Page 1

®

CoreBuilder

®

9400

Getting Started Guide

http://www.3com.com/

Part No. 10013143

Published August 1999

Page 2

3Com Corporation

■ 5400 Bayfront Plaza ■ Santa Clara, California ■ 95052-8145

Copyright © 1999, 3Com Corporation. All rights reserved. No part of this

documentation may be reproduced in any form or by any means or used to

make any derivative work (such as translation, transformation, or adaptation)

without written permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make

changes in content from time to time without obligation on the part of 3Com

Corporation to provide notification of such revision or change.

3Com Cor poration provides this documentation without warranty of any kind,

either implied or expressed, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. 3Com may

make improvements or changes in the product(s) and/or the program(s)

described in this documentation at any time.

UNITED STATES GOVERNMENT LEGENDS

If you are a United States government agency, then this documentation and

the software described herein are provided to you subject to the following:

All technical data and computer software are commercial in nature and

developed solely at private expense. Software is delivered as “Commercial

Computer Software” as defined in DFARS 252.227-7014 (June 1995) or as a

“commercial item” as defined in FAR 2.101(a) and as such is provided with

only such rights as are provided in 3Com’s standard commercial license for the

Software. Technical data is provided with limited rights only as provided in

DFAR 252.227-7015 (Nov 1995) or FAR 52.227-14 (June 1987), whichever is

applicable. You agree not to remove or deface any portion of any legend

provided on any licensed program or documentation contained in, or delivered

to you in conjunction with, this User Guide.

EMISSIONS COMPLIANCE STATEMENTS FOR CLASS A PRODUCTS

United States — Federal Communications Commission Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide responsible protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in

which case the user will be required to correct the interference at his or her

own expense.

Canada — Emissions Requirements

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

Japan — VCCI Class A Compliance

This is a Class A product based on the standard of the Voluntary Control

Council for Interference by Information Technology Equipment (VCCI). If

this equipment is used in a domestic environment, radio disturbance may

arise. When such trouble occurs, the user may be required to take

corrective actions.

Page 3

EMC DIRECTIVE COMPLIANCE

This equipment was tested and found to conform to the Council Directive

89/336/EEC for electromagnetic compatibility. Conformity with this

Directive is based upon compliance with the following harmonized

standards:

EN 55022 Limits and Methods of Measurement of Radio Interference

EN 50082-1 Electromagnetic Compatibility Generic Immunity Standard:

Residential, Commercial, and Light Industry

Warn ing:

product may cause radio interference, in which case you may be required

to take adequate measures.

LOW VOLTAGE DIRECTIVE COMPLIANCE

This equipment was tested and found to conform to the Council Directive

72/23/EEC for safety of electrical equipment. Conformity with this Directive

is based upon compliance with the following harmonized standard:

EN 60950 Safety of Information Technology Equipment

UK GENERAL APPROVAL STATEMENT

This equipment is manufactured to the international Safety Standard

EN60950 and is approved in the UK under the General Approval Number

NS/G/12345/J/100003 for indirect connection to the public

telecommunication network.

AUSTRALIAN EMC FRAMEWORKS COMPLIANCE

This product conforms to the EMC Frameworks and meets the Class A

limits of AS3548.

This is a Class A product. In a domestic environment, this

TRADEMARKS

Unless otherwise indicated, 3Com registered trademarks are registered in

the United States and may or may not be registered in other countries.

3Com, the 3Com logo, CoreBuilder, SuperStack, and Transcend are

registered trademarks of 3Com Corporation. 3Com Facts is a service mark

of 3Com Corporation.

Apple, AppleTalk, and Macintosh are trademarks of Apple Computer, Inc.

Ultrajet is a trademark of Chemtronics. IBM and NetView AIX are registered

trademarks of International Business Machines Corporation. HP and

OpenView are registered trademarks of Hewlett-Packard Co. MS-DOS and

Windows are registered trademarks of Microsoft Corporation. SunNet

Manager, SunOS, and OpenWindows are trademarks of Sun Microsystems,

Inc. Microswabs and Texwipe are registered trademarks of Texwipe.

Liqui-Tool is a trademark of Triangle Tool Group. UNIX is a registered

trademark in the United States and other countries, licensed exclusively

through X/Open Company, Ltd.

All other company and product names may be trademarks of the respective

companies with which they are associated.

Page 4

Page 5

C

ONTENTS

BOUT THIS GUIDE

A

Introduction 7

Finding Specific Information in This Guide 7

Conventions 8

CoreBuilder 9400 Documentation 9

Paper Documents 9

Software and Documents on CD-ROM 10

Documentation Comments 10

Year 2000 Compliance 10

1

2

YSTEM AND SETUP OVERVIEW

S

CoreBuilder 9400 Intelligent Switch 11

System Features and Benefits 11

System Management 12

Network Configuration Example 12

Speeding Up Server Access 12

System Overview — Front Panel 13

System Overview — Back Panel 14

System Overview — Sample Application 15

NSTALLING THE SYSTEM

I

Before You Begin 17

Installing the System on a Table Top 17

Installing the System in a Distribution Rack 18

3

4

ABLING COREBUILDER

C

Overview of Cabling 19

Fiber Safety Precautions 19

Cabling Gigabit Ethernet Ports 20

Guidelines for Gigabit Ethernet Cabling 20

Recommended Distances for 1000BASE-SX Ports or

Tr an sce i ve rs 2 0

Recommended Distances for

1000BASE-LX Transceivers 20

Cabling 1000BASE-SX Ports 21

Cabling 1000BASE GBIC Ports 22

Connecting the LX Transceiver to MMF 24

Cabling the Console Port 26

Console Port Pin Assignments 27

Cabling the Out-of-Band Management Port 27

YSTEM POWER UP

S

Power Up 29

Power-up Diagnostics 30

System Diagnostics 30

Power LED Activity 30

Fault LED Activity 30

Gigabit Ethernet Port Diagnostics 30

Packet LED Activity 30

Status LED Activity 30

System Checks 31

Next Step: Software Configuration 31

9400 P

ORTS

Page 6

5

UICK SETUP FOR MANAGEMENT ACCESS

Q

About CoreBuilder 9400 System Management 33

Terminal Connection 34

Modem Connection 34

IP Management Interface 34

Initial Management Access 35

Changing the Console Port Baud Setting 35

Configuring the IP Interface 36

In-band Management 36

Out-of-band Management 36

C

ITE REQUIREMENTS AND SAFETY CODES

S

General Safety Requirements 47

Wiring Closet Recommendations 47

Distribution Rack Requirements 48

Protective Grounding for the Rack 48

Space Requirements for the Rack 48

Mechanical Requirements for the Rack 49

Building and Electrical Codes 50

U.S. Building Codes 50

U.S. Electrical Codes 51

6

A

B

ROUBLESHOOTING THE SYSTEM

T

Getting Additional Help 37

Diagnosing Problems 37

Power Failures 37

Abnormal LED Activity 37

Cleaning Dirty Fiber Optic Ports and Connectors 40

YSTEM SPECIFICATIONS

S

IELD-REPLACEABLE UNITS

F

Audience 43

Safety Precautions 43

Power Supply Assembly Removal and Replacement 43

Removing and Replacing the Power Supply 43

Fan Tray Assembly Removal and Replacement 45

D

ECHNICAL SUPPORT

T

Online Technical Services 53

World Wide Web Site 53

3Com Knowledgebase Web Services 53

3Com FTP Site 54

3Com Bulletin Board Service 54

Access by Analog Modem 54

Access by Digital Modem 54

3Com Facts Automated Fax Service 54

Support from Your Network Supplier 55

Support from 3Com 55

Returning Products for Repair 57

NDEX

I

3COM C

ORPORATION LIMITED WARRANTY

Page 7

A

BOUT

T

HIS

G

UIDE

Introduction

This guide provides all the information that you need

to set up your CoreBuilder

operating in your network. This guide provides an

overview of your system and step-by-step procedures

for planning your configuration, installing your

system, cabling, powering up, configuring, and

troubleshooting. When you are ready to configure

your CoreBuilder 9400 system, see the Command

Reference Guide and the Corebuilder 9400

Implementation Guide on the Software and

Documentation CD.

If the information in the Software Installation and

Release Notes that are shipped with your system

differs from the information in this guide, follow the

instructions in the Release Notes.

This guide is intended for the system or network

administrator who is responsible for installing and

managing network hardware. It assumes that you

have a working knowledge of local area network

(LAN) operations, but it does not assume prior

knowledge of the CoreBuilder 9400 system.

®

9400 system and get it

Finding Specific Information in This Guide

This table shows where to find specific information.

For information on Tu r n t o

Best ways to use the

CoreBuilder

The front and back panels “System Overview — Front

Site requirements and other issues

to consider before you install your

CoreBuilder 9400 system

Installing the system on a table or

in a distribution rack

Cabling the CoreBuilder 9400

system

Checking system power-up

diagnostics and LEDs

Deciding how to manage your

system

Setting the Console port baud “Changing the Console Port

Configuring the IP management

interface

Troubleshooting hardware and

software problems

Removing and replacing the

power supply

®

9400 system

“System Features and Benefits”

on page 11

Panel” starting on page 13

“General Safety Requirements”

starting on page 47

“Installing the System on a Table

Top” on page 17 and “Installing

the System in a Distribution

Rack” on page 18

Chapter 3

“Power Up” on page 29

“How Do You Want to Manage

the System?” on page 33

Baud Setting” on page 35

“IP Management Interface” on

page 34

“Diagnosing Problems” on

page 37

“Removing and Replacing the

Power Supply” on page 43

Page 8

8 A

BOUT THIS GUIDE

For information on Turn t o

Removing and replacing the fan

tray assembly

Complying with environmental

and compliance specifications

Installing field-replaceable

components

Checking your site for

environmental and safety

“Fan Tray Assembly Removal and

Replacement” on page 45

Appendix A: System

Specifications

Appendix B: Field-Replaceable

Units

Appendix C: Site Requirements

and Safety Codes

requirements

Getting help from your network

Appendix D: Technical Support

supplier or 3Com

Returning 3Com products to

3Com for repair

“Returning Products for Repair”

on page 57

Conventions

Table 1 and Table 2 list conventions that are used

throughout this guide.

Tab l e 1

Icon Type Description

Notice Icons

Information

Note

Information that describes important

features or instructions

Caution Information that alerts you to potential loss

of data or potential damage to an

application, system, or device

Warning Information that alerts you to potential

personal injury

Ta b le 2

Text Conventions

Convention Description

Screen

display

Commands

This typeface represents information as it appears

on the screen.

The word “command” means that you must

enter the command exactly as shown and then

press Return or Enter. Commands appear in bold.

