Page 1

Operator Manual

Version 2.0

Model #3960 – Control Module

Model #3968 – Test Module

Page 2

3M is a trademark of 3M

RAMP is a registered trademark of Response Biomedical Corporation.

Microsoft is a registered trademark of Microsoft Corp.

Microsoft Windows is a registered trademark of Microsoft Corp.

Microsoft Excel is a registered trademark of Microsoft Corp.

Zebra is a registered trademark of ZIH Corp.

Symbol is a registered trademark of Motorola, Inc.

© 3M 2009 All rights reserved

Made in Canada for:

3M Health Care

St. Paul, MN U.S.A.

55144 – 1000

www.3M.com

Technical Assistance:

3M Health Care Helpline 1-800-228-3957

Outside the U.S.A. and Canada, contact your local 3M Subsidiary

3M™ Rapid Detection Reader Operator Manual

34-8703-4755-5 (August 2009) Version 2.0 For use with Software Version 1.1

R0833 – AW, Manual, 3M Rapid Detection, v1_1 – 1r0

3M Health Care

D-41453 Neuss, Germany

Page 3

3M™ Rapid Detection Reader Table of Contents

Table of Contents

Warnings and Precautions........................................................................................................1

Summary of Warnings and Precautions...................................................................................2

Introduction...............................................................................................................................3

Overview.................................................................................................................................3

Intended Use..........................................................................................................................3

Unpacking and Setup................................................................................................................4

3M Rapid Detection Reader Components................................................................................4

Optional Accessories (Available from 3M)...............................................................................4

3M Rapid Detection Reader Setup..........................................................................................5

3M RAPID DETECTION Control Module............................................................................7

3M RAPID DETECTION Test Module.................................................................................7

3M Rapid Detection Reader (MODULES)..................................................................................8

Turning on the 3M Rapid Detection Reader.............................................................................8

Display Icons..........................................................................................................................9

Port Identification Nomenclature..............................................................................................9

Performing an Assay...............................................................................................................10

Using Lot Cards.....................................................................................................................10

Starting an Assay...................................................................................................................10

Running Quality Control.........................................................................................................12

LQC Icons..............................................................................................................................13

Running IQC..........................................................................................................................14

Working with Results and Logs..............................................................................................15

Viewing Saved Results...........................................................................................................15

Viewing Saved Logs...............................................................................................................15

Searching Results..................................................................................................................16

Searching Logs......................................................................................................................16

Manually Transferring / Printing Results or Logs.....................................................................17

Managing Settings...................................................................................................................18

Accessing the Settings Menus................................................................................................18

Assay................................................................................................................................19

LQC..................................................................................................................................19

Timer................................................................................................................................20

Printer...............................................................................................................................21

i

Page 4

3M™ Rapid Detection Reader Table of Contents

Login.................................................................................................................................21

File....................................................................................................................................22

About................................................................................................................................23

Edit Settings...........................................................................................................................24

Timers...............................................................................................................................24

Date/Time.........................................................................................................................25

Language..........................................................................................................................25

Misc..................................................................................................................................25

Restoring Defaults.................................................................................................................26

Managing Operators..............................................................................................................26

Adding/Modifying an Operator...........................................................................................27

Searching for an Individual Operator..................................................................................28

Editing Settings Using the Reader Configuration Utility (RCU)............................................29

Overview................................................................................................................................29

Installation.............................................................................................................................29

Getting Started.......................................................................................................................29

Emergency Password Reset Mechanism................................................................................30

Choosing a Configuration File Access Method........................................................................30

Setting Up a USB Flash Drive............................................................................................30

Setting Up Web Services Access:......................................................................................30

Accessing Configuration Files................................................................................................31

Setting Up Communications Between RCU and Readers.......................................................32

Files..................................................................................................................................32

Identifying Readers through the RCU.....................................................................................33

Non-networked Environment.............................................................................................33

Networked Environment....................................................................................................33

Importing Files.......................................................................................................................34

Exporting Files.......................................................................................................................34

Deleting Results.....................................................................................................................35

Maintenance.............................................................................................................................36

Exterior Cleaning...................................................................................................................36

Upgrading Device Software....................................................................................................37

Disposal of Equipment...........................................................................................................37

Troubleshooting......................................................................................................................38

Restoring the Supervisor Operator ID / Password...................................................................38

General..................................................................................................................................38

ii

Page 5

3M™ Rapid Detection Reader Table of Contents

Power On Self Test Message / IQC Messages.......................................................................39

Test Run Messages...............................................................................................................39

Lot Card Messages................................................................................................................41

Settings Messages.................................................................................................................42

LQC Related Messages.........................................................................................................43

Warnings and Confirmation Requests....................................................................................44

Printer Errors.........................................................................................................................44

Communications Errors..........................................................................................................45

USB Device Errors.................................................................................................................45

Specifications..........................................................................................................................47

Index........................................................................................................................................49

iii

Page 6

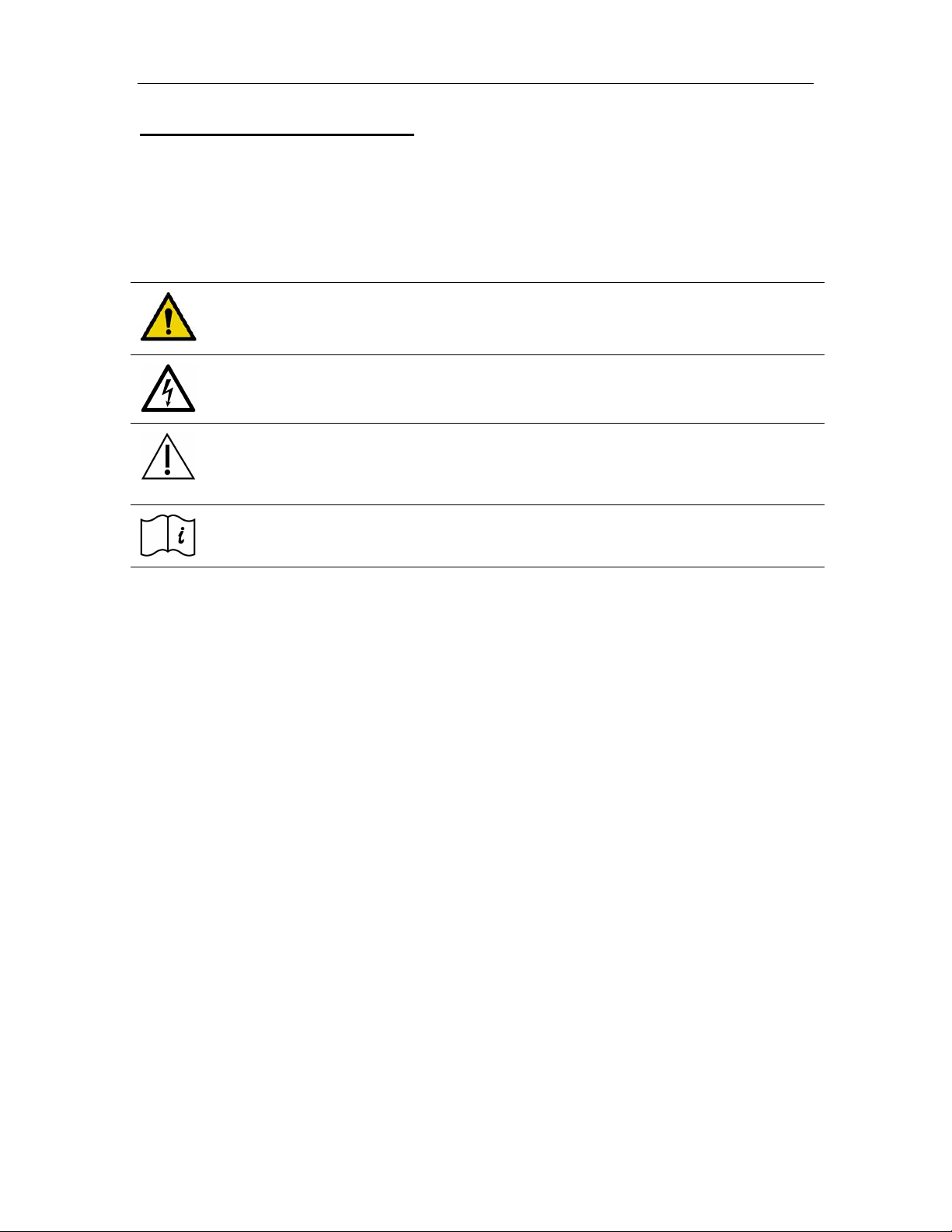

3M™ Rapid Detection Reader Warnings and Precautions

Warnings and Precautions

Read all contents of this manual prior to use.

The following symbols are used on the 3M Rapid Detection Reader, related components and

accessories, or in the text of this user manual:

WARNING!

Indicates a hazardous situation, which if not avoided, could result in death or injury,

e.g., fire, electrical shock or explosion.

WARNING! Hazardous Voltage

CAUTION. Indicates a situation, which if not avoided, could result in damage to the

device.

