Page 1

3B SCIENTIFIC

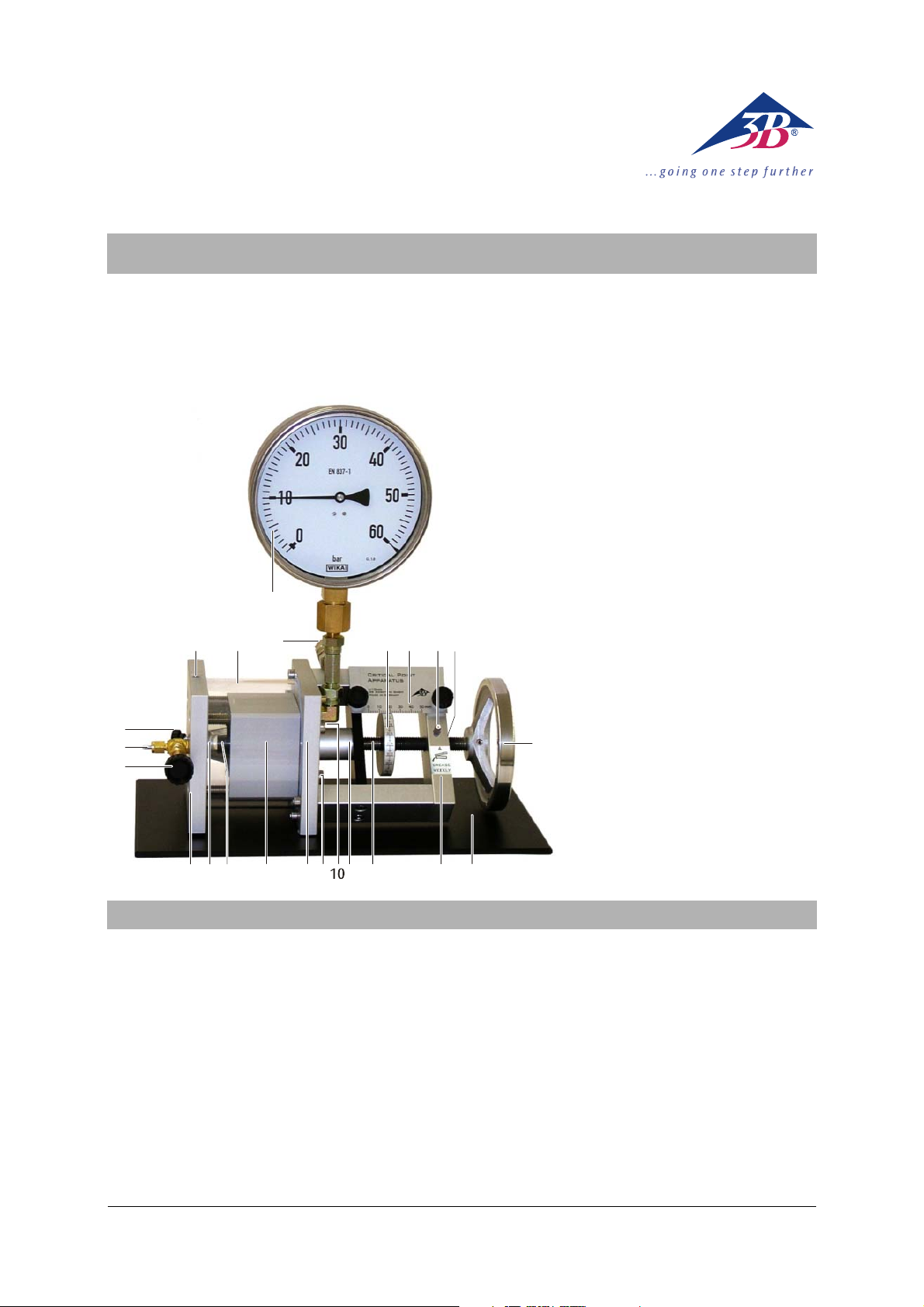

Critical Point Apparatus 1002670

Instruction sheet

02/13 MH/JS

23

22

19

18

17

®

PHYSICS

1 Vernier scale

2 Fixed scale

3 Grease nipple

4 Threaded bush

5 Handwheel

6 Base

7 Frame

8 Threaded axle with piston

9 Piston cover

10 Outlet for thermal medium

11 Inlet for thermal medium

12 End plate

13 Cylinder

14 Conical seal

1220 21

3 4

15 Measuring cell

16 Valve plate

17 Regulating valve

18 Gas connection fittings 1/8"

(for Minican® gas container)

19 Flush valve

20 Hole for thermocouple

5

21 Heat casing

22 Safety valve

23 Manometer (excess pressure indicator)

876

On delivery, the critical point apparatus is filled with

hydraulic fluid. The test gas is not included.

Before filling with the test gas, carry out a volume

calibration, as described in chapter 6, using air as an

approximation of an ideal gas.

Filling with the test gas is described in chapter 7.

Experimental investigations are described in chap-

ter 8.

Important notes on storage of the test gas and

equipment (if not in use for a long period) are stated

in chapter 9.

1516 14

1213

911

1. Contents of instruction manual

Owing to the inevitable diffusion of the test gas

through the conical seal, it is necessary to degas the

hydraulic fluid in the equipment, as described in

chapter 10. This must be done before the equipment

is put away for storage (after removing the test gas) or

if it has been in use for a long time.

The threaded bush in the frame must be lubricated

regularly and also inspected at lengthier intervals.

Refer to section 11 for instructions.

Maintenance work as described in chapter 12 is only

required if the rubber components get worn out and

their functionality is adversely affected.

1

Page 2

2. Safety instructions

When used properly, the operation of the critical

point apparatus is not dangerous, since both the

experimenter and the equipment are protected by a

safety valve. However, it is extremely important to

observe a few precautionary measures:

• Read the instruction sheet thoroughly and follow

the instructions therein.

• Do not exceed the maximum permissible values

for pressure and temperature (60 bar and 1060°C).

• Do not operate the equipment without qualified

supervision.

• Always wear safety goggles.

Only increase the temperature at low pressure with

pure gas phase in the measuring cell.

• Before increasing the temperature, wind the

handwheel outwards so that maximum volume is

attained in the measuring cell.

When conducting adjustments, make sure that the

safety valve does not point in the direction of people

who could be injured or objects that could be damaged if the valve cover shoots out. When conducting

experiments, pay special attention too to the alignment of the safety valve.

• When setting up the apparatus, make sure that

the safety valve does not point in the direction of

people who could be injured or objects that could

be damaged.

• When adjusting the safety valve, wrap your arms

around the apparatus to reach the valve at the

back.

If the conical seal is overtaxed, it could get damaged

or even destroyed.

• Never set a pressure above 5 bar if the regulating

valve or the flush valve is open, i.e. if there is no

back pressure from the gas in the measuring cell.

