Page 1

3

3M-Matic

800rf Type 39800

Automatic Random Case Sealer with

AccuGlide

II Taping Heads

Service Manual

Printed in U.S.A.

3M Packaging Systems Division Copyright © 1999, 3M IPC.

3M Center, Building 220-8W-01 3M-Matic and AccuGlide are trademarks of 3M, All rights reserved.

St. Paul, MN 55144-1000 St. Paul, MN 55144-1000 78-8114-0965-1 Rev. B

Page 2

Page 3

Replacement Parts and Service Information

To Our Customers:

This is the 3M-Matic/AccuGlide/Scotch brand equipment you ordered.

It has been set up and tested in the factory with Scotch brand tapes.

If technical assistance or replacement parts are needed, call or Fax the

appropriate number listed below.

Technical Assistance

3M-Match Helpline − 1-800/328 1390. Please provide the customer support

coordinator with the machine number, machine type/model and serial number.

If you have a technical question that does not require an immediate response,

you may Fax it to 715/381 0248.

Replacement Parts

Order parts by part number, part description and quantity required. Also include

machine name, number and type. A parts order form is provided at the end of

Section 7 of this manual, Illustrated Parts Breakdown.

3M/Tape Dispenser Parts

241 Venture Drive 1-800/344 9883

Amery, WI 54001-1325 FAX# 715/268 8153

Minimum billing on parts orders will be $25.00. Replacement part prices available on request.

Note: Outside the U.S., contact the local 3M subsidiary for parts ordering information.

$10.00 restocking charge per invoice on returned parts.

3

3M Packaging Systems Division

3M Center, Building 220-8W-01

St. Paul, MN 55144-1000

Page 4

Replacement Parts and Service Information

To Our Customers:

This is the 3M-Matic/AccuGlide/Scotch brand equipment you ordered.

It has been set up and tested in the factory with Scotch brand tapes. If

any problems occur when operating this equipment, and you desire a service call, or phone consultation, call, write, or Fax the appropriate number

listed below.

SERVICE AND PARTS AVAILABLE DIRECT FROM:

Order parts by part number, part description and quantity required. Also include

machine name, number and type.

3

3M Packaging Systems Division

3M Center, Building 220-8W-01

St. Paul, MN 55144-1000

Page 5

3M-Matic 800rf Case Sealer Revision History

3M-Matic 800rf Service Manual

Revision History

The original issue of this manual and subsequent revisions are identified as follows:

Issue date (Rev. A): 12/98, (Rev. B): 9/99

Revision B revised pages include:

Page Date

Title Page 9/99

Revision History 9/99

vi 9/99

5-3 through 5-8 9/99

5-11, 5-12 9/99

5-21 9/99

7-5 9/99

7-8 through 7-11 9/99

7-18 through 7-20 9/99

7-40 9/99

7-42 9/99

7-48 9/99

7-54 9/99

7-56 through 7-58 9/99

7-61 9/99

7-65 9/99

A-i 9/99

A-13 through A-42 9/99

Copyright 1999, 3M IPC. All rights reserved. i

Page 6

Revision History 3M-Matic 800rf Case Sealer

This page intentionally left blank.

ii Copyright 1999, 3M IPC. All rights reserved.

Page 7

3M-Matic 800rf Case Sealer Table of Contents

Section 1. Description and Specifications

1-1. Intended Use ............................................................................................................................................. 1-1

1-2. Description ............................................................................................................................................... 1-2

1-3. Specifications ........................................................................................................................................... 1-3

1-4. Case Sealing Rate Approximation Formula .............................................................................................1-4

1-5. Machine Dimensions ................................................................................................................................1-5

Section 2. Installation

2-1. General ..................................................................................................................................................... 2-1

2-2. Unpacking................................................................................................................................................. 2-2

2-3. Setup Procedure ........................................................................................................................................ 2-3

2-3-1. Case Sealer Bed Height ............................................................................................................... 2-3

2-3-2. Rear Emergency Stop Switch Installation ................................................................................... 2-3

2-3-3. Warning Beacon Installation ....................................................................................................... 2-4

2-3-4. Pneumatic Connection................................................................................................................. 2-4

2-3-5. Air Pressure Indicator.................................................................................................................. 2-5

2-3-6. Air Pressure Regulators ............................................................................................................... 2-5

2-3-7. Electrical Connection .................................................................................................................. 2-6

2-4. Tape Loading ............................................................................................................................................2-8

2-4-1. Top Tape Head Loading ..............................................................................................................2-9

2-4-2. Bottom Tape Head Loading.......................................................................................................2-10

2-5. Tape Drum Friction Brake...................................................................................................................... 2-11

2-6. Checkout Inspection (to be performed by an authorized 3M Service Technician) ................................ 2-11

2-6-1. Static Tests ................................................................................................................................. 2-11

2-6-2. Programmable Controller Inputs and Outputs...........................................................................2-15

2-6-3. Dynamic Tests ...........................................................................................................................2-19

2-7. Placing 800rf Case Sealer in Production Line ....................................................................................... 2-20

2-8. Special Setup Procedure .........................................................................................................................2-21

2-8-1. Relocating Pneumatic and Electrical Control Panels ................................................................2-21

Section 3. Adjustments

3-1. Case Sealer Bed Height ............................................................................................................................3-1

3-2. Pneumatic Device Factory Set Points ...................................................................................................... 3-2

3-3. Main Air Pressure Regulator ....................................................................................................................3-4

3-4. Box Centering Pressure Regulator ........................................................................................................... 3-4

3-5. Side Belt Pressure Regulator .................................................................................................................... 3-5

3-6. Side Belts Closure Drive Chain................................................................................................................ 3-5

3-7. Side Belts In/Out Rates ............................................................................................................................ 3-6

3-8. Side Belt Inner Limit ................................................................................................................................3-7

3-9. Side Belt Tension...................................................................................................................................... 3-8

3-10. Motor Drive Belts, Upper and Lower ...................................................................................................... 3-9

3-11. Drive Chain ............................................................................................................................................ 3-10

3-12. Safety Door Interlock ............................................................................................................................. 3-10

3-13. Flap Folder Arm and Flap Folder Flow Controls - Speed Controls ....................................................... 3-11

3-14. Flap Folder Arm Reed Switch ................................................................................................................ 3-12

3-15. Cylinder Cushion Setting ....................................................................................................................... 3-13

3-16. Paddle Pressure Regulator ...................................................................................................................... 3-13

Copyright 1999, 3M IPC. All rights reserved. iii

Page 8

Table of Contents 3M-Matic 800rf Case Sealer

3-17. Counter-Balance Pressure Regulator...................................................................................................... 3-14

3-18. Case Top Sensitivity ............................................................................................................................... 3-14

3-19. Fork Cylinder Flow Controls - Speed Controls...................................................................................... 3-15

3-20. Infeed Box Stop-Gate Flow Control - Speed Control ............................................................................ 3-16

3-21. Box Centering Rails In/Out Rates .......................................................................................................... 3-17

3-22. Upper Head Assembly Down/Up Rates ................................................................................................. 3-18

3-23. Top Flap Compression Rollers ...............................................................................................................3-19

3-24. Tape Web Alignment .............................................................................................................................. 3-19

3-25. Tape Drum Friction Brake...................................................................................................................... 3-20

3-26. Tape Applying Mechanism Spring ......................................................................................................... 3-20

3-27. One-Way Tension Roller ........................................................................................................................ 3-21

3-28. Low Air Pressure Switch ........................................................................................................................3-22

3-29. Overload Circuit Breaker ....................................................................................................................... 3-23

3-30. Head Travel Limit Switch ...................................................................................................................... 3-23

Section 4. Disassembly/Reassembly

4-1. General ..................................................................................................................................................... 4-1

4-2. Format....................................................................................................................................................... 4-1

4-3. Side Drive Belt Assembly ........................................................................................................................ 4-2

4-4. Side Drive Belt ......................................................................................................................................... 4-3

4-5. Motor Drive Belts, Upper and Lower ...................................................................................................... 4-4

4-6. Case Sealer Bed Plates ............................................................................................................................. 4-6

4-7. Fork Cylinder............................................................................................................................................ 4-7

4-8. Side Drive Belts Cylinder......................................................................................................................... 4-7

4-9. Flap Folder Cylinder ................................................................................................................................ 4-8

4-10. Flap Folder Arm Cylinder ........................................................................................................................ 4-8

4-11. Knife Replacement, Upper Taping Head ..................................................................................................4-9

4-12. Knife Replacement, Lower Taping Head ............................................................................................... 4-10

4-13. Belt Drive Pulley Assembly Ribbed Rings ............................................................................................ 4-10

4-14. Infeed Rollers ......................................................................................................................................... 4-12

4-15. Overload Circuit Breaker ....................................................................................................................... 4-14

Section 5. Theory of Operation

5-1. General ..................................................................................................................................................... 5-1

5-2. Operation Summary.................................................................................................................................. 5-1

5-2-1. Random Mode ............................................................................................................................. 5-1

5-2-2. Fixed Mode ................................................................................................................................. 5-2

5-2-3. Bypass Mode ............................................................................................................................... 5-2

5-3. Sequence Tables ....................................................................................................................................... 5-2

5-4. Electrical System ....................................................................................................................................5-14

5-4-1. Power Distribution ....................................................................................................................5-14

5-4-2. Special Circuits/Components ....................................................................................................5-14

5-4-3. Electrical Schematic ..................................................................................................................5-16

5-5. Pneumatic System .................................................................................................................................. 5-20

Pneumatic Diagram ................................................................................................................... 5-21

iv Copyright 1999, 3M IPC. All rights reserved.