Consult Accompanying Documents

Consult Operator Manual

1

Page 7

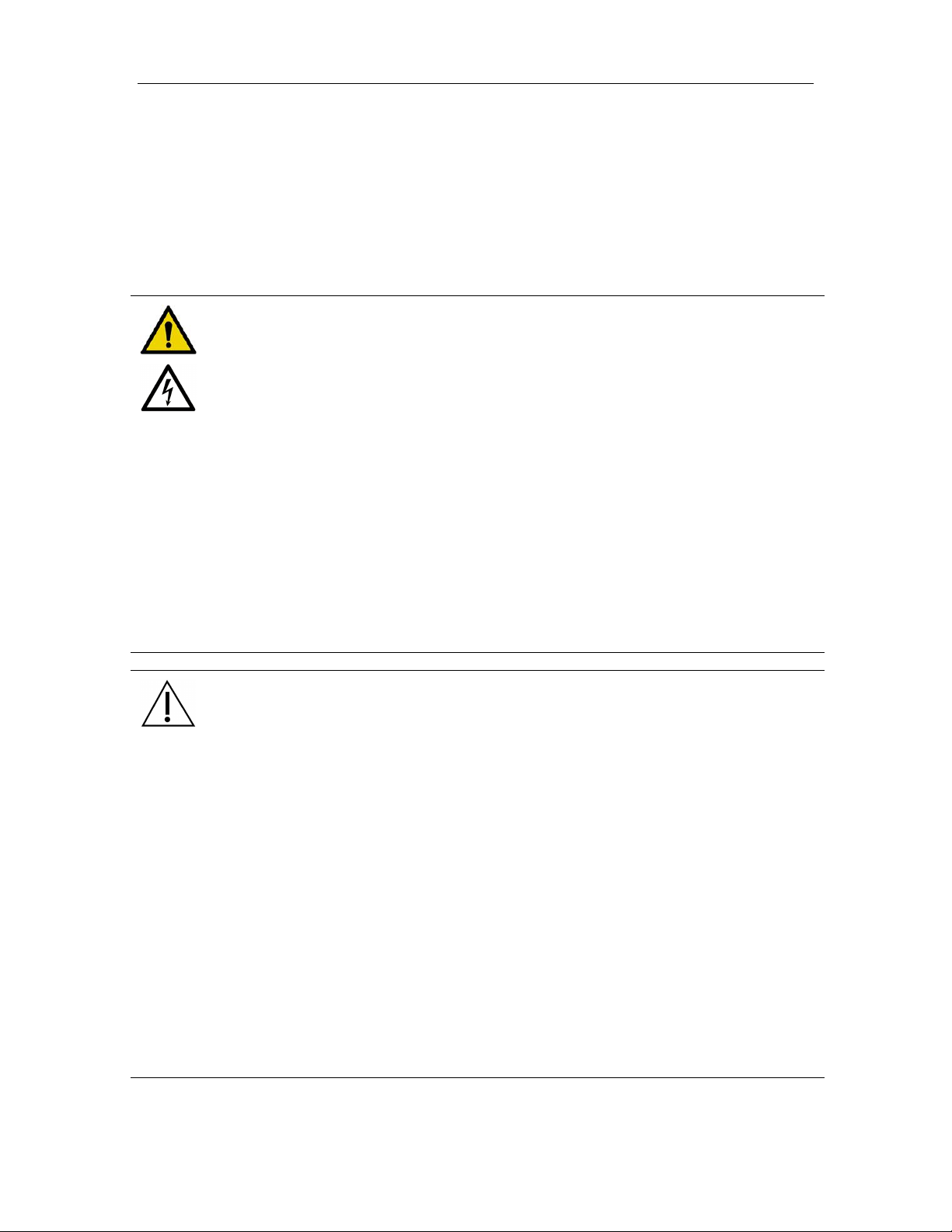

3M™ Rapid Detection Reader Warnings and Precautions

Summary of Warnings and Precautions

The 3M Rapid Detection Reader and its related devices and accessories are designed to provide

safe and reliable service when used according to the instructions provided in this Operator

Manual.

The following warnings and precautions should be followed in order to avoid unsafe actions with

the 3M Rapid Detection Reader that could potentially result in personal injury or device damage.

WARNING!

To reduce the risk associated with hazardous voltage:

• Unplug the 3M Rapid Detection Reader before cleaning.

• Do not disassemble the 3M Rapid Detection Reader or any of its related

components and accessories. The instrument contains no operator-serviceable

components.

• Do not immerse any of the 3M Rapid Detection Reader components in any liquid.

• Do not use the 3M Rapid Detection Reader if there is apparent damage to a power

cord or power supply.

To reduce the risk associated with potentially infectious patient samples:

• Do not spill specimen or sample fluids on any of the 3M Rapid Detection Reader

components or on the outside of the Test Cartridge.

• If a spill occurs, disinfect external surfaces only, using a soft cloth containing a

solution of 0.5% bleach, 70% isopropyl alcohol or 70% ethanol.

CAUTION.

To reduce the risk associated with incorrect results:

• 3M Rapid Detection Reader should only be used by trained professionals and

operated in accordance with facility policies and procedures.

• 3M Rapid Detection Reader should only be operated in ambient temperature

conditions between 15-30°C (59-86°F) and out of direct sunlight.

To reduce the risk of instrument or accessory damage:

• 3M Rapid Detection Reader is not designed to withstand moisture, temperature

extremes, severe shock or vibration.

• 3M Rapid Detection Reader is intended for use indoors, located on a stable,

stationary surface such as a counter top.

• Do not open any 3M Rapid Detection Reader device enclosures, this will void the

warranty.

To reduce the risk associated with environmental contamination:

• Dispose of instrument and accessories in accordance with federal, state, and local

requirements.

2

Page 8

3M™ Rapid Detection Reader Introduction

Introduction

Overview

The 3M Rapid Detection Reader is a rapid immunochromatographic system for performing in vitro

diagnostic analyses.

The 3M Rapid Detection Reader is comprised of the 3M Rapid Detection Control Module (CM)

and the 3M Rapid Detection Test Module (TM). Each Test Module has two ports. Up to three

Test Modules are connected to each Control Module providing the user the ability to test 1-6

samples simultaneously. The configuration software and USB flash provided drive allow the user

to customize the Reader and maintain the test data. The optional barcode scanner and printer

provide ease and accuracy for data entry and record keeping.

Calibration and expiration information for Test Cartridges are input to the 3M Rapid Detection

Control Module (CM) through Lot Cards enclosed with the Test Kits.

To perform an assay, the operator places a sample into the well of a Test Cartridge and inserts

the Test Cartridge into the 3M Rapid Detection Test Module (TM).

Once the Test Cartridge has been inserted, no further intervention is required. A barcode on the

bottom of the Test Cartridge is read to determine the Test Kit lot number. Information loaded with

the Lot Card identifies lot specific parameters and expiration date. This ensures that an expired

cartridge is not used.

Analysis time is analyte specific and typically less than 20 minutes per sample. Results may be

viewed on the 3M Rapid Detection Reader display screen and/or output to the USB flash drive, a

printer, or network.

The 3M Rapid Detection Reader only accepts Test Cartridges specified for use with 3M Rapid

Detection Test Kits.

The 3M Rapid Detection Reader can operate in either local or network mode. Operator input is

accepted from the touch screen or an optional barcode scanner. Stored data including results

can be transferred via USB flash drive or sent to a printer or network file.

Intended Use

The 3M Rapid Detection Reader is a general use fluorometer that analyzes results produced by

immunoassays specified by 3M.

Full operation requires the use of 3M RAPID DETECTION Test Kit. Optional accessories include

a printer and barcode scanner.

3

Page 9

3M™ Rapid Detection Reader Unpacking and Setup

Unpacking and Setup

Inspect all components carefully. If any damage is visible, notify the carrier and your distributor or

3M to arrange for repair or replacement.

3M Rapid Detection Reader Components

Item Description

3M RAPID

DETECTION

Control Module

(CM)

Catalog # 3960

3M RAPID DETECTION Control Module

Operator Manual

Reader Configuration Utility CD

Power Supply*

USB Flash Drive**

3M RAPID

DETECTION

Test Module

(TM)

Catalog # 3968

*Only use the approved power cord provided with the 3M RAPID DETECTION CM. A power cord

approved for the North American market will be provided with each CM. Outside the North

American market, the CM will be supplied with an additional power cord approved for that market.

**Use manufacturer supplied USB Flash Drive. If a USB Flash drive is supplied by the operator,

ensure the drive folders match those folders listed in the Manually Transferring / Printing Results

or Logs section.

3M RAPID DETECTION Test Module

Interconnect Cable

Optional Accessories (Available from 3M)

Optional USB devices supported by the 3M Rapid Detection Reader include a printer and a

barcode scanner. Only use the approved USB cables supplied with these devices.

NOTE: Only one of each type of device can be connected to the CM at any given time.

Item Description

Printer

Catalog # 3965

Printer for self-adhesive roll labels, 2 - 2.5-inches

wide. Connects to the CM via USB. Zebra®

Technologies TLP 2824™.

Consumables:

Requires 2.25” W x 3” L Z-Select 4000T labels from

Zebra® Technologies (p/n: 800222-305).

Requires 57mm x 74m Wax/Resin Ribbon from

Zebra® Technologies (p/n: 800132-102).

Additional information available at www.zebra.com

or 1.847.634.6700.

4

Page 10

3M™ Rapid Detection Reader Unpacking and Setup

Item Description

Barcode Scanner

Catalog # 3967

Omni-directional, hands-free barcode scanner with

cradle for entering Operator and Patient/Sample ID.

The barcode scanner is shipped in the correct

configuration and is ready for use after connecting to

the CM via USB. Symbol Technologies Inc. model

LS9208. Additional information available at

www.symbol.com, 1.800.653.5350 or

1.631.738.2400.

3M Rapid Detection Reader Setup

The 3M Rapid Detection Reader is comprised of:

§ 3M RAPID DETECTION Control Module (CM)

User interface and connectors for all peripherals. Stores and displays test results (view, print,

transfer, search, filter/sort)

§ 3M RAPID DETECTION Test Module (TM)

1 – 3 TMs per CM

Each TM has two test cartridge ports for performing simultaneous 3M RAPID DETECTION

Tests

§ 3M RAPID DETECTION Reader Configuration Utility Software (RCU)

CD allows customized settings for the 3M Rapid Detection Reader

§ Power supply and interconnect cable

§ USB flash drive

Pre-configured with 4 subdirectories (folders) named: patient, lqc, iqc and log, for use in bidirectional information transfer in a non-networked environment. Also contains “File

Converter 1_1.xls”. See Manually Transferring/Printing Results or Logs section.

To set-up 3M Rapid Detection Reader:

1. Place the 3M Rapid Detection Reader components on a stable work surface within reach of

an electrical outlet. Access to the back of each module is required to connect components.

2. Remove dust protection stickers from TM ports

3. Connect the TM and any optional devices to the CM using the supplied interconnect cable(s).

Refer to Figure 1 for connector locations.

Refer to manufacturer’s instructions for optional printer or barcode scanner for additional

information on set-up for these accessories.

