Page 1

ZXSDRR8860

CDMARemoteRadioUnit-8860

InstallationManual

ZTECORPORATION

ZTEPlaza,KejiRoadSouth,

Hi-TechIndustrialPark,

NanshanDistrict,Shenzhen,

P .R.China

518057

Tel:(86)75526771900

Fax:(86)75526770801

URL:http://ensupport.zte.com.cn

E-mail:support@zte.com.cn

Page 2

LEGALINFORMATION

Copyright©2006ZTECORPORATION.

Thecontentsofthisdocumentareprotectedbycopyrightlawsandinternationaltreaties.Anyreproductionordistributionof

thisdocumentoranyportionofthisdocument,inanyformbyanymeans,withoutthepriorwrittenconsentofZTECORPORATIONisprohibited.Additionally ,thecontentsofthisdocumentareprotectedbycontractualcondentialityobligations.

Allcompany ,brandandproductnamesaretradeorservicemarks,orregisteredtradeorservicemarks,ofZTECORPORA TION

oroftheirrespectiveowners.

Thisdocumentisprovided“asis”,andallexpress,implied,orstatutorywarranties,representationsorconditionsaredisclaimed,includingwithoutlimitationanyimpliedwarrantyofmerchantability ,tnessforaparticularpurpose,titleornon-infringement.ZTECORPORATIONanditslicensorsshallnotbeliablefordamagesresultingfromtheuseoforrelianceonthe

informationcontainedherein.

ZTECORPORATIONoritslicensorsmayhavecurrentorpendingintellectualpropertyrightsorapplicationscoveringthesubject

matterofthisdocument.ExceptasexpresslyprovidedinanywrittenlicensebetweenZTECORPORA TIONanditslicensee,

theuserofthisdocumentshallnotacquireanylicensetothesubjectmatterherein.

ZTECORPORATIONreservestherighttoupgradeormaketechnicalchangetothisproductwithoutfurthernotice.

UsersmayvisitZTEtechnicalsupportwebsitehttp://ensupport.zte.com.cntoinquirerelatedinformation.

TheultimaterighttointerpretthisproductresidesinZTECORPORATION.

RevisionHistory

RevisionNo.RevisionDateRevisionReason

R1.0

08/30/2008FirstEdition

SerialNumber:sjzl20082714

Page 3

Contents

Preface...............................................................i

SafteyDescription.............................................1

SafetySpecicationsGuide..............................................1

SafetySymbols..............................................................2

SafetyInstructions.........................................................3

InstallationOverview........................................7

ComponentstobeInstalled.............................................7

InstallationFlow.............................................................7

InstallationPreparation...................................................8

EngineeringConditionInspection..................................8

ToolsandInstrumentsPreparation................................9

On-siteDocuments...................................................10

UnpackingAcceptance................................................11

CountingGoods................................................11

CrateUnpacking...............................................11

CartonUnpacking.............................................12

AcceptanceandGoodsHandover.........................12

CabinetInstallation.........................................15

EngineeringIndices.......................................................15

InstallationModeInstruction...........................................16

Pole-mountedInstallationMode.......................................17

ComponentsUsedinPole-mountInstallation.................17

InstallingT woZXSDRR8860C806Pole-mountCabinets

(WithoutWaveT rap)..........................................19

InstallingT woZXSDRR8860C806Pole-mountCabinets

(WithWaveT rap)...............................................22

InstallingThreeZXSDRR8860C806CabinetsonPole

(WithoutWaveT rap)..........................................25

InstallingThreeZXSDRR8860C806CabinetonPole

(WithWaveT rap)...............................................27

Wall-mountedInstallationMode.......................................33

Page 4

ComponentsUsedinWall-MountInstallation.................33

InstallingCabinetonWall(Wall-Mount)........................34

FloorGantry-mountedInstallationMode...........................37

ComponentsUsedingantry-mountInstallation..............37

InstallingCabinetonGantry(WithoutWaveT rap)..........41

InstallingCabinetonGantry(WithWaveT rap)...............44

SimpliedCabinetIntegratedInstallationMode.................54

ComponentsUsedinIntegratedInstallation..................54

InstallingIntegratedCabinet.......................................57

InstallingSunshield......................................................65

ExternalCableInstallation..............................67

ExternalCableLayout....................................................67

ExternalCableInstallationFlow.......................................69

InstallingPowerCable....................................................70

InstallingGroundingCable..............................................71

InstallingFiberbetweenBBUandRRU..............................72

InstallingFiberbetweenRRUandRRU..............................73

InstallingEnvironmentMonitoringCable...........................75

InstallingAISGControlCable..........................................76

InstallingFrequencyPointExtensionCable........................77

InstallingJumper...........................................................78

MainAntennaFeederSystemInstallation........79

MainAntennaFeederSystemStructure............................79

MainAntennaFeederSystemInstallationPreparation.........85

MainAntennaFeederSystemInstallationFlow..................86

AntennaInstallation.......................................................87

AntennaInstallationT echnicalSpecications.................87

AntennaInstallationPosition.......................................88

DirectionalAntennaInstallation...................................88

OmniAntennaInstallation..........................................91

ConnectJumperandAntenna......................................91

FeederInstallation.........................................................92

FeederCuttingPrinciple..............................................92

FeederInstallationonT opofBuilding...........................93

FeederInstallationonT ower.......................................94

FeederLayoutPrinciples.............................................96

FeederFixingProcedures............................................97

FeederGroundingPrinciple.........................................97

FeederGroundingClipsInstallation..............................99

ConnectJumperandFeeder......................................102

Page 5

InstallingFeederHermetic-window................................102

FeederIndoorIngoing..................................................104

FeederIndoorArrangementPrinciple..........................104

LeadingMainFeederintoRoom................................105

InstallingTop-equipmentJumper...............................107

PerformingAntennaFeederSystemTest.........................108

PerformingOutdoor-connectorWaterproofProcess-

ing....................................................................109

PerformingFeederHermetic-windowWaterproof

Processing..........................................................111

CabinetJumperInstallationDescription..........................114

VSWRTest..................................................................115

HardwareInstallationInspection..................117

CheckingCabinetInstallation........................................117

CheckingCableInstallation...........................................117

CablesInstallationGeneralSpecication.....................117

PowerandGroundingCablesInstallationCheck...........119

OpticalFiberInstallationCheck.................................120

CheckingMainAntennaSystemInstallation....................120

Poweronandoff...........................................123

PoweronPreparation...................................................123

PowerON...................................................................123

PowerOFF..................................................................123

Cabinet-combinedInstallation......................125

ComponentsUsedinCabinet-combiningInstallation.........125

PerformingCabinet-combination....................................127

CascadingCabinetInstallation......................129

ComponentsUsedinCascadingInstallation.....................129

PerformingCabinetCascading.......................................130

OAU...............................................................131

OAUTechnicalIndices..................................................131

OAUAppearanceandInterface......................................132

OAUPoleInstallation...................................................134

OAUOn-wallInstallation...............................................140

OAUCableInstallation.................................................143

OLP48-2........................................................149

OLP48-2TechnicalIndices............................................149

OLP48-2AppearanceandInterface................................149

OLP48-2InstallationDescription....................................151

Page 6

ILP48-3.........................................................157

ILP48-3TechnicalIndices.............................................157

ILP48-3AppearanceandInterface.................................158

ILP48-3InstallationDescription.....................................159

ACLightningArrester....................................161

ACLightningT echnicalIndices.......................................161

ACLightningAppearanceandInterface..........................162

ACLightningInstallationDescription..............................163

ShieldedGroundingKitInstallation................................168

PDM...............................................................173

PDMAppearanceandInterface......................................173

PDMInstallation..........................................................174

Figures..........................................................177

Tables...........................................................183

ListofGlossary..............................................185

Page 7

PrerequisiteSkill

andKnowledge

WhatisinThis

Preface

PurposeZXSDRR8860isanoutdoorremoteRFunit.Composinganinte-

gratedBTS,ZXSDRR8860andBBUimplementwirelesstransmissionwithincoverageareas,controlofwirelesschannelaswellas

communicationwithBSC.

ThismanualprovidesbasicinstallationguideforengineeringpersonnelwhoperformZXSDRR8860hardwareinstallation.Atthe

sametime,itservesforthereferencematerialforthepersonnel

responsibleforoperationandmaintenance.

Intended

Audience

Manual

ThisdocumentisintendedforengineersandtechnicianswhoperforminstallationactivitiesonZXSDRR8841C804remoteradio

unit.

Tousethisdocumenteffectively ,usersshouldhaveageneralunderstandingofZXSDRR8860equipmentanditscomponents.Familiaritywiththefollowingishelpful:

