Page 1

3B SCIENTIFIC3B SCIENTIFIC

3B SCIENTIFIC®

3B SCIENTIFIC3B SCIENTIFIC

Steam engine, transparent U10055

Instruction Sheet

07/05 ALF

bp

bq

br

bs

bt

bu

PHYSICSPHYSICS

PHYSICS

PHYSICSPHYSICS

1

23

4

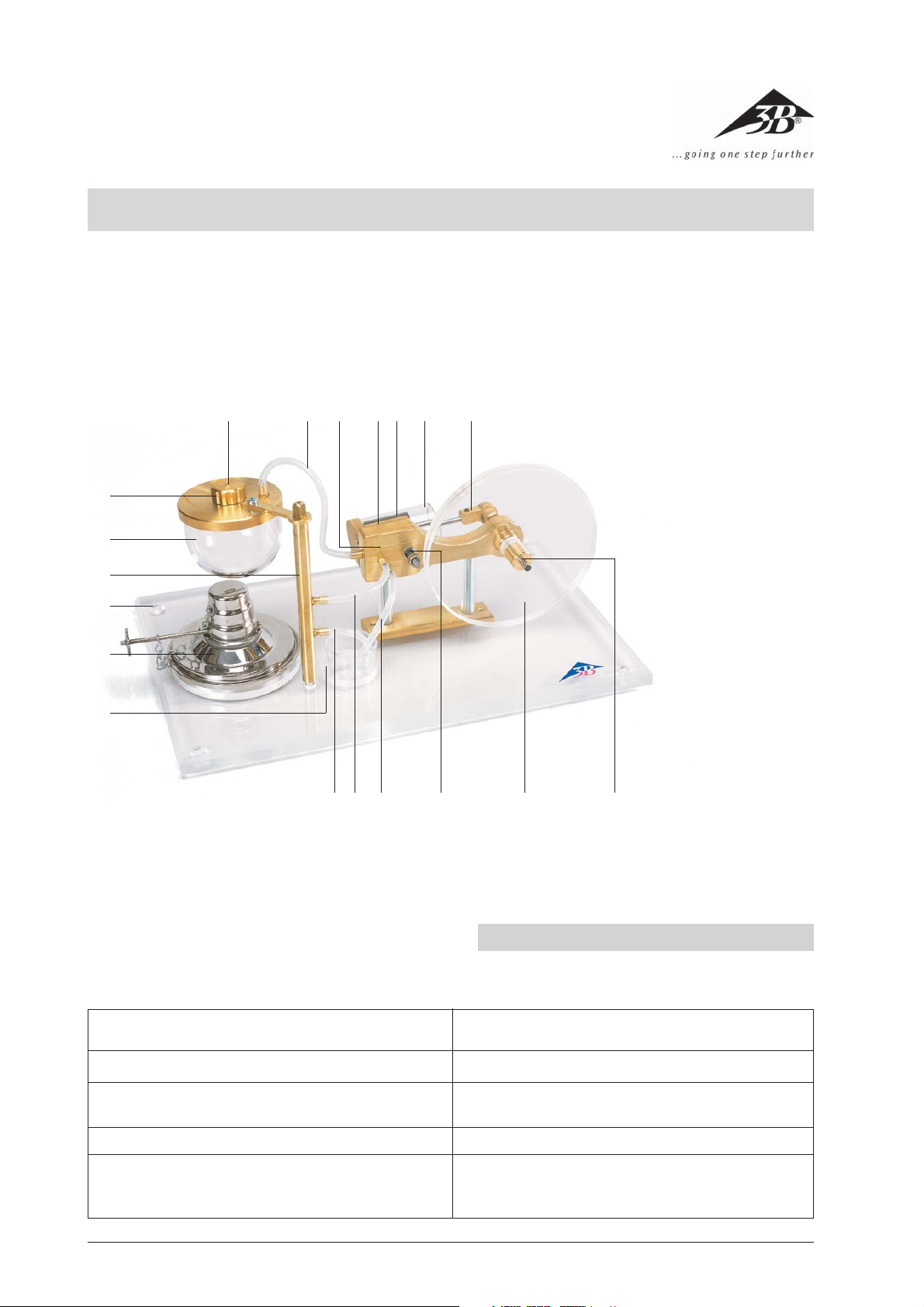

1 Condensation hose

2 Exhaust steam hose

789blbmbnbo

3 Drainage hose

4 Spring

5 Flywheel

6 Crankshaft

7 Connecting rod

8 Main cylinder

9 Main piston

bl Cylinder flank

bm Support frame

bn Steam feeding hose

bo Safety valve

bp Boiler cap

bq Boiler

br Exhaust steam pipe

5

6

bs Base plate

bt Spirit burner

bu Condensation beaker

The steam engine is used to demonstrate how an oscillating steam engine functions.

General safety standards applicable to steam engines Specific conformance of steam engine U10055

1. No sharp corners or edges

2. Protection against corrosion 2. No materials that are subject to corrosion have been

3. Temperature limiting for operating elements 3. The wick of the spirit burner can be adjusted.

4. The boiler capacity of the steam engine may not

exceed 2000 cc Maximum operating pressure may not

exceed 1.5 bars.

• The safety standards applicable to the steam engine

are specified in DIN 31000:1979-03.

1. There are no sharp corners or edges on this device.

used.

4. The boiler capacity is 50 cc. The operating pressure is

0.5 bars.

4

1. Safety instructions

Page 2

General safety standards applicable to steam engines

Specific conformance of steam engine U10055

5. An adjustable spring-operated safety valve made of

non-rusting material with a safety threshold of no

more than 3.0 bars (double the operating pressure)

must be provided.

6. The bursting pressure of the boiler should be no less

than 3-times the operating pressure.

7. The water level must be visible, if possible, with the

aid of an inspection window.

8. An easy to understand instruction sheet is required

plus a label with the name or logo of the manufacturer.

• Only put the steam engine into operation if all of the

components are in perfect condition and their functionality is assured. Special attention must be made

to ensure that there are no cracks or any other damage to the glass boiler bq.

