Page 1

Description

Electronic Pipettor - 5mL

Each unit includes the following items:

Pipette Electronique - 5mL

Elektronische Pipette - 5mL

Pipetta Elettronica - 5mL

Pipeteador electrónico - 5mL

•1 Electronic Pipettor

•1 Charging Stand

•1 AC Adapter

•1 Test Performance Certificate

•1 Instruction Manual

•1 Quick Reference Card

•Replacement Tip Cone Filters (50/bag)

Page 1 of 15 - June 2001

charging stand pipettor

5mL

Make sure that all items are included

and that no damage has occurred during

shipment. Also check that the AC adapter matches your electrical requirements.

Pipettor Controls

These controls are often referred to in this manual.

Speed Key Changes aspiration and dispense speeds

Mode Key Shifts to next mode

Up Key Increases open volume or speed

Down Key Decreases open volume or speed

Recall Key Flips back to last mode entered

Enter Key Selects mode,speed or volume changes

Start Button Triggers all mechanical operations

Tip Ejector Lever Squeezed to remove pipette tip

ON-OFF SWITCH

The On-Off Switch is located at the

back of the pipettor. Slide to the left

position to switch "ON" and to the

right to switch "OFF".

AC adapter

keypad

display

start button

tip ejector

lever

6483

FOD# 1210

ON

OFF

tip ejector

collar

tip cone

filter

2

Page 2

Precautions

4

• Always follow Good Laboratory Practices.

• Avoid contamination of the tip cone. Do not rest the pipettor on its side. Always

place the pipettor in the charging stand when not in use.

• Ensure consistent technique to maintain precise results.

• Never strike the pipettor tip cone against the tip tray when mounting tips. This

can damage internal components.

• Avoid excessive shock to pipettor. Do not drop the pipettor, charging stand or AC

adapter.

• Avoid exposing the unit to extreme temperature changes, humidity and dust.

• Avoid rough handling when using the unit. Moderate keystroke pressure is all that

is required for all operating buttons.

Indications

3

The easy-to-use 3M Electronic Pipettor - 5mL is pre-programmed to perform the

most common dilutions used with 3M

™

Petrifilm™Plates and 3M™Redigel™Tests.

The self-calibrating, microprocessor-based system reduces the possibility of human

error and instrument contamination by controlling pipetting speed, calibration and

volume selection. It is a simple yet sophisticated instrument for handling microvolumes of liquids with high accuracy and precision. Its light-weight and ergonomic

controls take the effort out of pipetting to help reduce the risk of repetitive strain

injuries that are frequent in manual pipetting.

The 3M Electronic Pipettor 5mL includes:

