Zumex Speed Pro Installation Manual

USER’S MANUAL •

MANUAL DE USUARIO •

MANUEL DE L’UTILISATEUR • BEDIENUNGSANLEITUNG • MANUALE D’USO

ENGLISH. USER’S MANUAL 25

ESPAÑOL. MANUAL DE USUARIO 55

FRANÇAIS. MANUEL DE L’UTILISATEUR 85

DEUTSCH. BEDIENUNGSANLEITUNG 115

ITALIANO. MANUALE D’USO 145

ES

1

ANEXO

Drawing and description

Figuras y descripción general

Figures et vue d’ensemble

Abbildung und beschreibung

Figure e descrizione generale

SPEED PRO

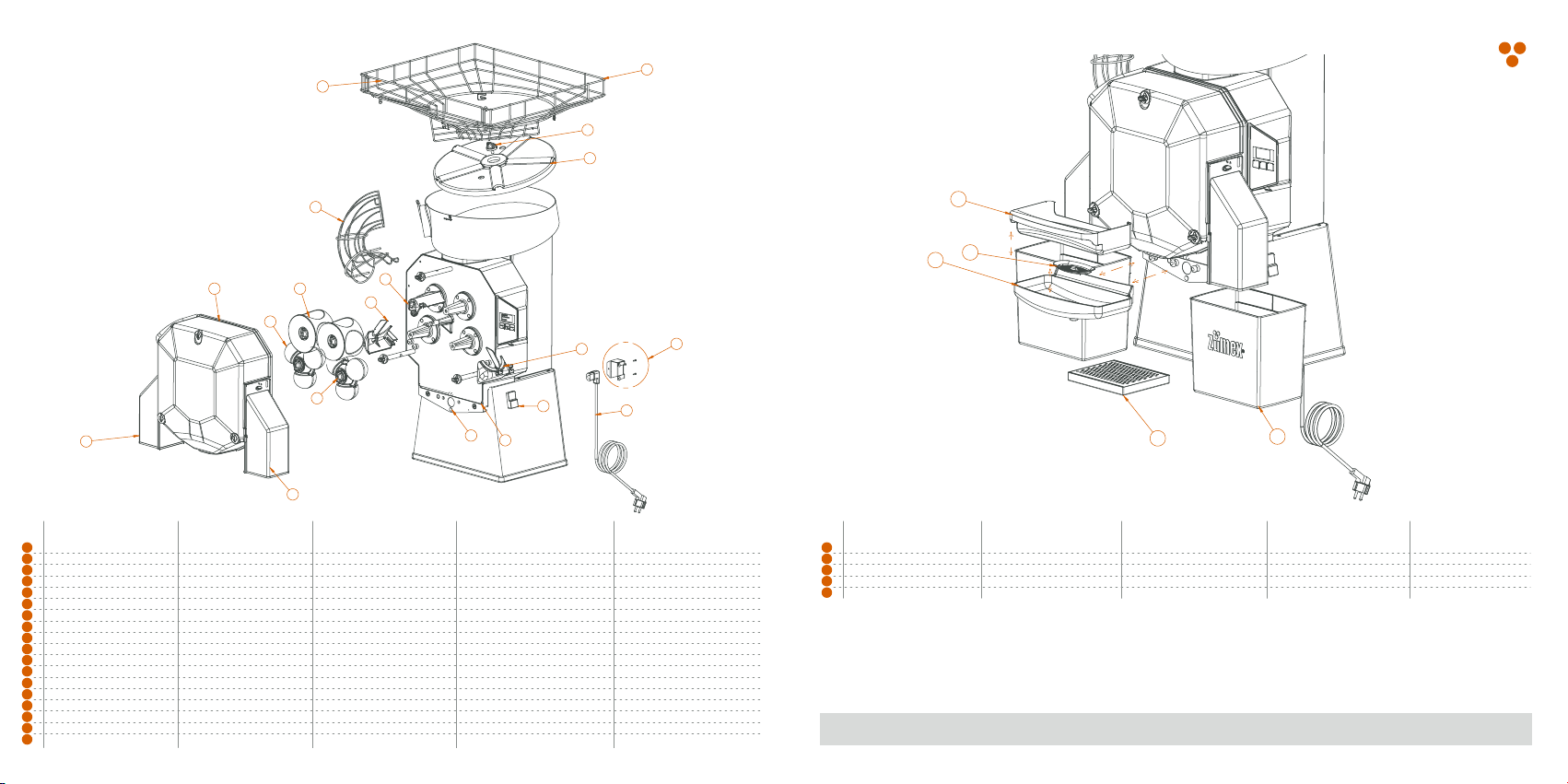

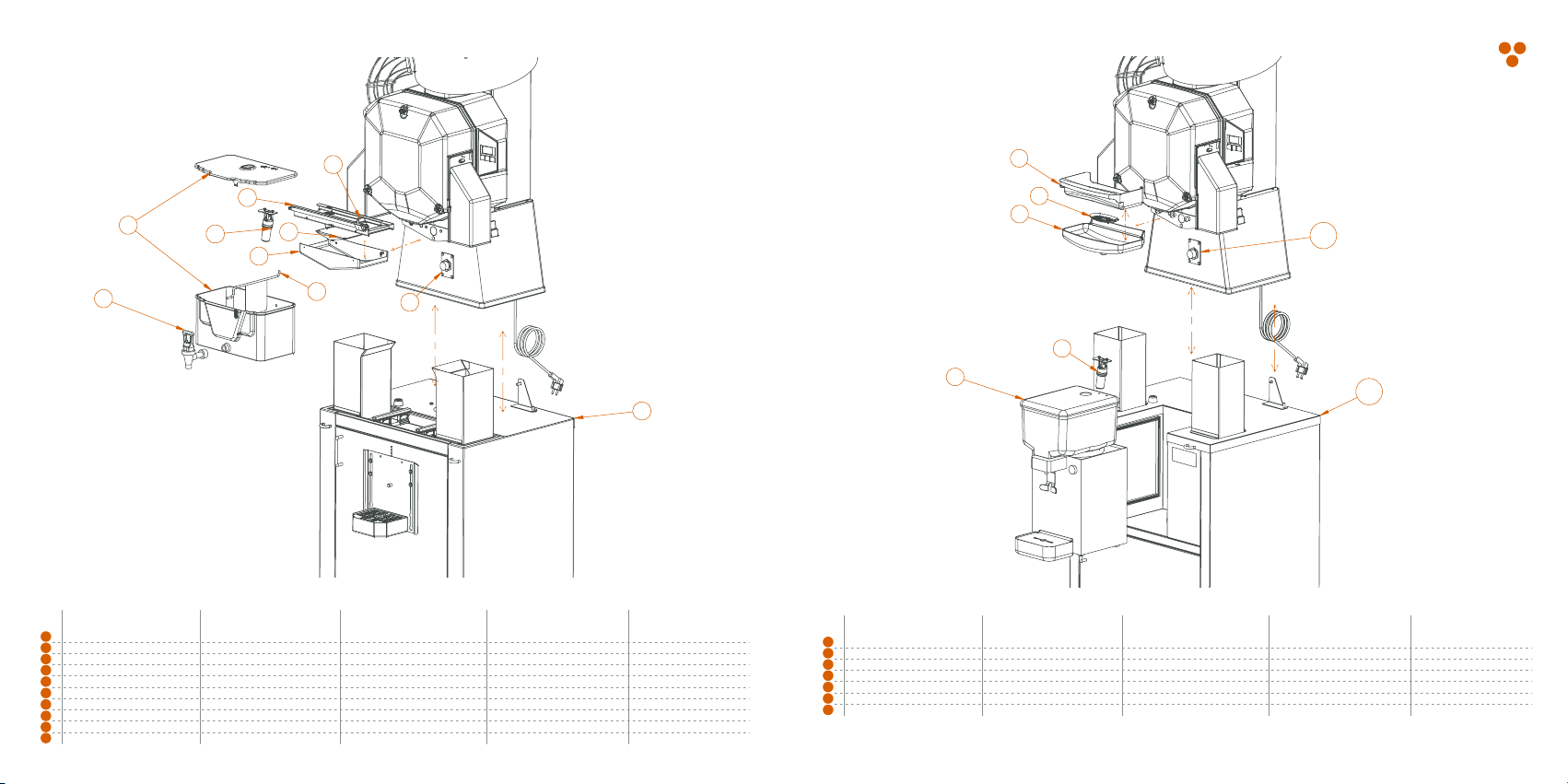

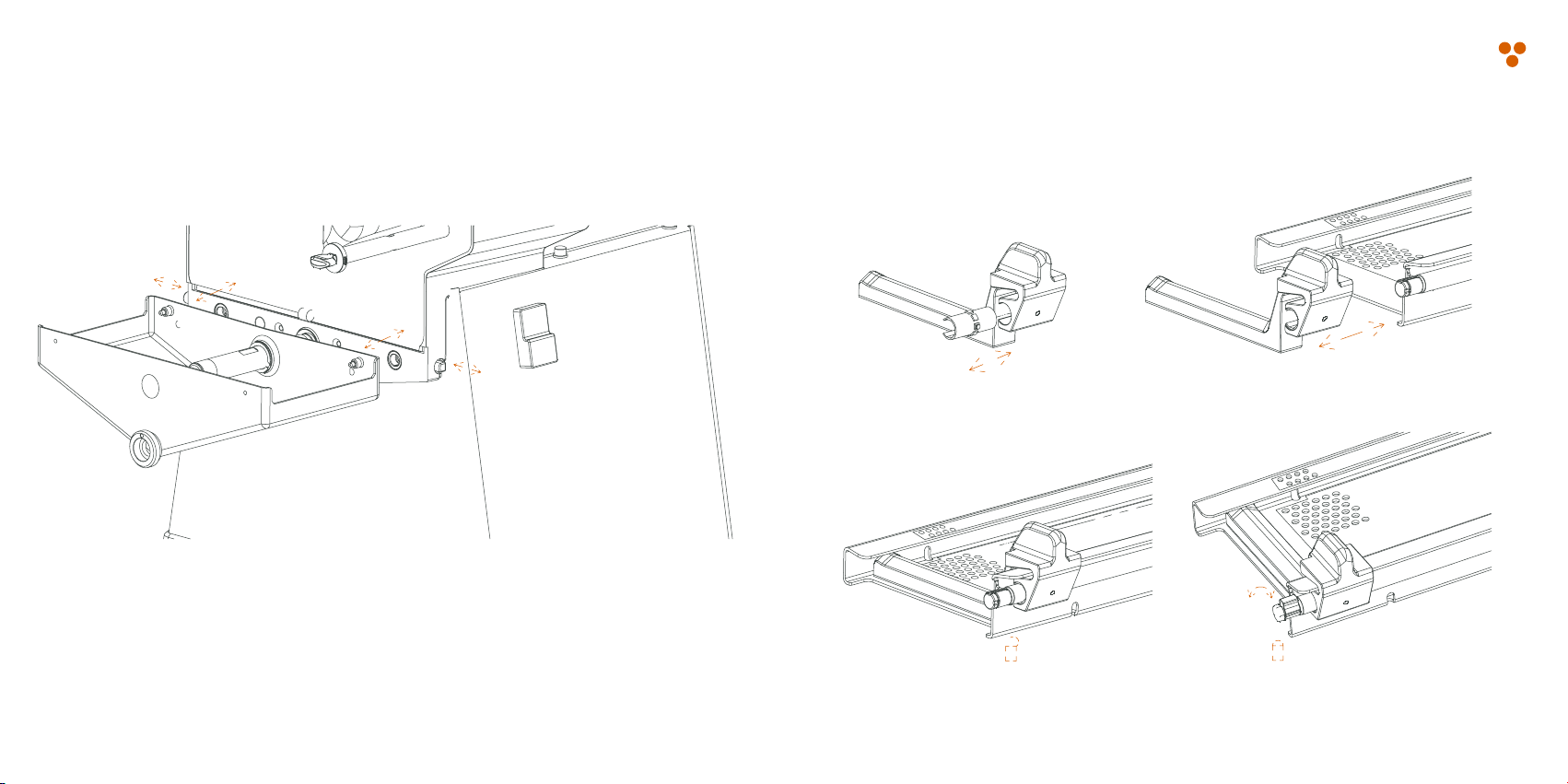

FIG. 1

14

13

6

12

SPEED PRO

FIG. 2

3

EN

SPEED PRO COVER

1

RIGHT COVER SIDE OUTLET

2

LEFT COVER SIDE OUTLET

3

LOWER PRESSING UNIT

4

UPPER PRESSING UNIT

5

PLASTIC SECURING KNOB

6

LEFT PEEL EJECTOR

7

RIGHT PEEL EJECTOR

8

BLADE HOLDER

9

BUTTON RUBBER PROTECTION

10

11

FEEDER ELBOW D85 WITH LOCKING SYSTEM

12

FEEDER PLATE

13

FEEDER BASKET

14

FEEDER BASKET DOOR

15

POWER CABLE

16

CABLE PROTECTOR

17

SS/TANK TRAY GASKET

18

CONTAINER BOLT

1

4

ES

CUBIERTA SPEED PRO

SALIDA LATERAL CUBIERTA DERECHA

SALIDA LATERAL CUBIERTA IZQUIERDA

TAMBOR MACHO PLÁSTICO

TAMBOR HEMBRA PLÁSTICO

VOLANTE PLÁSTICO INYECCIÓN

CUÑA EXTRACTORA IZQUIERDA

CUÑA EXTRACTORA DERECHA

PORTACUCHILLAS

GOMA PROTECCIÓN PULSADOR

CODO ALIMENTACIÓN D85 CON BLOQUEO

PLATO ALIMENTADOR

CESTA ALIMENTADOR

PUERTA CESTA ALIMENTADOR

CABLE ALIMENTACIÓN

PROTECTOR CABLE

JUNTA CUBETA SS/TANK

ESPÁRRAGO CUBETA

11

5

2

7

6

FR

CAPOT SPEED PRO

SORTIE LATÉRALE CAPOT DROITE

SORTIE LATÉRALE CAPOT GAUCHE

TAMBOUR MÂLE PLASTIQUE

TAMBOUR FEMELLE PLASTIQUE

ECROU PAPILLON PLASTIQUE INJECTION

EXTRACTEUR D’ÉCORCE GAUCHE

EXTRACTEUR D’ÉCORCE DROITE

PORTE-LAMES

CACHE-INTERRUPTEUR

COUDE D’ALIMENTATION D85 À FERMETURE

PLATEAU CHARGEUR

PANIER CHARGEUR

PORTE DU PANIER CHARGEUR

CÂBLE D’ALIMENTATION ÉLECTRIQUE

PROTECTEUR CÂBLE

JOINT BAC SS/TANK

GOUJON BAC

32

31

9

16

15

CARTER SPEED PRO

USCITA LATERALE CARTER DESTRO

USCITA LATERALE CARTER SINISTRO

TAMBURO MASCHIO PLASTICA

TAMBURO FEMMINA PLASTICA

VITE DI SICUREZZA PLASTICA INIEZIONE

ESTRATTORE DI BUCCE SINISTRO

ESTRATTORE DI BUCCE DESTRO

PORTALAMA

RIVESTIMENTO PROTETTIVO IN GOMMA PULSANTE

TUBO A GOMITO ALIMENTATORE D85 CON BLOCCAGGIO

PIATTO ALIMENTATORE

CESTA ALIMENTATORE

PORTACESTA ALIMENTATORE

CAVO DI ALIMENTAZIONE

GUAINA CAVO

GUARNIZIONE VASCHETTA SS/TANK

BULLONE VASCHETTA

EN

PEEL BUCKET

20

DRIP TRAY

21

PLASTIC JUICE CONTAINER

30

PLASTIC INNER FILTER

31

PLASTIC JUICE FILTER

32

SS: Speed Pro Self Service / Speed Pro Self Service Podium. Tank: Speed Pro Tank Podium. Cooler: Speed Pro Cooler Podium.