Page 9

3M-Matic 800rf Case Sealer Table of Contents

Section 6. Troubleshooting

6-1. General ..................................................................................................................................................... 6-1

6-2. Troubleshooting Guide ............................................................................................................................. 6-1

6-3. Pneumatic Component Testing .................................................................................................................6-6

6-4. Electrical Circuit Fault Conditions ........................................................................................................... 6-8

Section 7. Illustrated Parts Breakdown

7-1. How to Order Replacement Parts .............................................................................................................7-1

7-2. Spare Parts ................................................................................................................................................7-1

7-3. Suggested Spare Parts .............................................................................................................................. 7-1

7-4. Illustrations and Parts Lists ...................................................................................................................... 7-2

Figure 7-1. 800rf Case Sealer Breakdown .............................................................................................. 7-2

Figure 7-2. Conveyor Frame ................................................................................................................... 7-4

Figure 7-3. Conveyor Center Bed and Fork ............................................................................................ 7-8

Figure 7-4. Conveyor Bed Rollers......................................................................................................... 7-10

Figure 7-5. Side Belt Centering .............................................................................................................7-12

Figure 7-6. Column Assembly ...............................................................................................................7-16

Figure 7-7. Flap Folder Assembly ......................................................................................................... 7-18

Figure 7-8. Paddle Assembly................................................................................................................. 7-22

Figure 7-9. Side Belt Rail Assembly ..................................................................................................... 7-24

Figure 7-10. Head Cylinder Assembly .................................................................................................. 7-26

Figure 7-11. Upper Tape Head Mount................................................................................................... 7-28

Figure 7-12. Upper Tape Drum Bracket Assembly ............................................................................... 7-30

Figure 7-13. Side Belt and Drive Assemblies ....................................................................................... 7-32

Figure 7-14. Side Belt Drive Pulleys (Detail) ....................................................................................... 7-36

Figure 7-15. Upper Head Conduit Assembly ........................................................................................ 7-38

Figure 7-16. Electrical Control Panel ....................................................................................................7-40

Figure 7-17. Electrical Control Panel (Detail) ...................................................................................... 7-44

Figure 7-18. Pneumatic Control Panel .................................................................................................. 7-46

Figure 7-19. Pneumatic Components, #1 .............................................................................................. 7-48

Figure 7-20. Pneumatic Components, #2 .............................................................................................. 7-50

Figure 7-21. Pneumatic Components, #3 .............................................................................................. 7-52

Figure 7-22. Sliding Door Assembly .....................................................................................................7-56

Figure 7-23. Infeed Conveyor Frame .................................................................................................... 7-60

Figure 7-24. Infeed Conveyor Drive Assembly ..................................................................................... 7-64

Figure 7-25. Infeed Conveyor Centering Assembly .............................................................................. 7-66

Figure 7-26. Taping Head Assemblies - AccuGlide

Figure 7-27. Frame Assembly for Upper Head ..................................................................................... 7-72

Figure 7-28. Applying Assembly for Upper and Lower Heads ............................................................. 7-74

Figure 7-29. Buffing Assembly for Upper Head ................................................................................... 7-76

Figure 7-30. Link Assembly for Upper and Lower Heads ....................................................................7-78

Figure 7-31. Knife Assembly for Upper and Lower Heads................................................................... 7-80

Figure 7-32. Tape Drum and Bracket for Upper and Lower Heads ...................................................... 7-82

Figure 7-33. Frame Assembly for Lower Head ..................................................................................... 7-84

Figure 7-34. Buffing Assembly for Lower Head ...................................................................................7-86

II STD 2-Inch ................................................... 7-70

Copyright 1999, 3M IPC. All rights reserved. v

Page 10

Table of Contents 3M-Matic 800rf Case Sealer

Section 8. Preventative Maintenance

8-1. General ..................................................................................................................................................... 8-1

8-1-1. Maintenance ................................................................................................................................ 8-1

8-1-2. Tool Kit ....................................................................................................................................... 8-1

8-2. Cleaning.................................................................................................................................................... 8-1

8-3. Lubrication ............................................................................................................................................... 8-2

8-3-1. Taping Heads ............................................................................................................................... 8-2

8-3-2. Main Assembly and Infeed Assembly ......................................................................................... 8-2

8-4. Maintenance Schedule.............................................................................................................................. 8-4

8-4-1. Taping Heads ............................................................................................................................... 8-4

8-4-2. Infeed Assembly .......................................................................................................................... 8-4

8-4-3. Main Assembly ............................................................................................................................ 8-5

Appendix A. PLC Addendum

A-1. SLC 500 Controller Description ............................................................................................................. A-1

A-2. SLC 500 Specifications ........................................................................................................................... A-1

A-3. Programming ........................................................................................................................................... A-4

A-4. Troubleshooting....................................................................................................................................... A-4

A-5. Ladder Logic Diagram .......................................................................................................................... A-13

A-6. Cross Reference..................................................................................................................................... A-36

A-7. Replacement Parts ................................................................................................................................. A-40

A-8. Documentation ...................................................................................................................................... A-41

vi Copyright 1999, 3M IPC. All rights reserved.

Page 11

3M-Matic 800rf Case Sealer Safety Information

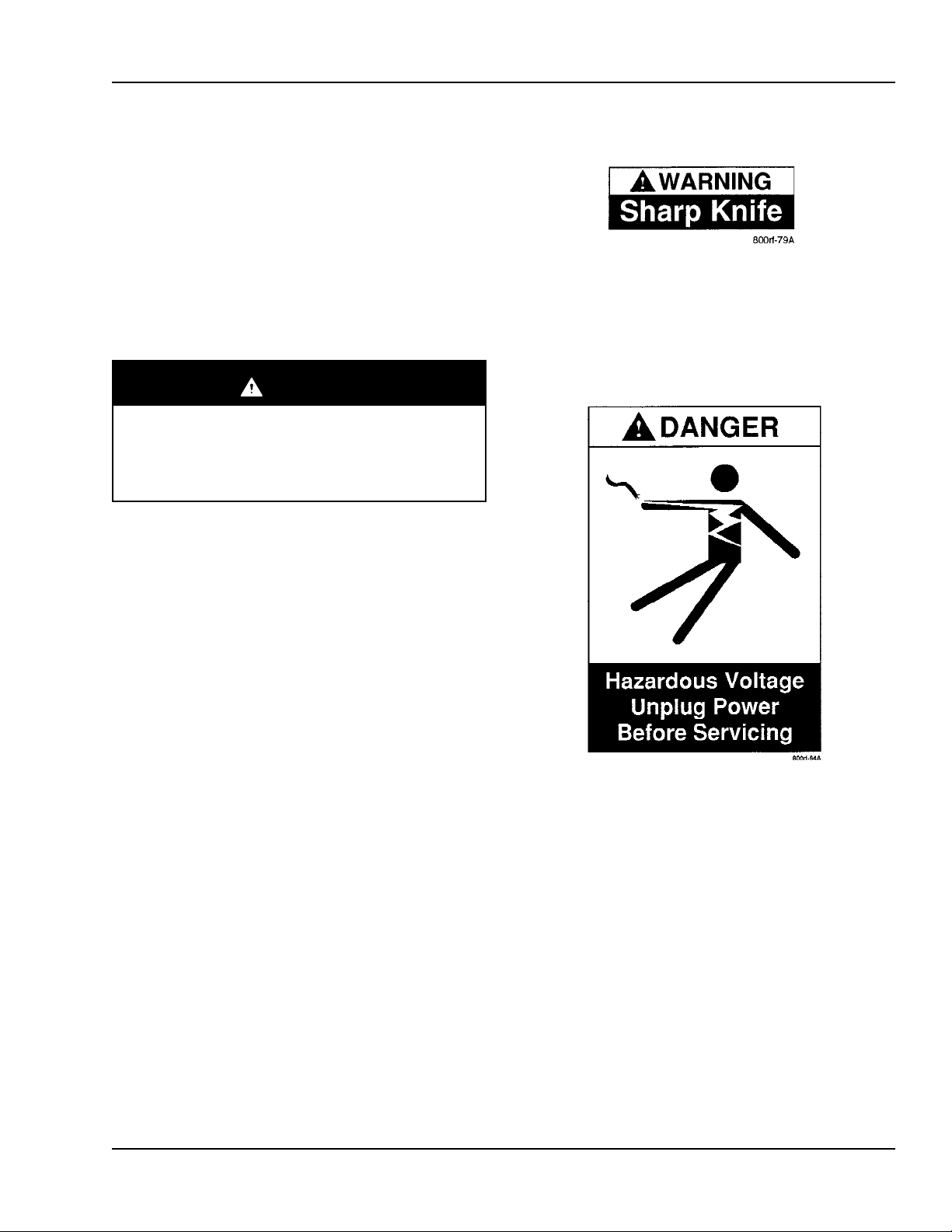

Warning Label

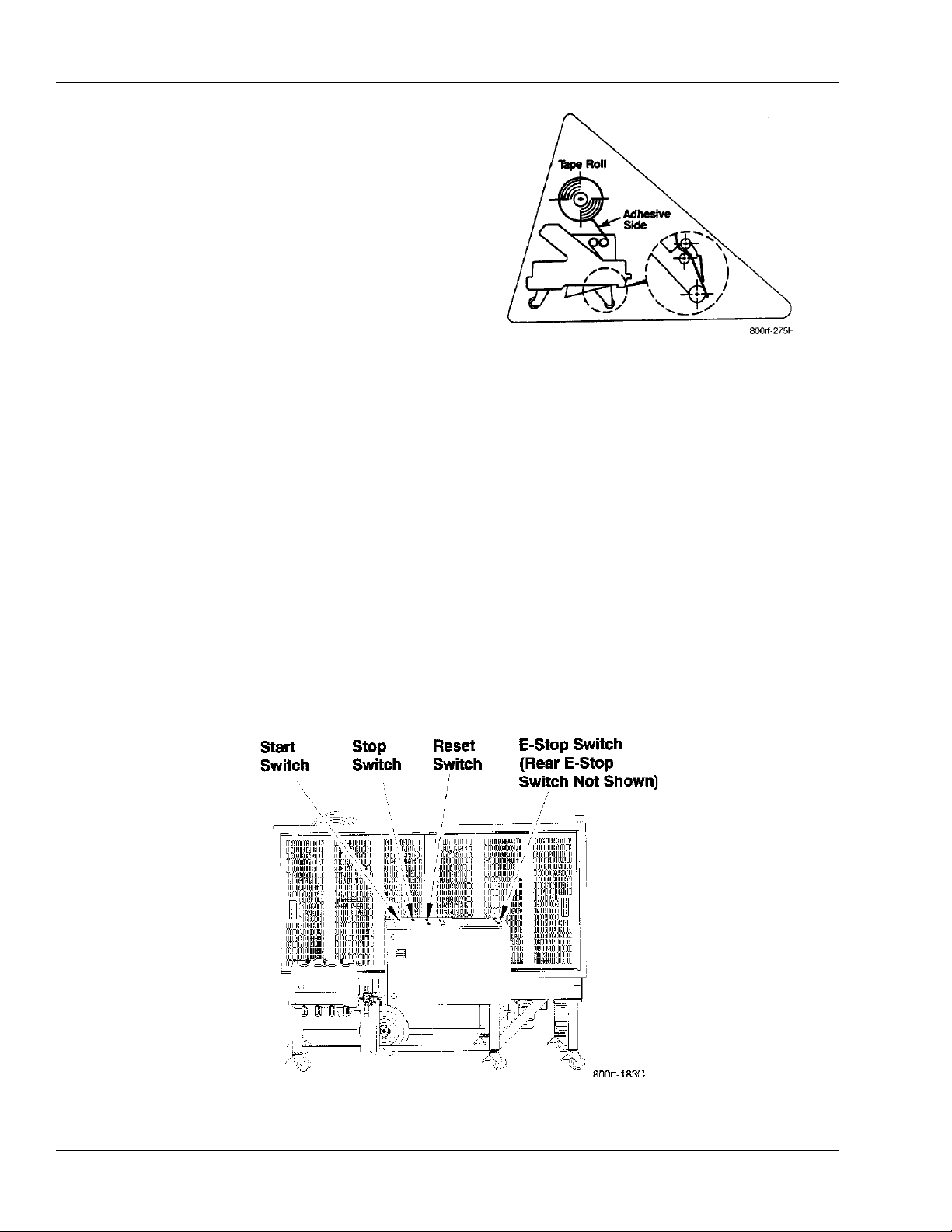

The WARNING Sharp Knife label, shown in

Figure 1, is attached to the orange cut-off knife

guard on both taping heads. The label warns the

operator and service personnel of the very sharp

knife located behind the guard and to keep hands

out of this area except for tape loading and servicing

the taping heads.