• Pre-programmed diluting, pipetting, and dispensing modes

• Self-calibrating, microprocessor-controlled system

• Full-grip; low-effort tip ejector

• Soft-touch operating button

• Open programming mode for user-set pipetting and diluting

• Recall button for selecting previous mode

• LCD screen for viewing speed, mode and volume

• 5 speeds for aspiration and dispensing

• Cordless operation

• Magnetic-mount recharging stand

• Replaceable NiMH battery

• Weighs less than 6 ounces

• Standard Methods for the Examination of Dairy Products (SMEDP) accuracy

Page 2 of 15 - June 2001

Page 3

Instructions For Use

6

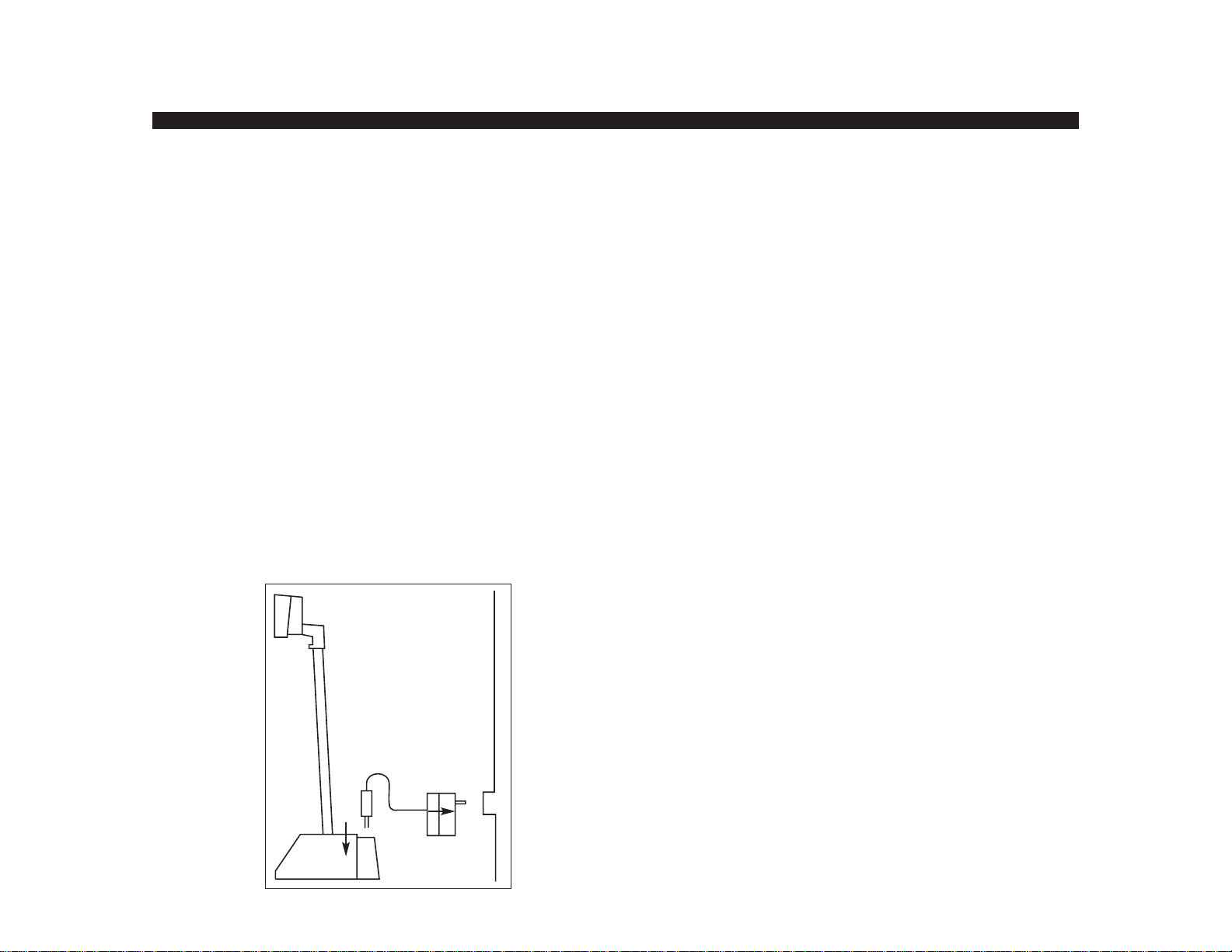

1. Connect the AC adapter into the connector jack at the rear of the charging

stand's base.

2. Plug the AC adapter into an AC electrical outlet.

3. The green light at the top of the charging stand indicates that the stand is in

operation. The light will always be on when plugged in and operating properly.

Charging the Pipettor Battery

1. Switch the pipettor “ON” (see page 2).

2. Mount the pipettor into the charging stand. The top of the pipettor will fit snugly

into the head of the charging stand. The magnetic mount will lock the pipettor into

the proper charging position.

3. If the battery is new or has been allowed to fully discharge, keep the pipettor in

the stand for 10 hours to fully charge the battery before continuing use.

• The unit will charge when “ON” or “OFF”. Leave the pipettor “ON” and in the

charging stand when not in use to retain user-selected pipettor settings.

• Switching the unit “OFF”clears user-set programming and resets the pipettor to

default settings.

Instructions For Use

5

Only use and store the pipettor in accordance with the following

operating conditions:

Condition Range or Limit

Performance Testing Temperature +19 to + 25°C

Mechanical Operating Temperature +15 to + 35°C

Storage Temperature -20 to + 40°C

Maximum Humidity 95%

The following recommendations should always be followed for best results:

1. During aspiration, hold the pipettor vertically. For greatest accuracy, the pipettor

should never be tilted at an angle greater than 15° during aspiration.