10

18

17

DE

ABDECKUNG SPEED PRO

SEITLICHE AUSGANGSÖFFNUNG ABDECKUNG RECHTS

SEITLICHE AUSGANGSÖFFNUNG ABDECKUNG LINKS

TROMMELEINSATZ KUNSTSTOFF

TROMMELGEHÄUSE KUNSTSTOFF

SICHERHEITSSCHRAUBE SPRITZGUSSKUNSTSTOFF

ENTSAFTERKEIL LINKS

ENTSAFTERKEIL RECHTS

MESSERHALTER

TASTENSCHUTZGUMMI

ZUFÜHRUNGSBOGEN D85 MIT ARRETIERUNG

ZUFÜHRUNGSTELLER

ZUFÜHRUNGSKORB

TÜR ZUFÜHRUNGSKORB

ANSCHLUSSKABEL

KABELSCHUTZ

DICHTUNG BEHÄLTER SS/TANK

BOLZEN BEHÄLTER

8

IT

30

20

DE

SCHALENBEHÄLTER

TROPFAUFFANGSCHALE

SAFTBEHÄLTER KUNSTSTOFF

INNENFILTER KUNSTSTOFF

SAFTFILTER KUNSTSTOFF

IT

VASCHETTA BUCCE

VASCHETTA RACCOGLIGOCCE

VASCHETTA SUCCO PLASTICA

FILTRO INTERNO PLASTICA

FILTRO SUCCO PLASTICA

ES

CUBETA CORTEZAS

BANDEJA GOTEO

CUBETA ZUMO PLÁSTICO

FILTRO INTERIOR PLÁSTICO

FILTRO ZUMO PLÁSTICO

21

FR

BAC À DÉCHETS

BAC ANTIGOUTTES

BAC À JUS EN PLASTIQUE

FILTRE INTÉRIEUR EN PLASTIQUE

FILTRE À JUS EN PLASTIQUE

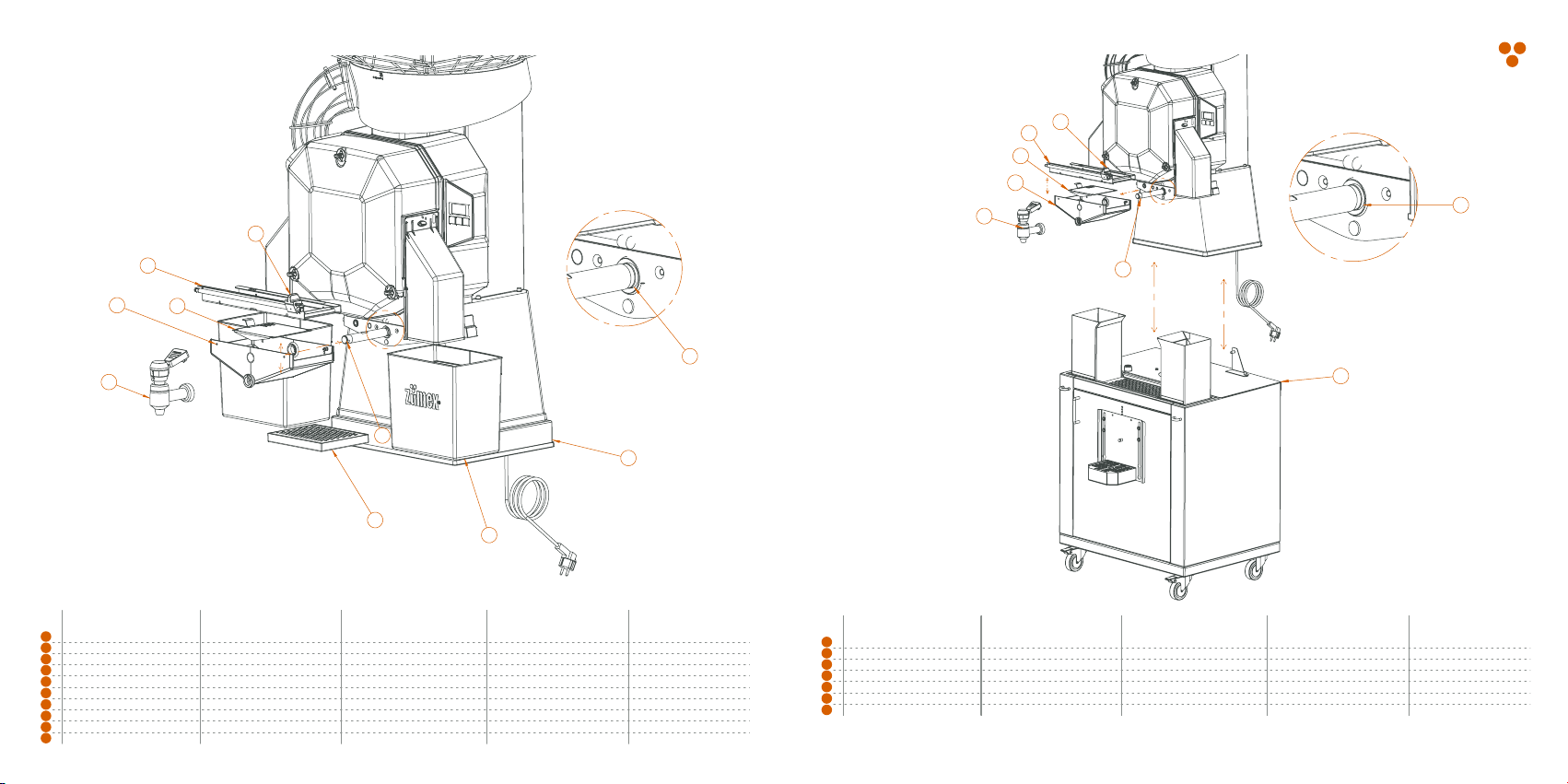

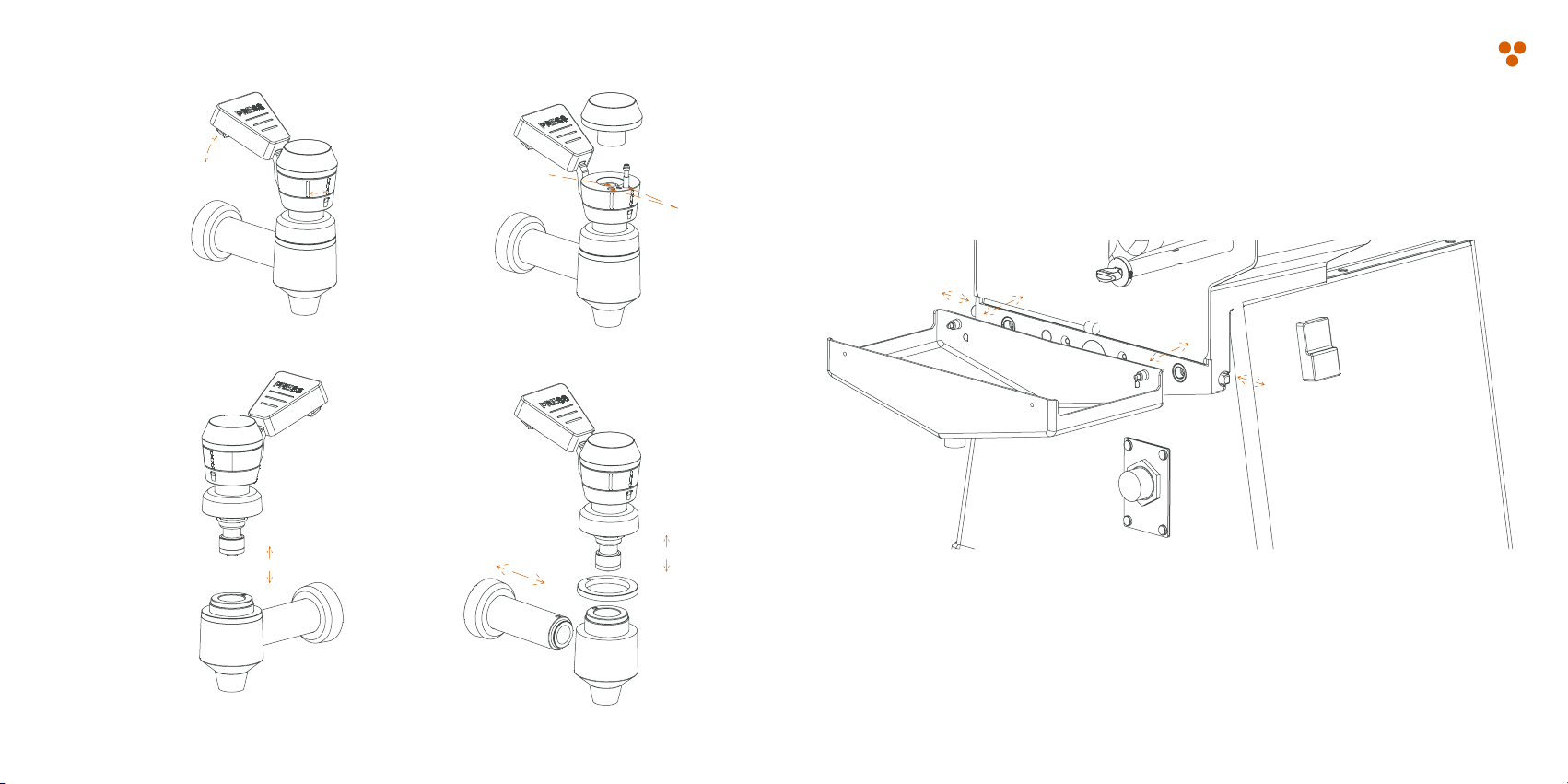

SPEED PRO

FIG. 3

SPEED PRO

FIG. 4

43

42

41

40

44

A

43

46

EN

PEEL BUCKET

20

DRIP TRAY

21

SS JUICE CONTAINER

40

SS SUB-FILTER

41

SS/TANK FILTER

42

PULP SWEEPER

43

SS SPOUT

44

SPOUT DETECTOR TUBE

45

DETECTOR TUBE GASKET

46

MACHINE SUPPLEMENT

47

42

40

41

45

DETALLE A

DETALLE A

A

44

46

90

45

47

21

20

ES

CUBETA CORTEZAS

BANDEJA GOTEO

CUBETA ZUMO SS

SUBFILTRO SS

FILTRO SS/TANK

BARREDOR DE PULPA

GRIFO SS

TUBO DETECTOR DE GRIFO

JUNTA TUBO DETECTOR

SUPLEMENTO MÁQUINA

FR

BAC À DÉCHETS

BAC ANTIGOUTTES

BAC À JUS SS

SOUS-FILTRE SS

FILTRE SS/TANK

BALAYEUSE À PULPE

ROBINET SS

TUBE DÉTECTEUR DE NIVEAU ROBINET

JOINT TUBE DÉTECTEUR

ACCESSOIRE DE LEVAGE MACHINE

DE

SCHALENBEHÄLTER

TROPFAUFFANGSCHALE

SAFTBEHÄLTER SS

UNTERFILTER SS

FILTER SS/TANK

FILTERREINIGUNGSVORRICHTUNG

SB-HAHN SS

SENSORROHR HAHN

DICHTUNG SENSORROHR

ERGÄNZUNGSTEIL MASCHINE

IT

VASCHETTA BUCCE

VASCHETTA RACCOGLIGOCCE

VASCHETTA SUCCO SS

SOTTOFILTRO SS

FILTRO SS/TANK

RIMUOVI-POLPA

RUBINETTO SS

TUBO SENSORE DI RUBINETTO

GUARNIZIONE TUBO SENSORE

SUPPLEMENTO MACCHINA

EN

SS SUB-FILTER

41

SS/TANK FILTER

42

PULP SWEEPER

43

SS SPOUT

44

SPOUT DETECTOR TUBE

45

DETECTOR TUBE GASKET

46

SS/TANK STAND

90

ES

SUBFILTRO SS

FILTRO SS/TANK

BARREDOR DE PULPA

GRIFO SS

TUBO DETECTOR DE GRIFO

JUNTA TUBO DETECTOR

MUEBLE SS/TANK

FR

SOUS-FILTRE SS

FILTRE SS/TANK

BALAYEUSE À PULPE

ROBINET SS

TUBE DÉTECTEUR DE NIVEAU ROBINET

JOINT TUBE DÉTECTEUR

MEUBLE SS/TANK

DE

UNTERFILTER SS

FILTER SS/TANK

FILTERREINIGUNGSVORRICHTUNG

SB-HAHN SS

SENSORROHR HAHN

DICHTUNG SENSORROHR

UNTERSCHRANK SS/TANK

IT

SOTTOFILTRO SS

FILTRO SS/TANK

RIMUOVI-POLPA

RUBINETTO SS

TUBO SENSORE DI RUBINETTO

GUARNIZIONE TUBO SENSORE

MOBILE SS/TANK

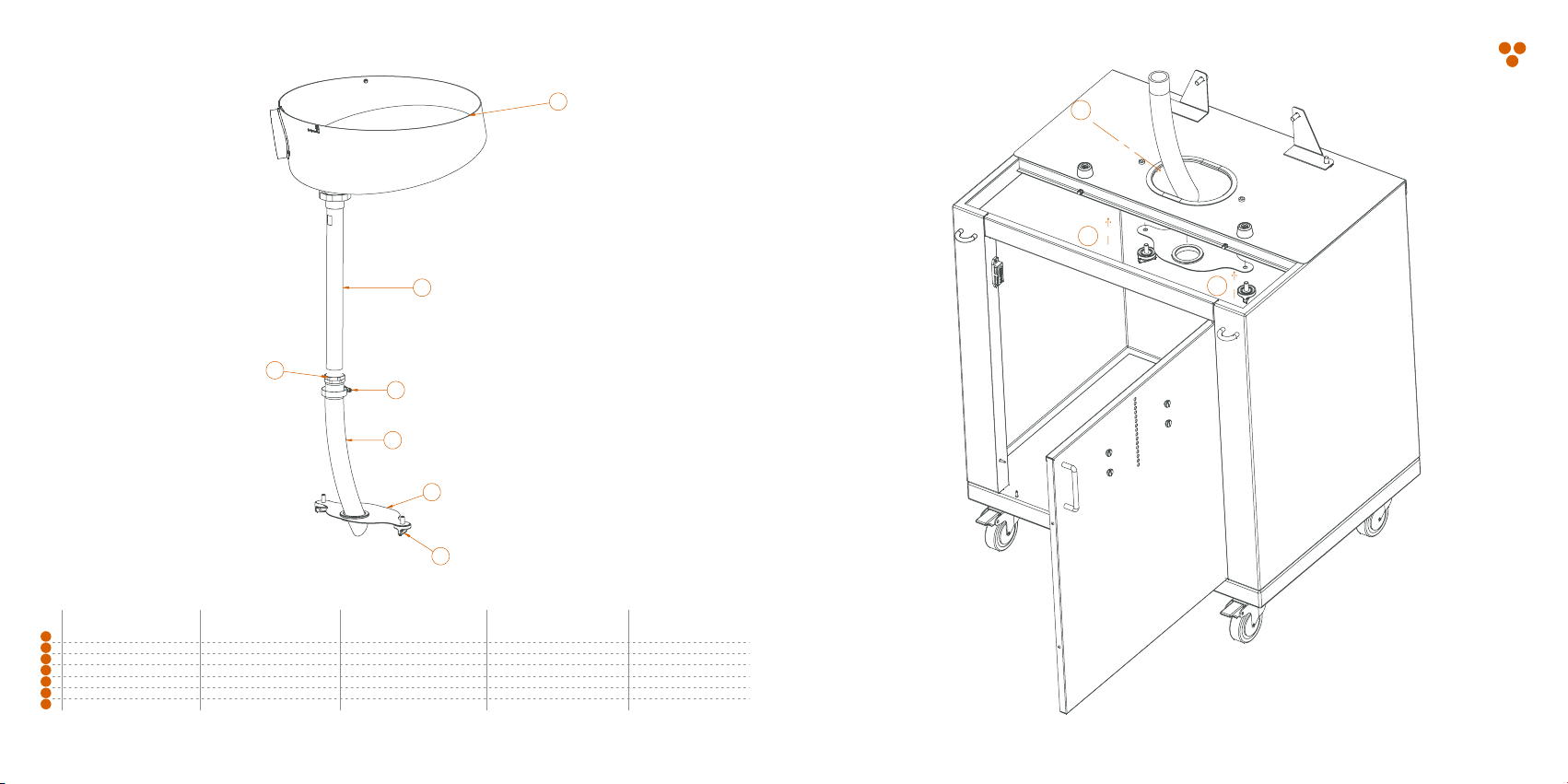

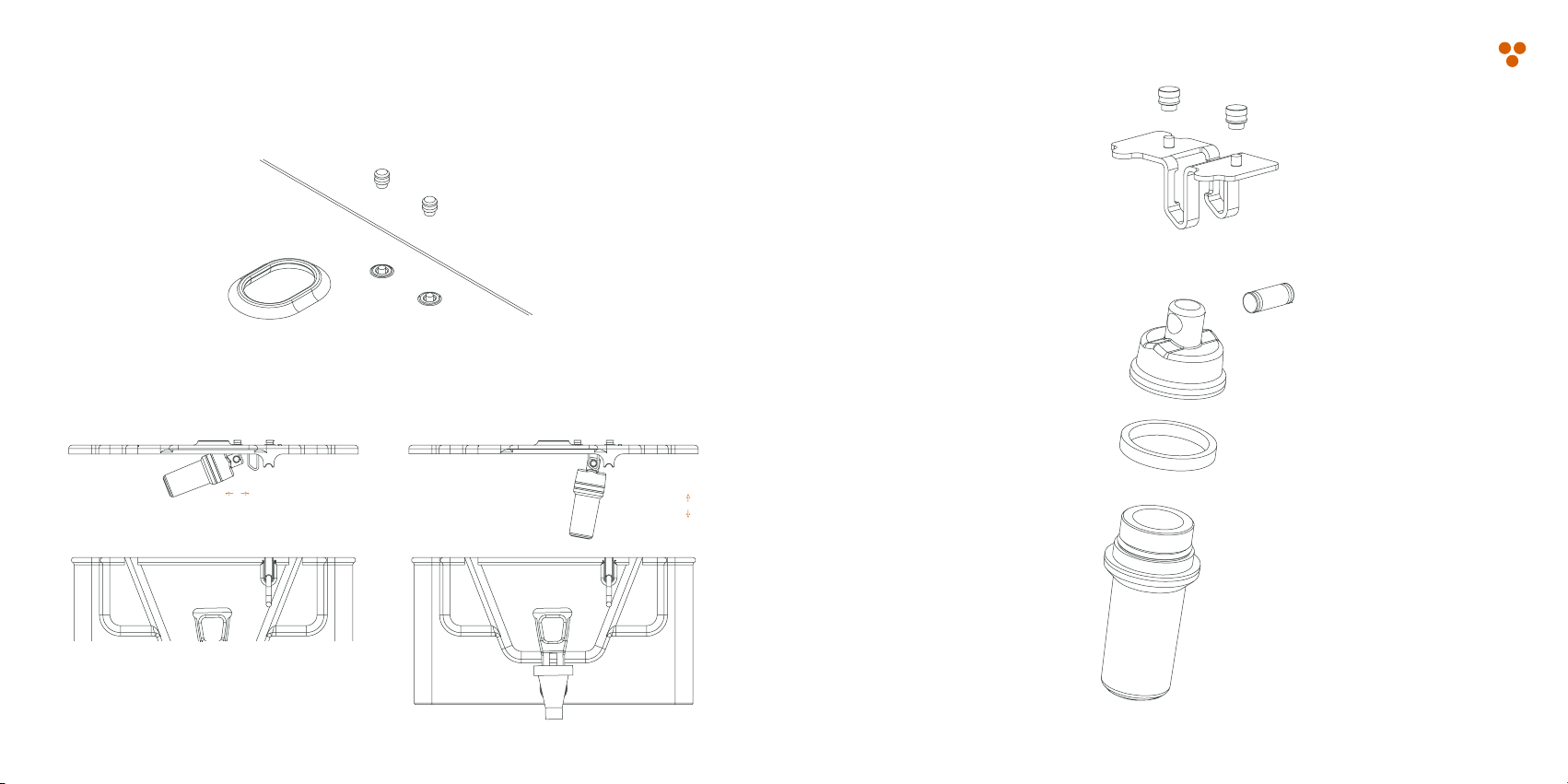

SPEED PRO

FIG. 5

SPEED PRO

FIG. 6

EN

42

43

50

51

52

53

54

55

56

90

53

55

SS/TANK FILTER

PULP SWEEPER

TANK JUICE CONTAINER

TANK SUB-FILTER

TANK/COOLER BUOY

TANK

SHAKER

TANK TAP

LEVEL DETECTOR

SS/TANK STAND

52

ES

FILTRO SS/TANK

BARREDOR DE PULPA

CUBETA ZUMO TANK

SUBFILTRO TANK

BOYA TANK/COOLER

TANK

AGITADOR

GRIFO TANK

DETECTOR DE NIVEL

MUEBLE SS/TANK

43

42

32

31

30

51

56

50

54

56

52

70

100

90

FR

FILTRE SS/TANK

BALAYEUSE À PULPE

BAC À JUS TANK

SOUS-FILTRE TANK

FLOTTEUR TANK/COOLER

TANK

MÉLANGEUR

ROBINET TANK

DÉTECTEUR DE NIVEAU

MEUBLE SS/TANK

DE

FILTER SS/TANK

FILTERREINIGUNGSVORRICHTUNG

SAFTBEHÄLTER TANK

UNTERFILTER TANK

