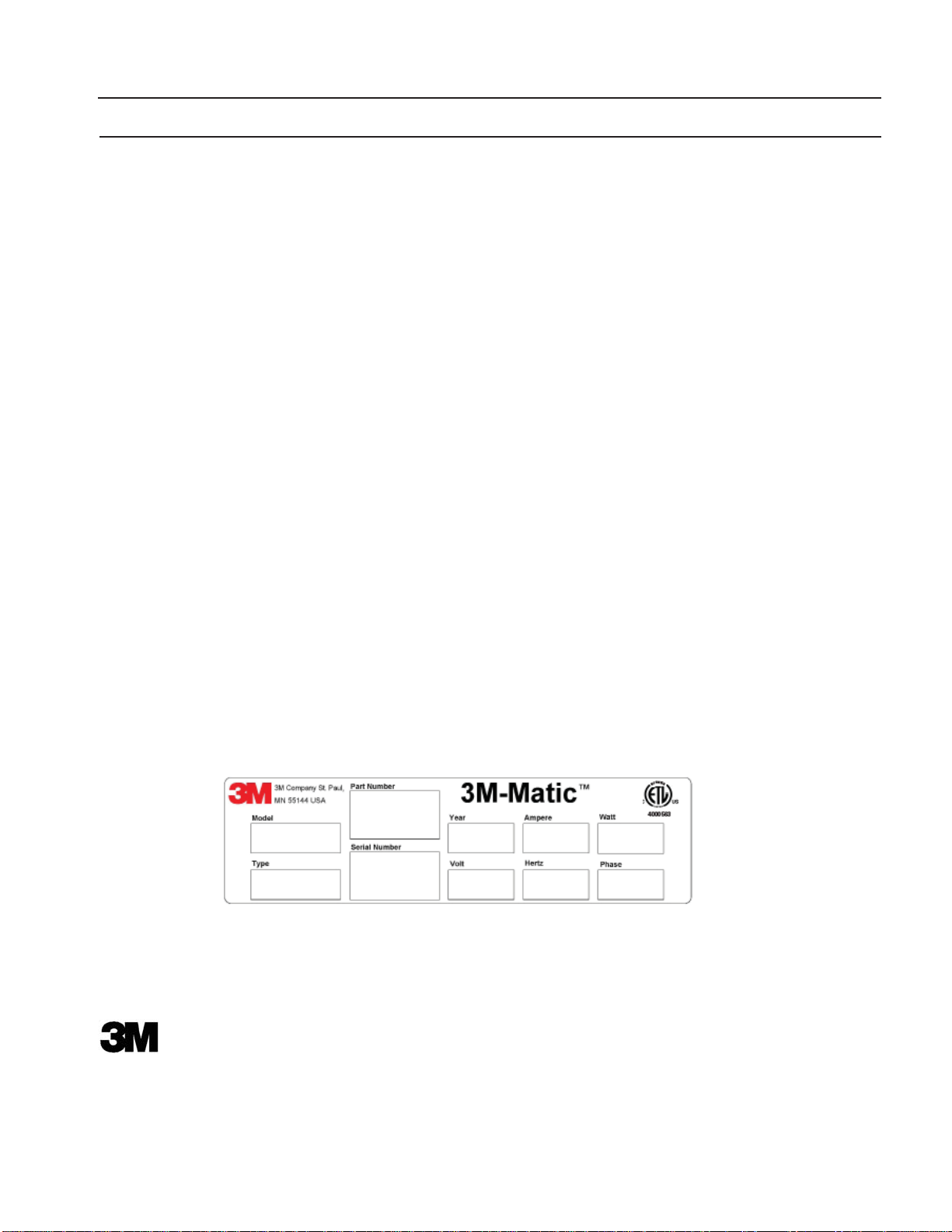

For technical assistance, contact our help line at 1-800-328-1390. Provide the customer support coordinator

with the model/machine name, machine type, and serial number that are located on the identifi cation plate

(For example: Model 200a3 - Type 40800 - Serial Number 13282).

To order replacement parts, contact us:

CSPD division of Combi Packaging Systems LLC.

5365 East Center Dr. N.E.

Canton, OH 44721

Identifi cation Plate

For Commercial Use Only

1-800-344-9883

e-mail: sparepartsCSR@combi.com

www.combi.com

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

3M-Matic™, AccuGlide™ and Scotch™

are Trademarks of

3M St. Paul, MN 55144-1000

Printed in U.S.A.

i

THIS PAGE IS BLANK

TABLE OF CONTENTS - MANUAL 1: 200a3 Adjustable Case Sealer

(For Taping Head Information - See MANUAL 2: AccuGlide™ 3 Taping Heads - 3 inch)

200a3 Adjustable Case Sealer Page

Cover Page

Replacement Parts and Service Information ........................................................................ i - ii

Table of Contents ................................................................................................................. iii - v

Acronyms and Abbreviations ................................................................................................ vi

1. Introduction

1.1 Manufacturing Specifi cations / Description / Intended Use ......................................... 1 - 2

1.2 How to Read and Use the Manual ................................................................................ 2

1.2.1 Importance of the Manual ..................................................................................

1.2.2 Manual Maintenance ......................................................................................... 2

1.2.3 Consulting the Manual ........................................................................................ 2

1.2.4 How to Update the Manual in Case of Modifi cations ........................................... 2

2. General Information

2.1 Identifi cation Data ......................................................................................................... 3

2.2 After-Sale Service ......................................................................................................... 3

2.3 Warranty / Contents ...................................................................................................... 4

2

3. Safety

3.1 General Safety Information ........................................................................................... 5

3.2 Signal Words Explanation ............................................................................................. 5

3.3 Table of Warnings .......................................................................................................... 6 - 7

3.4 Operator’s Qualifi cations Defi nition .............................................................................. 8

3.5 Number of Operators .................................................................................................... 8

3.6 Safe Use of the Machine Instructions ........................................................................... 8

3.7 Residual Hazards .......................................................................................................... 8

3.8 Prevent Other Hazards - Recommendations and Measures ........................................ 8

3.9 Personal Safety Measures ........................................................................................... 8

3.10 Incorrect / Predictable Actions Not Allowed .................................................................. 8

3.11 Operator's Required Skill Levels .................................................................................. 9

3.12 Component Locations .................................................................................................. 10

3.13 Table of Warnings and Replacement Labels ................................................................ 11

4. Technical Specifications

4.1 Power Requirements .................................................................................................... 12

4.2 Operating Rate

4.3 Operating Conditions .................................................................................................... 12

4.4 Tape .............................................................................................................................. 12

4.5 Tape Width .................................................................................................................... 12

4.6 Tape Roll Diameter ....................................................................................................... 13

4.7 Tape Application Leg Length - Standard .......................................................................13

Tape Application Leg Length - Optional

4.8 Box Board ..................................................................................................................... 13

4.9 Box Weight and Size Capacities ................................................................................... 13

4.10 Machine Dimensions ..................................................................................................... 14

4.11 Machine Noise Levels ................................................................................................... 14

4.12 Set-Up Recommendations ............................................................................................ 14

............................................................................................................. 12

200a3-NA

iii

2011 June

THIS PAGE IS BLANK

6

TABLE OF CONTENTS (continued)

5. Shipment, Handling, and Storage

5.1 Packed Machine Shipment and Handling ........................................................................... 15

5.2 Overseas Shipment Packaging (Optional) .......................................................................... 15

5.3 Handling and Transportation of Uncrated Machine ............................................................. 15

5.4 Machine Storage ................................................................................................................. 15

6. Unpacking

6.1 Uncrating ............................................................................................................................. 16

6.2 Packaging Materials Disposal ............................................................................................. 16

7. Installation

7.1 Operating Conditions .......................................................................................................... 17

7.2 Space Requirements for Machine Operation and Maintenance ......................................... 17

7.3 Tool Kit Supplied with the Machine ..................................................................................... 17

7.4 Machine Positioning ............................................................................................................ 17

7.5 Plastic Ties Removal ........................................................................................................... 18

7.6 Assembly Completion .......................................................................................................... 18

7.7 Taping Heads Completion ................................................................................................... 19

7.8 Outboard Tape Roll Holder ................................................................................................. 19

7.9 Preliminary Electric Inspection ............................................................................................ 19

7.10 Main Power Machine Connection and Inspection .............................................................. 19

7.11 Phases Inspection ............................................................................................................... 19

8. Theory of Operation

8.1 Working Cycle Description .................................................................................................. 20

8.2 Running Mode Defi nition ..................................................................................................... 20

8.3.1 Normal Stop Procedure .............................................................................................20

8.3.2 Emergency Stop ....................................................................................................... 20

9. Controls

9.1 Box Width Adjusting Knobs ................................................................................................. 21

9.2 Box Height Adjusting Crank ................................................................................................ 21

9.3 Start / Stop Main Switch ....................................................................................................... 21

9.4 Emergency Stop Button (Latching) ..................................................................................... 21

10. Safety devices

10.1 Blade Guards ..................................................................................................................... 22

10.2 Emergency Stop Button ..................................................................................................... 22

10.3 Electric System ................................................................................................................... 22

11. Set-Up and Adjustments

11.1 Box Width Adjustment ........................................................................................................ 23

11.2 Box Height Adjustment ....................................................................................................... 23

11.3

11.4 Changing the Tape Leg Length .......................................................................................... 23

11.5 Run Boxes to Check Adjustment ........................................................................................ 24

Top Flap Compression Roller Adjustment .......................................................................... 23

200a3-NA

iv

i

2011 June

THIS PAGE IS BLANK

TABLE OF CONTENTS (continued)

12. Operation

12.1 Operator’s Correct Working Position ............................................................................... 25

12.2 Starting the Machine ........................................................................................................ 25

12.3 Starting Production .......................................................................................................... 25

12.4 Tape Replacement ........................................................................................................... 25

12.5 Box Size Adjustment ........................................................................................................ 25

12.6 Cleaning ...........................................................................................................................25

12.7 Table of Adjustments ........................................................................................................25

12.8 Safety Devices Inspection ............................................................................................... 25

12.9 Trouble Shooting ............................................................................................................. 26 - 28

13. Maintenance

13.1 Safety Measures (see section 3) ..................................................................................... 29

13.2 Tools and Spare Parts Supplied with Machine ................................................................ 29

13.3 Maintenance Operations - Recommended Inspections and Frequency ........................... 29

13.4 Inspections to be Performed Before and After Every Maintenance Operation ................. 29

13.5 Safety Features (Inspection Effi ciency) ........................................................................... 29

13.6 Machine Cleaning ............................................................................................................ 29

13.7 Blade Cleaning ................................................................................................................ 29

13.8 Drive Belt Replacement ................................................................................................... 30

13.9 Drive Pulley Ring ............................................................................................................. 31

13.10 Drive Belt Tension ............................................................................................................ 31 - 32

13.11 Maintenance Work Log .................................................................................................... 33

14. Additional Instructions

14.1 Machine Disposal Information ......................................................................................... 35

14.2 Fire emergency ................................................................................................................ 35

15. Enclosures and Special Information

15.1 Statement of Conformity .................................................................................................. 35

15.2 Hazardous Substances Emission .................................................................................... 35

16. Technical Documentation and Information

16.1 Electric Diagrams ............................................................................................................. 37

16.2 Spare Parts / Ordering ..................................................................................................... 39 - 41

Drawings and Parts Lists ......................................................................................................... 43 - End of Manual

TAPING HEAD INFORMATION MANUAL 2: AccuGlide™ 3 Taping Heads - 3 inch (See MANUAL 2 for Table of Contents)

200a3-NA

9

v

2011 June

ABBREVIATIONS AND ACRONYMS

LIST OF ABBREVIATIONS, ACRONYMS

3M-Matic - Trademark of 3M St. Paul, MN 55144- 1000

AccuGlide - Trademark of 3M St. Paul, MN 55144-1000

Scotch - Trademark of 3M St. Paul, MN 55144-1000

Drw. - drawing

Ex. - for example

Fig. - exploded view fi gure no. (spare parts)