• Only use distilled water that has been demineralised

as per VDE 0510. If conventional tap water is used the

associated deposits that form on the safety-relevant

components mean that functionality can no longer

be guaranteed.

• Carefully pour alcohol into the burner bt. Make sure

that nothing spills.

• Never pour in alcohol while the wick is still glowing or

if there is any other open flame in the immediate

proximity.

• Seal the bottle of alcohol immediately after use.

• Keep away from the open flame. Be careful! Only ex-

tinguish the burner flame by means of the attached

cover. Do not blow on the flame in the proximity of

the boiler, as any sudden temperature change could

cause the boiler to crack.

• The boiler may not be heated unless it is filled with

water. For that reason it is important to extinguish

the lamp’s flame before it boils dry.

• Do not touch any components steam carrying, par-

ticularly the boiler bq, hoses 1, 2, 3, bn, steam

exhaust pipe br and support frame bm. Do not

touch the spirit burner bt during or after operating

the steam engine either. Risk of burns!

• Let the steam engine cool before storing.

2. Description, technical data

The oscillating steam engine has been designed for use

in a training and educational environment. In order that

individual operations and dynamic processes should be

observable, particular emphasis has been placed on transparent construction. For that reason the main cylinder

8 and boiler bq are made of heat-resistant special glass

and the flywheel 5 is made of acrylic. The hardened

crankshaft 6 and the connecting rod 7 are ball-bear-

ing mounted. The graphite piston 9 runs dry in the

5. This unit is equipped with an adjustable spring-operated safety valve made of non-rusting material with

a safety threshold of 1.0 bar (double the operating

pressure)

6. The boiler’s bursting pressure is at least 1.5 bars (at

least three times the operating pressure). Each boiler

is checked for safety and leaks by means of a burst

pressure test (2 bars+).

7. The water level is visible at all times because of the glass

boiler.