Warning

The taping heads are equipped with an

orange knife guard that covers the knife.

The taping heads must never be operated

with the knife guards removed.

Figure 1. Warning Label

Danger Label

The DANGER Hazardous Voltage Unplug Power

Before Servicing label, shown in Figure 2, is

attached to the front of the Electrical Control Panel,

at the front of the machine. When power is on,

opening the panel door allows access to +24 VDC

and 220 VAC.

Figure 2. Danger Label

Copyright 1999, 3M IPC. All rights reserved. vii

Page 12

Safety Information 3M-Matic 800rf Case Sealer

Tape Threading Label

The Tape Threading Label, shown in Figure 3, is

attached to the left side of both the upper and lower

taping heads. This label provides a convenient tape

threading diagram. More detailed tape loading and

threading information is provided in this manual in

Section 2, Installation.

Figure 3. Tape Threading Label

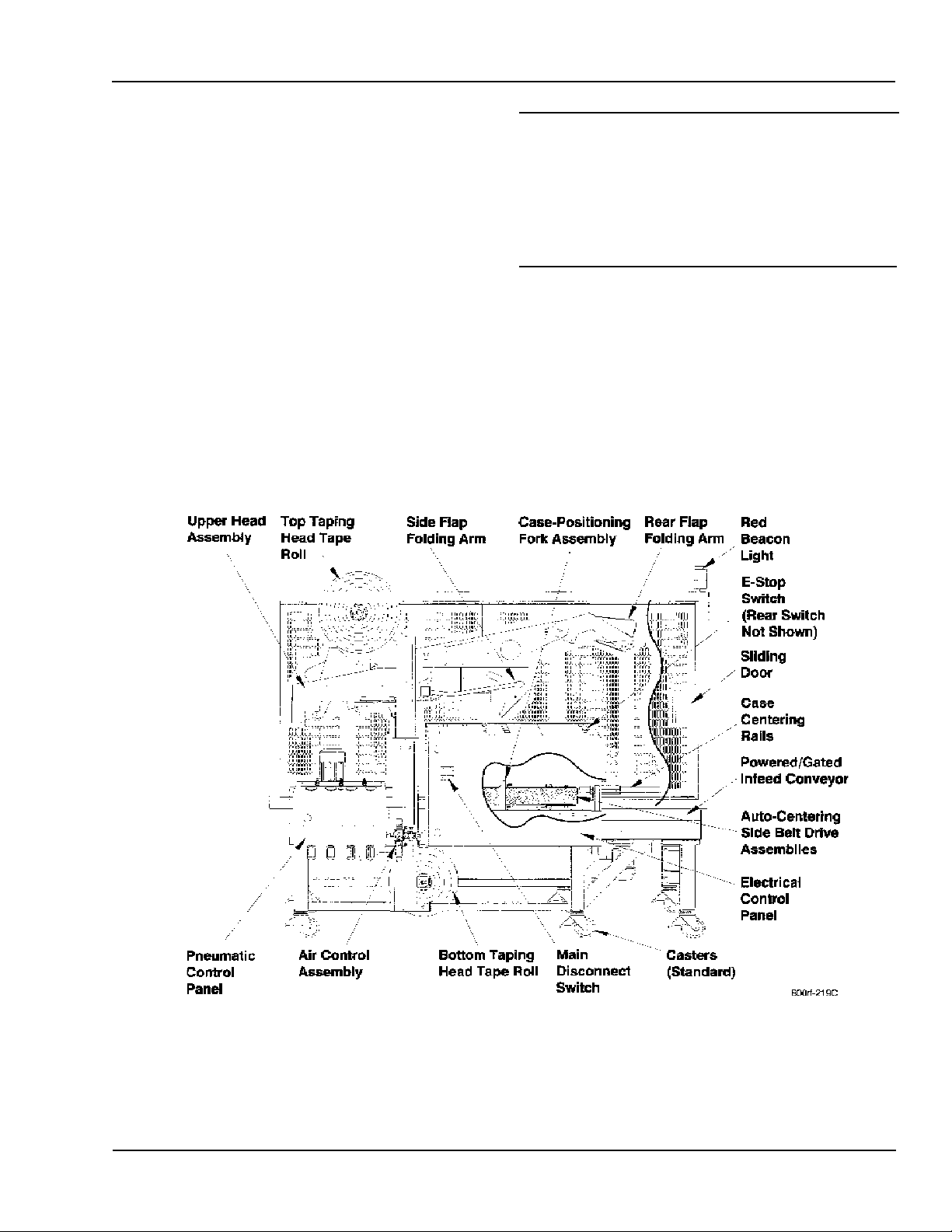

STOP Switches

The Model 800rf Type 39800 Case Sealer is

equipped with three STOP switches. Their locations

are shown in Figure 4. Pressing either of the red EStop switches stops the machine, removing electrical power and air pressure from the case sealer. To

restart the machine, you must turn and release the EStop switch and then press the RESET button and

the START button on the Electrical Control Panel.

Pressing the STOP button on the Electrical Control

Panel stops the machine and does not remove power

from the controller. To restart the machine, you must

press the RESET button and then the START button.

Figure 4. STOP Switch Locations

viii Copyright 1999, 3M IPC. All rights reserved.

Page 13

3M-Matic 800rf Case Sealer Warranty

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF

DEALING, A CUSTOMER OR USAGE OF TRADE:

3M sells its 3M-Matic

1. The Taping Head knife blades, springs and rollers will be free from all defects for ninety (90) days after

delivery.

2. All other Taping Head parts will be free from all defects for three (3) years after delivery.

3. All other parts will be free from all defects for ninety (90) days after delivery.

If any part is proved to be defective within its warranty period, then the exclusive remedy and 3Ms and sellers

sole obligation shall be, at 3Ms option, to repair or replace the part, provided the defective part is returned

immediately to 3Ms factory or an authorized service station designated by 3M. A part will be presumed to have

become defective after its warranty period unless the part is received or 3M is notified of the problem no later

than five (5) calendar days after the warranty period. If 3M is unable to repair or replace the part within a

reasonable time, then 3M at its option, will replace the equipment or refund the purchase price. 3M shall have no

obligation to provide or pay for the labor required to install the repaired or replacement part. 3M shall have no

obligation to repair or replace: (1) those parts failing due to operation misuse, carelessness or due to any

accidental cause other than equipment failure, or (2) parts failing due to non-lubrication, inadequate cleaning,

improper operating environment, improper utilities or operator error.

Limitation of Liability: 3M and seller shall not be liable for direct, indirect, special, incidental or consequential

damages based upon breach of warranty, breach of contract, negligence, strict liability or any other legal theory.

The foregoing Equipment Warranty and Limitation of Liability may be changed only by a written agreement

signed by authorized officers of 3M and seller.

800rf Fully Automatic Random Case Sealer with the following warranties:

Copyright 1999, 3M IPC. All rights reserved. ix

Page 14

Warranty 3M-Matic 800rf Case Sealer

This page intentionally left blank.

x Copyright 1999, 3M IPC. All rights reserved.

Page 15

3M-Matic 800rf Case Sealer Description and Specifications

Table of Contents

1. Description and Specifications ..................................................................................................................... 1-1

1-1. Intended Use ............................................................................................................................................. 1-1

1-2. Description ............................................................................................................................................... 1-2

1-3. Specifications ........................................................................................................................................... 1-3

1-4. Case Sealing Rate Approximation Formula .............................................................................................1-4

1-5. Machine Dimensions ................................................................................................................................1-5

Copyright 1999, 3M IPC. All rights reserved. 1-i

Page 16

Description and Specifications 3M-Matic 800rf Case Sealer

This page intentionally left blank.

1-ii Copyright 1999, 3M IPC. All rights reserved.

Page 17

3M-Matic 800rf Case Sealer Description and Specifications

1. Description and Specifications

1-1. Intended Use

The 3M-Matic Model 800rf Type 39800 Automatic

Random Case Sealer with AccuGlide II Taping

Heads is designed to accept filled, regular slotted

containers from an existing conveyor, fold the top

flaps, and apply a C clip of Scotch brand Pressure-Sensitive Film Box Sealing Tape to the top and

bottom center seams. Two side-drive belt assemblies

convey the cases through the machine.

The 800rf Case Sealer is to be used with infeed and

exit conveyors supplied by the customer. Do not

attempt to run the case sealer without infeed and exit

conveyors in place.

ü Note

In this manual, the end of the case sealer that accepts cases

for taping is the infeed end. The end of the case sealer where

the taped cases leave is the exit end. The side containing the

Electrical Control Panel and the Pneumatic Control Panel is

the front or left side of the machine, and the opposite side is

the back or right side of the machine.