Figure - Illustration

Max. - maximum

Min. - minimum

Nr. - number

N/A - not applicable

OFF - machine not operating

ON - machine operating

PLC - Programmable Logic Control

PP - Polypropylene

PU/PU Foam - Polyurethane Foam

PTFE - Polytetrafl ourethelene

PVC - Poly-vinyl chloride

W - Width

H - Height

L - Length

200a3-NA

vi

2011 June

1-INTRODUCTION

1.1 Manufacturing Specifications / Description / Intended Use

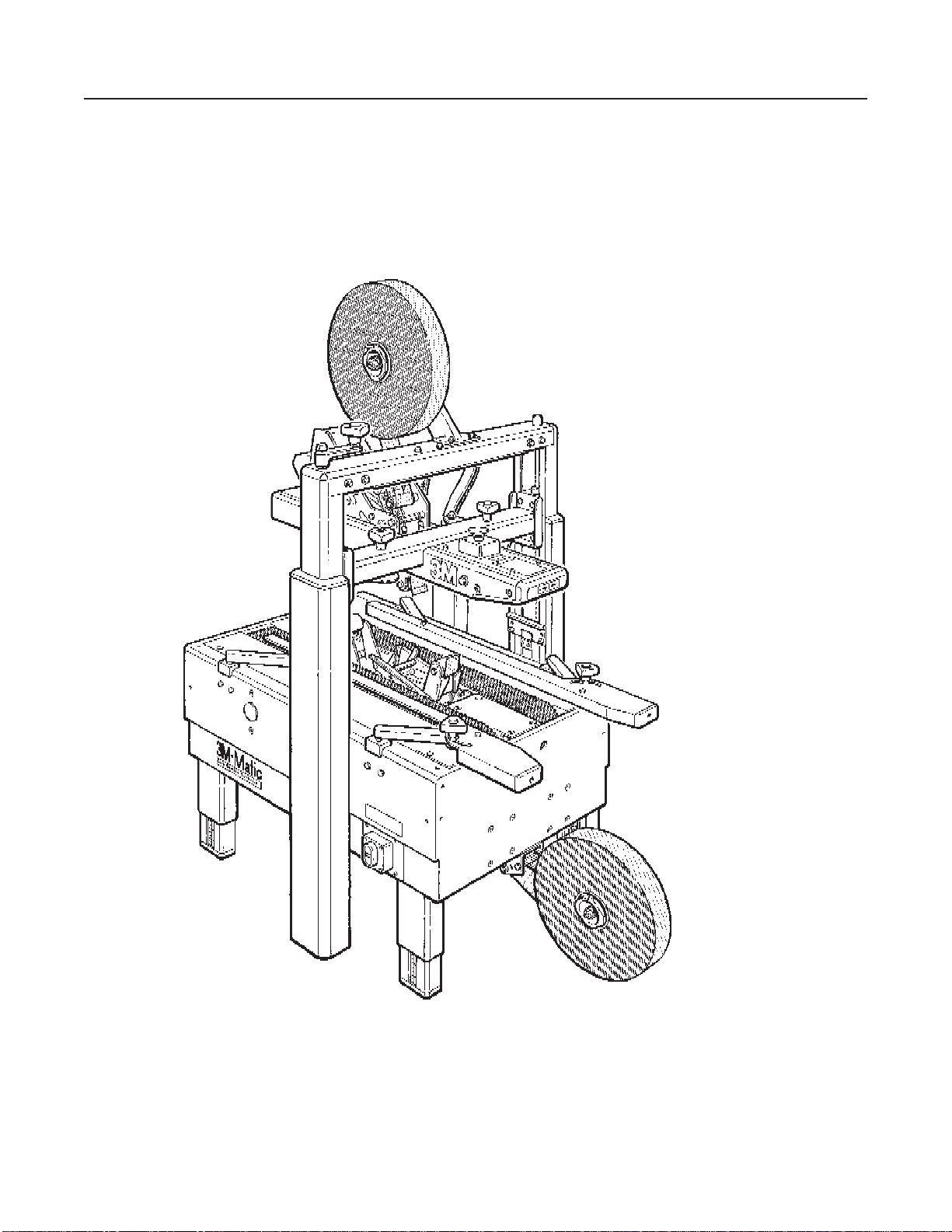

The 3M-MaticTM 200a3 Adjustable Case Sealer with AccuGlideTM 3 Taping Heads is designed to apply a “C”

®

clip of Scotch

pressure-sensitive fi lm box sealing tape to the top and bottom center seam of regular slotted

containers. The 200a3 is manually adjustable to a wide range of box sizes (see "Specifi cations Section – Box

Weight and Size Capacities").

TM

3M-Matic

200a3 Adjustable Case Sealer, Type 40800

Note – Shown above is the lower tape supply roll and bracket assembly in the alternate location.

200a3-NA

1

2011 June

1-INTRODUCTION (continued)

1.1 Manufacturing Specifications / Description /

Intended Use (continued)

The 3M-MaticTM case sealing machines have been

designed in compliance with the legal

requirements at the date of inception.

1.2 How to Read and Use the Instruction Manual

This instruction manual covers safety aspects,

handling and transport, storage, unpacking, preparation, installation, operation, set-up and adjustments,

technical and manufacturing specifi cations, mainte-

nance, troubleshooting, repair work and servicing,

electric diagrams, warranty information, disposal

(ELV), a defi nition of symbols, plus a parts list of the

3M-MaticTM 200a3 Adjustable case sealer 3M Industrial Adhesives and Tapes Division 3M Center, Bldg.

220-5E-06 St. Paul, MN 55144-1000 (USA) Edition

June 2011 Copyright 3M 2011 All rights reserved

The manufacturer reserves the right to change the

product at any time without notice Publication © 3M

2011 44-0009-2073-4.

1.2.2 Manual Maintenance

Keep the manual in a clean and dry place near the

machine. Do not remove, tear, or rewrite parts of

the manual for any reason. Use the manual without

damaging it. In case the manual has been lost or

damaged, ask your after sale service for a new copy.

1.2.3 Consulting the Manual

The manual is composed of:

- Pages which identify the document and the machine

- Index of the subjects

- Instructions and notes on the machine

- Enclosures, drawings and diagrams

- Spare parts (last section)

All pages and diagrams are numbered. The spare

parts lists are identifi ed by the fi gure identifi cation

number. All the notes on safety measures or

possible dangers are identifi ed by the symbol:

1.2.1 Importance of the Manual

The manual is an important part of the machine; all

information contained herein is intended to enable

the equipment to be maintained in perfect condition

and operated safely. Ensure that the manual is available to all operators of this equipment and is kept

up to date with all subsequent amendments. Should

the equipment be sold or disposed of, please ensure

that the manual is passed on. Electrical and pneumatic diagrams are included in the manual. Equipment using PLC controls and/or electronic components will include relevant schematics or programs in

the enclosure and in addition, the relevant documentation will be delivered separately.

1.2.4 How to Update the Manual in Case of

Modifications to the Machine

Modifi cations to the machine are subject to manu-

facturer’s internal procedures. The user receives a

complete and up-to-date copy of the manual together with the machine. Afterwards the user may

receive pages or parts of the manual which contain

amendments or improvements made after its fi rst

publication. The user must use them to update this

manual.

200a3-NA

2

2011 June

2-GENERAL INFORMATION

2.1 Data Identifying Manufacturer and Machine

2.2 Data for Technical Assistance and Service

For Commercial Use Only

200a3-NA

3

2011 June

2-GENERAL INFORMATION (continued)

2.3 Warranty

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, A CUSTOM OR

USAGE OF TRADE:

™

3M sells its 3M-Matic

200a3 Adjustable Case Sealer, Type 40800 with the following warranties:

1. The drive belts and the taping head knives, springs and rollers will be free from all defects for ninety (90)

days after delivery.

2. All other taping head parts will be free from all defects for three (3) years after delivery.

3. All other parts will be free from all defects for two (2) years after delivery.

If any part is proved to be defective within its warranty period, then the exclusive remedy and 3M’s and seller’s

sole obligation shall be, at 3M’s option, to repair or replace the part, provided the defective part is returned

immediately to 3M’s factory or an authorized service station designated by 3M. A part will be presumed to have

become defective after its warranty period unless the part is received or 3M is notifi ed of the problem no later than

fi ve (5) calendar days after the warranty period. If 3M is unable to repair or replace the part within a reasonable

time, then 3M at its option, will replace the equipment or refund the purchase price. 3M shall have no obligation

to provide or pay for the labor required to install the repaired or replacement part. 3M shall have no obligation

to repair or replace (1) those parts failing due to operator misuse, carelessness, or due to any accidental cause

other than equipment failure, or (2) parts failing due to non-lubrication, inadequate cleaning, improper operating

environment, improper utilities or operator error.

Limitation of Liability: 3M and seller shall not be liable for direct, indirect, special, incidental or consequential

damages based upon breach of warranty, breach of contract, negligence, strict liability or any other legal theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by a

written agreement signed by authorized offi cers of 3M and seller.

Contents—200a3 Adjustable Case Sealer

(1) 200a3 Adjustable Case Sealer, Type 40800

(1) Tool and Spare Parts Kit

(1) Instruction and Parts Manual

200a3-NA

4

2011 June

3-SAFETY

3.1 General Safety Information

Read all the instructions carefully before starting

work with the machine; please pay particular attention to sections marked by the symbol:

Figure 3-1

3.2 Explanation of Signal Word and

Possible Consequences

This safety alert symbol identifi es

important messages in this manual.

READ AND UNDERSTAND THEM

BEFORE INSTALLING OR

OPERATING THIS EQUIPMENT.

CAUTION:

WARNING:

Indicates a potentially hazardous

situation, which, if not avoided,

may result in minor or moderate

injury and/or property damage.

Indicates a potentially hazardous

situation, which, if not avoided,

could result in death or serious

injury and/or property damage.