2. During aspiration, consistently place the tip no deeper than 5mm into the liquid.

3. During dispensing, position the tip at least 5mm above the surface to prevent

bubbles from forming.

Connecting the AC Adapter

• Be sure that the voltage rating of the AC adapter correctly corresponds to the

voltage from the electrical outlet.

• Do not use electrical outlets that are timed or switched.

• Use only the AC adapter provided with the unit or an approved replacement

from 3M.

1.

2.

Page 3 of 15 - June 2001

Page 4

Power “ON” Display and Startup

The display of a switched “ON” pipettor indicates that programming has been reset

to default settings.

1. Switch the unit “ON”. Display:

2. Press the Start Button twice. The display

shows that the unit is ready for the

default 1:5 dilution (Mode d1, 5mL) or

for program changes.

Switching the pipettor “OFF” and then

“ON” will reset the unit to the default

settings (Mode d1, 1:5, 5mL dilution).

Mode Selection and Mode Recall

Selecting available modes on the pipettors is done with the use of these three keys:

1. Press once to display the default dilution mode of the pipettor.

2. Press repeatedly to view each of the modes available.

3. Press when the desired mode is displayed. This will enter the mode

selection and allow you to use this mode.

Mode recall allows you to flip back and forth between the last two

modes used.

or may not be used in the middle of an aspiration or

dispensing cycle.

Pipettor Programming

8

Pipettor Programming

7

The Program Menu

1. The following five dilutions have been pre-programmed.

Dilution Diluent Sample Total

Mode Ratio Volume Volume Volume

d1 1:5 4.00mL 1.00mL 5.00mL

d2 1:10 4.50mL 0.50mL 5.00mL

d3 1:20 4.75mL 0.25mL 5.00mL

d4 1:5 0.80mL 0.20mL 1.00mL

d5 1:10 0.90mL 0.10mL 1.00mL

2. Repeat Dispense 1mL ModeThis mode performs repeat 1mL dispensing.

Mode Volume Repetitions

rd 1.00mL 1-5

3. Pipette Modes These modes perform standard 1mL and 5mL pipetting with blow-out.

Mode Volume

P1 1.00mL

P5 5.00mL

4. Open Dilution Mode This mode allows selection of any dilution ratio within the range of the pipettor

Diluent Sample Max.