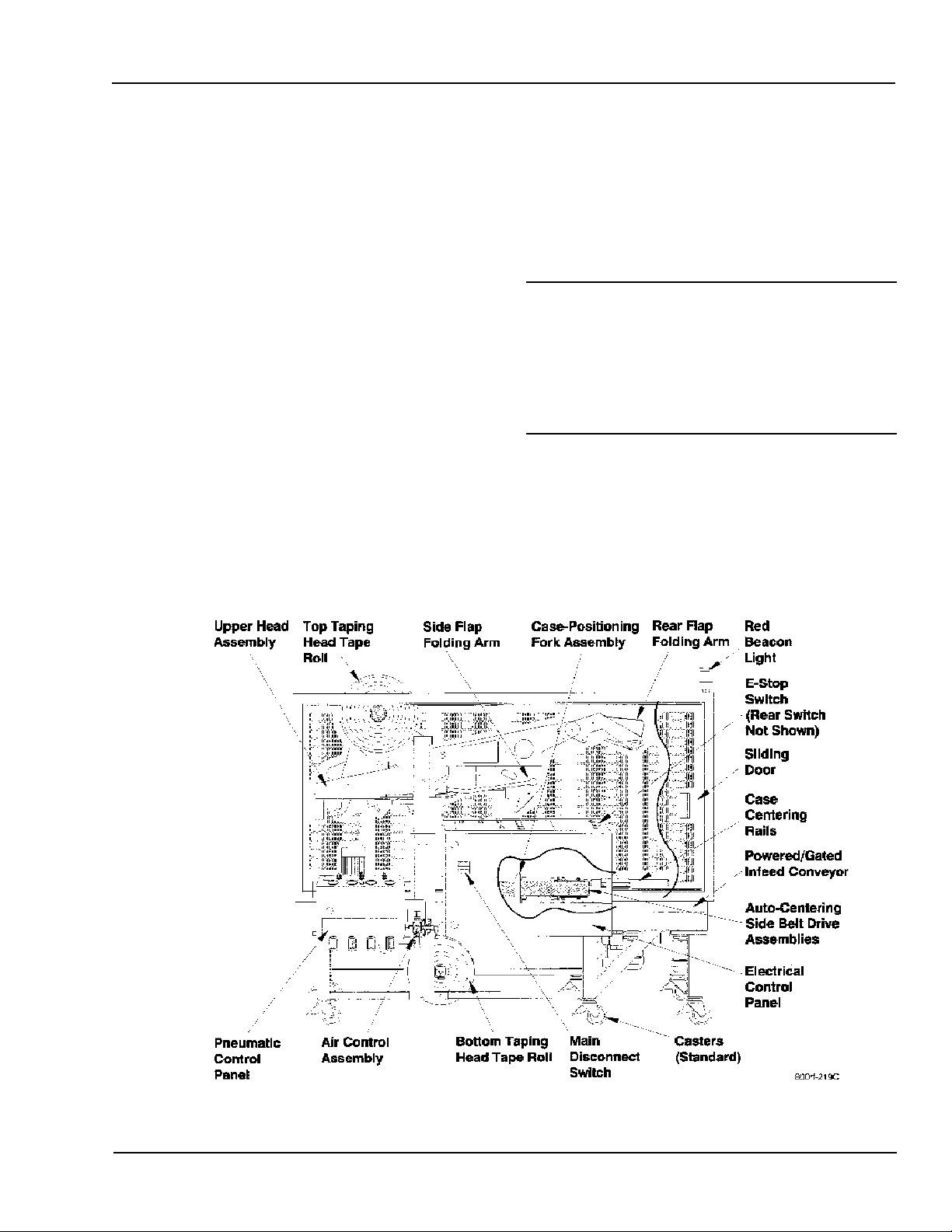

Figure 1-1 shows the 800rf Case Sealer with callouts

to identify its major components.

Figure 1-1. 3M-Matic 800rf Case Sealer

3M-Matic, AccuGlide, and Scotch are trademarks of 3M, St. Paul, MN 55144-1000

Copyright 1999, 3M IPC. All rights reserved. 1-1

Page 18

Description and Specifications 3M-Matic 800rf Case Sealer

1-2. Description

The 800rf Case Sealer is controlled from two operator

control panels located on the front left side of the case

sealer. These control panels (Electrical Control Panel

and Pneumatic Control Panel) have the most-used

controls within easy reach of the operator. The case

sealer is microprocessor-based and firmware controlled to maintain maximum and precise control over

all operations within the case sealer.

The case sealer may be operated in Random, Fixed, or

Bypass mode. A selector switch is located on the top

of the Electrical Control Panel.

!

Caution

Never change operating modes while a box is

in the case sealer. Change modes only after a

box exits the case sealer and before the next

box enters the case sealer.

• In Random mode, the case sealer automatically

adjusts itself for a wide range of case sizes,

providing a tape seal on the top and bottom of the

cartons. Random mode is considered the standard

operating mode.

• In Fixed mode, the case sealer runs multiple

cartons of the same (fixed) size, providing a tape

seal on the top and bottom of the cartons.

• In Bypass mode, the case sealer passes certain

containers through the machine, providing a tape

seal only on the bottom of the containers. The top

of these containers is not sealed.

1-2 Copyright 1999, 3M IPC. All rights reserved.

Page 19

3M-Matic 800rf Case Sealer Description and Specifications

1-1. Specifications

Tape:

3M brand pressure-sensitive film box sealing tapes.

Tape Width:

Standard 3M-Matic 800rf Case Sealer.

This model offers tape widths from 1-1/2 inches

[36 millimeters] minimum to 2 inches [48

millimeters] maximum.

3M-Matic 800rf-3 Case Sealer.

This model offers 3-inch wide upper and lower

AccuGlide II Taping Heads for tape widths

from 2 inches [48 millimeters] to

3 inches [72 millimeters].

Tape Roll Diameter:

Up to 15-1/2 inches [394 millimeters] maximum, on

a 3-inch [76.2 millimeters] diameter core.

Box Dimensions:

Length: 8 inches [203 millimeters] minimum,

24 inches [610 millimeters] maximum.

Width: 5-1/2 inches [140 millimeters] minimum,

20 inches [508 millimeters] maximum.

Height: 6 inches [152 millimeters] minimum,

20 inches [508 millimeters] maximum.

Box Weight Capacity: (filled)

65 pounds [29 kilograms] maximum; minimum must

be sufficient to hold case on the conveyor bed with

bottom flaps flat.

Box Type:

Box board, 125 to 275 PSI bursting test, single wall

A, B, or C flute.

ü Note

The case sealer accommodates most boxes within the

size range identified above. However, if the ratio of

box length (in the taping direction) to box height is

0.6 or less, several boxes should be test-run to ensure

proper machine performance.

Operating Conditions:

o

Use in dry, relatively clean environments at 40

o

120

F [5oC to 49oC] with clean, dry boxes. The

F to

machine should not be washed down or subjected to

conditions causing moisture condensation on components.

Machine Specifications:

Length: 86-3/4 inches [2.20 meters].

Width: 57 inches [1.45 meters].

Height: 74 inches [1.88 meters] minimum

with casters to 80 inches [2.03 meters]

maximum with casters.

Weight: Unit uncrated, approximately

1130 pounds [513 kilograms].

Unit crated, approximately

1200 pounds [544 kilograms].

Case sealer bed height: Adjustable up from

factory-set height of 25-7/8 inches

[657 millimeters] to 32 inches

[815 millimeters] with casters.

Power Requirements:

Electrical: 208 to 240 VAC, 50/60 Hz, 5.5 Amps,

3-phase.

Pneumatic: Machine requires 75 140 PSIG

[5.2 9.5 BAR] 7.0 SCFM

3

[11.89 m

/h 21oC, 101 kPa] at the

regulator, maximum at maximum

cycle rate.

The optimum operating set point on

the gauge is 95 100 PSIG.

Infeed Conveyor Speed:

The customers infeed conveyor box delivery

speed must not exceed 60 feet/minute.

!

Caution

Do not connect a lubricator or lubricated

air to this machine. This machine has a

non-lubricated air circuit.

DETERMINE THE BOX LIMITATIONS BY

COMPLETING THIS FORMULA:

Box (tape) Length

> 0.6

Box Height

Copyright 1999, 3M IPC. All rights reserved. 1-3

Page 20

Description and Specifications 3M-Matic 800rf Case Sealer

1-1. Case Sealing Rate Approximation Formula

To determine the case sealing rate for your application:

1. Obtain a representative sample of boxes in the proportion that will be run through the machine. Use as many

boxes as necessary to get an accurate sample.

Example:

1. Determine (add up) the

2. Determine (add up) the

3. Determine (add up) the

Number of boxes: _____________

Total length (inches): _____________

Total width (inches): _____________

Total height (inches): _____________

4. Divide the dimension totals by the number of boxes to determine average length, width, and height.

Total length _____________ = ____________ Average length

Number of boxes

Total width _____________ = ____________ Average width

Number of boxes

Total height _____________ = ____________ Average height

Number of boxes

total length of all boxes.

total width of all boxes.

total height of all boxes.

800rf Case Sealing Rate (cases per minute)

Rate = 5.97 + (0.42 X ave. length) (1.06 X ave. width) + (0.72 X ave. height)

1-4 Copyright 1999, 3M IPC. All rights reserved.