Example:

To update the system software, enter the

following command:

system software Upda te

This guide always gives the full form of a

command in uppercase and lowercase letters.

However, you can abbreviate commands by

entering the fewest letters in each command that

identify a unique command. Commands are not

case sensitive.

The words “enter”

and “type”

When you see the word “enter” in this guide,

you must type something, and then press Return

or Enter. Do not press Return or Enter when an

instruction simply says “type.”

Keyboard key

names

If you must press two or more keys

simultaneously, the key names are linked with a

plus sign (+). Example:

Press Ctrl+Alt+Del

Words in

italics

Italics are used to:

■

Emphasize a point.

■

Denote a new term at the place where it is

defined in the text.

Page 9

CoreBuilder 9400 Documentation 9

CoreBuilder 9400 Documentation

The following documents comprise the

CoreBuilder 9400 documentation set. Documents are

available in three forms:

■ Paper documents that are shipped with your

system or with optional components. They are

listed in the next section.

CoreBuilder 9400 Software and Documentation

■

CD

with online versions of the paper documents

To order a paper copy of a document that you see

on the compact disc, or to order additional

compact discs, contact your supplier.

■ Most 3Com documentation is also available on the

3Com Web site:

http://support.3com.com/index.htm

Paper Documents

These documents are shipped with your system:

CoreBuilder 9400 Unpacking Instructions

■

How to unpack your CoreBuilder 9400 system.

Also, an inventory list of items that are shipped

with your system.

CoreBuilder 9400 Software Installation and Release

■

Notes

All of the new features, system issues, and known

problems for the software release.

CoreBuilder 9400 Quick Installation Guide

■

A quick checklist for how to install your system.

CoreBuilder 9400 Getting Started Guide

■

guide)

All of the procedures necessary for getting your

system up and running, including information on

installing, cabling, powering up, configuring, and

troubleshooting the system.

CoreBuilder 9400 Command Quick Reference Card

■

All of the Administration Console switching

commands for the CoreBuilder 9400. For complete

descriptions of commands, see the

Reference Guide

CoreBuilder 9400 Web Management User Guide

■

(this

Command

.

How to use the Web Management suite of

applications for your system.

Page 10

10 A

BOUT THIS GUIDE

These documents are shipped with optional devices:

■ CoreBuilder 9400 Power Supply Assembly Removal

and Replacement Guide

How to install an optional additional power supply

for the CoreBuilder 9400.

■ CoreBuilder 9400 Fan Tray Removal and

Replacement Guide

Overview information and removal and

replacement instructions for the fan tray.

Software and Documents on CD-ROM

The compact disc that is shipped with your system

contains the system software, online versions of the

paper guides that are shipped with your system, and

these guides:

■ Command Reference Guide

A complete multiplatform reference guide to all

Administration Console commands for this system

and several others.

■ CoreBuilder 9400 Implementation Guide

Information and examples about how to use the

features of your system.

Documentation Comments

Your suggestions are very important to us. They help

us to make our documentation more useful to you.

Please send e-mail comments about this guide to:

sdtechpubs_comments@ne.3Com.com

Please include this information when you comment:

■

Document title

■

Document part number (found on the front or

back page of the document)

■

Page number (if appropriate)

Example:

CoreBuilder 9400 Getting Started Guide

Part Number: 10013143

Page 26

Year 2000 Compliance

For information on Year 2000 compliance and 3Com

products, visit the 3Com Year 2000 Web page:

http://www.3com.com/products/yr2000.html

Page 11

1

S

YSTEM AND

S

ETUP

O

VERVIEW

This chapter contains:

■ An overview of the CoreBuilder

how it provides solutions for your network

■ A description of the major features and

components of the system

■ A network configuration example

®

9400 system and

CoreBuilder 9400 Intelligent Switch

The CoreBuilder 9400 system delivers full line rate

switching among all 24 Gigabit Ethernet ports. The

system has the following ports (shown in Figure 1 on

page 15):

■ 12 1000BASE-SX (MMF) ports with SC connectors

■ 12 GBIC ports that can accept 1000BASE-LX or

1000BASE-SX GBIC transceivers

The system supports full-duplex mode on all Gigabit

Ethernet ports and up to 32,000 MAC addresses. To

deliver even higher performance rates among

switches, the system supports trunking, which allows

you to group up to six Gigabit Ethernet ports into a

single multigigabit connection for a maximum of

12 trunks per system.

System Features and Benefits

The CoreBuilder 9400 is part of 3Com’s CoreBuilder

family. To combine technologies as your network

grows, install the CoreBuilder 9400 in your network.

Some key features of the CoreBuilder 9400 system:

■ High-density Gigabit Ethernet configuration

This system exhibits no packet loss or delays even

under maximum network traffic on its 24 Gigabit

Ethernet ports.

■ Trunking of Gigabit Ethernet ports

This system allows you to configure up to six

Gigabit Ethernet ports into a single multigigabit

connection for a maximum of 12 trunks per unit.

■ Trunking links and Spanning Tree Protocol support

The CoreBuilder 9400 protects against cable and

equipment failures with Spanning Tree Protocol

and trunking links.

■ Failure protection

To protect your network, this system has an

optional second power supply.

Page 12

12 C

■

1: S

HAPTER

YSTEM AND SETUP OVERVIEW

Resilient links

Resilient links technology protects your network

against an individual link or device failure by

providing a secondary backup link that is inactive

until it is needed.

■

Manageability

The CoreBuilder 9400 provides full support for

VLANs and RMON-1, as well as a roving analysis

port through SNMP management.

System Management

The CoreBuilder 9400 system includes integrated

management to provide fault tolerance and

maximum network availability. This management is

accessible in three ways:

■

CoreBuilder 9400 Administration Console

■

Standard network management applications based

on SNMP, such as 3Com’s Transcend applications,

Sun’s SunNet Manager, HP’s OpenView, and IBM’s

NetView AIX applications

■

Web Management suite of applications, with

forms for many management tasks, charts and

wizards to help you configure and monitor your

system, and online Help (separately installed) give

you instant information about your configuration

choices.

