Page 1

3B SCIENTIFIC

Instruction Sheet

02/11 ALF

1. Safety instructions

®

PHYSICS

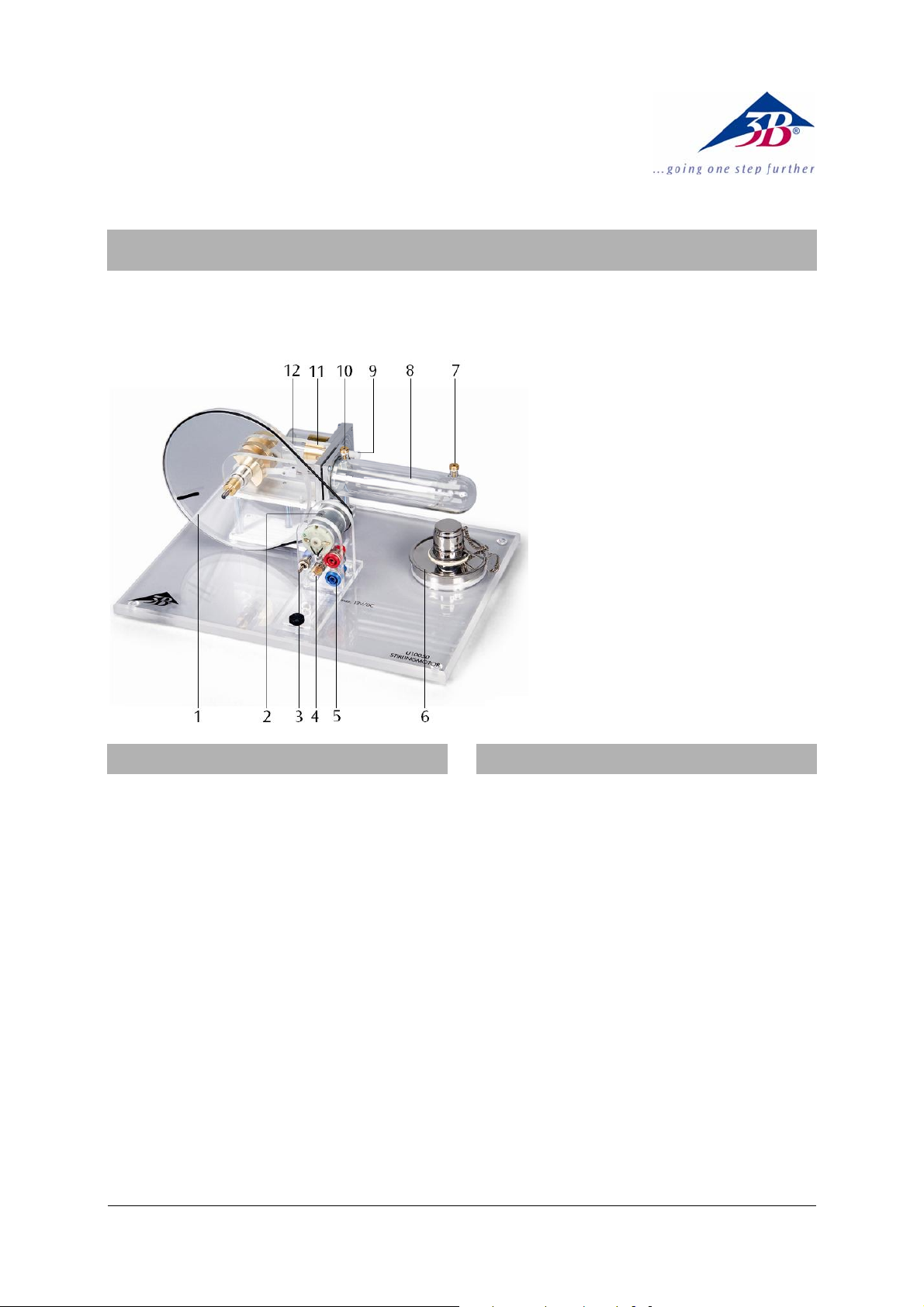

Stirling Engine G U10050

1 Flywheel with marking for

speed determination

2 Motor-generator unit with

2-stage pulley

3 Switch

4 Bulb

5 4-mm safety plugs

6 Alcohol burner

7 Temperature measure-

ment connector 1

8 Displacement piston

9 Capped hose connection

for pressure measure-

ments

10 Temperature measure-

ment connector 2

11 Working piston

12 Threaded rod M3 (con-

nected with the working

piston)

2. Description

• Pour the fuel alcohol carefully into the alco-

holburner, making sure that none of it is spilt.

• Never fill the alcoholburner as long the wick is

still smoldering or another open flame is in close

proximity.

• Immediately close the fuel container after use.

• Keep away from the open flame.

• Caution! Only extinguish the flame by fitting the

cover provided for this purpose.

The Stirling engine becomes hot when it is operated

with an open flame.

• Do not touch the displacement cylinder during

or immediately after operation of the Stirling

motor.