SCHWIMMER TANK/COOLER

TANK

RÜHRELEMENT

HAHN TANK

FÜLLSTANDSENSOR

UNTERSCHRANK SS/TANK

IT

FILTRO SS/TANK

RIMUOVI-POLPA

VASCHETTA SUCCO TANK

SOTTOFILTRO TANK

GALLEGGIANTE TANK/COOLER

TANK

AGITATORE

RUBINETTO TANK

SENSORE DI LIVELLO

MOBILE SS/TANK

EN

PLASTIC JUICE CONTAINER

30

PLASTIC INNER FILTER

31

PLASTIC JUICE FILTER

32

TANK / COOLER BUOY

52

LEVEL DETECTOR

56

COOLER UNIT

70

100

COOLER STAND

ES

CUBETA ZUMO PLÁSTICO

FILTRO INTERIOR PLÁSTICO

FILTRO ZUMO PLÁSTICO

BOYA TANK/COOLER

DETECTOR DE NIVEL

CONJUNTO ENFRIADOR

MUEBLE COOLER

FR

BAC A JUS EN PLASTIQUE

FILTRE INTERIEUR EN PLASTIQUE

FILTRE A JUS EN PLASTIQUE

FLOTTEUR TANK/COOLER

DETECTEUR DE NIVEAU

ENSEMBLE REFROIDISSEUR

MEUBLE COOLER

DE

SAFTBEHÄLTER KUNSTSTOFF

INNENFILTER KUNSTSTOFF

SAFTFILTER KUNSTSTOFF

SCHWIMMER TANK/COOLER

FÜLLSTANDSENSOR

KÜHLEINHEIT

UNTERSCHRANK COOLER

IT

VASCHETTA SUCCO PLASTICA

FILTRO INTERNO PLASTICA

FILTRO SUCCO PLASTICA

GALLEGGIANTE TANK/COOLER

SENSORE DI LIVELLO

SISTEMA REFRIGERANTE

MOBILE COOLER

SPEED PRO

FIG. 7.1

80.1

SPEED PRO

FIG. 7.2

1

2

EN

80. 1

FEEDER WITH DRAIN

80. 2

SS MAIN TUBE

80. 3

METAL CLAMP

80. 4

HOSE

80. 5

INNER STAND COVER

80. 6

PLASTIC SECURING KNOB

80. 7

TUBE NUT

ES

ALIMENTADOR C/DESAGÜE

TUBO CENTRAL INOX

ABRAZADERA METÁLICA

TUBO FLEXIBLE

TAPA INTERIOR MUEBLE

VOLANTE PLÁSTICO

TUERCA TUBO

80.7

80.3

80.4

FR

DISTRIBUTEUR AVEC VIDANGE

TUBE CENTRAL INOX

COLLIER METALLIQUE

TUBE FLEXIBLE

PLAQUE INTÉRIEURE MEUBLE

ECROU PAPILLON EN PLASTIQUE

TUBE NUT

80.2

80.5

80.6

DE

ZUFÜHRUNG MIT ABLAUF

ZENTRALES ROHR ROSTFREI

METALLSCHELLE

SCHLAUCH

INNENDECKEL UNTERSCHRANK

SICHERHEITSSCHRAUBE KUNSTSTOFF

ROHRMUTTER

IT

ALIMENTATORE C/SCARICO

TUBO CENTRALE INOX

FLANGIA METALLICA

TUBO FLESSIBILE

COPERCHIO INTERNO MOBILE

VITE DI SICUREZZA PLASTICA

TUBE NUT

2

S

PEED PR

O

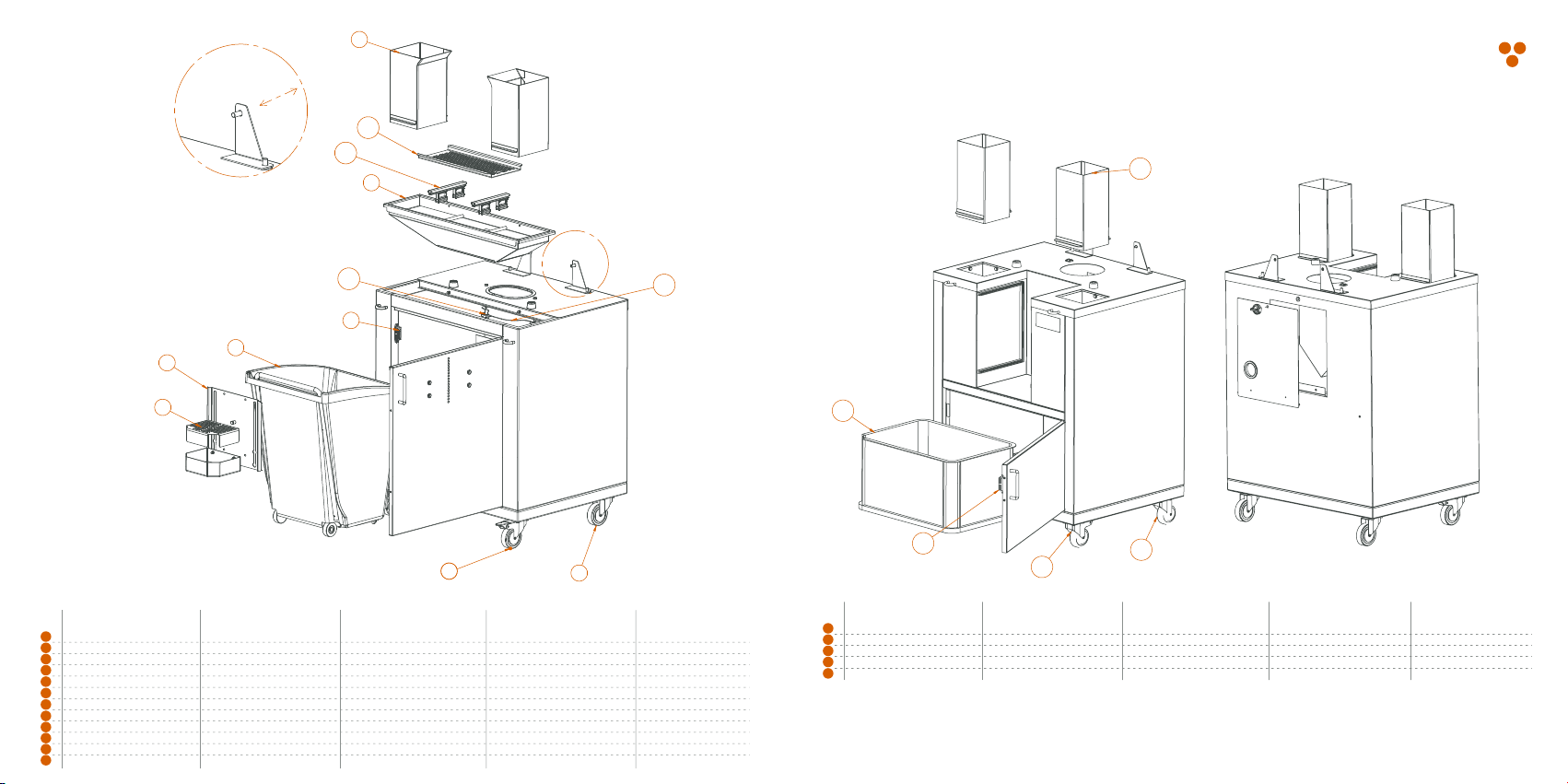

FIG. 8

DETALLE A

90.7B

90.6

90.7A

90.3

SPEED PRO

FIG. 9.1 - 9.2

100.5

90.10

90.5

90.8

90.9

EN

90. 1

SWIVEL WHEEL WITH BRAKE

90. 2

SWIVEL WHEEL WITHOUT BRAKE

90. 3

STAND HOPPER

90. 4

WASTE BIN

90. 5

DOOR LOCK MAGNET

90. 6

PEEL OUTLET

90. 7 A

SS STAND FILTER

90. 7 B

TANK GUIDES

90. 8

TRAY FRONT

90. 9

TRAY FILTER

90. 10

PLASTIC SECURING KNOB

90. 11

SS/TANK STAND COVER

90.4

ES

RUEDA GIRATORIA CON FRENO

RUEDA GIRATORIA SIN FRENO

TOLVA MUEBLE

CARRITO RESIDUOS

IMÁN CIERRE PUERTA

CAÍDA CORTEZAS

FILTRO MUEBLE SS

GUIAS DEPÓSITO TANK

FRONTIS BANDEJA

FILTRO BANDEJA

VOLANTE PLÁSTICO INYECCIÓN

TAPA MUEBLE TANK-SS

FR

ROUE TOURNANTE AVEC FREIN

ROUE TOURNANTE SANS FREIN

ENTONNOIR MEUBLE

CHARRIOT À DÉCHETS

AIMANT FERMETURE PORTE

RÉCUPÉRATEUR DECHETS

FILTRE MEUBLE SS

GUIDES TANK

PLAQUE FACE BAC

FILTRE BAC

ECROU PAPILLON PLASTIQUE INJECTION

PLAQUE MEUBLE SS/TANK

90.1

DE

SCHWENKROLLE MIT BREMSE

SCHWENKROLLE OHNE BREMSE

TRICHTER UNTERSCHRANK

ABFALLWAGEN

TÜRVERSCHLUSSMAGNET

SCHALENAUSTRITT

FILTER UNTERSCHRANK SS

BEHÄLTERFÜHRUNGEN TANK

FRONTBLENDE TABLETT

FILTER TABLETT

SICHERHEITSSCHRAUBE SPRITZGUSSKUNSTSTOFF

UNTERSCHRANK SS/TANK

90.2

A

90.11

IT

RUOTA GIREVOLE CON FRENO

RUOTA GIREVOLE SENZA FRENO

TRAMOGGIA MOBILE

CARRELLO SCARTI

CALAMITA CHIUSURA SPORTELLO

CADUTA BUCCE

FILTRO MOBILE SS

GUIDA SERBATOIO TANK

FRONTALINO VASCHETTA

FILTRO VASCHETTA

VITE DI SICUREZZA PLASTICA INIEZIONE

COPERCHIO MOBILE SS/TANK

100.3

EN

100. 1

SWIVEL WHEEL WITH BRAKE

100. 2

SWIVEL WHEEL WITHOUT BRAKE

100. 3

PEEL BUCKET

100. 4

DOOR LOCK MAGNET

100. 5

