Zund M-1600, L-3200, L-2500, XL-3200, 2XL-1600 Operating Manual

...

Digital flatbed cutter

G3 series

(M-1600, M-2500, L-2500, L-3200, XL-1600, XL-3200, 2XL-1600, 2XL-3200, 3XL-1600, 3XL-3200)

Operating manual

EN

Original operating instructions

Author Technical Communications

Department, Zünd Systemtechnik AG

Composition and publication Zünd Systemtechnik AG

Copyright

©

Version:

Menu version:

Date:

Doc. no.:

Zünd Systemtechnik AG

09

1.45

05-2010

5106015

G3 series

0

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Using the documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Structure of the operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Points to note when reading this operating manual . . . . . . . . . . . . . . . . . . 4

1.4 Care of the documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Current status of documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Standardisation, tests, marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6.2 CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6.3 UL testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7 Legal notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 Troubleshooting, hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.9 Documented cutter models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.10 Publishing details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2.1 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2.2 UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4 Cutter - overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Modules, tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.2 UM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.2.1

2.5.3 RM-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.4 PUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.5 MAM-S/D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Material handling, options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.1 Laser pointer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.2 ICC camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.3 Cutter with static work surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.4 Cutter with conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.5 Sheet feeder options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.6 Drip tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7.1 Complete machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7.2 Schedule of work sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7.3 Complete machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.4 Movement system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7.5 Processing materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.8 Technical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.8.1 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.8.1.1

2.8.1.2

2.8.2 Electrical connection, power consumption . . . . . . . . . . . . . . . . . . . . . . . . 19

Tools for the UM

Basic device

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cutter extension

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

000017,03,06-2009, jmu

0-1

0

G3 series

2.8.3 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.8.4 Basic device compressed air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.8.5 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.8.6 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.8.7 Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.8.8 FCC approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.3 Examples of improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.4 Hazard warnings, important instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4.1 Explanation of the hazard warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4.2 Structure of the hazard warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.5 Areas of responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.6 Personnel requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.7 Rules and safety at work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.8 Procedure in case of malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.9 Danger areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.9.1 General danger area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.9.2 Danger area on the module carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.9.3 Danger area during the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.10 Working and traffic area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.11 Safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.11.1 Responsibility of the operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.11.2 Position of the safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.12 Safety and monitoring devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.12.1 Protective system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.12.2 Operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.12.3 Emergency stop switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.12.4 Safety cut-off feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.13 Personal protective equipment, clothing . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.14 Mechanical hazards . . . . . . . . . . . . . . . . . . . . . .

3.14.1 Gathering, retraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.14.2 Gathering, impacts of foreign objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.14.3 Cuts and stab wounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.15 Risk of burns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.16 Electrical hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.17 Risks arising from the emission of toxic dust . . . . . . . . . . . . . . . . . . . . . . 21

3.18 Risks arising from the processing of toxic/hazardous materials . . . . . . . . 21

3.19 Environmental hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.20 Handling and storage of chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.21 Risk of fire and explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.22 Danger caused by laser beam (laser pointer) . . . . . . . . . . . . . . . . . . . . . . 25

3.23 Safety instructions for operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.24 Safety precautions for service personnel . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.25 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . 18

0-2

000017,03,06-2009, jmu

G3 series

4 Controls and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.2 Safe working practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.3 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4.3.1 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4.3.1.1

4.3.1.2

4.3.1.3

4.3.1.4

4.3.1.5

4.3.1.6

4.3.1.7

4.3.2 Emergency stop switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.3 Maintenance unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3.4 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Menu navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4.1 Menus and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4.2 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4.3 Info menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4.4 Popups/dialogues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4.5 User level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4.6 Function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5.1 Set language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5.2 Set display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5.3 Setting the volume of the signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5.4 Delete data buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6.1 Daily checks prior to start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6.3 Operating status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.3.1

4.6.3.2

4.6.3.3

4.6.4 Moving the bar/module manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7 Handling modules/tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7.1 Module/tool/tool insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7.2 Set module/tool change position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.7.3 Inserting/replacing the module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.7.3.1

4.7.3.2

4.7.4 Activating a module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.7.5 Tool handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.7.5.1

4.7.5.2

4.7.5.3

4.7.6 Attaching/selecting a tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.7.6.1

4.7.6.2

4.7.6.3

Operating unit

Navigation keys

Numerical keys

Function keys

Travel keys

Soft keys

Special keys, shortcuts

OFFLINE

STOPPED

ONLINE

Module mount

Inserting/replacing the module (e.g. UM)

Marking the tool (e.g.)

Switching the tool manager on/off

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Tool manager — change tool (UM module)

Creating a new tool

Selecting a tool

Deleting a tool

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . 31

0

000017,03,06-2009, jmu

0-3

0

G3 series

4.7.6.4

4.7.7 Inserting and connecting a tool (e.g. oscillating tool) . . . . . . . . . . . . . . . . 33

4.7.8 Connecting driven tools - allocating port . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.7.8.1

4.7.8.2

4.7.9 Tool positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.8 Material hold-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.8.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.8.2 Defining/checking the vacuum range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.8.3 Setting the strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.8.4 Switching on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.8.5 Working with air-permeable materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.9 Feeding options* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.9.1 Feeding clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.9.2 Feed guide rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.9.3 Feeding options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.9.3.1

4.9.3.2

4.10 Automatic tool initialisation (AKI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.10.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.10.2 Adjusting the height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.10.3 Initialisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.11 Laser pointer, reference point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.11.1 Laser pointer settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.11.2 Reference point settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.11.3 Choose laser pointer as pointer type . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.11.4 Define reference point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.12 Material stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.13 Module carriage slot protective plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.14 Module and tool holder* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.15 Switch off the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Saving tool-specific cutter settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connection - electrical tools (EOT, DRT, etc.)

