Page 1

3B SCIENTIFIC

Langensiepen Current Balance U8496820

Instruction Sheet

06/09 ERL

®

PHYSICS

1 Cylinder for friction brake

2 Glycerine

3 Balance beam with pointer

4 Current input terminals

5 Stand

6 Counterweight

7 Pointer for zero calibration

8 Coil, 5 turns

9 Aluminium tube

10 Conductor loop

11 10 g weight

12 Dynamometer

(from accessory set)

13 Drive weight, 100 g

14 Rubber bung

15 Drive weight ,200 g

16 Nylon thread

17 Piston for friction brake

18 Yoke

19 Transformer core

20 Coil, 600 turns

21 Dynamometer 0,1 N

22 Storage block

23 Spacer rings

24 200 g weight

25 100 g weight

26 Fixing clamp

27 Pole shoe set

1

Page 2

1. Safety instructions

All the components of the instrument are safe to work

with, provided that they are used in accordance with

instructions and regulations.

The transformer core, yoke and pole shoes should be

handled carefully to avoid the risk of injuries resulting

from their considerable weight.

In experiments involving a strong magnetic field, do

not allow any ferromagnetic materials to come near

the instrument, as they would be powerfully attracted

towards it with a risk of damage or injury, for example

through trapping of fingers.

Equipment that is to be connected to the mains must

be checked for any damage before it is used.

2. Description

The Langensiepen current balance is used for experiments on electrodynamics and Lorentz forces and

involves measurements in which the force on a conductor in a magnetic field is balanced mechanically.