4. Connect the supplied power cord to the CM. Plug the other end into a wall socket.

5

Page 11

3M™ Rapid Detection Reader Unpacking and Setup

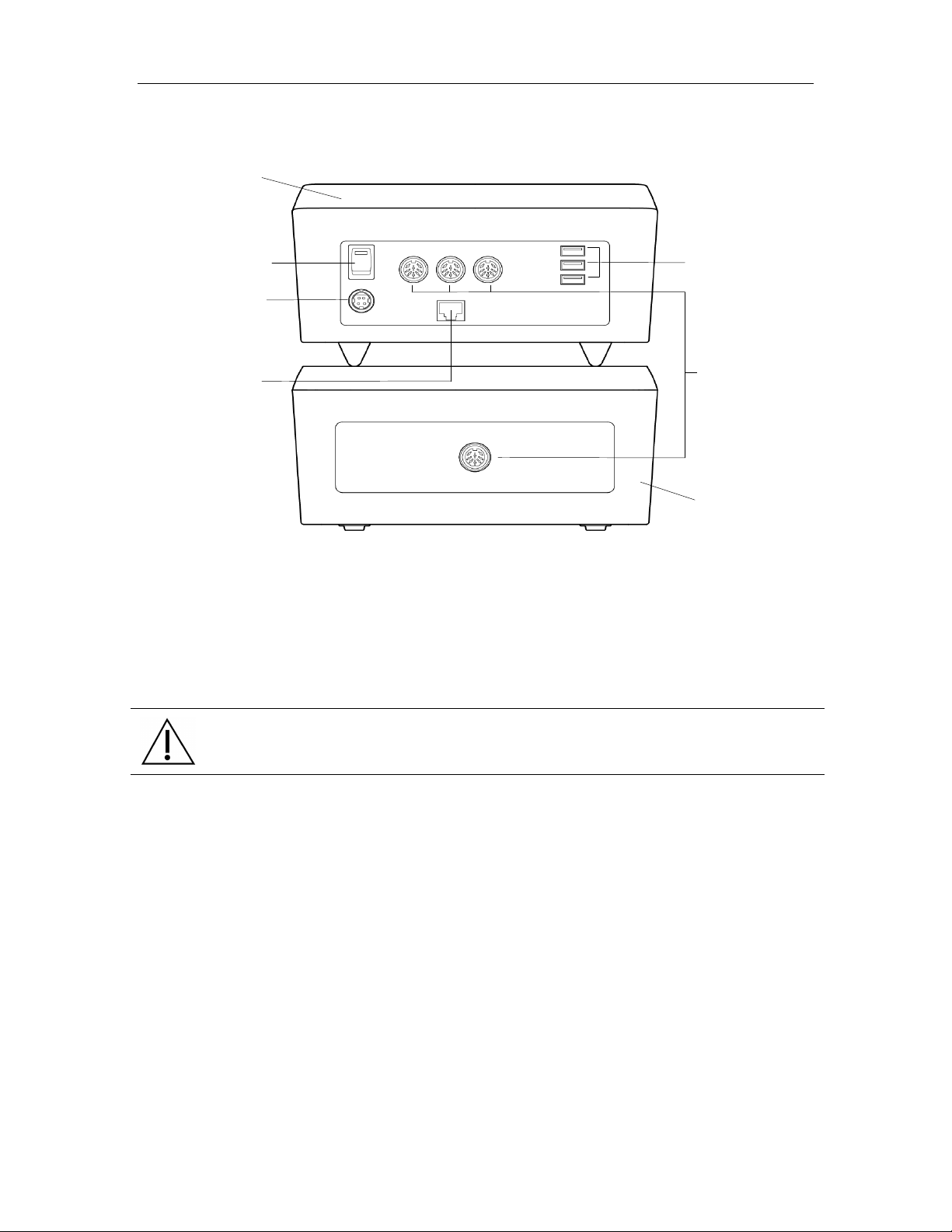

3M Rapid Detection

Control

Module

Power On/Off

Power cord

Ethernet

connector for

3M Rapid

Detection Reader Test

USB connectors for

Figure 1. 3M Rapid Detection Reader - Rear View Showing Connectors and Power Switch

Reader

optional printer,

optional barcode

scanner and Flash

Drive

port

3M Rapid Detection

Reader Control

connection

to a network

Module to 3M Rapid

Module port

Detection Reader

Test Module

NOTE:

• 1, 2, or 3 TMs can be connected to each CM

• TMs can be stacked

• CM can be placed on top of the TM

• Do not place anything on top of the CM.

CAUTION.

Do not stack CM on top of TM unless all four feet are in place.

6

Page 12

3M™ Rapid Detection Reader Unpacking and Setup

0 - OFF Switch

Safety

Date of

Ethernet

Electrical

Consult

manual

Hardware

Serial

Figure 1a. 3M Rapid Detection Reader – Rear view panel labels and description

3M RAPID DETECTION Control Module

I - ON Switch

TM Ports

USB Ports

certification

marking

Caution

rating

CE Marking

WEEE

connection

3M RAPID DETECTION Test Module

CM Port

revision

number

manufacture

number

7

Page 13

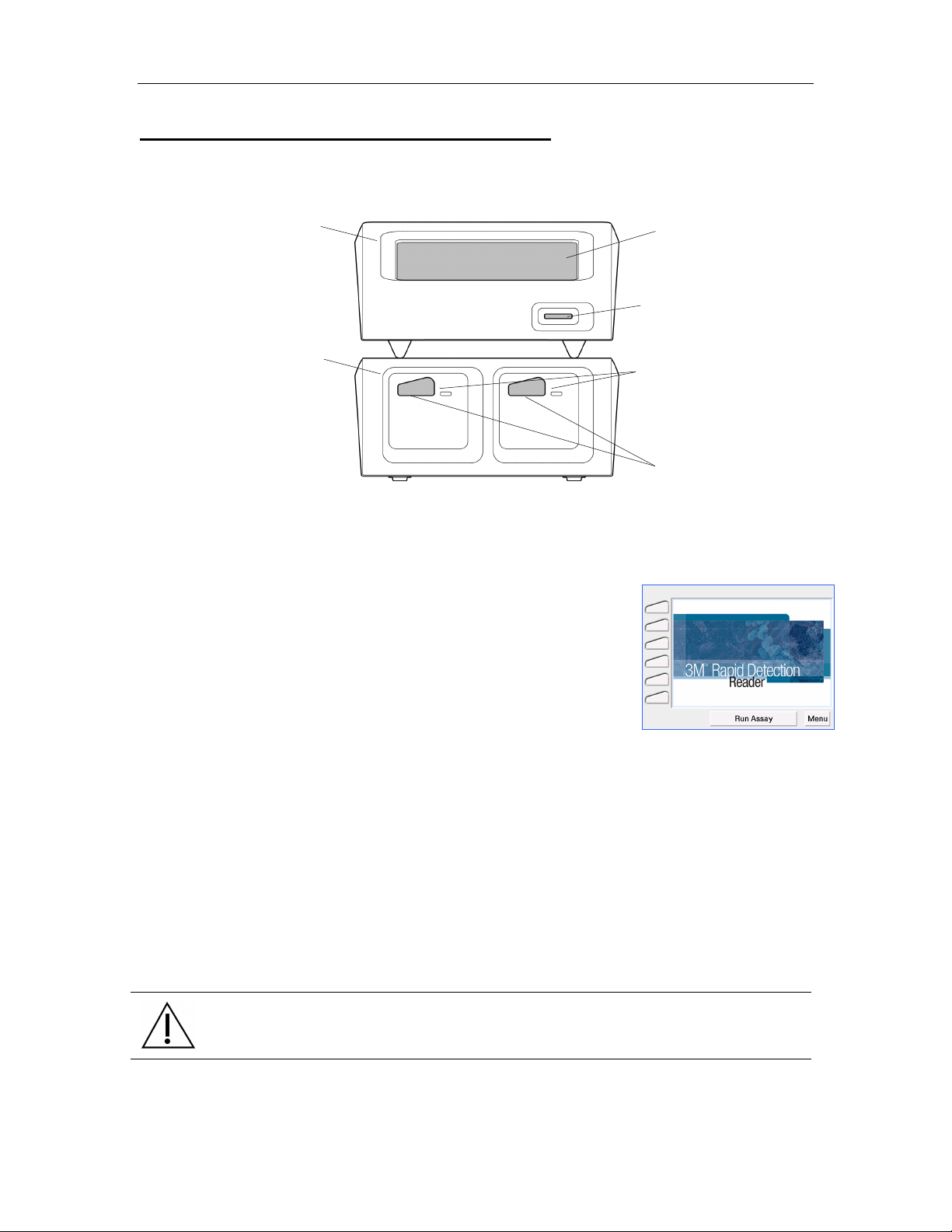

3M™ Rapid Detection Reader 3M Rapid Detection Reader (MODULES)

Touch

Lot Card

Test Cartridge

3M Rapid Detection Reader (MODULES)

Figure 2. 3M Rapid Detection Reader Features - Front View

Control Module

Screen

Display

Insertion Slot

Test Module (3 max)

Port LEDs

Ports

Turning on the 3M Rapid Detection Reader

The power On/Off switch is located on the rear panel of the CM

(Figure 1). When the power is switched on, the 3M Rapid Detection

Reader performs a number of internal self-tests, including IQC, to

ensure the system is operating within specifications. For additional

information, refer to Running Quality Control section.

When switched ON, the LEDs on the front of the TM illuminate blue.

When the power-on sequence is complete, the Home screen is

displayed (Figure 3). The power-on sequence takes approximately

1 minute.

Once the Home screen is displayed, selections can be made by

touching the appropriate prompt on the display (i.e., Run Assay to

initiate an assay, or Menu to go to the Main Menu screen (Figure 4)).

The display is touch-sensitive and can accept input from a bare/gloved

finger or a blunt stylus.

The 3M Rapid Detection Reader can be operated immediately after

set-up using the pre-programmed default settings. The date, local

time and some settings can be edited manually through the Settings

menu on the CM touch screen. Most settings can be edited using the

Reader Configuration Utility (RCU) supplied with the CM. For

additional information on editing user settings, refer to Managing

Settings and Editing Settings Using the Reader Configuration Utility

(RCU).

Figure 3. Home

CAUTION.

Pens or other sharp instruments will damage the touch screen.

8

Page 14

3M™ Rapid Detection Reader 3M Rapid Detection Reader (MODULES)

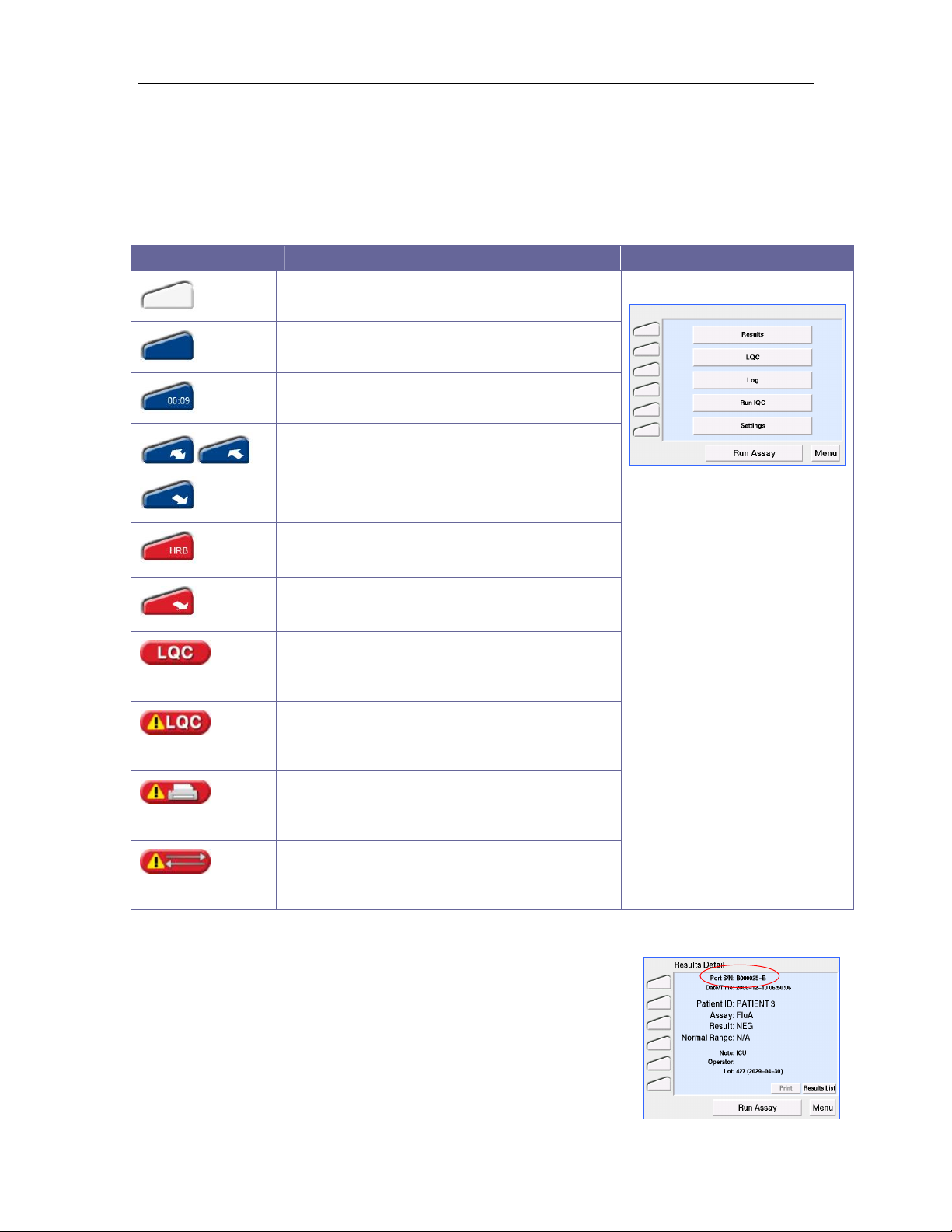

Display Icons

The left hand column of the screen displays an icon for each available port. Touching these icons

leads to a full screen display of the status of that port.