Connection - pneumatic tools

Automatic feed

Manual feed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . 35

5 Description of menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5.2 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5.3 Description of menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6.2 Locate error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6.2.1 Error display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6.2.2 Error code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.3 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

0-4

000017,03,06-2009, jmu

G3 series

7 Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7.2 Safe maintenance of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7.3 Operating resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7.3.1 Handling operating materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7.3.2 Cleaning fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.3.3 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.3.4 Adhesives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.4 Steps for maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7.5 Lubrication diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.6 Accessories case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.7 Maintenance jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.7.1 Service flaps and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.7.2 Maintenance position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.7.3 Visually inspect the machine for damage . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.7.4 Clean the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.7.5 Clean X axis guide rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.7.6 Oil X axis guide bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.7.7 Cleaning/oiling Y axis guide rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.7.8 Lubricating the Y axis bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.7.9 Clean the chipping protection brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.7.10 Cleaning the feeding clamps/feed guide rail . . . . . . . . . . . . . . . . . . . . . . . 23

7.7.11 Draining the maintenance unit condensation water . . . . . . . . . . . . . . . . . 24

7.7.12 Automatic circuit breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.7.13 Conveyor belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.7.13.1

7.7.13.2

7.7.13.3

7.8 Instructions for disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.9 Starting up after periods at a standstill . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.9.1 Vacuum generator 1-9 KW/1-15 KW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removing the conveyor belt

Removing the covers

Fitting a conveyor belt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

0

8 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

10 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

11 Material handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12 Additional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

13 Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

14 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

000017,03,06-2009, jmu

0-5

0

G3 series

0-6

000017,03,06-2009, jmu

G3 series Introduction

Foreword

1 Introduction

Zünd Systemtechnik AG

Altstätten, Switzerland

1

1.1 Foreword

Dear customer,

By purchasing our product you are participating in the worldwide success of Zünd

cutter systems.

The modular design of our systems ensures:

• A system solution that is suited to your individual requirements in terms of speed

and quality

• The availability of the most up-to-date technology thanks to constant developments

Our approach

Constant and intensive cooperation with successful users is a prerequisite for

innovative and practical solutions. We are therefore grateful for any comments or

suggestions on how we can improve.

Contact

Zünd Systemtechnik AG Industriestrasse 8 CH - 9450 Altstätten

Tel. ++41 71-757 8181

Fax ++41 71-757 8191

Email

www zund.com

info@zund.com

000009,06,11-2009, jmu

1-1

1

Introduction G3 series

Using the documentation

1.2 Using the documentation

The instruction handbook supplied is intended to help you to:

– Operate the machine safely

– Perform routine machine maintenance

– Use the machine optimally in all permitted areas

To do this, you need to be able to find what you want within the documentation.

The instruction handbook comprises:

Volume 1 - Operating manual

This volume contains information on the engineering, installation, operation and

maintenance of the basic machine.

The technical documentation for the service personnel is contained in volumes 2 and

3:

Volume 2 - Service manual *

This volume contains information on the structure of the machine and on servicing

by authorised service personnel

Volume 3 - Spare parts catalogue * (See Zünd homepage)

1.2.1 Structure of the operating manual

The operating manual consists of individual, consecutively numbered chapters.

These sections are arranged according to the ring binder tabs.

The table of contents provides information on the structure of the individual chapters.

The numbers of pages and certain large graphics are prefixed with the number of the

relevant chapter. Page number "2-10", for example, means the tenth page of chapter

2 "Product description".

1-2

000009,06,11-2009, jmu

G3 series Introduction

Using the documentation

1.2.2 Symbols

Illustration

Close, fix, tighten, in

Open, release, loosen, out

Higher

1

Lower

Text structuring

Task: Steps to perform

Result: Outcome of the tasks performed.

Prerequisites for performing a task

List of tools

Optional accessories

There are a number of optional accessories available for the machine. Any

description relating to an optional accessory is identified in the operating manual by

the * symbol.

000009,06,11-2009, jmu

1-3

1

Introduction G3 series

Points to note when reading this operating manual

1.3 Points to note when reading this operating manual

Text references

Chapter headings are numbered consecutively, with the first figure corresponding to

the chapter number. Where reference is made to sections outside the current

chapter, note the first figure and turn to the corresponding chapter, which contains

the cited section. See chapter 2-4 "Overview of the machine", for example, leads to

chapter 2 "Product description", which contains section 4 "Overview of the machine".

Sketches and schematic representations

These are provided for general information and do not necessarily correspond to the

latest version of the machine.

Dimensional information

Dimensional information is listed in the SI/US unit system according to the place of

installation.

1.4 Care of the documentation

Volume 1 "Instruction manual" must always be kept in close vicinity of the

workstation.