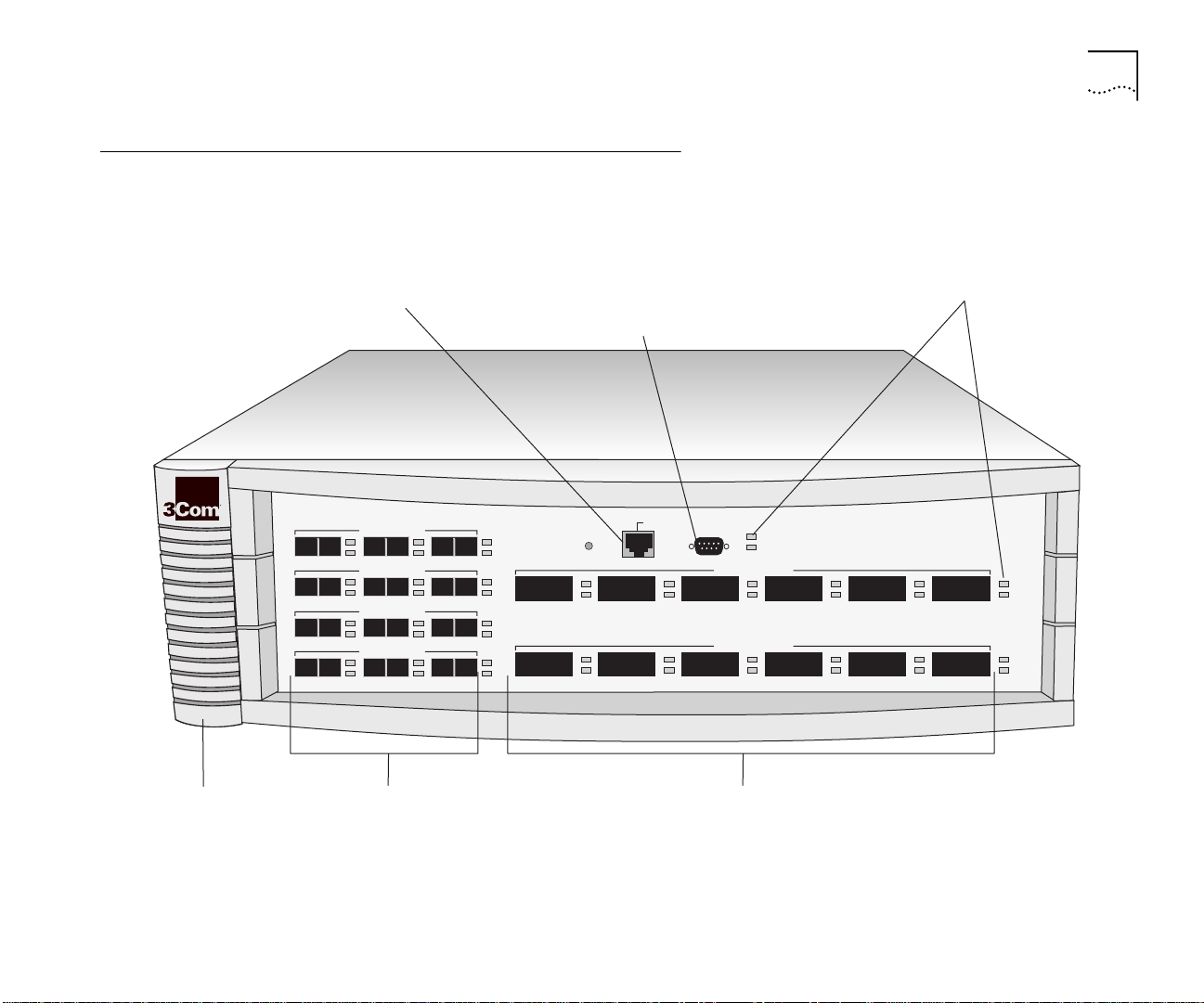

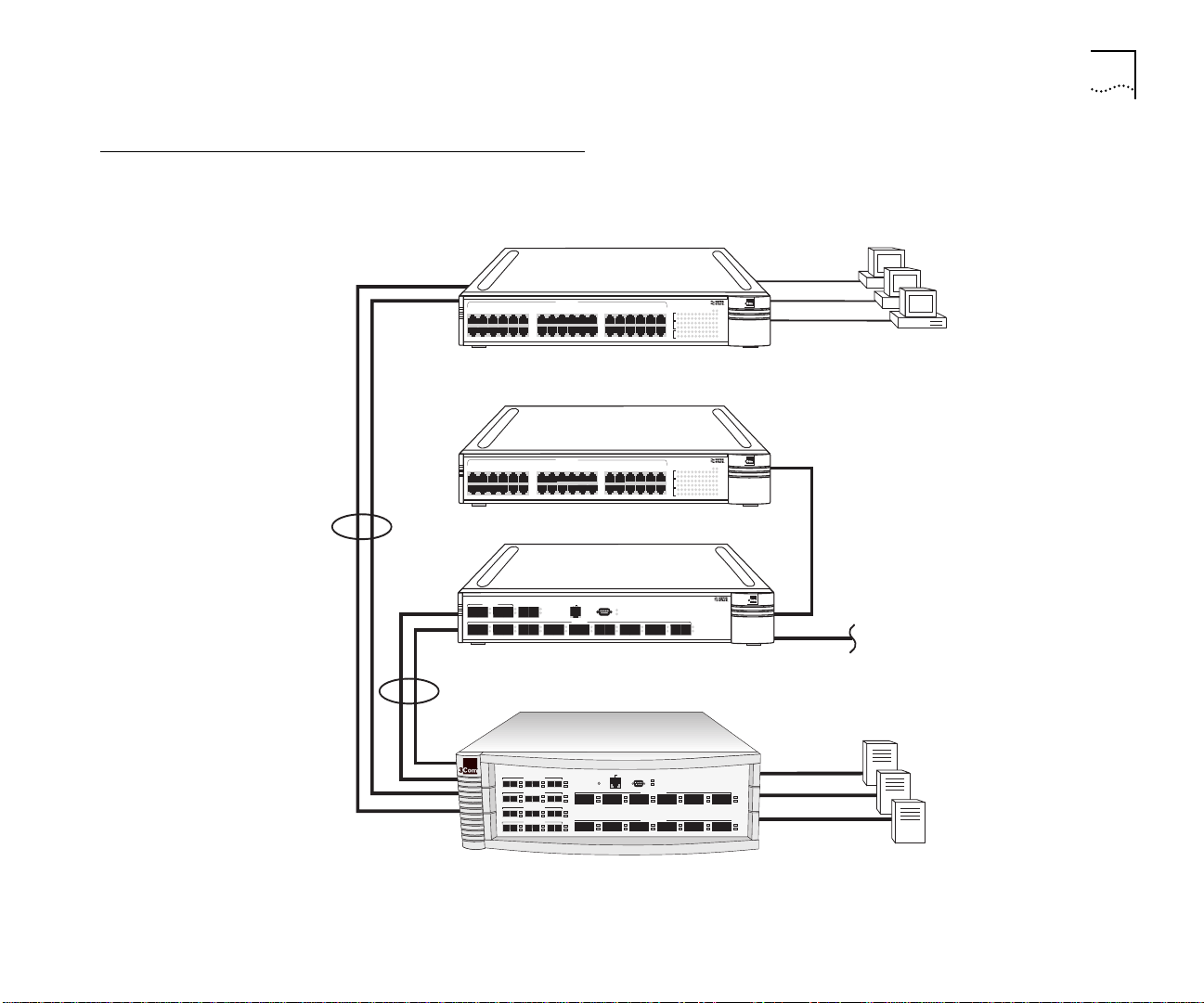

Network Configuration Example

This section discusses one way to place the

CoreBuilder 9400 in your network.

Speeding Up Server Access

To centralize your servers for easier service and

support, use a configuration like the one shown in

Figure 3.

Suppose that all of your organization’s servers are

located in that physical space. These servers must

support a large number of clients that are distributed

throughout the organization’s campus. The clients are

switched Fast Ethernet desktops.

First, you can multiplex the traffic from each group of

desktop clients into one higher-bandwidth stream

(trunk) through a SuperStack II Switch 3900.

Each SuperStack II 3900 can, in turn, pass its traffic

along to a CoreBuilder 9400, which multiplexes the

traffic into Gigabit Ethernet streams for the servers.

This architecture eliminates bottlenecks caused by

each Fast Ethernet device as it vies for access to the

server.

You can also use the CoreBuilder 9400 for many

other applications, such as to consolidate LAN

backbones or to provide more flexible trunking

configurations.

Page 13

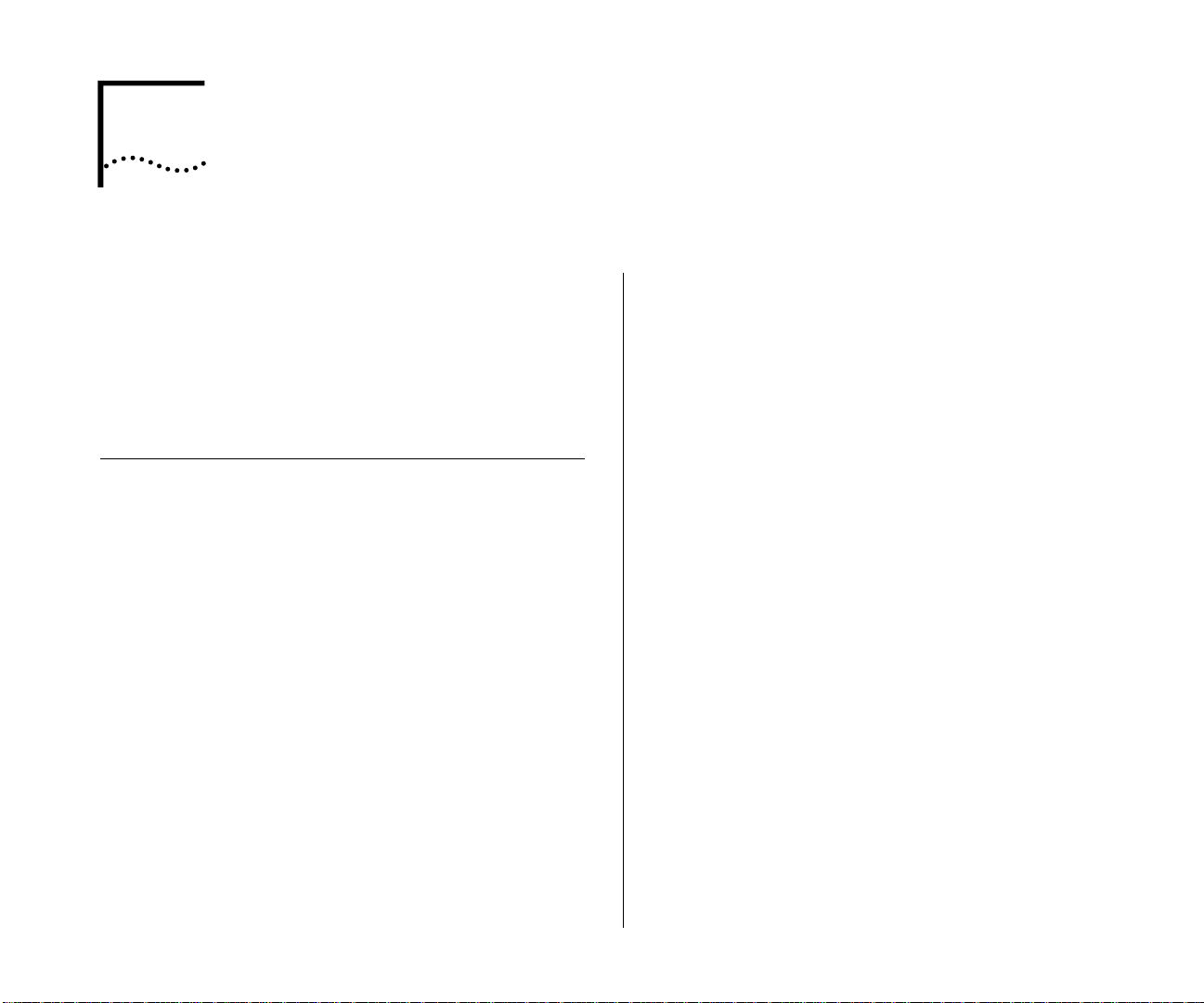

System Overview — Front Panel

Console Port

Allows you to connect a

workstation/terminal/modem to

the CoreBuilder

®

9400 system

for management access

10BASE-TX

Out-of-band

Management Port

LEDs

Provide information about

the system and each port

1000BASE GBIC Ports1000BASE-SX PortsFan tray

®

CONSOLE

10BASE TX

STATUS PACKET

R

STAT

PCKT

STAT

PCKT

STAT

PCKT

STAT

PCKT

3C94024

SERVICE

POWER

FAULT

1000BASE (GBIC)

1000BASE SX

2

TX RX

1000BASE (GBIC)