The lower left corner of the display screen, below the port icons, displays LQC, Printer and

Communication warning icons.

The meaning of the displayed icons is as follows:

Icon Meaning

(Non-selectable)

(Non-selectable)

Port Idle

Port Busy

Assay Timing

Sample processing and cartridge movement

Error – (HRB for example only). For detailed

information see Troubleshooting

Aborting assay, cartridge ejecting, error

message to follow

Liquid Quality Control Warning

See Running Quality Control

Liquid Quality Control Expired Warning

See Running Quality Control

Figure 4. Main Menu

(Non-selectable)

(Non-selectable)

Printer Error

See Troubleshooting

Data Transfer Error

See Transferring Results or Troubleshooting

Port Identification Nomenclature

Ports on the 3M Rapid Detection Reader are identified by a multicharacter nomenclature system. The first set of characters is the

serial number of the TM; the last character is a letter (A or B) referring

to the left (A) or right (B) port for a particular TM. This is displayed at

the top of the screen (Figure 5) when the port icon is touched or if

there is an IQC port error and in the IQC results log.

9

Figure 5. Port Identification

Page 15

3M™ Rapid Detection Reader Performing an Assay

Performing an Assay

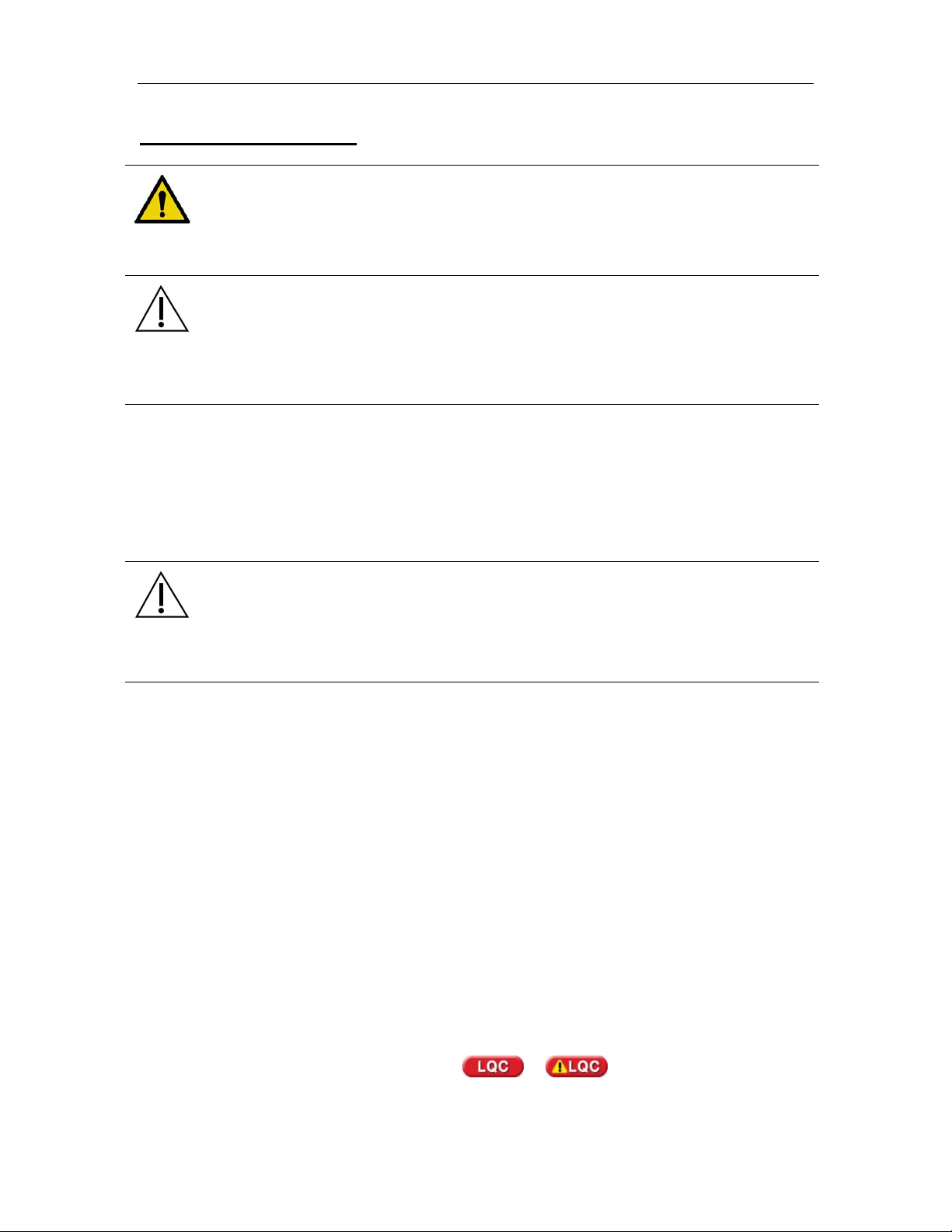

WARNING!

To reduce risk to the operator:

• Observe local protocols and appropriate precautions in the collection, handling,

and disposal of specimens.

CAUTION.

• When entering data via the CM touch screen (e.g., Sample/Patient/User ID), enter

characters one at a time as failure to do so may result in erroneous data entry.

• Be familiar with all of the instructions in the Test Kit Package Insert including

Warnings and Precautions prior to performing an assay.

Using Lot Cards

The Lot Card provides lot specific information and the expiration date for each Test Kit and is only

required to be read once for each Test Kit lot. Prior to performing any assay, insert the Lot Card

for that Test Kit lot into the Lot Card Insertion Slot (Figure 2). The CM can store information from

50 different Test Kit lots. If the maximum is exceeded, the oldest entry is overwritten.

CAUTION.

To avoid damaging the Lot Card:

• Do not touch the contact pads on the Lot Card.

• Store the Lot Card in the anti-static pouch provided.

To use the Lot Card:

1. Remove the Lot Card from the anti-static pouch.

2. Hold the Lot Card so that the arrow is on the top side and pointing away.

3. Insert the Lot Card, contact end first, into the slot located on the front of the CM.

4. The display provides status messages: Reading Lot Card, Complete, Lot ID: XXX,

Remove Lot Card.

5. Remove Lot Card and store in its original pouch.

6. If an error message is displayed, or if there is no response to insertion of a lot card, refer

to the Troubleshooting Section.

7. Keep the Lot Card for the life of the Test Kit.

Starting an Assay

NOTE: The default setting of the 3M Rapid Detection Reader does not require an Operator ID or

password. These login requirements can be edited via the Edit Operator settings menu or RCU

(See Managing Settings). If using default settings, Figure 6 will not appear.

If the following Liquid Quality Control warnings or appear, refer to Running

Quality Control.

10

Page 16

3M™ Rapid Detection Reader Performing an Assay

NOTE: The message Lot # XXX Not Found, Insert Lot Card or Cancel will be displayed if a

Test Cartridge is inserted and the Lot Card data is not stored in the CM. The Lot Card must be

inserted within 40 seconds or the assay will be aborted. Touch OK to return to the Home screen.

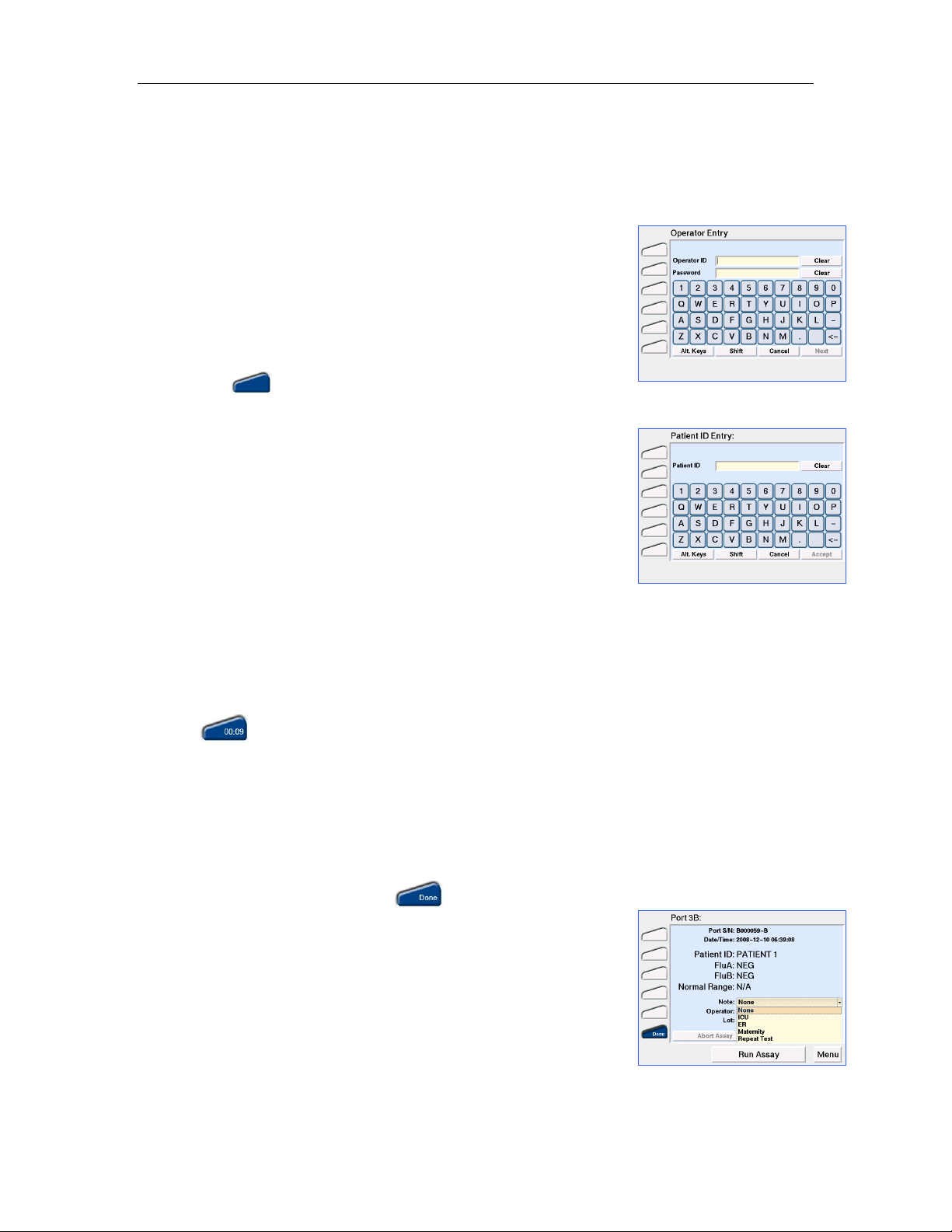

1. Touch Run Assay. If prompted, enter Operator ID and/or

Password (Figure 6) using either the touch screen or the barcode

scanner. To accept the displayed information, touch Accept.