Volume Volume Total

Mode Increment Range Range Volume

d0 0.05mL 0.10-5.00mL 0.00-4.90mL. 5.00mL

Page 4 of 15 - June 2001

Page 5

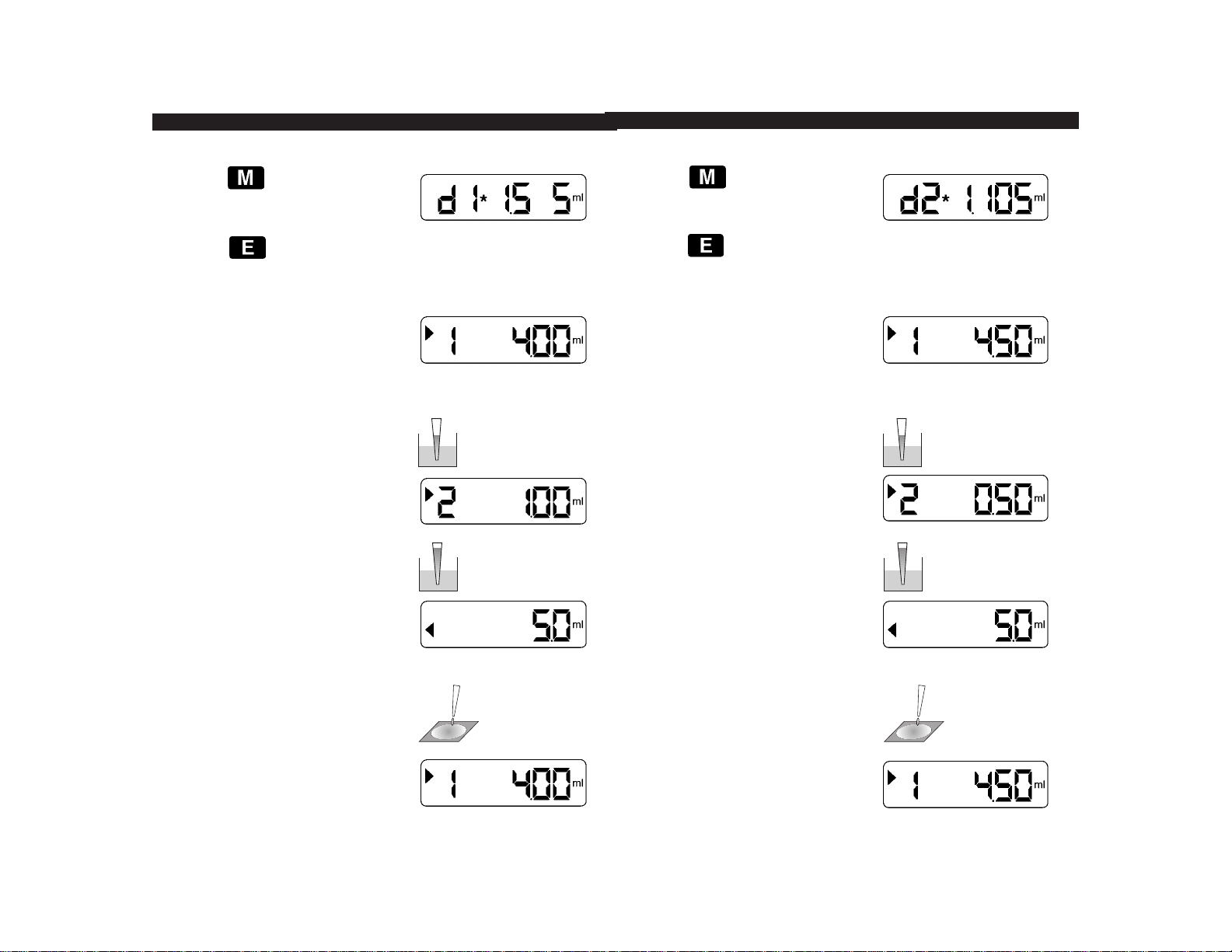

1:10 Dilution (5mL Total Volume)

1. Press repeatedly until the

display reads:

2. Press to enter selection.

3. Attach a pipette tip to the tip cone.

The pipettor is now ready to begin the

1:10 dilution (5mL total volume). The

display indicates that the pipettor is

ready to aspirate 4.50mL.

4. Place the tip in the diluent and press the

Start Button. The unit will aspirate

4.50mL.

The following display indicates that the

unit is ready to aspirate 0.50mL.

5. Place the tip in the sample solution

and press the Start Button to aspirate

0.50mL.

The next display indicates that the unit

is ready to dispense the total volume

(5mL) with blowout.

6. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the unit

is ready to repeat the dilution sequence,

beginning with the 4.50mL aspiration.

10

Pipettor Programming

1:5 Dilution (5mL Total Volume)

1. Press repeatedly until the

display reads:

2. Press to enter selection.

3. Attach a pipette tip to the tip cone.

The pipettor is now ready to begin the

1:5 dilution (5mL total volume). The

display indicates that the pipettor is

ready to aspirate 4.00mL.

4. Place the tip in the diluent and press the

Start Button. The unit will aspirate

4.00mL.

The following display indicates that the

unit is ready to aspirate 1.00mL.

5. Place the tip in the sample solution

and press the Start Button to aspirate

1.00mL.

The next display indicates that the unit

is ready to dispense the total volume

(5mL) with blowout.

6. Position the pipette tip to dispense

and press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the unit

is ready to repeat the dilution sequence,

beginning with the 4.00mL aspiration.

9

Pipettor Programming

Page 5 of 15 - June 2001

Page 6

1:5 Dilution (1mL Total Volume)

1. Press repeatedly until the

display reads:

2. Press to enter selection.

3. Attach a pipette tip to the tip cone.

The pipettor is now ready to begin the

1:5 dilution (1mL total volume). The

display indicates that the pipettor is

ready to aspirate 0.80mL.