1000BASE SX

1000BASE SX

1000BASE SX

1

TX RX

3

TX RX

5

TX RX

4

TX RX

6

TX RX

8

TX RX

7

TX RX

9

TX RX

11

TX RX

10

TX RX

12

TX RX

13 14 15 16 17 18

19 20 21 22 23 24

STATUS

green = enabled, link OK

flashing green = disabled, link OK

off = link fail

System Overview — Front Panel 13

Figure 1

Front Panel of the CoreBuilder 9400 System

Page 14

14 C

HAPTER

1: S

YSTEM AND SETUP OVERVIEW

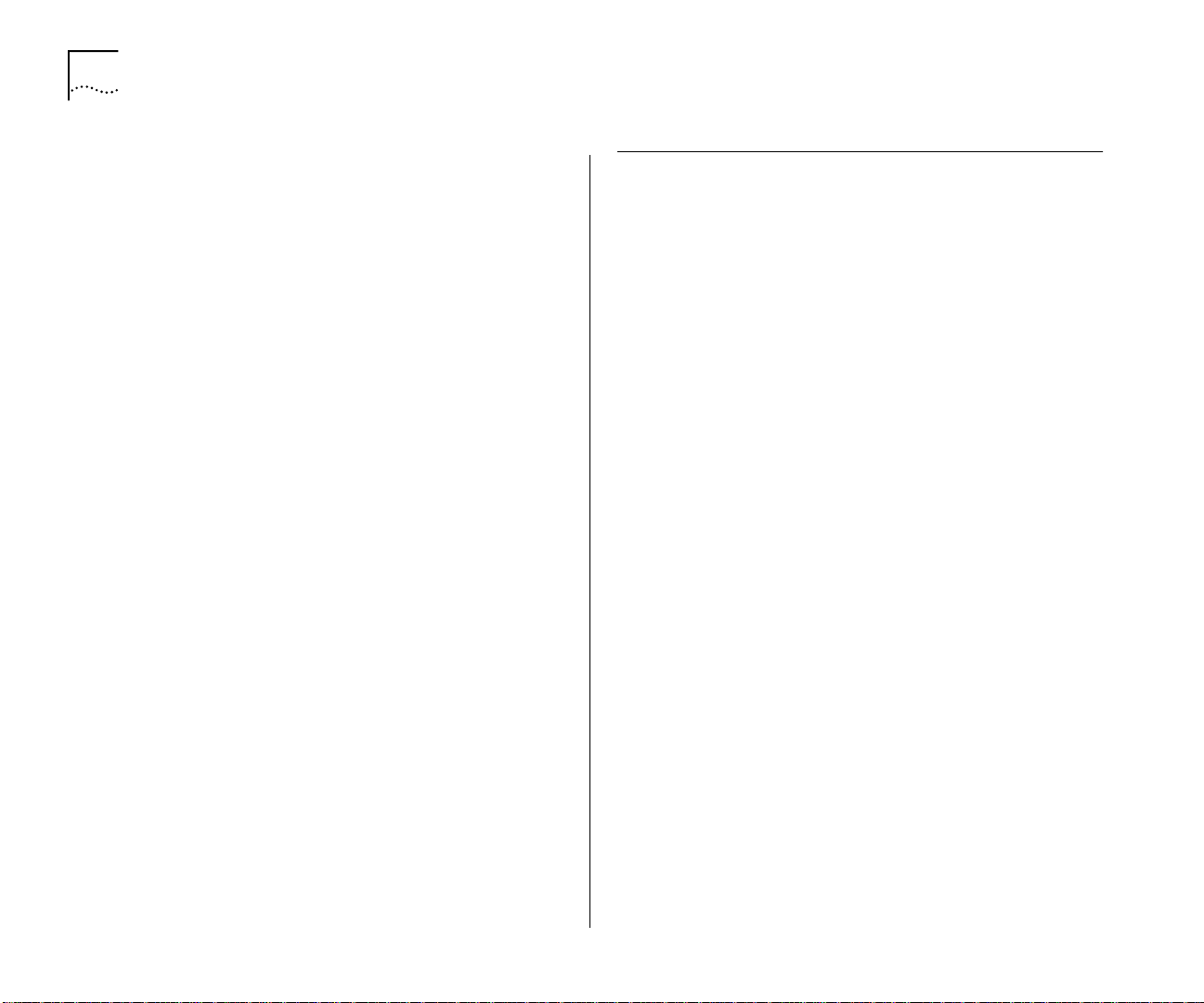

System Overview — Back Panel

Figure 2

Back Panel of the CoreBuilder 9400 System

DC OK

!

Power supply latch

DC OK

!

Power Supply No. 2

Power Supply No. 1

Page 15

System Overview — Sample Application

System Overview — Sample Application 15

Figure 3

Centralizing a Data Center with the CoreBuilder 9400 System

10/100 BASE - TX

6x

1x

7x

13

12x

19x

SuperStack® II Switch 3900

10/100 BASE - TX

6x

13

12x

19x

SuperStack II Switch 3900

10 Base - TX

1000 Base - SX

1000 Base - LX

TX RX2TX RX

3

2000 Mbps Trunk

1x

7x

TX RX

1

TX RX4TX RX5TX RX6TX RX7TX RX8TX RX9TX RX10TX RX11TX RX

SuperStack® II Switch 9300

1000 Base - SX

Status

green = enabled, link OK

flashing green = disabled, link OK

FaultPower

off = link fail

25

18

31x

24x

30

3110

2

3110

2

1

1

1

1

2

2

2

2

36x

456789

456789

117118192021 22

117118192021 22

229230313233 34

229230313233 34

11 12

Pckt

11 12

Stat

23 24

Pckt

23 24

Stat

35 36

Pckt

35 36

Stat

Switched 100 Mbps

desktop systems

Status

green = enabled, link OK

flashing green = disabled, link OK

FaultPower

off = link fail

25

18

31x

24x

Console

StatPckt

30

456789

3110

11 12

2

Pckt

456789

3110

11 12

2

Stat

117118192021 22

23 24

1

1

Pckt

117118192021 22

23 24

1

1

Stat

229230313233 34

35 36

2

2

Pckt

229230313233 34

35 36

2

2

green = enabled, link OK

flashing green = disabled, link OK

off = link fail

12

Stat

Status

Packet

Status

Super Stack II

Switch 9300

To other Switch 3900s

36x

Pckt

Stat

R

3C94024

1000BASE SX

TX RX

TX RX3TX RX

1

1000BASE SX

TX RX4TX RX6TX RX

1000BASE SX

TX RX7TX RX9TX RX

1000BASE SX

TX RX10TX RX12TX RX

STATUS PACKET

RESET

PCKT

STAT

2

5

13 14 15 16 17 18

PCKT

STAT

8

19 20 21 22 23 24

11

CoreBuilder

10BASE TX

CONSOLE

1000BASE (GBIC)

1000BASE (GBIC)

®

9400

STATUS

green = enabled, link OK

flashing green = disabled, link OK

FAULT

off = link fail

POWER

PCKT

STAT

PCKT

STAT

Dedicated 1000 Mbps

bandwidth to each server

Page 16

16 C

HAPTER

1: S

YSTEM AND SETUP OVERVIEW

Page 17

2

I

NSTALLING THE

S

YSTEM

This chapter describes how to install your

CoreBuilder

distribution rack.

See Appendix C for site requirements.

■ To install the CoreBuilder 9400 system on a table

top, read these sections:

■

■

■ To install the CoreBuilder 9400 system in a

distribution rack, read these sections:

■

■

®

9400 system on a table top or in a

“Before You Begin” (the next section)

“Installing the System on a Table Top” on

page 17

“Before You Begin” (the next section)

“Installing the System in a Distribution Rack” on

page 18

Before You Begin

Before you begin this procedure, be sure to:

■ Move the CoreBuilder 9400 system close to where

you plan to install it.

Install the system near an easily accessible power

outlet. You can power down the system only by

removing the power cord from the power source.

■ Have a No. 2 Phillips screwdriver available.

■ Have the system mounting kit available. See

Ta bl e 3 .

Ta b le 3

Item Qty To u s e i n

Rubber feet

(self-adhesive)

Mounting brackets 2 Installing the system in a

8-32 x 1/2 Phillips

flat-head screws

10-32 x 1/2 Phillips

pan-head screws

CoreBuilder 9400 System Mounting Kit

4 Installing the system on a

table top

distribution rack

8 Installing distribution-rack

mounting brackets

4 Installing the system in a

distribution rack

Installing the System on a Table Top

To install the CoreBuilder 9400 system on a table top,

follow these instructions:

1

See Appendix C for site requirements.

2

Turn the system on its side.

3

Remove the protective covering from the rubber feet

and place one foot in each marked area at the four

corners of the unit.

4

Turn the system onto its feet.

5

Verify that the air intake vents and fan exhaust vents

at the sides of the system are not blocked.

You are now ready to cable your system. For

instructions, see Chapter 3.

Page 18

18 C

R

3C94024

1000BASE SX

2

TX RX

1000BASE SX

1000BASE SX

1000BASE SX

1

TX RX TX

5

TX RX

4

TX RX TX

8

TX RX

7

TX RX TX

11

TX RX

10

TX RX TX

Mounting bracket

Mounting screws

HAPTER

2: I

NSTALLING THE SYSTEM

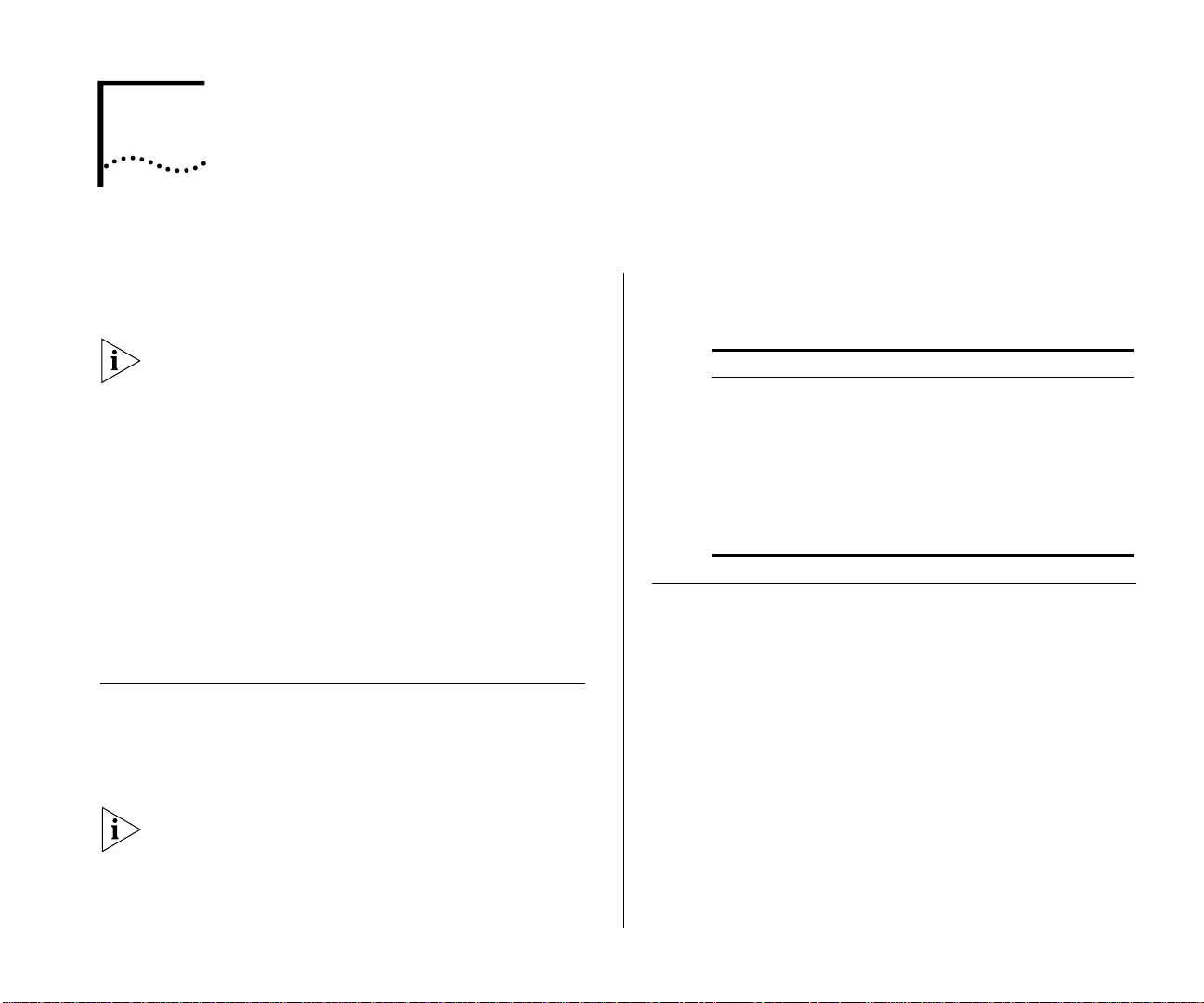

Installing the System in a Distribution Rack

1

2

You can mount the CoreBuilder 9400 system into a

48.26 mm (19-in.) distribution rack. This section

describes how to prepare the system and distribution

rack for installation and how to mount the system in

the rack.