Figure 6. Operator Entry

NOTE: The Operator ID and Password entries are casesensitive.

2. When prompted, enter the Patient ID/Sample ID using either the

touch screen or barcode scanner (Figure 7). Touch Accept.

3. When prompted to Add Sample & Insert the Test Cartridge, the

LED on a free port of the TM will flash blue and the corresponding

port icon on the display will illuminate blue (Refer to Test

Kit Package Insert for detailed instructions on sample handling).

4. Prepare Sample and Test Cartridge as stated in the Test Kit

Figure 7. Patient ID Entry

Package Insert and insert Test Cartridge into the flashing port.

If the cartridge is not inserted within 5 minutes of the Add

Sample & Insert prompt, the system will time-out. Touch OK to

return to the Main Menu.

NOTE: The Test Cartridge must be inserted into the TM within

~30 seconds of sample application. Otherwise, FAIL will be

displayed in the port icon and the assay will be aborted.

Do not use excessive force when inserting the Test Cartridge. The TM will guide the Cartridge

into place.

NOTE: If the cartridge won’t fit or won’t enter the cartridge port, clear the cartridge port of any

obstruction or blockage.

Once the Cartridge Inserted message clears, the previous screen is displayed and the active port

icon shows a timer that counts up until sample flow is detected, then counts down until the

assay is complete.

Another assay can be started once Assay Initialization is complete by touching Run Assay.

5. To check the assay progress, touch the port icon. The details of the assay will be displayed.

Touch Exit to return to the previous screen. Touching Abort Assay will cause the cartridge to be

ejected and a Failed Assay to be recorded in the Events Log.

6. When an assay is complete, the Test Cartridge is ejected and the

corresponding port icon displays . To view the test details

touch the icon.

Figure 8. Results, prior to

cartridge removal

7. Before removing the Test Cartridge from the TM, a predefined

note can be added to the result from the drop down menu on the

Result Details screen (Figure 8). Once the Test Cartridge is

removed, a note cannot be added or changed.

Up to 10 notes can be defined using the RCU (Refer to Editing

Settings Using the Reader Configuration Utility section).

8. Remove the Test Cartridge and discard according to local

hazardous waste policy.

11

Page 17

3M™ Rapid Detection Reader Running Quality Control

Running Quality Control

Two types of quality control test records are stored by the 3M Rapid Detection Reader:

• LQC (Liquid Quality Control) - external surrogate sample test results.

• IQC (Internal Quality Control) - self-diagnostic test results including a check of the power

supply voltage, system memory, cartridge transport system, cartridge barcode sensor, LED

function, and incubator function for heated assays.

Running LQC

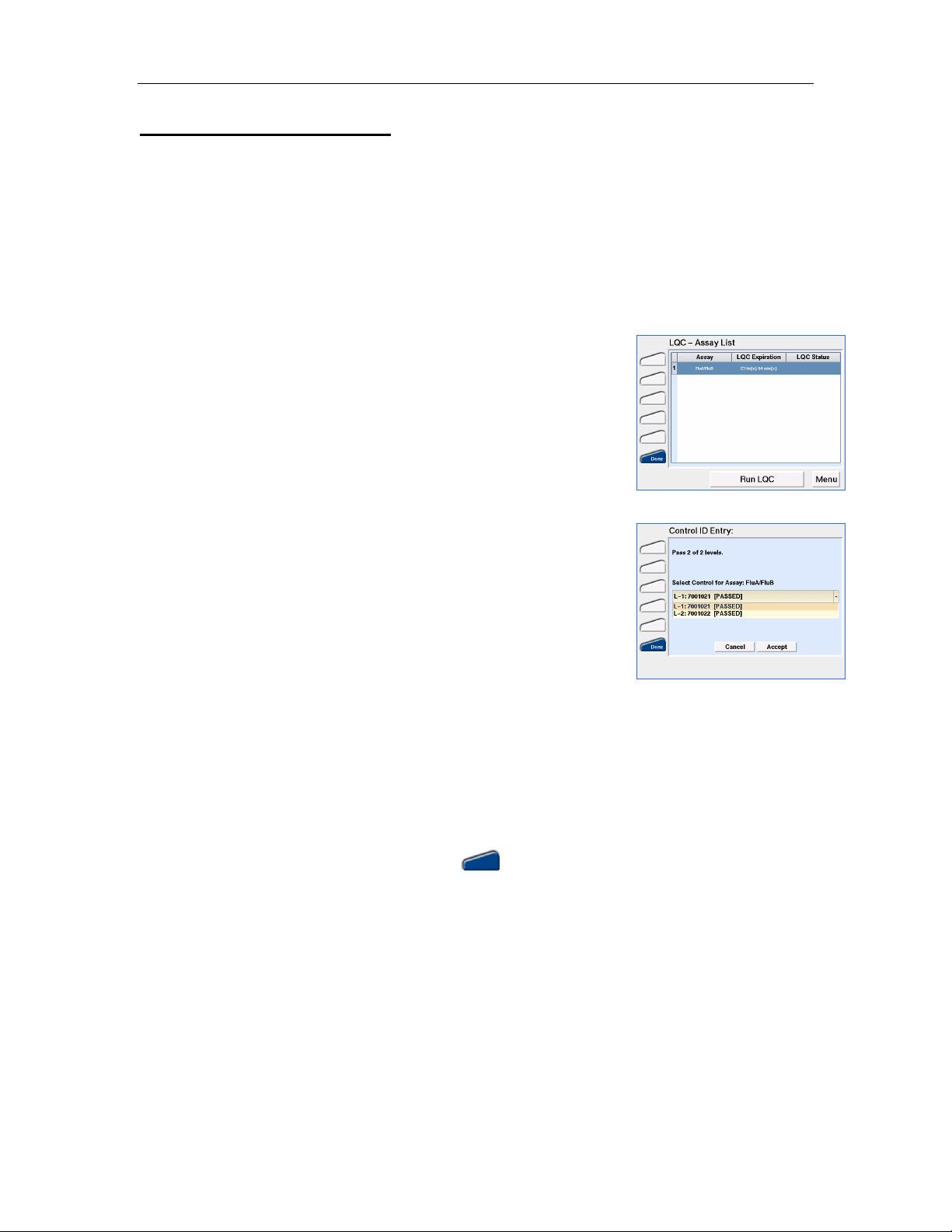

1. From the Main Menu screen (Figure 4) touch LQC. The LQC –

Assay List screen will open (Figure 9). This screen will display

the entire list of assays sorted in ascending order by the Time to

Figure 9. LQC - Assay List

Expiry before assay lockout as displayed in the LQC Expiration

column. If LQC is due, this column will display “Run x of y levels”

where x is the number of levels required and y is the number of

defined LQC levels for that assay. Both the number of levels

required and the available defined levels are set using the RCU.

The LQC status column shows the requirements for any LQC

levels that have failed. If any LQC fails, that specific control level

must be run successfully prior to proceeding with a patient’s test.

If the maximum number of Failures before LQC Lockout is

reached, this column will display “LQC Lockout”.

Figure 10. Control ID Entry

NOTE: The assay list is defined in RCU. Any new assays added

in the RCU or through the CM will default to LQC disabled and

will be listed with N/A in the LQC Expiration column. Refer to the

RCU Help Manual for further instruction.

2. Select the assay for which LQC will be performed. Touch Run

LQC. If prompted, enter Operator ID and/or Password using

either the touch screen or the barcode scanner. To accept the

displayed information touch Accept.

NOTE: Both the Operator ID and Password are case-sensitive.

3. When prompted (Figure 10), select the appropriate Control ID using the drop down menu. Touch

Accept.

NOTE: If LQC has failed for the assay selected, the number of LQC attempts allowed prior to

assay lockout is displayed.

4. When prompted to Add Control & Insert the Test Cartridge, the LED on a free port of the TM will

flash blue and the corresponding port icon on the display will illuminate blue (Refer to Test

Kit and Quality Control Package Inserts for detailed instructions).

5. Prepare Test Cartridge as per Test Kit Package Insert and insert Test Cartridge into the flashing

port.

If the cartridge is not inserted within 5 minutes of the Add Control & Insert prompt, the system

will time-out and return to the Main Menu.

NOTE: The Test Cartridge must be inserted into the TM within ~30 seconds of sample

application. Otherwise, FAIL will be displayed in the port icon and the assay will be aborted.

12

Page 18

3M™ Rapid Detection Reader Running Quality Control

Do not use excessive force when inserting the Test Cartridge. The TM will guide the Cartridge

into place.

Once the Cartridge Inserted message clears, the previous screen is displayed and the active port

icon shows a timer that counts up until sample flow is detected, then counts down until the

assay is complete.

NOTE: Touching Run Assay or Run LQC will start another assay/LQC and the test sequence

will begin again using a different available port. The assay progress can be checked by touching

the port icon. Touch Exit to return to the previous screen.

6. When an assay is completed, the corresponding port icon displays and the Test Cartridge

is ejected. Touch the icon to view the test details.

7. Remove the Test Cartridge and discard according to local hazardous waste policy.

LQC Icons

Icon Meaning

LQC will be due shortly. Appears when the LQC timer for an assay has less than the

user defined % of time remaining until lockout.

LQC has expired for one or more assays. If icon is

displayed, the Assay Status Warnings screen

(Figure 11) will display upon touching the Run Assay

Figure 11. Assay Status Warnings

button. Touch Continue if the desired assay is not

listed.

A limited number of overrides can be configured via

the RCU. If overrides are available, touch Continue

to override lock out (i.e., perform a patient test after

LQC is due). The decision to use an Override will be

confirmed (Figure 12). Once all overrides have been

used, LQC must be performed prior to any further

patient testing. If an assay with no overrides is

inserted into the TM, an LQC Overdue, Assay

Figure 12. Override Confirmation

Locked warning will display and the assay will be

aborted.