• Never create underpressure by turning the hand

wheel inwards when the valves are shut.

In the frame there is a threaded bush, which is to be

regarded as a safety-related feature (see section 9).

• Lubricate the threaded bush every 100 cycles.

• Inspect the threaded bush annually.

To prevent damage by corrosion inside the instrument,

• use a 2:1 mixture of water and anti-freeze fluid as

the thermal medium.

Only as real gas for SF

and nitrogen as ideal gas.

6

3. Description

The critical point apparatus allows us to investigate

the compressibility and liquefaction of a gas. Measurements allow determination of the critical point for

the gas as well as the recording of isotherms for an

adiabatic p-V diagram (Clapeyron diagram). The gas

used for testing is sulphur hexafluoride (SF

). SF6 has a

6

critical temperature of 318.6°K (45.5°C) and a critical

pressure of 3.76 MPa (37.6 bar) which makes for a

simple experiment set-up.

The critical point apparatus consists of a transparent

measuring cell of particularly well sealed, pressureresistant design. The volume of the measuring cell

can be modified by turning a fine-adjustment wheel

and can be read by means of a fixed scale and a rotating vernier scale to an accuracy of one thousandth of

the maximum volume. The pressure is applied via a

hydraulic system using castor oil approved for medicinal use. The measuring cell and hydraulic system

are isolated from one another by a conical seal which

rolls up when there is an increase in pressure. This

design means that any pressure difference between

the measuring cell and the oil reservoir is negligible

in practical terms. A manometer measures not the

pressure of the actual gas but that of the oil, thus

eliminating any need for a space within the measuring cell. When observing transitions from gas to liquid

or vice versa, the lack of such a dead space means

that the development of the very first drop of liquid

as well as the disappearance of the last bubble of gas

can be observed. The measuring cell is surrounded by

a transparent chamber of water. A circulating thermostat arrangement (water bath) means that a constant

temperature can be maintained during the experiment with a high degree of accuracy. The temperature can be read and monitored using a thermometer.

The fact that volume, pressure and temperature can

all be read with a high degree of accuracy means that

accurate p-V diagrams or pV-p diagrams can be recorded without much difficulty. Pressure and temperature-dependent volume correction enable us to

achieve accurate quantitative results which are well in

agreement with published values.

4. Contents

1 Critical point apparatus, filled with hydraulic fluid

(castor oil). With attached gas connection fittings

for MINICAN® gas container and protection for gas

supply connections. Test gas (SF

) not included.

6

1 Oil filling device

1 Allen key, 1.3 mm (for grub screw on the vernier

scale)

1 Plastic tubing, 3 mm diameter

1 1/8" tube fitting (wrench width 11 mm)

1 Grease gun

2

Page 3

J

Δ⋅=

Δ

5. Technical data

Sulphur hexafluoride:

Critical temperature: 318.6 K (45.5°C)

Critical pressure: 3.76 MPa (37.6 bar)

Critical volume: 197.4 cm

3

/mol

Critical density: 0.74 g/mol

Maximum values:

Temperature range: 10-60°C

Maximum pressure: 6.0 MPa (60 bar)

Threshold value for

safety valve: 6.3 MPa (63 bar)

Theoretical long-term

pressure: 7.0 MPa (70 bar)

Theoretical rupture

pressure: >20.0 MPa (200 bar)

Materials:

Test gas: Sulphur hexafluoride (SF

)

6

Hydraulic fluid: Castor oil

Measuring cell: Transparent acrylic

Temperature coating: Transparent acrylic

Recommended

thermal medium: mixture of water and anti freeze in the ratio 2:1

Determination of volume:

Piston diameter: 20.0 mm

Piston surface: 3.14 cm

Displaced volume: 3.14 cm

Maximum volume: 15.7 cm

2

2

× displacement

3

Scale division for

displacement: 0.05 mm

Maximum displacement: 50 mm

Determination of pressure:

Manometer: Class 1.0 (max. 1% deviation

from full scale value)

Measured quantity: Excess pressure

Indicator: 60 bar max.

Manometer diameter: 160 mm

Connections:

Hole for

temperature sensor: 6 mm dia.

Connections for

thermal medium: 7 mm dia.

Connection for

regulating valve: 1/8’’ dia.

Gas connection: 1/8’’ (3.17 mm) dia. (as

supplied)

General specifications:

Dimensions: 380 x 200 x 400 mm

3

Weight: 7 kg approx.