�cdma2000fundamental

�ZXSDRR8860hardwarestructure

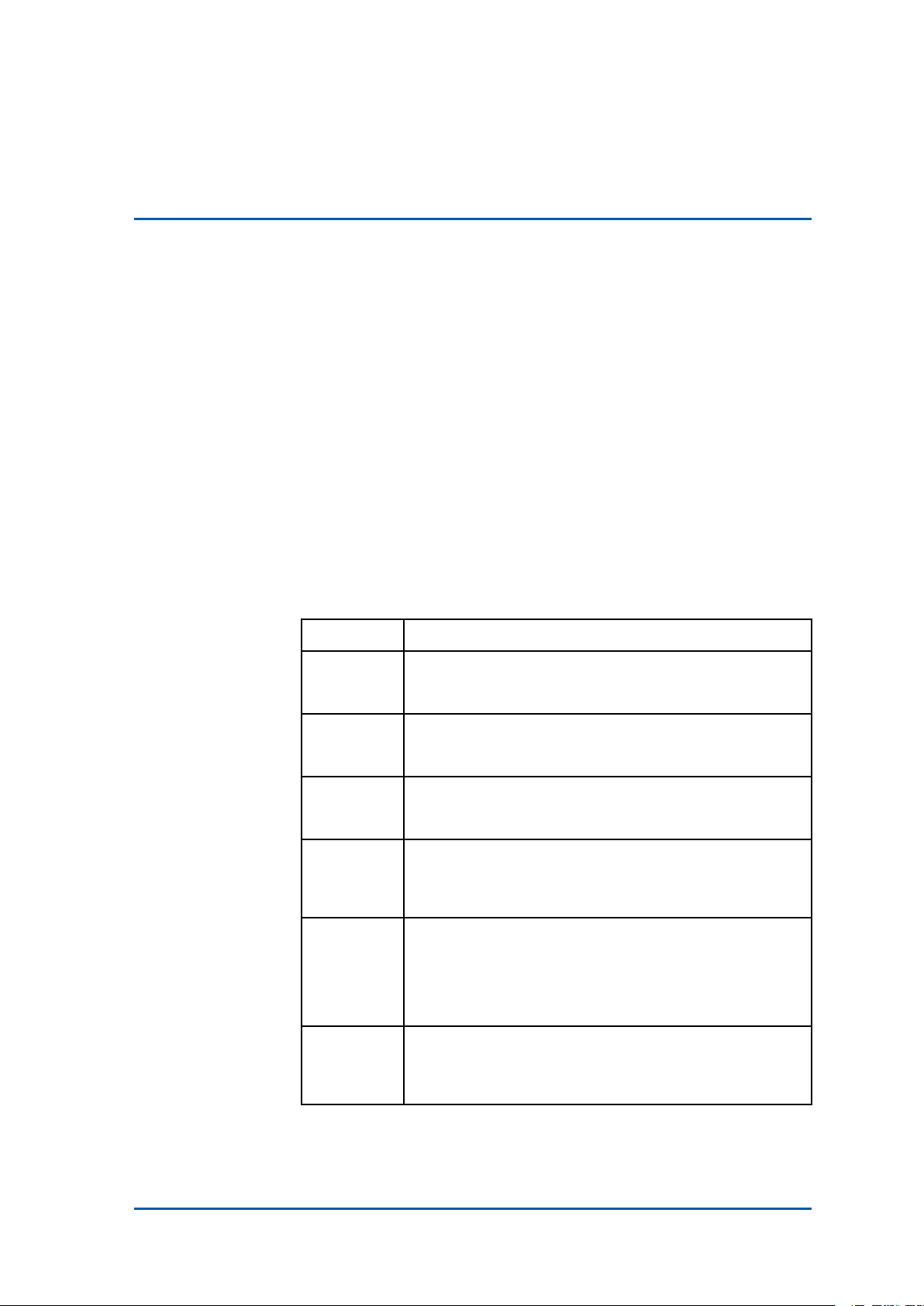

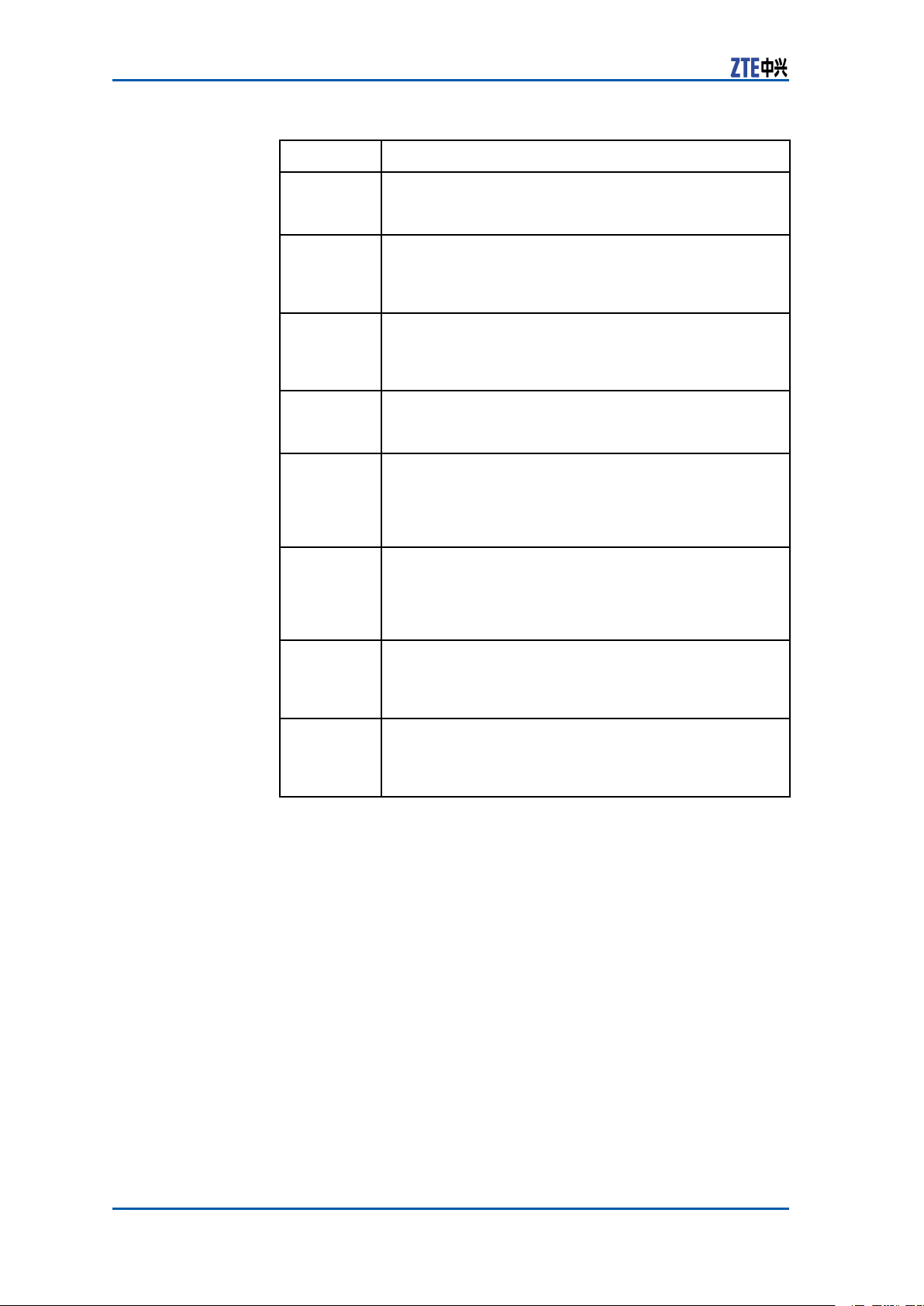

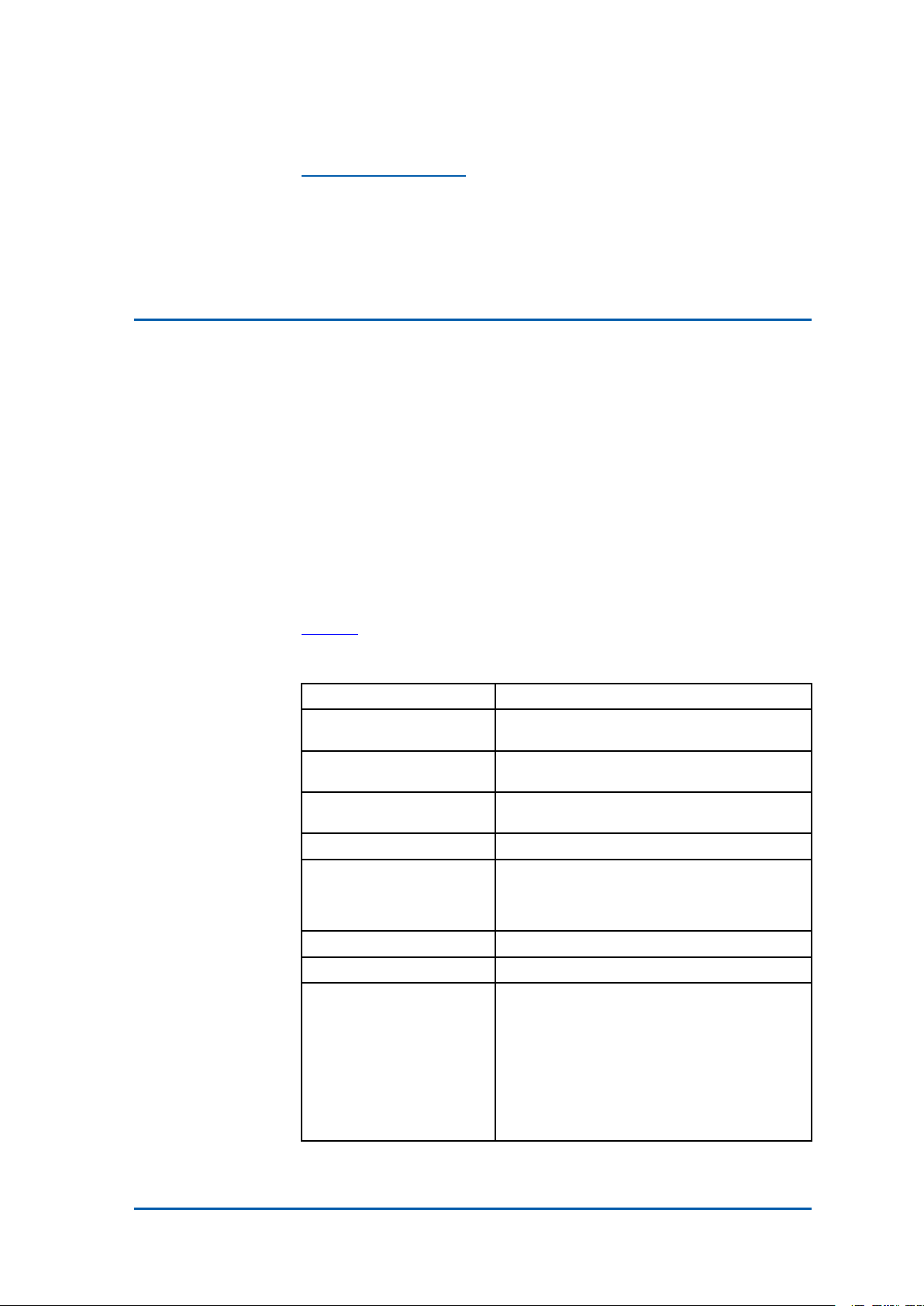

Thismanualcontainsthefollowingchaptersandappendixes:

Chapter

Chapter

1Safety

Instruction

Chapter2

Installation

Overview

Chapter

3Cabinet

Installation

Chapter4

External

Cable

Installation

Chapter

5Main

Antenna

Feeder

System

Installation

Chapter6

Hardware

Installation

Inspection

Summary

DescribesprecautionsinZXSDRR8860installationor

operationmaintenanceaswellasthemeaningsof

varioussafetysymbols.

DescribestherequirementsforZXSDRR8860

installationpersonnel,theinstallationowsand

installationpreparation.

DescribesfourinstallationmodesofZXSDRR8860

cabinetandinstallationsituations.

DescribestheinstallationmethodsofvariousZXSDR

R8860externalcables.

Describestheinstallationowsandinstallationmethods

ofZXSDRR8860mainantennafeedersystem.

Describestheinspectionmethodsofcabinetandcables

afterinstallationcompletion.

ConfidentialandProprietaryInformationofZTECORPORATIONi

Page 8

ZXSDRR8860InstallationManual

Chapter

Chapter7

Poweron

andoff

Appendix

ACabinetcombined

Installation

AppendixB

Cascading

Cabinet

Installation

AppendixC

OutdoorAC

UnitOAU

AppendixD

OutdoorDC

Lightning

Box

(OLP48–2)

AppendixE

IndoorDC

Lightning

Box

(ILP48–3)

Summary

DescribesthemethodsandprecautionsofZXSDR

R8860poweronandoff.

DescribesthemethodofZXSDRR8860cabinetcombinedinstallation.

DescribesthemethodofZXSDRR8860cascading

cabinetinstallation.

Describestechnicalindices,appearanceinterfaces,

installationintroductionandcableconnectionofOAU.

Describestechnicalindices,appearanceinterfaceand

installationintroductionofoutdoorDClightningbox.

Describestechnicalindices,appearanceinterfaceand

installationintroductionofindoorDClightningbox.

Appendix

FAC

Describesappearanceinterfacesandcableconnection

ofAClightningbox.

Lightning

Box

Appendix

GPower

Describesappearance,interfaceandinstallation

introductionofPDM.

Distribution

Box(PDM)

iiConfidentialandProprietaryInformationofZTECORPORATION

Page 9

Chapter1

SafteyDescription

TableofContents:

SafetySpecicationsGuide..................................................1

SafetySymbols..................................................................2

SafetyInstructions.............................................................3

SafetySpecificationsGuide

Thesesafetyinstructionsmustbeconsideredassupplementaryfor

localsafetyregulations.Theprioritymustbegiventolocalsafety

regulationsifthereisanyconictbetweenthetwo.

Themaintenancepersonnelmusthavetheknowledgeofsafety

operationsandmaintenancewithrequiredqualicationandtechnicalbackground.

Warning:

Thisdevicecomplieswithpart15oftheFCCRules.Operationis

subjecttothefollowingtwoconditions:(1)Thisdevicemaynot

causeharmfulinterference,and(2)thisdevicemustacceptany

interferencereceived,includinginterferencethatmaycauseundesiredoperation.Changesormodicationsnotexpresslyapproved

bythepartyresponsibleforcompliancecouldvoidtheuser’sauthoritytooperatetheequipment.

Alltheoperationandmaintenancepersonnelmustfollowthe

safetyprecautionsandinstructionsprovidedbyZTECorporation

toavoidanyaccident.

Note:

ZTECorporationdoesnotbearanyliabilitiesincurredbecauseof

violationoftheuniversalsafetyoperationrequirements,orviolationofsafetystandardsfordesigning,manufacturingandusing

theequipment.

ConfidentialandProprietaryInformationofZTECORPORATION1

Page 10

ZXSDRR8860InstallationManual

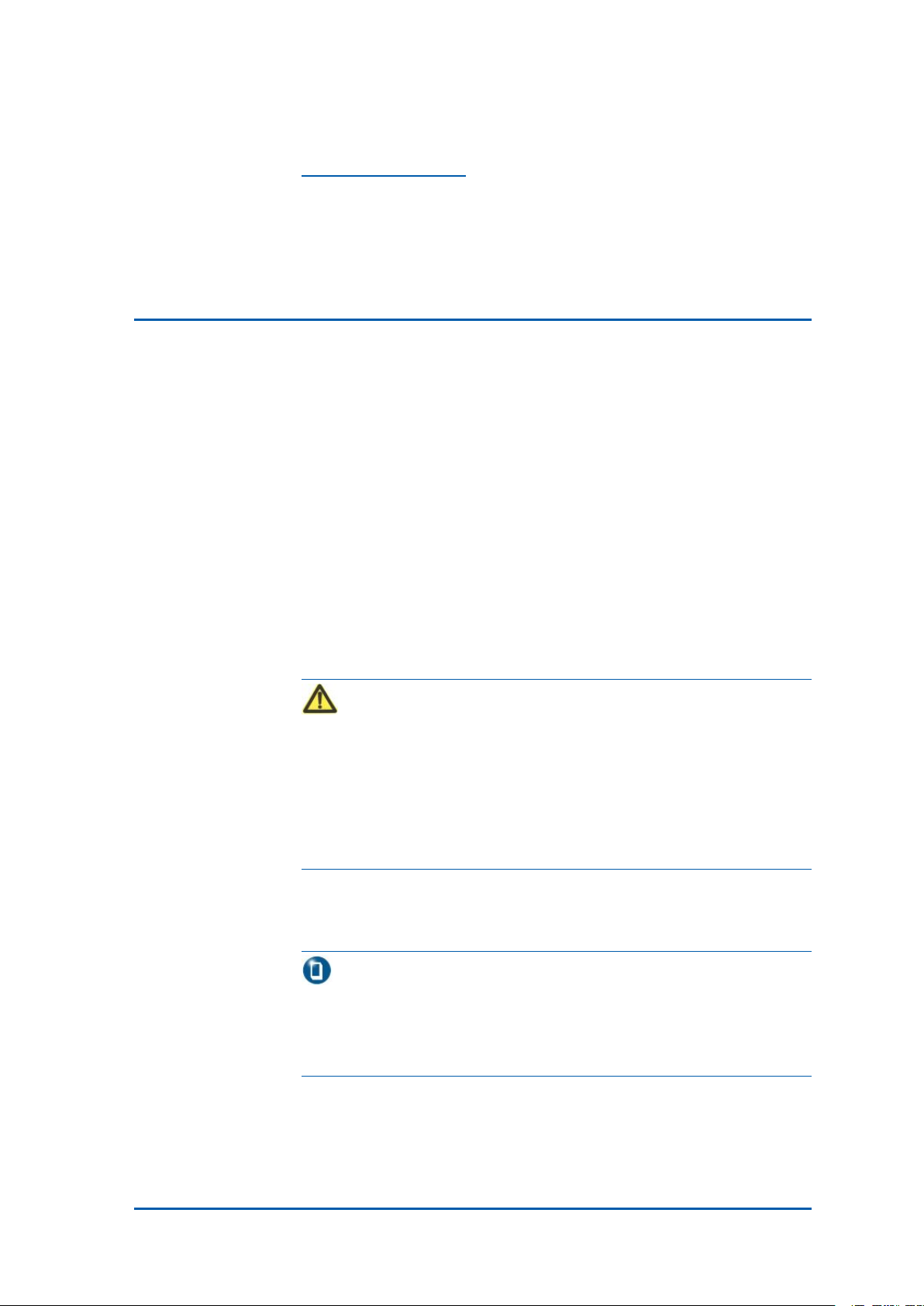

SafetySymbols

Table1listssafetysymbols.Theyaretoprompttheuserofthe

safetyprecautionstobeobservedduringZXSDRR8860operation

andmaintenance.

TABLE1SAFETYSYMBOLSDESCRIPTION

SafetySymbols

Meaning

Nosmoking:Smokingisforbidden

Noflammables:Noflammablescanbestored.

Notouching:Donottouch.

Universalalertingsymbol:Generalsafety

attentions.

Electricshock:Riskofelectricshock.

Electrostatic:Thedevicemaybesensitiveto

staticelectricity.

Microwave:Bewareofstrongelectromagnetic

field.

Laser:Bewareofstronglaserbeam.

Scald:Bewareofscald.

Amongstthesesafetysymbols,theuniversalalarmsymbolsare

classiedintothreelevels:danger ,warning,andcaution.The

formatsandmeaningsofthethreelevelsaredescribedasbelow:

Danger:

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,

willresultindeathorseriousinjuryofpeople,orequipmentdamagesandbreakdown.

2ConfidentialandProprietaryInformationofZTECORPORATION

Page 11

Chapter1SafteyDescription

Warning:

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,

couldresultindeathorseriousinjury.

Caution:

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,

couldresultinseriousinjuries,equipmentdamagesorinterruption

ofpartservices.

SafetyInstructions

ElectricalSafety

Thissectiondescribesthesafetyinstructionsrelatedtoelectrical

safety,antistatic,heavyobjectsandboards.

Thefollowingaretheelectricalsafetyinstructionsabouttools,high

Instructions

voltage,powercables,holesandlightning:

�Tools

Usespecialtoolsratherthancommontoolsforhigh-voltage

andACoperations.

�HighVoltage

Danger:

Highvoltageishazardous.Directorindirectcontactwithhigh

voltageormainsupplyusingawetobjectcouldresultindeath.

�StrictlyfollowlocalsafetyrulestoinstallACpowerequip-

ments.

�Installationstaffmustbequaliedforperforminghigh-volt-

ageandACoperations.

�Donotwearanywatch,handchain,bracelet,ringorany

otherconductiveobjectduringsuchoperations.

�Preventmoisturefromaccumulatingontheequipmentdur-

ingoperationsinadampenvironment.

�PowerCable

ConfidentialandProprietaryInformationofZTECORPORATION3

Page 12

ZXSDRR8860InstallationManual

Neverinstalloruninstallpowercableswhiletheyarelive.Otherwise,thepowercable,whencontactingaconductor ,mayresultinsparksorelectricarccausingareorevendamageto

eyes.

�Makesuretoshutoffpowersupplybeforeinstallingordis-

�Beforeconnectingthepowercable,makesurethatthecon-

�DrillingHoles

Itisnotallowedtodrillcabinetholeswithoutpermission.

Warning:

connectingapowercable.

nectingcableanditslabelisappropriatefortheactualinstallationrequirements.

Warning:

AntistaticSafety

�Unqualieddrillingcoulddamagewiringandcablesinside

thecabinet.Additionally,metalpiecesinsidethecabinetcreatedbythedrillingcouldresultinashortedcircuit

board.Useinsulationprotectionglovesandmovecables

withinthecabinetawayrstwhendrillingisnecessaryon

acabinet.

�Protecteyesduringdrillingasdustoryingdebrismay

damageeyes.

�Cleananydebrisintimeafterdrilling.

�Lightning

Danger:

Donotperformhigh-voltage,AC,irontowerormastoperations

inathunderstorm.

Thunderstormswouldgiverisetoastrongelectromagnetic

eldintheatmosphere.Therefore,theequipmentmustbe

groundedandprotectedintimeagainstlightningstrikes.

Instructions

Electrostatic:

Staticelectricityproducedbyhumanbodycandamagestatic-sensitivecomponentsoncircuitboard,suchaslarge-scaleintegrated

circuits.

�Frictioncausedbyhumanbodyactivitiesistherootcauseof

electrostaticchargeaccumulation.Staticvoltagecarriedbya

humanbodyinadryenvironmentcanbeupto30kV ,and

canremaininthereforalongtime.Anoperatorwithstatic

4ConfidentialandProprietaryInformationofZTECORPORATION

Page 13

HoistingHeavy

Chapter1SafteyDescription

electricitymaydischargeelectricitythroughacomponentwhen

he/shetouchestheconductorandcausingdamage.

�Wearanantistaticwriststrap(theotherendofwriststrapmust

bewellgrounded)beforetouchingtheequipmentorholding

aplug-inboard,circuitboard,IntegratedCircuit(IC)chipor

otherdevices,topreventhumanstaticelectricityfromdamagingsensitivecomponents.

�Aresistorover1MΩshouldbeconnectedinseriesonthecable

betweentheantistaticwriststrapandthegroundingpoint,to

protecttheoperatoragainstaccidentalelectricshock.Resistanceover1MΩislowenoughtodischargestaticvoltage.

�Theantistaticwriststrapusedmustbesubjecttoregular

check.Donotreplacethecableofanantistaticwriststrap

withanyothercable.

�Donotcontactstatic-sensitiveboardswithanyobjectthateas-

ilygeneratesstaticelectricity.Forexample,frictionofpackage

bag,transferboxandtransferbeltmadefrominsulationplasticmaycausestaticelectricityoncomponents.Dischargeof

staticelectricitymaydamagecomponentswhentheycontact

ahumanbodyortheground.

�Boardshouldonlycontactmaterialssuchasantistaticbag.

Keepboardsinantistaticbagsduringstorageandtransportation.

�Dischargestaticelectricityofthetestdevicebeforeuse,that

is,groundthetestdevicerst.

�DonotplacetheboardnearastrongDCmagneticeld,such

asthecathode-raytubeofamonitor .Keeptheboardatleast

10cmaway.