Volume 2 "Service manual" must be made available to maintenance and service

personnel when required.

1-4

000009,06,11-2009, jmu

G3 series Introduction

Current status of documentation

1.5 Current status of documentation

Act accordingly to make sure that the documentation is complete and up-to-date at

all times:

– Do not remove parts of the documentation

– Request copies of missing or illegible pages from the manufacturer, or download

and print them from the Zünd homepage

– If any new documentation is delivered as a result of conversions taking place, file

it away immediately

– If documentation is changed, file the new information and destroy the old

– If the documentation exists in more than one language, ensure that all languages

are kept up-to-date

1.6 Standardisation, tests, marking

1.6.1 Standards

Scope of the documentation supplied

Volume 1: Operating manual

Volume 2: Service manual *

Volume 3: Spare parts catalogue *

1

Execution

This operating manual makes reference to the following standards:

• EN 62079

• EN 62023

• ANSI Z535-6

• EN ISO 12100-2

Important!

EU standards and guidelines which are applied are listed in the declaration of

conformity.

In the interests of our customers, we reserve the right to make changes as a result

of technical improvements. This document therefore corresponds to the technical

status of the product supplied and not the manufacturer's current state of

development.

1.6.2 CE marking

Within the EU, the cutter system is delivered with CE marking and an EC declaration

of conformity according to Annex II A of the EC Machinery Directive 2006/42/EC (see

chapter "Documents")

000009,06,11-2009, jmu

Important!

If the purchaser adds additional devices to the cutter system, or if the system is

integrated into an larger system then the device is supplied with a "Declaration for

the installation of an incomplete machine" according to Appendix II A of the EU

1-5

1

Introduction G3 series

Standardisation, tests, marking

Machinery Directive 2006/42/EC and/or without CE marking. As a result, the

declaration of conformity must be issued again by the purchaser.

1.6.3 UL testing

Zünd G3 cutters have been UL tested and comply with the ISO 60950 standard.

The certification can be accessed under UL number E176661.

1-6

000009,06,11-2009, jmu

G3 series Introduction

Legal notice

1.7 Legal notice

The information contained in this publication is intended for information purposes

only and is subject to change without notice at any time. This does not constitute an

obligation on the part of Zünd Systemtechnik AG.

No part of this document may be copied, distributed, used or disclosed to third parties

without express permission. Offenders will be liable for damages.

1.8 Troubleshooting, hints and tips

Important!

You can find information about troubleshooting and useful hints and tips on the Zünd

homepage. (www.zund.com)