6. Volume calibration

6.1 Preliminary notes:

NOP M

Q

L

K

R

S

A

B C E F

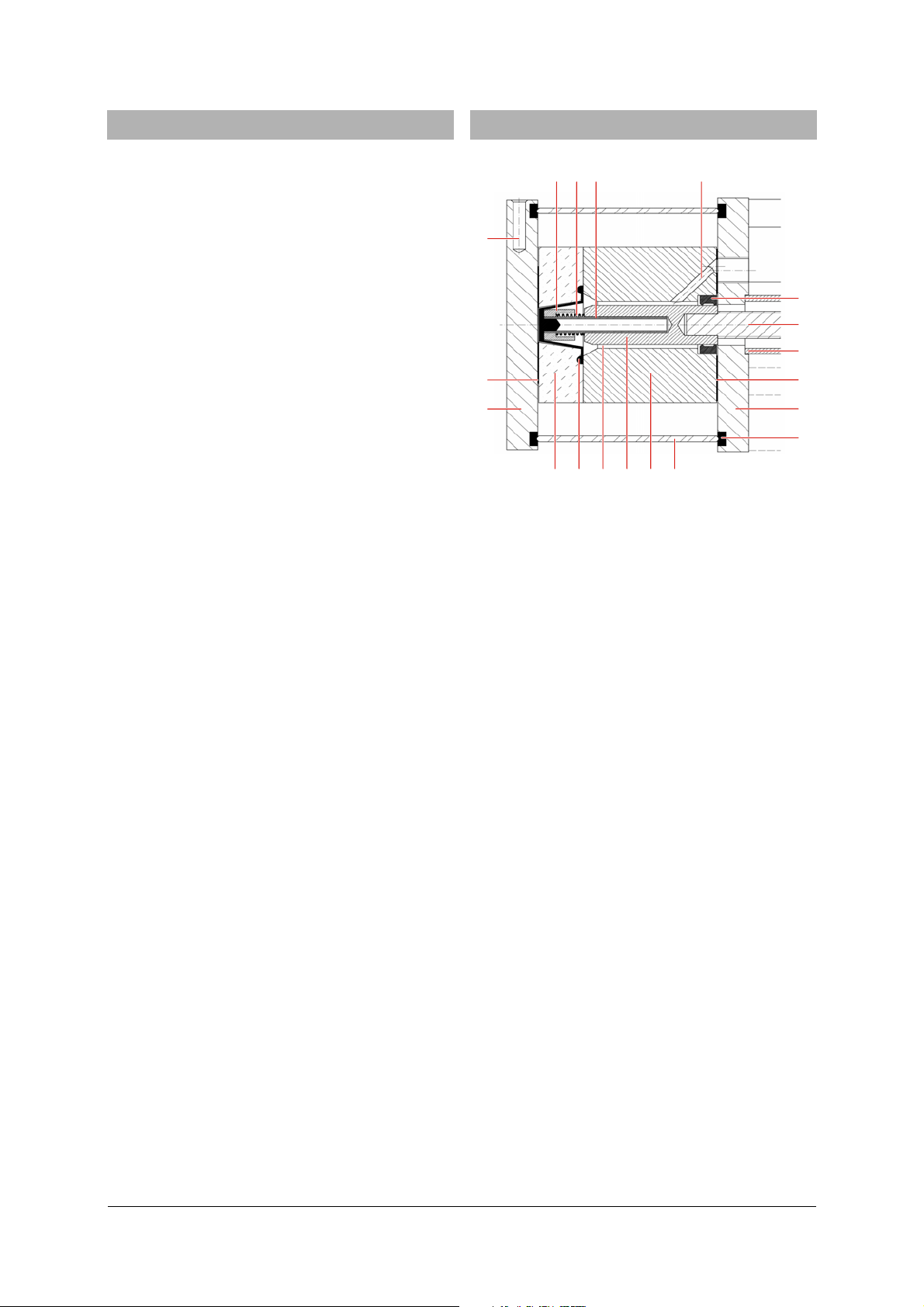

Fig. 1: Cross-section of apparatus with measuring cell (A),

conical seal (B), oil chamber (C), piston (D), cylinder (E), heat casing (F), silicone seal (G), end

plate (H), square grommet (I), piston cover (J),

threaded axle (K), gasket (L), manometer connection (M), guide tube (N), spring (O), sleeve (P), hole

for temperature sensor (Q), circular grommet (R) and

valve plate (S)

D

I

H

G

One turn of the handwheel winds the piston into/out

of the cylinder by means of a threaded axle. This

leads to a change of volume in the oil chamber (see

Fig. 1). Since oil is practically incompressible and all

the other components other than the conical seal are

almost rigid, a change in volume in the oil chamber

causes the conical seal to deform, thereby creating an

almost equal change in volume ΔV

cell. As a first approximation for ΔV

sAV

G

where

(1)

2

cm143.A= and Δs = displacement of piston.

in the measuring

G

, we can assume:

G

The piston displacement is shown in divisions of

2 mm on the fixed scale. Intermediate values are read

on the vernier scale in divisions of 0.05 mm.

The fixed scale can be moved by loosening the two

knurled screws. The vernier scale can be repositioned

and turned around the threaded axle on loosening

the grub screw (between scale positions 0 9 and 1 0).

6.2 Zero point calibration:

The zero point for the volume scale must be determined by conducting a calibration.

For this, we take advantage of the fact that in a pressure range of 1-50 bar and in a temperature range of

270-340 K, air acts as a near-ideal gas (the real gas

factor has a deviation of less than 1% from 1). Therefore, at a constant temperature (e.g. room temperature) for two piston displacements s

and s1 and for

0

3

Page 4

the corresponding pressures p0 and p1 of the trapped

T

⋅

⋅

=

air, we get:

spsp ⋅=⋅ (2)

1100

Substituting

p

s Δ⋅

1

0

=

pp

−

s

01

sss Δ+=

10

and rearranging gives:

(3)

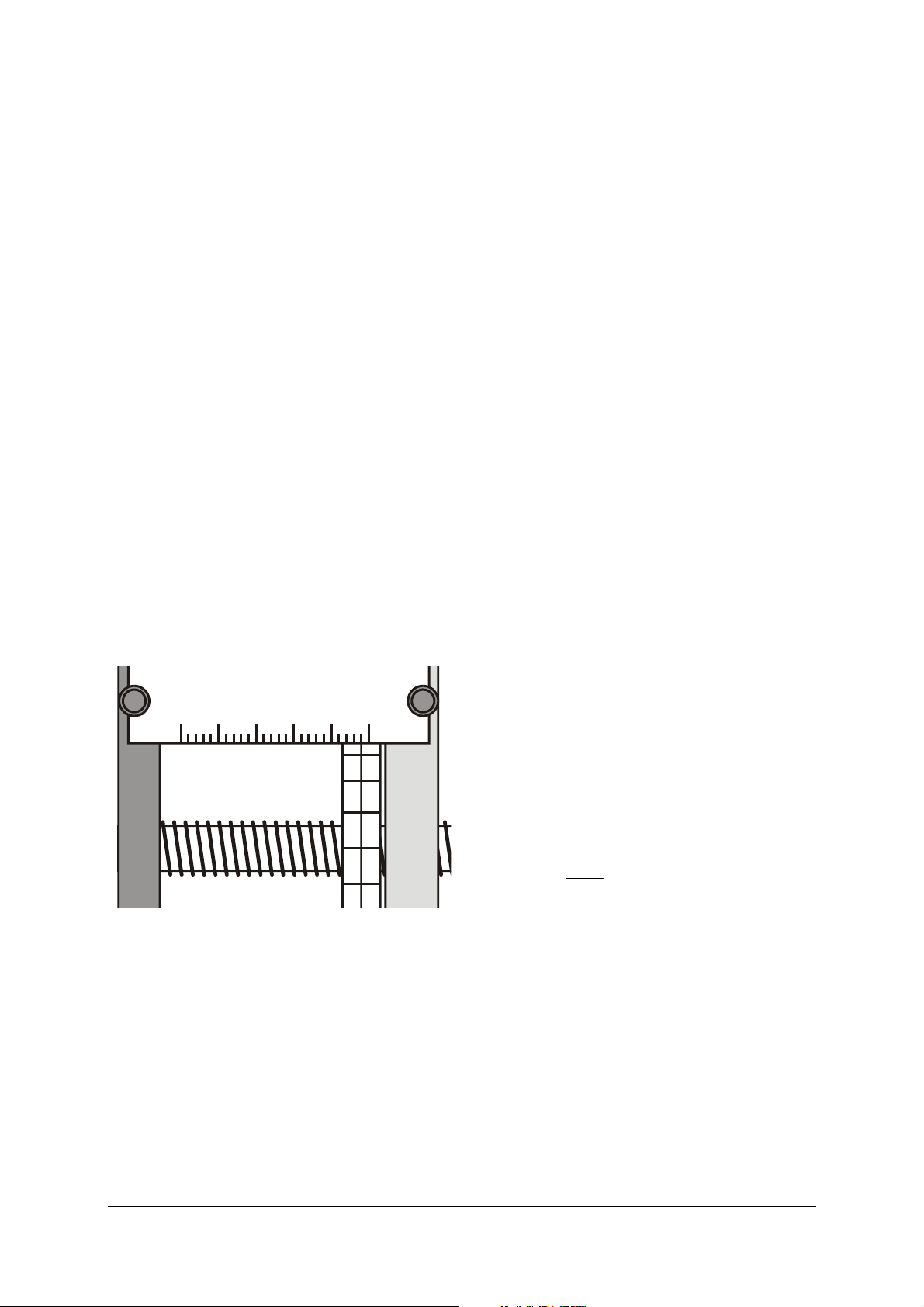

Rough calibration of scales:

• Open the regulating valve wide.

