Page 1

3B SCIENTIFIC

®

PHYSICS

Control Unit for Critical Potential Tubes (1 15 V, 50/60 Hz)

Control Unit for Critical Potential Tubes (230 V, 50/60 Hz)

1000633 (115 V, 50/60 Hz)

1008506 (230 V, 50/60 Hz)

Instruction manual

01/14 ALF

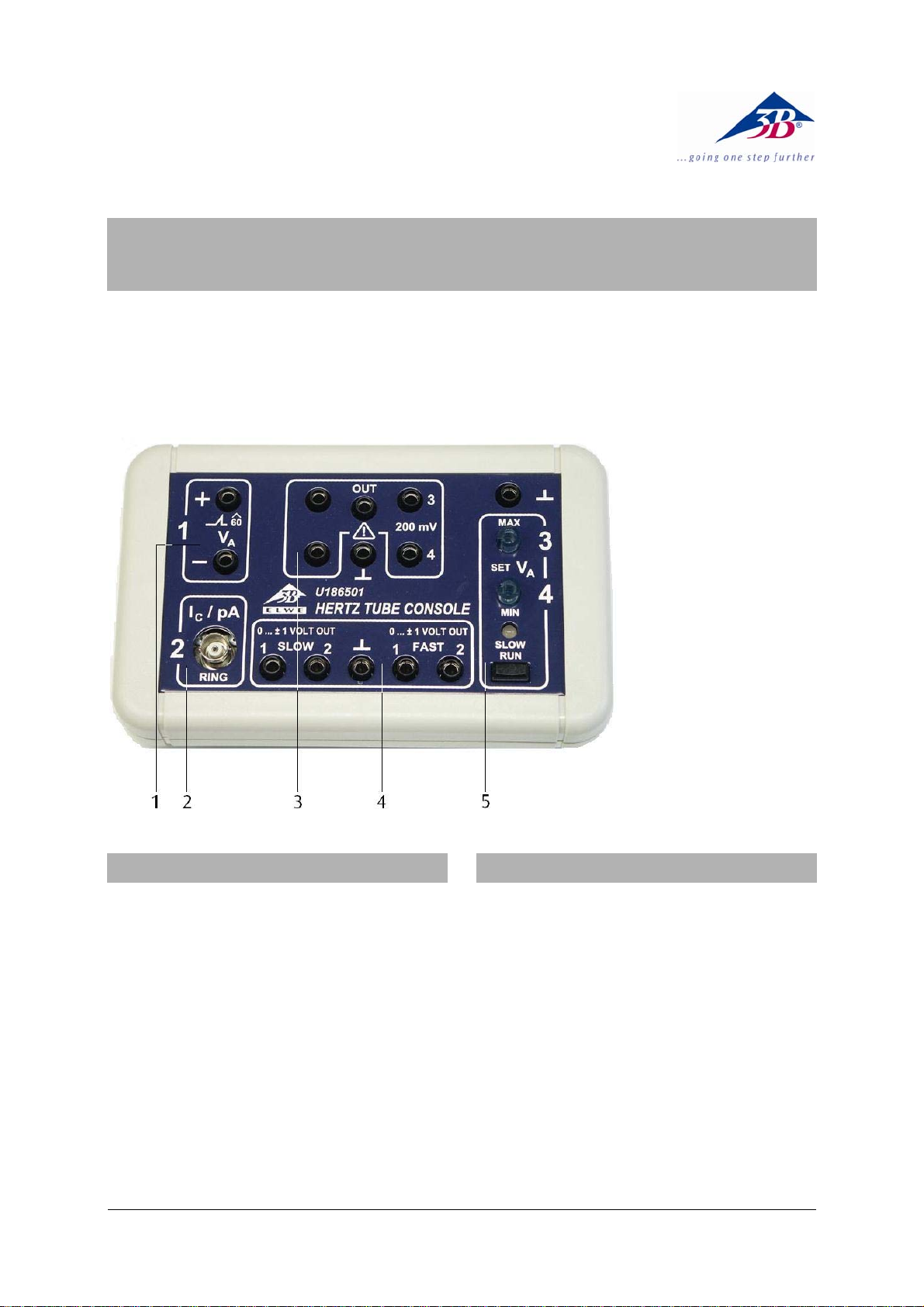

1 Output for accelerating

voltage

2 Input for picoamp ampli-

fier

3 Terminal panel for mul-

timeter

4 Terminal panel for oscil-

loscope or data logger

5 Output voltage control

panel

1. Safety instructions

The control unit for critical potential tubes conforms to the safety stipulations for electrical

measuring, control and laboratory instruments

as specified in DIN EN 61010 part 1. It is intended for use in dry rooms suitable for the operation of electrical equipment.