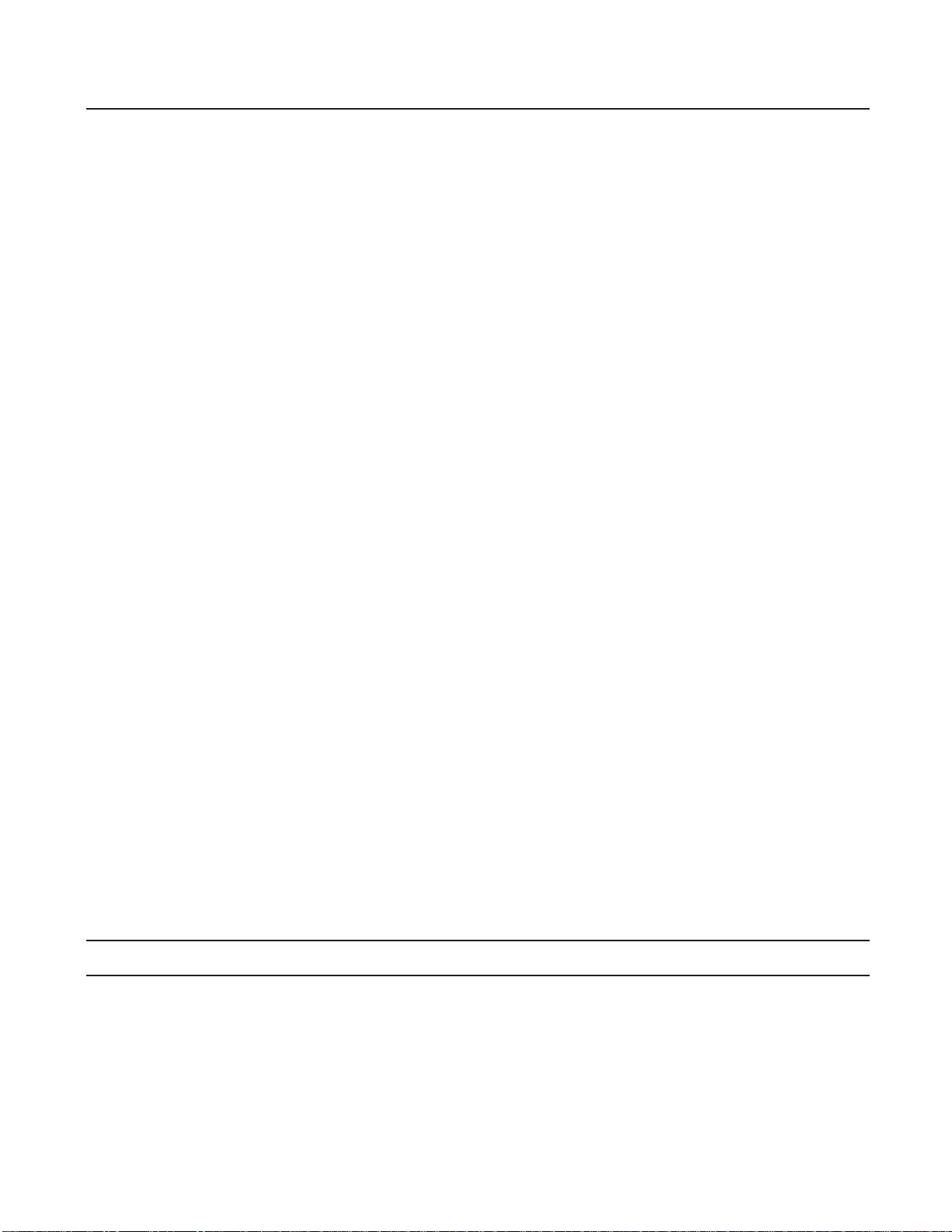

The machine is provided with a LATCHING EMERGENCY STOP BUTTON (Figure 3-1); when this

button is pressed, it stops the machine at any point

in the working cycle. Maintain clear access to power

cord while machine is operating. Disconnect plug

from power source before machine maintenance

(Figure 3-1). Also disconnect air if the machine has

a pneumatic system. Keep this manual in a handy

place near the machine. This manual contains information that will help you to maintain the machine in

a good and safe working condition.

200a3-NA

5

2011 June

3-SAFETY (continued)

3.3 Table of Warnings

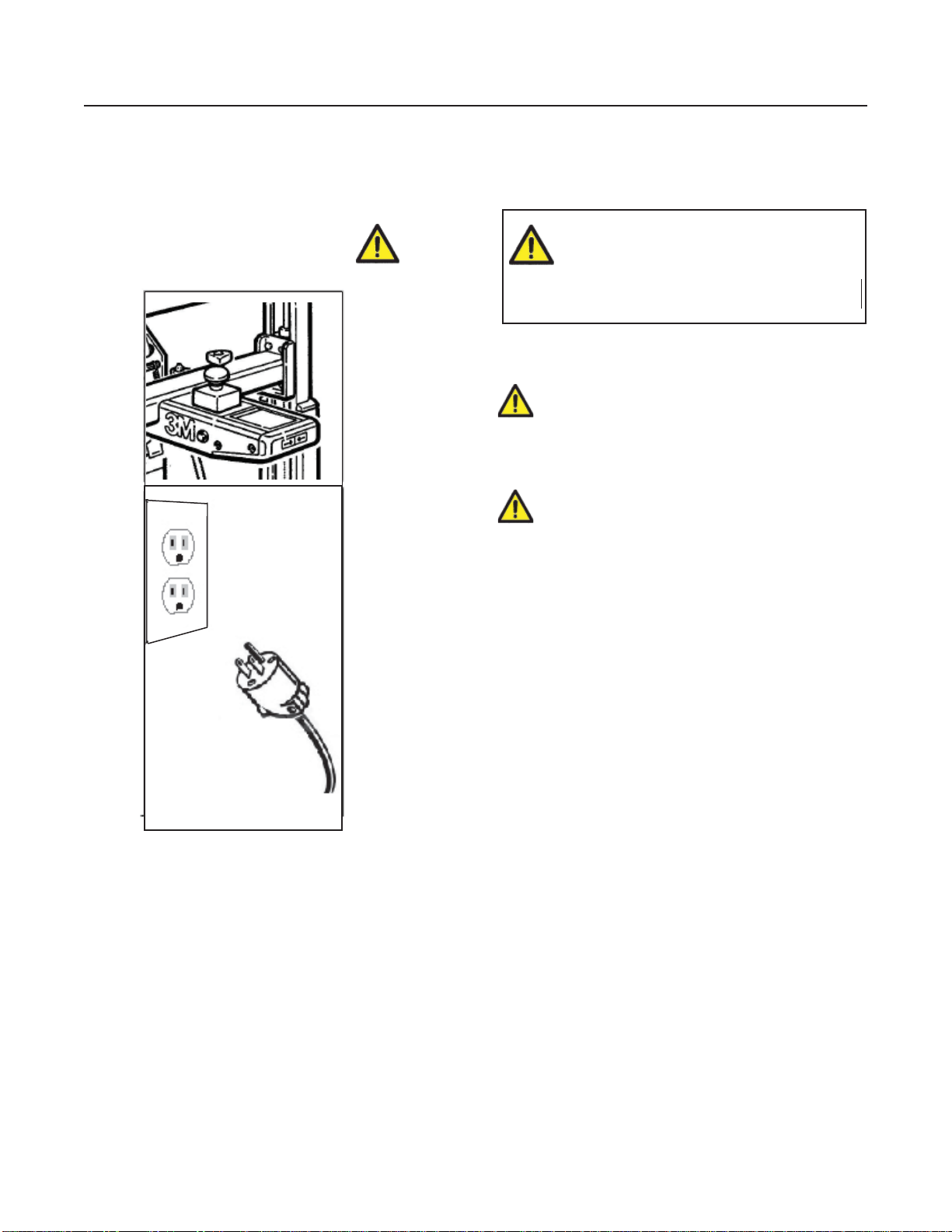

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand, and follow all safety

and operating instructions before operating

or servicing the case sealer.

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

WARNING

• To reduce the risk associated with

hazardous voltage:

− Position electrical cord away from foot

and vehicle traffi c.

Figure 3-2

WARNING

• To reduce the risk associated with

pinches, entanglement and

hazardous voltage:

− Turn electrical supply off and

disconnect before performing any

adjustments, maintenance or servicing

the machine or taping heads.

WARNING

• To reduce the risk associated with

pinches and entanglement hazards:

− Do not leave the machine running

while unattended.

− Turn the machine off when not in use.

− Never attempt to work on any part of

the machine, load tape, or remove

jammed boxes from the machine while

the machine is running.

Figure 3-3

Figure 3-4

200a3-NA

200a-NA

2011 June

3-SAFETY (continued)

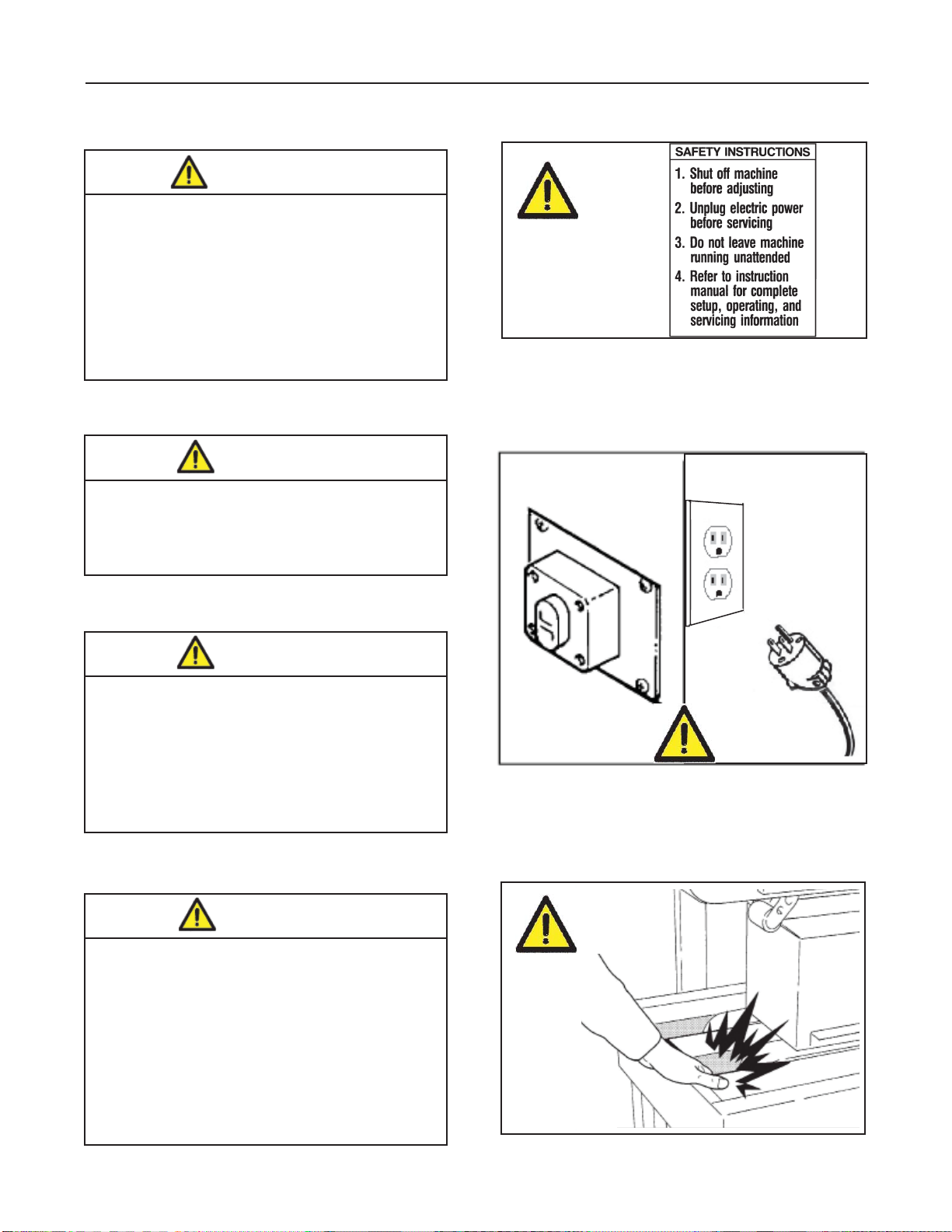

WARNING

• To reduce the risk associated with

sharp blade hazards:

− Keep hands and fi ngers away from

tape cutoff blades under orange blade

guards. The blades are extremely sharp.

Important! Tape cutting blade. Never remove

the safety device which covers the blade on the top

and bottom taping units. Blades are extremely sharp.

Any error may cause serious injuries (Figure 3-5).

WARNING

• To reduce the risk associated with

fire and explosion hazards:

− Do not operate this equipment

in potentially fl ammable/explosive

environments.

Figure 3-5

WARNING

Sharp Blade

WARNING

• To reduce the risk associated with

muscle strain:

− Use the appropriate rigging and

material handling equipment when

lifting or repositioning this equipment.

− Use proper body mechanics when

removing or installing taping heads

that are moderately heavy or may be

considered awkward to lift.

CAUTION

• To reduce the risk associated with

pinch hazards:

− Keep hands clear of the upper head

support assembly as boxes are

transported through the machine.

− Keep hands, hair, loose clothing, and

jewelry away from box compression rollers.

− Always feed boxes into the machine by

pushing only from the end of the box.

− Keep hands, hair, loose clothing, jewelry

away from moving belts and taping heads.