Page 21

3M-Matic 800rf Case Sealer Description and Specifications

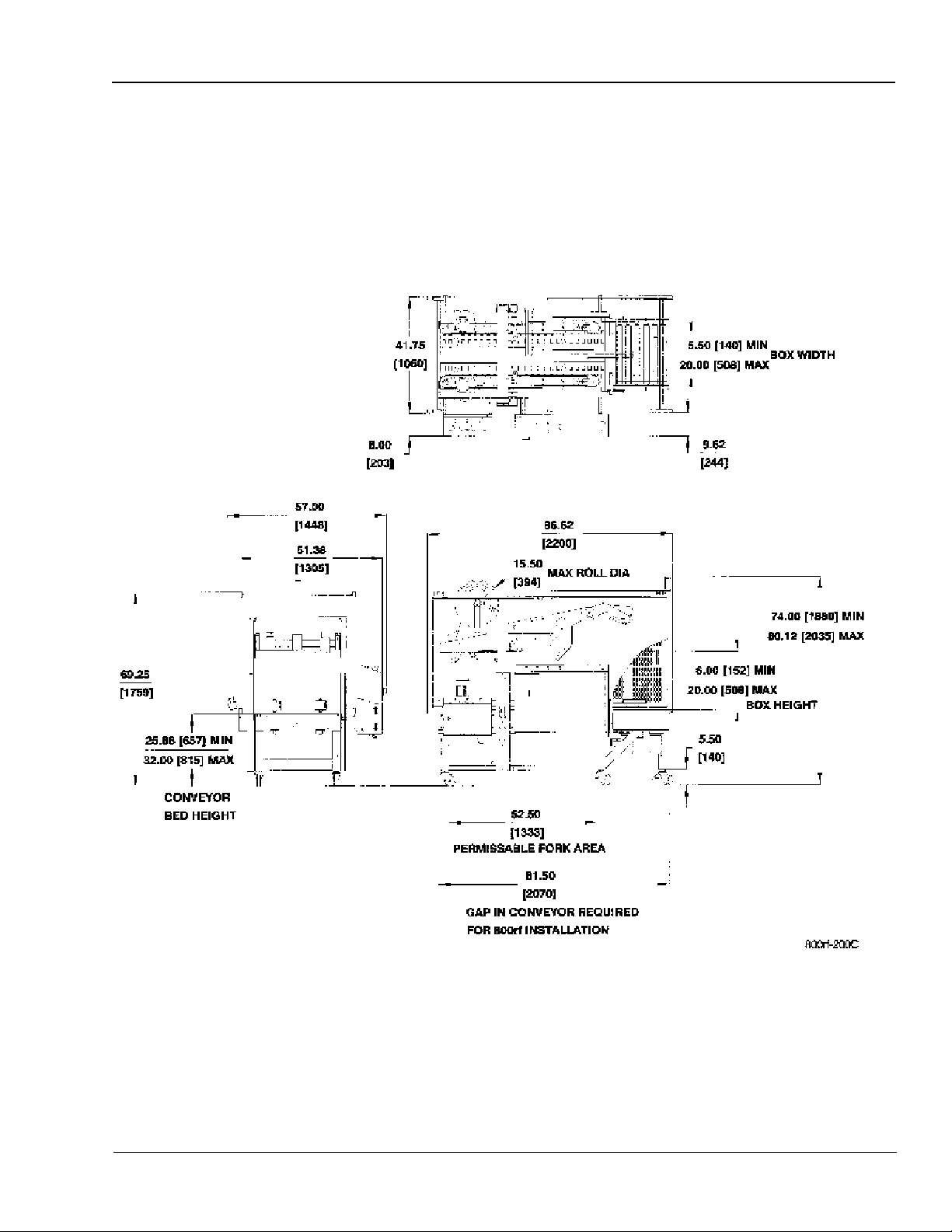

1-1. Machine Dimensions

Figure 1-2 shows machine dimensions for the 800rf

Case Sealer. The dimensions are given in both inches

and millimeters. For example, 20.00 inches [508

millimeters] is shown as 20.00 [508].

Figure 1-2. Machine Dimensions

Copyright 1999, 3M IPC. All rights reserved. 1-5

Page 22

Description and Specifications 3M-Matic 800rf Case Sealer

This page intentionally left blank.

1-6 Copyright 1999, 3M IPC. All rights reserved.

Page 23

3M-Matic 800rf Case Sealer Installation

Table of Contents

2. Installation .....................................................................................................................................................2-1

2-1. General ............................................................................................................................................... 2-1

2-2. Unpacking ..........................................................................................................................................2-2

2-3. Setup Procedure ................................................................................................................................. 2-3

2-3-1. Case Sealer Bed Height ........................................................................................................ 2-3

2-3-2. Rear Emergency Stop Switch Installation ............................................................................ 2-3

2-3-3. Warning Beacon Installation ................................................................................................. 2-4

2-3-4. Pneumatic Connection .......................................................................................................... 2-4

2-3-5. Air Pressure Indicator ........................................................................................................... 2-5

2-3-6. Air Pressure Regulators ........................................................................................................ 2-5

2-3-7. Electrical Connection............................................................................................................ 2-6

2-4. Tape Loading ..................................................................................................................................... 2-8

2-4-1. Top Tape Head Loading ........................................................................................................ 2-9

2-4-2. Bottom Tape Head Loading ................................................................................................ 2-10

2-5. Tape Drum Friction Brake ............................................................................................................... 2-11

2-6. Checkout Inspection (to be performed by an authorized 3M Service Technician) .......................... 2-11

2-6-1. Static Tests .......................................................................................................................... 2-11

2-6-2. Programmable Controller Inputs and Outputs .................................................................... 2-12

2-6-3. Dynamic Tests ..................................................................................................................... 2-12

2-7. Placing 800rf Case Sealer in Production Line .................................................................................2-12

2-8. Special Setup Procedure .................................................................................................................. 2-12

2-8-1. Relocating Pneumatic and Electrical Control Panels ......................................................... 2-12

Copyright 1999, 3M IPC. All rights reserved. 2-i

Page 24

Installation 3M-Matic 800rf Case Sealer

This page intentionally left blank.

2-ii Copyright 1999, 3M IPC. All rights reserved.

Page 25

3M-Matic 800rf Case Sealer Installation

2-1. General

The following instructions are presented in the order

recommended for installing and setting up the 800rf

Case Sealer, as well as for learning the operating

functions and adjustments. Following these instructions step-by-step results in a thorough understanding of the case sealer and its installation in a production line that best uses the many features of the case

sealer. Refer to Figure 2-1 for nomenclature.

Uncrating and setting up the case sealer consists of

four steps:

1. Uncrating the equipment.

2. Assembling the case sealer as described in this

section.

3. Providing the electrical and pneumatic connections.

4. Installation of the case sealer in a production line.

Once you decide on a schedule to accomplish these

steps, contact:

3M Packaging Systems Division

Customer Support Center

Phone 1-800-328-1390

A 3M technician will be sent to your site to perform a

final checkout inspection.

ü Note

We recommend that you do not operate the case

sealer in a production situation until the final check-

out inspection is complete. For the final checkout

inspection, have a sufficient supply of cases in

representative sizes and weights to check the case

sealer under normal operating conditions.

Figure 2-1. 3M-Matic 800rf Case Sealer

Copyright 1999, 3M IPC. All rights reserved. 2-1

Page 26

Installation 3M-Matic 800rf Case Sealer

2-2. Unpacking

ü Note

It is the responsibility of the customer to uncrate

the case sealer. Lifting equipment (forklift,

overhead crane, etc.) is necessary to lift the case

sealer from its pallet.

The case sealer is delivered in one crate.

Perform the following inspection upon receipt of the

case sealer.

1. Inspect the shipping crate for damage that could

indicate internal damage to the case sealer.

Report any damage, missing parts, or other

problems to:

3M Packaging Systems Division

Customer Support Center

Phone 1-800-328-1390

2. Dismantle the crate.

3. Inspect the case sealer and uninstalled components for damage or missing parts. The crate

should also contain the following:

• One tool box containing:

1 wrench, tube, 17 mm

1 wrench, box/open, 13 mm & 10 mm

1 wrench, box/open, 8 mm & 7 mm

1 wrench, open end, 25 mm

1 wrench, hex key, 3 mm

1 wrench, hex key, 4 mm

1 wrench, hex key, 5 mm

1 wrench, hex key, 6 mm

1 spring, main upper (78-8070-1274-1)

1 spring, main lower (78-8070-1273-3)

4 springs, cutter (78-8052-6602-6)

2 blades, cutter (78-8017-9173-8)

1 tool, tape threading (78-8076-4726-4)

4. Report any damage, missing parts, or other

problems to:

3M Packaging Systems Division

Customer Support Center

Phone 1-800-328-1390

5. Move the case sealer to the point of use, but do

not place it into production until after the 3M

technician completes the checkout inspection.

• One latching emergency stop switch with bracket

(electrically connected, but not mounted in place)

• One warning beacon with bracket (electrically

connected, but not mounted in place)

2-2 Copyright 1999, 3M IPC. All rights reserved.

Page 27

3M-Matic 800rf Case Sealer Installation

2-3. Setup Procedure

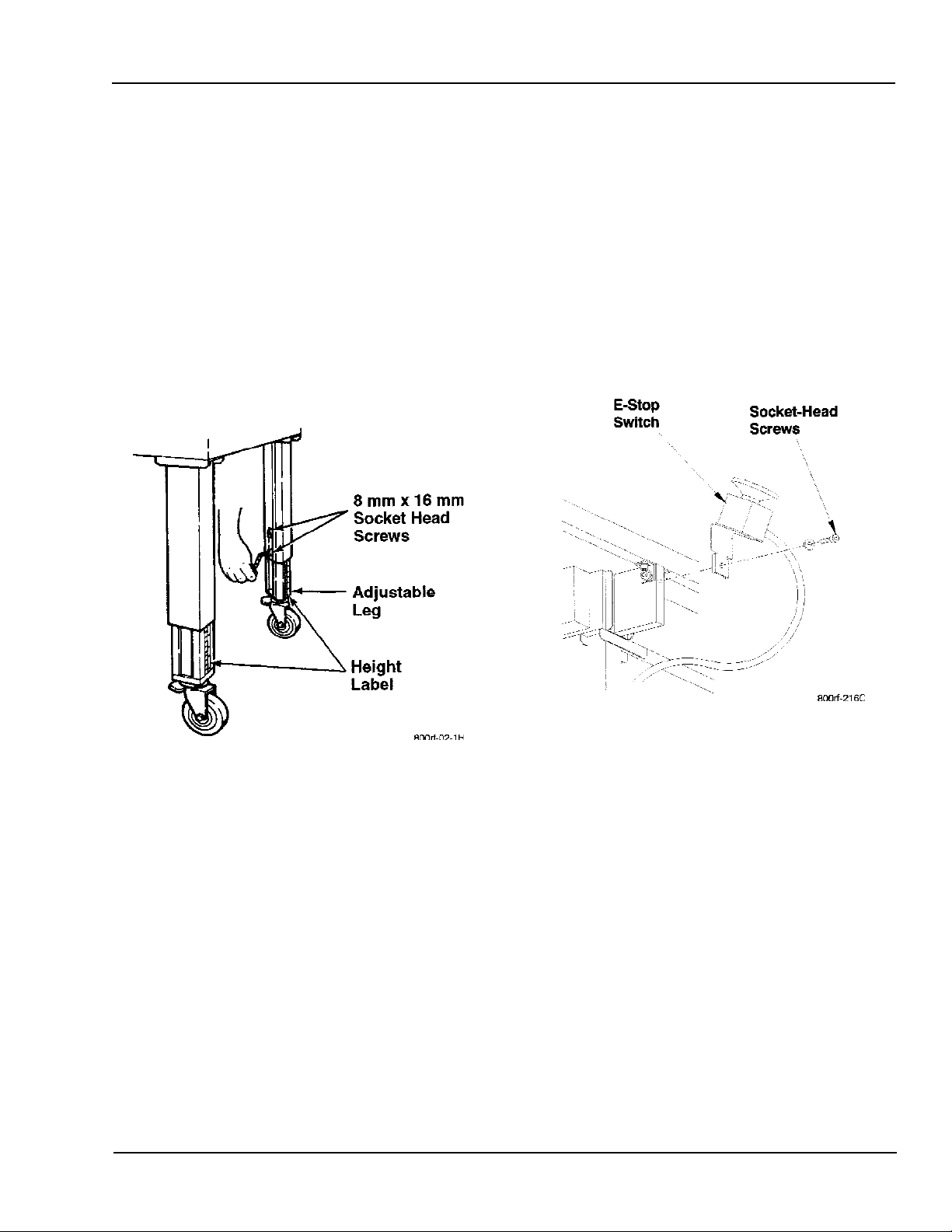

2-3-1. Case Sealer Bed Height

The legs on the case sealer can be adjusted to obtain

different bed heights from the factory set-point. The

bed height can be set from 25-7/8 inches [657 mm]

minimum through 32 inches [815 mm] maximum. Set

the bed height as follows:

1. Block up the case sealer frame to allow adequate

leg adjustment.