Install your distribution rack near an easily accessible

power outlet. You can power down the system only

by removing the power cord from the power source.

To prepare the system and distribution rack for

installing the CoreBuilder 9400 system:

See Appendix C for distribution rack requirements.

Attach one of the L-shaped mounting brackets to one

side of the CoreBuilder 9400 using the 8-32 x 1/2

Phillips flat-head screws. Attach the other bracket to

the other side. See Figure 4.

Figure 4

3

Carefully lift the system into place, aligning the

Installing System Mounting Brackets

bracket holes with the distribution rack holes.

4

While you hold the system in place, insert the four

mounting screws (10-32 x 1/2 Phillips pan-head) into

the mounting holes on each side of the rack.

5

Tighten the mounting screws.

You are now ready to cable the system. For cabling

instructions, see Chapter 3.

Page 19

3

CLASS 1

LASER PRODUCT

C

ABLING

C

OREBUILDER

9400 P

ORTS

This chapter describes how to cable your

CoreBuilder

network. It gives an overview of cabling and describes

how to cable:

■ Gigabit Ethernet ports

■ Console port

■ Out-of-band management port

When all of your Gigabit Ethernet and system

network connections are complete, see Chapter 4.

If you are staging the system, you do not need to

connect it to the network at this point. See Chapter 4

to start your system before you cable it.

®

9400 system for connection to the

Overview of Cabling

The CoreBuilder 9400 system is a Gigabit Ethernet

switch with this fixed configuration:

■ Twelve 1000BASE-SX ports

■ Twelve 1000BASE GBIC ports (LX or SX

transceivers)

Fiber Safety Precautions

The CoreBuilder 9400 system uses lasers in its fiber

optic ports. To ensure your safety, comply with the

following precautions.

WARNING: The fiber optic lasers used in this system

meet the regulatory requirements for casual exposure

to the eye. As with any source of bright light,

however, 3Com recommends that you do not look

into the laser light source.

IEC 825, Class 1 Laser Devices are for connection only

to Class 1 Laser Devices. MMF and SMF fiber optic

interfaces use lasers.

Page 20

20 C

HAPTER

3: C

ABLING COREBUILDER

9400 P

Cabling Gigabit Ethernet Ports

Before you cable the system, consider this Caution.

CAUTION:

network cables before you power on the system

(chapter 4) if you need to configure trunks, resilient

links, or the Spanning Tree Protocol (STP). To avoid

bridge loops, configure trunks, resilient links, and

STP using the Administration Console

connect the cables and after you power up the

system. See the

the

Implementation Guide

Guidelines for Gigabit Ethernet Cabling

For all Gigabit Ethernet cabling, keep the ports and

connectors free of dust. See “Cleaning Dirty Fiber

Optic Ports and Connectors” on page 40 for details.

Recommended Distances for

1000BASE-SX Ports or Transceivers

When you cable 1000BASE-SX ports or transceivers,

verify that the length of the fiber cable from the

system to any attached device does not exceed these

recommended distances:

■

Use 62.5-micron MMF fiber with a modal

bandwidth specification of 160 MHz*km for

distances of up to 220 m (722 ft).

■

Use 62.5-micron MMF fiber with a modal

bandwidth specification of 200 MHz*km for

distances of up to 275 m (902 ft).

may not

Yo u

want to connect the

Command Reference Guide

for your system.

ORTS

before

you

and

■

Use 50-micron MMF fiber with a modal bandwidth

specification of 400 MHz*km for distances of up

to 500 m (1645 ft).

■

Use 50-micron MMF fiber with modal bandwidth

specification of 500 Mhz*km for distances of up to

550 m (1805 ft).

Recommended Distances for

1000BASE-LX Transceivers

When you cable 1000BASE-LX transceivers, verify

that the length of the fiber cable from the system to

any attached device does not exceed these

recommended distances:

■

Use 62.5-micron MMF fiber with a modal

bandwidth specification of 160 MHz*km for

distances of up to 550 m (1805 ft).

■

Use 62.5-micron MMF fiber with a modal

bandwidth specification of 200 MHz*km for

distances of up to 550 m (1805 ft).

■

Use 50-micron MMF fiber with a modal bandwidth

specification of 400 MHz*km for distances of up

to 550 m (1805 ft).

■

Use 50-micron MMF fiber with a modal bandwidth

specification of 500 MHz*km for distances of up

to 550 m (1805 ft).

■

Use 9-micron SMF fiber for distances of up to

10 km (6.2 mi). The specification requires and

specifies 5 km (3.1 mi).

Use a conditioned launch cable to connect the

1000BASE-LX transceiver to multimode fiber. Using

this cable ensures reliability over the maximum 550 m

distance.

Page 21

Cabling Gigabit Ethernet Ports 21

R

STAT

PCKT

STAT

PCKT

3C94024

R

1000BASE SX

2

TX RX

1000BASE SX

1000BASE SX

1000BASE SX

1

TX RX

3

TX RX

5

TX RX

4

TX RX

6

TX RX

8

TX RX

7

TX RX

9

TX RX

11

TX RX

10

TX RX

12

TX RX

13

19

Cabling 1000BASE-SX Ports

To cable one of the 1000BASE-SX ports with SC

connectors:

1 Read the Caution at the beginning of “Cabling

Gigabit Ethernet Ports” earlier in this chapter.

2 Remove the dust covers and save them for future use.

3 Examine the port and connector pair for dust. Verify

that nothing blocks the light transmission between

the port and its connectors.

4 Attach one male connector of the SC cable connector

pair to the right side of a fixed Gigabit Ethernet port.

5 Attach the remaining connector of the SC cable

connector pair to the left side of the Gigabit Ethernet

port.

6 To cable another port, repeat steps 1 through 4.

When you cable GBIC transceivers, notice that the SC

Receive (RX) port is on the left and the SC Transmit

(TX) port is on the right. See Figure 9.

Figure 5 shows cabling for the 1000BASE-SX ports.

Figure 5

Cabling the 1000BASE-SX Port

SC connector

Fiber cables

Page 22

22 C

CONSOLE

STAT

PCKT

STAT

PCKT

POWER

FAULT

1000BASE (GBIC)

1000BASE (GBIC)

15 16 17 18

21 22 23 24

STATUS

green = enabled, link OK

flashing green = disabled, link OK

off = link fail

HAPTER

3: C

ABLING COREBUILDER

9400 P

ORTS

Cabling 1000BASE GBIC Ports

Each 1000BASE GBIC (Gigabit Interface Converter)

port accepts one of these transceivers:

■

1000BASE-SX GBIC

— Use this transceiver to

connect the GBIC port directly to multimode

fiber-optic cable. For instructions, see the

procedure in this section.

■

1000BASE-LX GBIC

— Use this transceiver to

connect the GBIC port directly to single-mode

fiber-optic cable or to multimode fiber using a

conditioned launch cable. For instructions on using

this transceiver to connect to single-mode fiber,

see the procedure in this section. To connect this

transceiver to multimode fiber, see “Connecting

the LX Transceiver to MMF” on page 24 for details.

To ensure optimal compatibility, performance, and

regulatory compliance, use only GBIC transceivers and

conditioned launch cables that 3Com supports. For a

list of currently supported GBICs and launch cables,

visit this 3Com Web site:

http://www.3Com.com/gigabit_ethernet/gbics

You can insert and remove the GBIC transceiver while

the system is powered on and running.

To connect a GBIC port directly to single-mode fiber

with an LX transceiver, or to connect a GBIC port

directly to multimode fiber with an SX transceiver,

follow these steps:

1

Read and follow the “Fiber Safety Precautions” on

page 19 and the Caution at the beginning of

“Cabling Gigabit Ethernet Ports” earlier in this

chapter.

2

Orient the transceiver so that the duplex SC

connector is toward you, as shown in Figure 6.

Figure 6

Inserting the GBIC Transceiver

1000BASE

GBIC port

GBIC transceiver with

duplex SC connector

Page 23

Cabling Gigabit Ethernet Ports 23

3 Do one of the following, depending on the

transceiver that you are using:

■

Side tabs

— Compress the side tabs and gently

slide the transceiver into the GBIC port until it

clicks into place.

OR

■

Front lever

— Move the front lever to the upright

position and gently slide the transceiver into the

GBIC port until it clicks into place (or until you

cannot insert it any further). Then move the front

lever to the downward position to lock the

transceiver into place.

4 If you haven’t already done so, remove the SC

connector cover from the transceiver, as shown in

Figure 7.

Figure 7

Removing the SC Connector Cover

5 Plug the male duplex SC connector on the fiber optic

network cable into the duplex SC port on the GBIC

transceiver, as shown in Figure 8. If you are using an

SX transceiver, the fiber optic cable must support

multimode transmission. If you are using an LX

transceiver, the fiber optic cable must support

single-mode transmission or multimode transmission

with a conditioned launch cable.

You can also connect an LX transceiver to multimode

fiber. See “Connecting the LX Transceiver to MMF” on

page 24 for details.

In the event that you need to remove the GBIC

transceiver, follow these steps, depending on the

transceiver that you are using:

■ Side tabs

— Compress the side tabs and gently

pull the transceiver out of the port.

OR

■ Front lever

— Move the front lever to the upward

position. Then grasp the lever and gently pull the

transceiver out of the port.

SC connector cover

Page 24

24 C

CONSOLE

STAT

PCKT

STAT

PCKT

POWER

FAULT

1000BASE (GBIC)

1000BASE (GBIC)

STATUS

green = enabled, link OK

flashing green = disabled, link OK

off = link fail

HAPTER

3: C

ABLING COREBUILDER

9400 P

ORTS

6

7

Figure 8

Cabling the GBIC Transceiver

GBIC

transceiver

Fiber optic

network cable

Duplex

SC connector

Attach the other end of the network fiber-optic cable

to the network device that you want to connect.

Repeat steps 1 through 6 for additional GBIC ports.

Connecting the LX Transceiver to MMF

The LX transceiver supports a connection to

multimode fiber using a conditioned launch cable.