PEEL CHUTE

100.4

100.1

ES

RUEDA GIRATORIA CON FRENO

RUEDA GIRATORIA SIN FRENO

CUBO CORTEZAS

IMÁN CIERRE PUERTA

CAÍDA CORTEZAS

100.2

FR

ROUE TOURNANTE AVEC FREIN

ROUE TOURNANTE SANS FREIN

BAC À DECHETS

AIMANT FERMETURE PORTE

RÉCUPÉRATEUR DECHETS

DE

SCHWENKROLLE MIT BREMSE

SCHWENKROLLE OHNE BREMSE

SCHALENEIMER

TÜRVERSCHLUSSMAGNET

SCHALENAUSTRITT

IT

RUOTA GIREVOLE CON FRENO

RUOTA GIREVOLE SENZA FRENO

DEPOSITO BUCCE

CALAMITA CHIUSURA SPORTELLO

CADUTA BUCCE

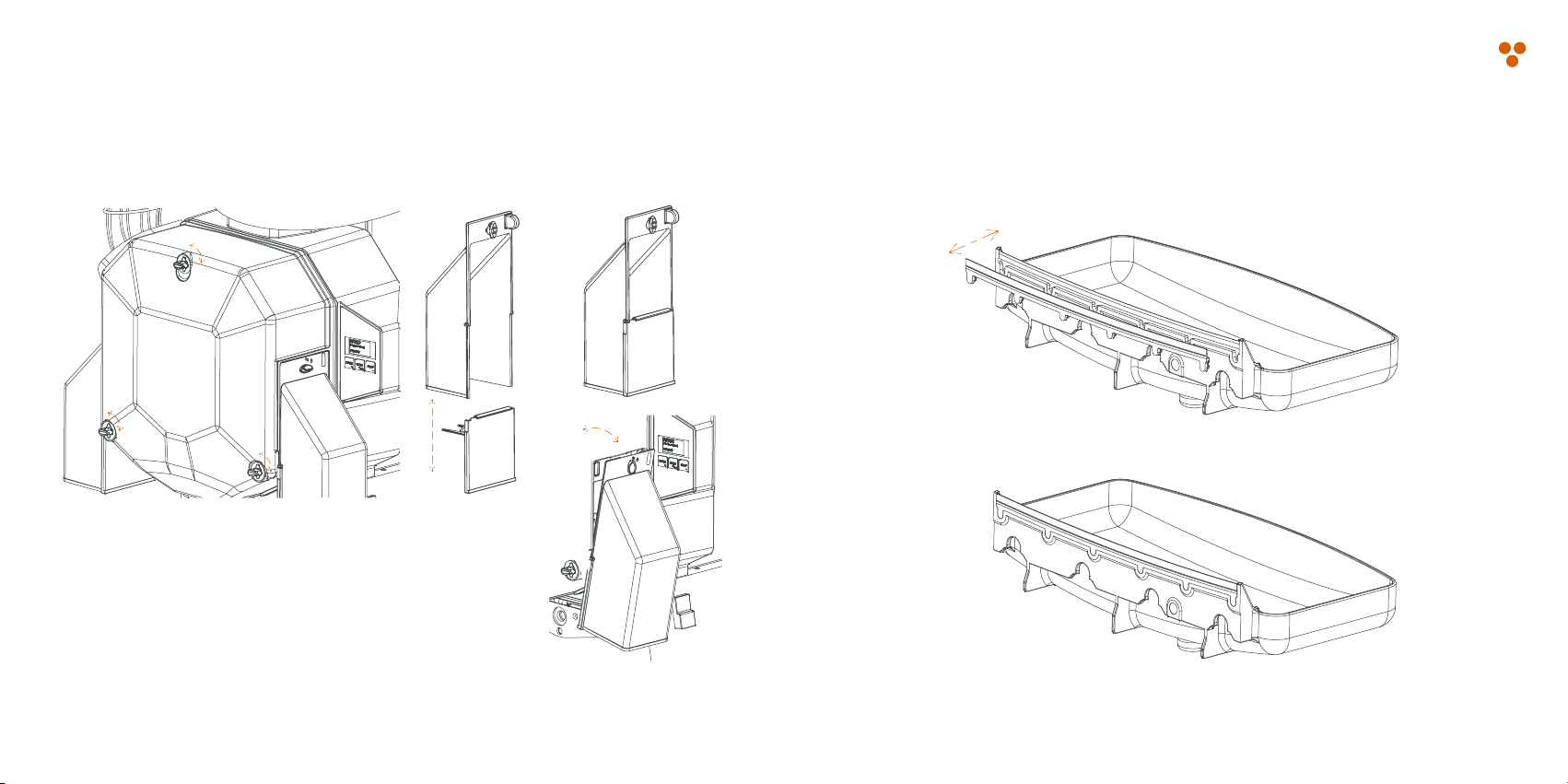

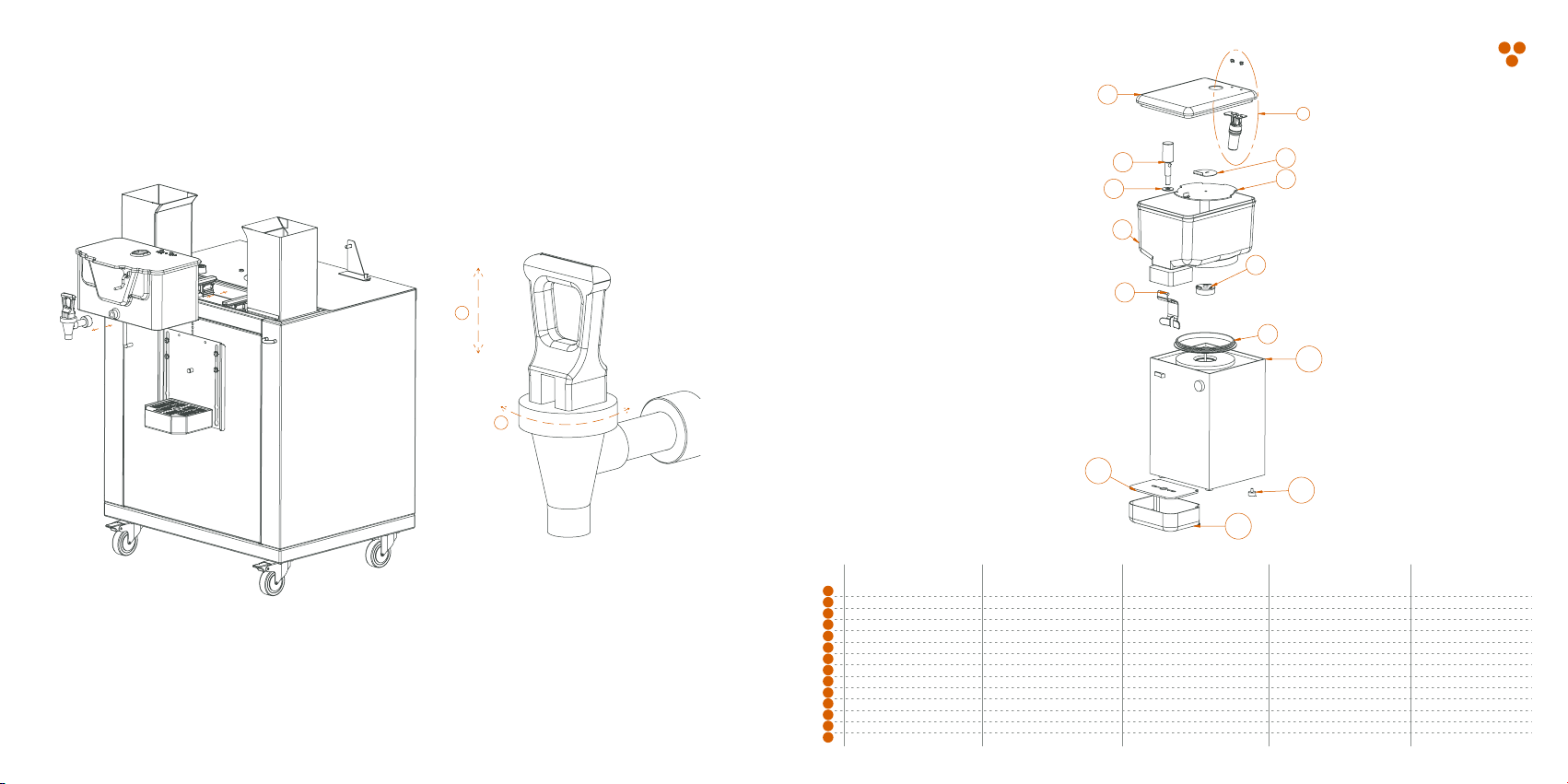

SPEED PRO

FIG. 10

SPEED PRO

FIG. 11

1

1

32

4

2

SPEED PRO

FIG. 12

SPEED PRO

FIG. 13

12

34

12

34

SPEED PRO

FIG. 14

SPEED PRO

FIG. 15

a

b

23

SPEED PRO

FIG. 16

1

SPEED PRO

FIG. 17

SPEED PRO

FIG. 18.1 - 18.2

SPEED PRO

FIG. 19

70.1

52

70.3

70.4

70.2

70.5

70.6

70.7

70.8

2

70.9

70.10

1

70.11

70.13

70.12

IT

GALLEGGIANTE TANK/COOLER

TAPPO SERBATOIO

PIASTRA DI ATTACCO

PISTONE RUBINETTO

GUARNIZIONE RUBINETTO

COPERCHIO POMPA

SERBATOIO

TURBINA POMPA

LEVA COMANDO RUBINETTO

GUARNIZIONE SERBATOIO

SISTEMA REFRIGERANTE

GRIGLIA VASCHETTA

VASCHETTA RACCOGLIGOCCE H

PIEDINO LIVELLATORE

52

70. 1

70. 2

70. 3

70. 4

70. 5

70. 6

70. 7

70. 8

70. 9

70. 10

70. 11

70. 12

70. 13

EN

TANK / COOLER BUOY

TANK COVER

COUPLER PLATE

TAP PISTON

TAP GASKET

PUMP COVER

TANK

PUMP TURBINE

TAP CONTROL LEVER

TANK GASKET

COOLER UNIT

TRAY GRATING

DRIP TRAY H

LEVELLING FOOT

ES

BOYA TANK/COOLER

TAPA DEPÓSITO

PLACA DE ENGANCHE

PISTÓN GRIFO

JUNTA GRIFO

TAPA BOMBA

DEPÓSITO

TURBINA BOMBA

PALANCA MANDO GRIFO

JUNTA DEPÓSITO

UNIDAD ENFRIADORA

REJILLA CAJÓN

CAJÓN RECOGE GOTAS H

PIE NIVELADOR

FR

FLOTTEUR TANK/COOLER

COUVERCLE RÉSERVOIR

PLAQUE CONNECTEUR

PISTON ROBINET

JOINT ROBINET

COUVERCLE POMPE

RÉSERVOIR

TURBINE POMPE

TIRETTE DE COMMANDE ROBINET

JOINT RÉSERVOIR

UNITÉ REFROIDISSEUR

GRILLE BAC

BAC ANTIGOUTTES H

VIS DE REGLAGE HAUTEUR

DE

SCHWIMMER TANK/COOLER

DECKEL SAFTBEHÄLTER

BEFESTIGUNGSPLATTE

KOLBEN HAHN

DICHTUNG HAHN

DECKEL PUMPE

BEHÄLTER

TURBINE PUMPE

BETÄTIGUNGSHEBEL HAHN

DICHTUNG BEHÄLTER

KÜHLEINHEIT

GITTER KASTEN

TROPFAUFFANGKASTEN H

NIVELLIERFUSS

Welcome to the Zumex new

series of the fastest and most

robust machine.

Speed pro presents a new generation of juicers, ready to offer the best

juice at your point of sale, in the easiest possible way.

A new range that has been especially designed for cafeterias,

hotels, service areas and supermarkets where there is a large juice

demand, which strive to offer their clients a high quality service and a

Life Essence experience.

EN

25

Speed Pro

User’s Manual. Original instructions.

In this manual, you will nd all the information you need to assemble

and start up your new Speed Pro series juicier, as well as about its

operation, features, accessories, tips and precautions.

Please read the instructions carefully to get the most out of your

Speed Pro and begin to feel the difference.

EN

CONTENTS

IMPORTANT GENERAL INFORMATION

TECHNICAL FEATURES

INSTRUCTIONS FOR USE

• PREPARATION

• UNPACKING AND START-UP

• ASSEMBLY AND DETACHMENT

OF COMPONENTS ACCORDING TO MODEL

• ACCESSORIES

• GENERAL OPERATION

• CONFIGURATION

• CLEANING

TROUBLESHOOTING AND TIPS

EU DECLARATION OF CONFORMITY

ANNEX

DRAWING AND DESCRIPTION. PAGE 2.

27

IMPORTANT GENERAL INFORMATION

This manual refers to the following

Zumex models

COUNTERTOP MODELS

ZUMEX SPEED PRO

ZUMEX SPEED PRO SELF SERVICE

Before you start, we recommend you to take the following