Figure 3-6

Figure 3-7

Figure 3-8

200a3-NA

7

7

2011 June

3-SAFETY (continued)

3.4 Operator's Qualifications

- Machine Operator

- Mechanical Maintenance Technician

- Electrical Maintenance Technician

- Manufacturer’s Technician/Specialist

(See Section 3)

3.5 Number of Operators

The operations described below have been analyzed

by the manufacturer; the recommended number of

operators for each operation provides the best and

safest work performance.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand, and follow all safety

and operating instructions before operating

or servicing the case sealer.

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

3.9 Personal Safety Measures

Note: A smaller or greater number of operators

could be unsafe.

3.6 Instructions for a Safe Use of the Machine /

Definition of Operator's Qualifications

Only persons who have the skills described in the

skill levels section should be allowed to work on the

machine. It is the responsibility of the user to appoint

the operators having the appropriate skill level and

the appropriate training for each category of job.

3.7 Residual Hazards

The case sealer 200a3 incorporates various safety

protections which should never be removed or

disabled. It is essential that the operator and service

personnel be warned that hazards exist which cannot be eliminated.

Safety glasses, safety gloves, safety helmet, safety

shoes, air fi lters, ear muffs - None is required except

when recommended by the user.

3.10 Predictable Actions which are Incorrect and

Not Allowed

- Never try to stop/hold the box while being driven

by the belts.

- Never remove or disable the safety devices.

- Only authorized personnel should be allowed

to carry out the adjustments, repairs or main tenance which require operation with reduced

safety protections. During such operations,

access to the machine must be restricted.

When the work is fi nished, the safety protec-

tions must immediately be reactivated.

- The cleaning and maintenance operations must be

performed after disconnecting the electric power.

- Do not modify the machine or any part of it.

3.8 Recommendations and Measures to Prevent

Other Hazards which Cannot be Eliminated

- The operator must stay on the working position

shown in the Operation Section. He must never

touch the running driving belts or put his hands

inside any cavity.

- The operator must pay attention to the blades

during the tape replacement.

200a3-NA

- Clean the machine using only dry cloths or

light detergents. Do not use solvents, petrols, etc.

- Install the machine following the suggested layouts

and drawings.

2011 June

8

3-SAFETY (continued)

3.11 Operator's Skill Levels Required to Perform

the Main Operations on the Machine

The Table shows the minimum operator's skill for

each machine operation.

Important: The factory manager must ensure that

the operator has been properly trained on all the

machine functions before starting work.

Skill 1: Machine Operator

This operator is trained to use the machine with the

machine controls, to feed cases into the machine,

make adjustments for different case sizes, to change

the tape and to start, stop and restart production.

Skill 2: Mechanical Maintenance Technician

This operator is trained to use the machine as the

MACHINE OPERATOR and in addition is able to:

• Work with the safety protection disconnected

• Check and adjust mechanical parts

• Carry out machine maintenance operations/repairs

He is not allowed to work on live electrical components

Operator's Skill Levels Required to Perform the Main Operations on Machine

Skill 2a: Electrical Maintenance Technician

This operator is trained to use the machine as the

MACHINE OPERATOR and in addition is able to:

• Work with the safety protection disconnected

• Check and adjust mechanical parts

• Carry out machine maintenance operations / repairs / adjustments / repair electrical components

He is allowed to work on live electrical panels,

connector blocks, control equipment, etc.

Skill 3: Specialist from the Manufacturer

Skilled operator sent by the manufacturer or its

agent to perform complex repairs or modifi cations

(on agreement with the customer).

• To reduce the risk associated with

mechanical and electrical hazards:

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

WARNING

Operation Machine Status

Machine installation and setup Running with safety

protections disabled

Adjusting box size

Tape replacement

Blade replacement Electric power

Drive belt replacement Electric power

Ordinary maintenance Electric power

Stopped by pressing the

EMERGENCY STOP

button

Stopped by pressing the

EMERGENCY STOP

button

disconnected

disconnected

disconnected

Required

Operator

Skill

2 and 2a 2

11

11

21

21

21

Number of

Operators

Extraordinary mechanical

maintenance

Extraordinary electrical

maintenance

200a3-NA

Running with safety

protections disabled

Running with safety

protections disabled

9

31

2a 1

2011 June

3-SAFETY (continued)

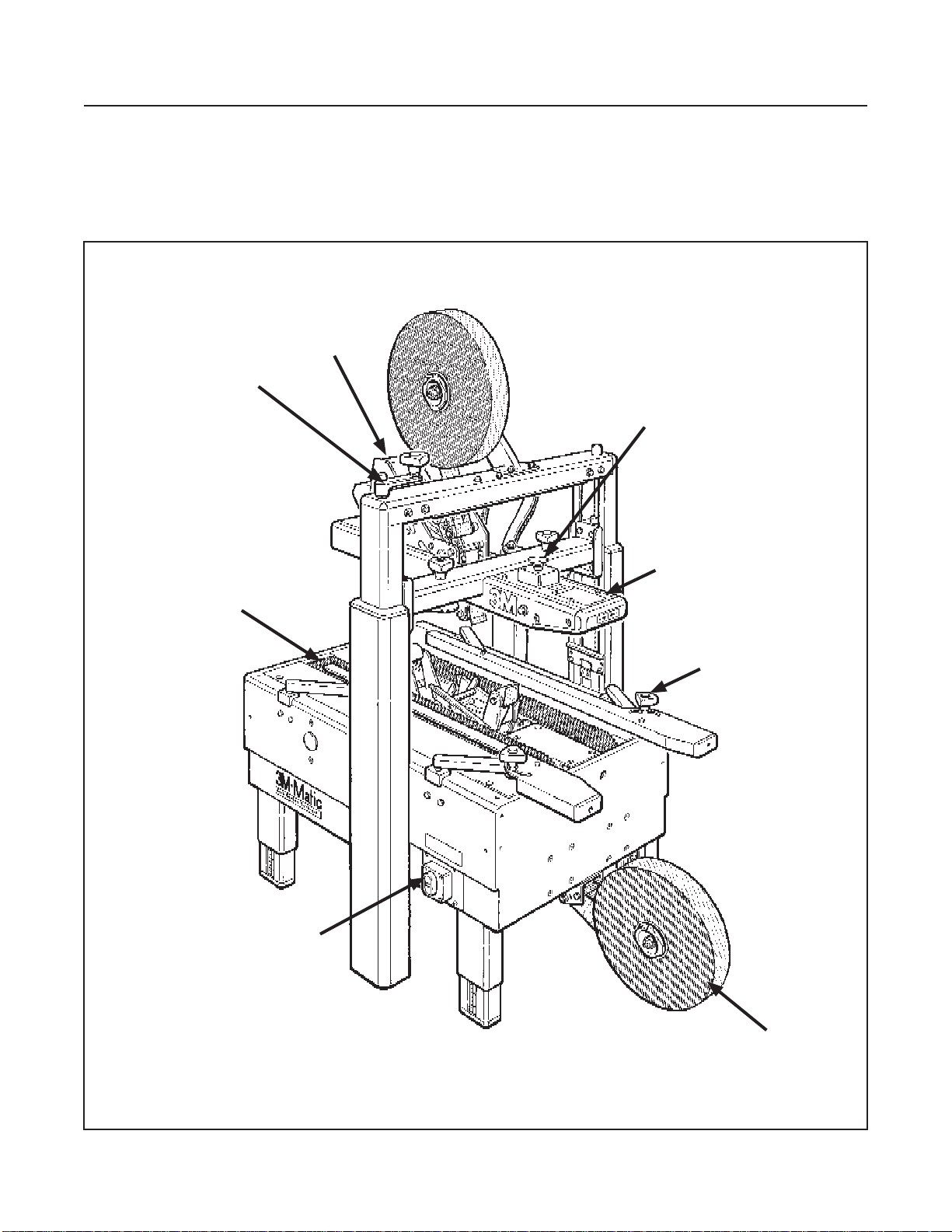

3.12 Component Locations

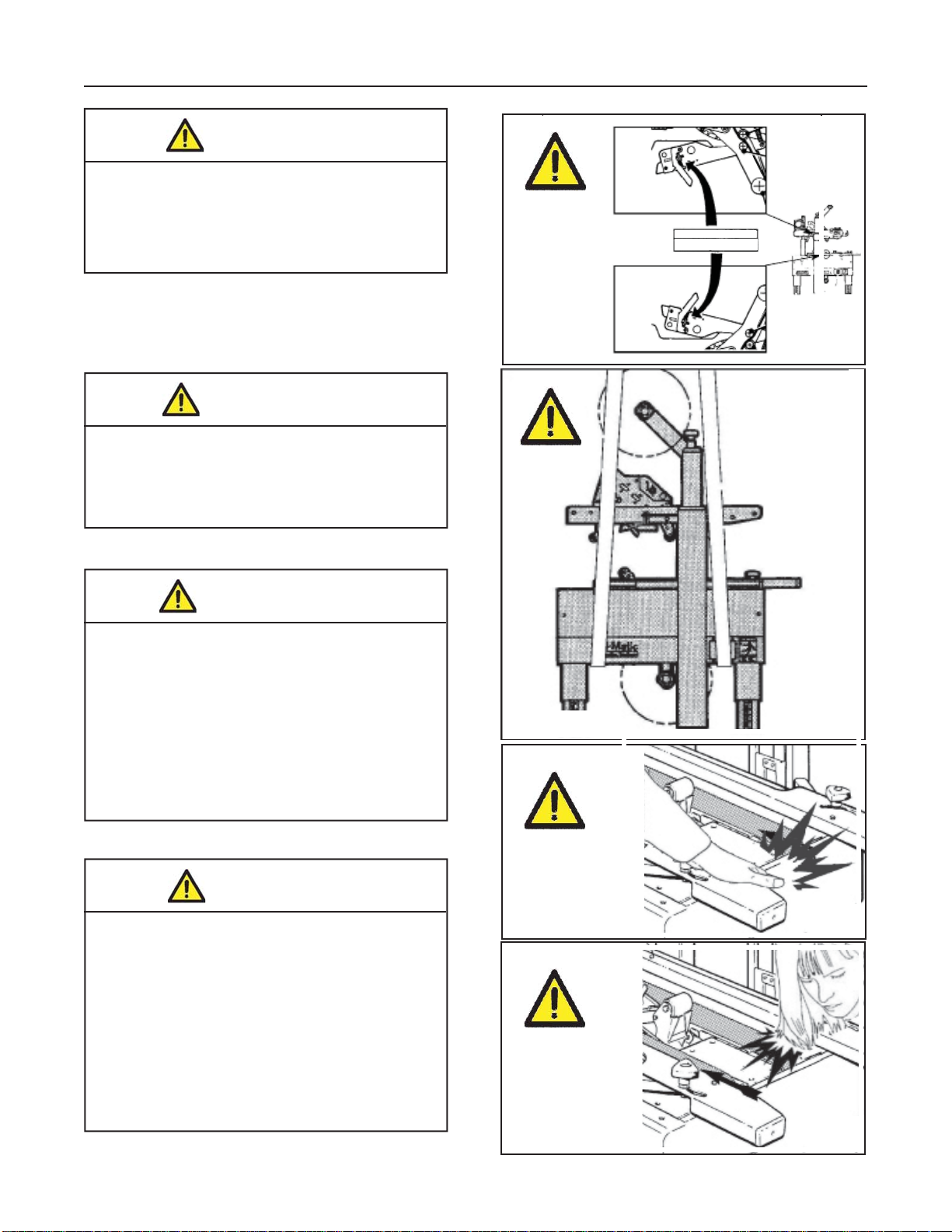

Refer to Figure 3-9 below to acquaint yourself with the various components and controls of the case sealer.

Also refer to Manual 2 for taping head components.