2. Using a 6 mm hex key wrench, loosen, but do not

remove, two M8 x 16 mm socket-head cap screws

in one leg. Refer to Figure 2-2.

2-3-2. Rear Emergency Stop Switch

Installation

A latching Emergency Stop (E-Stop) switch is

electrically connected to the case sealer, but not

mounted to the machine. Install this E-Stop switch on

the rear side of the case sealer.

1. Remove the protective wrap from the E-Stop

switch and bracket assembly.

2. Secure the E-Stop switch bracket to the rear

sliding door support bracket with the socket-head

screw provided. Refer to Figure 2-3.

Figure 2-3. Rear E-Stop Switch Installation

Figure 2-2. Bed Height Adjustment

3. Using the height label as a guide, adjust the leg

length to the desired conveyor bed height. Retighten the two screws to secure the leg.

4. Adjust the five remaining legs in the same way.

Copyright 1999, 3M IPC. All rights reserved. 2-3

Page 28

Installation 3M-Matic 800rf Case Sealer

2-3-3. Warning Beacon Installation

A red warning beacon is electrically connected to the

case sealer, but not mounted to the machine. Install

this warning beacon on top of the frame support

member to which it is connected.

1. Remove the protective wrap from the warning

beacon and L-bracket assembly.

2. Remove the top hex-head screw from the frame

support member. Refer to Figure 2-4.

3. Secure the warning beacon L-bracket to the

frame support member with the screw just

removed.

2-3-4. Pneumatic Connection

The case sealer requires a compressed air supply of

75 140 PSIG [5.2 9.5BAR] 7.0 SCFM [11.89m

o

C, 101kPa] maximum at maximum cycle rate. The

21

optimum operating set-point on the gauge is 95 100

PSIG. As shown in Figure 2-5, an On/Off Valve, Main

Air Pressure Regulator, and Filter are provided to

service the air supply.

Connect the air supply line to the Main Air Pressure

Regulator On/Off Valve.

ü Note

The air supply On/Off Valve has provisions for

lockout/tagout according to plant regulations.

3

/h

Figure 2-4. Warning Beacon Installation

Figure 2-5. Air Supply Components

2-4 Copyright 1999, 3M IPC. All rights reserved.

Page 29

3M-Matic 800rf Case Sealer Installation

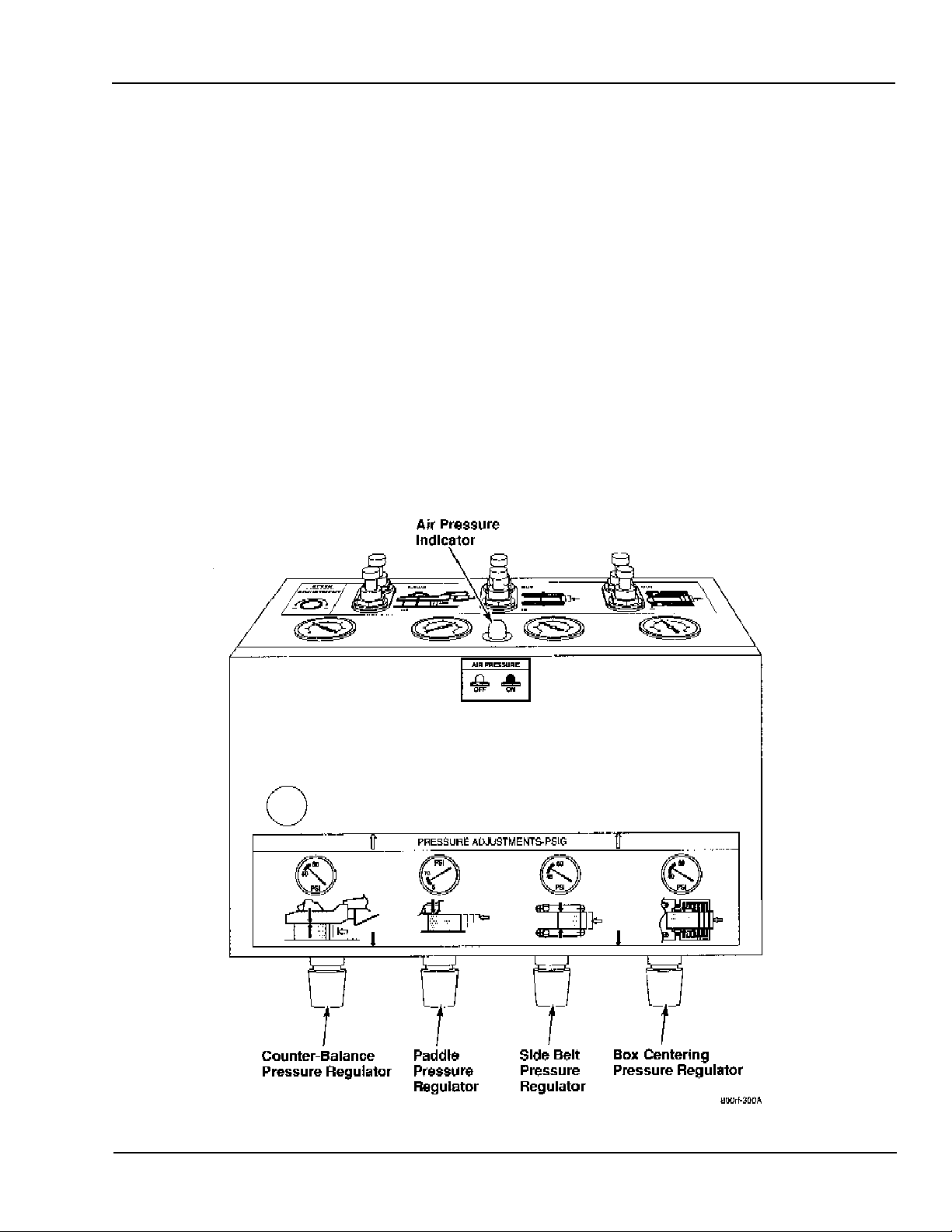

2-3-5. Air Pressure Indicator

The Pneumatic Control Panel (Figure 2-6) is

equipped with an Air Pressure Indicator to show, in

red, when the air circuit is energized. The Air

Pressure Indicator is located in the top center of

the control panel.

2-3-6. Air Pressure Regulators

There are four air pressure regulator control knobs

located on the underside of the Pneumatic Control

Panel. Their corresponding gauges are located across

the top of the Pneumatic Control Panel. Refer to

Figure 2-6.

Refer to the Adjustments section of this manual for

the recommended set points for each regulator

(Counter-Balance Pressure Regulator, Paddle Pressure Regulator, Side Belt Pressure Regulator, and

Box Centering Pressure Regulator). Also refer to the

label located on the lower front portion of the Pneumatic Control Panel.

To adjust any of these air pressure regulators, turn

its control knob clockwise (CW) to increase

pressure and counterclockwise (CCW) to decrease

pressure.

Figure 2-6. Pneumatic Control Panel

Copyright 1999, 3M IPC. All rights reserved. 2-5

Page 30

Installation 3M-Matic 800rf Case Sealer

2-3-7. Electrical Connection

!

Caution

Before making the electrical connection,

make sure that the red Latching Emergency

Stop switch located on the Electrical

Control Panel is depressed. Also ensure

that all packaging materials and tools are

removed from the case sealer.

The case sealer and its Electrical Control Panel are

wired for 208 240 VAC, 50/60 Hz, 3-phase power

and a power cord is connected. However, no power

plug is supplied. The power cord can be wired

directly into a power distribution box or a plug can be

installed. The recommended plug is a L15-20, 4-pin

twist-lock. Possible wire code combinations are:

Black Phase X or Black Phase X

White Phase Y Brown Phase Y

Red Phase Z Blue Phase Z

Green Ground Yel/Grn Ground

1. Turn the electrical power on by rotating the Main

Disconnect switch CW. Refer to

Figure 2-8. The white POWER indicator lights to

show that power is available. Refer to

Figure 2-7.

2. The red lights on the Electrical Control Panel

indicate a Fault/E-Stop switch condition. Turn

the red latching E-Stop switch CW to release

the switch. The red FAULT and E-STOP/

SLIDING DOOR indicators should turn off.

3. Press the blue RESET button on the Electrical

Control Panel. You should observe air-powered

movement of the Upper Head Assembly and the

Rear Flap Folding Arm, which moves to an

upright (extended) position.

4. Press the green START button on the Electrical

Control Panel. Pressing this button applies

electrical power to the two side belt drive motors

and the infeed roller drive motors. The RUN

indicator should light.

Viewing the case sealer from its infeed end, you

should observe the right/rear drive belt turning in

a CW direction and the left/front drive belt

turning in a CCW direction. With the belts

rotating as described, they will draw a carton

into the machine. This is the normal operating

condition.

ü Note

If the drive belts rotate in reverse, interchange any

two of the black, white, or red 208 220 VAC

wires at the plug or power distribution box. This

will restore the motors to the correct rotation.

2-6 Copyright 1999, 3M IPC. All rights reserved.

Page 31

3M-Matic 800rf Case Sealer Installation

Figure 2-7. Electrical Control Panel

(Top View)

Figure 2-8. Electrical Control Panel

(Front View)

Copyright 1999, 3M IPC. All rights reserved. 2-7

Page 32

Installation 3M-Matic 800rf Case Sealer

2-4. Tape Loading

Warning!

Turn air and electrical supplies off and

disconnect before servicing taping heads.

Never attempt to work on the taping heads

or load tape when the box drive system is

running. Each taping head is equipped

with an extremely sharp cut-off knife.

Before working with the taping heads or

attempting to load/thread tape, identify the

knife locations. Keep hands out of these

areas except as necessary to service the

taping heads. Failure to comply with these

warnings can result in severe personal

injury and/or equipment damage.