precautions into account:

• The specic details about your Zumex juicer (voltage, frequency and other data of interest), can

be found on the Identication Label attached to the actual machine.

• Remember that if you have any technical queries, you should get in touch with your Regular

Dealer / Ofcial Technical Support Service, always stating the Serial Number on the machine

Identication Label.

• Zumex adopts the necessary measures to ensure that the machines placed on the market are

selectively collected and managed in an environmentally respectful manner. Please contact your

authorised Zumex dealer to correctly dispose of these machines.

Do not manipulate the machine in such a way that it works

•

without safety elements.

• This appliance can be used by children over the age of 8 or older,

or by people with impaired physical, sensorial or mental capacities

or who lack experience or knowledge, if they are supervised or

have received adequate training with respect to the safe operation

of the appliance and they understand the risks entailed.

EN

MODELS WITH STAND

ZUMEX SPEED PRO SELF SERVICE PODIUM

ZUMEX SPEED PRO SELF SERVICE PODIUM DRAIN&CLEAN SYSTEM

ZUMEX SPEED PRO TANK PODIUM

ZUMEX SPEED PRO TANK PODIUM DRAIN&CLEAN SYSTEM

ZUMEX SPEED PRO COOLER PODIUM

• Children should be supervised to make sure they do not play

with the appliance.

• The cleaning and maintenance to be performed by the user

must not be carried out by children without supervision.

• This machine contains an equipotential terminal on the rear

to connect the Earth Tap of other appliances to the Earth Tap

29

of your installation through this terminal. If you use it, slacken

the nuts and washers, couple the Earth Tap cable of the auxiliary

appliance and rmly tighten the nuts and washers again. This

equipotentiality point is indicated with the following symbol:

• Do not spray the appliance with water to clean it.

• This machine is designed for squeezing citrus fruit of the size

indicated in this manual: Orange, Mandarin, Pomegranate and

Grapefruit.

• Do not use other different fruit to that specied in the manual.

• When you clean, perform maintenance or replace parts, make

sure that you have always unplugged the power cable from the

socket and it is visible.

• Use the cutting elements with great care, to avoid possible cuts.

• The parts that are in contact with food must be cleaned

according to the instructions that you can read in the cleaning

chapter.

• The cable is sent with a protector in order to prevent accidentally

pulling the cable out. Please make sure you t this protection as

indicated below in the instructions, to guarantee the safety of

the appliance.

The instructions may be updated. You can consult the updated instructions on our website

www.zumex.com, in the section of the selected model.

If you have any suggestions or comments that you believe may improve our machines or service

network, please get in touch with Zumex directly at the address below:

ZUMEX GROUP, S.A.

Polígono Ind. Moncada III C/Molí 2. 46113 Moncada. Valencia. España.

Tel. +34 961 301 251 Fax: +34 961 301 255

zumex@zumex.com / www.zumex.com

EN

• If the power cable is damaged, it must be replaced with a cable

or special unit to be supplied by the manufacturer or by the aftersales service.

31

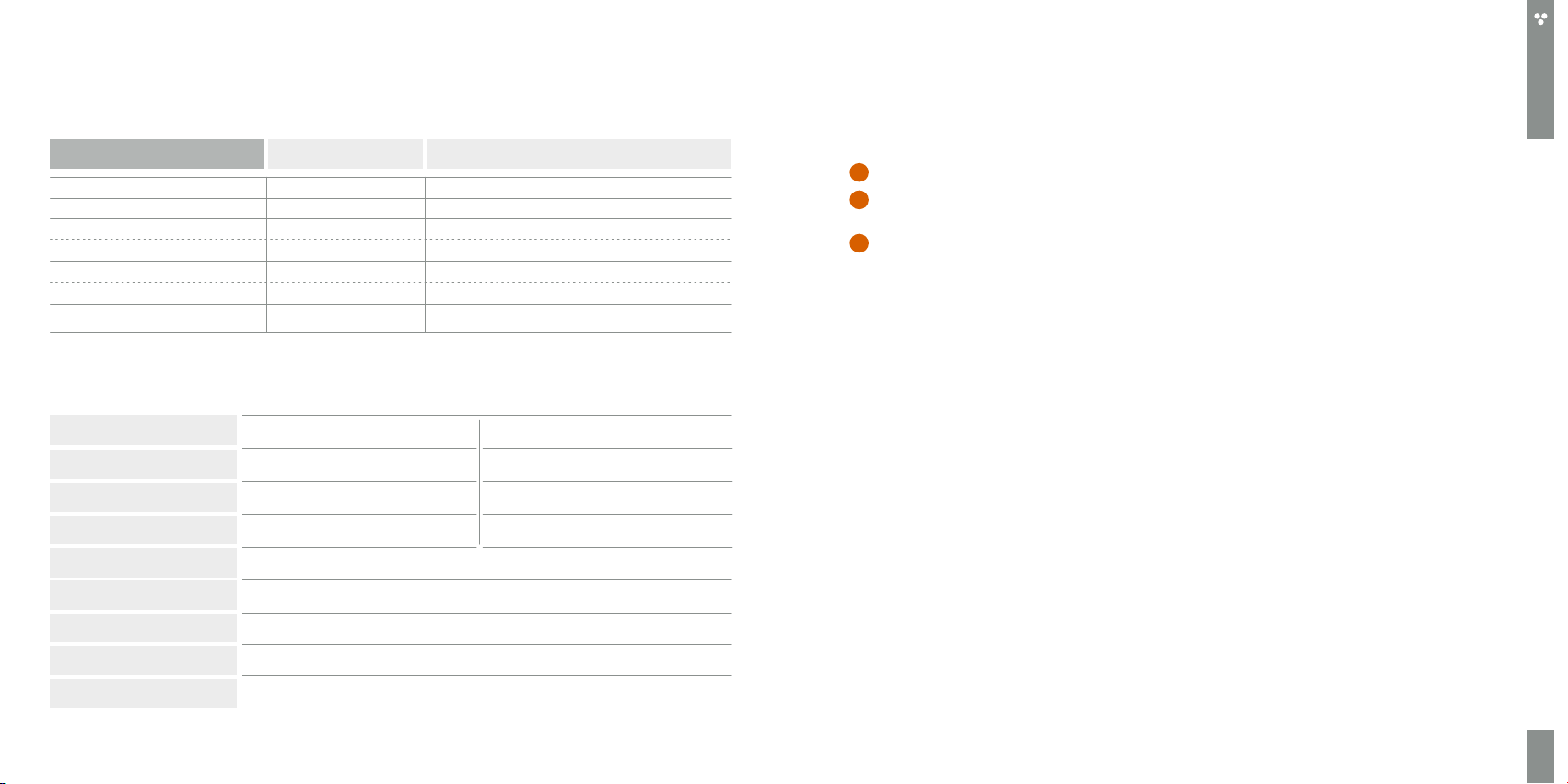

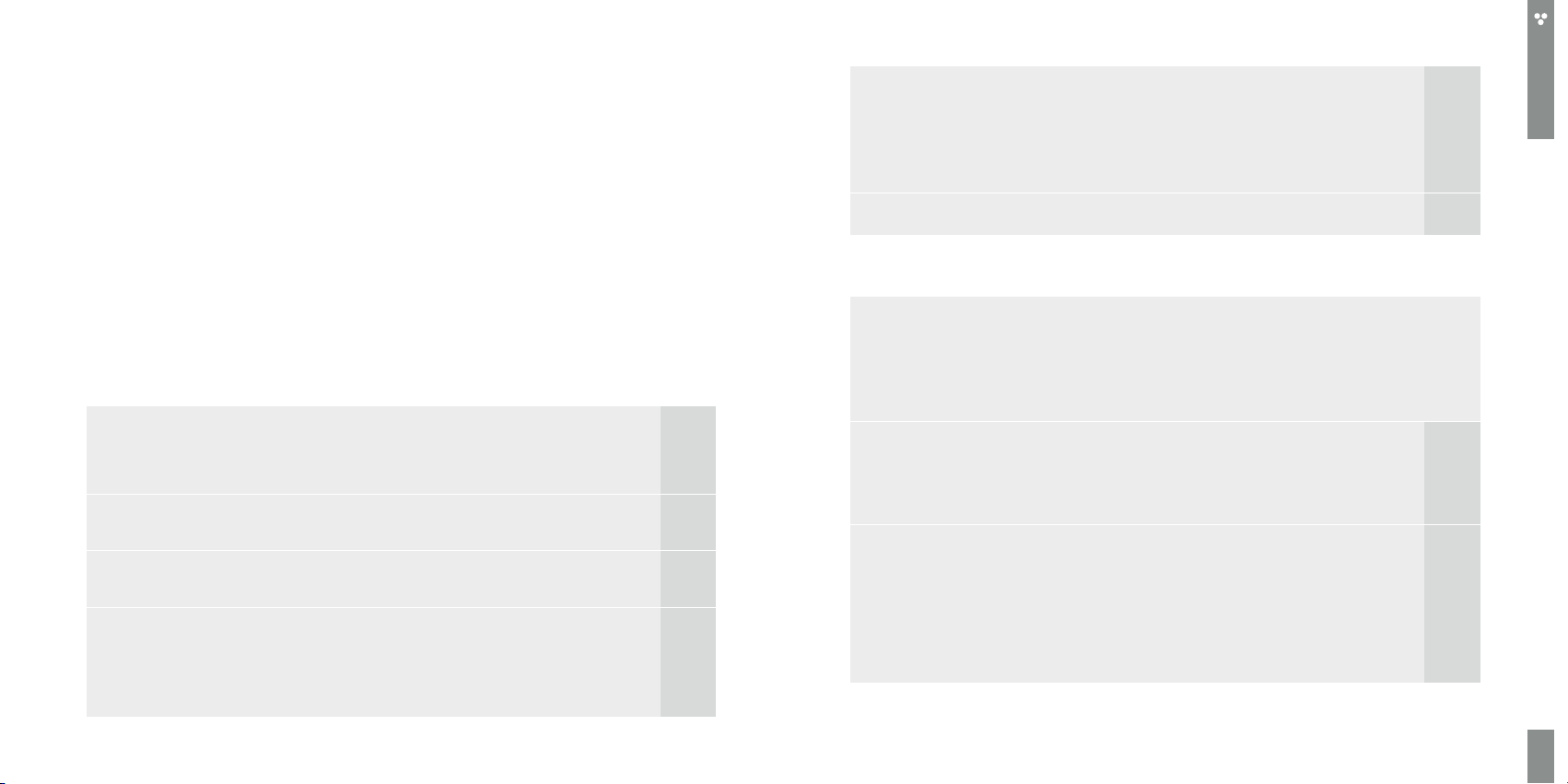

TECHNICAL FEATURES

MODEL Weight Dimensions I WIDTH X HEIGHT X DEPHT I

SPEED PRO 64.7 kg 142.4 lb 593 x 574 x 989 mm 23.35 x 22.6 x 38.94 ”