Upper

Taping

Height

Adjustment

Handle

Machine

Bed

Head

Emergency

Stop

Switch

Upper

Head

Assembly

Power

Switch

Assembly

Figure 3-9—200a3 Case Sealer Components (Left Front View)

Adjustable

Side

Guides

Lower Tape

Roll Mount

200a3-NA

10

2011 June

3-SAFETY (continued)

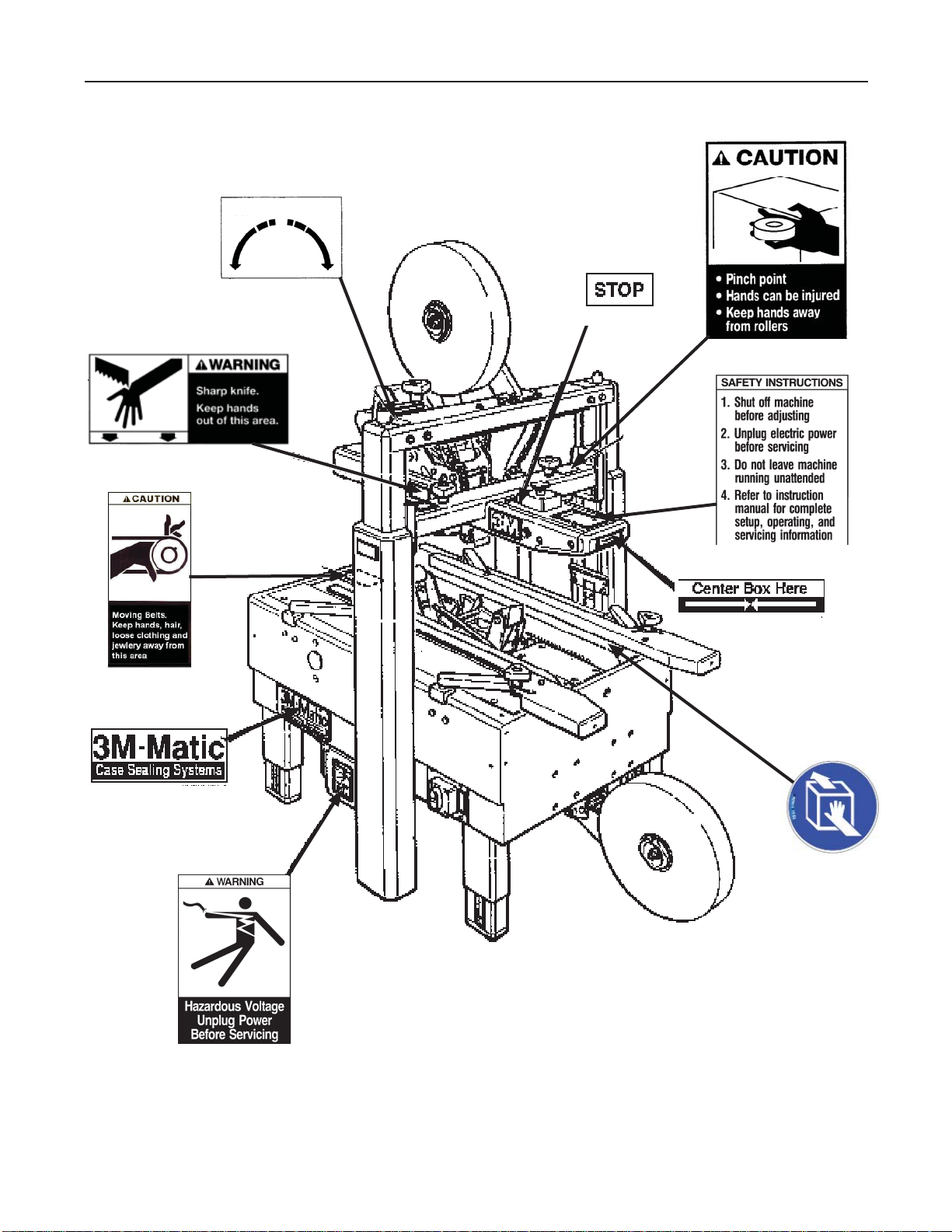

3.13 Table of Warnings and Replacements Labels (continued)

UP DOWN

78-8095-1628-8

78-8070-1336-8

78-8095-1141-9

78-8113-8912-9 (2)

78-8113-6717-2

78-8062-4266-1

78-8070-1366-5

78-8070-1318-6

78-8137-0886-0

78-8060-8481-6

Leg Height Adjustment Label

(not shown)

78-8070-1329-3

Figure 3-10 - Replacement Labels / 3M Part Numbers

200a3-NA

11

78-8070-1339-2

3M Logo

(not shown)

2011 June

4-SPECIFICATIONS

1. Power Requirements

Electrical: 120 Volt, 60Hz, 2 A (240 watts)

The machine is equipped with a 2.4m [8 foot] standard neoprene covered power cord and a grounded plug.

Contact your 3M Representative for power requirements not listed above.

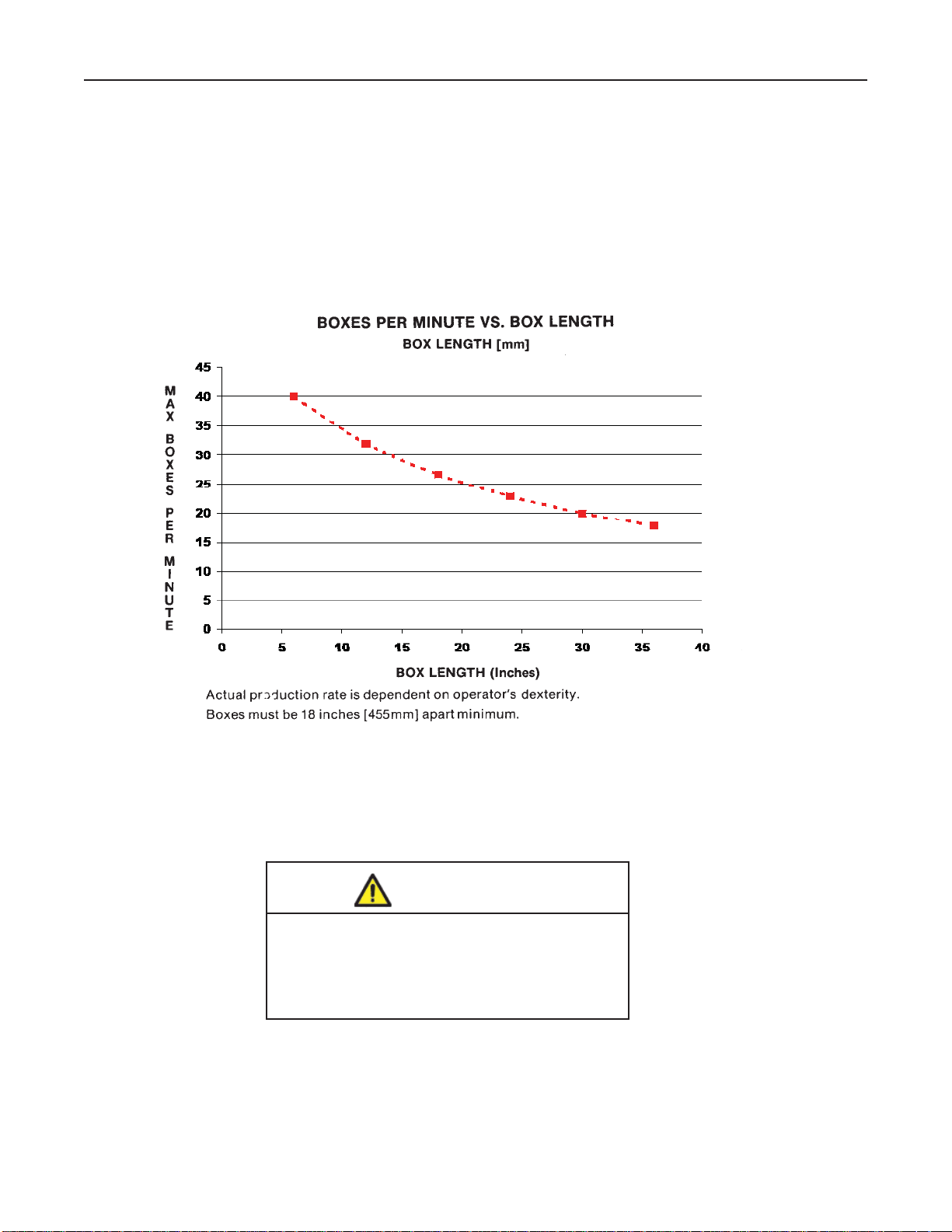

2. Operating Rate

Box drive belt speed is approximately 0.5 m/s [100 feet per minute].

3. Operating Conditions

Use in dry, relatively clean environments at 5o C to 50o C [40o F to 120o F] with clean, dry boxes.

Note: Machine should not be washed or subjected to conditions causing moisture condensation on

components.

IMPORTANT SAFEGUARD

WARNING

• To reduce the risk associated with fire

• To reduce the risk associated

and explosion hazards:

with fire and explosion hazards:

− Do not operate this equipment in poten-

− Do not operate this equipment in poten-

tially fl ammable or explosive environments.

tially fl ammable or explosive environments.

4. Tape

®

Scotch

5. Tape Width

50mm [2 inch] minimum to 75mm [3 inch] maximum

200a3-NA

pressure-sensitive fi lm box sealing tapes.

2011 June

12

4-SPECIFICATIONS (continued)

Specifications

6. Tape Roll Diameter

Up to 405mm [16 inch] maximum on a 76.2mm [3 inch] diameter core.

®

(Accommodates all system roll lengths of Scotch

fi lm tapes.)

7. Tape Application Leg Length – Standard

70 mm ± 6mm [2.75 inch ±. 25 inch ]

Tape Application Leg Length – Optional

50 mm ± 6mm [2 inch ±. 25 inch]

(See "Removing Taping Heads Procedure – Changing the Tape Leg Length")

8. Box Board

Style – regular slotted containers – RSC

125 to 275 P.S.I. bursting test, single wall or double wall B or C fl ute.

23-44 lbs. per inch of width Edge Crush Test (ECT)

9. Box Weight and Size Capacities

A. Box Weight, fi lled: 5 lbs.–65 lbs. [2.3 kg–29.5 kg]. Contents must support fl aps.

B. Box Size: Minimum Maximum

Length – 150mm [6.0 inch] Unlimited

Width – 178mm [7.0 inch]* 550mm [21.5 inch]

Height – 120mm [4.75 inch]** *** 620mm [24.5 inch] ***

* Cartons narrower than 275mm [11 inch] in width may require more frequent belt replacement

because of limited contact area.

** 90mm [3.5 inch] height with heads adjusted to apply 50mm [2 inch] tape leg lengths. (See "Special

Setup Procedure—Changing the Tape Leg Length".)

*** 165mm [6.5 inch] minimum to 725mm [28.5 inch] maximum height with columns adjusted to

upper position. (See "Special Setup Procedure – Box and Machine Bed Height Range".)

Note: The case sealer can accommodate most boxes within the size range listed above. However, if the box

length (in direction of seal) to box height ratio is 0.6 or less, test run several boxes to ensure proper

machine performance.

DETERMINE THE BOX LIMITATIONS BY COMPLETING THIS FORMULA:

BOX LENGTH IN DIRECTION OF SEAL = SHOULD BE GREATER THAN 0.6

BOX HEIGHT

Any box ratio approaching this limitation should be test run to ensure performance.