Figure 2-9 shows the components of the top taping

head.

The taping heads are pre-set to accommodate 2-inch

[48 mm] wide tape rolls. To use and apply 1-1/2 inch

[36 mm] or 1-3/4 inch [42 mm] wide tapes, refer to

the Adjustments section for set up information.

A tape-threading tool is shipped with the case sealer

for tape loading convenience. Retain the tool for

continued use in the tape loading operation. For

operator assistance, a threading diagram is applied to

the taping heads. However, it is recommended that

the more detailed instructions and illustrations in this

manual be referred to the first few times the tape is

loaded until the operator becomes thoroughly familiar

with the tape loading operation.

For convenience in loading, the bottom taping head

can be removed by lifting it out of the bed of the case

sealer. The upper head assembly must be in its

uppermost position to load tape in the top tape head.

Figure 2-9. Top Taping Head Components

2-8 Copyright 1999, 3M IPC. All rights reserved.

Page 33

3M-Matic 800rf Case Sealer Installation

2-4-1. Top Tape Head Loading

1. Turn off the Main Disconnect Switch on the

Electrical Control Panel.

2. Insert the tape-threading tool downward around

the rollers, as shown in Figure 2-10.

Figure 2-11. Attach Tape to Threading Tool

Figure 2-10. Insert Tape Threading Tool

3. Place the tape roll on the drum to dispense tape

from the bottom of the roll toward the infeed end

of the machine with the tape adhesive-side up.

Attach the tape leading end to the upper end of

the tape-threading tool, as shown in

Figure 2-11.

4. Manually turn the tape roll to create slack tape

while pulling the tape-threading tool through the

tape-applying mechanism until the tool is in

alignment with the applying roller.

5. Cut off the excess tape with a scissors or knife

below the applying roller. Refer to Figure 2-12.

Retain the tape-threading tool for future use.

Figure 2-12. Cut Off Tape

Copyright 1999, 3M IPC. All rights reserved. 2-9

Page 34

Installation 3M-Matic 800rf Case Sealer

2-4-2. Bottom Tape Head Loading

The bottom taping head is loaded and threaded in the

same manner as the top taping head. For ease in

loading, lift the bottom taping head from the conveyor bed and follow the top tape head loading

procedure. Refer to Figure 2-13.

Figure 2-13. Bottom Taping Head

2-10 Copyright 1999, 3M IPC. All rights reserved.

Page 35

3M-Matic 800rf Case Sealer Installation

2-5. Tape Drum Friction Brake

1. Refer to Figure 2-14. Turn the locking nut

clockwise to increase the braking force or counterclockwise to decrease the force.

2. Adjust the friction brake for the minimum

braking force that prevents excessive overtravel.

ü Note

Excessive braking force causes poor tape application

and may lead to tape tabbing on the trailing tape leg.

2-6. Checkout Inspection

(to be performed by an authorized

3M Service Technician)

2-6-2. Static Tests

1. Connect the air supply line and the electrical

power to the case sealer and power up the machine.

a. Turn the Air On/Off Valve to the ON posi-

tion.

b. Turn the Main Disconnect Switch on the

Electrical Control Panel to the ON position.

c. Press the RESET button on the Electrical

Control Panel.

2. Verify the following conditions:

• Air Pressure Indicator on the Pneumatic

Control Panel is red, showing that air pressure

is applied to the system, the rear flap folding

arm is extended, and the flap folder is retracted.

Figure 2-14. Friction Brake Adjustment

• Paddle is down.

• Side belts are out.

• Box centering rails are out.

• Box stop gate is up.

3. Check the Main Input Air Pressure Regulator.

The pressure gauge should read 95 PSIG.

a. If the pressure is lower, check the input

pressure at the source. If the pressure is lower

than 75 PSIG, there is not enough pressure to

operate the case sealer properly.

b. If the pressure is above 95 PSIG, adjust the

air pressure regulator to read 95 PSIG on the

gauge. (CW increases pressure,

CCW decreases pressure).

Copyright 1999, 3M IPC. All rights reserved. 2-11

Page 36

Installation 3M-Matic 800rf Case Sealer

4. Check the Box Centering Pressure gauge on the

Pneumatic Control Panel. Refer to Figure 2-15.

The gauge should read 40 60 PSIG. If the

pressure does not fall within this range, adjust the

pressure regulator (CW increases pressure,

CCW decreases pressure).

5. Check the Side Belt Pressure gauge on the

Pneumatic Control Panel. The gauge should read

40 60 PSIG. If necessary, adjust the Side Belt

Pressure Regulator to this setting. (CW increases pressure, CCW decreases pressure).

6. Check the Paddle Pressure gauge on the Pneumatic Control Panel. The gauge needle should be

at 7 PSIG. Adjust as needed.

7. Check the Counter-Balance Pressure gauge on the

Pneumatic Control Panel. The gauge should read

40 60 PSIG. If the pressure does not fall within

this range, adjust the pressure regulator (CW

increases pressure, CCW decreases pressure).

Figure 2-15. Pneumatic Control Panel

2-12 Copyright 1999, 3M IPC. All rights reserved.

Page 37

3M-Matic 800rf Case Sealer Installation

8. Press the START button on the Electrical Control

Panel. Refer to Figure 2-16. Verify that the side

belts and the infeed rollers start turning.

ü Note

If pressing the START button does not result in

continuous running of the side belt drive motors and

the infeed drive motors, then a Fault Condition

exists. Check the motor overload circuit breakers

OL1, OL2, OL3, and OL4, which are the most likely

cause. These circuit breakers are located inside the

Electrical Control Panel. Make sure the green

START buttons are all pushed in.

Figure 2-16. Electrical Control Panel

9. Check the operation of the red latching

Emergency Stop switches (one E-Stop switch is

located on the Electrical Control Panel and the

other switch is located at the rear of the machine)

and the STOP button on the Electrical Control

Panel. Verify that the drive motors stop when

either E-Stop switch is pressed or the STOP

button is pressed.

The case sealer must be restarted each time it

stops before checking the next switch. Restart the

machine by pressing the RESET button and then

the START button.

Caution

!

If the EMERGENCY STOP switches or the

STOP button do not function properly, do

not continue with the checkout. Refer to the

Theory of Operation and Troubleshooting

sections and correct the situation before

continuing.

Warning!

Steps 10 and 11 require opening the

Electrical Control Panel door. This exposes

220 VAC. Be cautious or personal injury

can result.

Copyright 1999, 3M IPC. All rights reserved. 2-13

Page 38

Installation 3M-Matic 800rf Case Sealer

10. Check the operation of the electrical interlocks

for the sliding doors. With the drive motors

running, move each sliding door, one at a time,

from its closed position. Verify that the drive

motors stop and that they cannot be restarted by

pressing the RESET button and then the START

button until the door is closed.

Verify also that when the door is open only

OUTPUT LEDs 13 and 14 are ON and no INPUT

LEDs are displayed on the Programmable Controller located inside of the Electrical Control

Panel.

11. Refer to Figure 2-17. Check the operation of the

photocells PC1 through PC6. Cover each photocell in turn and observe the associated INPUT

LED number displayed on the Programmable

Controller. The INPUT LED should be ON when

the associated photocell is covered.

Photocell INPUT LED

PC1 IN 4

PC2 IN 5

PC3 IN 6

PC4 IN 7

PC5 IN 8

PC6 IN 9

Figure 2-17. Photocell Locations

2-14 Copyright 1999, 3M IPC. All rights reserved.

Page 39

3M-Matic 800rf Case Sealer Installation

2-6-2. Programmable Controller Inputs and

Outputs

Figure 2-18 shows the SLC 500 Programmable

Controller used in the 3M-Matic 800rf Type 39800

Case Sealer. The Programmable Controller is located

inside of the Electrical Control Panel.

Figure 2-18. SLC 500 Programmable Controller

Copyright 1999, 3M IPC. All rights reserved. 2-15

Page 40

Installation 3M-Matic 800rf Case Sealer

Figure 2-19 shows the Programmable Controller

lights that turn on during the following startup

conditions.

POWER ON RESET START

POWER POWER POWER

PC RUN PC RUN PC RUN

INPUT 3 INPUT 0, 3, 11, 15 INPUT 0, 3, 11, 15

OUTPUT 1, 3 , 7, 12, 15

Figure 2-19. Programmable Controller Startup Conditions

2-16 Copyright 1999, 3M IPC. All rights reserved.

Page 41

3M-Matic 800rf Case Sealer Installation

Table 2-1 lists the INPUT LEDs displayed on the

Programmable Controller, the names of the input

signals that feed the LEDs, and the conditions that

cause the LEDs to turn ON or OFF.

View the LEDs with the Main Disconnect Switch and

the Air On/Off Valve turned to their ON positions.

Table 2-1. Programmable Controller Inputs

INPUT LED Input Signal Name LED Condition

0 Stop OFF when STOP button is pushed.

1 Start ON when START button is pushed.

2 Reset ON when RESET button is pushed.

3 E-Stop/Sliding Door OFF when E-Stop switch is pushed or door is opened.

4 PC1 ON when photocell PC1 is blocked.

5 PC2 ON when photocell PC2 is blocked.

6 PC3 ON when photocell PC3 is blocked.

7 PC4 ON when photocell PC4 is blocked.

8 PC5 ON when photocell PC5 is blocked.

9 PC6 ON when photocell PC6 is blocked.

10 Box Height (Paddle) Switch ON when paddle is pushed up.

11 Head Upper Limit Switch ON when upper head assembly is at its upper limit.

12 Minimum Width Switch ON when side belt assemblies close to innermost position.

13 Fixed Mode Switch ON when selector switch is set to FIXED position.

14 Bypass Mode Switch ON when selector switch is set to BYPASS position.

15 Low Air Pressure Switch ON when air pressure is above 50 PSIG.

16 Flap Folder Arm Switch ON when cylinder piston is near reed switch.

17 Overload ON when any motor overload switch trips.

18 Not used

19 Not used

20 Not used

21 Not used

22 Not used

23 Not used

Copyright 1999, 3M IPC. All rights reserved. 2-17

Page 42

Installation 3M-Matic 800rf Case Sealer

Table 2-2 lists the OUTPUT LEDs displayed on the

Programmable Controller, the names of the output

signals that feed the LEDs, and the conditions that

cause the LEDs to turn ON or OFF.

View the LEDs with the Main Disconnect Switch and

the Air On/Off Valve turned to their ON positions.