SPEED PRO SELF SERVICE 72.2 kg 158.9 lb 593 x 658 x 1050 mm 23.35 x 25.91 x 41.34 ”

SPEED PRO SELF SERVICE PODIUM 118.1 kg 259.9 lb 675 x 700 x 1765 mm 26.57 x 27.56 x 69.49 ”

with DRAIN&CLEAN SYSTEM 119.4 kg 262.8 lb 675 x 700 x 1765 mm 26.57 x 27.56 x 69.49 ”

SPEED PRO TANK PODIUM 116.7 kg 256.6 lb 675 x 700 x 1765 mm 26.57 x 27.56 x 69.49 ”

with DRAIN&CLEAN SYSTEM 118.0 kg 259.5 lb 675 x 700 x 1765 mm 26.57 x 27.56 x 69.49 ”

SPEED PRO COOLER PODIUM 128.3 kg 282.2 lb 675 x 727 x 1850 mm 26.57 x 28.62 x 72.83 ”

OTHER CHARACTERISTICS (For all models)

115V | 60 Hz 220/240 V | 50/60 Hz

Voltage

320 W (560 W COOLER) 300 W (560 W COOLER)

Power

2.7 A (4.87 A COOLER) 1.2 A (2.4 A)

Consumption

40 37/40

Oranges per minute

Fruits * Oranges, tangerines, limas, grapefruits, pomegranates

Size of fruit 65 - 85 mm (50 - 65 mm with Kit D65)

Feeder capacity 20 kg | 44 lb

Protection IPX4

Sound pressure level Lower 70 dB (A)

INSTRUCTIONS FOR USE

PREPARATION

To start to extract juice, you must follow the steps below:

Unpack your juicer and place it on as at a surface as possible.

1

Make sure that the mains voltage coincides with the voltage indicated on the machine

2

identication label that you will nd on the machine.

3

Ensure that no obstacles hinder you during the unpacking process.

UNPACKING AND START-UP

Follow the instructions given, depending on the machine model you have purchased.

SPEED BASIC PRO

The following components come loose and must be mounted if necessary: Right cover side outlet

(2), Left cover side outlet (3), Power cable (15), Cable protector (16), Peel bucket (20), Drip try (21),

Plastic juice container (30), Inner plastic lter (31), Plastic juice lter (32).

See Figures 1 and 2.

SPEED PRO SELF SERVICE

The following components come loose and must be mounted if necessary: Right cover side outlet

(2), Left cover side outlet (3), Power cable (15), Cable protector (16), Peel bucket (20), Drip try (21),

SS juice container (40), SS Sublter (41), SS/TANK lter (42), Pulp sweeper (43), SS tap (44), Machine

supplement (47).

See Figures 1 and 3.

SPEED PRO SELF SERVICE PODIUM, SPEED PRO SELF SERVICE PODIUM DRAIN&CLEAN SYSTEM

The following components come loose and must be mounted if necessary: Right cover side

outlet (2), Left cover side outlet (3), Power cable (15), Cable protector (16), SS juice container (40), SS

Sublter (41), SS/TANK lter (42), Pulp sweeper (43), SS tap (44).

See Figures 1 and 4. See section SS/TANK STAND (90) for information about your machine stand.

EN

* For other fruits squeezed always check with your nearest dealer.

33

SPEED PRO TANK PODIUM, SPEED PRO TANK PODIUM DRAIN&CLEAN SYSTEM

The following components come loose and must be mounted if necessary: Right cover side outlet

(2), Left cover side outlet (3), Power cable (15), Cable protector (16), SS/Tank lter (42), Pulp sweeper

(43), Tank juice container (50), Tank sub-lter (51), Tank/Cooler buoy (52), Tank (53), Shaker (54), Tank

Tap (55).

See Figures 1 and 5. See section SS/TANK STAND (90) for information about your machine stand.

SPEED PRO COOLER PODIUM

The following components come loose and must be mounted if necessary: Right cover side outlet

(2), Left cover side outlet (3), Power cable (15), Cable protector(16), Plastic juice container (30),

Plastic inner lter (31), Plastic juice lter (32), Cooler unit (70), Tank/Cooler buoy (52).

See Figures 1 and 6. See section COOLER STAND (100) for information about your machine stand..

ASSEMBLY AND DETACHMENT OF

COMPONENTS ACCORDING TO MODEL

EN

1. ASSEMBLY

SPEED PRO COVER (1)

Line up the 3 holes of the cover with the 3 shaft knobs. Turn these 90º in clockwise direction

(Figure 10).

RIGHT COVER SIDE OUTLET (2), LEFT COVER SIDE OUTLET (3)

Make sure that the side outlets are fully mounted and correctly in place (Figure 10).

The Side Outlets are not the same. Make sure you place the respective Side Outlet on the correct side.

Line up the lower part of the Side Outlet and turn towards the cover until the clip clicks in.

DRAIN&CLEAN SYSTEM (80)

If you have purchased a Drain&Clean System model, your machine will have a drain that goes from

the feeder to the waste bin inside the machine.

See Figure 7.1.

SELF SERVICE STAND/TANK PODIUM STAND (90)

COOLER STAND (100)

You will receive it in a different package, depending on the machine model you have received.

All the stand components can be found inside the stand.

LOWER PRESSING UNIT (4), UPPER PRESSING UNIT (5)

Place the pressing units in the shafts (Figure 1).

Always mount the lower and upper pressing units of the same side at the same time to make it

easier to position them.

INJECTION PLASTIC SECURING KNOB (6)

Screw in the knobs to secure the pressing units and the feeder plate (Figure 1).

LEFT PEEL EJECTOR (7), RIGHT PEEL EJECTOR (8)

Place the ejectors on the respective side on the guides (Figure 1).

BLADE-HOLDER (9)

Place the blade carefully on its guide and push inwards (Figura 1).

35

FEEDER BASKET (13)

The feeder basket can be removed and re-attached facing guides and making a slight movement

until it stops (Figure 1).

PLASTIC JUICE CONTAINER (30)

Make sure that the sealing gasket is correctly mounted on the container (Figure 11). Then place

the container in the machine. Line up and place under the container on the four lugs that you will

see on the machine (Figure 2).

EN

FEEDER BASKET DOOR (14)

The feeder basket has an easy-to-open door to make it easier to ll the basket up with oranges

(Figure 1).

POWER CABLE (15)

When you receive the machine, you must connect the cable to the machine base (Figure 1).

CABLE PROTECTOR with 3 screws (16)

Fit to prevent the cable from being accidentally removed (Figure 1).

SS/TANK TRAY GASKET 6.3 x 3.5 (17)

If required, this gasket can easily be removed for cleaning and tted back in by hand (Figure 1).

TRAY BOLT (18)

This component only has to be handled if a spare SS Juice container (40) or Tank juice container (50)

is requested (Figure 1). After inserting the spare container, adjust the bolt from the rear to adjust

the container position.

PEEL BUCKET (20)

Place the peel buckets under the side outlets of the cover (Figure 2 or 3 depending on model).

DRIP TRAY (21)

Place under the juice outlet (Figure 2 or 3 depending on model).

PLASTIC INNER FILTER (31)

Place on the inside of the juice extraction container (Figure 2).

PLASTIC JUICE FILTER (32)

Place on the inside of the juice extraction container (Figure 2).

SS JUICE CONTAINER (40)

Line up the container in the main opening. At the same time, line up the two side lugs at the ends

of the container and press. Pressing the side buttons may help mount it (Figure 12).

SS SUB-FILTER (41)

Place on the inside of the juice extraction container (Figure 3).

SS/TANK FILTER (42)

Line up the 2 rear openings with the 2 inner rear lugs of the container. Let the lter fall forwards

and line up the front openings with the front lugs.

The lter rests on the SS juice container (40) (Figure 3) or Tank juice container (59) (Figure 5).

PULP SWEEPER (43)

Make sure that the inner guide of the pulp sweeper is correctly mounted (Figure 13).

You can extract or insert the pulp sweeper by turning the side catch 90º (Figure 13).

Note: Make sure that the catch is in its closed position, so that the pulp sweeper can never

accidentally drop from the lter.

37

SELF SERVICE TRAY TAP (44)

To mount the Self Service tap in the container, line up the rear lug and screw the oating nut on

the rear of the tap (Figure 3).

TAP OPERATION

You can make the tap work normally by pressing and releasing it to extract the juice

(Figure 14.1).

You can lock/unlock the “free spout” or “discontinuous spout” function by leaving the catch

in position “a” (free position) or in either of the 2 positions “b” for locking the relative spout

(Figure 14.2).

You can anchor the button in “free spout” position. To this end, turn the ring with the dotted/

solid lines until the solid line coincides with the glass symbol.

Release the button. This will secure it.

To release it, just press the button again (Figure 14.1).

For daily cleaning, you can remove the upper part of the tap and the inlet spout (Figures 14.3

and 14.4).

TANK SUB-FILTER (51)

Place on the inside of the juice extraction container (Figure 5).

EN

TANK/COOLER BUOY (52)

TANK MODEL

Line up the lugs of the buoy support with the holes on the lid and screw the nut (Figure 16.1)

Insert the buoy and place the lid on the tank (Figure 16.2 and 16.3).

The BUOY unit can be detached as indicated in Figure 17 for cleaning.

COOLER or TANK MODEL

Slacken the upper lugs. Line up the plate with the openings from below. Tighten the upper

lugs again (Figure 19).

TANK (53)

Use the thread to secure the Self Service tap to the Tank container. Make sure that it is in

upright position (Figure 18.1).

DETECTOR TUBE GASKET (46)

If required, this gasket can be removed for cleaning (Figure 3 or 4).

MACHINE SUPPLEMENT (47)

Use this supplement to raise the machine (Figure 3).

Important! The machine must never be placed on the supplement by one single person.

TANK JUICE CONTAINER (50)

Line up the two side lugs at the ends of the container and press. Pressing the side buttons may

help mount it (Figure 15).

To remove the container, just press the side buttons and pull out towards you.

TANK TAP (55)

Use the thread to secure the Self Service tap to the Tank container. Make sure that it is in upright

position (Figure 18.1).

The Tank tap can work continuously or discontinuously. Just turn the handle 180º and it will be

locked when the handle is lowered, thus permitting free spout.

For cleaning, you can remove the upper part of the Self Service tap (Figure 18.2).

LEVEL DETECTOR (56)

This component only needs to be manipulated if a spare part is requested. Remember to place the

detector in the same position as the original detector. If you have a Tank machine, the detector

is located in the upper part; if you have a Cooler machine, it is located in the lower part (Figure 5

and Figure 6).

39

COOLER UNIT (70)

Place the cooler unit in its housing in the stand (Figure 6).

Mount the components as indicated in Figure 19 in this order.

Mount the piston-gasket and the lever in the tank following the steps indicated in the

enclosed drawing.

Fit the tank.

Adjust the pump lid inside the tank with the arrow pointing towards you.

Secure the metal coupler plate, securing the tank with it.

SS/TANK STAND (90), COOLER STAND (100)

Machine placement on display stand:

IMPORTANT: This operation must be carried out by 2 or 3 people. It must never be attempted

by just one person.

Lock the front wheels of the stand with the brake pedal to prevent it from moving during the

installation.

After unpacking the stand, remove the screws from the xing brackets and put them on one

side for later. See detail “A” of Figure 8.

The peel chutes and the drip tray of the stand with lter are located on the inside of the stand.

Place the machine on the stand, making the inside corners of the machine base coincide

with the two rubber blocks of the stand. Thus, the xing bracket holes will coincide with

the machine holes. You can now secure the machine with the screws mentioned above (See

Figure 5 or 6).

Remember:

The machine and display stand are joined together with the screws supplied, as indicated in

this instructions manual.

Never try to tilt the machine or the stand. To move, unlock the wheels.

INDIVIDUAL FEATURES FOR SS/TANK STAND (90)

For the Self Service and Tank stands, secure the drip tray with its lter in the display stand.

