Page 1

3B SCIENTIFIC

Stirling Engine D U8440450

Instruction manual

05/10 THL/ALF

®

PHYSICS

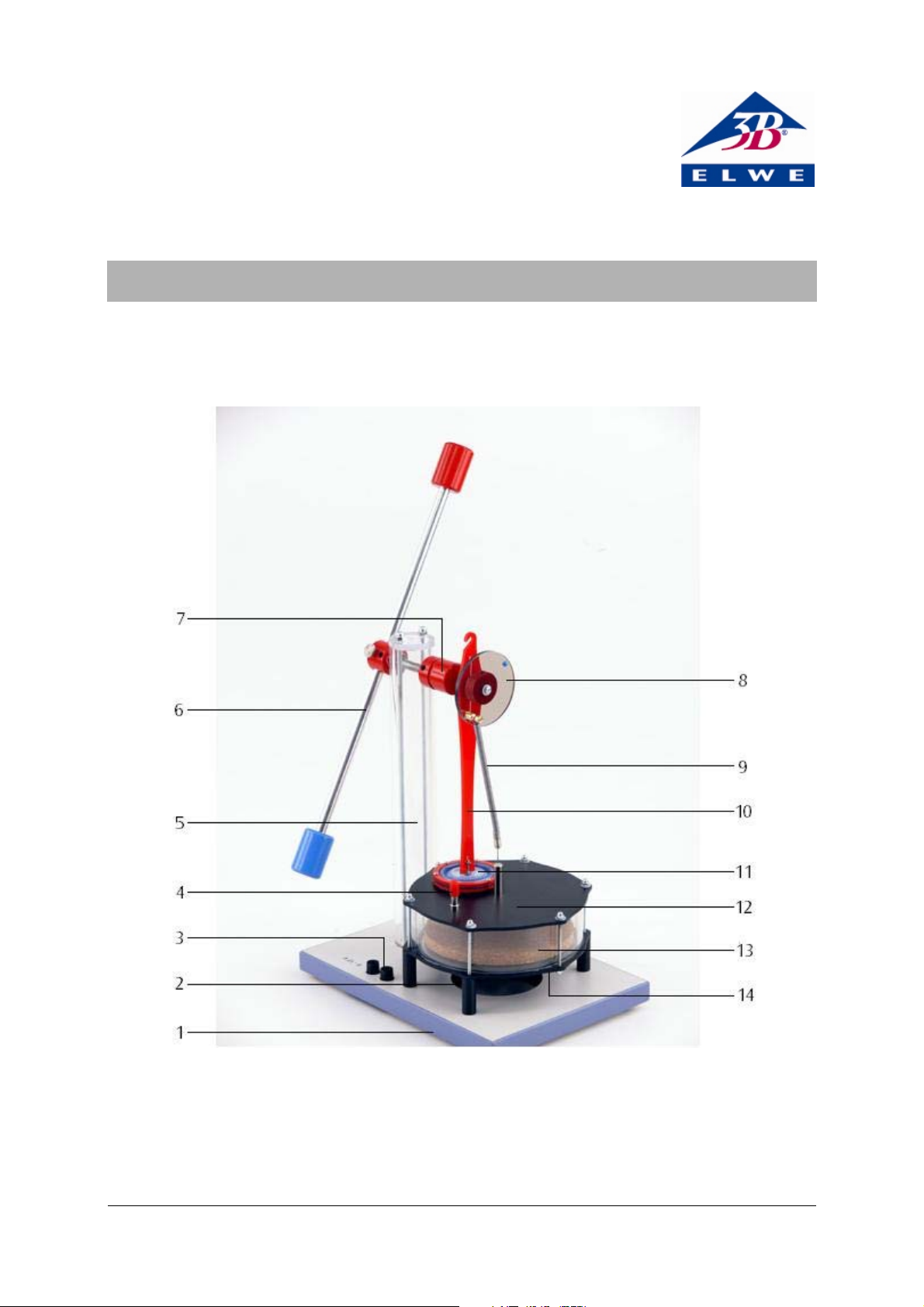

1 Base plate

2 Hole for tea candle

3 Hot plate connector

4 Hose nozzle with sealing cap

5 Stand

6 Rotor with weights

7 Eccentric with groove

8 Torque disc

9 Tension spring

10 Connector rod with hook

11 Working piston (membrane)

12 Upper plate

13 Displacement piston

14 Lower plate with electric heater

1

Page 2

1. Safety instructions

When working with naked flames, there is always a

risk of fire and injury.