NOTE: These warnings are display only and are not selectable. To determine the assay(s) for

which LQC is due, view the LQC – Assay List (Figure 9).

NOTE: If there is more than one level of LQC defined for an assay, and LQC has expired for this

assay, the LQC timer will be reset to the time at which the earliest LQC level passes in the set.

e.g.: Two levels of QC are required, Level 2 passes LQC but Level 1 fails; once Level 1 is

repeated and passes, the "Time to Expiry" column in the LQC menu will display the count down

from the time when Level 2 passed.

13

Page 19

3M™ Rapid Detection Reader Running Quality Control

Running IQC

IQC runs automatically every time the 3M Rapid Detection Reader is turned on. IQC can also be

initiated manually or configured to run at predefined intervals. IQC takes less than 1 minute to

complete.

When IQC is initiated, the appropriate tests are performed on each port in each attached TM.

IQC verifies the power supply voltage, system memory, cartridge transport system, LED function

and incubator function for heated assays. During IQC the system also determines system power,

verifies the system clock and verifies the Reader calibration.

Should there be a test in progress in a port, IQC will begin for that port once the test cartridge is

removed on assay completion. Results of the IQC are stored for each cartridge port in the IQC

results database.

To run IQC manually:

1. From the Main Menu screen (Figure 4), touch Run IQC. If

prompted, enter the Operator ID and/or Password using either the

touch screen or barcode scanner. To accept the displayed

information, touch Accept. The IQC Status screen is displayed

(Figure 13).

Figure 13. IQC Status

NOTE: Both the Operator ID and Password are case-sensitive.

IQC is started on all idle ports and will automatically start as ports

become free.

2. Touch OK to return to the Main Menu. If IQC fails, the TM port

LED illuminates red, the port icon turns red and the failed port can

no longer be used. e.g.,

To run IQC automatically:

To run IQC automatically at predefined intervals, the Reader is configured using the RCU or the

CM.

To configure the Reader to run IQC at defined intervals through the RCU, refer to Editing Settings

Using the Reader Configuration Utility (RCU) section.

To configure the Reader to run IQC at defined intervals through the CM, refer to the Managing

Settings section.

14

Page 20

3M™ Rapid Detection Reader Working with Results and Logs

1. From the

Main Menu

screen

(

Figure 4

), touch

Log

. If prompted,

Working with Results and Logs

The 3M Rapid Detection Reader can store up to 900 results (300 assay results, 300 LQC results

and 300 IQC results). When the CM database is full, the oldest result is over-written. Dual

analyte assay results are stored as two separate patient records. IQC results are stored

separately for each individual test port.

In manual transfer mode only (i.e., when 3M Rapid Detection Reader is not connected to a

network), the warning “Database Almost Full, Backup Data” will be displayed when the assay or

LQC result databases have less than 20 spaces left. This message will continue to be displayed

until the database is cleared.

In auto transfer mode, only new results that have not been previously transferred are transferred

during an upload. Data is not deleted from the CM upon transfer.

The 3M Rapid Detection Reader can store up to 500 Log records (including system power up,

upload/download of data, assay and LQC errors). When the database is full, the oldest result is

over-written. A warning message is not displayed when the Log database is full.

Viewing Saved Results

1. From the Main Menu screen (Figure 4), touch Results. If

prompted, enter Operator ID and/or Password using either the

touch screen or the barcode scanner. To accept the displayed

information, touch Accept.

Figure 14. Assay Results

NOTE: Both the Operator ID and Password are case-sensitive.

The screen displays a list of all Assay Results (Figure 14). The

most current assay result is the first listed. For each assay result,

the Patient ID, assay name, result value, and date/time is

displayed.

To view a list of LQC or IQC results, touch the circle next to the

words LQC Results or IQC Results (in the display header) to

specify the type of results to be viewed. The list of results will be

displayed.

2. To view the details of a particular result, touch the result, and

then touch View. To return to the result list, touch Results List.

Viewing Saved Logs

enter Operator ID and/or Password using either the touch screen

or the barcode scanner. To accept the displayed information,

touch Accept.

NOTE: Both the Operator ID and Password are case-sensitive.

Figure 15. Results Detail

Figure 16. All Events

A list of all events will be displayed (Figure 16). The most recent

event is listed first. For each event, the Date/Time is displayed.

To view a list of assay or LQC errors only, touch the circle next to

the words Failed Assays or Failed LQC (in the display header)

to specify the type of results to be viewed. The list of events will

15

Page 21

3M™ Rapid Detection Reader Working with Results and Logs

be displayed.

To view the details of a particular event, touch the event, and

then touch View.

2. To return to the event list, touch Events List.

Searching Results

Result Type Search Options

Assay

LQC

IQC

Operator Name Sample/Patient ID Assay Name

Operator Name Control ID Assay Name

Operator Name Port

1. From the Assay (or IQC or LQC) Results screen, touch Search to

open the Search Assay Results screen (Figure 17).

2. Use the drop down arrow € on the Operator Name to change the

Figure 17. Search Assay Results

search parameter.

3. Use the touch screen or barcode scanner to enter the desired

value to search. Touch Alt. Keys or Shift to display extended

character sets.

NOTE: Enter the first few characters or the entire name or ID to

be found.

4. Touch either All Results or Date Range. All Results is the default

setting. When Date Range is touched, the From/To Y M D fields

become active. Enter the desired dates in YYYY MM DD format.

5. Touch Search to generate a list of results based on the search criteria entered or touch Cancel to

clear the search criteria and return to the main Results screen.

6. If no results matching the search criteria are found, Empty Search will be displayed.

7. When viewing the records for a particular search, touch View All to return to viewing the complete

Results list.

Searching Logs

Log Type Search Options

All Events

Failed Assays

Failed LQC

Operator Name

Operator Name Sample/Patient ID Assay Name

Operator Name Control ID Assay Name

Follow the directions above for Searching Results.

Event Text (enter any part of field, not casesensitive)

16

Page 22

3M™ Rapid Detection Reader Working with Results and Logs

Manually Transferring / Printing Results or Logs

Results (assay, patient or IQC) that have been selected on the Results screen can be transferred

to a printer, USB flash drive or to a network. It is important to note that the user should manually

delete the results from the Reader after manual transfer or they will be transferred again, unless a

specific range of results is selected when the next manual transfer is performed.

Log events (All, Failed Assays or Failed LQC) that have been selected on the Events screen can

be transferred to a USB flash drive or to a network. Only Failed Assays and Failed LQC can be

printed from the CM.

NOTE: A single USB flash drive can be used to transfer results from all Readers as the file

names start with their respective control module serial numbers. The USB flash drive must be

preconfigured with 4 subdirectories (folders) named: patient, lqc, iqc and log, for this use.

CAUTION.

Do not remove the USB flash drive from the control module while data is being

transferred.

1. From the Assay Results (Figure 14) or All Events (Figure 16)

screen, select record(s) by touching the desired record(s). Touch

Transfer to open the Results or Events Transfer screen (Figure

18 shows results transfer as an example).

Figure 18. Results Transfer

IQC and LQC results or failures can be transferred or printed in

the same manner from their respective screens.

2. On the Results or Events Transfer screen, touch Print, USB or

Network as desired. On the Events Transfer screen, touch

USB or Network as desired. Only options for which the

connections are available will be functional.

3. Confirm the transfer by touching Confirm. Touch Cancel to

Figure 19. Result Transfer

Confirmation

abort transfer. (Figure 19)

When the transfer is complete, touch OK and the Results screen

(or Events screen) will be displayed. If transfer fails the

warning icon and a failure message are displayed, touch OK to

return to Results or Events screen (the screen depends on the

previous context, e.g., if transferring LQC results, then LQC

Results screen will be shown).

Once results have been transferred, File Converter 1_1.xls on the

supplied USB flash drive may be used to convert the data files to

an Excel format.

Open the file “File Converter 1_1.xls”, enable Macros, and follow the directions on the screen.

You will be prompted to save the Excel-formatted file.

NOTE: File Converter 1_1.xls must be used for this purpose. Data will not be formatted properly

if an earlier version of File Converter.xls is used.

17

Page 23

3M™ Rapid Detection Reader Managing Settings

Managing Settings

The 3M Rapid Detection Reader can be operated immediately after set-up using the preprogrammed default settings. Each Reader also has customizable features which can be

configured to enhance its functionality and data management capability. Customizable features

include LQC timer, Operator ID and password, and data transfer options (USB, print, network).

Some of these features can be configured in the CM Settings menu. In the default configuration,

these settings can only be viewed or changed by an operator with Supervisor access. Most

feature configurations are set using the Reader Configuration Utility (RCU) by a Full Access User.

For instruction on configuring settings on the CM, refer to Edit Settings and Edit Operators. For

instructions on configuring settings using the RCU, refer to Editing Settings Using the Reader

Configuration Utility (RCU).

Feature (See Detailed

Descriptions Below)

Assay defaults √

LQC √

Update / Upload Features √

Printer Settings √

Full Access User

Edit on RCU

Supervisor

Edit on CM

Login Requirements √ √ (limited)

File Settings √ √

Menu Idle / Timeout √

Date / Time (without Network

NTP only √

Time Protocol – NTP)

Language √

Auto IQC Interval √ √

Network Transfer Timers √

Sound √

Accessing the Settings Menus

From the Main Menu (Figure 4), touch Settings. Access to the

Settings menu is Operator ID and Password protected. The default

login for access to the Settings menus is:

Operator ID: SUPERVISOR

PASSWORD: PASSWORD

Both entries are case-sensitive. To provide additional security, it is

highly recommended that this login be changed.

Figure 20. Settings Menu

NOTE: The default privilege access to the Settings menu is Supervisors only (Figure 25). The

privilege access to this menu can only be changed via the RCU. In the default setting, any operator

defined in the Operator List as Supervisor [Operator Type] is able to access the Settings menu. Refer

to Managing Operators for additional information.

Touch View Settings from the Settings menu (Figure 20). This will open the screen shown in Figure

21. Settings in the View Settings screen cannot be edited.

18

Page 24

3M™ Rapid Detection Reader Managing Settings

Settings: View Tabs

Tab Screen

Assay

Edit through RCU only.

Sample/Patient ID

Purpose: Define the field name as Patient ID or Sample ID.

Default: Patient ID.

String length can be set from 1 to 18.

Default: Min Length 1, Max Length 18.

New Assay Lockout

Purpose: Define ability of operators to perform assays not in the

assay list. The assay list is displayed on the LQC-Assay List

screen (Figure 9). Set as either Yes or No.

Yes: End users cannot run any assays that are not on the RCU

defined assay list.

No: End users can run any 3M Rapid Detection Reader assay.

Default: No.

Predefined Notes

Purpose: Define up to 10 notes that an operator can attach one

of these notes to each patient test result prior to removing the

Test Cartridge from the TM. The Note becomes part of the result

record when the Cartridge is removed from the TM.

Figure 21. Settings: View Assay

Tab

NOTE: The predefined note can be up to 20 characters in length.

Make sure the note entered through the RCU is less than or

equal to 20 characters in length.