• Loosen the grub screw for the vernier scale by

half a turn (it is now possible to turn the scale

easily on the threaded axle without moving the

handwheel, although a counterpressure acts

against this independent movement).

• Wind the handwheel out till you detect a notice-

able resistance.

• Without turning the handwheel, turn the vernier

scale on the threaded axle till the 0.0 mark is on

the top and the fixed scale shows approx. 48 mm.

• Loosen the knurled screws of the fixed scale and

shift the scale to the side till the 48-mm bar is exactly above the centre line of the vernier scale

(see Fig. 2).

• Tighten the knurled screws again. In doing so,

make sure that the fixed scale does not press

against the vernier scale.

100 20304050mm

00

19

18

17

• Calculate the zero corrected piston position s

1, corr

using Equation 3.

• Adjust the vernier scale to the corrected value

and, if necessary, move the scale again.

• If required, wind the handwheel out a little and

secure the vernier scale with the grub screw.

Measurement example:

= 1 bar, p1 = 16 bar, p1 – p0 = 15 bar

p

0

s

= 48.0 mm, s1 = 3.5 mm, Δs = 44.5 mm

0

Therefore,

s

= 2.97 mm.

1, corr

The vernier scale must therefore be adjusted so that

now only 2.97 mm are shown instead of 3.50 mm.

Note:

After calibrating the zero point, it is possible to obtain

qualitatively accurate measured values. With regard

to temperature

T and pressure p, it is also possible to

obtain quantitatively accurate measurements of the

isotherms in range around to the critical point where

the two phases exist simultaneously. However, especially in the liquid phase, the measured isotherms are

rather too widely separated.

6.3 Detailed calibration:

The exact relation between the volume VG in the

measuring cell and the scale reading

s is dependent

on the volume of oil in the oil chamber. The oil

chamber also expands marginally in proportion to the

pressure as a result of the spring in the manometer

tube. Additionally, when the temperature is increased, the castor oil expands to a greater extent

than the rest of the equipment. This means that the

pressure rises at a slightly greater rate at higher temperatures. All of these phenomena can be calculated

if appropriate calibration has been effected using air

as an ideal gas.

The ideal gas equation would thus be:

Vp

Rn

(4)

⋅=

16

with

J

3148.R =

molK

Fig. 2: Piston position reading at 48.0 mm

Zero correction:

• Shut the regulating valve (the pressure in the

measuring cell now corresponds to the ambient

pressure

p

= 1 bar. To within the accuracy of the

0

measurement, the manometer should display an

excess pressure of 0 bar).

• Wind the handwheel in till an excess pressure of

15 bar has been reached (absolute pressure

p

= 16 bar).

1

• Read the piston position s

displacement

Δs = s

– s1.

0

and calculate the

1

After taking the overpressure reading

pressure can be calculated from:

p = p

+ 1 bar (6)

e

The absolute temperature is given by:

T = ϑ + ϑ

where ϑ0 = 273.15°C (7)

0

The volume is given by:

sAV

G

where

(8)

2

cm143,A= and s is the “effective” piston

displacement.

From the measured displacement

p

, the absolute

e

s

, it is possible to

e

calculate the effective piston displacement as follows:

4

Page 5

(9)

(

)

ϑ⋅−⋅++=

CpCsss

ϑ

pe 0

By substituting in equation 4, we get:

⋅ϑ⋅β−⋅β++⋅

0

pe

ϑ+ϑ

0

Apssp

ϑ

(10)

0

=⋅−

Rn

If we take several readings at various temperatures

and pressures, we can calculate the term:

n

()

⎛

⎜

Q

=

∑

⎜

=

1i

⎝

p

ϑ+ϑ

0

Apssp

⋅ϑ⋅β−⋅β++⋅

ϑ

ii0ii

2

⎞

⎟

Rn

(11)

⋅−

⎟

⎠

Sample measurements:

Table 1: Measured values for calibration

i s

/ mm

e

ϑ

p / bar

1 40.0 20.0°C 6.6

2 20.0 20.0°C 12.4

3 10.0 20.0°C 23.3

4 5.0 20.0°C 41.8

5 3.5 20.0°C 53.9

The free parameters s

, βP, βϑ and n should be appro-

0

priately selected so that the value of Q is reduced to a

minimum.

Additionally required (see also chapter 8):

1 Compressor or bicycle pump and valve

1 Bath/circulating thermostat 1008653/1008654

1 Dig. quick-response pocket thermometer 1002803

1 Type K NiCr-Ni immersion sensor, -65°C-550°C

1002804

2 Silicone tubes, 1 m 1002622

1 l Anti-freeze fluid with corrosion-inhibiting additive

for aluminium engines (e.g., Glysantin® G30 ma-

nufactured by BASF)

Conducting the calibration:

• Connect the circulation thermostat as described

in chapter 8 and fill it with the water/anti-freeze

mixture.

• Connect the plastic tube (3-mm internal diameter)

to the 1/8" gas connection fittings.

• Open the regulating valve.

• Wind the handwheel outwards, making the piston

move till it reaches say the 46.0 mm position.

• Use a compressor or a bicycle pump to create an

excess air pressure of approx. 3-8 bar in the

measuring cell.

• Shut the regulating valve.

• To record measurements, vary the volume in the

measuring cell or the temperature of the thermostat and wait till a stationary equilibrium has

been attained. Then take a pressure reading.

• Use appropriate adjustment software to set the s

β

, βϑ and n parameters so that the quadratic

P

,

0

equation for the errors Q is reduced to a minimum (see equation 11).

• If you like, you can adjust the vernier scale

around s

so that this correction is not necessary.

0

With the set parameters, it is possible to calculate the

“effective” piston displacement s from the measured

displacement s

using Equation 9 and then to calcu-

e

late the calibrated measuring cell volume using Equation 8.

6 5.0 20.0°C 41.8

7 5.0 10.0°C 38.9

8 5.0 30.0°C 45.3

9 5.0 40.0°C 49.0

10 5.0 50.0°C 53.5

The following parameter values are obtained:

s

= 0.19 mm,

0

P

mm

0230

.=β

bar

n = 0.00288 mol.