The conditioned launch cable consists of an offset

mechanism on the transmit side of the cable that

aligns the single-mode laser launch away from the

center of the multimode fiber core, creating a

transmission signal similar to typical multimode

light-emitting-diode (LED) launches. This offset allows

the transmission of LX signals over multimode fiber

cable.

You need a conditioned launch cable to complete the

following procedure. To ensure optimal compatibility,

performance, and regulatory compliance, use only

conditioned launch cables that 3Com supports. For a

list of currently supported launch cables, visit this

3Com Web site:

http://www.3Com.com/gigabit_ethernet/gbics

To cable a GBIC port to multimode fiber using an LX

transceiver:

1

Read and follow the “Fiber Safety Precautions” on

page 19 and the Caution at the beginning of

“Cabling Gigabit Ethernet Ports” earlier in this

chapter.

2

Insert a GBIC LX transceiver into a GBIC port until it

clicks into place, as shown in Figure 6.

3

If you haven’t already done so, remove the SC

connector cover from the transceiver, as shown in

Figure 7.

Page 25

Cabling Gigabit Ethernet Ports 25

CONSOLE

STAT

PCKT

STAT

PCKT

POWER

FAULT

1000BASE (GBIC)

1000BASE (GBIC)

STATUS

green = enabled, link OK

flashing green = disabled, link OK

off = link fail

When you cable GBIC transceivers, note that the SC

Receive (RX) port is on the left and the SC Transmit

(TX) port is on the right. See Figure 9.

4 Insert the SC connectors on the conditioned launch

cable into the transceiver as shown in Figure 9,

ensuring that you:

■ Insert the SC connector on the multimode Receive

(RX) side of the conditioned launch cable into the

RX port on the transceiver.

■ Insert the SC connector on the single-mode

Transmit (TX) side of the conditioned launch cable

into the TX port on the transceiver.

You can think of the conditioned launch cable as an

extension to the multimode network cable.

5 Attach the other end of the conditioned launch cable

to the multimode network cable, ensuring that you:

■ Connect the multimode RX side of the conditioned

launch cable to the RX side of the network cable.

■ Connect the multimode TX side of the conditioned

launch cable to the TX side of the network cable.

If necessary, use fiber-optic couplers to connect the

male SC connectors on the multimode end of the

conditioned launch cable to the multimode network

cable.

6 Attach the other end of the network fiber-optic cable

to the network device that you want to connect.

Figure 9

Connecting Using a Conditioned Launch Cable

RX

TX

SC connector

To network

cable

B

A

A

A

Offset

= Multimode fiber

A

= Single-mode fiber

B

7 Repeat steps 1 through 6 for additional 1000BASE

GBIC ports.

Page 26

26 C

CONSOLE

STAT

PCKT

STAT

PCKT

POWER

FAULT

1000BASE (GBIC)

1000BASE (GBIC)

15 16 17 18

21 22 23 24

STATUS

green = enabled, link OK

flashing green = disabled, link OK

off = link fail

DB-9 connector

HAPTER

3: C

ABLING COREBUILDER

9400 P

ORTS

Cabling the Console Port

The Console port provides access for either local or

remote administration.

For local administration of the CoreBuilder 9400, the

Console port provides an RS-232 connection to a

local terminal or workstation that runs a terminal

emulation program and acts as the console.

For remote administration, the Console port provides

the means to connect an external modem, which you

can use to establish a connection between your

current Administration Console session and the

modem port.

The Console port has a male 9-pin, D-type connector.

See “Console Port Pin Assignments” next for pin-out

information.

To cable the Console port:

1

Attach the female DB-9 cable connector to the

Console port’s male connector. See Figure 10.

2

Attach the other end of the serial cable to your

terminal or workstation.

Figure 10

Cabling the Console Port

You can also remotely access the system through any

Gigabit Ethernet port using Telnet. See the

Reference Guide

To use the Administration Console to configure the

system for management access through the Console

port, see Chapter 5.

Command

.

Page 27

Cabling the Out-of-Band Management Port 27

Console Port Pin Assignments

Table 4 shows the Console port pin assignments.

Tab l e 4

Pin No. Signal Description

1 DCD Data Carrier Detect

2 RDA Received Data

3 TD Transmitted Data

4 DTR Data Terminal Ready

5 GND Signal Ground

6 DSR Data Set Ready

7 RTS Request To Send

8 CTS Clear To Send

9 — Not used

Console Port Pin Assignments

Cabling the Out-of-Band Management Port

You can use the 10BASE-TX port on the

CoreBuilder 9400 to manage your network

out-of-band. Out-of-band management lets you

diagnose network problems easily because you

manage your network from a workstation on a

different network.

To cable the out-of-band 10BASE-TX port:

1 Plug the male RJ-45 connector on the 10BASE-TX

cable into the 10BASE-TX port until it clicks into

place. See Figure 11.

2 Attach the other end of the 10BASE-TX cable to the

workstation or to a different network connection.

To configure your CoreBuilder 9400 to use

out-of-band network management, see the

Command Reference Guide

This port is not a switch port, that is, it carries no

network traffic. It is a port for management purposes

only.

.

Page 28

28 C

CONSOLE

10BASE TX

STATUS PACKET

STAT

PCKT

STAT

PCKT

POWER

FAULT

1000BASE (GBIC)

1000BASE (GBIC)

14 15 16 17 18

20 21 22 23 24

STATUS

green = enabled, link OK

flashing green = disabled, link OK

off = link fail

HAPTER

3: C

ABLING COREBUILDER

9400 P

ORTS

Figure 11

Out-of-band

management

port

Cabling the Out-of-Band Management Port

Male RJ-45 connector

10BASE-T cable

Page 29

4

DC OK

!

Power supply latchPower supply

Power receptacle

S

YSTEM

P

OWER

U

P

Power Up

1

2

This chapter contains:

■ “Power Up” instructions for the

CoreBuilder

■ A description of “Power-up Diagnostics”

■ A list of “System Checks” after power up

For information on troubleshooting the system during

power up, see Chapter 6.

To get your CoreBuilder 9400 powered up and ready

to operate, follow the steps in this section.

See Chapter 3 and Chapter 5 for information about

cabling and configuring the Console port.

To view error messages while the system runs

power-up diagnostics, connect a terminal, a

workstation, or a PC that has terminal emulation to

the system’s Console port.

Verify that the power outlet is near the system and

easily accessible. You can turn the system off only by

removing the power cord from the power source or

from the system itself.

On the back panel, slide the power supply latch up

and plug the power cord into the power receptacle.

®

9400 system

See Figure 12 for the location of the power

receptacle.

Figure 12

3

Plug the other end of the power cable into a power

outlet.

4

If you want add an additional power supply, repeat

step 2 and step 3 for the second power supply.

CoreBuilder 9400 System Power Receptacle

Page 30

30 C

HAPTER

4: S

YSTEM POWER UP

Power-up Diagnostics

The CoreBuilder 9400 system runs diagnostic

software at power up. This software verifies that the

system works before you add it to the network.

If any component fails during power-up diagnostics,

the system fails to power up.

During power up, the system and port status LEDs

provide information about the CoreBuilder 9400

system. See Figure 1 in Chapter 1 for the location of

the LEDs.

To view error messages that are displayed during

power-up diagnostics, connect a terminal,

workstation, or PC that has terminal emulation to the

system’s Console port. See Chapter 3.

System Diagnostics

This section describes the LEDs that provide

information about the system as a whole.

Power LED Activity

■

■

— The system is on; the system is running

Green

or has run diagnostics.

No Light

— The system has no power; no

diagnostics are running.

Fault LED Activity

■

No Light

— System diagnostics have been

successfully completed and the system is

operational.

■

Solid or Blinking Yellow

— The system has failed

diagnostics, or some other operational error has

occurred.

See Chapter 6 for troubleshooting information.

Gigabit Ethernet Port Diagnostics

This section summarizes the information displayed by

the port LEDs.

Packet LED Activity

■

No light

— Data is not being transmitted or

received by the port.

■

Blinking yellow

— Data is not being transmitted

or received by the port.

■

Yellow

— Data is passing through the port.

Status LED Activity

■

No light

■

Blinking green

■

Green

— The port is off-line.

— The port is online but disabled.

— The port is online and enabled.

See Chapter 6 for troubleshooting information.

Page 31

System Checks 31

System Checks

After the system has successfully completed the

power-up diagnostics, check the items in Table 5 to

verify that the system is operating correctly. If you

discover abnormal conditions, see Chapter 6.

Tab l e 5

Check Description

Power-up

error messages

Normal LED

activity

System Power-Up Checklist

If there is a problem during power-up, the

messages are displayed in the Administration

Console connection through the Console port.

When the power-up diagnostics are running,

the LEDs light in a certain pattern as described in

the “Power-up Diagnostics” section. After you

properly cable the system and the system

successfully completes the power-up diagnostics,

look for the following normal LED activity:

System:

Power

LED = Not lit

Fault

Each port:

status LED = Yellow

Pckt

status LED = Green

Stat

If an LED does not light or shows a color different

from the one indicated here, see Chapter 6 for

information about the cause of the problem.

LED = Green

Next Step: Software Configuration

Your CoreBuilder 9400 system is shipped from the

factory with the software installed and IEEE 802.1d

Spanning Tree Protocol

system for your particular networking environment

(including setting up SNMP), you must first establish

management access. See Chapter 5.

disabled

. To configure your

Page 32

32 C

HAPTER

4: S

YSTEM POWER UP

Page 33

5

Q

UICK

S

ETUP FOR

M

ANAGEMENT

A

CCESS

This chapter provides easy instructions for configuring

the CoreBuilder

access. When you decide how you want to manage

your system, follow the configuration instructions for

your preferred type of management access.

®

9400 system for management

About CoreBuilder 9400 System Management

To configure and manage your CoreBuilder 9400

system, you can use one of several applications after

you establish a connection:

■ CoreBuilder 9400 Administration Console

■ Other SNMP-based network management

applications

■ Web Management suite of applications

The Administration Console is a character-oriented,

menu-driven user interface for administering the

system. You can access the Administration Console

out-of-band, using either the 10BASE-TX port or the

Console port, or in-band, using one of the Gigabit

Ethernet ports through the IP network protocol. For

more detailed information, see the Command

Reference Guide.

For more complete network management, use an

external SNMP-based management application such

as 3Com’s Transcend Enterprise Manager for UNIX or

Windows or another network management

application.

The Web Management suite of applications allows

you manage your system using a Web browser. It

consists of WebConsole (including Configuration

Wizards), DeviceView, Performance, and the

HTML-based Help system.

How Do You Want to Manage the System?

You can manage your system locally through a

terminal connection or through the network with an

IP connection. Table 6 describes the access

mechanisms.