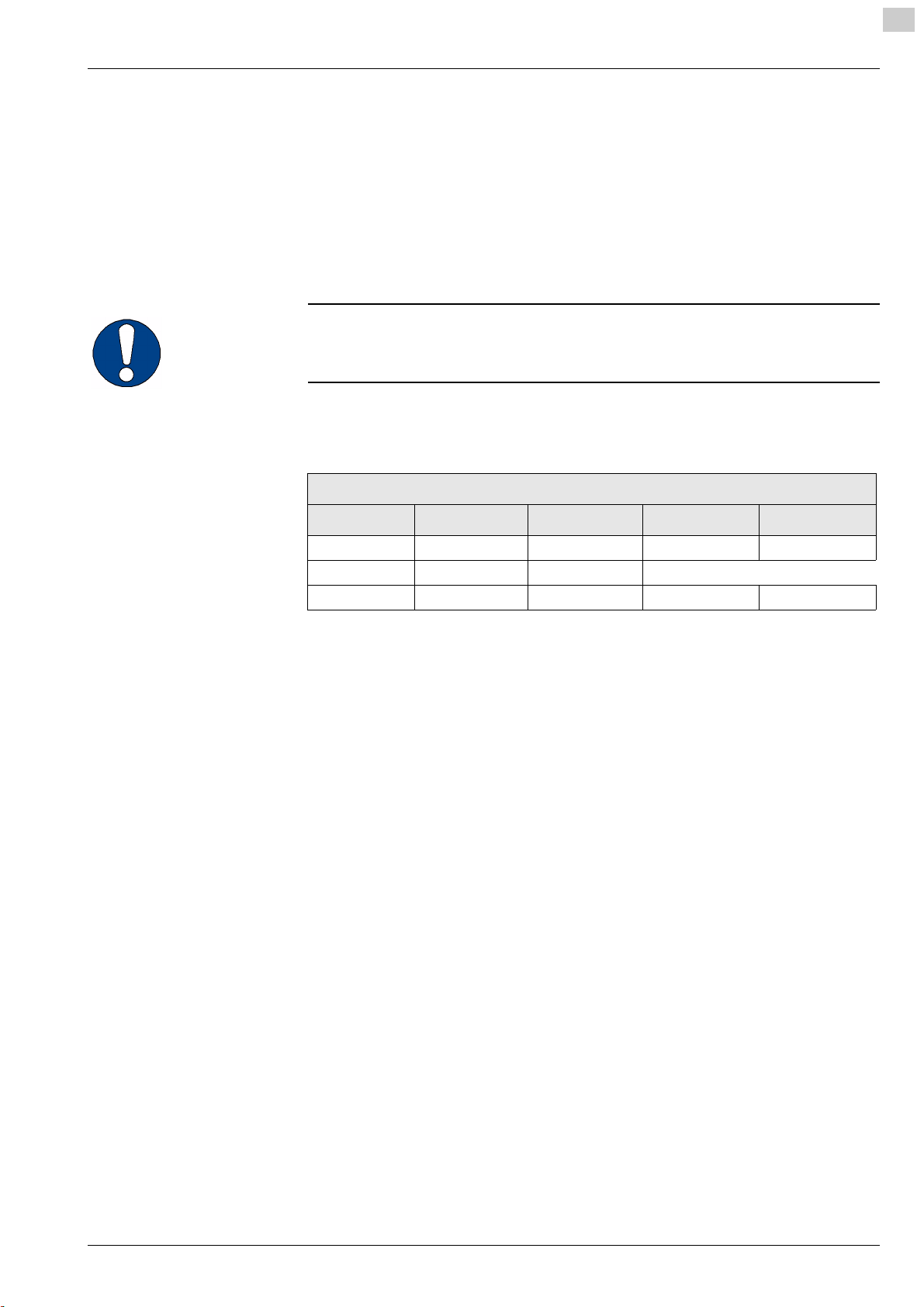

1.9 Documented cutter models

This documentation applies for the following types of G3 series cutters.

1

G3 series

M line L line XL line 2XL line 3XL line

M-1600 L-3200 XL-3200 2XL-3200 3XL-3200

M-2500 L-2500

1.10 Publishing details

Name

Operating manual for G3 series cutters, side-support version.

Composition, illustration and publication

Zünd Systemtechnik AG - Technical Communications Department

©Copyright

Zünd Systemtechnik AG

XL-1600 2XL-1600 3XL-1600

000009,06,11-2009, jmu

1-7

1

Introduction G3 series

Publishing details

1-8

000009,06,11-2009, jmu

G3 series Product description

General

2 Product description

2.1 General

This chapter contains information on the following:

– Representational conventions in the operating manual

– Possible uses of the machine

– Structure of the main components

– Important technical data

– General technical description of the device

Directional information

Directions such as "right, left" or "forwards, backwards" are specified according to the

operator's view of the machine during operation.

2

000003,07,05-2010, jmu

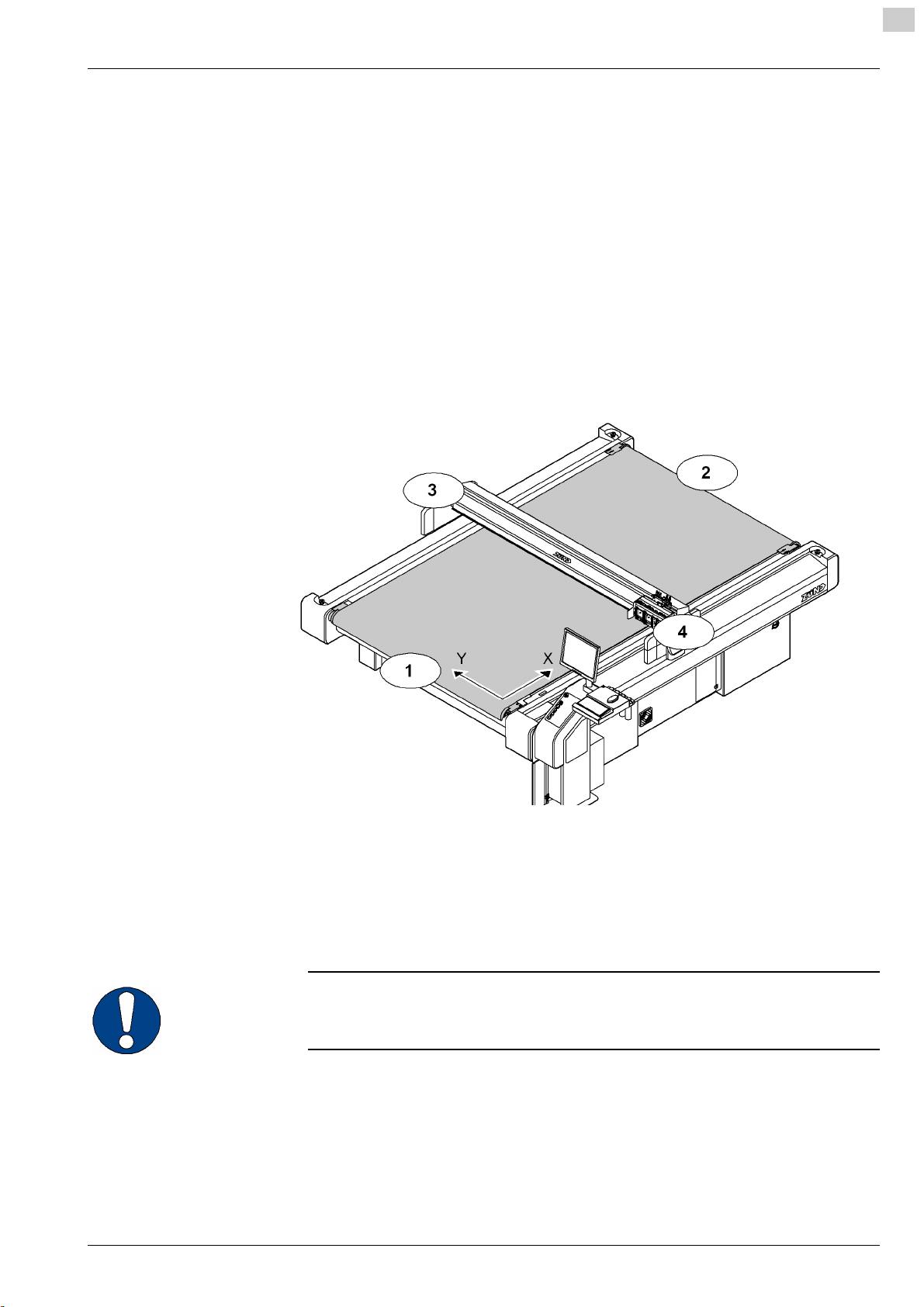

Fig. 2-1 Directional information

1 Front 3 Left

2 Back 4 Right

Y Y axis X X axis

Important information

Important!