Objects

Warning:

Whenhoistingheavyobjects,ensurethatnobodyisstandingor

walkingunderthehoistedobject.

�Ensurethehoistercanmeethoistingrequirementswhendis-

assemblingheavyequipment,ormovingandreplacingequipment.

�Theoperatormustbedulytrainedandqualiedforhoisting

operations.

�Hoistingtoolsmustbeinspectedandcompletebeforeservice.

�Makesurethathoistingtoolsarexedrmlyonasufciently

securedobjectorwallbeforethehoistingoperation.

�Givebrieforalinstructionsduringhoistingoperationstopre-

ventanymishap.

Unplugging/Plug-

gingaBoard

�Neverplugaboardwithexcessiveforce,toensurethatthe

pinsonthebackplanedonotgetdeformed.

�Plugtheboardrightintotheslotandmakesureboardcircuit

facesdonotcontacteachotherlestanyshortcircuitmayoccur .

�Keephandsofftheboardcircuit,components,connectorsand

cabletroughwhenholdingaboard.

ConfidentialandProprietaryInformationofZTECORPORATION5

Page 14

ZXSDRR8860InstallationManual

OtherSafety

Instructions

Donotperformmaintenanceordebuggingindependently,unless

aqualiedpersonispresent.

�Replacinganypartsormakinganychangestotheequipment

mightresultinanunexpecteddanger .Therefore,besurenot

toreplaceanypartsorperformanychangestotheequipment

unlessauthorizedotherwise.

�ContactZTEofceifyouhaveanyquestion,toensureyour

safety.

Note:

6ConfidentialandProprietaryInformationofZTECORPORATION

Page 15

Chapter2

InstallationOverview

TableofContents:

ComponentstobeInstalled.................................................7

InstallationFlow.................................................................7

InstallationPreparation.......................................................8

ComponentstobeInstalled

ForZXSDRR8860,thefollowingcomponentswillbeinstalled:

�ZXSDRR8860cabinetandcomponents

Note:

Theinnercablesandfunctionalmodules/boardsinthecabinet

arealreadyinstalledbeforeequipmentdelivery.

�Sunshield(usedfortheoutdoorZXSDRR8860installation)

�Cables

�Antennafeedersystemincludingantenna,jumpersandfeeder

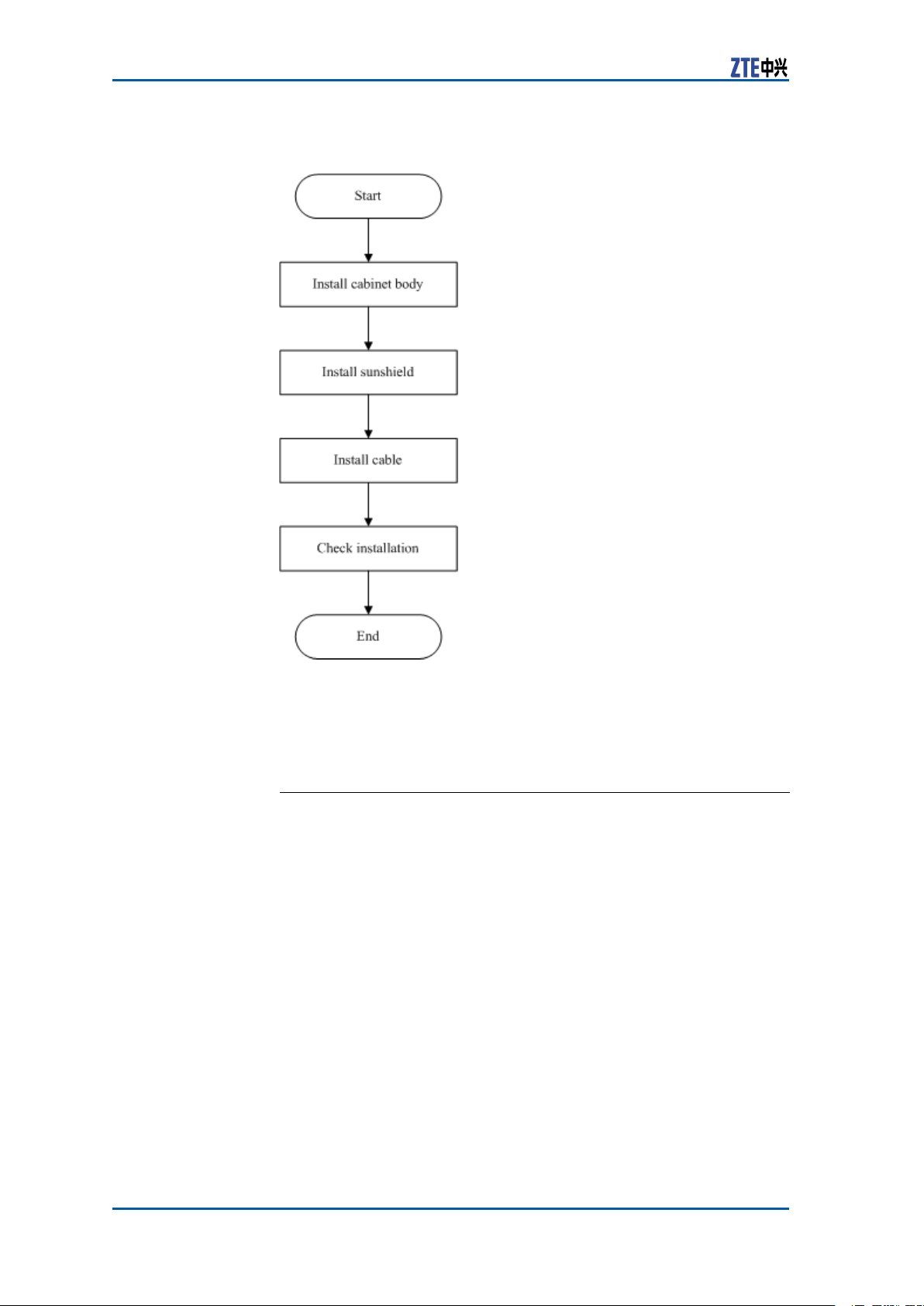

InstallationFlow

TheinstallationowofZXSDRR8860isdemonstratedinFigure1

.However ,itisnotrequiredtostrictlyfollowthestepsshowedin

thisow.Theactualinstallationproceduresdependontheonsite

requirements.

ConfidentialandProprietaryInformationofZTECORPORATION7

Page 16

ZXSDRR8860InstallationManual

FIGURE1INSTALLATIONFLOW

InstallationPreparation

EngineeringConditionInspection

Beforeinstallingdevices,followtherequirementsofEnvironment

AcceptanceReportandcheckinstallationenvironment.Thefol-

lowingcontentisjustasareference.

Installation

Position

Inspection

Temperature

andHumidity

Inspection

ZXSDRR8860installationpositionshouldaccordwiththerequirementsofengineeringdesign,thespeciedrequirementsasfollows:

�Avoiddusty,harmful-gasorexplosive-goodsenvironment;

�Avoidtheplaceswithbigshockorstrongnoise;

�Farawaysubstation;

�Farawaypollutionsource;

�Avoidanindustrialboilerandheatingboiler;

�Farawayhigh-powerwirelessinterferencesource.

ZXSDRR8860temperatureandhumidityinworkenvironment

shouldmeettherequirements,asshownin

8ConfidentialandProprietaryInformationofZTECORPORATION

Page 17

Chapter2InstallationOverview

PowerSupply

Inspection

TherequirementsofZXSDRR8860powersupplyaredescribedas

follows.

1.DCpowersupply:ZXSDRR8860is–48VDCpowersupplyand

thevoltageofpowersupplyis–40VDC~–57VDC.

2.IndirectACpowersupply:adoptanoutdoorACunit(OAU);

theOAUcanprovide220VACpowersupplyforoneZXSDR

B8200C100andoneZXSDRR8860atthesametime.

Lightning

Inspection

TheZXSDRR8860lightningrequirementsaredescribedasfollows.

�OutdoorInstallation

i.ForDCpowersupply,congureanoutdoorDClightningbox

OLP48-2.IftheDCpowerisexportedfromtheequipment

room,thelengthofpowercableismorethan10m(less

than50m)andtheoutputendofindoorDCpowerisnot

conguredwithB-levelorabovelightningdevices,itisrequiredtocongureanindoorDClightningboxILP48–3in

theequipmentroom.

ii.ForindirectACpowersupply,itisrequiredtocongurean

AClightningbox(ZXPCScombinedarrester).

�Forindoorinstallation,ifthepowercableisdistributedout-

doors,congurethepowerlightningboxaccordingtotheconditionsofoutdoorinstallation.

Grounding

Inspection

OtherInspections1.Thecorollarydevicesorcomponentsshouldaccordwiththe

ZXSDRR8860adoptsanassociatedgroundingmode.Thevalue

ofgroundingresistanceisnotmorethan5ohm.

requirementsofZXSDRR8860engineeringdesigndrawing.

2.ThetransmissiondevicesinterconnectedwithBBUshouldhave

beenprepared.

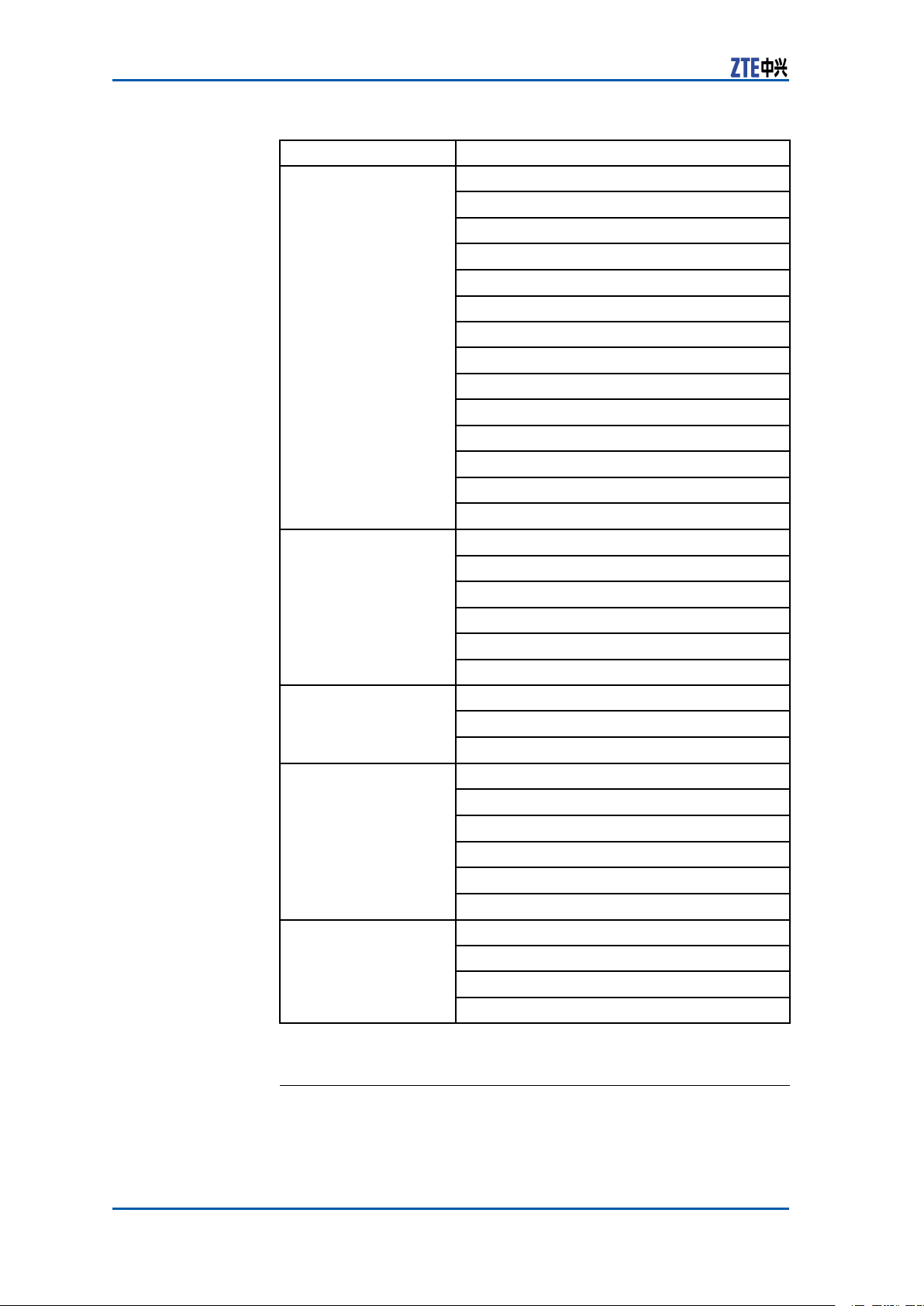

ToolsandInstrumentsPreparation

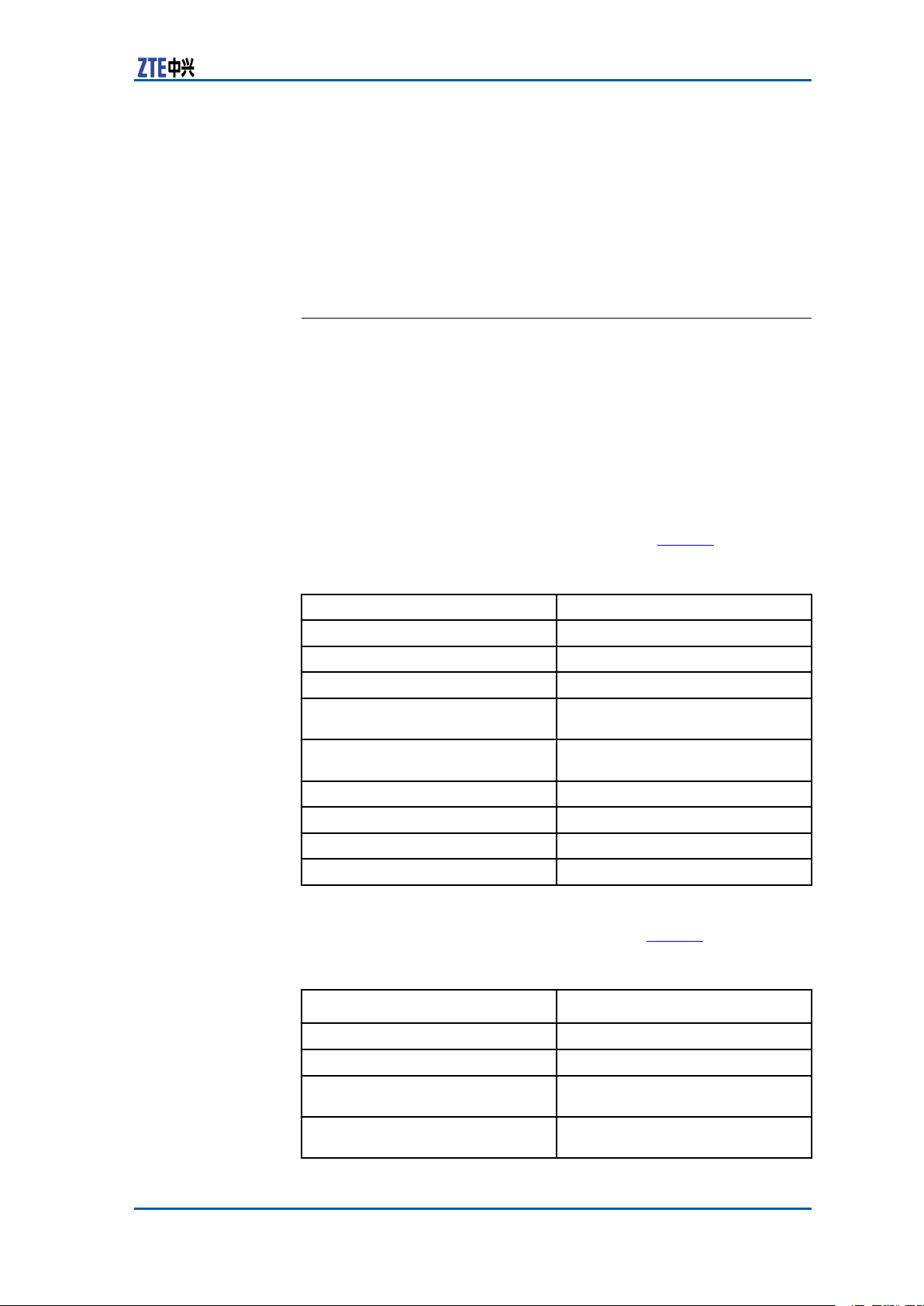

Table2showstoolsandmeterslistrequiredduringinstallation.