Safe operation of the equipment can be assured

as long as it is used as stipulated. However,

safety cannot be guaranteed if the equipment is

used incorrectly or handled without due care

and attention.

If it may be assumed that the equipment may no

longer be operated safely (e.g. in the event of

visible damage), it must be taken out of use

immediately.

2. Description

The control unit is designed for the operation of

S-series critical potential tubes filled with helium

(1000620) or neon (1000621).

The equipment outputs a saw-tooth waveform

with a frequency of 20 Hz to be used as the

accelerating voltage at the anode of such tubes.

This voltage is galvanically isolated from the

operational earth of the device. This means that

an additional voltage supply of the user’s choice,

such as a battery, can also be connected between the anode and the collector electrode.

The initial and final voltages of the saw-tooth

generator can be adjusted continuously between

0 and 60 V. This makes it possible to observe a

specific section of the curve more accurately.

With the help of the built-in picoamp amplifier, it

1

Page 2

is possible to trace the curve for the collector

current on an oscilloscope. The in-built SLOW

function allowing for a lower frequency (1/6 Hz

approx.) enables recording of this characteristic

with the aid of a slower measuring interface or

an XY plotter.

The equipment with the order number 1000633

includes a plug-in power supply for a mains voltage of 115 V (±10%), whereas the one with order

number 1008506 includes one for 230 V (±10%).