Refers to user tips and useful information which enhance the usability and prolong

the service life of the machine and make the work significantly easier.

2-1

2

Product description G3 series

Product identification

2.2 Product identification

2.2.1 Rating plate

Important!

The rating plate is used to uniquely identify your machine.

Fig. 2-2 Position of rating plate

1 Manufacturer

2 Product category

3 Device type

4 Serial number

1

see chapter "Introduction", "Standardisation, CE marking"

Structure of the serial number

Example:

Serial number Description

G3 Product

00L Bar length

25 Table length

0001 Consecutive device number

5 Year of manufacture

6 CE marking

7 Manufacturer's address

1

2-2

000003,07,05-2010, jmu

G3 series Product description

Intended use

2.2.2 UL marking

2

Fig. 2-3 UL marking

1 UL marking (Canada, USA)

2 Voltage range

2.3 Intended use

The cutter system can be used for the following purposes:

– As an output device for CAD/CAM data

– For processing and labelling materials arranged on the table

Aside from this, the intended use and the limits of the application are as follows:

– Depending on the tools and material feed system available,

– Described in the chapters "Tools", "Modules" and "Material transport".

3 Max. current

4 Frequency

000003,07,05-2010, jmu

2-3

2

Product description G3 series

Cutter - overview

2.4 Cutter - overview

2-4

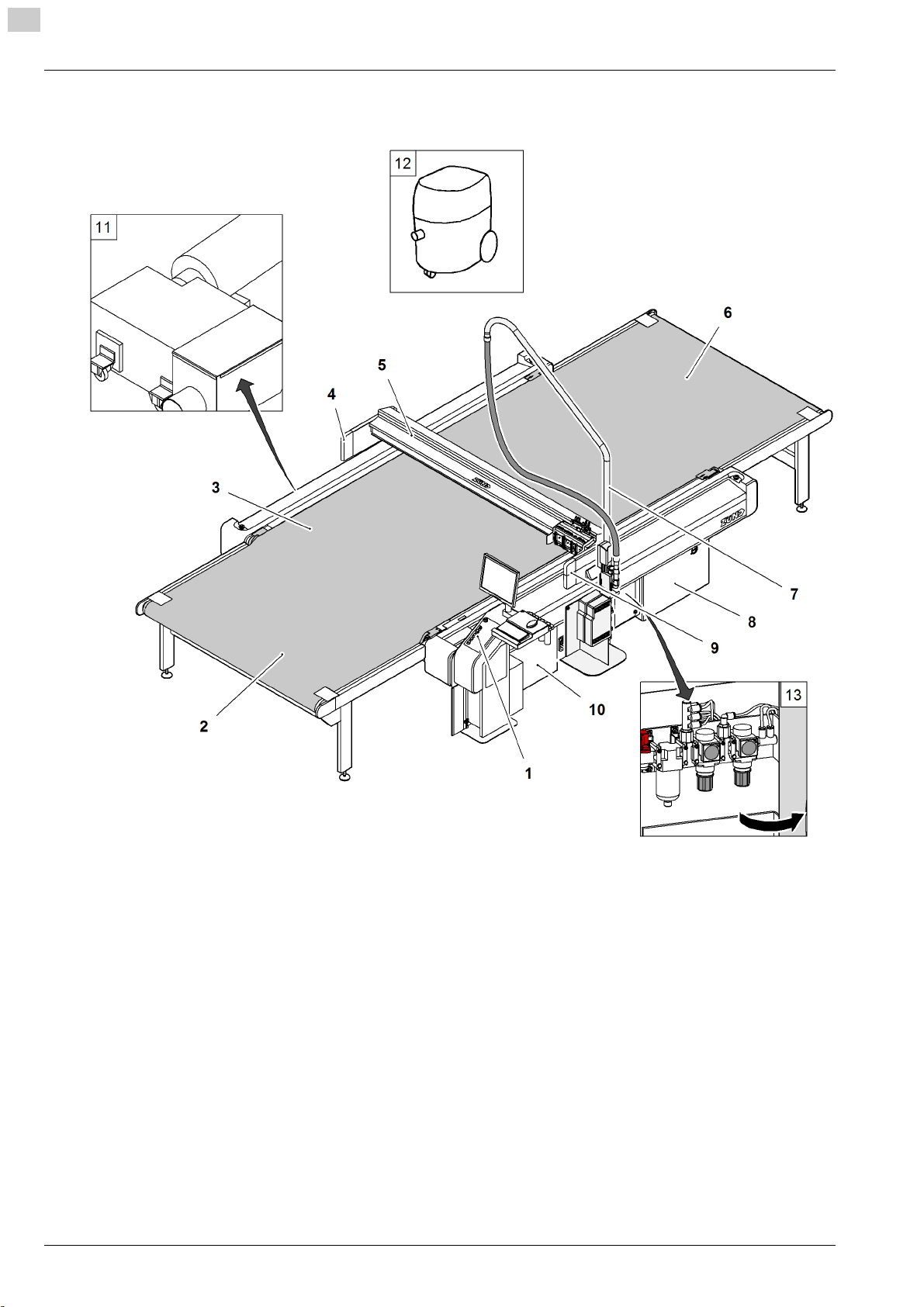

Fig. 2-4 Cutter - overview

1 Work station

2 Cutter extension, front

3 Table with vacuum

4 Left-hand safety device

5 Bar

6 Cutter extension, rear

7 Boom for router option

8 Power unit

9 Right-hand safety device

10 Electronics unit

11 Vacuum generator

12 Extractor (optional)

13 Maintenance unit (air pressure setting)

000003,07,05-2010, jmu

G3 series Product description

Modules, tools

2.5 Modules, tools

2.5.1 General

Modules

The use of modules and tool inserts means that Zünd

cutters can be highly specialised on the one hand,

whilst still being able to be easily converted for

processing other materials on the other hand.

As standard three modules can be fastened onto the

module carriage.

Instructions on the operation of your module can be

found in the chapter "Modules"/"Tool inserts".

Tools

Zünd offers tools for processing the most wide ranging

materials. A selection of important tool inserts can be

found under the corresponding module.

On the Zünd homepage (www.zund.com) you can find

Fig. 2-5 Modules - tool inserts - tools

1 1 Modules (UM/RM/PUM)

2 2 Tools (EOT/POT/DRT)

3 3 Module carriage

4 4 Router, blade, etc.

all the current tool inserts or contact your Zünd partner

for detailed information.

Instructions on the operation of your tool/module can

be found in the chapter "Modules"/"Tools".

2

2.5.2 UM

Tangentially controlled high-performance module for

the following tool inserts:

•POT

•EOT

• DRT

• Various insert sleeves and tool holders

000003,07,05-2010, jmu

2-5

2

Product description G3 series

Modules, tools

2.5.2.1 Tools for the UM

POT: Pneumatic oscillating tool for thick or tough

materials such as foam, filling materials, thick leather,