7. Filling with test gas

7.1 Handling of sulphur hexafluoride:

Sulphur hexafluoride (SF6) is a non-toxic gas and is

absolutely safe for humans. The MAC value for danger

of suffocation on account of oxygen deprivation is

1000 ppm. That is equivalent to 6 filled measuring

cells per 1 m

However, SF

3

of air.

is extremely harmful to the environment

6

and can give rise to a greenhouse effect 24,000 times

stronger than CO

. Therefore, do not allow large quan-

2

tities to be released into the environment.

7.2 Gas connection via fixed pipes:

Additionally required:

1 SF

gas cylinder with manufacturer’s/supplier’s rec-

6

ommended gas fittings/valves, e.g. SH ILB gas cylinder

and Y11 L215DLB180 regulating valve from Airgas

(www.airgas.com).

1 Pipes with outer diameter of 1/8" and, if necessary,

adapters, e.g. from Swagelok (www.swagelok.com).

1 open-end spanner (13 mm), 1 open-end spanner

(11 mm)

According to the principles of “good laboratory practice”, it is recommended to utilise a gas supply via

fixed pipes, especially if the equipment is regularly in

operation.

Filling begins with several flush cycles in which the air

is flushed out of the pipe. The number of cycles required to flush out the air depends on the length of

mm

,

0340.=β

ϑ

grd

and

5

Page 6

the pipe (more precisely, on the ratio of the pipe

m

m

length to the volume of the measuring cell). In the

process, care should be taken that the quantity of the

greenhouse gas SF

released in the environment is

6

reduced to a minimum.

Connecting a fixed pipe:

100 20304050m

00

19

18

17

16

15

ab

Fig. 3: Connecting a fixed pipe

(a) flush valve, (b) regulating valve

• If necessary, pull out the protection for the gas

connection and loosen the valve nut (11 mm) to

remove the 1/8" gas connection fittings.

• Connect the pipe (if necessary with adapters) to

the gas fitting.

• Beginning with the valve nut, slide the supplied

screw joints onto the tubing. (See Fig. 3: follow

the sequence and alignment specified along with

the cable binder)

• Insert the pipe into the regulating valve and

tighten the valve nut till the point is reached

where it is no longer possible to move the pipe

any further using only your fingers.

• Hold the regulating valve still with an open-end

spanner (13 mm) and tighten the valve nut by a

further 270°.

Now, the connection is gas-tight. When loosening the

valve nut afterwards, the regulating valve also needs

to be held still with a spanner.

Flushing out air:

• Use the handwheel to set the piston position to

10 mm.

• Slowly open the regulating valve and let in the SF

6

till a pressure of approx. 10 bar has been attained.

• Shut the regulating valve.

• Open the flush valve slightly till the pressure has

dropped to almost 0 bar.

• Shut the flush valve.

Filling with test gas:

• After at least four flush cycles, open the regulat-

ing valve till the pressure attained is once again

10 bar.

• Shut the regulating valve.

• Turn the handwheel in the reverse direction till

the piston reaches a position of say 46 mm.

• Slowly open the regulating valve and shut it again

when a pressure of 10 bar has been attained.

7.3 Filling with gas from a MINICAN®:

Additionally required:

1 MINICAN® gas container with SF

, e.g. from the

6

company Westfalen (www.westfalen-ag.de

If the equipment is used only occasionally, it is more

practical to draw the test gas from a MINICAN® gas

container. The gas connection of a MINICAN® container is similar in design to a commercial spray can,

i.e. it opens when the MINICAN® container is pressed

directly onto the gas connection fittings.

Here too, filling begins with several rinsing cycles for

flushing out the air.

SF

6

ab

Fig. 4: Filling with test gas from a MINICAN® gas container

(a) flush valve, (b) regulating valve

Flushing out air:

• If necessary, pull off the protection for the gas

connection.

• Use the handwheel to set the piston position to

10 mm.

• After removing the protective cap, position the

MINICAN® container with SF

tion fittings.

onto the gas connec-

6

• Press the MINICAN® container onto the gas con-

nection fittings, slowly open regulating valve (b)

and let in SF

till a pressure of approx. 10 bar has

6

been attained.

• Shut the regulating valve.

10020304050m

00

19

18

17

16

15

6

Page 7

• Open the flush valve slightly till the pressure has

dropped to almost 0 bar.

• Shut the flush valve.

Filling with test gas:

• After at least four flush cycles, press the MINI-

CAN® gas container against the gas connection fittings. Slowly open the regulating valve and let in

till a pressure of approx. 10 bar has been at-

SF

6

tained.

• Shut the regulating valve.

• Wind the handwheel in the opposite direction till

the piston reaches a position of say 46 mm.

• Press the MINICAN® gas container against the gas

connection fittings, slowly open the regulating

valve and shut it again when a pressure of 10 bar

has been attained.

7.4 Recommendation for storage lasting for short

periods of time:

One gas filling can remain in the measuring cell for

several days.

If no experiments are being conducted, wind the

handwheel back till the piston is in a position where

it is subjected to the lowest possible pressure – say,

for instance, 46 mm.

If possible the apparatus should always be kept filled

with the thermal medium.

8. Experiments

8.1 Experiment set-up:

Additionally required:

1 Bath/circulating thermostat 1008653/1008654

1 Dig. quick-response pocket thermometer 1002803

1 Type K NiCr-Ni immersion sensor, -65°C-550°C

1002804

2 Silicone tubes, 1 m 1002622

1 l Anti-freeze fluid with corrosion-inhibiting additive

for aluminium engines (e.g., Glysantin® G30 ma-

nufactured by BASF)

• Place the equipment at a suitable height so that it

is convenient to observe the measuring cell. Position it so that the safety valve does not point in

the direction of any people who could be injured

or objects that could be damaged.

• Connect the silicone tubing from the outlet of the

circulation thermostat to the inlet of the heat casing and from the outlet of the heat casing to the

inlet of the circulation thermostat.

• Prepare the thermal medium consisting of 2 parts

water to 1 part anti-freeze by volume.

• Fill the circulated thermostat bath.

8.2 Qualitative observations:

Liquid and gaseous states, dynamic state during phase

transformation, transition points occurring at different temperatures.

• Vary the volume by turning the handwheel and

the temperature by means of the thermostat. Observe the safety instructions while doing so.

• Carefully shake the set-up to conduct simple

observations on the boundary between liquid and

gas.

In the vicinity of the critical point, it is also possible to

observe the critical opalescence. Owing to the constant changing of state between liquid and gaseous

states in small regions of the measuring cell, a kind of

“mist” develops and the sulphur hexafluoride appears

to be turbid.

8.3 Measuring isotherms in a p-V diagram:

• At maximum volume, set the desired temperature

on the circulation thermostat.

• Gradually reduce the volume in the measuring

cell (in steps down to a position of 10 mm). Wait

till a stationary equilibrium has been attained before taking pressure readings.

• Then, beginning with the minimum volume,

gradually increase the volume till the piston position is once again at 10 mm. Wait till a stationary

equilibrium has been attained before taking pressure readings.