• Allow the Stirling engine to cool before putting it

away.

The Stirling engine can be used for qualitative and

quantitative investigations of the Stirling cycle.and

can be operated in three different modes: heat engine, heat pump and refrigerator.

The displacement cylinder and piston are made of

heat-resistant glass; the working cylinder, flywheel

and transmission covers are made of acrylic glass.

This allows a very clear observation of the individual

motion sequences at all times. The crankshafts are

equipped with ball bearings and made of hardened

steel. The connecting rods consist of wear-resistant

plastic.

The integrated motor-generator unit with a 2-stage pulley allows the generated mechanical energy to be converted into electrical energy. A switchover mechanism

permits operation of an integrated lamp or external

loads, as well as a feeding of electrical energy in order to

simulate a heat pump or refrigerator.

By attaching the thin cord supplied with the apparatus to the threaded rod on the work piston, the

stroke length can be measured.

1

Page 2

3. Technical data

5. Operation

Motor-generator unit: max. 12 V DC

2-stage pulley: 30 mm dia., 19 mm dia.

Working piston: 25 mm dia.

Path of working piston: 24 mm

25 mm

Volumetric change: 24 mm

⎛⎞

⎜⎟

2

⎝⎠

⋅π=

12 cm

Minimum volume: 32 cm³

Maximum volume: 44 cm³

Power of the Stirling motor: 1 W approx.

Dimensions: 300x220x160 mm³ approx.

Weight: 1.65 kg approx.

4. Functioning principle

An ideal Stirling cycle has 4 phases (refer to Fig. 1):

Phase 1: Isothermal change of state, during which

the air expands at constant temperature.

Phase 2: Isochoric change of state, during which the

air cools at constant volume in the regenerator.

Phase 3: Isothermal change of state, during which

the air is compressed at constant temperature.

Phase 4: Isochoric change of state, during which the

air in the regenerator is heated back to its

initial temperature.

The process that takes place in the Stirling engine

only approximates to such an ideal cycle because in

fact the four phases overlap. Gas changes from hot to

cold while the expansion is still taking place and not

all the air will yet be in the colder part of the engine

while the compression phase is occurring.

5.1 The Stirling Engine as a heat engine

• Fill the methylated-spirit burner, place it in the

recess in the base-plate, twist out about 1-2 mm

of the wick, and ignite it.

• Move the displacer piston to its farthest-back

3

position, and after a short heating-up time

(about 1-2 minutes) push the flywheel gently in

the clockwise direction (as seen from the motorgenerator unit) to set it turning (see Fig. 2).

• If necessary, adjust the tension of the drive belt

by moving the motor-generator unit.

• Turn on the filament lamp by moving the switch

to the “up” position.

• Alternatively, connect an external load through

the 4 mm sockets and drive it by moving the

switch to the “down” position.

Speed without a load: 1000 rpm approx.

Speed with a generator as the load: 650 rpm approx.

Generator voltage: 6 V DC approx.

