Page 1

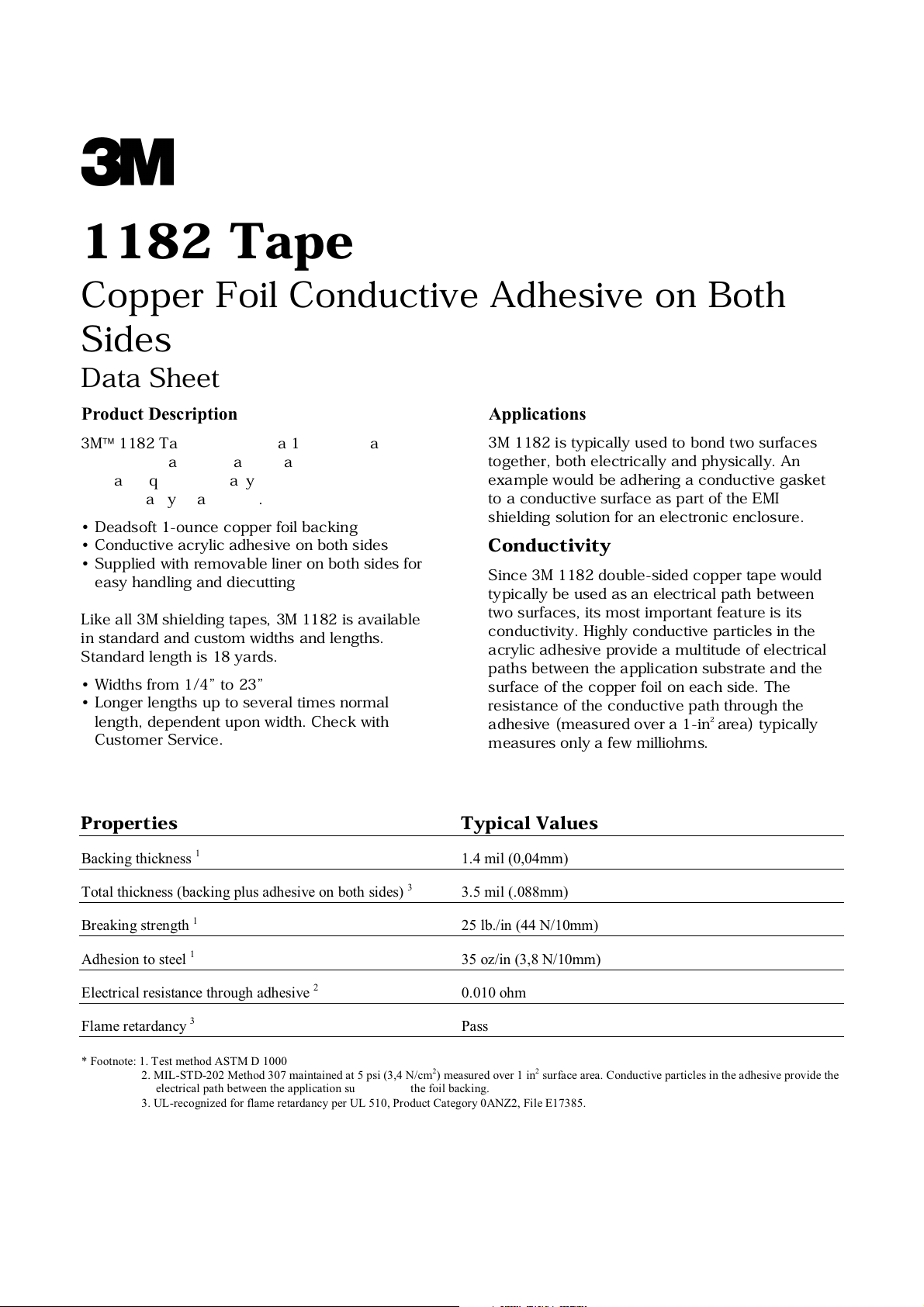

1182 Tape

Copper Foil Conductive Adhesive on Both

Sides

Data Sheet

Product Description

3M 1182 Tape consists of a 1-ounce deadsoft

copper foil backing that is coated on both sides

with a unique electrically conductive pressure-

sensitive acrylic adhesive.

• Deadsoft 1-ounce copper foil backing

• Conductive acrylic adhesive on both sides

• Supplied with removable liner on both sides for

easy handling and diecutting

Like all 3M shielding tapes, 3M 1182 is available

in standard and custom widths and lengths.

Standard length is 18 yards.

• Widths from 1/4” to 23”

• Longer lengths up to several times normal

length, dependent upon width. Check with

Customer Service.

Applications

3M 1182 is typically used to bond two surfaces

together, both electrically and physically. An

example would be adhering a conductive gasket

to a conductive surface as part of the EMI

shielding solution for an electronic enclosure.

Conductivity

Since 3M 1182 double-sided copper tape would

typically be used as an electrical path between

two surfaces, its most important feature is its

conductivity. Highly conductive particles in the

acrylic adhesive provide a multitude of electrical

paths between the application substrate and the

surface of the copper foil on each side. The

resistance of the conductive path through the

adhesive (measured over a 1-in

2

area) typically

measures only a few milliohms.

Properties Typical Values

Backing thickness

1

1.4 mil (0,04mm)

Total thickness (backing plus adhesive on both sides)

3

3.5 mil (.088mm)

Breaking strength 1 25 lb./in (44 N/10mm)

Adhesion to steel 1 35 oz/in (3,8 N/10mm)

Electrical resistance through adhesive 2 0.010 ohm

Flame retardancy 3 Pass

* Footnote: 1. Test method ASTM D 1000

2. MIL-STD-202 Method 307 maintained at 5 psi (3,4 N/cm

2

) measured over 1 in2 surface area. Conductive particles in the adhesive provide the

electrical path between the application substrate and the foil backing.

3. UL-recognized for flame retardancy per UL 510, Product Category 0ANZ2, File E17385.

Page 2

3M is a trademark of 3M.

Important Notice

All statements, technical information and recommendations

related to the Seller’s products are based on information believed

to be reliable, but the accuracy or completeness thereof is not

guaranteed. Before utilizing the product, the user should

determine the suitability of the product for its intended use. The

user assumes all risks and liability whatsoever in connection with

such use.

Any statements or recommendations of the Seller which are not

contained in the Seller’s current publications shall have no force

or effect unless contained in an agreement signed by an

authorized officer of the Seller. The statements contained herein

are made in lieu of all warranties, expressed or implied, including

but not limited to the implied warranties of merchantability and

fitness for a particular purpose which warranties are hereby

expressly disclaimed.

SELLER SHALL NOT BE LIABLE TO THE USER OR ANY

OTHER PERSON UNDER ANY LEGAL THEORY, INCLUDING

BUT NOT LIMITED TO NEG LIGENCE OR STRICT LIABILITY,

FOR ANY INJURY OR FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES SUSTAINED

OR INCURRED BY REASON OF THE USE OF ANY OF THE

SELLER’S PRODUCTS THAT WERE DEFECTIVE.

Electrical Products Division

6801 River Place Blvd.

Austin, TX 78726-9000

800 676 8381

http://www.3m.com/elpd

© 3M 1998

78-8124-4703-1

Loading...

Loading...