upholstery fabrics etc.

EOT: Electrical oscillating tool for cutting soft to

average toughness materials.

DRT: Driven tool for rotating knives for cutting textiles,

fibrous materials such as Kevlar, carbon

VCT: Cutting tool for producing V-cuts

UCT: Cutting tool which can be used universally

KCT: Cutting tool for foils with and without mount

material

UDT: Drawing tool

PPT: Passepartout (all-purpose) tool

2-6

000003,07,05-2010, jmu

G3 series Product description

Modules, tools

2.5.3 RM-A

Router module for the use of 1000 W Zünd motor

spindles.

2

2.5.4 PUM

Motor spindle with 1000 W for the processing of the

most wide-ranging materials.

Punching and stamping module for the processing of

leather materials.

000003,07,05-2010, jmu

2-7

2

Product description G3 series

Modules, tools

2.5.5 MAM-S/D

Single/double marking module for use of ballpoint pens

and other marking inserts.

2-8

000003,07,05-2010, jmu

G3 series Product description

Material handling, options

2.6 Material handling, options

2.6.1 Laser pointer

The laser pointer is used as an aid for the precise

definition of the reference point

2.6.2 ICC camera

2

The ICC camera is used as an aid for importing the

registration marks. The processing of the data is

dependent on the communication software.

2.6.3 Cutter with static work surface

The feeding and removal of the processing material

takes place on the work surface of the cutter. The work

surface is protected against damage using a cutting

base.

Fig. 2-6 Static work surface

000003,07,05-2010, jmu

2-9

2

Product description G3 series

Material handling, options

2.6.4 Cutter with conveyor

Conveyor systems are used for pulling the materials to

be worked with. The conveyor belt is used as a cutting

base and conveyor belt at the same time.

During the processing, the material to be processed is

fixed in place using a vacuum. After cutting, the bar

moves backwards. The conveyor clamping elements

fix the conveyor belt and the feeding clamps are

pressed onto the material to be pushed forward. The

bar tightens the conveyor belt to the set position.

The shape of the feeding clamps varies depending on

the material to be worked with. An auxiliary drive is

used in the case of larger tables or processing

Fig. 2-7 Conveyor

materials that are heavier for transportation.

Cutter extensions guarantee efficient work. The

material supply/removal is carried out while the cutter

is completing its jobs. These extensions are available

in different sizes, either with or without auxiliary drive.

Fig. 2-8 Cutter extension

2.6.5 Sheet feeder options

Fully-automatic sheet feeding

2-10

000003,07,05-2010, jmu

G3 series Product description

Material handling, options

2.6.6 Drip tray

Catches cutting waste

2

000003,07,05-2010, jmu

2-11

2

Product description G3 series

Technical description

2.7 Technical description

2.7.1 Complete machine

The G3 cutter is a variable processing system for flexible and rigid materials with

various tool systems. Extension options are available to provide improved handling

and for the adjustment of the system to special requirements or for processing

specific materials.

