Page 1

SCIENTIFIC

SW Set – Physical Pendulum 1012853

Instruction manual

10/13 TL/ALF

®

PHYSICS

1 Weight, 200 g

2 Weight, 150 g

3 Acrylic ring

4 Pendulum rod

5 Coupling spring

6 Bearing rod

7 Tension spring

1. Description

The physical pendulum set is designed for assembly of a physical pendulum with a movable

bob, a double coupled pendulum, a reversible

(Kater) pendulum or a metronome pendulum in

a space-saving table-top experiment set-up.

It consists of pendulum rods, bearing rods and

weights for constructing the pendulums themselves, as well as additional components for

attaching them to the dynamic force sensors

from the SW sensors set in order to record and

extensively analyse the oscillations with the help

of an oscilloscope.

2. Equipment

2 Pendulum rods

2 Bearing rods

2 Weights, 200 g

1 Weight, 150 g

1 Acrylic ring

1 Tension spring

2 Coupling springs

1

Page 2

3. Technical data

Pendulum rods

• Attach a 200-g weight (pendulum bob) to the

pendulum rod with the knurled screw.

Length: 450 mm

Weight: 45 g

Separation of bearing holes : 330 mm

Material: Transparent

acrylic

Weights

Weights: 2x 200 g approx.

1x 150 g approx.

Acrylic ring: 10 g approx.

Tension springs

Spring constant: 2.5 N/m

4. Set-up of pendulums without sensors

4.1 General information

The following additional equipment is necessary

in order to carry out the experiments:

1 SW stand equipment set 1012849

1 Digital stopwatch 1002811

A stopwatch can provide sufficiently accurate

results as long as at least 10 periods are measured.

• Make sure the stand rods are firmly fitted

into the base and that all other mounting elements are also firmly fitted to the stands.

• Do not bend the pendulum rods over the

bearings (otherwise they could break).

4.2 Set-up for a physical pendulum without

sensors

• Screw a stand rod with both external and

internal threads into the central threaded sockets of the base plate and extend the rod

by screwing one with external thread only

onto the end.

• Slip a double clamp onto the rod.