2. Controls

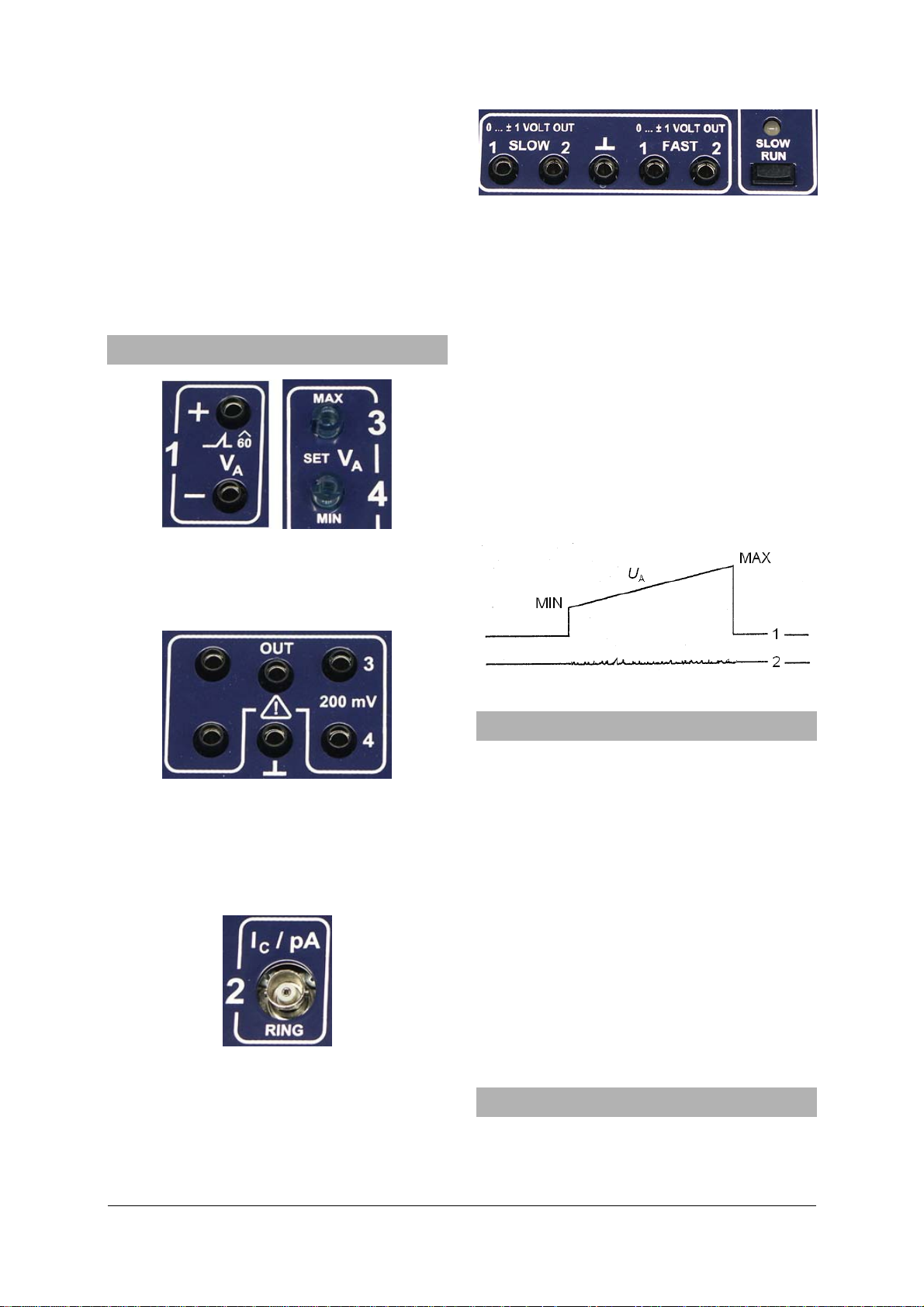

Output 1 is designed to supply the saw-tooth

accelerating voltage V

. The initial voltage is set

A

using knob 4 and the final voltage is set via knob

3.

To display the collector current as a function of

the accelerating voltage, the XY mode of the

oscilloscope can be used. You can record the

relevant voltages at 20 Hz by connecting the

scope to the FAST output.

The SLOW output allows values to be output at

lower frequency using a slow interface or an XY

plotter. The output is provided by means of a

built-in sampling method by pressing the SLOW

RUN button.

When the SLOW function is activated the LED

will light up in green. When it finishes, the LED

will turn back to red.

In both cases, the output for the saw-tooth voltage is taken from socket 1 (Y deflection) and the

output from the measuring amplifier is from output 2 (X deflection).

To set the desired parameters for the saw-tooth

voltage, a multimeter can be connected into

circuit. The voltage measured between socket 3

and ground (V

MIN) is smaller than the actual voltage by a

(V

A

MAX) or socket 4 and ground

A

factor of 1000.

The collector current I

(pA) is fed to the equip-

C

ment via socket 2 (BNC socket). When amplified

by the built-in picoamp amplifier, the current can

be measured via the terminals of an oscilloscope/data logger in the form of an equivalent

voltage (1 V/nA).

3. Technical data

Supply voltage: 12 V AC

Current measurement: 1 V/nA, BNC

Output voltage: 0 - 60 V/20 Hz, saw-

tooth

Measurement output: Socket 1: 0 - 1 V, pro-

portional to output voltage

Socket 2: 0 - 1 V, pro-

portional to collector

current I

C

Operating modes: FAST: measurement

output 20 Hz

SLOW: measurement

output 1/6 Hz

Dimensions: 170x105x45 mm approx.