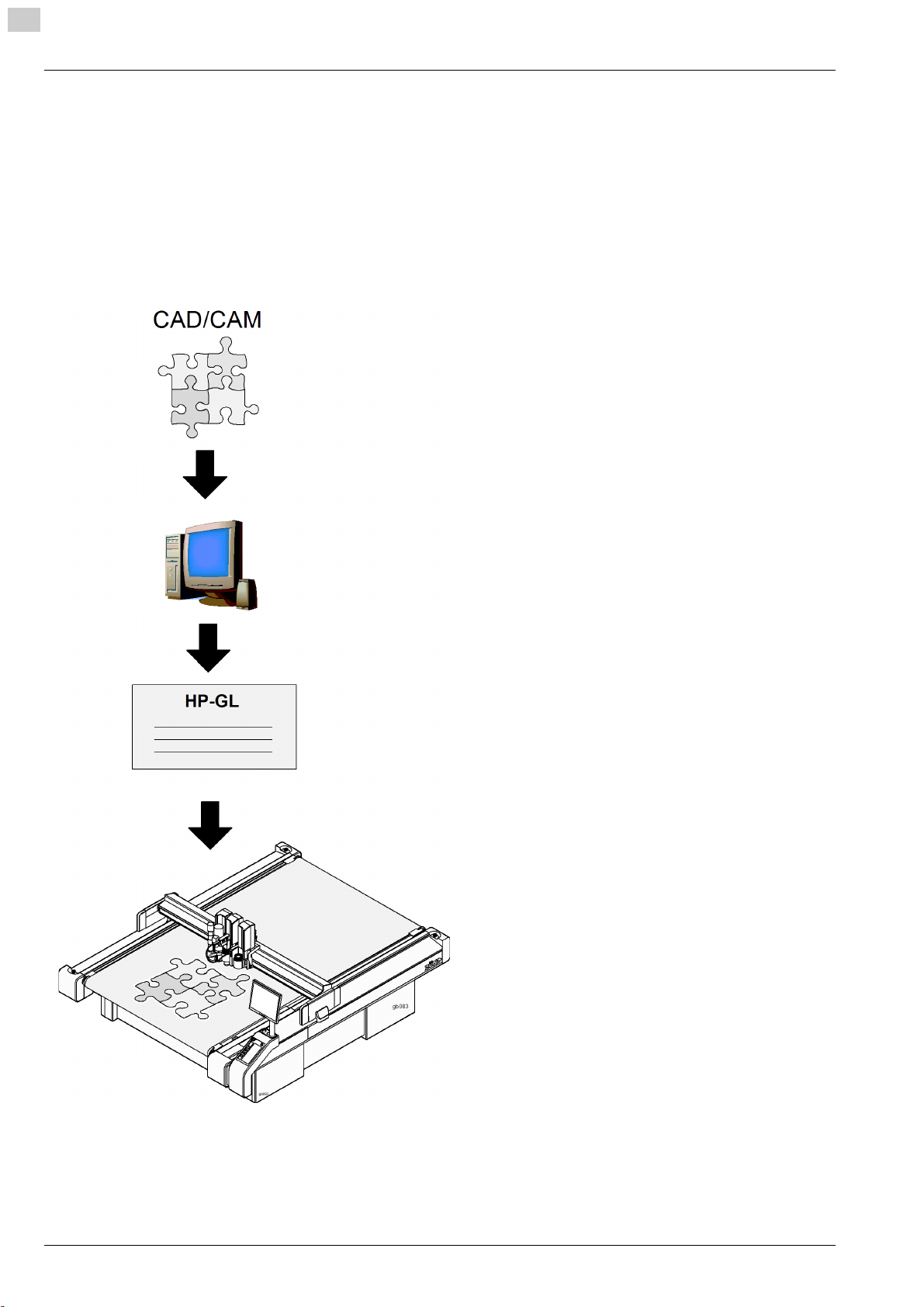

2.7.2 Schedule of work sequences

Starting point: CAD/CAM data

Communication software (e.g. ZCC)

Sending the HP-GL data to the cutter

Processing the sent data

2-12

000003,07,05-2010, jmu

G3 series Product description

Technical description

2.7.3 Complete machine

Table/vacuum plate

The work surface is designed as a perforated sheet. Vacuum zones are arranged

under this perforated sheet which are connected to a high-performance vacuum

generator via a distributor.

The vacuum is used for holding down and tightening the material to be processed.

The cutter control permits sequential activation/deactivation of the individual vacuum

zones and therefore reduces energy consumption. The vacuum generator (turbine

vacuum generator, vacuum pump) automatically regulates the vacuum strength (100

mBar).

Electronics unit

The electronics unit is housed in the front right-hand side of the cutter and is only

accessible for service personnel via a removable cover. The cutter control is housed

in the electronics unit.

Power unit

The power unit is housed in the rear right-hand side of the cutter and is only

accessible for service personnel via a removable cover. The power unit contains the

power supply of the complete cutter and is activated/deactivated using an on/off

switch. The connection of the individual consumers takes place using software

control if required.

2

Pneumatics

Air pressure and air flow are adjusted for the respective consumer via a maintenance

unit. The maintenance unit is accessible via a service door so that settings and

maintenance work can be carried out.

000003,07,05-2010, jmu

2-13

2

Product description G3 series

Technical description

2.7.4 Movement system

The G3 series has four electronically driven axes.