4. Place the tip in the diluent and press the

Start Button. The unit will aspirate

0.80mL.

The following display indicates that the

unit is ready to aspirate 0.20mL.

5. Place the tip in the sample solution

and press the Start Button to aspirate

0.20mL.

The next display indicates that the unit

is ready to dispense the total volume

(1mL) with blowout.

6. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the unit

is ready to repeat the dilution sequence,

beginning with the 0.80mL aspiration.

12

Pipettor Programming

Pipettor Programming

11

1:20 Dilution (5mL Total Volume)

1. Press repeatedly until the

display reads:

2. Press to enter selection.

3. Attach a pipette tip to the tip cone.

The pipettor is now ready to begin the

1:20 dilution (5mL total volume). The

display indicates that the pipettor is

ready to aspirate 4.75mL.

4. Place the tip in the diluent and press the

Start Button. The unit will aspirate

4.75mL.

The following display indicates that the

unit is ready to aspirate 0.25mL.

5. Place the tip in the sample solution

and press the Start Button to aspirate

0.25mL.

The next display indicates that the unit

is ready to dispense the total volume

(5mL) with blowout.

6. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the unit

is ready to repeat the dilution sequence,

beginning with the 4.75mL aspiration.

Page 6 of 15 - June 2001

Page 7

1:10 Dilution (1mL Total Volume)

1. Press repeatedly until the

display reads:

2. Press to enter selection.

3. Attach a pipette tip to the tip cone.

The pipettor is now ready to begin the

1:10 dilution (1mL total volume). The

display indicates that the pipettor is

ready to aspirate 0.90mL.

4. Place the tip in the diluent and press the

Start Button. The unit will aspirate

0.90mL.

The following display indicates that the

unit is ready to aspirate 0.10mL.

5. Place the tip in the sample solution

and press the Start Button to aspirate

0.10mL.

The next display indicates that the unit

is ready to dispense the total volume

(1mL) with blowout.

6. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the unit

is ready to repeat the dilution sequence,

beginning with the 0.90mL aspiration.

13

Pipettor Programming

Repeat Dispensing (1-5 repetitions of 1mL)

1. Press repeatedly until the

display reads:

2. Press or to select a

new number of 1ml repetitions (1-5).

In this case 3.

3. Press to enter selection.

4. Attach a pipette tip to the tip cone.

The display indicates that the pipettor is

ready to aspirate 3.00mL.

5. Place the tip in the liquid and press the

Start Button. The unit will aspirate

3.00mL.

The following display indicates that the

unit is ready to dispense the first of the

three 1.00mL aliquots:

6. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the first 1.00mL aliquot.

The following display indicates that unit

is ready to dispense the second of the

three 1.00mL aliquots:

Pipettor Programming

14

Page 7 of 15 - June 2001

Page 8

7. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the second 1.00mL aliquot.

The following display indicates that unit

is ready to dispense the third of the

three 1.00mL aliquots.

8. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the third 1.00mL aliquot.

The following display indicates that unit

is ready to perform a new repeat

dispensing series.

9. Eject the disposable tip and repeat the

series beginning with Step 4.

Pipettor Programming

15

Pipettor Programming

1mL Pipetting

1. Press repeatedly until the

display reads:

2. Press to enter selection.

3. Attach a pipette tip to the tip cone.

The pipettor is now ready to aspirate

1.00mL.

4. Place the tip in the sample and press

the Start Button. The unit will aspirate

1.00mL.

The next display indicates that the unit

is ready to dispense the total volume

(1mL) with blowout.

5. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the unit

is ready to repeat the 1mL pipetting,

beginning with the 1.00mL aspiration.

16

Page 8 of 15 - June 2001

Page 9

Pipettor Programming

18

Open Dilution Programming

1. Press repeatedly until the

display reads:

2. Press to enter selection.

The display shows the default setting

for the diluent aspiration volume.

3. Press or to select a

new diluent volume (0.10 - 5.00mL).

(In this case 4.50mL)

4. Press to enter selection.

The display shows a default setting

for the sample aspiration volume.