LQC

Edit through RCU only.

Default: Timer Reset (hours) = 0, LQC will not time-out.

Hide Numeric LQC Results

Purpose: To Hide LQC results and report only PASS/FAIL

Yes: Pass/Fail will be displayed in place of results.

No: Actual result will be displayed.

Default: No.

LQC Timeout Warning (% remaining)

Purpose: Define the percentage of the LQC interval remaining (if

LQC Timer is set in RCU) before LQC expires for any assay.

Default: 10%.

Figure 22. Settings: View LQC Tab

19

Page 25

3M™ Rapid Detection Reader Managing Settings

Settings: View Tabs

Tab Screen

LQC continued

Max Failures Before Lockout

Purpose: Define the number of LQC failures allowed before the

assay is Locked Out when LQC Timer is set in RCU. LQC

Failure count is reset upon successful completion of LQC. Can

be set from 1-9.

Default: 9.

Control ID

Purpose: Define control IDs.

Default: Min length 1, Max length 18.

Timer

The ability to edit the settings of the TIMER tab varies by item

and is defined below.

Timer Intervals

Menu Idle Timeout

Edit on CM. Cannot edit through RCU.

Purpose: Define the amount of idle time before the 3M Rapid

Detection Reader returns to the Home screen.

Range: 1 -10 minutes.

Default: 5 minutes.

Update/Upload Start Date/Time

Edit through RCU only.

The date and time used to calculate the start of the following

intervals.

Update Interval

Edit through RCU only.

Purpose: Interval at which the Reader checks for changes to

settings in a networked environment. Disable by entering 0.

Figure 23. Settings: View Timer

Tab

Range: 0 – 1440 minutes.

Default: 1.

Upload Results Interval

Edit through RCU only.

Purpose: Interval at which the Reader sends changes or

additions to the result and event logs in a networked environment.

Disable by entering 0.

Range: 0 - 1440 minutes.

Default: 0 (Disabled).

20

Page 26

3M™ Rapid Detection Reader Managing Settings

Settings: View Tabs

Tab Screen

Timer continued

NOTE: Only new results that have not been previously

transferred are transferred during an upload. Data is not deleted

from CM upon transfer. When the CM database is full, the oldest

result is over-written.

NOTE: It is important that the upload interval be set to ensure

data capture and transfer prior to records being overwritten.

Auto IQC Interval

Edit on CM and through RCU.

Purpose: The interval between automatic IQC self-diagnostics in

either local or networked environment. Disable by entering 0.

Range: 0 – 1440 minutes.

Default: 0 (Disabled).

Printer

Edit through RCU only.

Auto Print

Purpose: Defines if automatic printing is enabled. Settings are

independent for assay, LQC and IQC results.

On: Result will automatically print upon completion.

Off: Result will not print automatically.

Default: Off.

Print Headers

Purpose: Define customized print header information that will be

visible on every printout.

Login

Edit through RCU only.

Device Name

Purpose: Define name assigned to the device.

Default: Blank.

Lockout

Figure 24. Settings: View Printer

Tab

Figure 25. Settings: View Login

Tab

Purpose: Disable Reader.

Device Locked: Assays cannot be run.

Device Unlocked: Assays can be run (Default).

21

Page 27

3M™ Rapid Detection Reader Managing Settings

Settings: View Tabs

Tab Screen

Login continued

Login Requirements

Purpose: Define login requirements independently for Operators

and Supervisors requiring None, ID and Password, ID only or

Password only. If None, an Operator ID cannot be entered when

running assays.

Default: Operators – None, Supervisors – ID and Password.

Privilege Requirements

Purpose: Defines the access privileges for each level user.

All Operators: Operators and Supervisors have access.

Supervisor only: Only Supervisors have access.

Default: Default settings are shown in Figure 25.

File

Edit through RCU only.

Purpose: Define network settings for the Reader

Network Settings

Manual Transfer mode: 3M Rapid Detection Reader is being

used without being connected to a shared network.

IP Address: Automatically assigned when the 3M Rapid

Detection Reader is connected to a network and in Auto transfer

mode.

MAC Address (Machine Address Control): This is a static

address that represents the identity of the 3M Rapid Detection

Reader.

Default: Manual Transfer Mode.

File Locations

Purpose: Define the directory where the 3M Rapid Detection

Reader files reside, defined when implementing connectivity

through the RCU.

Please consult the local IT administrator and the online help for

guidance on the use of these settings.

Figure 26. Settings: View File Tab

22

Page 28

3M™ Rapid Detection Reader Managing Settings

Settings: View Tabs

Tab Screen

About

Purpose: This tab displays the details the Serial Number,

software and hardware versions of the 3M Rapid Detection

Reader System. This information will assist in discussions with

Technical Support.

Figure 27. Settings: View About

Tab

23

Page 29

3M™ Rapid Detection Reader Managing Settings

Edit Settings

From the Main Menu select Settings. Only a Supervisor, when in the default systems

configuration, can access the Settings menu. (Refer to Access the Settings Menus for

additional information.) Touch Edit Settings on the Settings menu, and use the tabs to select

those settings to be changed.

On all the Settings: Edit dialogs:

• Use the touch screen or dropdown lists to enter/select the desired settings.

• Touch Save to save your settings.

• Touch Cancel to return to the previous screen without saving your changes.

• Touch Reset to undo entry and return to the default setting.

• Touch Alt. Keys or Shift to display extended characters (available characters will vary

depending on Language setting).

Settings: Edit Tabs

Tab Screen

Timers

The ability to edit the settings of the TIMER tab varies by item

and is defined with each item below.

IQC Interval (minutes) – Edit on CM and RCU.

Purpose: The interval between automatic IQC self-diagnostics.

Range: 0 – 1440 minutes.

Default: 0 (Disabled).

Menu Idle Timeout (minutes)

Edit on CM. Cannot be edited through RCU.

Purpose: Amount of idle time before the 3M Rapid Detection

Reader returns to the Home screen.

Range: 1 – 10 minutes.

Default: 5 minutes.

File

Edit on CM and RCU.

Purpose: Define the locations for the device, group and time

server settings.

Please consult the local IT administrator and the online help for

guidance on the use of these settings.

Figure 28. Settings: Edit Timer

Tab

Figure 29. Settings: Edit File Tab

24

Page 30

3M™ Rapid Detection Reader Managing Settings

Settings: Edit Tabs

Tab Screen

Date/Time

Edit on CM. Can only edit through RCU if NTP is enabled.

Purpose: Set the current date and time for the 3M Rapid

Detection Reader.

If in Auto transfer Mode, the 3M Rapid Detection Reader date and

time may be synchronized with the NTP server. The date format

in the Reader is variable.

To Change:

1. Use drop down menu to scroll through times zones and select

correct time zone offset for your location.

2. Enter Current time.

NOTE: When adjusting for changes in daylight savings time

ensure the time zone offset is adjusted – not only the current

time.

NOTE: After changing the date or time, the CM power must be

cycled to reset auto-IQC and data transfer timers.

NOTE: The date format in the RCU is the same as for other

applications running on that PC.

NOTE: Periodically check that the clock is correct and has not

been inadvertently changed.

Figure 30. Settings: Edit

Date/Time Tab

Language

Edit on CM only.

Purpose: Set the display language for the 3M Rapid Detection

Reader.

Misc.

Manual / Auto Transfer Mode

Edit on CM. Cannot edit through RCU.

Manual Transfer Mode: 3M Rapid Detection Reader is set up for

stand-alone operation.

Auto Transfer Mode: 3M Rapid Detection Reader is set up for

network operation.

Default: Manual Transfer Mode.

Figure 31. Settings: Edit

Language Tab

Figure 32. Settings: Edit Misc. Tab

25

Page 31

3M™ Rapid Detection Reader Managing Settings

Settings: Edit Tabs

Tab Screen

Misc. continued

Sound

Edit on CM. Cannot edit through RCU.

Test: Touch to hear indicator.

On: The audio indicator is ON and sounds at the completion of

an assay and when a USB device is connected or disconnected.

Off: The audio indicator is OFF.

Default: On

There is no volume adjustment feature.

Restoring Defaults

NOTE: Restoring device settings to factory defaults will erase all stored settings, assay results

and operator information. Back up all device databases prior to restoring factory defaults. To

transfer files from the 3M Rapid Detection Reader to another device, see Exporting Files.

1. From the Settings Menu (Figure 20), touch Restore Defaults.

The Settings: Restore Defaults screen will open (Figure 33).

2. Touch Restore Defaults to restore factory defaults or Cancel to

Figure 33. Settings: Restore

Defaults

return the Settings menu.

3. After selecting Restore Defaults, a confirmation prompt will

appear. Touch Confirm to restore defaults or Cancel to return to

the settings menu.

4. When prompted, turn 3M Rapid Detection Reader off and on

again to complete restoration of defaults.

Managing Operators

If an Operator ID or password is required, only individuals with Operator IDs stored on the 3M

Rapid Detection Reader can perform assays and LQC, or select Menu options. The operator

login requirements can be set on CM and RCU.

To access the Operator List on the Reader:

1. From the Main Menu screen (Figure 4), touch Settings and

enter the Operator ID and Password (Figure 6).

The default login for access to the Settings menu is:

Figure 34. Settings: Operators

Operator ID: SUPERVISOR

Password: PASSWORD

Both entries are case-sensitive

26

Page 32

3M™ Rapid Detection Reader Managing Settings

2. From the Settings menu (Figure 20), touch Edit Operators.

The Settings: Operators screen will open (Figure 34).

A complete list of all operators authorized to use the device with

Figure 35. Settings: Operator

Detail

Display Name and Operator Type is displayed.

The 3M Rapid Detection Reader will store a maximum of 600

operators.

The default Operator List includes the Operator ID defined as

SUPERVISOR; the Display Name as DefaultUser; the Type set

as Supervisor. This is the default login (see step 1 above).

The Operator Login Requirements (Figure 34) determines if an

Operator (Operator Type = Operator) requires an Operator ID

and/or Password. The Operator Login Requirements can be

set to None, Operator ID only, or ID and Password by selecting

the € icon.

NOTE: The login requirements for operators (Operator Type = Supervisor) are defined and

changed through the RCU. The default Login Requirements for Supervisors is ID and Password

(Figure 25).

3. To view detailed information for an Operator, touch the Operator’s entry and touch View.

4. To modify an existing operator, touch the Operator’s entry and touch Modify. The Add button

changes to Modify. (For additional instructions see Adding/Modifying an Operator.)

5. To add a new operator, touch Add when no operator entry is highlighted. (For additional

instructions see Adding/Modifying an Operator.)

6. To search for a specific operator, touch Search. (For additional instructions see Searching for an

Individual Operator.)

7. To delete an operator, touch Delete Operator while viewing an operator’s details.

Adding/Modifying an Operator

The 3M Rapid Detection Reader will store a maximum of 600

operators.

Access the Settings: Operators: Add screen (Figure 36) as

described above.

To Add an Operator

1. Enter the Operator ID, Display Name, Password, Verify and, if

desired, the Expire information.