• Insert a bearing rod into the double clamp

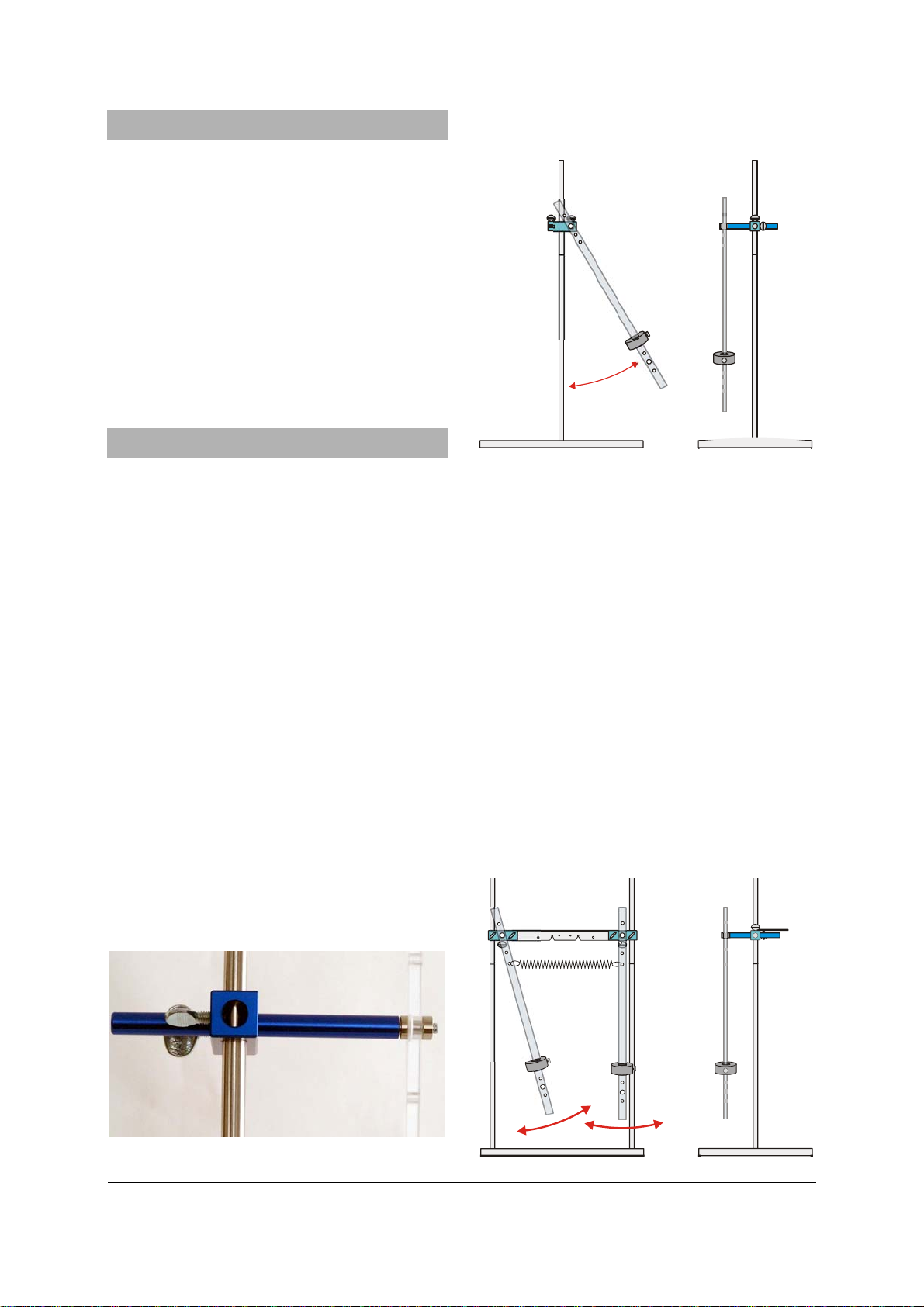

Fig. 2 Set-up for physical pendulum without sensors

4.3 Set-up for a double pendulum without

sensors

• Screw the stand rods with both external and

internal threads into the outer threaded sockets of the base plate.

• Extend both rods by screwing rods with ex-

ternal thread only onto the ends of them.

• Attach double clamps near the top of both

stand rods and turn them to point inwards so

that the slots are vertical and facing one another.

• Clamp the cross bar into the slots of the two

double clamps.

• Insert bearing rods into the double clamps

and slot pendulum rods over the bearings.

• Couple the pendulum rods together with a

tension spring.

• Attach 200-g weights (pendulum bobs) to

the pendulum rods with the knurled screws.

and slot the pendulum rod over the bearing.

Fig. 1 Set-up of pendulum rods

Fig. 3 Set-up for coupled pendulum without sensors

2

Page 3

4.4 Set-up for a reversible (Kater) pendulum

• Set up the pendulum stand as described in

4.2.

• To set up a reversible pendulum, position a

200-g weight between the bearing holes and a

150-g weight at the top end of the pendulum.

Note:

• Only deflect the pendulum by small angles.

If the bearing holes are l = 330 mm apart, as

long as the pendulum is correctly adjusted, the

oscillation about either bearing should have a

period T = 1.152 s (g = 9.81 m/s²).

2

l

⋅π

4

T

=

g

Fig. 4 Set-up for reversible pendulum

4.5 Set-up for metronome pendulum

• Set up the pendulum stand as described in

4.2.

• Attach a 200-g weight at the bottom of the

pendulum rod with the knurled screw.

• Attach the acrylic ring near the top of the

pendulum.

Note: This pendulum can be used to achieve a

wide variety of periods.

By moving the large weight, the oscillating sys-

tem can be adjusted to approach an indifferent

equilibrium. Period durations are then effectively

limited only by friction at the bearings.

Fig. 5 Set-up for a metronome pendulum

5. Set-up for pendulums with sensors

5.1 General information

The following additional equipment is necessary

in order to carry out the experiments:

1 SW stand equipment set 1012849

1 SW sensors set (@230V) 1012850

or

1 SW sensors set (@115V) 1012851

1 USB oscilloscope 2x 50 MHz 1017264

1 PC, operating system Win XP, Vista, Win 7

or

1 Analog oscilloscope 2x 30 MHz 1002727

Caution: Dynamic force sensors must not be

subjected to mechanical overloading

• Neither sensor hook may be loaded with

more than 5N in the axial direction and 1 N

in transverse direction.

• Be especially careful with the maximum

loading force when assembling the system

or suspending loops or springs from the

hook.

• Make sure stand rods are firmly fitted into

the base and that all other mounting elements are also firmly fitted to the stands.

• Do not bend the pendulum rods over the

bearings (otherwise they could break).

The force sensors can be set up with high or low

pre-tensioning of the coupling springs (by attaching them to two different positions on the

cross bar). This means that the distance between pendulum rod and force sensor may differ. One position allows for high amplitudes with

long pendulum swings, whereas the other provides for low bearing friction but only short pendulum swings and therefore small amplitudes

are possible.

3

Page 4

5.2 Set-up for coupled pendulum with sensors

• Set up the pendulum stand as described in

4.3.

• Attach a force sensor to the cross bar with

the knurled screw.

• Stretch a coupling spring between the pen-

dulum rod and the force sensor.

• Clamp the bearing rod into the double clamp

in such a way that the coupling springs and

pendulum rod move in roughly the same

plane as the hook of the force sensor.

• Set up the second force sensor in the same

way.

• Couple the two pendulum rods together with

the tension spring.

• Connect the force sensors to the inputs for

channels A and B of the MEC amplifier

board.

• Connect the outputs to an oscilloscope and

start the experiment.

Fig. 8 Set-up for coupled pendulum with sensors and

USB oscilloscope

6. Disposal

• Packaging and compo-

nents should be disposed of, where necessary, at local recycling

centres.

Fig. 6 Coupling of force sensor

Fig. 7 Set up of force sensors

3B Scientific GmbH ▪ Rudorffweg 8 ▪ 21031 Hamburg ▪ Germany ▪ www.3bscientific.com

Subject to technical amendments

© Copyright 2013 3B Scientific GmbH

Loading...

Loading...