200a3-NA

13

2011 June

4-SPECIFICATIONS (continued)

Right Side

Left Side

Box Travel

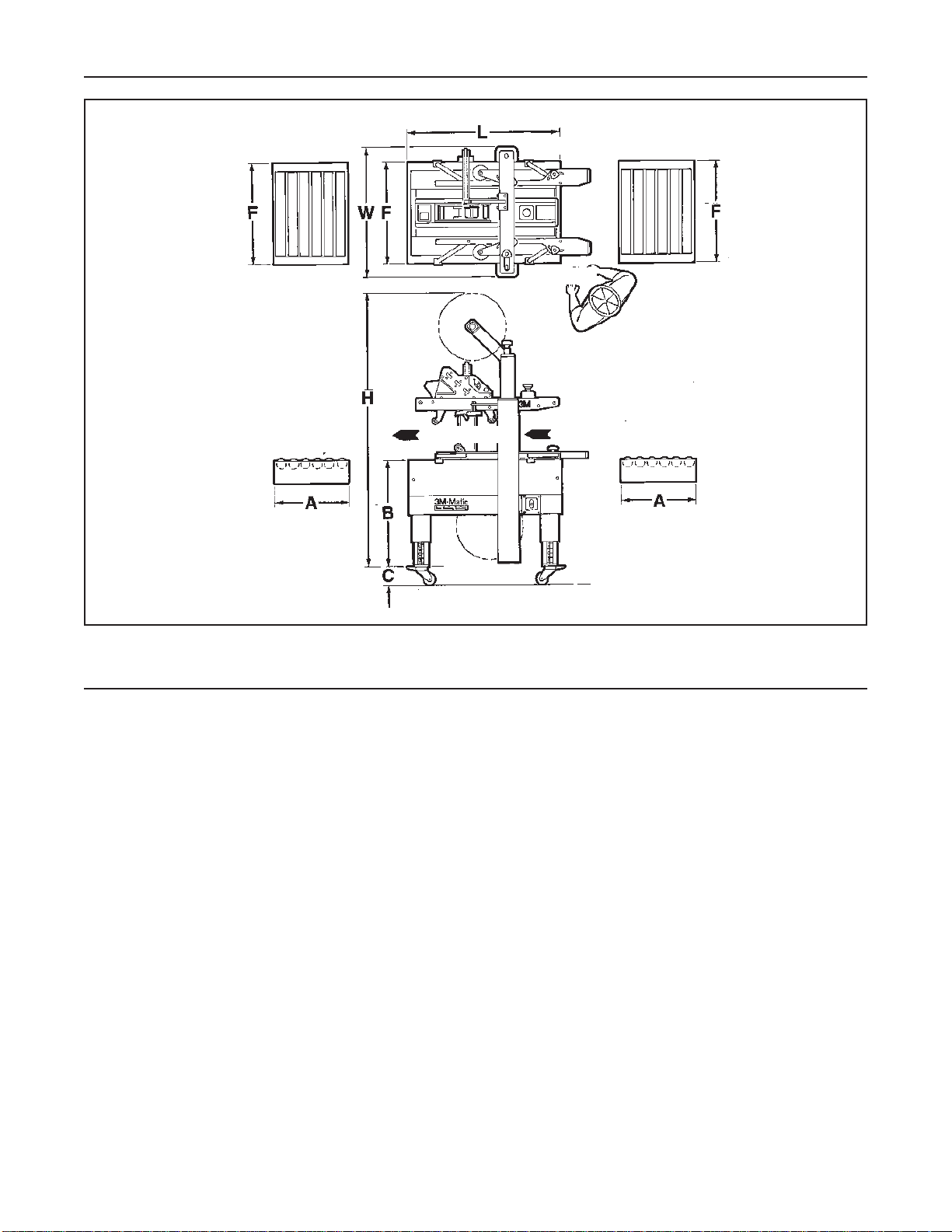

10. Machine Dimensions

W L H A* B C** F

Minimum

mm 790 930 1350 460 610 100 620

[Inches] [31] [36 1/2] [53] [18] [24***] [4] [24 1/2]

Maximum

mm 2185 890

[Inches] - - - - [86***] - - [35***] - - - -

* Infeed/Exit conveyors are optional

** Casters are optional

*** When columns are adjusted to upper position, "B" minimum/maximum dimension decreases by 90 mm

[3 1/2 inches] and "H" maximum dimension increases by 100 mm [4 inch]. (See "Special Set-Up Procedure –

Box and Machine Bed Height Range".)

Weight – 145.6 kg [320 lbs] crated (approximate)

123.4 kg [280 lbs] uncrated (approximate)

11. Machine Noise Level: Acoustic pressure measured at a distance of 1m. from machine with

Scotch PVC adhesive tape in operation; 78dB Acoustic radiation pressure at 1.6m. height with

Scotch PVC adhesive tape in operation; 73dB Measurement taken with appropriate instrument:

(Type SPYRI-MICROPHON 11).

12. Set-Up Recommendations:

• Machine must be level.

• Customer supplied infeed and exit conveyors (if used) should provide straight and level box entry and exit.

• Exit conveyors (powered or gravity) must convey sealed boxes away from machine.

200a3-NA

14

2011 June

5-SHIPMENT-HANDLING-STORAGE, TRANSPORT

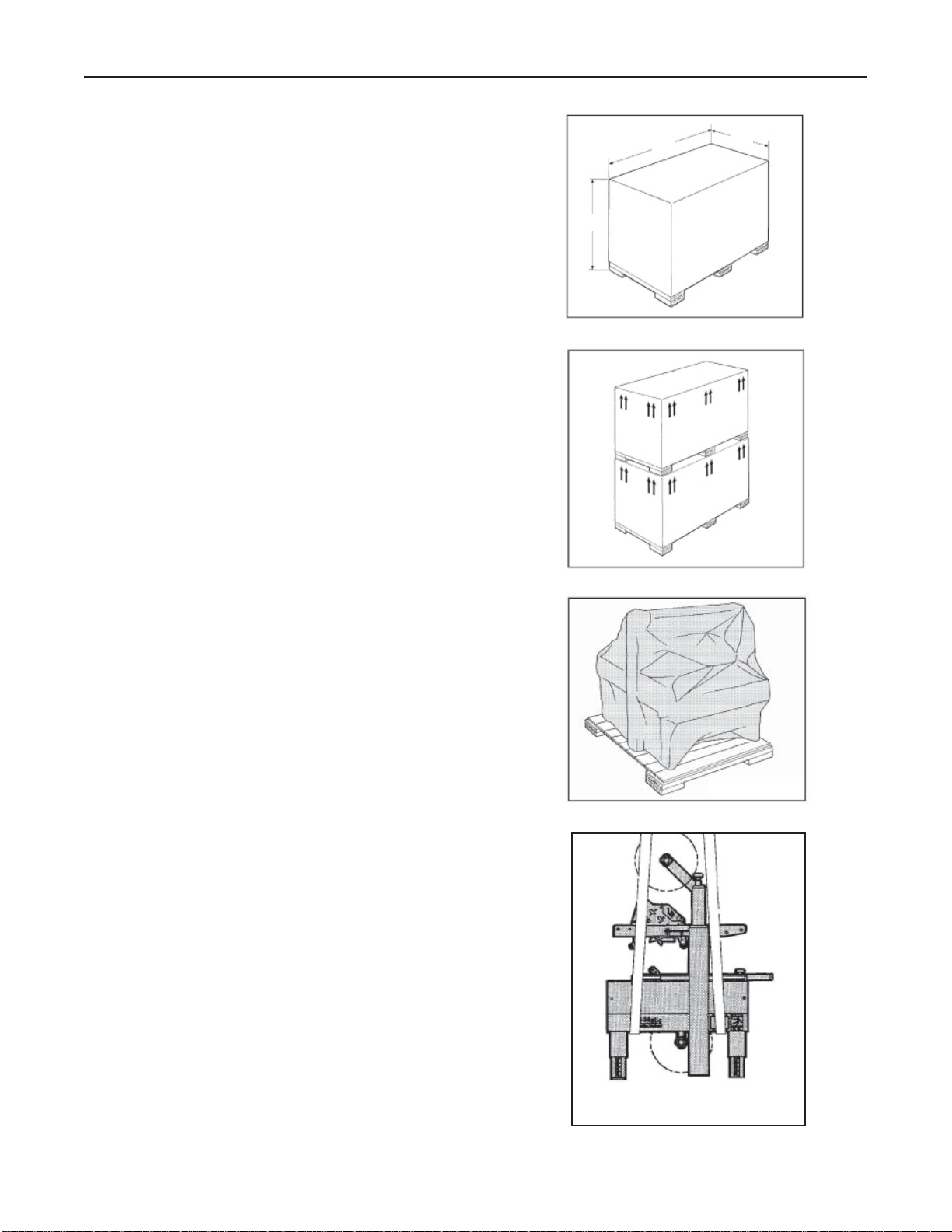

5.1 Shipment and Handling of Packed Machine

- The machine is fi xed on the pallet with four (4) bolts

and can be lifted by using a fork truck.

- The package is suitable to travel by land and by air.

- Optional sea freight package is available.

Packaging Overall Dimensions

(Figure 5-1)

W

L

L

H

H

W

See Specifi cations.

During the shipment it is possible to stack a

maximum of 2 machines (Figure 5-2).

5.2 Packaging for Overseas Shipment

(Optional - Figure 5-3)

The machines shipped by sea freight are covered by

an aluminum/polyester/polythene bag which

contains dehydrating salts.

5.3 Handling and Transportation of Uncrated

Machine

The uncrated machine should not be moved except for

short distances and indoors ONLY. Without the supporting pallet, the machine is exposed to damage and

may cause injuries. To move the machine use belts or

ropes, paying attention to place them in the points indicated using care to not interfere with the lower taping

head (Figure 5-4).

Figure 5-1

Figure 5-2

Figure 5-3

5.4 Storage of the Packed or Unpacked Machine

If the machine is not used for a long period,

please take the following precautions:

- Store the machine in a dry and clean place.

- If the machine is unpacked it is necessary to

protect it from dust.

- Do not stack anything over the machine.

- It is possible to stack a maximum of 2 machines

(if they are in their original packing).

200a3-NA

Figure 5-4

2011 June

15

6-UNPACKING

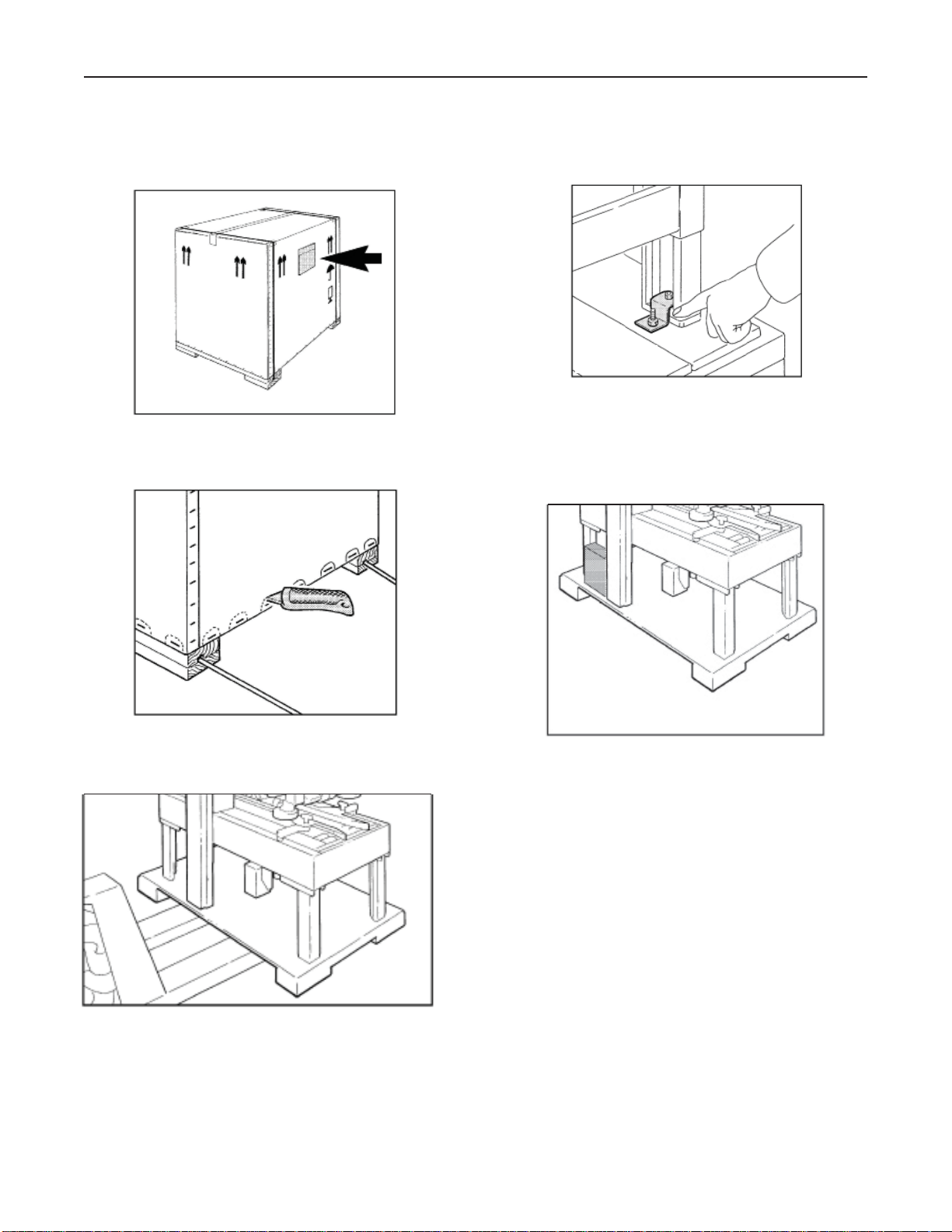

6.1 Uncrating

The envelope attached to the shipping box contains

the uncrating instructions of the machine (Figure 6-1).