Operator ID: Characters entered to access 3M Rapid Detection

Reader (Maximum length 18 characters).

Display Name: Characters displayed with results for this

Operator ID (Maximum length 50 characters).

NOTE: Although 50 characters may be entered for a Display

Name, the CM screen and print out will truncate. The full 50

character Display Name will only be visible in the Edit Operators

screen in the Settings menu or through the RCU.

Figure 36. Settings: Operators:

Add

Password: Maximum length 18 characters.

Verify: Re-enter Password.

27

Page 33

3M™ Rapid Detection Reader Managing Settings

Expire: Date that operator’s permission to use the 3M Rapid Detection Reader expires. Operator

will be locked out after that date.

Disable expiration feature by leaving the field blank.

2. Use the € arrow to select the desired Operator Type: Supervisor or Operator.

3. Touch Accept. (The Next button changes to Accept.)

4. An entry verification screen appears. Select Confirm to add the operator information or Cancel to

reject.

To Modify an Operator

If modifying an existing operator, the screen title will be Settings: Operators: Modify and the fields

will be populated.

1. Modify the desired fields.

2. Touch Accept. (The Next button changes to Accept.)

3. An entry verification screen appears. Select Confirm to add the operator information or Cancel to

reject.

Searching for an Individual Operator

1. Access the Settings: Operators: Search screen (Figure 37) as

described above.

Settings: Operator: Search screen allows selection of operators

Figure 37. Settings: Operator

Search

by:

• Operator Name

• Operator ID

• Expiry Date

2. To search for a specific Operator, select Operator Name or

Operator ID using the € arrow and the drop down list. Enter the

desired Name / ID to search.

Touch All Operators to disable expiry date fields for searching.

3. To search for operators whose permission to use the 3M Rapid Detection Reader expires in a

given date range, touch Expiry Date and enter the date range.

Default: from current date to current date + 10 years.

4. Touch Search or Cancel.

5. To return to the main list of operators, touch View All.

28

Page 34

3M™ Rapid Detection Reader Editing Settings Using the Reader Configuration Utility (RCU)

Editing Settings Using the Reader Configuration Utility (RCU)

Overview

The Reader Configuration Utility (RCU) allows the user to set up Readers according to the needs

of their institution. The RCU stores this setup information in a set of Reader configuration files.

Each Group of one or more Readers has its own directory containing a set of configuration files

that define how the Readers in that Group operate. These files include assay lists and settings,

LQC lists and settings and operator lists and settings. Note that more than one Group can share

the same assay list, control list and/or operator list by either setting the list locations to the same

directory for each Group OR by using Save As to save a list in multiple directories.

In a network environment, Readers can be set to periodically check their assigned Group

directory for configuration changes. In addition, Readers can be configured to send new results

and log information to a network directory.

In non-networked environments, a portable USB flash drive (supplied) is used to download the

configuration files to the Reader and gather result and log files from the Reader. It is

recommended that a separate USB flash drive should be used for configuring each Reader

Group, this provides safe archive/restore functionality.

Complete instructions on the use of the RCU may be found in the RCU program under HELP or

from the START menu under All Programs > Reader Configuration > Reader Configuration

Manual.

Installation

The RCU is a software only product that can be installed on Client workstations running the

Microsoft® Windows Operating System (2000/XP/Vista). Before beginning installation, be sure to

have the necessary login privileges for installation of software on your workstation.

1. Insert the RCU CD into an available CD drive on your workstation.

2. A welcome menu should be displayed on your workstation.

3. Select “Install Reader Configuration Utility”.

4. Follow the on-screen prompts to complete the installation.

NOTE: If the installation does not auto-start, go to START>Run and type {CD drive}:install.hta

<enter>.

Getting Started

Open the RCU from the START menu: All Programs >Reader

Configuration> Reader Configuration Program (Figure 38).

Login

When the RCU is initially installed, the default login is User ID:

“Supervisor” and Password: “password” (case-sensitive). For

increased security, it is strongly recommended to change these login

details immediately to limit program access.

Figure 38. Configuration Login

29

Page 35

3M™ Rapid Detection Reader Editing Settings Using the Reader Configuration Utility (RCU)

To change the default login

1. Select the Settings menu to open the Reader Configuration:

System Settings screen (Figure 39).

2. Under Reader Configuration Utility Accounts, change the User ID,

Account Name and Password.

3. Be certain that the Privilege level remains as Full Access.

To save your settings select File > Save.

New RCU accounts may also added from this screen. These

accounts may be “Limited” or “Full Access”.

“Limited Access" accounts only have access to the Controls

Editor feature.

"Full Access" users have complete access to all the program's

functions.

See the RCU Help for information on adding / editing and deleting

users.

Figure 39. Reader Configuration

System Settings: Settings

Emergency Password Reset Mechanism

If you forget your password, it may be temporarily reset to allow access to the encoded password

list. To use this feature, type "override" in the User ID field of the RCU Login screen and select

the "Login" button.

You will be presented with a message that says to contact Tech Support with a five digit number

(Permit #). Please leave this prompt on the screen until you speak with your Technical Support

Representative.

After receiving an override number, type this number into the "Password" field and click the

"Login" button. You will have temporary access to the "Settings" screen, where you can view the

user list and passwords.

NOTE: If the override number is entered incorrectly, it can be re-entered. If the number is

entered incorrectly the second time, a new number is required.

Choosing a Configuration File Access Method

The RCU can be configured to access configuration files stored on a USB flash drive, a Network

shared drive and/or a Web server.

Setting Up a USB Flash Drive

1. Select the Settings menu to open the Reader Configuration: Systems Settings screen

(Figure 39).

2. Select the Connection type: USB.

3. Enter the “drive letter:” for the USB port that will be used.

4. Save your settings by selecting File > Save from the menu.

Setting Up Web Services Access:

1. Select the Settings menu to open the Reader Configuration: Systems Settings screen

(Figure 39).

2. Select the Connection type: Web.

30

Page 36

3M™ Rapid Detection Reader Editing Settings Using the Reader Configuration Utility (RCU)

3. Enter the Web server directory. Contact the local IT administrator for the appropriate

Web server directory.

4. Save your settings by selecting File > Save from the menu.

No additional setup is required to access configuration files on a network shared drive.

Accessing Configuration Files

A Group is defined as a common configuration shared by multiple Readers. As many Groups as

necessary can be defined. Each Group MUST have its own Directory. A Directory contains a set

of configuration files that define how the Readers in that Group operate. For example, one Group

may be defined for Readers in an emergency department environment with files saved in a

directory “ED”, while a separate set of configuration files, for use in an intensive care setting,

would be defined in the Group “ICU” and saved in a directory “ICU”.

A default Group Directory (C:\Program Files\Reader Configuration\) is set up during software

installation. If only one group is needed, the initial files can be modified and saved in this

directory.

If more than one group is needed, copy the default folder (C:\Program Files\Reader

Configuration) and re-name or use the Save As command to save all files to a new directory.

Each new folder MUST contain the following files: assays.dtv, controls.dtv, grp_settings.dtv, and,

userlist.opl.

If transferring files by USB, all files in the Group Directory MUST be copied to the root directory of

the USB.

CAUTION.

Do not change the file names.

To open all files for a group

Figure 40. Reader Configuration

System Settings: File

Click File > Open Group..., select the folder containing the files to be

used and click OK. If only one group is being used, the default

location is C:\Program Files\Reader Configuration\. This will open the

following files: group settings, userlist, controls and assays.

Detailed information on the use of the RCU files can be found in the

RCU HELP sections.

31

Page 37

3M™ Rapid Detection Reader Editing Settings Using the Reader Configuration Utility (RCU)

To open an Individual Configuration File

Figure 41. Open Default

Configuration

If only one configuration file requires modification, for example, when

updating Operator Lists, there is no need to open all the Group files,

just the file to be changed (in this example, userlist.opl). To do this,

click on File > Open, and then select Defaults..., Network... or USB

Device....

A “File Open” screen will display allowing navigation to the drive

containing the files of interest (Figure 41).

To select different types of files to load, select the Files of Type

dropdown list. As each file type is selected, a list of those files

present in the currently selected directory will be made available.

Select the desired file name and then click Open.

Setting Up Communications Between RCU and Readers

In the RCU: Open the default Group Settings file (Figure 42).

Files

This page sets the file locations where the Reader(s) looks for specific configuration information.

The Reader supports the HTTP, HTTPS, FTP and FTPS file transfer protocols. Directories are

specified in URL notation. Please consult the local IT administrator for guidance on the use of

these settings in the local network environment. If Readers will use the USB flash drive for

configuration information, all file location fields should be set to: file:/// as in the default settings

(except time server, which should be blank).

Examples of supported configurations are listed below.

• USB Flash drive: "file:/// "

Figure 42. Reader Configuration:

Group Settings

• Web Server: "http://medsvr/3M Rapid Detection Reader/ "

• Network drive: "ftp://fileserver/3M Rapid Detection

Reader_share/"

The Group Directory field identifies where the Reader(s) looks for all

group specific information.

The Assay List field identifies where the Reader(s) looks for its list of

supported assays.

The LQC Controls List field identifies where the Reader(s) looks for

its list of LQC controls.

The Operator Accounts List field identifies where the Reader(s)

looks for its operator list.

The Results Directory field identifies where the Reader(s) places

exported result files. In a networked environment one or more groups

can share the same destination directory.

The Device Directory field identifies where the Reader(s) should read and write device specific

information – this is typically set to the same directory as the Group Directory.

The Time Server Location allows the Reader group to access an NTP (Network Time Protocol)

server to keep the Reader's internal clocks set to the correct time. This field should be left blank

in non-networked environments or networked environments that lack access to an NTP server.

32

Page 38

3M™ Rapid Detection Reader Editing Settings Using the Reader Configuration Utility (RCU)

Identifying Readers through the RCU

The RCU uses Reader information files to identify the Readers installed within an institution.

Once a Reader has been identified, the RCU may be used to change Reader specific settings.

Non-networked Environment

A USB flash drive is used to transfer Reader settings between the Reader and the RCU. It is

recommended that the USB flash drive provided with the 3M Rapid Detection Reader is used as it

is pre-configured with the appropriate folders.

1. Insert a USB flash drive in an available USB port on the CM. Ensure that the USB drive

contains four folders named: lqc, patient, iqc, log.

2. Navigate to the Reader Settings screen and touch Export Configuration.

3. Touch Export to USB Flash Drive.

4. All settings files and result logs are exported.

5. Steps 1 to 3 can be repeated for additional Readers, if desired.

6. Insert the USB flash drive into the RCU computer’s USB drive.

7. From the RCU, click on File > Open, select USB Device (navigate to the correct location

of the USB Device if this function does not work automatically). Select the Files of Type

– Readers. Select the desired Reader Serial number and then click Open.

8. Changes to settings for the selected Reader may now be defined on the Reader Settings

menu.

For more information see Importing Files or Exporting Files below.

Networked Environment

Each Reader must be placed into network mode and must be assigned a device information