If you have purchased a model with Drain&Clean System:

Important! Unplug the machine from the wall socket.

If tted, remove the Peel chute (90.6), the SS stand lter (90.7A) and the Stand hopper (90.3)

(Figure 8). Open the front door (Figure 8).

Find the upper hole (Figure 7.2) and insert your hand, taking hold of the Flexible tube (80.4) and

placing it in the hole (Figure 7.1). Do not pull or hold any other part of the machine.

Later, place the lower cover of the tube with the two securing knobs supplied and t all the

previously removed parts back on.

See parts breakdown on how to t the components (Figure 8).

Component 90.7 varies depending on the stand model purchased:

Self Service stand: Component SS stand lter (90.7A).

Tank stand: Component TANK tank guides (90.7B).

The position of components Tray front (90.8) and Tray lter (90.9), can be adjusted to be able to

adapt them to different bottle and glass formats.

INDIVIDUAL FEATURES FOR COOLER STAND

See Figure 6 and 9.1 on how to t the components correctly.

Pass the power cable of the Cooler unit through the hole on the rear door. To do this, you can

unscrew the door if necessary (Figure 9.2).

2. DETACHMENT

The components are detached in reverse order to that indicated in each section.

EN

ACCESSORIES

Consult the different accessories you can attach to your machine on the Zumex website www.zumex.com.

You will nd a wide range of accessories to congure your juicer according to your needs: Bottles, Bottle

Rack Kit, Self Service Tray Kit, Dynamic Cutting System, etc.

41

GENERAL OPERATION

Once you have installed the machine correctly and before plugging it into the mains, conrm electrical

data coincide with the electricity supply. If everything is correct, plug the machine into the mains.

To switch the machine on, press the green ON button. The LED of the ON/OFF button and the digital

display of the machine will light up.

Before operating the machine with oranges, you must calibrate it without load. Enter the Calibration

section of the CLIENT MENU, or leave the machine operating without load for approximately 1

minute until it comes to a stop.

To make sure the count is correct, you may have to adjust the Offset parameter after calibrating the

machine.

To do so, enter MENU>5.Calibration>2.Offset and adjust the value. Exit the Menu and check the count

without load, and with 2 or 3 oranges. Repeat the process again until you nd the value that allows for

a correct machine count.

To avoid possible counting errors, try not to stop the machine with an orange trapped between the

upper and lower pressing units.

The orange counter is shown in all the models. (Deviation +-1%)

Remember to put a jug or glass under the juice outlet of your machine.

The machine will not work if any safety element is missing.

If necessary, you can always switch the machine off as follows:

A

Release the actuator used. For example, the tap.

Press the STOP button.

B

Press the red OFF button.

C

ONLY IN EMERGENCIES: Unplug the machine directly from the wall socket.

D

If the machine does not detect oranges, it will stop approximately 60” after the last orange has

E

passed through.

LOADING THE FEEDER

To load the machine feeder with oranges, you can open the Feeder basket (14) door and partially

empty the box of oranges into it. Close the door and nish lling the basket.

JUICE EXTRACTION UNIT

Make sure that all the elements that permit cutting the orange, extracting the juice and collecting

it are mounted on the machine. To do this, consult the machine model purchased on the diagram

indicated in section: UNPACKING AND START-UP. ASSEMBLY AND DETACHMENT OF COMPONENTS

ACCORDING TO MODEL.

Check the state of the containers and lter to guarantee quality juice.

If you have purchased a machine with Pulp sweeper (43), use this from side to side, to deposit remains

of pulp, seeds, etc. in the waste bins.

If you have purchased a machine with SS tap (44) or Tank tap (55), read the instructions for use of the

Self Service tap in section ASSEMBLY AND DETACHMENT OF COMPONENTS ACCORDING TO MODEL.

If you have purchased an automatic lling machine, the machine will stop automatically when it

reaches maximum level. Remember to t the Tank/Cooler buoy (2), following the assembly instructions.

You will also have to select lling quantity.

WASTE AREA

Make sure that the elements that collect the orange peel are correctly positioned.

Check if the tanks are getting full, to prevent the peel from owing over.

You can also use the new function, WASTE LIMIT, which enables you to programme an alarm so that

the machine will stop when the waste bin is full.

You can select the number of oranges you want to squeeze before the alarm sounds. Once you have

squeezed the amount of oranges programmed, the machine will stop and a warning will appear on the

display so that the operator knows the waste bin has to be emptied.

If you have purchased a machine with PODIUM, the peel will fall directly into the Waste bin (90.4) or

Peel bucket (100.3).

To switch the alarm off, press the “OK” button for approximately 2” until it comes to a stop.

EN

43

Remember!

“Short OK”, it doesn’t switch off.

“Long OK”, double “beep”, to switch off.

To switch the alarm off permanently, enter the Waste Limit section of the CLIENT MENU.

If the machine is turned off or unplugged, the waste alarm will be eliminated and it will start from

zero again.

MACHINE OPERATION

GENERAL

The machine can operate in Professional or Automatic mode in all the models. To shift from one mode

to another keep the Mode button pressed for a few seconds. Whenever you change from Automatic

to Professional, you will be asked to program the number of oranges to be squeezed. If you do not

want to change the quantity, just wait a few seconds or quickly press the OK button. If you wish to

modify the quantity, press the + - buttons to select the quantity, and then the OK button until the

Saved symbol appears.

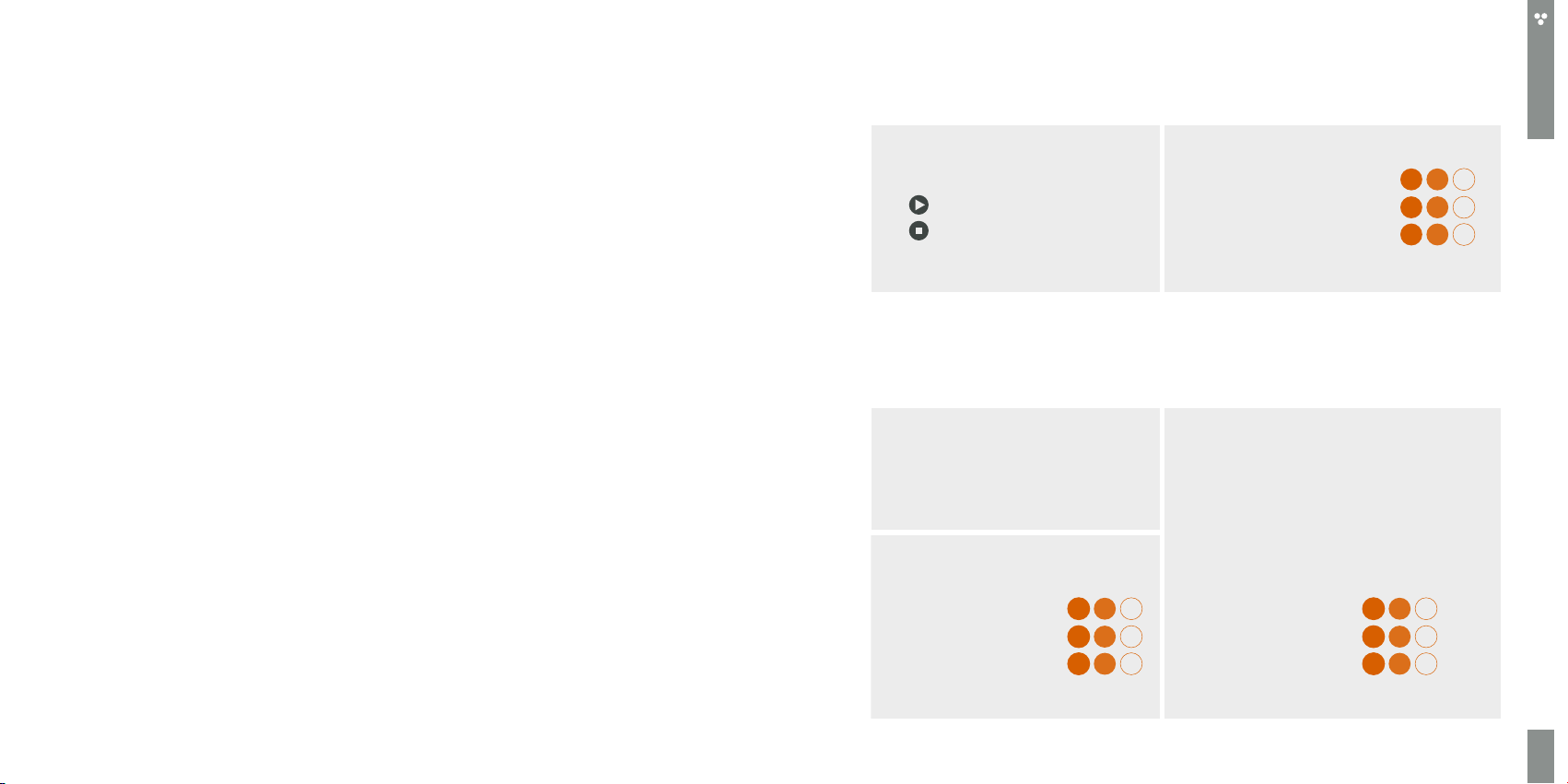

SPEED PRO BASIC MODEL

AUTOMATIC MODE

From automatic mode:

START STARTS THE MACHINE

STOP STOPS THE MACHINE

Uninterrupted operation.

PROFESSIONAL MODE

MINIMUM NUMBER OF ORANGES

MAXIMUM NUMBER OF ORANGES

DEFAULT VALUE

Operation until its reaches the quantity stipulated.

SPEED PRO SELF SERVICE, SPEED PRO SELF SERVICE PODIUM,

SPEED PRO SELF SERVICE PODIUM DRAIN&CLEAN SYSTEM

The START button is not active. It is only active in MANUAL mode.

EN

1

12

3

AUTOMATIC MODE

Control from SS tap (44).

Uninterrupted operation,

whilst the tap is pressed.

PROFESSIONAL MODE

Control from tap whilst pressed.

MINIMUM NUMBER OF ORANGES

MAXIMUM NUMBER OF ORANGES

DEFAULT VALUE

MANUAL MODE (If the tap does not work)

The START button becomes active in Manual mode.

In manual mode, it is still possible in Automatic

and Professional mode from the keypad.

“AUTOMATIC” MANUAL

Uninterrupted operation.

“PROFESSIONAL” MANUAL

1

MINIMUM NUMBER OF ORANGES

12

MAXIMUM NUMBER OF ORANGES

3

DEFAULT VALUE

The STOP button is always operative.

1

12

3

45

SELF SERVICE TAP (44)

3

4

2

1

2

You have purchased a multi-function tap. This enables you to produce juice either discontinuously

or continuously without having to press the button.

Locking: You may lock the tap at any time for it to only work in one of the 2 possible ways.

See the different possibilities in: ASSEMBLY OF COMPONENTS ACCORDING TO MODEL, SS TAP (44).

SPEED PRO TANK PODIUM, SPEED PRO TANK PODIUM DRAIN&CLEAN SYSTEM,

SPEED PRO COOLER

Make sure that the TANK (53) or Tank (70.6) is placed as close as possible to the sensor on the base.

Make sure that the buoy is placed correctly on the lid and that it moves freely (Figure 5 and Figure 6).

If the Tank/Cooler buoy (52) is not in place, the machine will not work.

AUTOMATIC MODE

When you connect the machine at the start of the day, select the START button

for the machine to start up.

The machine starts to squeeze until the tank is full and the Level detector (56)

does not find the Tank/Cooler buoy (52). The machine will stop then.

When the juice level gets low again, the machine will start up again, about 15” after it has not

detected the buoy, and so on and so forth, in automatic mode.

The full or half full tank symbol will appear unless STOP has been pressed, indicating that although

the machine is in automatic mode, it has stopped, waiting for the tank to be emptied, in order to

re-start the filling process. When you press STOP, the symbol will disappear as the machine is no

longer operating.

PROFESSIONAL MODE

The machine will start up when you press START and will stop when the Level detector (56)

does not find the Tank/Cooler buoy (52) or reaches the assigned volume. When the level

drops, the machine will not start up again until you press START again.

It has 3 different filling volumes, according to your juice needs.

MANUAL MODE (In case the sensor does not work)

If the Level detector (56) does not work, enter the menu and activate the MANUAL MODE.

When you do this, you will be able to enjoy all the machine functions without the detector,

until this is repaired.

“AUTOMATIC” MANUAL

Non stop operation.

“PROFESSIONAL” MANUAL

Program the number of oranges to be squeezed. The machine will stop when it reaches the

selected value or the STOP button is pressed.

Remember! In manual mode, you must keep a watch over the juice level so that it never flows

over, as level function has been annulled.

EN

47

SPEED PRO COOLER: COOLER UNIT

Switch the cooler unit on by activating the switch on the left of the juice outlet. You can adjust the

juice temperature with the control situated on the right. Turn in clockwise direction for colder juice

and anti-clockwise direction for less cold juice.

Activate the tank lever to ll a glass or jug.

Important! Remember to switch off the Cooler unit (70) when you switch off the main machine to

avoid unnecessary consumption.

MANUAL MODE (HELP MODE): Some machine models have an actuator or an auxiliary operating

sensor. This can be annulled by selecting the MANUAL mode. [Self Service Model: SS tap. Tank (44)

and Cooler Model: Level detector (56)].

EN

WASTE LIMIT: You can activate an alarm so that the machine will stop when the desired number of

oranges has been squeezed. Thus, you will know when the waste bin has to be emptied.

CALIBRATION: You can calibrate the machine to guarantee that the machine count is correct at

all times.