Table 2-2. Programmable Controller Outputs

OUTPUT LED Output Signal Name LED Condition

0 Side Belt Lock ON when side belts lock.

1 Side Drive Motors ON when side belt drive motors are running.

2 Flap Folder Arm ON when flap folder arm is down.

3 Infeed Gate ON when infeed gate is down.

4 Centering Rails ON when photocell PC1 is blocked.

5 Side Drive Assembly Closing ON when photocell PC3 is blocked.

6 Paddle Cylinder ON when paddle is pushed up.

7 Fork Cylinder ON when fork is up.

8 Head Assembly Cylinder Brakes ON when brakes turn on.

9 Head Raising Cylinder Lower Port ON when upper head assembly lowers.

10 Head Raising Cylinder Upper Port ON when upper head assembly raises.

11 Rear Flap Folder ON when rear flap folder folds last minor flap.

12 Infeed Motors (2) ON when infeed motors are running.

13 Alarm ON when any fault condition exists.

14 E-Stop Signal ON when either E-Stop switch is pushed.

15 Ready Signal ON when START button is pushed.

2-18 Copyright 1999, 3M IPC. All rights reserved.

Page 43

3M-Matic 800rf Case Sealer Installation

2-6-3. Dynamic Tests

The following procedures check the actual operation

of the 800rf Case Sealer. The following conditions

must be observed.

• Electrical power and compressed air are available

and turned on.

• The four safety doors are in their closed posi-

tions.

• Cases should have:

− the bottoms folded closed

− a minimum weight to hold the case on the

conveyor bed with the bottom flaps flat

− the front and rear flaps inside the side flaps

1. Apply air pressure and electrical power and press

the RESET and the START buttons on the

Electrical Control Panel.

2. If applicable, run the longest box (19 inches to 24

inches) through the case sealer. Check the

following sequence of events.

a. The box feeds from the infeed conveyor

rollers. The box is centered by the box

centering rails and the box stop gate moves

up.

f. The side belts restart.

g. Just before the sides of the box are folded

down, the rear flap of the box is folded down

into place.

ü Note

The timing of step g will vary depending on the

length of the box.

h. The sides of the box are folded down.

i. The top flap compression rollers touch the

sides of the top of the box without causing

the side flaps to overlap.

j. C-clips of tape are applied to both the top and

bottom center seams of the box.

k. The box exits the case sealer.

l. The head rises to its upper position, the side

belts return to their outer position, the fork

rises to its normal position, and the box stop

gate lowers to allow the next box to be fed

into the machine.

ü Note

If any of the steps outlined above do not occur

correctly, refer to the appropriate adjustment in the

Adjustments section of this manual.

b. The box is released and moves to the side

belts.

c. The side belts move inward and hold the box,

driving it toward the fork.

d. The box arrives at the fork and the side belts

stop driving the box.

e. The head lowers to the box, stopping at the

top of the box without distorting it.

3. If applicable, repeat the procedure outlined in

step 2 using the shortest box (8 inches to 13

inches).

4. If applicable, repeat the procedure outlined in

step 2 using a box between 12 and 19 inches.

5. Now that a representative sample of boxes has

been checked and appropriate adjustments have

been made, flood the infeed line with a random

array of boxes and check for consistent operation of the case sealer.

Copyright 1999, 3M IPC. All rights reserved. 2-19

Page 44

Installation 3M-Matic 800rf Case Sealer

2-7. Placing 800rf Case Sealer in

Production Line

When installing the 800rf Case Sealer into a production line, ensure compliance with the following

requirements:

• The case sealer must be level.

• The customers infeed conveyor may be powered

or inclined to the case sealer.

• The customers infeed conveyor box delivery

speed CANNOT exceed 60 ft/min.

• The customers exit conveyor may be powered or

inclined whichever positively conveys boxes

away from the exit end of the case sealer.

• The width of the customers infeed conveyor and

exit conveyor should fall within 22 inches [560

mm] minimum to 38 inches [965 mm] maximum.

Figure 2-20 shows the 800rf Case Sealer connected to

customer-supplied infeed and exit conveyors.

!

Caution

The 800rf Case Sealer must not be run in a

production line without being joined to the

customers infeed conveyor. This is to

restrict an operator from being exposed to

moving case sealer components during its

operation.

Figure 2-20. Typical Conveyor Setup

2-20 Copyright 1999, 3M IPC. All rights reserved.

Page 45

3M-Matic 800rf Case Sealer Installation

2-8. Special Setup Procedure

2-8-1. Relocating Pneumatic and Electrical

Control Panels

Warning!

Turn off electrical power and air supply and

disconnect power cord from electrical

supply before beginning this procedure.

Failure to comply with these warnings can

result in severe personal injury and/or

equipment damage.

Relocating the case sealer Pneumatic and Electrical

Control Panels from their standard position which is

the left/front side, as viewed from the infeed end of

the machine, enables the case sealer to be operated

from the right/rear side of the machine.

At various steps of this procedure it is recommended

that two (2) people be involved in moving certain

components from the front to the rear of the case

sealer.

ü Note

Following these procedures will accomplish having

the control panels located to the right/rear of the case

sealer and will orient the Electrical Control Panel on

the left and the Pneumatic Control Panel on the right,

as viewed by the operator facing the rear side of the

machine.

Removing Air On/Off Valve/Regulator/Filter,

Pneumatic Control Panel, and Brackets

1. Disconnect the air supply from the Air On/Off

Valve.

2. Open the Pneumatic Control Panel (use 8 mm hex

wrench) to assist in removing the input air line

from the air outlet on the Main Air Pressure

Regulator. Push in and hold the collet (release

ring) and pull the air line free. Refer to

Figure 2-21.

To prevent the case sealer from rolling, lock all the

casters before starting these procedures.

Figure 2-21. Disconnecting Air Line

Copyright 1999, 3M IPC. All rights reserved. 2-21

Page 46

Installation 3M-Matic 800rf Case Sealer

3. Disconnect the plastic conduit at the Electrical

Control Panel, which connects to the Pneumatic

Control Panel. This conduit contains the electrical wires for the valve solenoids.

4. Slide the left front sliding door all the way to the

right to provide additional access.

5. Remove the Air On/Off Valve/Regulator/Filter

bracket.

a. Remove the 2 socket-head screws (6 mm)

securing the bracket to the mainframe

bracket. Refer to Figure 2-22.

b. Set this bracket (with Air On/Off Valve/

Regulator/Filter attached) aside for use later.

6. Prepare two (2) blocks (10 long x 8 wide x 18

high). These blocks will be used to support the

control panels later in this procedure.

!

Caution

Blocks must be capable of supporting the

weight of the Electrical Control Panel, which

is about 50 pounds [22.7 kg].

7. Remove the Pneumatic Control Panel.

a. Place a block under the Pneumatic Control

Panel.

b. Remove the 4 socket-head screws (6 mm)

securing the control panel to the left and right

brackets. Refer to Figure 2-23.

c. Save these screws for use later.

d. Ease the control panel onto the block. Make

sure the block is centered under the control

panel so the panel is stable.

Figure 2-22. Removing Air On/Off Valve/

Regulator/Filter Bracket

Figure 2-23. Removing Pneumatic Control Panel

2-22 Copyright 1999, 3M IPC. All rights reserved.

Page 47

3M-Matic 800rf Case Sealer Installation

8. Remove the left and right mainframe brackets

that support the Pneumatic Control Panel. Refer

to Figure 2-24.

a. Remove 8 socket-head screws (6 mm)

securing the left support bracket to the case

sealer (4 screws holding the bracket to the

mainframe, and 4 screws holding the 2 L

brackets).

b. Remove 4 socket-head screws (6 mm)

securing the right support bracket to the case

sealer.

c. Save these screws and brackets for use later.

Moving Support Brackets and Installing Pneumatic Control Panel

9. Install the left support bracket and L brackets

(removed from the front of the machine) at the

rear of the machine. Refer to Figure 2-25. Secure

the brackets with the socket-head screws (6 mm).

10. Remove the right mainframe bracket from the

rear of the machine and install it at the front left

of the case sealer. Refer to Figure 2-25.

12. Install the Pneumatic Control Panel at the rear of

the case sealer.

a. Lift the Pneumatic Control Panel from the

block and slide it through the undercarriage

to the rear of the case sealer.

b. Block the control panel and then lift it and

carefully set it onto the support brackets.

c. Hold the control panel in place and secure it

to the support brackets with 4 socket-head

screws.

a. Remove the 6 socket-head screws (6 mm)

securing the mainframe bracket to the case

sealer (4 screws holding the bracket to the

mainframe, and 2 screws holding the bracket

to the underside of the door frame).

b. Install this bracket at the front left of the case

sealer. Secure the bracket to the mainframe

with 4 socket-head screws, and secure the

bracket to the underside of the door frame

with 2 socket-head screws.

11. Install the right support bracket (removed from

the front of the machine) at the rear right of the

case sealer. Refer to Figure 2-25. Secure the

bracket to the mainframe with 4 socket-head

screws.

Figure 2-24. Removing Support Brackets for

Pneumatic Control Panel

Copyright 1999, 3M IPC. All rights reserved. 2-23

Page 48

Installation 3M-Matic 800rf Case Sealer

Figure 2-25. Moving Support Brackets for Pneumatic Control Panel

2-24 Copyright 1999, 3M IPC. All rights reserved.

Page 49

3M-Matic 800rf Case Sealer Installation

Installing Air On/Off Valve/Regulator/Filter

13. Locate the Air On/Off Valve/Regulator/Filter and

bracket.

14. Rotate the bracket 180°.

a. Remove the lower socket-head screw (4

mm) and loosen the upper screw, but do not

remove it. Refer to Figure 2-26.

b. Punch a hole in the label. Then rotate the

bracket 180°. The label will be upside-down

(a replacement label is available and may

be ordered as replacement parts are ordered).

c. Secure the Air On/Off Valve/Regulator/

Filter to the bracket by installing the lower

socket-head screw and tightening the upper

screw. Refer to Figure 2-27.

15. Mount the bracket with the Air On/Off Valve/

Regulator/Filter to the left bracket that supports

the Pneumatic Control Panel.

Figure 2-26. Air On/Off Valve/Regulator/Filter

and Bracket

Figure 2-27. Air On/Off Valve/Regulator/Filter

and Bracket Rotated 180°

Copyright 1999, 3M IPC. All rights reserved. 2-25

Page 50

Installation 3M-Matic 800rf Case Sealer

16. Remove and separate the Air On/Off Valve

from the Regulator/Filter.

a. Loosen the hex screw in the bracket that

holds the two assemblies together. Refer to

Figure 2-28.

b. Separate the Air On/Off Valve from the