TABLE2TOOLANDMETERLIST

Category

Special-purposetools

Concretedrillingtools

Name

Onefeederconnectorknife

Onewirestripper

Onecrimpingpliers

Onemulti-functionalcrimpingpliersEarth

resistancetester

Oneelectricpercussiondrill

Auxiliaryandsamplebits

Onevacuumcleaner

Powersocket(two-phaseandthree-phase

socket,withcurrentcapacitygreaterthan15

A)

ConfidentialandProprietaryInformationofZTECORPORATION9

Page 18

ZXSDRR8860InstallationManual

Category

General-purposetools

Measurementtools

Protectiontools

Clamptools

Auxiliarytools

Name

Crossscrewdrivers(4”,6”and8”each)

Flatheadscrewdrivers(4” ,6”and8”each)

Adjustablewrenches(6’ ,8’ ,10’and12’)

Dual-purposespanners(17”and19”each)

Onesetofsocketwrench

5kg(11lb)nailhammer

One300Wiron

One40Wiron

Solderwires

Hotblower

Oilpaintbrush

Pliers

Scissor

Paperknife

One50m(164feet)tapemeasure

One5m(16feet)steeltape

One400mm(16inches)levelbar

Oneanglemeter

Onecompass

Plumb

Antistaticwriststrap

Safetyhelmet

Pairofgloves

Onehacksaw(withseveralsawblades)

Onepairofsharp-nosepliers(8″)

Onepairofdiagonalpliers(8″)

Onepairofslipjointpliers(8″)

Onepairofvices(8″)

Crowbar

Chainwheel

Rope

Ladder

Forklift

On-siteDocuments

ZXSDRR8860installationneedsthefollowingtechnicaldocuments

tobeready.

10ConfidentialandProprietaryInformationofZTECORPORATION

Page 19

Chapter2InstallationOverview

�ZXSDRR8860EngineeringExplorationReport

�ZXSDRR8860EnvironmentAcceptanceReport

ZXSDRR8860manualkitincludes:

�ZXSDRR8860CommissioningandCongurationManual

�ZXSDRR8860OperationandMaintenanceManual

�ZXSDRR8860TechnicalManual

UnpackingAcceptance

CountingGoods

PrerequisiteThetransportedcargoshouldhavereachedtheinstallationsite.

ContextTherepresentativeofcustomerandtheprojectsupervisormustbe

presentonsiteduringcountingofgoodsreceived.Ifanypartyis

notpresentatthattime,transportermustholdtheresponsibility

foranydiscrepanciesingoods.

Thestepsinvolvedincountinggoodsareasfollows:

Steps1.CheckDeliveryChecklistofZTECorporation.Checktotalnum-

berofgoods,intactnessofpackingboxes,andcheckwhether

arrivalplaceistheactualinstallationplaceagainstpackinglist

numberattachedtopackingboxes.Ifgoodsareintact,start

tounpackandinspectthem.

Note:

Itisrecommendedtounpackthegoodsafterabout30minutes

ofreceivingthecargo,sincethereisapossibilityofmoisture

contentduetotemperaturevariationsifany .

2.Equipmentinspectionlistandunpackingacceptancereportare

presentintherstpackingcarton.Firstly,openrstpacking

cartonandtakeouttheUnpackingAcceptanceReporttocheck

whetherthegoodsreceivedareinaccordancewiththeinspectionlist.

3.Duringthecountingandunpackinginspectionprocess,ifany

materialisfoundshort,orgoodsdamaged,thenll-inUnpack-

ingAcceptanceFeedbackTableandcontactZTEpromptly.

ENDOFSTEPS.

CrateUnpacking

PrerequisitePreparetheappropriatetoolssuchasstraightscrewdriver ,pliers,

andcrowbar .

ContextPerformthefollowingstepstoopenthecrate:

ConfidentialandProprietaryInformationofZTECORPORATION11

Page 20

ZXSDRR8860InstallationManual

Steps1.Insertastraightscrewdriverintotheslitbetweencrateand

frontcoverboardtomakeitloose;theninsertcrowbartounclenchcoverboard.

2.Pullthecoverboardoutfromthecrate.

3.Removetheotherboardsofthecrate.

ENDOFSTEPS.

CartonUnpacking

PrerequisitePreparetheappropriatetoolssuchasstraightscrewdriver ,diago-

nalpliers,andpaperknife.

ContextPerformthefollowingstepstounpackthecarton:

Steps1.Usediagonalplierstocutpackingstraps.

2.Useapaperknifetocutadhesivetapealongtheslitsoncarton

cover ,avoiddamaginggoodsinside.

3.Openthecarton,andremovethefoamboard.

4.Checkthegoodswithinthecarton.

Note:

�Avoiddamagingtheantistaticbag(Itcanbeusedinthe

futureforstorageofspareparts)duringunpacking.

�Whiletheequipmentismovedtoahotteranddamper

place,waitfor30minutesbeforeunpackingtheequipment.

Otherwise,moisturemaycondenseonthesurfaceofthe

equipmentandcausedamage.

�Properlydisposeofrecycledesiccants.

ENDOFSTEPS.

AcceptanceandGoodsHandover

ContextPerformthisprocedureforacceptinggoods,andhandingthem

overtooperators.

Steps1.Acceptance

Baseduponthename,categoryandnumbermentionedonthe

shippinglist,carefullycheckthegoodspiecebypiece.Make

surethatgoodsfullthefollowingconditions:

i.Makesurethattherearenobubbly ,peeling,nickandlth

markonthesurfaceofthechassis.

ii.Ensurethatoilpaintonthechassissurfaceisintact.

iii.Ensureclampingscrewsaretightandintact.

iv.Allthecomponentsareproperlyinstalledattheirrespective

positions.

12ConfidentialandProprietaryInformationofZTECORPORATION

Page 21

Chapter2InstallationOverview

v.Laydowntheinspectedgoodsaccordingtocategories.

2.Handover

Aftercompletingtheunpackingprocedure,representativeof

customerandprojectsupervisorshouldapproveandsignUn-

packingforInspectionReport.Eachpartyshouldhaveacopy

ofUnpackingforInspectionReport.Ifthegoodsarestillunderthesupervisionoftheoperatorevenafteracceptance,then

goodswillnotbehandedovertotheoperatoruntilbothparties

signonthereport.

ENDOFSTEPS.

ConfidentialandProprietaryInformationofZTECORPORATION13

Page 22

ZXSDRR8860InstallationManual

Thispageisintentionallyblank.

14ConfidentialandProprietaryInformationofZTECORPORATION

Page 23

Chapter3

CabinetInstallation

TableofContents:

EngineeringIndices...........................................................15

InstallationModeInstruction...............................................16

Pole-mountedInstallationMode...........................................17

Wall-mountedInstallationMode...........................................33

FloorGantry-mountedInstallationMode...............................37

SimpliedCabinetIntegratedInstallationMode.....................54

InstallingSunshield..........................................................65

EngineeringIndices

Table3describestheengineeringindicesofZXSDRR8860.

TABLE3ZXSDRR8860ENGINEERINGINDICES

Item

OverallDimensionWidthxHeightxDepth:320mmx500mm

UpperEnclosure

Dimension

LowerEnclosure

Dimension

Weight<22kg

Power

WorkTemperature

WorkHumidity

PowerConsumptionof

NormalWorkUnder-48V

DCPowerSupply

x172mm

WidthxHeightxDepth:320mmx370mm

x72mm

WidthxHeightxDepth:320mmx500mm

x100mm

-48VDC;-40V~-57V

220VAC:150V~285V/45Hz~65

Hz(viaexternalAC-to-DCconversion

lightningbox)

-40℃to55℃-40℉to131℉

5%RH~95%RH

�1Carrier

–OutputPower:20W/C/S

–PowerConsumption:170W

�2Carrier

–OutputPower:20W/C/S

–PowerConsumption:200W

�3Carrier

–OutputPower:20W/C/S

–PowerConsumption:230W

Indices

ConfidentialandProprietaryInformationofZTECORPORATION15

Page 24

ZXSDRR8860InstallationManual

ThetechnicalindicesoftheindoorDClightningbox,exemplied

byJD40K085C20H2–K1Z,arelistedinT able4,whichissubjectto

theactualeldtechnicalspecicationsforpracticalapplication.

TABLE4JD40K085C20H2–K1ZDCLIGHTNINGBOXTECHNICALINDICES

Item

Dimensions

NominalWorking

Voltage

InstallationModeIndoorwall-mountinstallation

WorkingTemperature

WorkingHumidity

WidthxHeightxDepth:400mmx450

mmx100mm(Theheightoftopcoverbox

lockexcluded)

–48V

-5℃to70℃

≤95%RH

Index

ThetechnicalindicesoftheexternalAC-to-DCconversionlightning

box,exempliedbyGPAD501M54-1A,arelistedinT able5,which

issubjecttotheactualeldtechnicalspecicationsforpractical

application.

TABLE5GPAD501M54-1AEXTERNALAC-TO-DCCONVERSIONLIGHTNING

BOXTECHNICALINDICES

Item

Dimensions

Weight4.65kg

InputVoltageMin.value:150V

InputFrequency

InstallationModePole-mountandwall-mountinstallation

WorkingTemperature

WorkingHumidity

WidthxHeightxDepth:217mmx288

mmx127mm

Typicalvalue:220V

Max.value:285V

Min.value:45Hz

Typicalvalue:50Hz

Max.value:65Hz

-40℃+65℃

5%95%

Index

InstallationModeInstruction

Accordingtodifferentinstallationenvironments,therearethree

modesofZXSDRR8860installation:

�Pole-mountinstallation

�Wall-mountinstallation

�Gantry-mountinstallation

�Simplied-cabinetintegrativeInstallation

16ConfidentialandProprietaryInformationofZTECORPORATION

Page 25

Chapter3CabinetInstallation

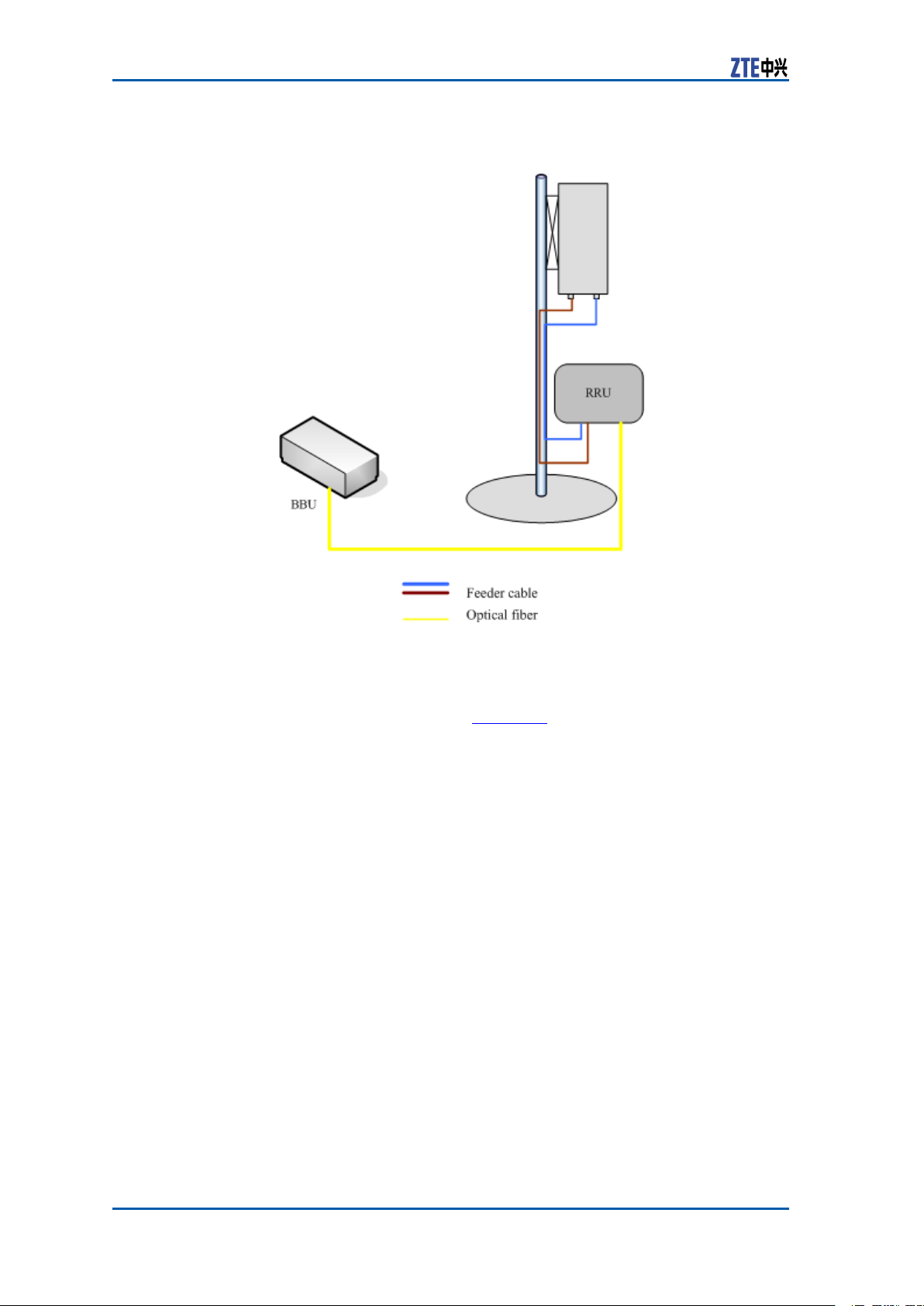

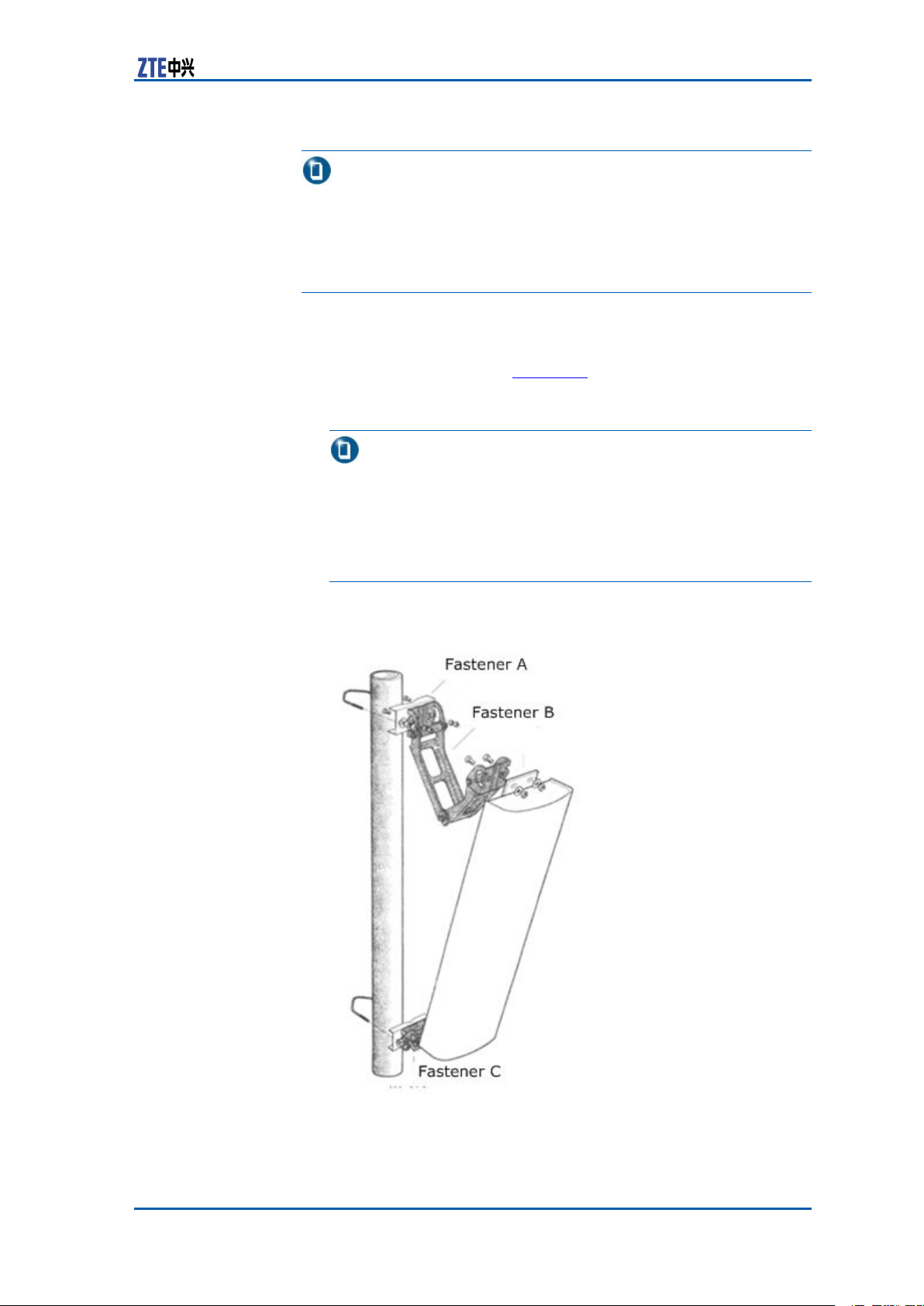

Pole-mountedInstallation Mode

ComponentsUsedinPole-mount Installation

Themaincomponentsusedinpole-mountinstallationinclude:

�Poleanchorclampcomponents;

�Polexingbracketcomponents.