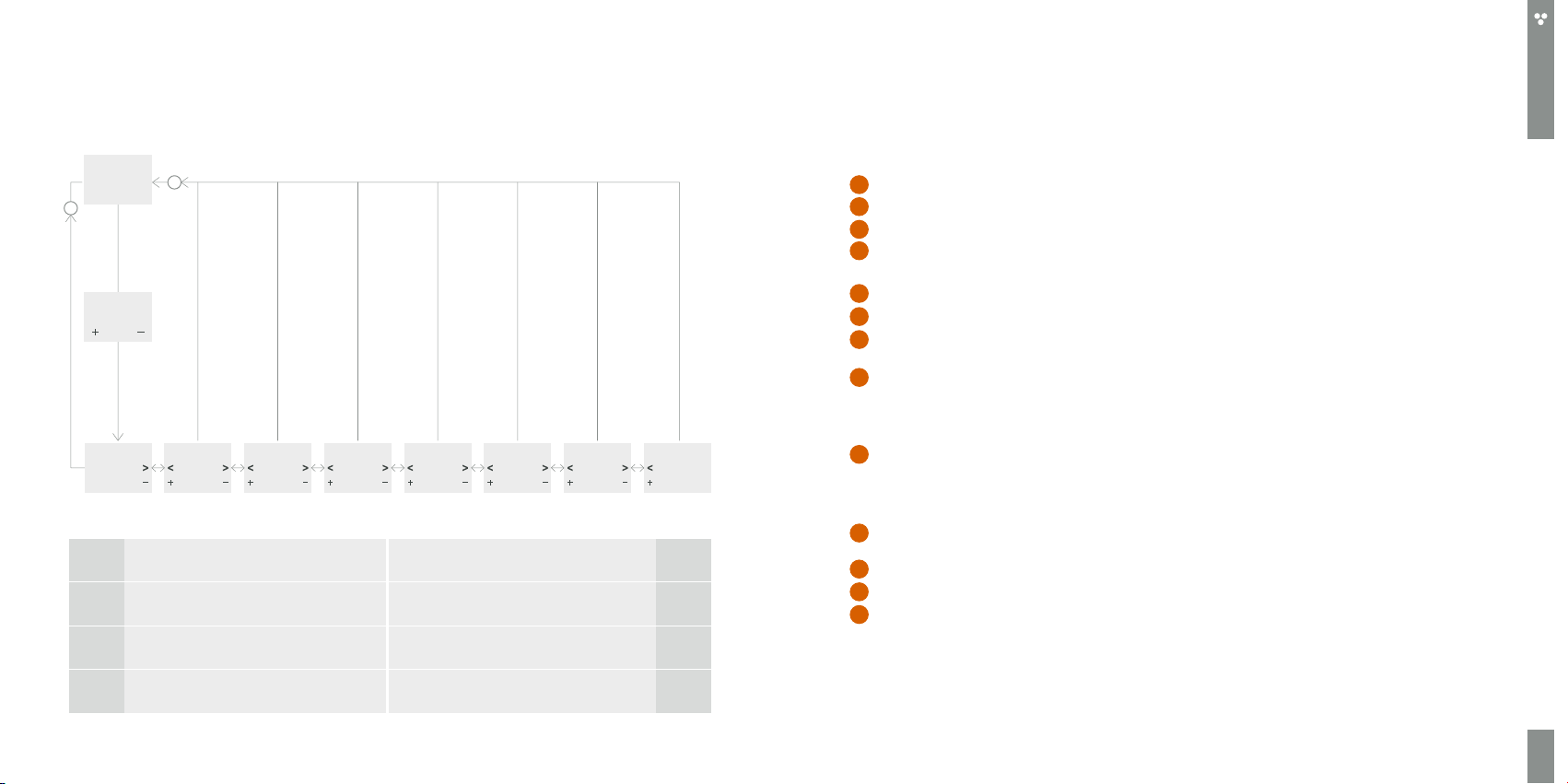

CONFIGURATION

Your Zumex Speed Pro juicer enables you to set parameters to your liking.

Use the electronic device to choose and program the operating mode of your machine. With it, you

can control attributes and functionalities following the MENUS enclosed.

To enter the MENU press the STOP and MODE buttons for at least 2 seconds and enter the default PIN

(0000).

After entering the menu, you can set:

LANGUAGE: You have a choice of 23 available languages.

PIN: See or change the current PIN so that nobody else can change the machine parameters.

COUNTER: See total or partial counter of the machine. Reset the partial counter, visible on the

main screen. To reset the machine counter, press STOP + START for 3 seconds until the counter

indicates 0000000.

Ascending or descending CREDIT: You can program the machine credit so the machine can be

stopped, in ascending order or descending order, until the machine has been programmed again.

MODE LOCKING SYSTEM: You can get the machine to only work in Automatic or Professional

and even so the number of oranges or volume to be squeezed cannot be changed, so that it only

squeezes the quantity set by you.

MACHINE STATUS: You have access to the different anomalies that a machine stoppage may have

caused.

CONTRAST: You can adjust the brightness level on the display.

Remember! Within the CLIENT MENU mode:

“Short OK” to go down a level.

“Long OK” to go up a level.

“Long OK” to save data (The save symbol will appear).

To exit CLIENT MENU, you must go up the same number of levels you have gone down.

49

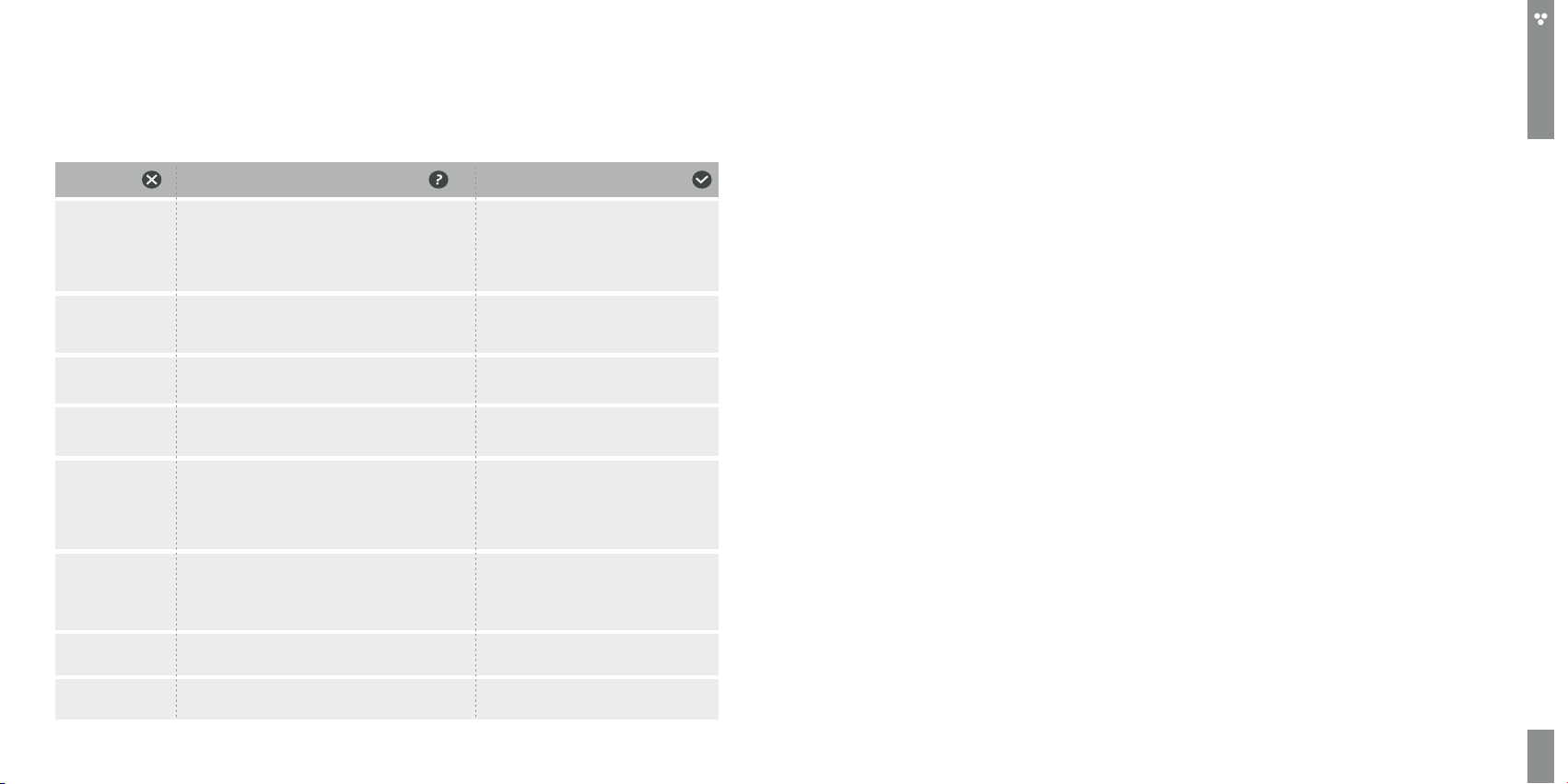

MENU DIAGRAM

5

7

3

4

MAIN MENU

CLEANING

Zumex recommends cleaning the machine at least once or twice a day, depending on how much it is

used in order to maintain optimal food hygiene conditions.

EN

BASIC

AUTOMATIC

015.030

PIN

****

OK

MENU

1.Language

OK

MENU

2.Pin

LANGUAGE . Select the language

to operate the machine.

PIN. See or change the PIN.

COUNTER. See total or partial

counter of the machine.

MODE. Select the working mode:

automatic or professional.

For correct cleaning you must follow the steps below:

1

Unplug the machine from mains.

2

Remove Side Outlets.

Remove the cover.

3

4

Remove the blade-holder, pulling towards you from the handle.

Warning! Handle this part with great care as you could cut yourself.

5

Extract the peel ejectors from their supports (Figure 1).

Remove the pressing units by pairs, previously unscrewing the securing knobs (Figure 1).

6

Remove the juice containers and lters; see the respective Figure according to model according

7

to section: UNPACKING AND START-UP.

In models with tap:

8

Unscrew the tap from the container, separate the button from the body to clean thoroughly.

Remove taps as indicated in the sections: SS tap (44), Tank tap (55) of ASSEMBLY AND DETACHMENT

OF COMPONENTS ACCORDING TO MODEL.

MENU

OK

3.Counter

OK

MENU

4.Mode

MENU

OK

5.Waste limit

OK

MENU

6.Calibrate

OK

MENU

7.State

OK

MENU

8.Contrast

OK

9

In models with Drain&Clean System. You can carry out a light cleaning by emptying a jug of warm

water into the feeder.

Whether your model has the Drain&Clean System or not, it is advisable to remove the feeder, to

completely eliminate wax.

Cleaning non-detachable elements. Use a damp cloth with lukewarm water and soap, and then

10

WASTE LIMIT. Activate a warning to know

when to empty the waste bin.

CALIBRATION. To calibrate the machine

for correct count.

STATUS. Access the different anomalies that

a machine stoppage may have caused.

CONTRAST. To adjust the brightness level on

the display.

rinse.

11

Remember that although some parts are similar they must be mounted on different sides.

12

Do not wash Speed Pro Cooler machine tank parts in the dish-washer.

Transparent parts and dish-washers: these parts can be washed in the dish-washer, although you

13

must make sure you use the correct soap, salt and brightener so that the parts remain shiny and

transparent.

51

TROUBLESHOOTING AND TIPS

ERROR POSSIBLE CAUSE ACTION

01 COVER Does not detect the cover safety device Check cover placement

Check side outlet placement

Check magnet placement

Check connected cables

Check cover detector

02 TRAY Does not detect container Check container placement

Check wiring connection

Check container detector

03 MOTOR POWER The motor does not work at correct voltage Check mains voltage

Check electronics plate

04 HALT Electricity cut Check mains voltage cable

Check inner connection of cables

05 OVERCURRENT The motor has over-consumption Check obstacles in juice

extraction system

Check fruit hardness

Check motor

Check cooling

06 NO FLOAT Does not detect buoy Position buoy correctly

Position tank correctly

Check wiring

Check detector

07 CREDIT Counter limit reached Eliminate counter limit

Reprogram counter limit

08 WASTE LIMIT Counter limit reached Press "OK" for longer until

you hear a double “beep”

To eliminate an error, press “OK” briey and check that the cause of the fault is corrected, as indicated in the

table below.

EU DECLARATION OF CONFORMITY

ZUMEX GROUP S.A., whose registered ofces are situated at Polígono Industrial de Moncada III, C/ Molí, 2 - 46113

- Moncada, Valencia (Spain) does here by declare, under its sole responsibility, that the Zumex Speed Pro Basic,

Zumex Speed Pro Self-Service, Zumex Speed Pro Self-Service Podium Drain&Clean System, Zumex Speed Pro

Tank Podium Drain&Clean System, Zumex Speed Pro Cooler Podium juicer machine models conform to the

following harmonised standards:

en 60335-1 2012

en 60335-2-64

+ a1

2000

2002

en 62233 2008

en 55014-1

+ a1

+ a2

en 55014-2

+ a1

+ a2

en 61000-3-2

+ a1

+ a2

2008

2009

2011

1997

2001

2008

2006

2009

2009

en 61000-3-3 2008

nsf/ansi 8 2012

nsf/ansi 51 2014

Safety of household electrical appliances and similar. Part 1: General requirements

Safety of household and similar electrical appliances. Part 2-64: Particular

requirements for commercial electric kitchen machines

Measurement methods for electromagnetic elds of household appliances and

similar apparatus with regard to human exposure

Electromagnetic compatibility. Requirements for household appliances, electric

tools and similar apparatus. Part 1: Emission

Electromagnetic compatibility (EMC). Part 3-2: Limits. Limits for harmonic current

emissions (equipment input current <= 16 A per phase)

Electromagnetic compatibility (EMC). Part 3-2: Limits. Limits for harmonic current

emissions (equipment input current <= 16 A per phase)

Electromagnetic compatibility (EMC). Part 3-3: Limits. Limitation of voltage

changes, voltage uctuations and icker in public low-voltage supply systems,

for equipment with rated current <= 16 A per phase and not subject to conditional

connection

National Sanitation Foundation. Commercial powered food preparation equipment

National Sanitation Foundation. Food equipment materials

EN

53

Loading...

Loading...