• Convert the excess pressure readings into abso-

lute pressure and the piston positions into volume, as described in chapter 6.

In the low-volume region, stationary equilibrium is

attained more quickly during transition from higher

to lower pressure – i.e. from a lower volume to a

greater volume – since the phase boundary layer for

the phase transition from liquid to gas is created by

vapour bubbles present throughout the liquid. Stationary equilibrium then takes around 1 to 5 minutes

to attain, whereby the measurements on the fringe of

the region where both phases exist take longest.

The recommended threshold value of 10 mm refers to

a filling pressure of 10 bar. Above this value, there

will certainly be no occurrence of a liquid phase in

the permissible temperature range. The threshold

value shifts to the “right” if the filling pressure is

higher.

8.4 Measuring isochores in a p-T diagram:

• Set the desired initial temperature. Subsequently

set the desired volume.

• Gradually allow the temperature to decrease.

• Wait till a stationary equilibrium has been at-

tained then take the pressure reading.

Measurements where both phases are present can be

plotted to generate a vapour-pressure curve.

Attainment of equilibrium takes up to 20 minutes

after each change of temperature due to the fact that

7

Page 8

the water bath and the measuring cell must attain the

desired temperature first.

8.5 Determining the mass of gas:

Blow the gas out of the measuring cell into a gas-tight

plastic bag and then weigh it:

• If necessary, remove the gas supply pipe and

attach gas connection fittings.

• Wind out the handwheel, say to 46 mm.

• Open the regulating valve a little and release the

gas through the gas connection fittings into the

plastic bag.

• Shut the regulating valve.

• Determine the mass of the released gas. In doing

this, take into consideration the empty weight of

the bag and the buoyancy of air.

• Reduce the volume of the measuring cell till the

pressure in the measuring cell has reached its

original value.

• Calculate the original mass of gas from the vol-

ume difference before and after emptying the

measuring cell and the volume which is still present in the measuring cell.

Comparison with quoted values:

Using tabulated values, e.g. Clegg et al. [4], it is alternatively possible to calculate the mass of gas in the

measuring cell from the measurements of ϑ, p, and V.

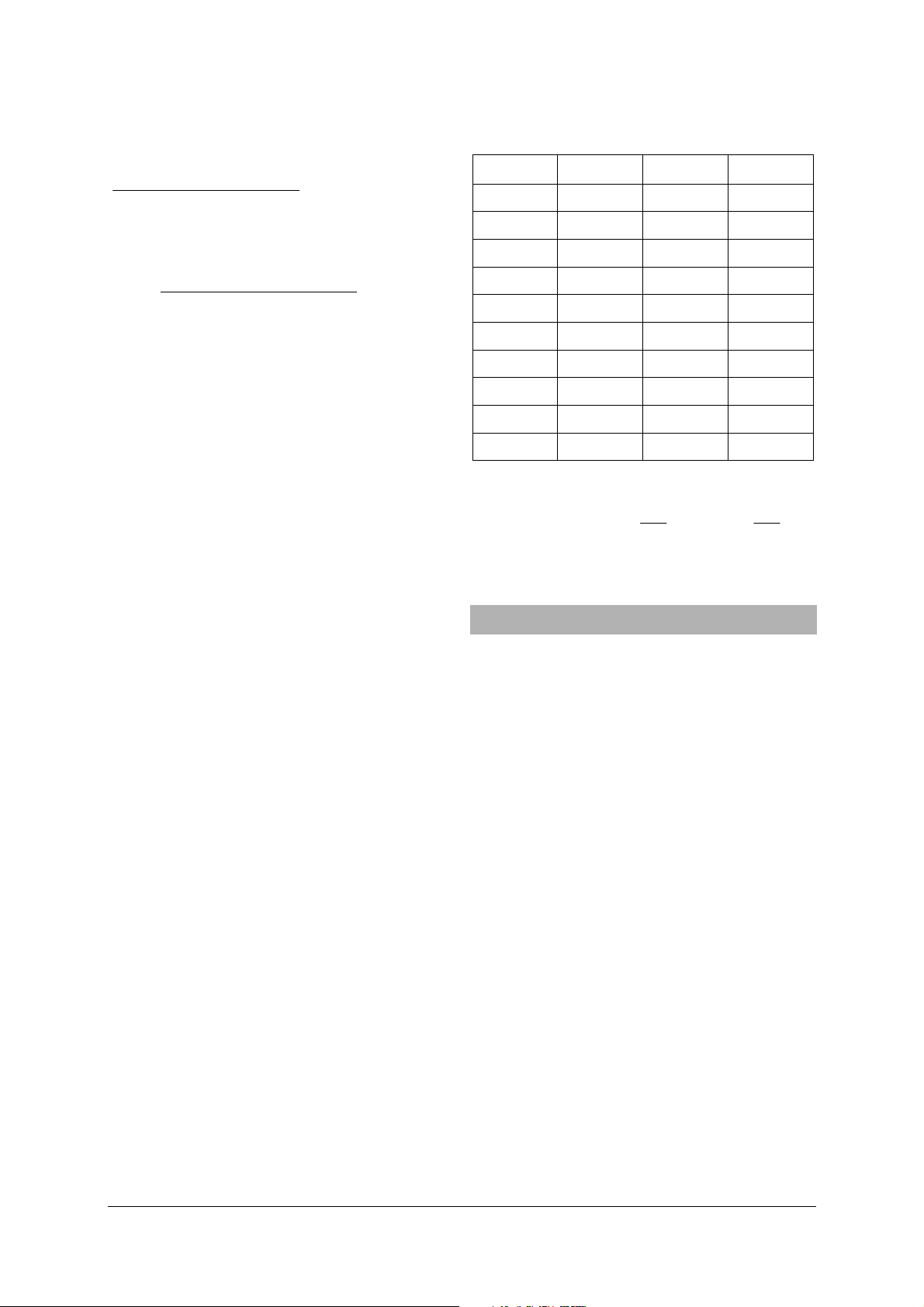

8.6 Evaluation:

We can clearly see from Fig. 5 that, despite the relatively simple equipment, it is possible to achieve

measurements which match closely to the reference

values plotted on the graph.

8.7 Bibliography:

[1, 2] Sulphur Hexafluoride, in-house publication,

pp. 27 [1], 30 [2], Solvay Fluor und Derivate GmbH,

Hannover, Germany, 2000

[3] Otto and Thomas: Landolt-Börnstein – Numerical

Data and Functional Relationships in Science and

Technology, Vol. II, Section 1, Springer-Verlag, Berlin,

1971

[4] Clegg et al.: Landolt-Börnstein – Numerical Data

and Functional Relationships in Science and Technology, Vol. II, Section 1, Springer-Verlag, Berlin, 1971.

