Page 1

3B SCIENTIFIC® PHYSICS

5g Accelerometer U11363

Instruction sheet

07/07 Hh

1. Safety instructions

• Never exceed the maximum acceleration of

1500 times gravitational acceleration in any direction, to avoid permanent damage to the

semiconductor built into the small black box!

• The maximum height from which the sensor

can survive dropping onto a hard surface is 1.2

m.

• Only use the accelerometer 5-g for educational

purposes!

The 5g accelerometer is not suitable for safetyrelated applications.

2. Description

Sensor box with permanently connected semiconductor acceleration sensor, Z-axis sensitive, for the

measurement of gravity and the general acceleration of masses up to ±5 x g.

The effective axis (Z-axis) is marked with an arrow

and the label “Earth’s Gravity Field” on the acceleration sensor.

“Capacitive" method of measurement (g-cell) with

built-in signal linearisation, low-pass filtering,

temperature compensation and automatic self-test.

The sensor box is automatically detected by the 3B

TM

NETlab

1 Sensor box with permanently connected accel-

1 Velcro strip, 500 mm long, 20 mm wide, self-

1 8-pin miniDIN connecting lead, 60 cm length

1 Instruction sheet for U11363

interface.

3. Scope of delivery

eration sensor, cable length 2 m.

adhesive

1

Page 2

4. Technical data

Measurement range: 0 to ±50 m/s²

Sensor type: Capacitive semiconduc-

tor sensor

Sensitivity: Typically 400mV/g

Non-linearity: No more than ±1% of

the full measurement

range.

Resolution: 0.03 m/s²

Band width: typically 50 Hz

Drill hole for sensor

attachment: 3 mm diam. max.

5. Operation

• Place the sensor box alongside the experiment

and attach the acceleration sensor (small black

box) to the mass to be investigated (target). Use

the supplied Velcro strip or a clamp for this

purpose.

• Read the value of the acceleration from the

display on the 3B NETlog

TM

unit.

• Run the 3B NETlab

TM

software with the appropriate template for the experiment using the

5g accelerometer.

• Attach the acceleration sensor to the weight

with a piece of Velcro.

• Suspend the weight and acceleration sensor

from the eye at the bottom of the coil spring

and be careful not to hinder the oscillating

motion.

• Drape the connecting lead for the acceleration

sensor over the universal clamp, as shown in

Fig. 1. This adds further to the damping.

• Pull down the weight by hand to the level of

the stand base and release it.

• Start recording the measurement data in 3B

• Analyse the recorded chart.

NETlab

TM

(Fig. 2).

6. Applications

Demonstration track and air track experiments:

Downward acceleration

Elastic and non-elastic impact

Oscillating spring-mass system

High-resolution measurement of objects’ inclina-

tion

Pendulum oscillations

Jumping experiments; “bungee jumping”

7. Sample experiment

Acceleration measurement in a damped oscillating spring-mass system

Required equipment:

1 3B NETlog

1 3B NETlab

TM

interface U11300

TM

software program U11310

1 5-g accelerometer U11363

1 Stand base U13270

1 Stand rod, 750 mm length U15003

1 Stand rod, 250 mm length U15001

2 Universal clamps U13255

1 Coil spring 3 N/m U15027

1 Weight 100 g, from U30016

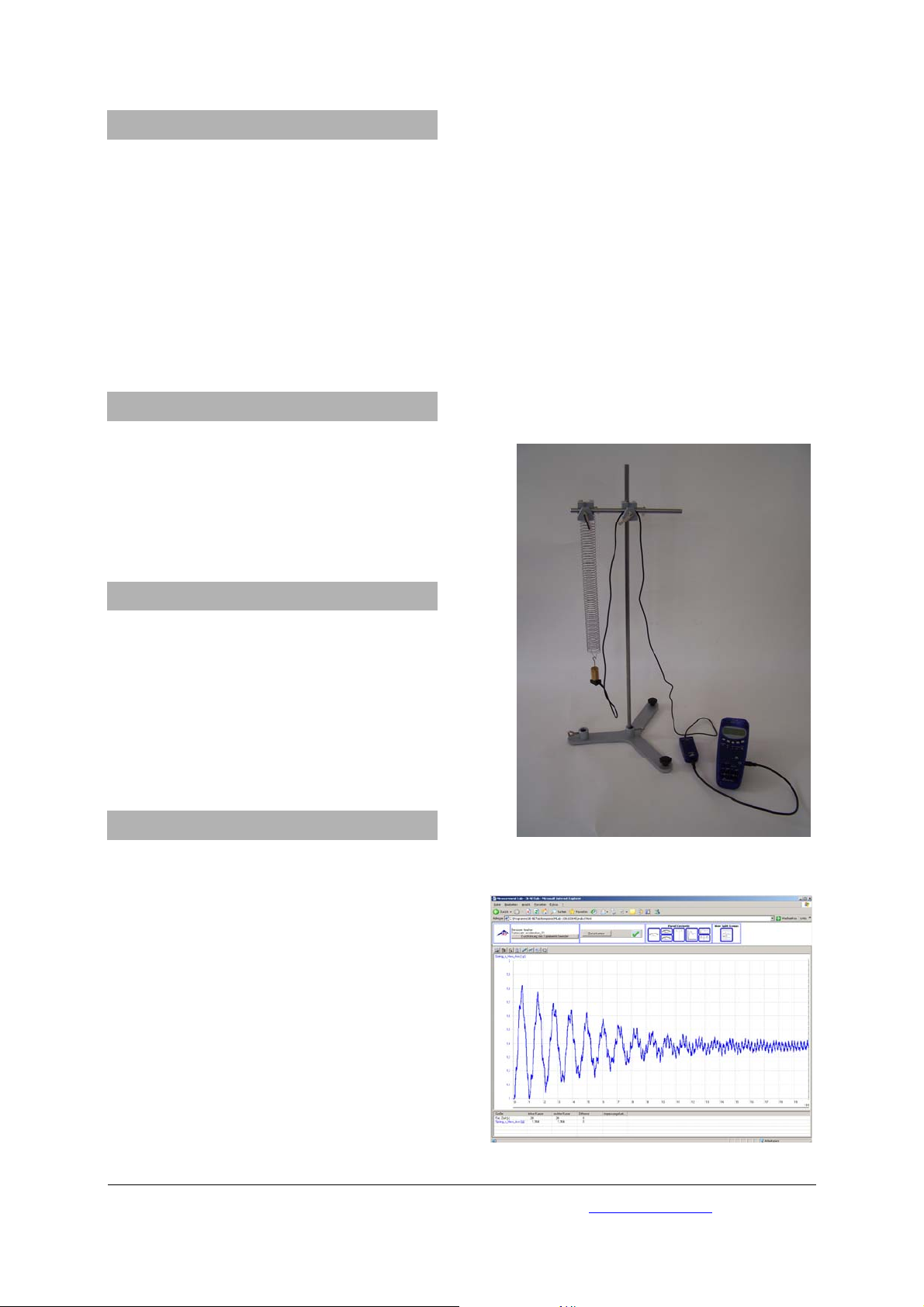

• Set up the equipment for the experiment as in

Fig. 1.

Fig. 1 Acceleration measurement for a damped oscilla-

tion of a mass on a spring

Fig. 2 Monitor display of the damped oscillation of a

mass on a spring in 3B NET

labTM (U11310)

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2007 3B Scientific GmbH

Loading...

Loading...