8. An instruction sheet is supplied with each apparatus.

An appropriate silk-screen printed label is located on

the base plate.

operating cylinder – i.e. without any added lubricant. For

that reason the steam engine runs very quietly and safely for long periods, providing a mechanical power output of approx. 1 W. The safety valve bo is located in the

boiler cap bp. It opens as soon as the boiler pressure

exceeds 1.0 bar. In addition, the machine is also equipped

with a second, independent excess pressure safety mechanism. Up to a pressure of approx. 1.5 bars the steam is

forced into the ducts of the support frame bm and discharged via the condensation hose 1. When the pressure exceeds 1.5 bars the cylinder flank bl is forced away

from the frame because the tension in the spring 4 is

overcome so that the steam can flow unimpeded out of

the steam inlet hole in the frame.

Piston diameter: 19 mm

Piston stroke: 10 mm

Boiler diameter: 50 mm

Boiler volume: 50 ml

Operating time per filling: approx. 20-25 mins

Speed: 800 rpm

Mech. Power output: approx. 1 W

Max. operating pressure: 0.5 bars

Trigger pressure

of the safety valve: 1.0 bars

Minimum boiler

bursting pressure test: 2.0 bars

3. How the apparatus works

Unlike a slide-valve steam-engine, an oscillating steam

engine has a cylinder that rotates on a central shaft causing steam inlet and outlet ducts to open and close. Water

in the boiler begins to boil, and thus steam is generated.

The steam flows via the steam inlet hose bn into the

frame then through the steam inlet hole. As soon the

opening of the cylinder is fed with fresh steam, steam

flows into the cylinder and displaces the piston (Fig. 1, a).

When the piston reaches its lowest point, the steam ducts

are closed. This slack point is passed thanks to the inertia

of a flywheel (Fig 1, b). In the next phase, the piston moves

back, opens the steam outlet and pushes out the steam

5

Page 3

(Fig. 1, c). The steam flows out via the exhaust steam

hose 2 and the exhaust steam pipe br. The condensed

water that accumulates drips out via the condensation

hose 1 into the condensation beaker bu.

ab

When the piston has reached the dead point at the top,

both of the steam ducts are closed again. The flywheel

drags the engine past this top slack point, after which

steam is once again fed in and the procedure repeats

from the start (Fig. 1, d).

Fig. 1: Work cycle of an oscillating steam engine

4. Operation

• Open the boiler cap bp and fill up the boiler with

distilled water (demineralised water conforming to

VDE 0510). Do not fill up the boiler to the brim, maintain an air column of approx. 5 mm. The steam engine functions equally well even if the boiler is only

half-filled. Only the operating duration is correspondingly reduced.

• Light the wick of the spirit burner and heat the boiler.

• Shut the steam inlet opening to enable quicker build

up of pressure.

• After approx. 2 minutes, the water in the boiler be-

gins to boil. From this point onwards, only approx.

2-3 minutes are needed to attain the required operating pressure. Steam flows via the steam feeding

hose into the steam inlet opening. Excess condensed

water drips into the condensate beaker via the drainage hose 3. For this purpose, channels that facilitate collection and transfer of the condensed water

are milled into the frame.

• The engine can now be operated by turning the fly-

wheel in a clockwise direction (while observing the

main cylinder).

dc

• The power of the engine decreases if there is not

enough water left in the boiler. It is not permitted to

heat the boiler if it is not filled with water. The spirit

burner should, therefore, be extinguished at the appropriate time.

• Do not blow out the flame in the proximity of the

boiler. Use the attached cap to extinguish the flame.

• During the cooling process, condensed water is sucked

up from the condensation beaker via the condensation hose, frame and steam feeding hose and transferred into the boiler.

5. Storage and maintenance

• Store the steam engine in a dust-free place.

• To clean use a damp cloth, if necessary, with some

washing-up liquid. Never use solvents or aggressive

cleaning agents to clean the acrylic glass components.

• Frequent use of the apparatus may cause a layer of

soot to deposit on the underside of the boiler bq due

to the constant play of a flame. This, however, can be

dissolved and removed by using a cloth soaked in

acetone.

• In order to prevent water stains appearing, dry thor-

oughly after cleaning.

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com • Technical amendments are possible

6

Loading...

Loading...