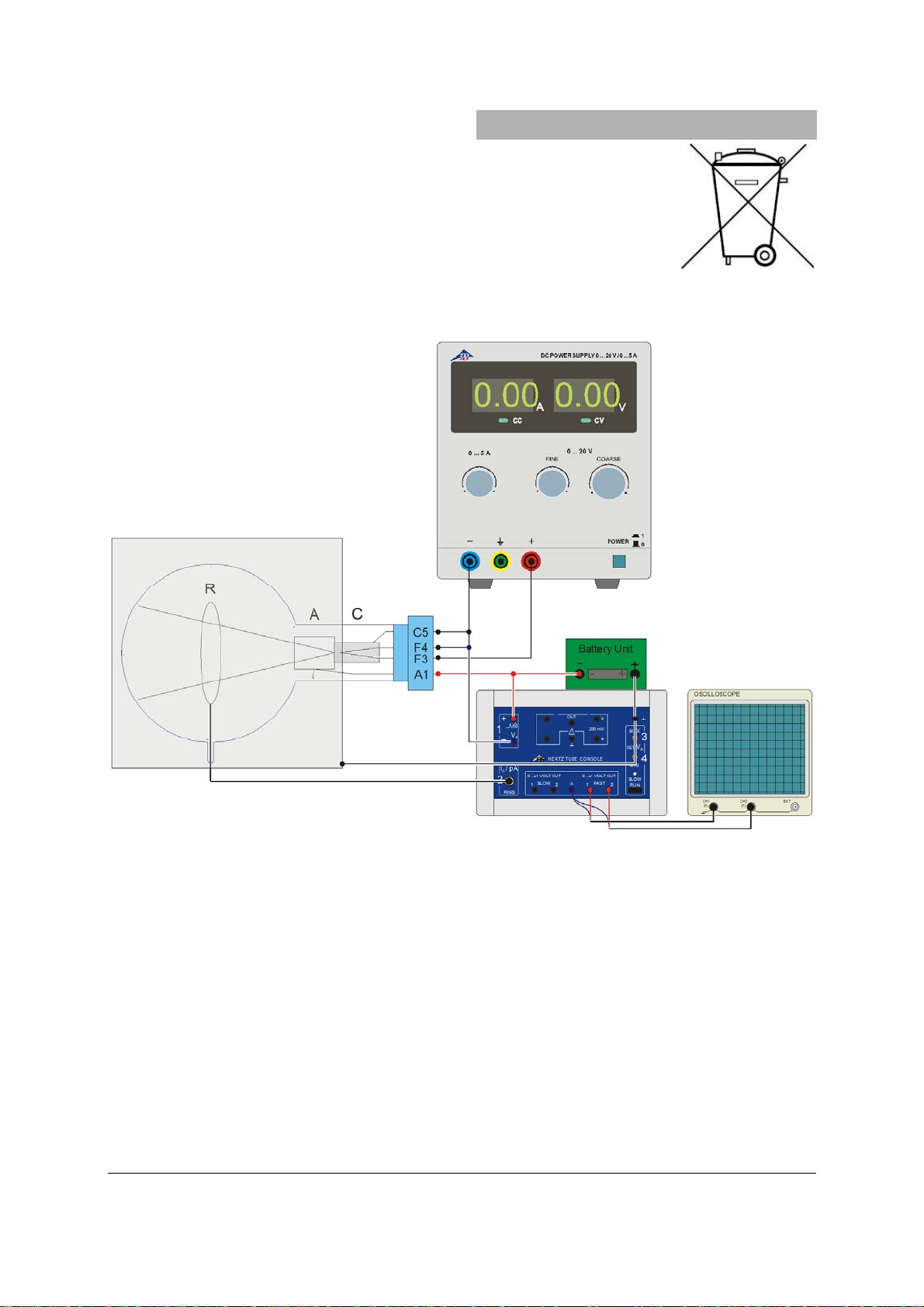

4. Operation

• Connect the control unit to its plug-in power

supply. The socket for it is on the base of

the equipment.

2

Page 3

•

f

Connect the control unit into the circuit for

the critical potential tube.

• In order to set up and carry out the critical

potential tube experiments correctly, read

the tube’s instruction manual first.

• Plug the power supply into the mains. The

LED will light up in red.

5. Disposal

• Should the equipment

need to be scrapped, it

must not be disposed o

in normal household

waste. Local regulations

for the disposal of electrical equipment should

be observed.

Fig. 1 Circuit for critical potential tube

3B Scientific GmbH ▪ Rudorffweg 8 ▪ 21031 Hamburg ▪ Germany ▪ www.3bscientific.com

Subject to technical amendments

© Copyright 2014 3B Scientific GmbH

Page 4

Loading...

Loading...