Thepoleanchorclampcomponentsareusedforpole-mountinstallationofoneortwoZXSDRR8860s.Thepolexingbracket

componentsareusedforpole-mountinstallationofthreeZXSDR

R8860s.

Themainpoleanchorclampcomponentsusedinpole-mountinstallationforsingleZXSDRR8860arelistedinT

able6

TABLE6MAINCOMPONENTLIST1

Name

Shortanchorclamp

Longanchorclamp

Standardspringwasher10

M10×120hexagonheadbolt(full

thread)

I-typecommonM10hexagonal

nut

Flatwasher10

Standardspringwasher8

M8×40hexagonheadbolt

Bigwasher8

Themainpoleanchorclampcomponentsusedinpole-mountinstallationfortwoZXSDRR8860arelistedinT

TABLE7MAINCOMPONENTLIST2

Name

Quantity

2

2

4

4

4

4

4

4

4

able7

Quantity

Longanchorclamp

Standardspringwasher10

M10×120hexagonheadbolt(full

thread)

M10×80hexagonheadbolt(full

thread)

ConfidentialandProprietaryInformationofZTECORPORATION17

4

4

4

4

Page 26

ZXSDRR8860InstallationManual

Name

I-typecommonM10hexagonal

nut

Flatwasher10

Standardspringwasher8

M8×40Hexagonheadbolt

Bigwasher8

Quantity

4

4

8

8

8

Themainpolexingbracketcomponentsusedinpole-mountinstallationforthreeZXSDRR8860arelistedinTable8

TABLE8MAINCOMPONENTLIST3

Name

Polefixingbracket

Standardspringwasher10

M10×120hexagonheadbolt(full

thread)

I-typecommonM10hexagonal

nut

Flatwasher10

Standardspringwasher8

M8×40hexagonheadbolt

Bigwasher8

Quantity

4

4

4

4

4

12

12

12

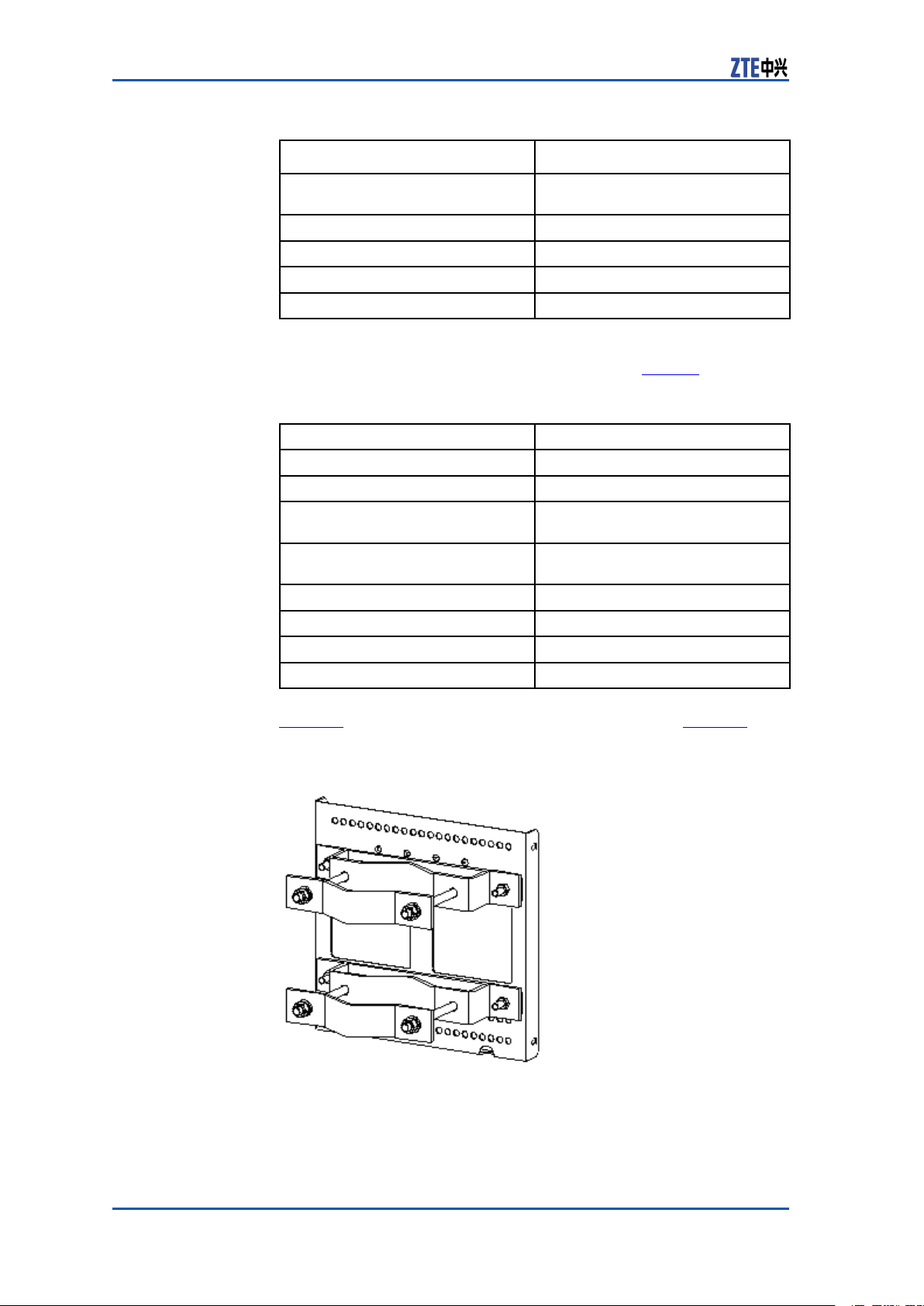

Figure2illustratespoleanchorclampcomponents.Figure3illus-

tratespolexingbracketcomponents.

FIGURE2POLEANCHORCLAMPCOMPONENTS

18ConfidentialandProprietaryInformationofZTECORPORATION

Page 27

Chapter3CabinetInstallation

FIGURE3POLEFIXINGBRACKETCOMPONENTS

Note:

ThepoleanchorclampcomponentsshowninFigure2isadoptedin

onepole-mountinstallation.Thepoleanchorclampcomponents

usedintwopole-mountinstallationonlychangestwoshortanchor

clampsintotwolonganchorclamps,thespeciclistdescribedin

Table7

InstallingTwoZXSDRR8860C806

Pole-mountCabinets(WithoutWave

Trap)

Steps1.Fixanchorclampsbacktobackontothepole,andalignthe

holesandscrewdownabitwithbolts.Adjustspacebetween

anchorclampsbasedonthescrews’positionofsupporting

panelasshowninFigure4.

ConfidentialandProprietaryInformationofZTECORPORATION19

Page 28

ZXSDRR8860InstallationManual

FIGURE4POLE-MOUNTINSTALLATION(1)

1.I-typecommonM10hexago-

nalnut

2.Standardspringwasher10

3.Bigatwasher10

4.Longanchorclamp

5.M10×120hexagonheadbolt

(fullthread)

Tip:

DuringtwoZXSDRR8860cabinetinstallation,thesuggested

polediameteris60to120mmandtherearetwokindsofbolt

lengths:

�Usetheboltoflength80mmforpolediameterof60mm

to90mm;

�Usetheboltoflength120mmforpolediameterof90mm

to120mm.

2.FixtwosupportingpanelsontheanchorclampwithM8bolts

andscrewM10boltstightly ,asshowninF

igure5.

20ConfidentialandProprietaryInformationofZTECORPORATION

Page 29

FIGURE5POLE-MOUNTINSTALLATION(2)

Chapter3CabinetInstallation

1.M8×40Hexagonheadbolt

2.Standardspringwasher8

3.Bigatwasher8

4.Insulationange

5.Supportingpanel

6.Insulationboard

7.Longanchorclamp

3.MountthetwoZXSDRR8860cabinetsonthesupportingpanel

andfastenthecabinetwithfourM6X20hexagonsocketcap

screwsasshowninF

FIGURE6POLE-MOUNTINSTALLATION(3)

igure6.

ConfidentialandProprietaryInformationofZTECORPORATION21

Page 30

ZXSDRR8860InstallationManual

ENDOFSTEPS.

InstallingTwoZXSDRR8860C806

Pole-mountCabinets(WithWave

Trap)

ContextWhileinstallingtheZXSDRR8860C806pole-mountinstallation

withtwowavetraps,adoptanchorclamps;forthepole-mount

installationofthreewavetraps,adoptxingbrackets.

Steps1.Fixanchorclampsbacktobackontothepole,aligntheholes

andscrewdownabitwithbolts.Adjustspacebetweenanchor

clampsasshowninF

FIGURE7POLE-MOUNTINSTALLATION(1)

igure7.

1.I-typecommonM10hexagonalnut

2.Standardspringwasher10

3.Flatwasher10

4.Longanchorclamp

5.M10×120hexagonheadbolt

(fullthread)

22ConfidentialandProprietaryInformationofZTECORPORATION

Page 31

Chapter3CabinetInstallation

Tip:

DuringtwoZXSDRR8860installation,thesuggestedpolediameteris60to120mmandtherearetwokindsofboltlengths:

�Usetheboltoflength80mmforpolediameterof60mm

to90mm.

�Usetheboltoflength120mmforpolediameterof90mm

to120mm.

2.FixtwosupportingpanelsontheanchorclampswithM8bolts

andscrewdownM10bolts,asshowninFigure8.

FIGURE8POLE-MOUNTINSTALLATION(2)

1.M8×40hexagonheadbolt

2.Standardspringwasher8

3.Bigatwasher8

4.Insulationange

5.Supportingpanel

6.Insulationboard

7.Longanchorclamp

3.RepeattheStep1~Step2toinstalltwoanchorclampsandtwo

supportingpanels.

4.MountthetwoZXSDRR8860cabinetsontothesupportingpanelsandfastenthecabinetwithfourM6X20hexagonsocketcap

screwsasshowninF

ConfidentialandProprietaryInformationofZTECORPORATION23

igure9.

Page 32

ZXSDRR8860InstallationManual

FIGURE9POLE-MOUNTINSTALLATION(3)

5.MountthetwowavetrapsontothesupportingpanelsandfastenthemtothesupportingpanelswithfourM6X20hexagon

socketcapscrewsasshowninFigure10.

FIGURE10WAVETRAPINSTALLATION

1.Wavetrap

2.Fixingbeam

24ConfidentialandProprietaryInformationofZTECORPORATION

3.Supportingpanel

Page 33

Chapter3CabinetInstallation

ENDOFSTEPS.

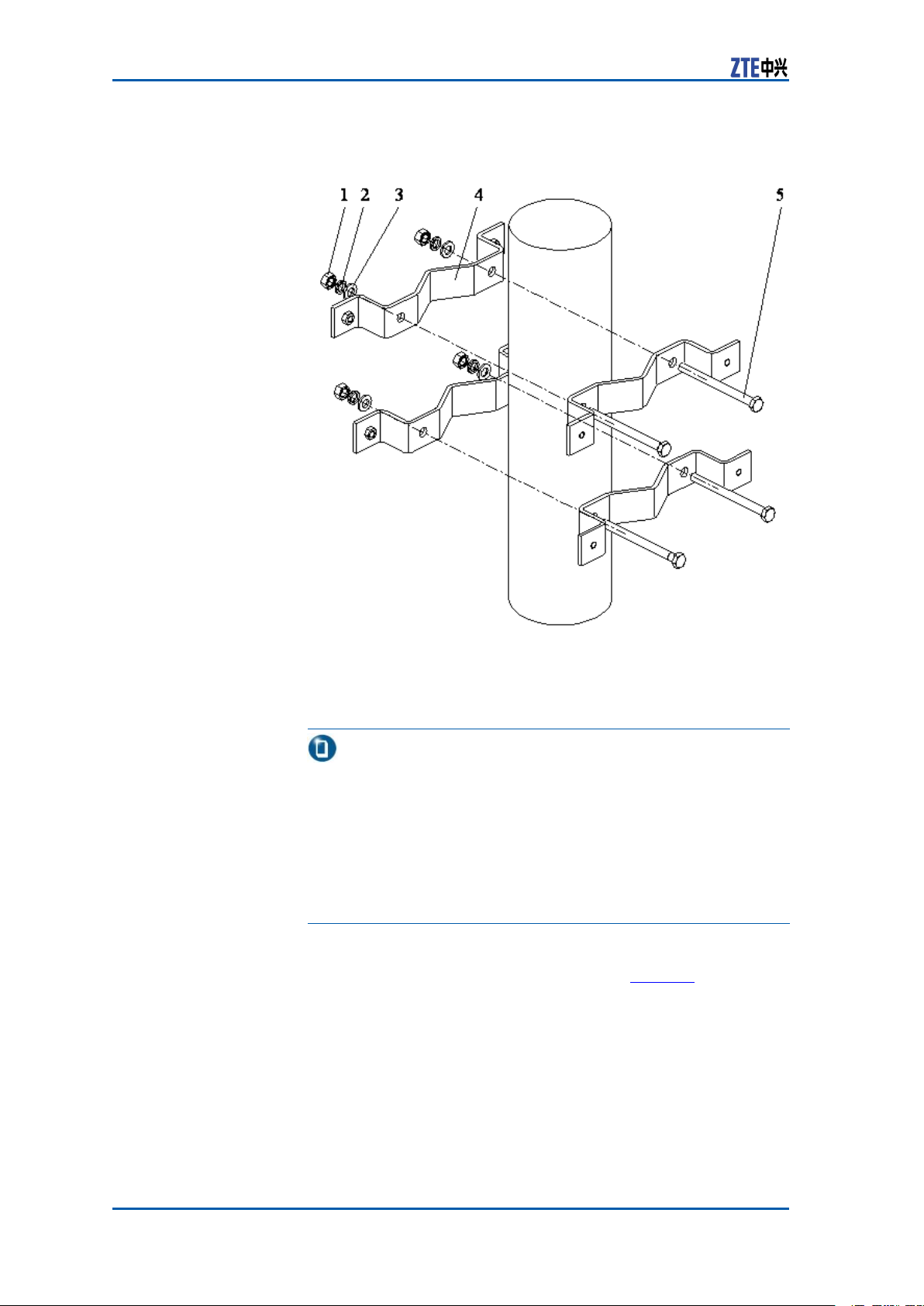

InstallingThreeZXSDRR8860C806

CabinetsonPole(WithoutWave

Trap)

Steps1.Fixthetwosetsofxingbracketsontothepoleandalignthe

holesandscrewitabitwithbolts,asshowninF

FIGURE11POLE-MOUNTINSTALLATION(1)

igure11

1.FixingBracket

2.M10×120hexagonheadbolt

(fullthread)

3.Standardspringwasher10

2.Adjustspacebetweenthexingbracketsbasedonthescrews’

positionofinsulationboardsatthebackofsupportingpanels

asshowninFigure12.Fixthreesupportingpanelsonthe

xingbracketswithM8bolts.Screwthexingbracketswith

M10bolts.

ConfidentialandProprietaryInformationofZTECORPORATION25

4.Flatwasher10

5.I-typecommonM10hexagonalnut

Page 34

ZXSDRR8860InstallationManual

FIGURE12POLE-MOUNTINSTALLATION(2)

1.Fixingbracket

2.Insulationboard

3.Supportingpanel

4.Insulationange

5.Bigatwasher8

6.Standardspringwasher8

7.M8×40Hexagonheadbolt

3.MounttheZXSDRR8860cabinetsonthesupportingpanelsand

fastenthecabinetswithM6X20hexagonsocketcapscrewsas

showninF

FIGURE13POLE-MOUNTINSTALLATION(3)

igure13.