[5] Din, F.: Thermodynamic Functions of Gases, Vol. 2,

Butterworths Scientific Publications, London, 1956

[6] Vargaftik, N.B.: Handbook of Physical Properties of

Liquids and Gases, 2

nd

ed., Hemisphere Publishing

Corporation, Washington, 1983

[7] Nelder, J. and Mead, R.: Comp. J., Vol. 7, p. 308,

1965

9. Storage for long periods without use

If no experiments are to be conducted over a long

period, the test gas should be released and the piston

should be turned to its rest position where the conical

seal is only very slightly curled and does not press

against the walls of the measuring cell.

• If necessary, allow the equipment to cool. Wind

the handwheel back till the lowest possible pressure is present.

• Release the test gas through the flush valve.

• Turn the handwheel to move the piston to its

“rest position”, at approx. 5 mm.

• Shut the flush valve again.

• Before storing away the equipment, the hydraulic

fluid needs to be degassed (as described in chapter 10) if the equipment has been in use over a

long period of time.

• Store the equipment in a safe place where it is

not exposed to direct sunlight.

• The thermal medium should be kept in the appa-

ratus during storage, as the additives inhibit corrosion and efflorescence caused by electrochemical potentials between the different materials. Alternatively, the apparatus can be flushed with deionised water and then dried using compressed

air (oil-free, max. 1.1 bar).

8

Page 9

1

p

/ MPa

5

4

3

2

1

0

0

Fig. 5: p-V diagram of SF6, measured with the critical point apparatus:

Readings taken at 10°C (

(

Reference values from [2] for pressure of liquid at 10°C (

and 50°C (

246 81012

V

/ ml g

), 20°C ( ), 30°C ( ), 40°C ( ), 45°C ( ) and 50°C ( ),

) threshold value of liquid-gas mixture, ( ) Reference values from [1] for vapour pressure,

), 20°C ( ), 30°C ( ), 40°C ( )

)

9

-

Page 10

10. Degassing the hydraulic fluid

Owing to the inevitable diffusion of the test gas

through the conical seal, the pressure in the measuring cell slowly decreases over a long period. The gas

diffusing through the conical seal first dissolves in the

hydraulic fluid but does not have any significant influence on the measurements.

However, if the test gas is removed from the equipment (for storage of the equipment) and the pressure

of the hydraulic fluid consequently falls to the ambient pressure, then the test gas will escape from the

hydraulic fluid due to Henry's law. This leads to a

gradual increase in pressure in the oil chamber which

must be avoided at all costs as there is no back pressure in the measuring cell. On account of this, it is

necessary to cleanse the hydraulic fluid of all gas

before storing the equipment.

To degas the hydraulic fluid, the oil is made to boil in

a vacuum. Since the pressure difference on both sides

of the conical seal should not exceed a particular

limit, it is necessary to maintain, as best as possible,

the existing underpressure constant on the gas side.

Additionally required:

1 Castor oil approved for medicinal use e.g. 1002671

1 Vacuum tube, 6 mm internal diameter

1 Stopcock (or variable-leak valve)

1 Vane-type rotary pump

1 Open-end spanner (14 mm), 1 pair of tweezers

Absorbent paper, cardboard box

Storage of the equipment:

• If necessary, allow the equipment to cool. Wind

the handwheel back till the lowest possible is present.

• Release the test gas through the flush valve and

shut the flush valve thereafter.

• If necessary, remove the gas supply pipe and

attach the gas connection fittings.

• Unscrew the vernier scale.

• Open the regulating valve.

• Wind the handwheel so that piston moves in till

an excess pressure of 1 bar has been attained.

• Shut the regulating valve.

• Wind the handwheel back by two turns.

• Place the equipment with the manometer facing

downwards towards the ground). The manometer

should rest on a support approx. 6-cm-thick (see

Fig. 6).

Caution: the piston should never be wound out to

more than 25 mm, since the guide tube may slip out

during subsequent operations.

Fig. 6: Storage of the equipment for oil filling

c, d

e

d

c

Fig. 7: Dismantling the safety valve

(c) counter nut, (d) valve cap, (e) compression spring,

(f) hexagonal piston, (g) steel ball bearing

f

g

Dismantling the safety valve:

• Loosen the counter nut (14 mm) and use a screw-

driver to remove the valve cap (see Fig. 7).

• Remove the compression spring, the hexagonal

piston and the steel ball bearing in succession

with a pair of tweezers and store them in a safe

place, for instance in a cardboard box.

Assembly of the oil filling device:

• Loosen the valve nut of the oil filling device, re-

move the cover and place the valve nut above the

safety valve (see Fig. 8).

• Do not screw the oil filling device on too tight (the

gasket ring should not be squeezed out).

• Open the regulating valve.

• Wind the handwheel inwards to its end position

up to the frame (if necessary, loosen the vernier

scale). Subsequently wind the handwheel out by 3

turns.

• Place absorbent paper underneath and fill the oil

container with castor oil to no more than half

way.

• Screw on the cover of the oil filling device with

the valve nut.

Connection of vacuum pump:

• Connect a plastic hose with 3 mm internal diame-

ter to the gas connection fittings of the equipment and the smaller connector of the oil filling

device.

10

Page 11

k

l

• In order to connect the vacuum pump, take a

vacuum hose with 6 mm internal diameter and

connect it via a stopcock or preferably via a threeway valve to the larger connector of the oil filling

device.

i

h

Fig. 8: Assembly of the oil filling device and connection of

vacuum pump (h) oil container, (i) valve nut,

(k) cover, (l) stopcock (or variable-leak valve)

Degassing:

• Check whether the regulating valve is open and

the flush valve is shut.

• Switch on the vacuum pump. Open the stopcock a

little and observe the formation of bubbles in the

castor oil.

Close the stopcock to interrupt the evacuation process

if the formation of bubbles is so strong that they can

reach the filter that is mounted on the cover. The

stopcock may be opened only after the bubbling has

subsided.

After several minutes (depending on the suction capacity of the connected vacuum pump), the vaporising pressure of the castor oil is attained and the oil

begins to boil. This can be noticed when vapour bubbles begin to form “out of the blue” and rapidly become larger in size as they move through the oil.

The oil is now is sufficiently degassed.

• Shut the regulating valve and the stopcock.

Dismantling:

• Pull out the vacuum hose from the stopcock (the

hose fitting with the stopcock continues to remain on the oil filling device).

• To avoid any surges, slowly open the stopcock

and wait for the pressure to even out.

• Pull out the hoses from both of the connectors on

the oil filling device.

• Unscrew the container from the safety valve.

Since castor oil is relatively viscous, it trickles out of

the container very slowly. Thus, this step can be conducted easily. A cleaning cloth (or kitchen paper)

which is held below the container immediately after

unscrewing it prevents any drops forming.

• With a cleaning cloth, remove excess oil from the

safety valve and subsequently wind the handwheel inwards very slightly till the oil level in the

valve is exactly at the same level as the edge

where the steel ball bearing sits.