5. Press or to select a

new sample volume (In this case

0.50mL)

6. Press to enter selection.

Pipettor Programming

17

5mL Pipetting

1. Press repeatedly until the

display reads:

2. Press to enter selection.

3. Attach a pipette tip to the tip cone.

The pipettor is now ready to aspirate

5.00mL.

4. Place the tip in the sample and press

the Start Button. The unit will aspirate

5.00mL.

The next display indicates that the unit

is ready to dispense the total volume

(5mL) with blowout.

5. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the unit

is ready to repeat the 5mL pipetting,

beginning with the 5.00mL aspiration.

Page 9 of 15 - June 2001

Page 10

Pipettor Programming

20

Speed Selection

Speed changes are made using these four keys:

Speed "1" is slowest and Speed "5" is fastest.

1. Press to display the

aspiration speed.

2. Press or to select a

new aspiration speed.

3. Press when the desired

aspiration speed is displayed.

Dispensing speed is then displayed.

4. Press or to select a

new dispensing speed.

5. Press when the desired

dispensing speed is displayed. The

display then returns to the diluent

aspiration readout.

may not be used in the middle

of any aspiration or dispensing cycle.

Pipettor Programming

19

7. Attach a pipette tip to the tip cone.

The pipettor is now ready to begin the

dilution. The display indicates that the

pipettor is ready to aspirate the selected

diluent volume.

8. Place the tip in the diluent and press the

Start Button. The unit will aspirate the

diluent volume selected.

The following display indicates that the

unit is ready to aspirate the selected

sample volume.

9. Place the tip in the sample solution

and press the Start Button to aspirate

0.50mL.

The next display indicates that the unit

is ready to dispense the total volume

with blowout.

10. Position the pipette tip to dispense and

press the Start Button. The unit will

dispense the full amount from the tip.

The display now indicates that the

unit is ready to repeat the dilution

sequence, beginning with the diluent

volume aspiration.

Page 10 of 15 - June 2001

Page 11

22

Troubleshooting

Liquid in Tip Cone

If liquid is aspirated beyond the tip cone filter, clean the tip cone as follows.

1. Switch the unit “OFF”.

2. Remove the tip ejector collar: hold down the tip ejector lever and twist off the tip

ejector collar.

3. Unscrew the tip cone from the control handle. Do not rest the pipettor

on the lab bench. Do not touch the stainless steel piston with any foreign objects

to avoid scratching or contamination.

4. Use ethanol and a soft lint-free wipe to gently clean the piston and tip cone.

5. Apply a thin layer of grease to the piston seal.

NOTE: Use only the piston grease specifically recommended by your 3M

representative. Other types of grease can permanently damage the piston.

6. Reassemble the unit and perform a calibration check.

piston

tip cone

tip

ejector

collar

“Er 1” Display

The 3M Electronic Pipettor - 5mL has a

built-in monitoring program to control the

pipettor mechanism. A display showing

“Er1” indicates that the pipettor has been

unable to perform a function properly. Go

through the following procedure to clear

this display and resume pipetting.

1. Allow the pipettor to charge on the stand for a minimum of 15 minutes.

2. Press to clear the error message.

The display should now show the Power “ON” reading. If the error message

remains displayed, consult your 3M representative for additional assistance.

Bubbles

The appearance of many small bubbles on the Petrifilm plate may indicate that the

dispense speed is too fast. Lower the dispense speed (see Speed Selection page 20).

In more viscous samples, a single large bubble may form if the tip is allowed to

contact the sample surface during dispensing. To prevent this, position the tip at least

5mm above the surface during dispensing.

“Frozen” Display

If this display is shown and the pipettor

will not operate, the has been

pressed.

1. Press twice to clear the display

and continue working.

See Speed Selection, page 20.

Troubleshooting

21

Page 11 of 15 - June 2001

Page 12

Care and Maintenance

The 3M Electronic Pipettor - 5mL requires regular cleaning to ensure trouble-free

operation. Use a soft cloth lightly moistened with a mild detergent to clean the outer

surface of the pipettor. DO NOT AUTOCLAVE.