• Take extra care when handling naked flames

and molten wax.

• The Stirling engine may not be heated electri-

cally at the same time as it is being heated by a

candle. There is a risk of damage to the

equipment.

• When operating the Stirling engine using a

spotlight or sunlight, it is essential that care be

taken not to expose the red plastic components

to intense heat.

2. Description

The Stirling engine D is a fully functional model,

optimised for teaching purposes and intended to

demonstrate how thermal energy can be converted

to mechanical energy as well as for investigating

the Stirling cycle.

The displacement piston moves discontinuously

with a delay during heating and cooling of the

working medium, air. This emulates the ideal Stirling cycle better than would be the case with a

continuously moving piston and also makes for

improved efficiency. The motion of the displacement piston is controlled by the torque disc. When

heat is supplied from below, either by means of the

electric heater or by a candle flame, the displacement piston precedes the working piston (membrane) by about 100°. The optimum angle is technically dependent on the speed of rotation.

Heat can be supplied either by the built-in electric

hot plate, a candle or by focussed heat radiation

from the sun or by a lamp. The direction of rotation depends on whether the heat is supplied from

above or below.

To record pV diagrams, the pressure in the working

cylinder can be measured by means of a hose attached to the nozzle provided and the volume can

be determined by attaching a thread to the hook

on the connecting rod in order to measure the

stroke of the working piston.

3. Scope of delivery

1 D-series Stirling engine U8450450

1 Set of transport packaging (foam plastic block,

rubber band and retaining rod)

4. Accessories

Supplementary set for Stirling engine D U8440455

The supplementary set for the Stirling engine D

provides accessories necessary for constructing

sensors. The set consists of the following:

1 Base plate for assembly of displacement sensor

(U11371)

1 Knurled screw for attaching the base plate to the

stand

1 Stem with a magnetic base for the displacement

sensor

1 Silicone tube for attaching a relative pressure

sensor, ±100 hPa (U11321)

1 Set of threads with suction cup

2 Weights with hook, both 20 g

5. Technical data

Heater voltage: 8 – 15 V, 1.5 A

Gas volume: 330 cm³ – 345 cm³

Speed: 30 – 100 rpm

Dimensions

not including rotor: 260×185×330 mm

3

Rotor: 400 mm

Weight: 2.2 kg

2

Page 3

6. Operating principle

The principle of a how a Stirling engine works can

be divided, in simplified form, into the following

four processes:

Heating:

During the heating phase, the displacement piston (P1)

moves upwards so that air is displaced down into the

heated part of the displacement cylinder. Temperature

and pressure both rise in a fashion that is almost isochoric. The working piston is in its lower rest position

(bottom dead centre) at this point (see Fig. 1). The displacement piston moves in advance of the working

piston till it reaches its top dead centre position. This is

the point where the air is at its lowest volume, but

highest temperature and pressure (see Fig. 2).

Expansion:

The heated air expands almost isothermally, thus

P

forcing the working piston (P2) upwards. In the

process, mechanical work is transferred via the shaft

to the rotor. The volume of air increases as the air

absorbs heat and the pressure reduces (see Fig. 3).

Cooling:

Cooling occurs while the working piston is at top

dead centre and the displacement piston (P1) is on

its downstroke, forcing air to move into the upper

part of the displacement cylinder. The air then

cools and the upper plate absorbs heat. The displacement piston finally reaches bottom dead

centre (see Figs. 4 and 5).

Compression:

The cooler air is compressed isothermally by the

working piston moving downwards. The mechanical work needed for this is supplied by the rotor

acting as a flywheel (see Fig. 6).

P

P1

Fig. 1 Heating

Fig. 2 Heating

P1

V

P

V

P

Fig. 4 Cooling

Fig. 5 Cooling

P

P

P2

Fig. 3 Expansion

P2

V

Fig. 6 Compression

3

Page 4

7. Getting the engine ready for use

• Connect the power supply to the pair of sockets

and set the heater voltage up to 12 V (1.5 A

approx.).

• After heating for about one or two minutes,

start the engine by pushing the rotor clockwise

as seen from the front of the engine.

• If the Stirling engine fails to keep moving of its

own accord, wait about a minute longer and

push the rotor round again.