Ta b le 6

Access

Mechanism

Te r m i n a l Connect directly to the

Modem Connect remotely to the

Management Access Mechanisms

Allows you to Using

Administration Console and

stay attached across system

reboots

Administration Console

Console port

Console port

Page 34

34 C

HAPTER

5: Q

UICK SETUP FOR MANAGEMENT ACCESS

Tab l e 6

Access

Mechanism

IP

Management Access Mechanisms

Allows you to Using

■

Use a dedicated network to

manage your network

out-of-band. Access the

Administration Console

in-band with the rlogin or

Telnet commands.

■

Access the Administration

Console in-band with the

rlogin or telnet commands.

Or use an external SNMP

management application to

communicate with the

CoreBuilder 9400 SNMP

agent.

■

Use the Web Management

interface.

These mechanisms are described more fully in the

next sections.

Terminal Connection

Direct access through the Console port is often

preferred because it allows you to remain on the

system during system boots. A Macintosh or PC

attachment can use any terminal emulation program

for connecting to the Console port. A workstation

attachment under UNIX can use the emulator TIP or

you can attach a terminal.

For more details, see the documentation that is

shipped with your terminal emulation program.

Ethernet 10BASE-TX

out-of-band port

One of the Gigabit

Ethernet ports

assigned to an IP

interface

Netscape Navigator

or Internet Explorer

Modem Connection

To access the system through a modem, establish a

connection between your workstation and the

Console port. When you configure the external

modem from the Administration Console menu

system, the Console appears to be directly connected

to the external modem. See the

Guide

for more information.

Use the Console port for either a terminal connection

or a modem connection.

IP Management Interface

An IP interface is the connection between the

CoreBuilder 9400 system and a subnetwork. Use the

IP interface to manage the system in two ways:

■

In-band

— Through a Gigabit Ethernet port

You can use this port for switching and managing

the system simultaneously.

This method decreases the total bandwidth available

on the port for switching.

■

Out-of-band

— Through the 10BASE-TX port that

is located to the left of the Console port

You can use this port only to manage the system,

not for switching network traffic. Managing your

system out-of-band conserves all available

bandwidth for the Gigabit Ethernet ports. Also, if

network problems exist, you can manage the

system from a different network. See the

Implementation Guide

in-band and out-of-band management.

Command Reference

for more information on

Page 35

Initial Management Access 35

With an IP interface and either the in-band or the

out-of-band port, you use the rlogin or Telnet

commands to access the Administration Console

using TCP/IP from a host computer. You can also use

the IP interface to manage the system with an

external management application via SNMP or the

Web Management software.

Initial Management Access

The first time that you access your system, you

connect through the Console port using a terminal or

terminal emulator. These are the default settings for

this port: 9600 baud, 8 bits, 1 stop bit, No parity.

When you access the Administration Console using

the Console port, you see this prompt:

Select access level (read, write, administer):

1 At the prompt, enter:

administer

2 At the password prompt, press Return.

The following menu appears:

Use this menu to change the Console port baud

setting for the terminal or to configure your system

for another management access mechanism.

Changing the Console Port Baud Setting

To change the baud setting of the Console port:

1 From the top level of the Administration Console,

enter:

system serialPort serialPortMode

2 At the prompt, if the default value shown in brackets

is

modem, enter console. Otherwise, press Return.

3 Enter baudRate.

4 Enter 9600 for the Console port. The system supports

these baud settings: 19200, 9600, 4800, 2400, and

1200.

The system displays this message:

Enter new value (1200-19200) [1200]: 9600

Error setting baud rate to 9600.

Baud rate will change upon next connection.

Menu options:

-----------------------------------------------------system - Administer system-level functions

management - Administer system management interface

ethernet - Administer Ethernet ports

bridge - Administer bridging/VLANs

ip - Administer IP

snmp - Administer SNMP

analyzer - Administer Roving Analysis

script - Run a script of console commands

logout - Logout of the Administration Console

Type ? for help.

-----------------------------------------------------Select menu option:

Page 36

36 C

HAPTER

5: Q

UICK SETUP FOR MANAGEMENT ACCESS

onfiguring the IP Interface

C

These instructions include information on how to

define an IP interface through which you can manage

your CoreBuilder 9400 system. An IP interface

contains the following parameters:

■

IP address

— This address, which is specific to

your network, is used to manage the system. The

IP address defines both the number of the network

to which the interface is attached and its host

number on that network.

■

Subnet mask

— This 32-bit number uses the

same format and representation as an IP address.

The subnet mask determines which bits in the IP

address are interpreted as the network number,

which as the subnet number, and which as the

host number. Each IP address bit that corresponds

to a 1 in the subnet mask is in the network and

subnet part of the address. Each IP address bit that

corresponds to a 0 is in the host part of the IP

address.

In-band Management

To set the IP interface parameters to manage the

system in-band:

1

From the top level of the Administration Console,

enter:

ip interface define

2

Enter the IP address of the interface.

3

Enter the subnet mask of the subnetwork to which

the interface is to be connected.

4

Enter the interface type:

5

Enter the VLAN interface index

For more detailed instructions on assigning interface

parameters, see the

Command Reference Guide.

Out-of-band Management

To set the IP interface parameters to manage the

system out-of-band:

1

From the top level of the Administration Console,

enter:

ip interface define

2

Enter the IP address for the out-of-band port.

3

Enter the subnet mask of the subnetwork to which

the interface is to be connected. Press Return to

accept the default subnet mask.

4

Enter the interface type:

For more detailed instructions on assigning interface

parameters, see the

Command Reference Guide.

vlan

system

Page 37

6

T

ROUBLESHOOTING THE

S

YSTEM

This chapter explains how to troubleshoot certain

problems with the CoreBuilder

covers:

■ Getting Additional Help

■ Diagnosing Problems

■ Cleaning Dirty Fiber Optic Ports and Connectors

Getting Additional Help

If you experience system problems that are not

addressed in this chapter, contact your network

supplier or 3Com Technical Support. Before you call,

gather the following information and have it

available:

■ System serial number

■ Maintenance agreement, or date of purchase and

warranty information from the last pages of this

guide.

■ Software revision number

■ Brief description of the problem

You can view some of this information in the

Administration Console. From the top-level menu,

enter

system display. In the WebConsole, select the

System folder and then click Summary.

®

9400 system. It

Diagnosing Problems

By observing system diagnostics, you can identify and

correct problems that might occur when the system

powers up.

Power Failures

If the system does not respond when you insert the

power cord, see the troubleshooting suggestions in

Ta bl e 7 .

Abnormal LED Activity

The CoreBuilder 9400 system has LEDs that indicate

system or port problems. If you see abnormal LED

activity, see Table 8 and Table 9 for troubleshooting

suggestions.

For additional information and phone numbers, see

Appendix D.

Page 38

38 C

HAPTER

6: T

ROUBLESHOOTING THE SYSTEM

Tab l e 7

Troubleshooting Power Failures

Symptom Possible Sources of the Problem Steps to Take

System does not power up.

■

System is not receiving power.

■

Power supply malfunctioned.

1

Verify that the building’s power outlet has power.

2

Verify that the power cord is firmly plugged into the system and into the

building’s power outlet.

3

Try another power cable.

4

If the system still does not operate, contact your network supplier or

3Com Technical Support.

Tab l e 8

Troubleshooting Abnormal System LED Activity

LED Status Possible Sources of the Problem Steps to Take

Fault

LED blinks yellow. Diagnostic software is not running.

Power

LED does not light. System has failed or power is not being

supplied.

1

Check the Administration Console display.

2

Call your network supplier or 3Com Technical Support.

1

Shut down the system by disconnecting the power plug.

2

Call your network supplier or 3Com Technical Support.

Page 39

Diagnosing Problems 39

Tab l e 9

Troubleshooting Abnormal Port LED Activity

LED Status Possible Sources of the Problem Steps to Take

LED does not light. System is not processing any packets.

Pckt

■ Cable problem.

■ No data being transmitted or

Check the Administration Console display.

received.

■ Port is disabled

■ Port is off-line.

LED does not light. System does not recognize a connection

Stat

to the port.

■ Cable is not fully attached to the port.

■ Port cable is faulty.

■ Device attached to port is not

powered on.

■ Fiber optic ports or connectors are

dirty.

■ If a GBIC port is affected, the

transceiver may not be properly

Verify that all cables are firmly plugged into both the system’s affected

1

port and the attached device.

If a GBIC port is affected, verify that the transceiver is properly seated.

2

Re-seat the GBIC. If the transceiver is properly seated, try another

transceiver.

Test for faulty cables.

3

Clean the fiber optic ports and connectors. See next section.

4

When the problem is corrected, the LED lights green.

If the LED still does not light, contact your network supplier or 3Com

Technical Support.

seated or is defective.

Page 40

40 C

HAPTER

6: T

ROUBLESHOOTING THE SYSTEM

Cleaning Dirty Fiber Optic Ports and Connectors

Fiber optic transceivers are sensitive optical devices.

Handle them carefully. If dirt collects on a fiber optic

lens, the associated LED may not light. You may also

notice degradation in port performance, indicated by

adverse changes in the Gigabit Ethernet statistics on a

port.

2

Reconnect the cable to the port to check whether

dusting has corrected the problem.

3

Gently wipe the ports with a lint-free, nonabrasive,

nonadhesive swab. Microswabs by Texwipe are

recommended.

4

Gently wipe the connectors with a lint-free,

nonabrasive wipe or pad. Texwipe pads are

recommended.

To prevent dust from collecting on the fiber optic lens,

keep the dust covers on the ports at all times when

they are not in use.

WARNING: The fiber optic lasers used in this system

meet the regulatory requirements for casual exposure

to the eye. As with any source of bright light,

however, 3Com recommends that you do not look

into the laser light source.

To clean a fiber optic lens, take these steps:

1

Remove any accumulated dust or debris from the port

or connector by blowing across all surfaces with a

canned air duster.

Compressed gas is recommended, such as

Chemtronics’ Ultrajet or the Triangle Tool Group’s

Liqui-Tool Dust-A-Way. Do not use commercial

compressed air or “house air” because of the risk of

oil contamination.

Avoid touching any connector surface after you clean

the connectors.

Page 41

A

S

YSTEM

S

PECIFICATIONS

Table 10

Specifications

Physical Dimensions

Environmental Requirements

Safety

Electromagnetic Emissions

Heat Dissipation

Power Supply

System Specifications for the CoreBuilder 9400

13.3 cm (H) x 44 cm (W) x 41.9 cm (D)

5.22 inches (H) x 17.32 inches (W) x 16.50 inches (D)

Weight: 14.5 kg (32 lbs)

Operating Temperature 0 to 50 °C (32 to 122 °F)

Operating Humidity 10 to 95% relative humidity, noncondensing

Storage Temperature –20 to 85 °C (–4 to 185 °F)

Storage Humidity 95% maximum relative humidity, noncondensing

Agency Certifications

Designed to Comply with...