3. Equipment supplied

1 Stand with agate cup bearings for balance beam

1 Balance beam with pointer and terminals for cur-

rent connections

1 Set of conductor loops

1 Coil, 5 turns

1 Pointer for zero calibration

1 Hydrodynamic friction brake

2 Special connecting leads

1 Bottle of glycerine (250 ml)

2 Drive weights, 100 g and 200 g

1 Counterweight weight

2 19 g weights

1 Reel of nylon thread

1 Instruction sheet

1 Transformer core with yoke and fixing clamp

1 Pole shoes set

2 100 g weights

1 200 g weight

2 Coils, 600 turns

1 Storage block

1 Dynamometer, 0.1 N

10 Spacer rings

4. Operation

4.1 Generating a strong magnetic field

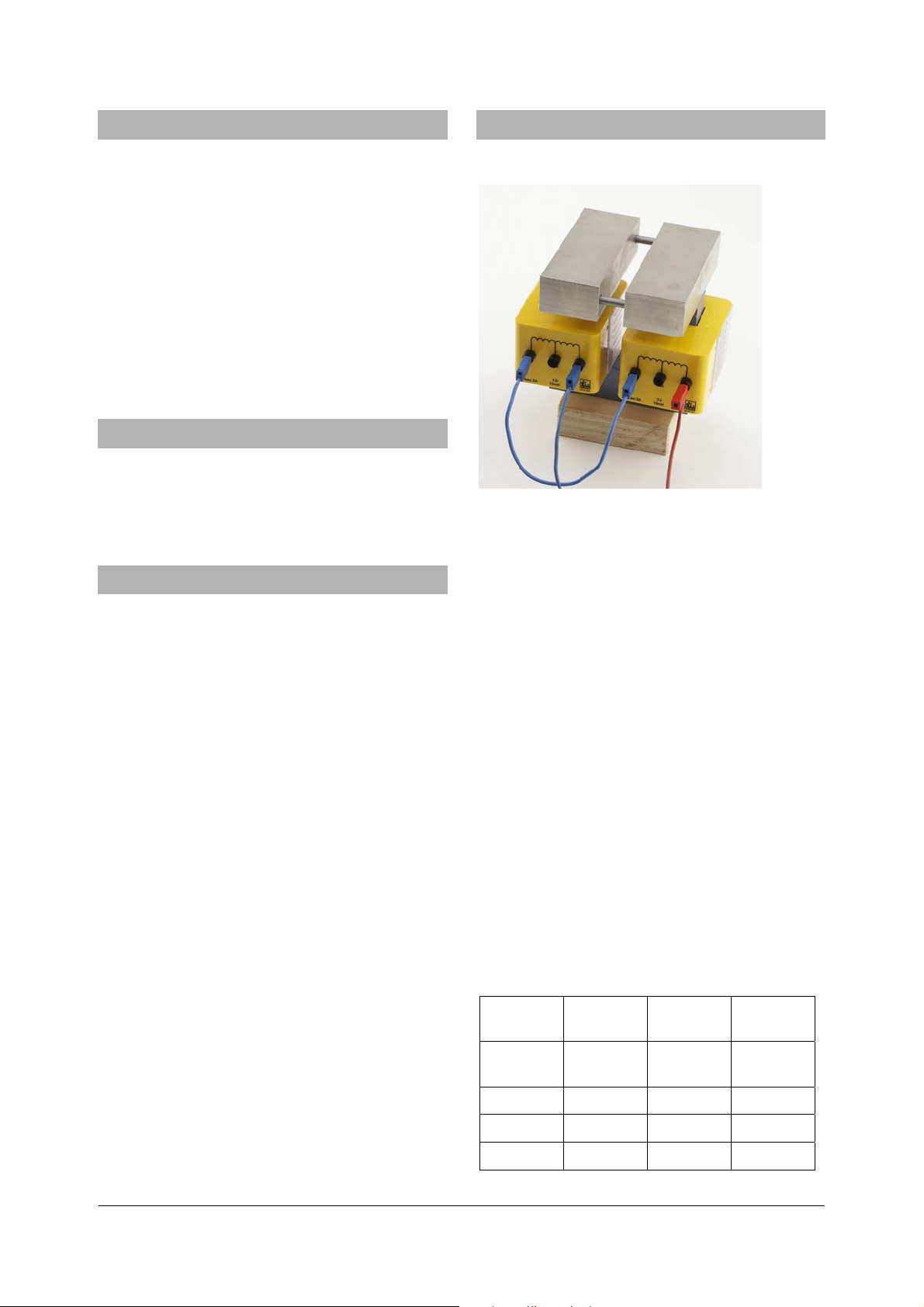

Fig. 1

The strong magnetic field generator is assembled as

shown in Figure 1 using the following components

from the accessories set U8496818: U-core (19), two

coils (20), pole shoes (27).

The connecting leads chosen must be long enough to

ensure that they do not cause any mechanical obstruction to the operation of the current balance.

The pole shoes (27) are placed on the core (19) without

any special fixing. They rest in place securely enough

under their own weight, and when the field is applied

they are held more firmly. The distance between the

pole shoes is determined by the choice of spacer rings

(23), giving a separation of 10, 15 or 20 mm when

used singly, or 25, 30, 35 or 40 mm by combining

them. The field between the pole shoes is approximately uniform.

It is recommended that a stabilised DC power supply

U33020 is used as the voltage source for excitation of

the magnet (see Fig. 3). When switching the field on or

off, the large inductance of the system must be taken

into account by avoiding switching a large current.

The following table contains some guideline data on

the magnetic flux density B that can be generated

with different values of the coil current and spacing of

the pole shoes. The magnet set-up consists of the Ucore with two 600-turn coils connected in series.

Pole shoe

separation

Excitation

current

2 A 0.18 T 0.15 T 0.12 T

1 A 0.13 T 0.09 T 0.07 T

0.5 A 0.06 T 0.04 T 0.03 T

1 cm 2 cm 3 cm

Flux B Flux B Flux B

2

Page 3

4.2 Current balance

F

F

⋅

F

⋅

Fig. 2

The current balance (Fig. 2) consists of a stand (5), the

balance beam (3), a pointer for zero calibration (7),

three interchangeable conductor loops (10) and a coil

with 5 turns (8).

The current in the loop or coil is applied via the stand

(maximum continuous current 2 A, or up to 4 A for

short periods).

The conductor loops are of different lengths. An aluminium tube (9) can be clipped into the 10 cm loop to

increase the conductor cross-section.

After fitting one of the loops in place, the instrument

must first be mechanically balanced. The zero position

is marked by setting a pointer. Coarse adjustment is

carried out using 10g weights (11), which are placed

on the pegs provided on the beam. That is followed by

a fine adjustment using the counterweight on the

beam.

4.3 Induction set-up

Fig. 3

The induction set-up (Fig. 3) consists of a current balance and a strong magnetic field, to which a drive for

moving the current loop (10) into or out of the nearuniform magnetic field between the pole shoes is

added. The drive provided by the weights (13, 15, 24,

25) in combination with the friction brake produces a

steady upward or downward movement of the cobductor loop (10) or the coil (8).

A choice of different spacer rings (23) between the

pole shoes gives a range of magnetic flux densities

with the same excitation current.

The induced voltage during the movement of the loop

or coil, as measured by a microvoltmeter (U8530501),

can remain constant over a period of up to 30 seconds.

4.4 Force on a current-carrying conductor

Fig. 4

Initially the distance between the pole shoes should

be set at 10 mm. The current loop (length l = 5 cm) is

connected in position and the current balance is adjusted for equilibrium.

The strong magnetic field is switched on and a DC

current (I = 2 A) is passed through the current loop

(using a second meter to measure the current).

The balance is restored to the equilibrium condition

by raising the dynamometer.

If the magnetic field generator is then shifted slightly

(without disturbing the current loop), the adjustment

of the current balance remains unaltered, showing

that the magnetic field between the pole shoes is

uniform.

When the length l of the loop and the current I pass-

ing through it are changed, the following can be observed:

l~

and I~F, also lI~

Varying the magnetic field excitation current or the

separation between the pole shoes also changes the

measured force.

Therefore the coefficient of proportionality in the

relationship where

lI~

can also be changed as a

3

Page 4

result changing the field arrangement. This is one

F

appropriate way of characterising the field set-up.

Definition:

lIB

⋅⋅= or

F

B⋅= .

lI

The measured force is independent of the crosssectional area of the conductor loop. This can be easily shown by clipping the aluminium tube that is provided into the loop (l = 10 cm).

Elwe Didactic GmbH • Steinfelsstr. 6 • 08248 Klingenthal • Germany • www.elwedidactic.com

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2009 3B Scientific GmbH

Loading...

Loading...