26ConfidentialandProprietaryInformationofZTECORPORATION

Page 35

Chapter3CabinetInstallation

Tip:

Thesidewithoutxingbracketcanbelocatedalongthewall.

ENDOFSTEPS.

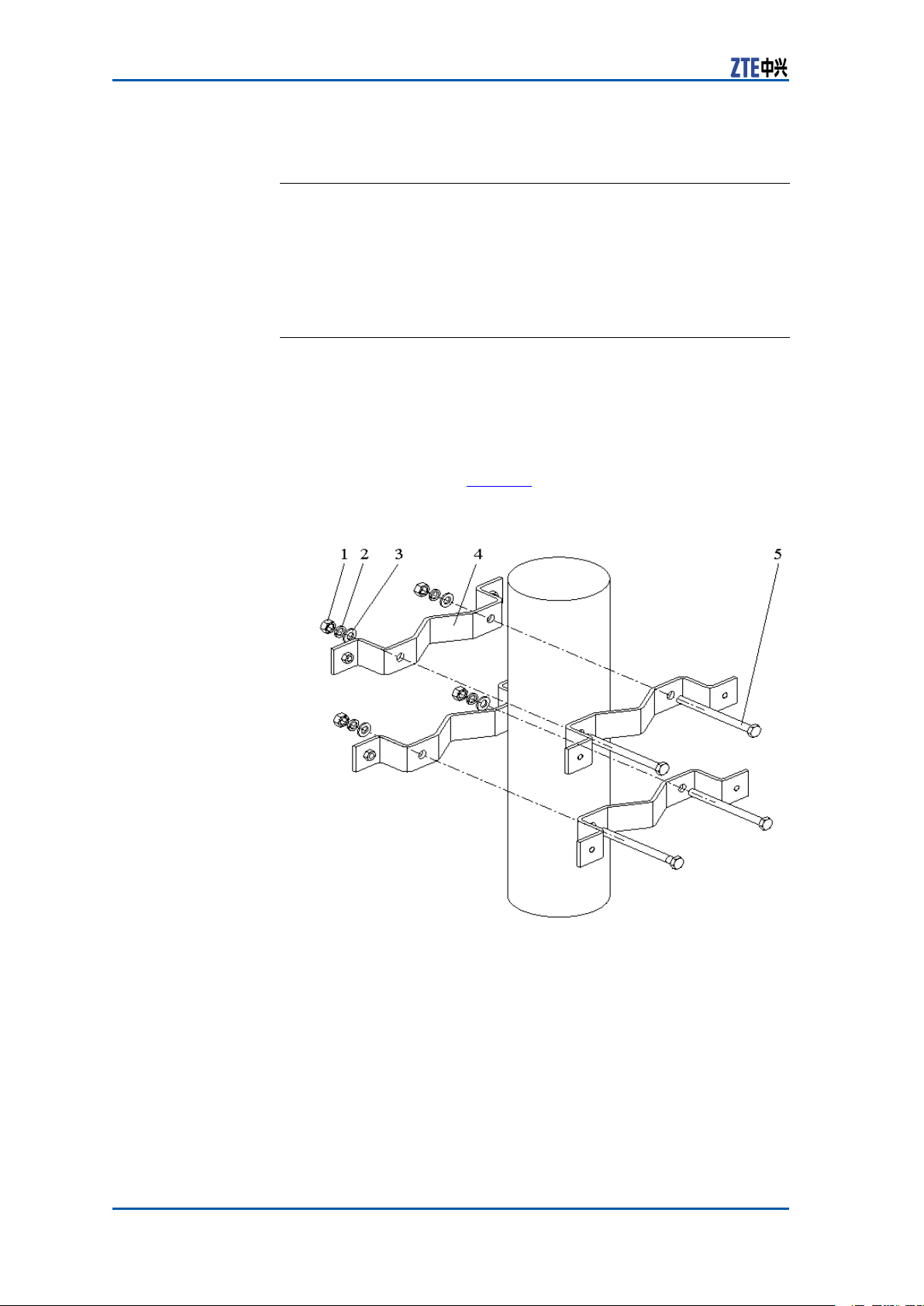

InstallingThreeZXSDRR8860C806

CabinetonPole(WithWaveTrap)

ContextWhileinstallingtheZXSDRR8860C806pole-mountinstallation

withtwowavetraps,adoptanchorclamps;forthepole-mount

installationofthreewavetraps,adoptxingbrackets.

Steps1.Fixthetwosetsofxingbracketsontothepoleandalignthe

holesandscrewitabitwithbolts,asshowninFigure14.

FIGURE14POLE-MOUNTINSTALLATION(1)

1.FixingBracket

2.M10×120hexagonheadbolt

(fullthread)

3.Standardspringwasher10

4.Flatwasher10

5.I-typecommonM10hexagonalnut

2.Adjustspacebetweenthexingbracketsbasedonthescrews’

positionofinsulationboardsatthebackofsupportingpanels

asshowninF

igure15.Fixthreesupportingpanelsonthexing

bracketswithM8bolts.Screwdownthexingbracketswith

M10bolts.

ConfidentialandProprietaryInformationofZTECORPORATION27

Page 36

ZXSDRR8860InstallationManual

FIGURE15POLE-MOUNTINSTALLATION(2)

1.Fixingbracket

2.Insulationboard

3.Supportingpanel

4.Insulationange

5.Bigatwasher8

6.Standardspringwasher8

7.M8×40Hexagonheadbolt

3.RepeattheStep1~Step2toinstalltwosetsofxingbrackets

andthreesetsofsupportingpanels,asshowninF

igure16.

28ConfidentialandProprietaryInformationofZTECORPORATION

Page 37

FIGURE16POLE-MOUNTINSTALLATION(3)

Chapter3CabinetInstallation

1.Supportingpanel

4.MounttheZXSDRR8860cabinetsonthesupportingpanelsand

fastenthecabinetswithM6X20hexagonsocketcapscrewsas

showninFigure17.

ConfidentialandProprietaryInformationofZTECORPORATION29

Page 38

ZXSDRR8860InstallationManual

FIGURE17POLE-MOUNTINSTALLATION(4)

Tip:

Thesidewithoutxingbracketcanbelocatedalongthewall.

5.Mountthewavetrapsontothesupportingpanelandfastenit

tothesupportingpanelwithfourM6X20hexagonsocketcap

screws,asshowninF

igure18.

30ConfidentialandProprietaryInformationofZTECORPORATION

Page 39

FIGURE18WAVETRAPINSTALLATION

Chapter3CabinetInstallation

1.Wavetrap

2.Fixingbeam

3.Supportingpanel

ENDOFSTEPS.

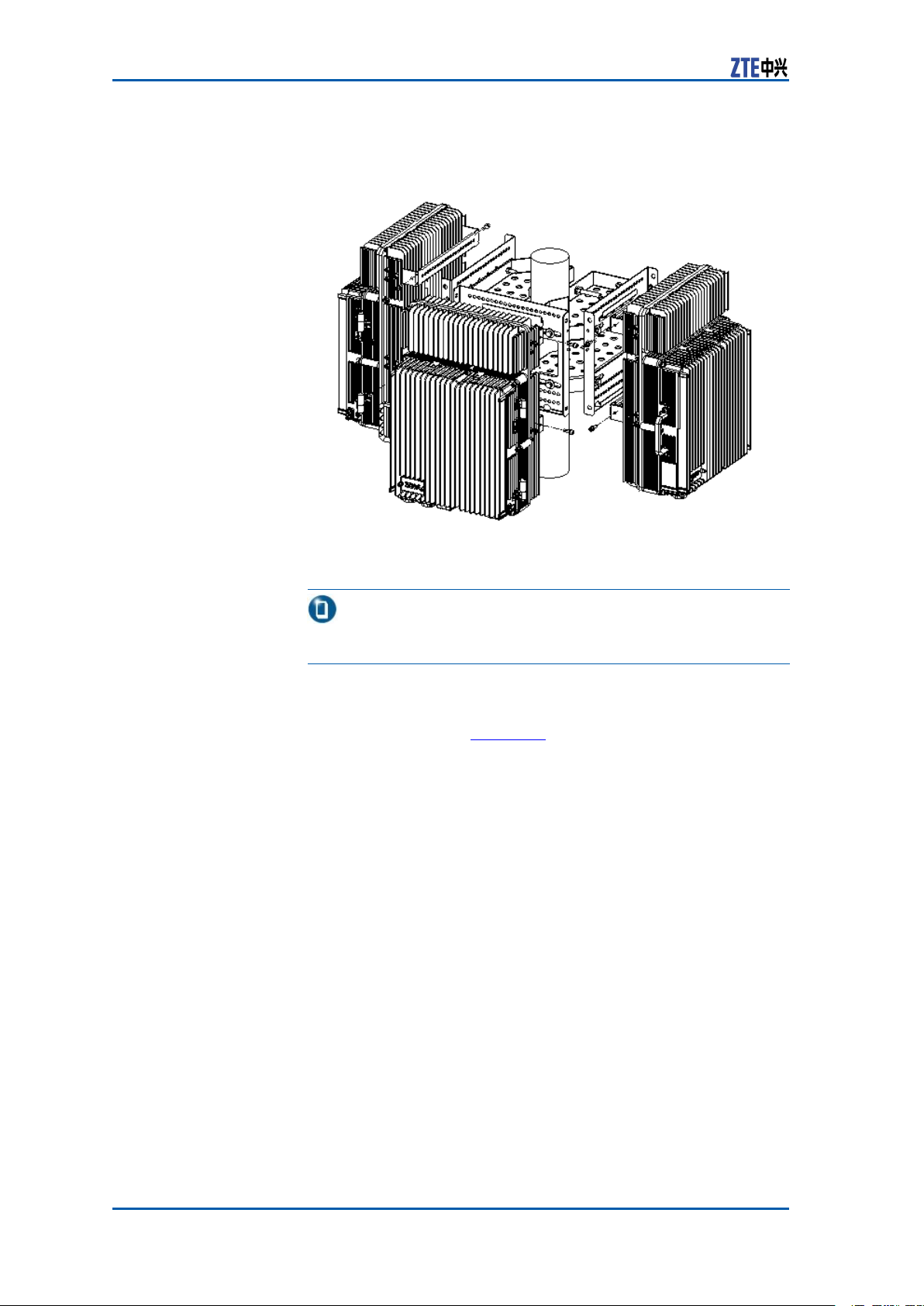

ExampleAfterinstallationcompleted,theappearanceisasshowninFigure

19.

ConfidentialandProprietaryInformationofZTECORPORATION31

Page 40

ZXSDRR8860InstallationManual

FIGURE19INSTALLATIONCOMPLETION

1.Pole

2.ZXSDRR8860

3.Wavetrap

4.LightningBox

32ConfidentialandProprietaryInformationofZTECORPORATION

Page 41

Chapter3CabinetInstallation

Note:

InFigure19,anoutdoorDClightningboxoranAClightningbox

canbeadoptable.Theapplicationandinstallationforbothrefer

toAppendixCandAppendixE.

Wall-mountedInstallation Mode

ComponentsUsedinWall-Mount Installation

Thecomponentsusedinwall-mountinstallationarelistedinTable

9

TABLE9MAINCOMPONENTS

Name

Supportingpanel

Drilltemplate

M8×80expansionbolt

Bigwasher8

ThesupportingpanelisshowninFigure20.Theholemarking

designtemplateisshowninFigure21.

FIGURE20SUPPORTINGPANEL

Quantity

1

1

4

4

ConfidentialandProprietaryInformationofZTECORPORATION33

Page 42

ZXSDRR8860InstallationManual

Thesupportingpanel,asthecommoncomponentinZXSDRR8860

installation,isusedinthewall-mount,pole-mountandgantrymountinstallationmodes.

FIGURE21HOLEMARKINGDESIGNTEMPLATE(UNIT:MM)

Note:

InstallingCabinetonWall (Wall-Mount)

ContextFigure22illustratesthespacerequirement(Unit:mm)forwall-

mountinstallation.

34ConfidentialandProprietaryInformationofZTECORPORATION

Page 43

Chapter3CabinetInstallation

FIGURE22SPACEREQUIREMENTFORWALL-MOUNTINSTALLATION(UNIT:

MM)

Steps1.Firstlymarktheholepositionsonthewallwithholedesign

template.Drillthemarkedpointsabout60mmwithpercussive

drillandinstalltheexpansionbolts.

2.Fixthesupportingpanelonthewallwithboltsasshownin

F

igure23

ConfidentialandProprietaryInformationofZTECORPORATION35

Page 44

ZXSDRR8860InstallationManual

FIGURE23SUPPORTINGPANELINSTALLATIONONWALL

1.M8×80expansionbolt

2.Insulationboard

3.Supportingpanel

4.Insulationange

5.Bigatwasher8

6.Standardspringmat8

7.M8nut

l

3.MounttheZXSDRR8860cabinetontothesupportingpanel,

andfastenthecabinetwithfourM6X20hexagonsocketcap

screwsasshowninF

igure24.

36ConfidentialandProprietaryInformationofZTECORPORATION

Page 45

FIGURE24MOUNTINGCABINET

Chapter3CabinetInstallation

1.Supportingpanel

2.M6safeguardscrew

ENDOFSTEPS.

3.Retainingboard

FloorGantry-mounted InstallationMode

ComponentsUsedingantry-mount Installation

Thecomponentsusedingantry-mountinstallationincludesa

gantryandsupportingpanels.Thequantityofsupportingpanels

isconsistentwiththatofZXSDRR8860s.ForeveryZXSDRR8860

cabinet,onesupportingpanelisrequired.

ConfidentialandProprietaryInformationofZTECORPORATION37

Page 46

ZXSDRR8860InstallationManual

Table10listssomecomponentsofgantry.

TABLE10MAINCOMPONENTS

Name

Gantry

Quantity

1

M5X16screw24

M10X40tappingscrew6

M10X100expansionbolt

4

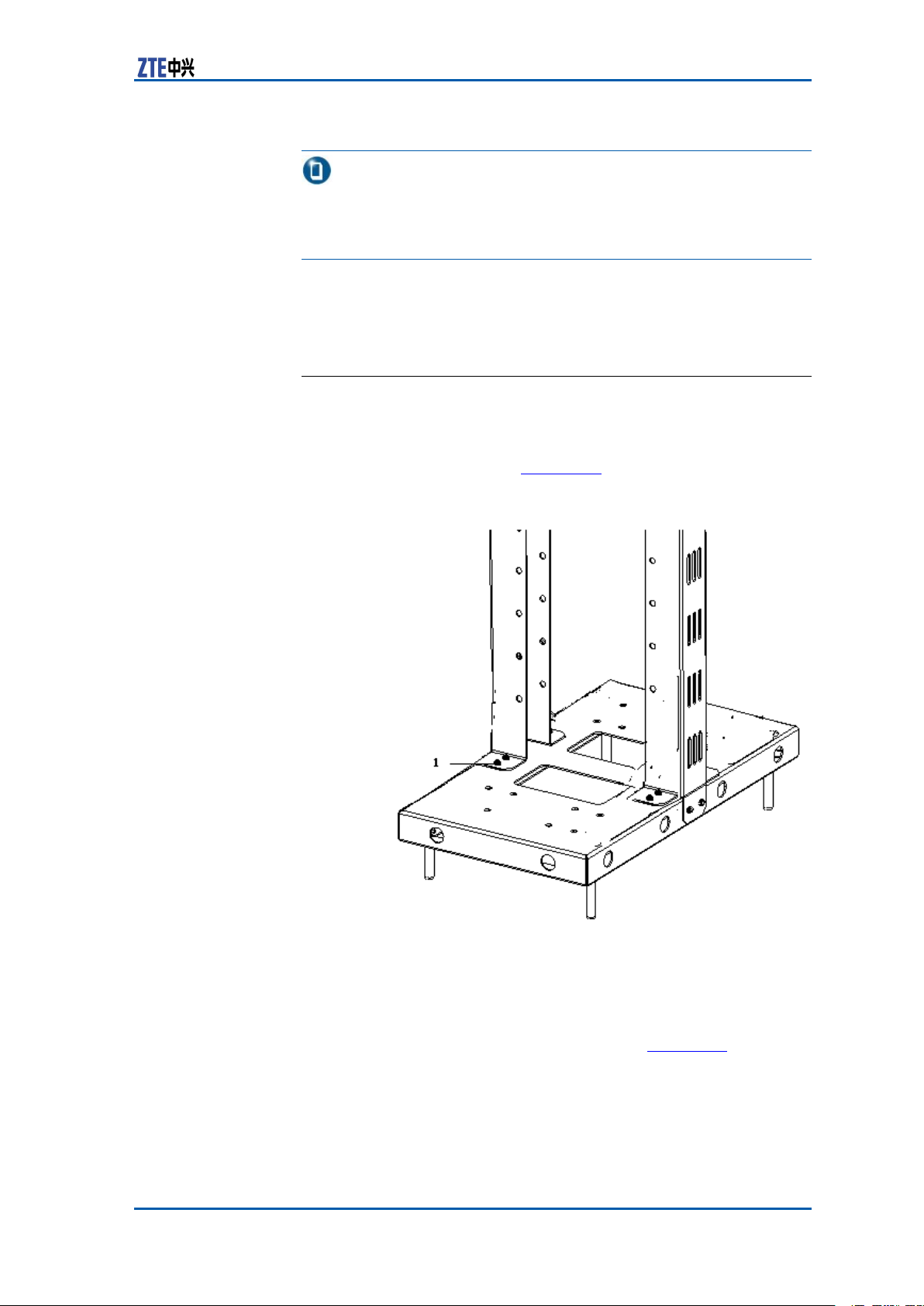

Figure25showstheappearanceofgantry.