Pressure difference: +250 hPa / -150 hPa

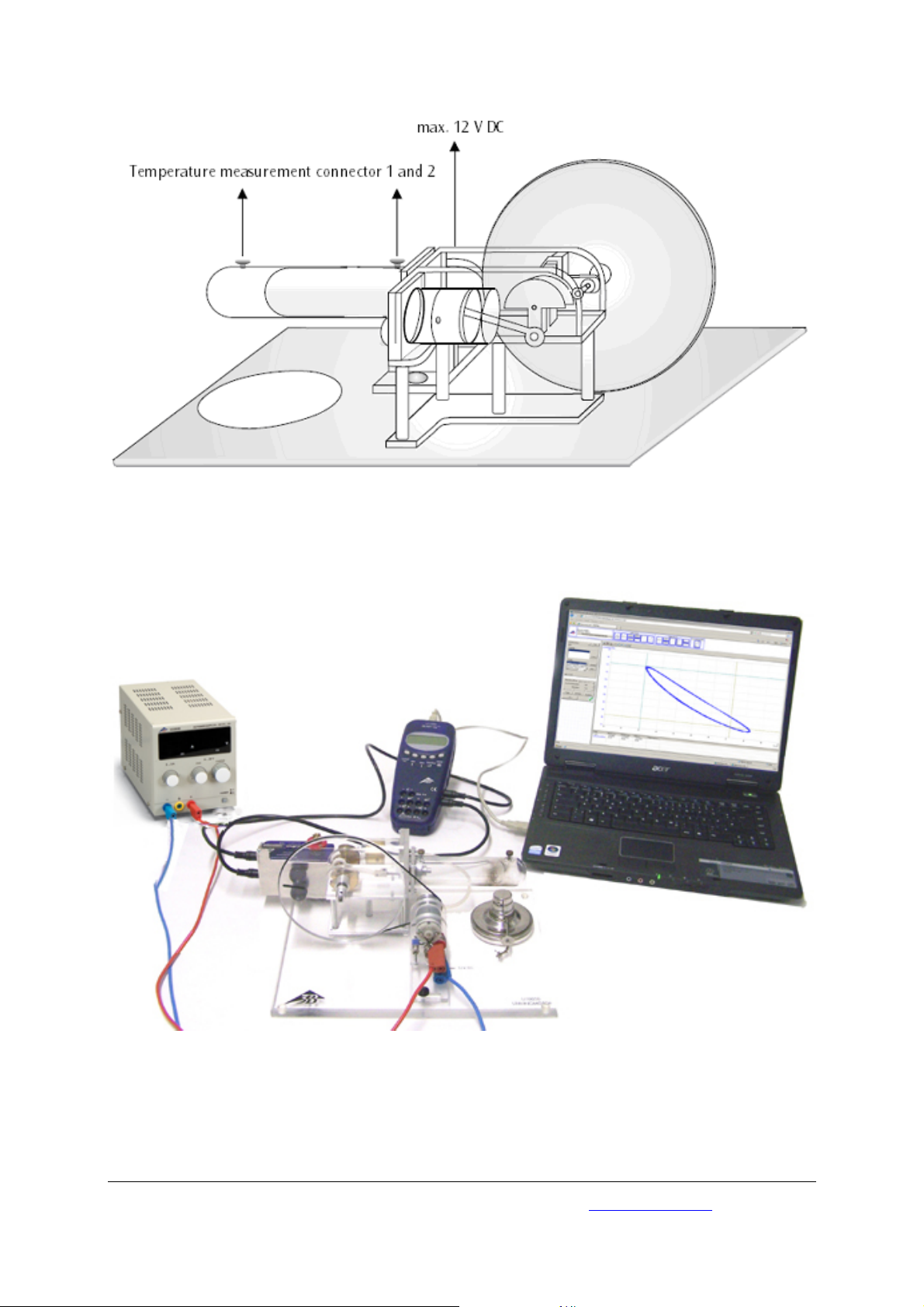

5.2 The Stirling motor as a heat pump or refrigerator

Additional instruments needed:

DC Power supply 15 V, 1.5 A U8521121-230

or

DC Power supply 15 V, 1.5 A U8521121-115

Digital thermometer U11818

• Insert temperature sensors into the thermome-

ter sockets and connect them to a measuring instrument (see fig. 3).

• Connect a DC voltage source through the 4 mm

sockets.

• Adjust the voltage (maximum 12 V) and operate

the Stirling engine with the switch in the “down”

position.

• Observe the increase or reduction in tempera-

ture.

In the refrigerator mode of operation, the flywheeI

rotates in the clockwise direction (as seen from the

motor-generator unit), whereas in the heat pump

mode it rotates in the anticlockwise direction.

Fig. 1 Functioning principle

(A: Displacement piston, B: Working piston)

• To switch between the two modes of operation,

reverse the polarity of the connections.

Pressure difference: +250 hPa / -150 hPa

Motor voltage: 9 V

Speed: 600 rpm

Temperature difference (with respect to 21° C):

Refrigerator: -4 K (reservoir: +6 K)

Heat pump: +13 K (reservoir: -1 K)

2

Page 3

5.3 Plotting a graph of pressure against volume

when the Stirling engine is being used as a

heat pump

Additional instruments needed:

DC Power supply 15 V, 1.5 A U8521121-230

or

DC Power supply 15 V, 1.5 A U8521121-115

3B NETlog

or

3B NETlog

3B NETlab

TM

U11300-230

TM

U11300-115

TM

U11310

Relative pressure sensor, ±1000 hPa U11322

Displacement sensor U11371

Sensor Holder for Stirling Engine G U11372

• Attach the holder for the sensor to the base plate

of the Stirling engine.

• Fit the relative pressure sensor to the bottom of

the sensor holder and the displacement sensor

at the top with the printed sides of the sensors

both facing upwards.

• Connect the nozzle marked “+” on the relative

pressure sensor to the nozzle on the working cylinder of the Stirling engine by means of the hose

included with the sensor holder (U11372) (see

Fig. 4).

• Screw the cap nut attached to the string (sup-

plied with the sensor holder) onto the thread of

the working piston, thread the string around the

displacement sensor pulley and attach a coil

spring to the threaded rod (a detailed description of how to attach the sensor to the sensor

holder is included in the instruction manual for

the sensor holder U11372).

• Connect the pressure sensor to analog input A of

the 3B NETlog

TM

unit and the displacement sen-

sor to analog input B.

• Connect a DC voltage source via the 4 mm sock-

ets.

• Adjust the voltage (maximum 12 V) and operate

the Stirling engine with the switch in the “down”

position.

• Run the 3B NETlab

TM

software, open the experiment “Stirling engine G” and plot a graph of

pressure against volume.

Fig.2 The Stirling motor as a heat engine

3

Page 4

Fig. 3 The Stirling motor as a heat pump or refrigerator

Fig. 4 Recording the pressure-volume diagram

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2011 3B Scientific GmbH

Loading...

Loading...