Figure 6-1

Cut straps. Cut out staple positions along the bottom

of the shipping box (or remove staples with an

appropriate tool - Figure 6-2)

Removal of Pallet

Loosen and remove nuts and brackets using the

open end spanner supplied in the tool box (Figure 6-4).

Figure 6-4

A cardboard box is located under the machine body.

Retrieve the instruction manual for additional procedures of the set up. The box also contains parts removed for shipping, spare parts and tools (Figure 6-5).

Figure 6-2

After cutting out or removing the staples, lift the

shipping box in order to clear the machine

(two persons required).

Figure 6-3

Transport the machine with a fork-lift truck to the operating position. Lift the pallet at the point indicated in

Figure 6-3 (weight of machine + pallet = See Specifi -

cations).

Figure 6-5

6.2 Disposal of Packaging Materials

The 200a3 package is composed of:

- Wooden pallet

- Cardboard shipping box

- Wooden supports

- Metal fi xing brackets

- PU foam protection

- PP plastic straps

- Dehydrating salts in bag

- Special bag of laminated polyester/aluminium/

Polyethylene (sea freight package only)

- Polyethylene protective material

For the disposal of the above materials, please follow

the environmental directives or the law in your country.

200a3-NA

16

2011 June

7-INSTALLATION

7.1 Operating Conditions

(See Specifi cations).

7.2 Space Requirements for Machine Operation

and Maintenance Work

Minimum distance from wall (Figure 7-1):

A = 1000mm.

B = 700mm.

Minimum height = 2700mm.

Figure 7-2

Figure 7-1

7.3 Tool Kit Supplied with the Machine

A tool kit containing some tools are supplied

with the machine. These tools should be

adequate to set-up the machine, however,

other tools supplied by the customer will be

required for machine maintenance.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

WARNING

• To reduce the risk associated with

muscle strain:

− Use the appropriate rigging and

material handling equipment when

lifting or repositioning this equipment.

− Use proper body mechanics when

removing or installing taping heads

that are moderately heavy or may be

considered awkward to lift.

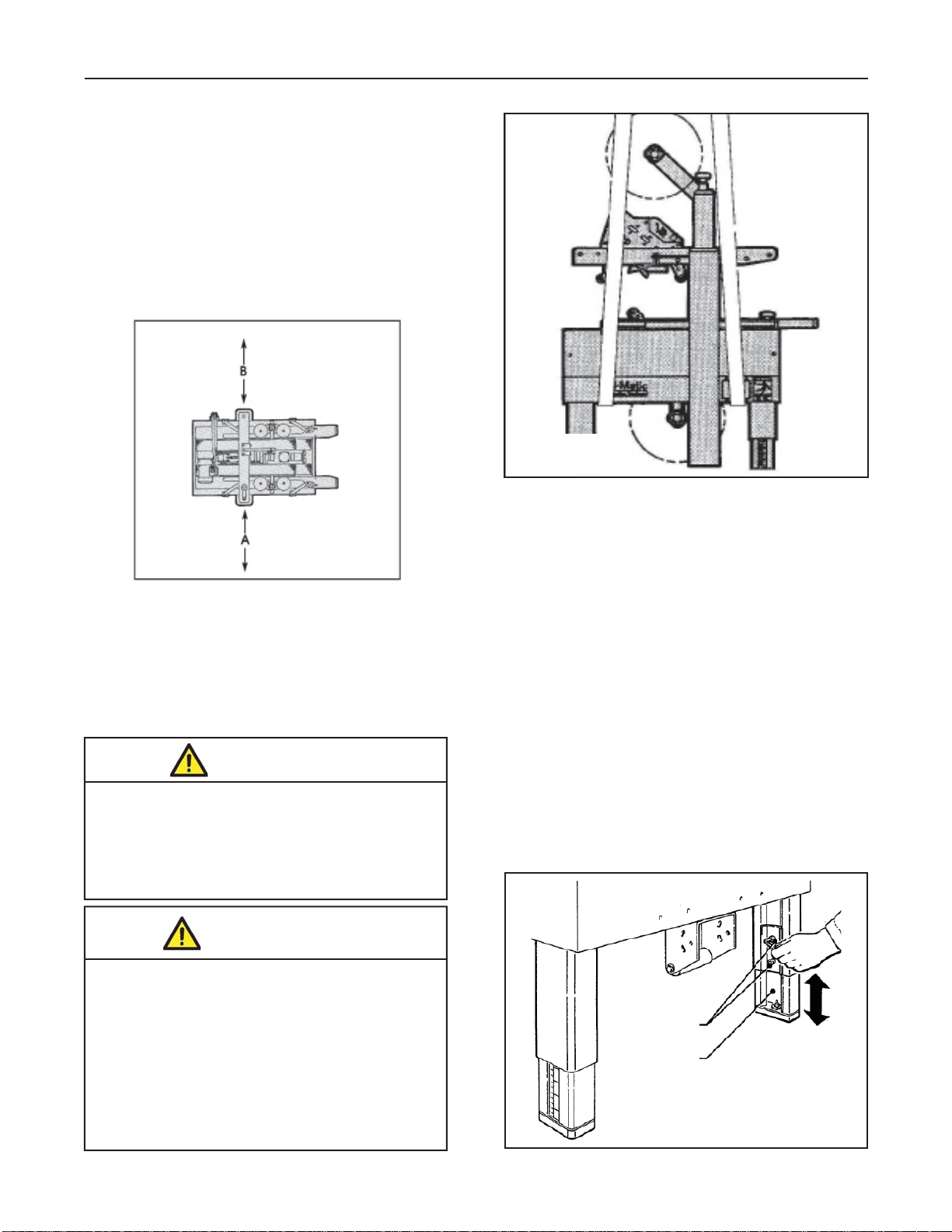

7.4 Machine Set-Up / Bed Height

Adjust machine bed height. The case sealer is

equipped with four (4) adjustable legs that are

located at the corners of the machine frame. The

legs can be adjusted to obtain different machine

bed heights (See Specifi cations).

Refer to Figure 7-3 and set the machine bed height

as follows:

1.

Raise and block up the machine frame to allow

adequate leg adjustment.

2. Loosen, but do not remove, two (2) M8 x 1.25mm

socket head screws in one leg (use M6 hex

wrench). Adjust the leg length for the desired

machine bed height. Retighten the two screws

to secure the leg. Adjust all four (4) legs equally.

M8 x 1.25mm

Socket Head

Screws

Adjustable

Leg

Figure 7-3

200a3-NA

17

2011 June

7-INSTALLATION (continued)

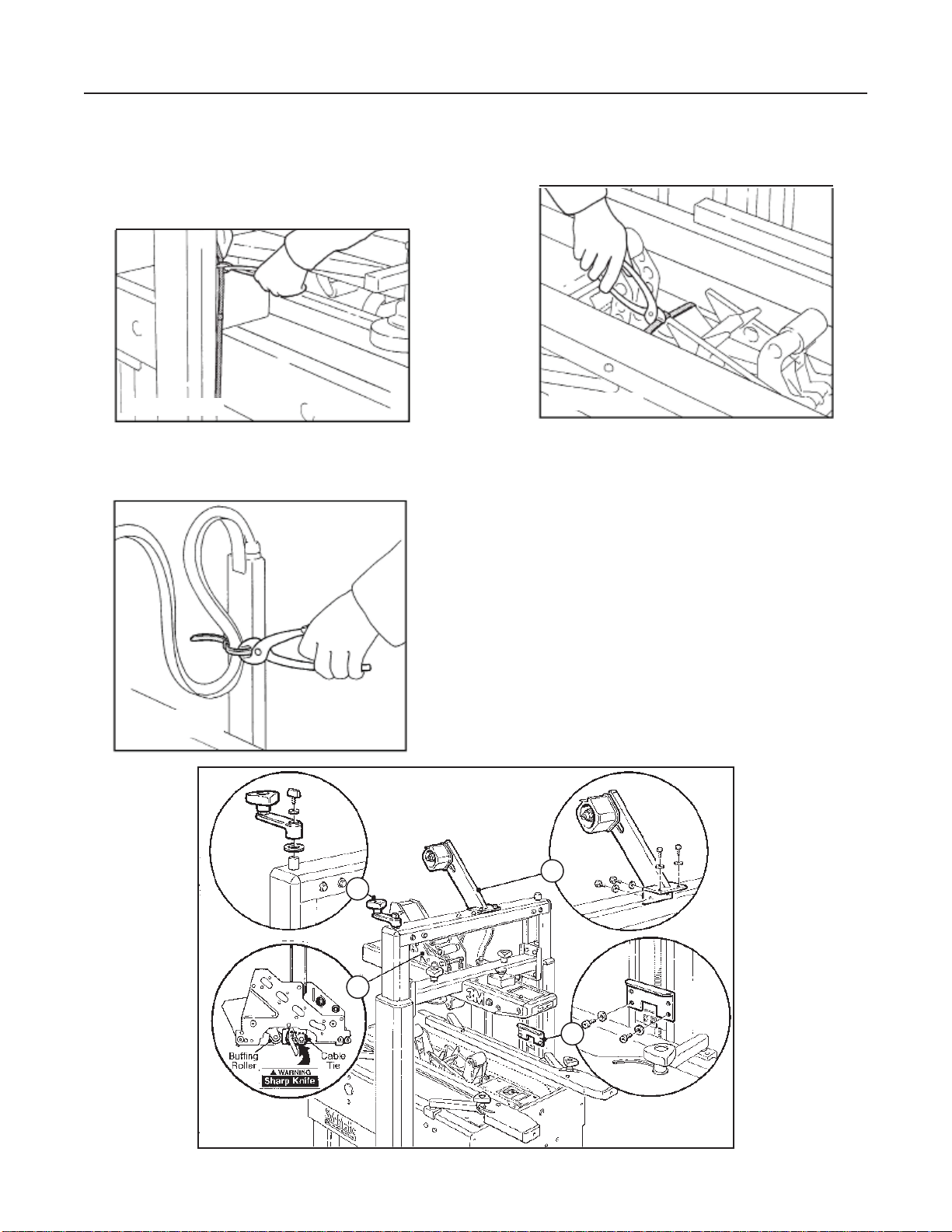

7.5 Removal of Plastic Ties

Cut the plastic which attaches the top head to the

frame and remove the polystyrene blocks (Figure 7-4).