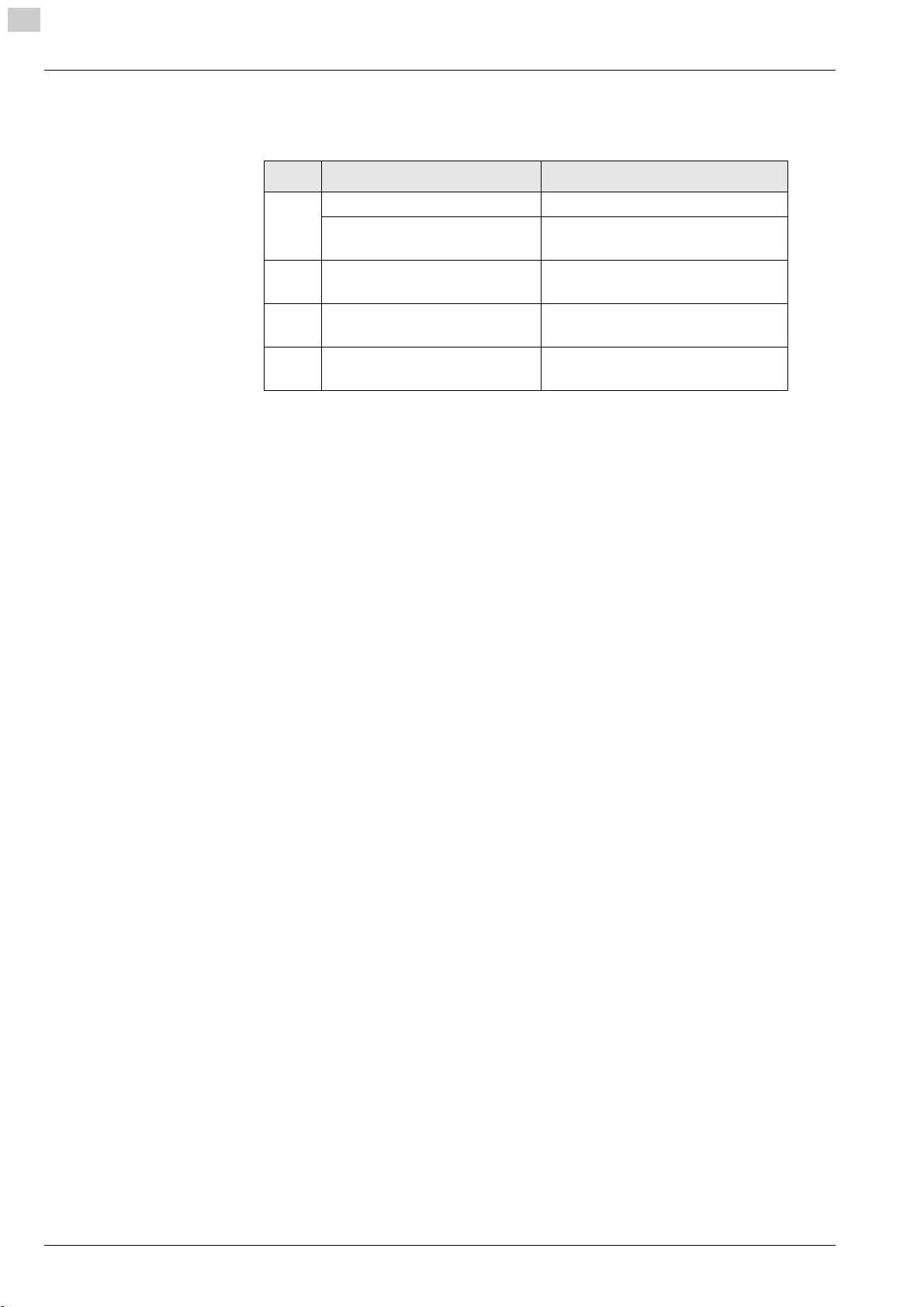

Axis Function Movement system

Bar Drive via toothed belt/steel belt

X

Material transport, material

transport extension

Y Movement of the module

carriage

Z Height adjustment of the

module

T Rotary movement of the

module

X axis - bar

The bar is driven by a motor via a toothed belt/gear mechanism and a toothed belt/

metal belt combination. The construction ensures that the function is backlash-free

and it also minimises wear on the drive system. The bar is supplied with control

signals and compressed air via an energy chain. All drive parts are protected against

direct access/contamination using covers.

Feed clamp elements, feeding

clamps, auxiliary drive

Drive via toothed belt/steel belt

Example: Universal module,

routing module

Example: Universal module

X axis - material transport

The material transport takes place via conveyor clamp elements and feed elements

on the bar, which move the conveyor belt including the material to be used via the

bar movement. In the case of large cutters, or cutters with material transport

extension, an auxiliary drive is also used.

Y axis - module carriage

The module carriage is driven by a motor via a toothed belt/gear mechanism and a

metal belt. The construction ensures that the function is backlash-free and it also

minimises wear on the drive system. The module carriage is supplied with control

signals and compressed air via an energy chain. All drive parts are protected against

direct access/contamination using covers.

Z axis - height adjustment of the module

Machine-controlled setting of the processing height (e.g. universal module)

T axis - rotary movement of the module

Modules with integrated T axis (e.g. universal module)

2-14

000003,07,05-2010, jmu

Loading...

Loading...