38ConfidentialandProprietaryInformationofZTECORPORATION

Page 47

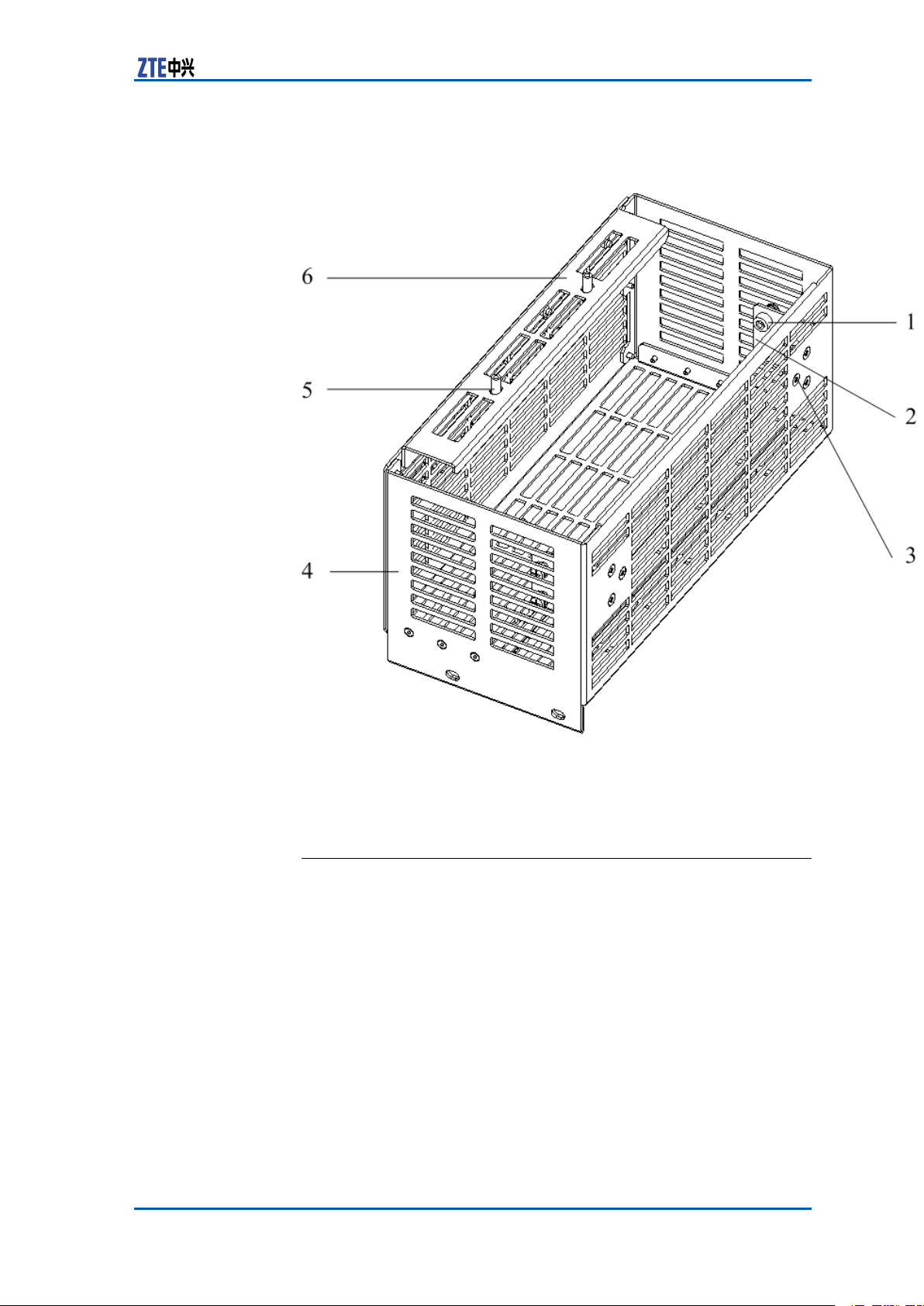

FIGURE25GANTRYAPPEARANCE

Chapter3CabinetInstallation

1.Coverplate

2.Uprightcolumn

3.Tiltedsupport

4.M5X16screw

5.Baseplate

6.M10X40tappingscrew

7.M10X100expansionbolt

ConfidentialandProprietaryInformationofZTECORPORATION39

Page 48

ZXSDRR8860InstallationManual

AdopttheM10X100expansionboltwhileinstallingthegantryon

aconcretebaseplate;adopttheM10X40tappingscrewwhileinstallingthegantryinsideabunker .

Table11listssomecomponentsofsupportingpanel.

TABLE11MAINCOMPONENTS

Note:

Name

Supportingpanel

M8×80expansionbolt

Bigwasher8

Quantity

1

4

4

Figure26showstheappearanceofsupportingpanel.

FIGURE26SUPPORTINGPANEL

40ConfidentialandProprietaryInformationofZTECORPORATION

Page 49

Note:

Thesupportingpanel,asthecommoncomponentinZXSDRR8860

installation,isusedinthewall-mount,pole-mountandgantrymountinstallationmodes.

InstallingCabinetonGantry(Without WaveTrap)

Steps1.Assemblethegantry

i.FixtheuprightcolumnuponthebaseplatewiththeM5X16

screws,asshowninFigure27.

FIGURE27FIXUPRIGHTCOLUMNANDBASEPLATE

Chapter3CabinetInstallation

1.M5X16screw

ii.Fastenthejunctionbetweenuprightcolumnandcoverplate

withtheM5X16screws,asshowninFigure28.

ConfidentialandProprietaryInformationofZTECORPORATION41

Page 50

ZXSDRR8860InstallationManual

iii.FastenthetiltedsupportwiththeM5X16screws,asshown

FIGURE28FASTENUPRIGHTCOLUMNANDCOVERPLATE

1.M5X16screw

inFigure29

FIGURE29FASTENTILTEDSUPPORT

1.M5X16screw

2.Installthegantry

Accordingtothespeciedinstallationpositionintheengineeringdesigndrawing,drillthemarkedholesandinstalltheexpansionbolts.

42ConfidentialandProprietaryInformationofZTECORPORATION

Page 51

Chapter3CabinetInstallation

Note:

AdopttheM10X100expansionboltwhileinstallingthegantry

onaconcretebaseplate;adopttheM10X40tappingscrew

whileinstallingthegantryinsideabunker .

3.InstalltheZXSDRR8860

i.Fastenthesupportingpanelsontotheproperpositionsof

gantrywithbolts.

ii.MounttheZXSDRR8860cabinetsontothesupporting

panels,andfastenthecabinetswithfourM6X20hexagon

socketcapscrews.

ENDOFSTEPS.

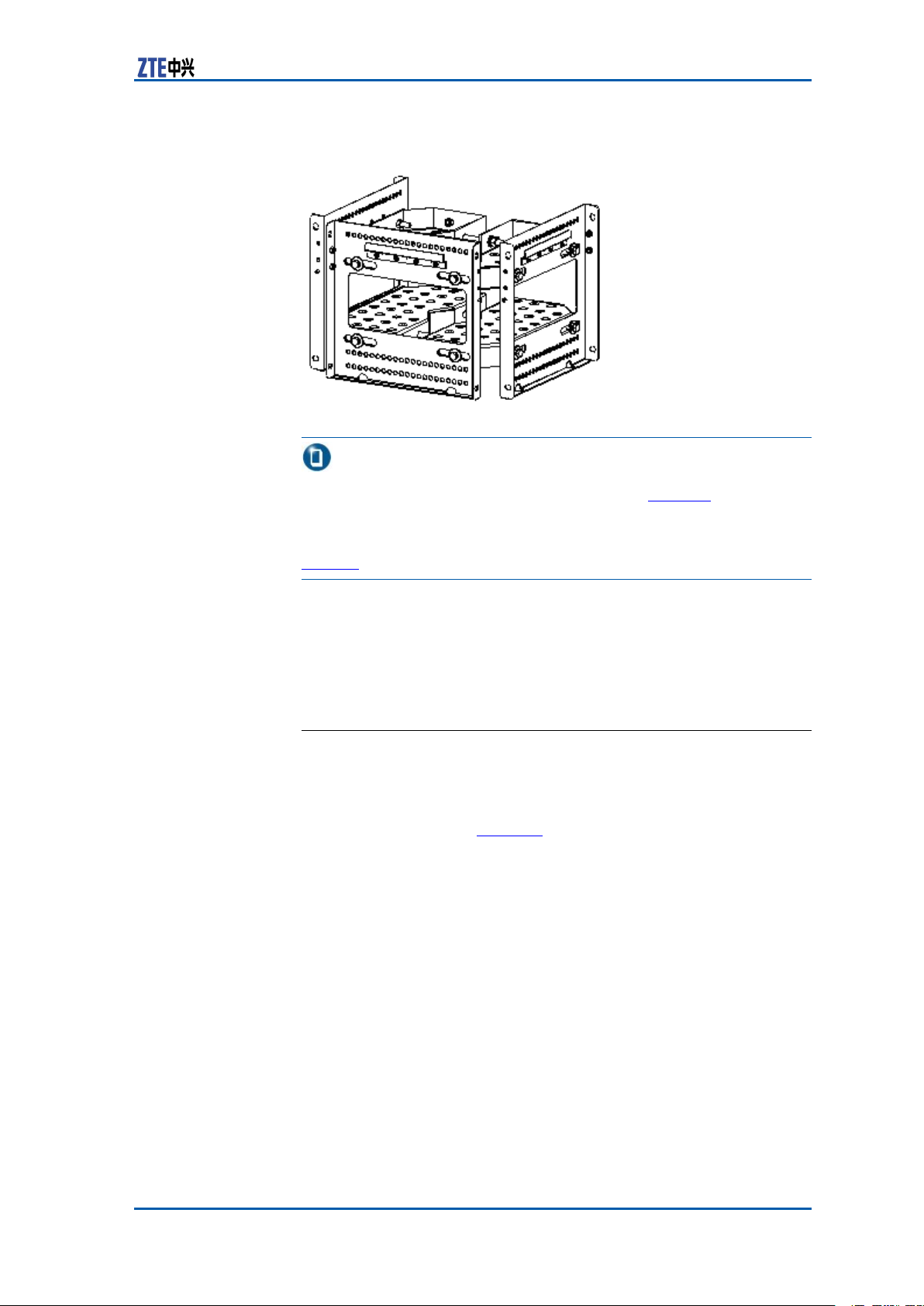

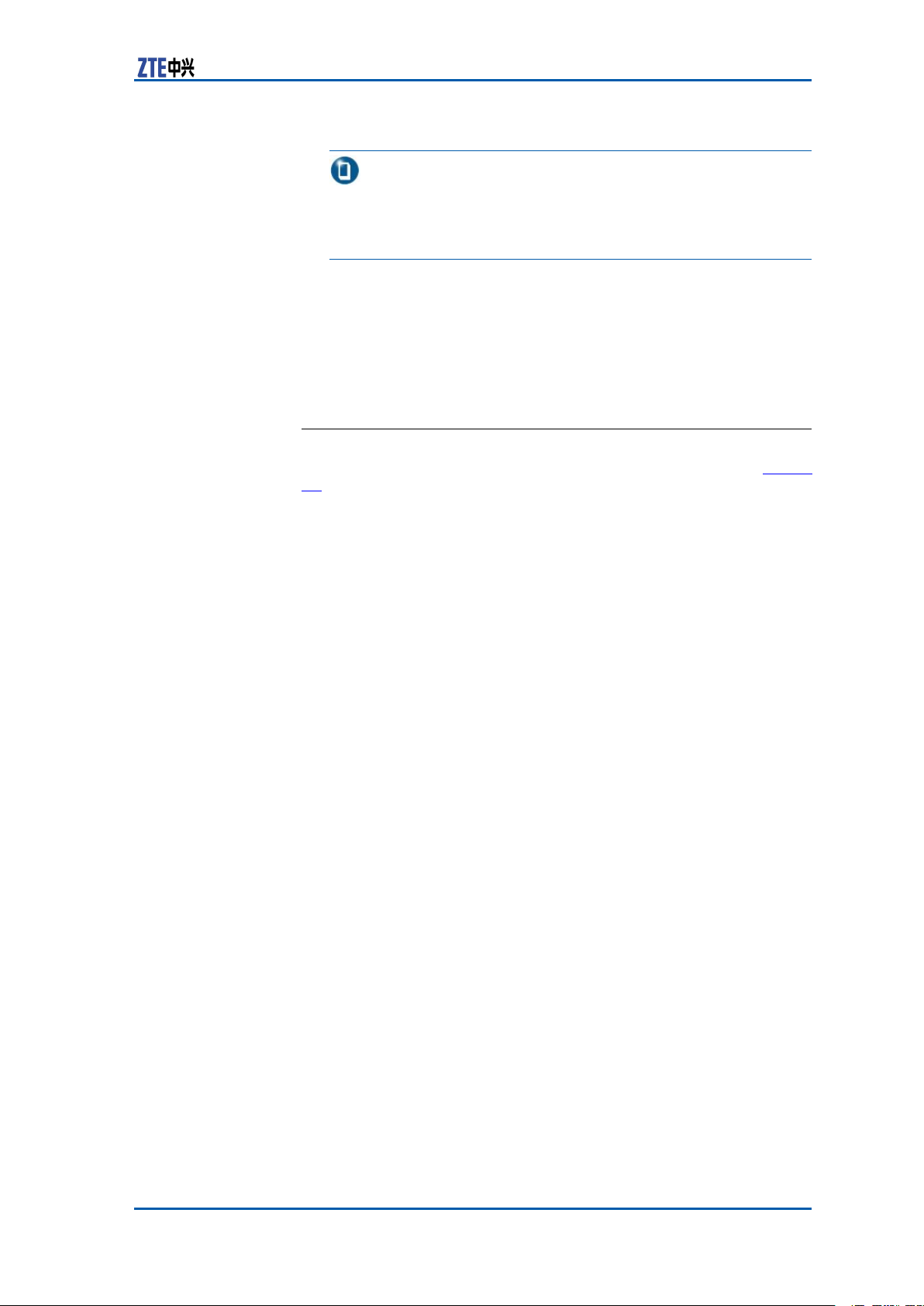

ExampleTheappearanceafterinstallationcompletionisasshowninFigure

30.

ConfidentialandProprietaryInformationofZTECORPORATION43

Page 52

ZXSDRR8860InstallationManual

FIGURE30ZXSDRR8860INDOORGANTRY-MOUNTINSTALLATION

APPEARANCE(ONLYRRUINSTALLED)

InstallingCabinetonGantry(With WaveTrap)

Steps1.Assemblethegantry.

44ConfidentialandProprietaryInformationofZTECORPORATION

Page 53

Chapter3CabinetInstallation

i.FixtheuprightcolumnuponthebaseplatewiththeM5X16

screws,asshowninFigure31.

FIGURE31FIXUPRIGHTCOLUMNANDBASEPLATE

1.M5X16screw

ii.Fastenthejunctionbetweenuprightcolumnandcoverplate

withtheM5X16screws,asshowninF

FIGURE32FASTENUPRIGHTCOLUMNANDCOVERPLATE

1.M5X16screw

igure32.

ConfidentialandProprietaryInformationofZTECORPORATION45

Page 54

ZXSDRR8860InstallationManual

iii.FastenthetiltedsupportwiththeM5X16screws,asshown

inFigure33.

FIGURE33FASTENTILTEDSUPPORT

1.M5X16screw

2.Installthegantry.

Accordingtothespeciedinstallationpositionintheengineeringdesigndrawing,drillthemarkedholesandinstalltheexpansionbolts.