• Insert the steel ball bearing, position the hexago-

nal piston with the short bore onto the ball bearing (use tweezers for this) and insert the compression spring into the longer bore.

• Carefully screw the valve cap on in its end posi-

tion (not too tight) and loosen it by two turns.

Positioning the safety valve:

• Set-up the equipment and place it in a way that

the safety valve does not point in the direction of

people who could get injured or objects which

could get damaged.

• Open the regulating valve. Wind the handwheel

fully out and shut the regulating valve again.

• Turn the handwheel in till an excess pressure of

approx. 65 bar has been attained.

• From the front, wrap your arms around the appa-

ratus to reach the safety valve located at the back.

Slowly unscrew the valve cap of the safety valve

till the pressure drops to approx. 63 bar.

• Tighten the counter nut (14 mm).

Rest position:

• Wind the handwheel back till the pressure has

dropped to max. 10 bar.

• Open the regulating valve and turn the hand-

wheel to its “rest position” at approx. 5 mm.

• Shut the regulating valve.

After completing these steps, the equipment can

either be stored or refilled with test gas.

11. Upkeep and maintenance of threaded bush

11.1 Lubricating the threaded bush

To minimise wear, the threaded bush in the frame

should be lubricated approximately every 100 cycles

(one cycle = a pressure increase from 10 to 60 bar and

the subsequent reduction to 10 bar), or once weekly.

Lubrication only takes about 1 min and extends the

service life of the bush significantly. For lubrication, a

light-coloured multi-purpose grease with no graphite

or similar additives is recommended.

Procedure:

• Inject one full stroke of lubricant from a conven-

tional grease gun into the threaded bush through

the nipple at the frame.

• Wipe up any surplus lubricant emerging from the

bush.

When it emerges, the lubricant will also pick up any

traces of plastic that might have worn off during operation, so that will be flushed out too.

11

Page 12

11.2 Examine threaded bush.

The threaded bush in the frame is subject to slow but

constant wear, and therefore the axial play must be

checked once a year:

• Release the pressure from the measuring cell and

adjust the piston to the 10 mm position.

• Using a vernier caliper, determine the minimum

and maximum distance between the handwheel

flange and frame; to do so, first wind in the

handwheel and then wind it out.

If the two distances differ by more than 0.3 mm, then

the bush needs to be replaced.

11.3 Replacing the threaded bush

Additionally required:

1 Threaded bush from set of seals (1002672)

The threaded bush is to be replaced no later than

every ten years even if the limit of wear has not been

reached (tests on a rig failed to produce any measurable wear [<0.05 mm] after 1000 cycles), because

reliable data on the long-term stability of the plastic

used (POM-C) are not yet available.

• Depressurise the measuring cell.

• Unscrew the fixed scale.

• Undo the grub screw of the handwheel flange and

remove handwheel.

• Loosen the four screws in the cross piece of the

frame and remove it along with the threaded

bush by winding it down the axle.

• Unscrew the lubricating nipple (size SW 7) and use

a 3-mm Allen key to loosen the threaded pin

screwed in across the threaded bush by 4 turns.

• Knock the threaded bush out from the side of the

handwheel using a suitable mandrel. Alternatively insert an M14 screw loosely into the bush

and force the bush by hitting the head of the

screw.

• Fit the new bush such that the cross piece is

aligned with the lubrication nipple.

• Clamp the bush in a vice (with flat jaws or suit-

able insert).

• Screw back in the threaded pin (min. 6.0 mm

countersunk) and the lubricating nipple.

Bush material: POM-C = Polyoxymethylene copolymer

Oversize (press fit): 0.05 – 0.1 mm.

12. Changing the seals

Additionally required:

1 Allen key (6 mm)

1 Set of seals for critical point apparatus 1002672

consisting of

1 Conical seal,

1 Circular grommet,

1 Grommet 78x78 mm

2

,

4 Copper gasket washers

1 Threaded bush

After a certain period of time, it may be necessary to

replace the conical seal or other seals, especially if the

equipment has been exposed to direct sunlight.

12.1 Dismantling the equipment:

• If necessary, allow the equipment to cool and

wind the handwheel back till the lowest possible

pressure is present.

• Release the test gas through the flush valve and

shut the flush valve.

• If necessary, dismantle the tubing.

• Open the regulating valve.

• Wind the handwheel back till it has come to a

position of 25 mm.

• Tilt the equipment to the right and place it in an

upright position on a suitable surface resting on

the handwheel and the edge of the equipment

base.

• Use the Allen key (6 mm) to uniformly loosen

each of the four screws in the valve plate by 1/8

of a turn till the tension has been reduced.

• Unscrew and remove the screws.

• Also remove the copper gasket washers.

• With increasing force, twist the valve plate to the

left and right till the seals have been loosened.

Do not twist the regulating valve.

• Remove the valve plate (the measuring cell might

still be sticking to the plate).

• Twisting the equipment some more to loosen the

remaining seals between the measuring cell and

the cylinder and between the measuring cell and

the valve plate.

• Twist the guide tube to remove it from the coni-

cal seal.

12.2 Cleaning the dismantled equipment:

Castor oil can be removed quite easily by using white

spirit. However, white spirit attacks the acrylic of the

casing and measuring cell. Use a (mild) washing-up

liquid solution to remove greasy finger marks and

other impurities. New seals too should be cleaned

with white spirit and a washing-up liquid.

12

Page 13

12.3 Assembling the equipment:

In case castor oil had been removed from the oil

chamber:

• Pour a fresh quantity of castor oil in up to about

5 mm below the upper edge of the cylinder (at

the beginning of the depression).

• Insert both of the silicone seals.

• Turn the conical seal inside out and dampen the

stud with some castor oil then screw it into the

guide tube.

• Unfold the conical seal back to its original shape,

position the spring on the piston and insert the

guide tube into the piston.

• Mount the measuring cell and position it flush

along the edges of the cylinder.

• Place the heat casing at the centre of the lower

silicone seal.

• Fit the circular grommet and, with the help of a

ruler placed on the heat casing, position it parallel to the cylinder (see Fig. 9, the semicircular

holes should then be below the valve openings).

Fig. 9: Positioning the circular grommet

• Place the valve plate at the centre and position it

parallel to the end plate.

• Fit the M8×40 screws with new copper gasket

washers and loosely screw them in.

• Tighten the screws. Take care to ensure that there

is uniform pressure on the circular grommet (if

the pressure is too high, the grommet makes a

greyish mark on the transparent acrylic, whereas

if the pressure is lower the surface looks milky).

12.4 Recommissioning:

• Degas the hydraulic fluid and pour the oil into

the equipment (see chapter 10).

• Position the safety valve (see chapter 10).

• Conduct a fresh volume calibration (see chap-

ter 6).

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2013 3B Scientific GmbH

Page 14

Loading...

Loading...