Cleaning the Tip Cone

Monthly tip cone cleaning is recommended. However, with heavy use, clean more

frequently. If liquid enters the shaft, clean tip cone immediately.

1. Switch the unit “OFF”.

2. Remove the tip ejector collar: Hold down the tip ejector lever and twist off the tip

ejector collar.

3. Use a soft, lint-free wipe lightly moistened with ethanol to gently clean the tip cone.

4. Replace the tip ejector collar allowing the ejector handle connection to snap into

the attachment notch of the ejector collar.

Care and Maintenance

23

Filter Replacement

If the pipettor is not performing due to a clogged filter or if sample fluid has

contaminated the filter, the filter should be replaced.

1. Remove the contaminated or clogged filter by simply pulling it straight out of the

end of the tip cone (see Figure 1).

2. Clean the outside surface and the inner filter placement surface of the tip cone

using a swab moistened with ethanol (see Figure 2).

3. Place the pipettor in the charging stand for 15 minutes to allow drying of the

tip cone.

4. Place a new filter into the tip cone (see Figure 3).

Care and Maintenance

Figure 3

Figure 1 Figure 2

Removing Contaminated or

Clogged Filter from Tip Cone

Cleaning the Tip Cone Before

Installing New Filter

24

tip cone

ejector

collar

filter

Page 12 of 15 - June 2001

Page 13

Care and Maintenance

26

1:5 Dilution

T est Volume> 4.00 mL 1.00 mL 5.00 mL

Volume (mL)

Tolerance

Range > 3.968-4.032 mL 0.979-1.021 mL 4.945- 5.055 mL

Weight (g) Weight (g) Weight (g)

Temperature Tolerance Range* Tolerance Range* Tolerance Range*

19°C 3.9585 - 4.0207g 0.9767 - 1.0181g 4.9332 - 5.0409g

20°C 3.9577 - 4.0199g 0.9765 - 1.0179g 4.9322 - 5.0399g

21°C 3.9569 - 4.0191g 0.9763 - 1.0177g 4.9312 - 5.0389g

22°C 3.9557 - 4.0179g 0.9760 - 1.0174g 4.9297 - 5.0374g

23°C 3.9549 - 4.0171g 0.9758 - 1.0172g 4.9287 - 5.0364g

24°C 3.9542 - 4.0163g 0.9756 - 1.0170g 4.9278 - 5.0354g

25°C 3.9530 - 4.0151g 0.9753 - 1.0167g 4.9263 - 5.0339g

26°C 3.9522 - 4.0139g 0.9751 - 1.0164g 4.9253 - 5.0324g

27°C 3.9510 - 4.0131g 0.9748 - 1.0162g 4.9238 - 5.0314g

28°C 3.9498 - 4.0119g 0.9745 - 1.0159g 4.9224 - 5.0299g

29°C 3.9487 - 4.0107g 0.9742 - 1.0156g 4.9209 - 5.0283g

30°C 3.9475 - 4.0099g 0.9739 - 1.0154g 4.9194 - 5.0273g

Table 1

Calibration Check Chart

* Weights adjusted for temperature and pressure effects using the “z factor”.

Care and Maintenance

25

Battery Replacement

If the battery does not hold a sufficient charge for proper operation of the pipettor,

follow these steps for replacement of the battery.

1. Switch the unit "OFF".

2. Remove the top two screws on the back of the pipettor and remove the battery cover.

3. Carefully remove the battery by lifting it straight out of the holder.

4. Install the new battery by pressing the positive (+) end against the contact spring

at the bottom of the holder. Guide the negative (-) end carefully into position.

5. Replace the cover and the screws. Do not overtighten the screws.

6. Dispose of battery according to local requirements or regulations.

Calibration Check (Mode d1, 1:5, 5mL dilution)

Genuine 3M Pipettor Tips are strongly recommended for verifying pipettor

performance. Perform a single-sample measurement following a change of any

removable parts. Perform a 4-sample test monthly–or more frequently, depending on

use. Perform a 10-sample test quarterly. Record all results and maintain records. Use

the procedure indicated in “Standard Methods for the Examination of Dairy Products.”