Figure 7-4

Cut the plastic strap which attaches the strip and the

EMERGENCY STOP cable to the frame (Figure 7-5).

Figure 7-5

Cut the plastic ties holding the lower taping head in

position (Figure 7-6).

Figure 7-6

7.6 Assembly Completion

1 Crank - Install the crank handle on the top of

the left column as shown (Figure 7-7B).

2 Tape Drum Bracket - Install the upper tape

drum bracket on the top cross bar as shown

(Figure 7-7A).

3 Stop Bracket - Raise upper head assembly

(turn crank handle counterclockwise) and install

the two stop brackets (provided in the parts

bag). Use lower set of holes as shown in Fig-

ure 7-7D. The upper set of holes should only be

used when both taping heads are adjusted to

apply 50mm tape legs.

200a3-NA

A

B

C

D

Figure 7-7

2011 June

18

7-INSTALLATION (continued)

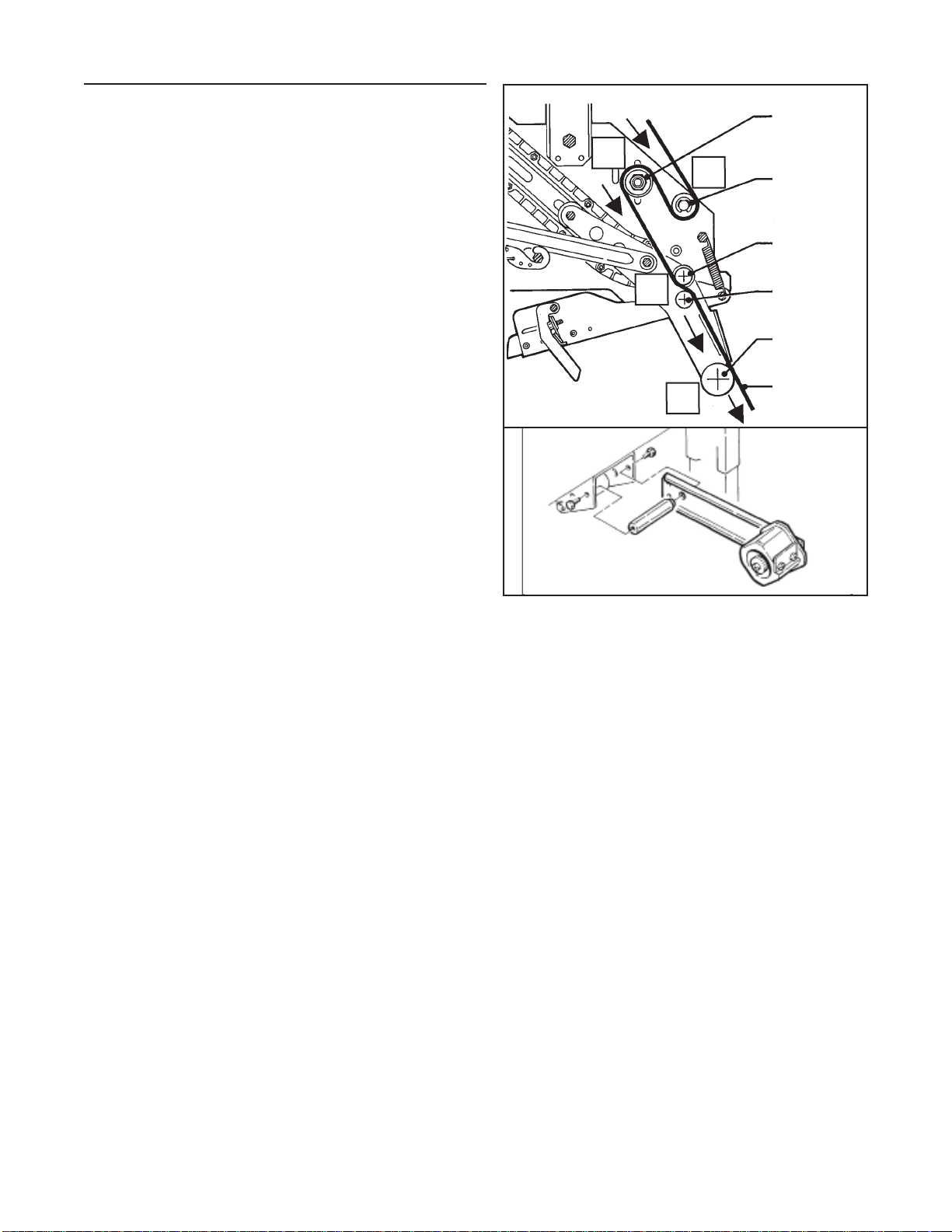

7.7 Completion of Taping Heads

See Manual 2 for Complete Instructions:

1. Place the Upper Taping Head in a convenient

working position

.2. Use Figure 7-8 and tape threading label.

Position the tape supply roll so the adhesive

side of tape is facing the front of the taping head

as it is pulled from the supply roll.

3. Attach the threading needle to the end of the

roll. Guide the threading needle around the wrap

roller (Position 1) then back around the oneway tension roller (Position 2).

4. Continue pulling the threading needle down and

guide it between the two (2) rollers on the apply

arm (Position 3).

5. Pull the threading needle down until the tape

travels between the apply plate and the ears of

the apply arm (Position 4) until it extends past

the applying roller. When properly threaded the

adhesive side of the tape should be facing the

knurled rollers at position 2 and also position 3.

6. Cut away any excess tape and repeat steps for

Lower Taping Head.

Important – Do not cut against the apply roller -

roller damage could occur.

Figure 7-8

Figure 7-9

#2

#3

#4

#1

One Way

Tension

Roller

Tension

Wrap

Roller

Knurled

Roller

Wrap

Roller

Applying

Roller

Threading

Needle

7.8 Outboard Tape Roller Holder

If you intend to use the outboard tape roll holder,

proceed as follows:

1 - Remove the lower taping head from the machine.

2 - Remove the tape drum bracket assembly, stud

spacer, and fasteners from the lower taping head.

3 - Install alternative wrap roller and bracket on the

head in place of tape bracket. Replace lower

head into machine.

4 - Install and secure tape drum bracket assembly

on the entry end of the lower frame (as shown in

Figure 7-9).

7.9 Preliminary Electric Inspection

Before connecting the machine to the mains please

carry out the following operations:

7.9.1 Make sure that the socket is provided with an

earth protection circuit and that both the mains

voltage and the frequency match the specifi -

cations on the name plate.

7.9.2 Check that the connection of the machine

to the mains meets the safety regulations in

your country.

7.9.3 The machine is fi tted with a main switch

and a circuit breaker. The user should check

that the electrical settings of the machine are

compatible with all the components of the

mains system.

7.10 Machine Connection to the Mains

For technical specifi cations: See Section 4 -

Specif cations

- Push the LATCHING EMERGENCY STOP

BUTTON.

- The main switch is normally turned OFF (O).

Connect the power cord supplied with the machine

to a wall socket using a plug which complies with the

safety regulations of your country.

7.11 Inspection of Phases

(For Three-Main Phases Only)

N/A for this machine.

200a3-NA

19

2011 June

8-THEORY OF OPERATION

8.1 Description of the Working Cycle

After having closed the top fl aps of the carton, the

operator pushes it under the top infeed end in order

to avoid the opening of the top fl aps. Further push-

ing causes the two top and bottom belts to drive the

box through the taping heads which automatically

seal the top and bottom seams. The carton is then

expelled on the exit conveyor.

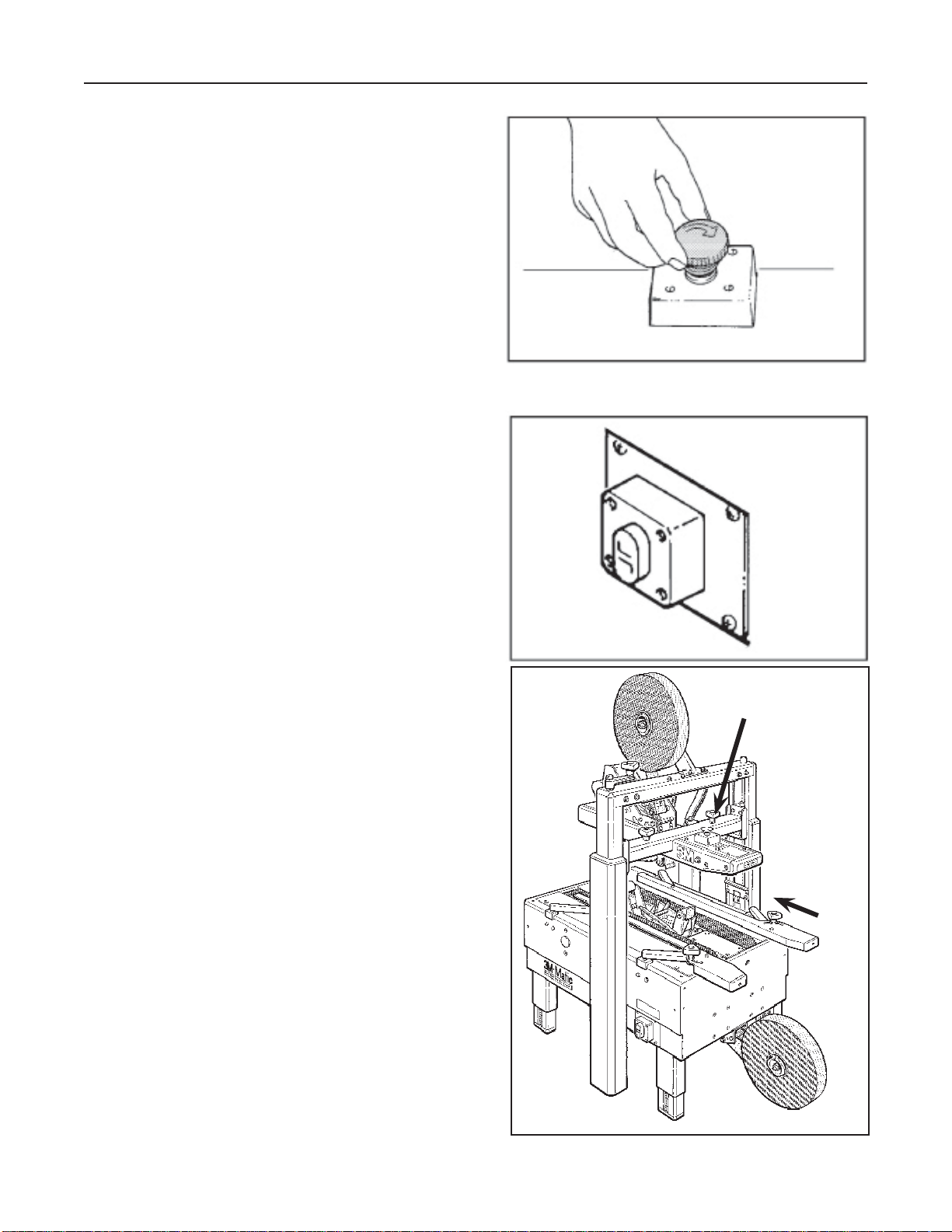

8.2 Definition of Running Mode

The case sealer 200a3 has only one (automatic)

operating mode with:

- The EMERGENCY STOP BUTTON unlocked

(Figure 8-1)

- The main switch start switch “ON” (I)

(Figure 8-2)

Figure 8-1

8.3.1 Normal Stop Procedure

When the main switch is turned OFF (O), the machine stops immediately at any point of the working

cycle. The same thing happens in case of electrical

failure or when the machine is disconnected from the

mains.

8.3.2 Emergency Stop

The LATCHING EMERGENCY STOP BUTTON is

located on the top center of the machine

(Figure 8-1).

Figure 8-2

E-Stop Location

Belt

Direction

200a3-NA

20

Figure 8-3

2011 June

Loading...

Loading...