Receptacles 15 ampere service receptacles, type N5/15 or NEMA 5-15R (United States and Canada only)

AC Line Frequency 47 to 63 Hz

Input Voltage Options 100 to 240 VAC

Current Rating 2.7 amperes at 120 volts

UL 1950, CSA 22.2 No. 950, TUV EN60950

UK General Approval Statement

The CoreBuilder 9400 is manufactured to the international Safety Standard EN60950 and is

approved in the UK under the General Approval Number NS/G/12345/J/100003 for indirect

connection to the public telecommunication network.

IEC 950

Meets FCC part 15, Class A limits, and CISPR22 Class A limits

Complies with EMC Council Directive 89/336/EEC, Class A limits

327 watts maximum (1116 BTU/hour maximum)

Page 42

42 A

PPENDIX

A: S

YSTEM SPECIFICATIONS

Table 11

Standards Supported by the CoreBuilder 9400

Standard Type RFC/IEEE Supported

SNMP

Software

■

SNMP protocol (RFC 1157)

■

MIB II (RFC 1213)

■

Ethernet MIB (RFC 1284)

■

Bridge MIB (RFC 1286)

tftp (RFC 959)

Installation

Terminal Emulation

Protocols Used for

Administration

■

telnet (RFC 854)

■

rlogin (RFC 1282)

■

UDP (RFC 768)

■

IP (RFC 791)

■

ICMP (RFC 792)

■

TCP (RFC 793)

■

ARP (RFC 826)

■

STP ((IEEE 802.1d))

■

Flow control (IEEE 802.3x)

■

VLANs (IEEE 802.1Q)

For updated MIB information, see the Release Notes.

Ta b le 1 2

LED Indicators on the CoreBuilder 9400

LED Type Description

System LEDs

■

Power■Green

■

■

Fault

■

■

Off

— System is receiving no power.

Off

— System is operational.

Solid or Blinking Yellow

failed diagnostics, or some other

operational failure has occurred.

Port LEDs

■

Stat

■

Off

— Port is off-line.

■

Blinking Green

disabled.

■

Green

■

Pckt

■

Off

— Port is off-line.

■

Blinking Yellow

data.

■

Ye l l ow

— System is on.

— System

— Port is online but

— Port is online and enabled.

— Port is passing

— Port is passing data.

Page 43

B

F

IELD

-R

EPLACEABLE

U

NITS

This appendix contains information on how to

remove and replace the CoreBuilder

Field-Replaceable Units (FRUs). The FRUs include:

■ Power supply assembly

■ Fan tray assembly

Only trained technical personnel should remove and

install the power supply.

Audience

This appendix is intended for

personnel

a CoreBuilder 9400 power supply if you have not had

the proper training from 3Com. For training

information, call 1-800-NET-3COM or see the

numbers for your country in Appendix D.

WARNING: Hazardous energy exists within the

CoreBuilder 9400 system. Use extreme caution when

you remove or replace the FRUs. Always be careful to

avoid electric shock or equipment damage. See

“Safety Precautions” next.

®

9400

trained technical

only. Do not attempt to remove or replace

Safety Precautions

Be sure that you follow all safety precautions when

you replace components in a CoreBuilder 9400

system. Hazardous energy exists inside the system

chassis. To avoid electric shocks, burns, or equipment

damage, read and following these warnings:

WARNING: Always unplug the power cord before

you open any electronics chassis box or enclosure.

When the system is on, do not touch any connections

within the chassis. Do not insert metal objects into

the system.

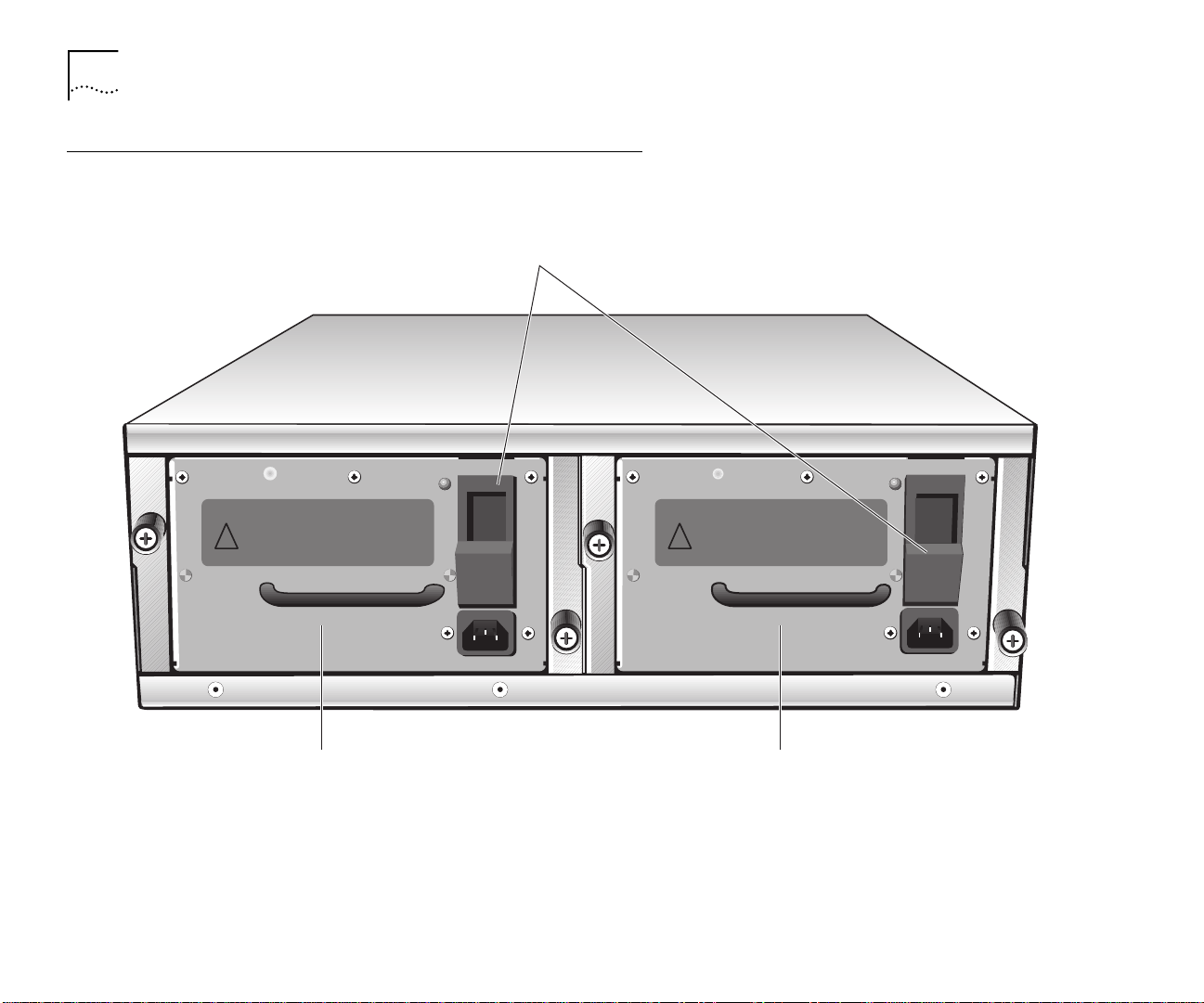

Power Supply Assembly Removal and Replacement

The CoreBuilder 9400 system operates using a single

power supply assembly. You can add a second power

supply to the system for redundancy. If either power

supply fails, the Fault LED lights yellow.

Removing and Replacing the Power Supply

1

Remove the power cord from the power supply.

2

Loosen the captive screws that secure the power

supply to the chassis.

3

Grasp the power supply handle and gently slide the

power supply out of the chassis.

Page 44

44 A

DC OK

!

Power supply latchPower supply

Power receptacle

PPENDIX

B: F

IELD-REPLACEABLE UNITS

4

Grasp the handle of the new power supply and gently

slide it into the chassis.

5

To seat the power supply, ensure that all connectors

are aligned. Then push the power supply inward until

the connectors engage and latch. The latch should

slide up. You feel a slight resistance as the connectors

engage.

CAUTION: If the resistance is too great, the

connectors may not be aligned. Forcing the power

supply inward could damage the connectors. If

necessary, remove and reinsert the power supply,

ensuring that the connectors are properly aligned.

6

Tighten the captive screws that secure the power

supply to the chassis.

7

Plug the power cord into the system.

8

Plug the other end of the power cord into the

building’s power outlet.

If your system has two power supplies, be sure to

plug in the second power supply. Leaving the second

power supply unplugged causes the system

diagnostics to generate a power supply error.

Figure 13

Removing and Replacing the Power Supplies

Page 45

Fan Tray Assembly Removal and Replacement 45

R

STAT

PCKT

STAT

PCKT

3C94024

1000BASE SX

2

TX RX

1000BASE SX

1000BASE SX

1000BASE SX

1

TX RX

3

TX RX

5

TX RX

4

TX RX

6

TX RX

8

TX RX

7

TX RX

9

TX RX

11

TX RX

10

TX RX

12

TX RX

Fan Tray Assembly Removal and Replacement

The CoreBuilder 9400 is cooled by the fan tray

assembly, which contains two 12-volt DC fans. The

fans are thermally controlled, which means that they

run at slower speeds when the system is operating at

temperatures of less than 30

when the system temperature is above that.

You need no tools to remove the fan tray. You can

remove and replace the fan tray with the power on.

To remove and replace the fan tray assembly, follow

these steps:

1 Facing the front of the system, squeeze the fan tray

latching tab.

2 Slide the fan tray out of the system.

3 Slide the new fan tray into the system chassis.

4 To seat the fan tray, ensure that the connectors are

aligned, and then push the fan tray inward until the

connectors engage and the fan tray latches. You feel

a slight resistance as the connectors engage.

°

C and at full speed

Figure 14

Fan tray

Removing and Replacing the Fan Trays

Fan tray

latching tab

CAUTION:

If the resistance is too great, the

connectors may not be aligned. Forcing the fan tray

inward could damage the connectors. If necessary,

remove and reinsert the fan tray, ensuring that the

connectors are properly aligned.

Page 46

46 A

PPENDIX

B: F

IELD-REPLACEABLE UNITS

Page 47

C

S

ITE

R

EQUIREMENTS AND SAFETY

C

ODES

For your reference, this appendix summarizes the

criteria that your site should meet for the