1. The pipettor, pipettor tips and test liquid should all be allowed to adjust to room

temperature (19°C-25°C) for one day before beginning the calibration check.

Note the temperature before starting.

2. Double-rinse the pipettor tip by aspirating water to the 5.0 mL level (4.0mL +

1.0mL) and then expelling it.

3. Place a 50mL or smaller vessel containing 20-25g of distilled water onto an

analytical balance. Note its weight. Re-tare balance to 0 (zero).

4. Aspirate 4.0mL of water from the vessel on the analytical balance. Note its

weight. Re-tare balance to 0.

5. Aspirate an additional 1.00 mL from the vessel on the analytical balance. Note its

weight. Re-tare balance to 0.

6. Expel the 5.0mL of water back into the vessel on the analytical balance. Note

its weight.

7. Repeat steps 4 - 6 as desired.

8. Calculate the average weight of the 4.0mL aspirations. Repeat this

calculation for the 1.00 mL and 5.0mL measurements.

9. Refer to Table 1, page 26. Find the temperature closest to the temperature you

recorded during step 1. Confirm that each average weight falls within the

corresponding weight tolerance range for that temperature.

Page 13 of 15 - June 2001

Page 14

Pipettor Tips

28

Genuine 3M Pipettor Tips are strongly recommended for use with the 3M Electronic

Pipettor - 5mL. Other tips may adversely affect the accuracy of the instrument and

may damage the tip cone and ejector mechanism.

Item No. Description

6489 5mL wide bore tip, 500/pkg, racked, sterile

6488 5mL wide bore tip, 500/pkg, racked, nonsterile

6487 5mL wide bore tip, 250/pkg, bulk, nonsterile

Specifications

27

Accuracy and Precision

Test Mode: d1 1:5 (5mL) dilution

T est Action Precision Accuracy

Aspirate 4.00mL 0.6% 0.8%

Aspirate 1.00mL 1.6% 2.1%

Dispense 5.00mL 0.8% 1.1%

Tolerances

T est Action Range

Aspirate 4.00mL 3.968 - 4.032 mL

Aspirate 1.00mL 0.979 - 1.021 mL

Dispense 5.00mL 4.945 - 5.055 mL

Materials

Part Material

Tip Cone Polypropylene

Ejector Collar Polypropylene

Piston Polypropylene

Control Handle ABS

Tip Ejector Lever POM

+

-

+

-

+

-

+

-

+

-

+

-

Accuracy and Precision

Tolerances

Materials

Page 14 of 15 - June 2001

Page 15

Limited Warranty

29

3M warrants that - except for depletion of the battery power or where due to product

abuse, product use outside the instructions or intended applications, or reasonable

wear and tear - the 3M Electronic Pipettor meets 3M’s manufacturing specifications

for a period of one year from the date of purchase except where prohibited by law.

3M DISCLAIMS ALL OTHER EXPRESS AND IMPLIED WARRANTIES

INCLUDING BUT NOT LIMITED TO THE WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

Limitation of Remedies:

At 3M’s option, 3M will repair, replace or refund the purchase price of a 3M

Electronic Pipettor that does not conform to 3M’s express limited warranty above.

You must notify 3M of any suspected nonconformance in a product within 20 days

after you discover it and return the nonconforming product to 3M. In the United

States, please call 3M Microbiology Products Sales Management (800-328-1671) for

a returned goods authorization. Outside of the United States, please contact the local

3M subsidiary.

These are your exclusive remedies except where prohibited by law.

3M WILL NOT BE LIABLE FOR ANY OTHER DIRECT, INDIRECT,

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING

LOST PROFITS.

Out of Warranty Service

Contact your 3M representative for service.

For spare parts, filters, piston assembly, piston grease, or batteries contact your

3M representative.

3

Made in Finland for

3M Microbiology Products

3M Center, Building 275-5W-05

St. Paul, MN 55144-1000

USA

©3M 2001 - 15 pages

Faxable Doc # 1210

34-7048-6067-4

3M Microbiology Products

D-46325 Borken, Germany

Page 15 of 15 - June 2001

Loading...

Loading...