The speed of the engine is nearly proportional to

the difference in temperature between the top

plate and the bottom plate and is thus largely dependent on the heat supplied.

• Reduce the heater voltage in steps down to

about 8 V and observe how the speed reduces.

8.1.2 Heating via a candle flame

• Light a tea candle and place it on a heat-

resistant mat.

• Place the Stirling engine over the candle so the

Fig. 7 Stirling engine as secured for storage

• Remove the rubber band (3) from the securing

hook (4) for the displacement piston and take

the hook out of the hose nozzle.

• Seal off the hose nozzle with the red cap (5).

• Remove the foam plastic block (2) between the

stand and the rotor weight.

• Undo the securing screw (1), align the rotor

horizontally so that it is balanced and tighten

the screw back up again.

The engine is then ready for use.

The Stirling engine must not be transported unless

the displacement piston is secured.

• To secure it, take the sealing cap of the hose

nozzle, put the securing hook back in and secure it in place with the rubber band.

• Secure the rotor as well.

8. Operation

8.1 Operation as a heat engine

8.1.1 Electric heating

The following power supplies are recommended for

heating the Stirling engine electrically:

1 DC power supply, 15 V, 1.5 A (230 V, 50/60 Hz)

U8521121-230

or

1 DC power supply, 15 V, 1.5 A (115 V, 50/60 Hz)

U8521121-115

hole in the middle is over the flame.

• Wait for several minutes until the lower plate

has heated up.

• Push the rotor clockwise as seen from the front

of the engine.

• If the Stirling engine fails to keep moving of its

own accord, wait about a minute longer and

push the rotor round again.

8.1.3 Heating via a lamp (spotlight)

• Shine a light on the top plate from about 1 or 2

cm using a lamp with a 60-W bulb and a focussed beam (spotlight). In this case it is the lower

plate that will cool the air in the displacement

cylinder.

• Alternatively, the upper plate can be heated

via sunlight focused using a concave mirror.

• Wait for about 8 to 10 minutes until the upper

plate has heated up.

• Push the rotor anti-clockwise as seen from the

front of the engine.

• If the Stirling engine fails to keep moving of its

own accord, wait about a minute longer and

push the rotor round again.

8.2 Recording a pV diagram

To record a pV diagram, the following pieces of

equipment are also required:

1 Supplementary set for Stirling engine D U8440455

1 3B NETlog™ unit (230 V, 50/60 Hz) U11300-230

or

1 3B NETlog™ unit (115 V, 50/60 Hz) U11300-115

4

Page 5

1 3B NETlab™ program U11310

1 Relative pressure sensor, ±100 hPa U11321

This load ensures that the pV diagram comes out

better.

1 Displacement sensor U11371

1 DC power supply, 15 V, 1.5 A (230 V, 50/60 Hz)

U8521121-230

or

1 DC power supply, 15 V, 1.5 A (115 V, 50/60 Hz)

U8521121-115

• Connect the relative pressure sensor to the

hose nozzle using silicone tubing.

• Attach the base plate to the stand using the

knurled screw.

• Screw the stem with the magnetic base into the

displacement sensor and place it on the base

plate.

• Loosen the screw on the displacement sensor’s

pulley. Wind a thread once around the pulley

and lead it out of the recess placing a loop

around the screw. Use the screw to fix the

thread in place (see Fig. 8).

• Attach one end of the thread to the hook of the

connector rod and suspend a weight from the

other end.

• Use the suction pad to attach a second thread

to the base plate. Thread this over the groove

in the eccentric and use the other weight as a

load on the free end.

Fig. 8 Schematic illustration of how the thread is wound

around the pulley of the displacement sensor (U11371)

• Connect the power supply to the heater plate

and set the voltage up to 12 V (1.5 A approx.).

• Connect both sensors to the 3B NETlog™ inter-

face.

• Run the software on a computer.

• After the Stirling engine has heated up, start it

running by pushing the rotor in a clockwise direction.

• Start a measurement using the software and

evaluate the data.

Fig. 9 Experiment set-up for recording a pV diagram

5

Page 6

Fig. 10 Pressure-volume diagram for D-series Stirling engine

Elwe Didactic GmbH • Steinfelsstr. 5 • 08248 Klingenthal • Germany • www.elwedidactic.com

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2010 3B Scientific GmbH

Loading...

Loading...