Note:

AdopttheM10X100expansionboltwhileinstallingthegantry

onaconcretebaseplate;adopttheM10X40tappingscrew

whileinstallingthegantryinsideabunker .

3.Installthesupportingbracketofwavetrap.

ThesupportingbracketofwavetrapisasshowninFigure34.

FastenthesupportingbracketontothegantrywithM8bolts,

asshowninF

igure35.

46ConfidentialandProprietaryInformationofZTECORPORATION

Page 55

FIGURE34SUPPORTINGBRACKET

Chapter3CabinetInstallation

1.M8bolt

2.Insulationboard

3.Supportingbracket

4.InstalltheZXSDRR8860.

i.Fastenthesupportingpanelsontotheproperpositionsof

gantrywithbolts,asshowninFigure35.

ConfidentialandProprietaryInformationofZTECORPORATION47

Page 56

ZXSDRR8860InstallationManual

FIGURE35SUPPORTINGBRACKETANDWALL-MOUNTASSEMBLIES

1.Gantry

2.Supportingbracket

ii.MounttheZXSDRR8860cabinetsontothesupporting

panels,andfastenthecabinetswithfourM6X20hexagon

socketcapscrews,asshowninFigure36.

48ConfidentialandProprietaryInformationofZTECORPORATION

3.Supportingpanel

4.BBUwall-mountframe

Page 57

FIGURE36ZXSDRR8860INSTALLATION

Chapter3CabinetInstallation

5.Installthewavetrap.

TheappearanceofwavetrapisasshowninF

thewavetrapintothesupportingbracketandfastenthemwith

M6bolts,asshowninFigure38.

ConfidentialandProprietaryInformationofZTECORPORATION49

igure37.Insert

Page 58

ZXSDRR8860InstallationManual

FIGURE37WAVETRAP

1.Guideblock

2.Wavetrap

3.M6bolt

4.Frontbafer

50ConfidentialandProprietaryInformationofZTECORPORATION

Page 59

FIGURE38WAVETRAPINSTALLATION

Chapter3CabinetInstallation

ENDOFSTEPS.

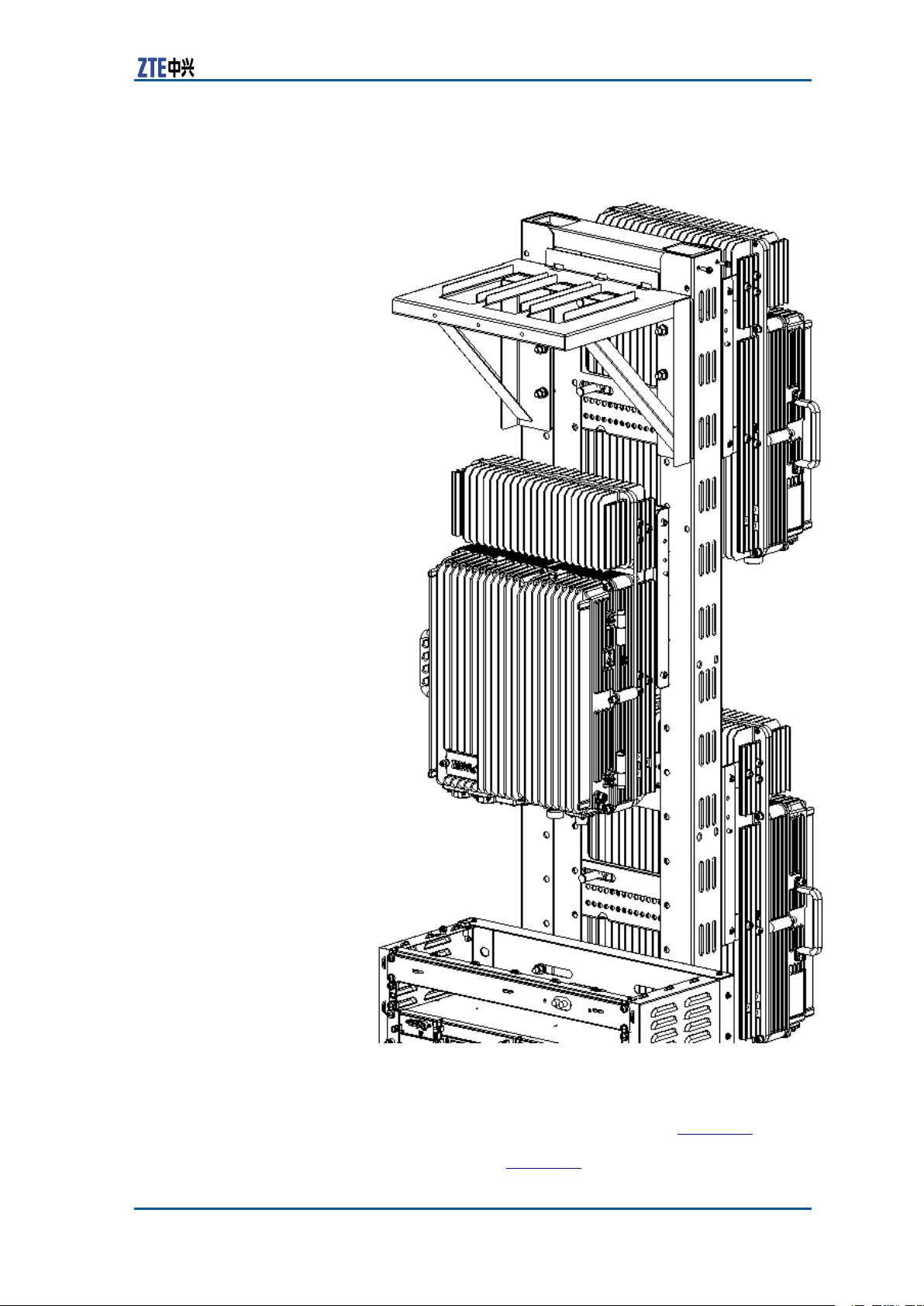

ExampleTheZXSDRR8860gantry-mountintegratedinstallationiscom-

pleted.TheprolesareasshowninFigure39andFigure40.

ConfidentialandProprietaryInformationofZTECORPORATION51

Page 60

ZXSDRR8860InstallationManual

FIGURE39GANTRY-MOUNTINTEGRATEDINSTALLATION

1.ZXSDRR8860

2.ZXSDRB8200C100

3.Groundingcopperbar

4.Gantry

5.Wavetrap

52ConfidentialandProprietaryInformationofZTECORPORATION

Page 61

Chapter3CabinetInstallation

FIGURE40GANTRY-MOUNTINTEGRATEDINSTALLATION(SIDE)

ConfidentialandProprietaryInformationofZTECORPORATION53

Page 62

ZXSDRR8860InstallationManual

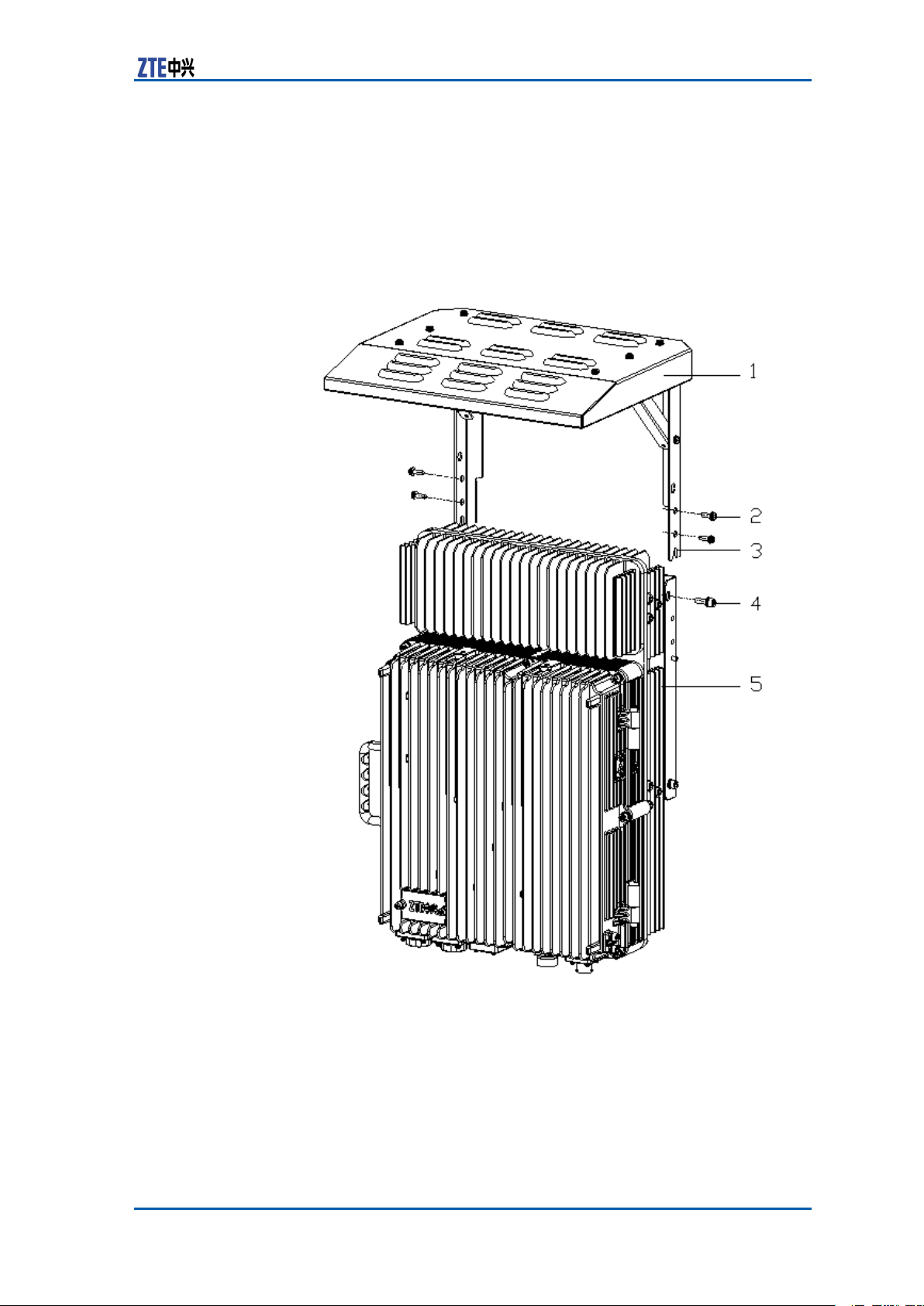

SimplifiedCabinetIntegrated InstallationMode

ComponentsUsedinIntegrated Installation

TheZXSDRR8860forintegratedinstallationneedsthefollowing

components:asimpliedcabinet,anupperxingframeanda

lowerxingframe.

Thedimensionofsimpliedcabinetis1650×600×450(H×W×D;

unit:mm),asshowninF

igure41.

54ConfidentialandProprietaryInformationofZTECORPORATION

Page 63

FIGURE41SIMPLIFIEDCABINETAPPEARANCE

Chapter3CabinetInstallation

1.M10×100expansionbolt

TheupperxingframeisasshowninFigure42.

ConfidentialandProprietaryInformationofZTECORPORATION55

Page 64

ZXSDRR8860InstallationManual

FIGURE42UPPERFIXINGFRAME

1.Upperxingframe

2.Supportingpanel

3.M6×16pan—headscrew

4.M4×12pan—headscrew

TheupperxingframeisasshowninFigure43.

56ConfidentialandProprietaryInformationofZTECORPORATION

Page 65

FIGURE43LOWERFIXINGFRAME

Chapter3CabinetInstallation

1.M6×16pan—headscrew

2.Supportingpanel1

3.M4×12pan—headscrew

4.Lowerxingframe

5.M6×16pan—headscrew

6.Supportingpanel2

InstallingIntegratedCabinet

PrerequisiteUnpackingandacceptancefortheZXSDRR8860andthesimplied

cabinetmeetrequirements.

Steps1.Installthesimpliedcabinet.

Accordingtoaninstallationpositionintheengineeringdesign

document,drillholesontheindooroor .Theholepositions

andthedimensionareasshownin.Fastenthecabinetonthe

oorwithM10×100expansionbolts.

ConfidentialandProprietaryInformationofZTECORPORATION57

Page 66

ZXSDRR8860InstallationManual

FIGURE44HOLEPOSITIONSANDDIMENSION

2.InstalltheZXSDRR8860.

showsallassembliesforZXSDRR8860integrated-cabinetinstallation.

58ConfidentialandProprietaryInformationofZTECORPORATION

Page 67

FIGURE45ZXSDRR8860ASSEMBLIES

Chapter3CabinetInstallation

1.Upperxingframe

2.Lowerxingframe

3.ZXSDRR8860

i.RemovethexingbeamsofZXSDRR8860.

TheZXSDRR8860carriestwoxingbeamsusedforwallmountandpole-mountinstallations,asshownin.Remove

thexingbeams.

ConfidentialandProprietaryInformationofZTECORPORATION59

Page 68

ZXSDRR8860InstallationManual

FIGURE46ZXSDRR8860FIXINGBEAM

1.Fixingbeam

ii.Installthelowerxingframe.

InserttheZXSDRR8860tothelowerxingframe.Fasten

thesupportingpanel2withtheZXSDRR8860byM6×12

pan-headscrewsandfastenthesupporting1withZXSDR

R8860byM6×16pan-headscrews,asshownin.

60ConfidentialandProprietaryInformationofZTECORPORATION

Page 69

FIGURE47LOWERFIXINGFRAMEINSTALLATION

Chapter3CabinetInstallation

1.Pan-headscrewM6×162.an-headscrewM6×12

iii.Installtheupperxingframe.

InserttheZXSDRR8860tothelowerxingframe.Fasten

thesupportingpanelofupperxingframewiththeZXSDR

R8860byM6×16pan-headscrews,asshownin.

ConfidentialandProprietaryInformationofZTECORPORATION61

Page 70

ZXSDRR8860InstallationManual

FIGURE48ZXSDRR8860INSTALLEDWITHUPPERANDLOWER

FIXINGFRAME

1.M6×16pan-headscrew

3.InstalltheZXSDRR8860tothesimpliedcabinet.

AligntheguidancechannelontheZXSDRR8860installedwith

theupperandlowerxingframestotherailonethesimplied

cabinet.ThenslidetheZXSDRR8860slowlyintothesimplied

cabinetandfastenthemwithfourM6×16pan-headscrews,as

shownin.

62ConfidentialandProprietaryInformationofZTECORPORATION

Page 71

Chapter3CabinetInstallation

FIGURE49ZXSDRR8860INSTALLATIONTOSIMPLIFIEDCABINET

1.M6×16pan-headscrew

4.InstallotherZXSDRR8860s.

RepeattheStep2~Step4toinstallotherZXSDRR8860sinto

thesimpliedcabinet.WhensixZXSDRR8860sareinstalled

completely,theappearanceisasshownin.

ConfidentialandProprietaryInformationofZTECORPORATION63

Page 72

ZXSDRR8860InstallationManual

FIGURE50ZXSDRR8860INSTALLATIONCOMPLETION

ENDOFSTEPS.

64ConfidentialandProprietaryInformationofZTECORPORATION

Page 73

Chapter3CabinetInstallation

InstallingSunshield

ContextThecomponentsusedforinstallingsunshademustbeprepared.

showsthesunshadetobeinstalled.

FIGURE51SUNSHIELDSTRUCTURE

1.Sunshield

2.M5screw

3.Fixingposition(wedgedontothe

boltatthesideofthecommonpart

forwallmounting)

Steps1.Assemblethesunshadeonsiteandxthebrackettothe

4.M6screw

5.ZXSDRR8860cabinet

shield.

ConfidentialandProprietaryInformationofZTECORPORATION65

Page 74

ZXSDRR8860InstallationManual

2.UnscrewthetwoM6screwatthesidetopofthecabinetand

inserttheboltsatbothsidesofthewall-mountingcommon

parttothesunshade.

3.ScrewthetwoM6screwsandfourM5screwsonbothsidesof

thecabinetandtightenthem.

ENDOFSTEPS.

66ConfidentialandProprietaryInformationofZTECORPORATION

Page 75

Chapter4

ExternalCable Installation

TableofContents:

ExternalCableLayout........................................................67

ExternalCableInstallationFlow...........................................69

InstallingPowerCable........................................................70

InstallingGroundingCable..................................................71

InstallingFiberbetweenBBUandRRU..................................72

InstallingFiberbetweenRRUandRRU..................................73

InstallingEnvironmentMonitoringCable...............................75

InstallingAISGControlCable..............................................76

InstallingFrequencyPointExtensionCable............................77

InstallingJumper...............................................................78

ExternalCableLayout

TheconnectionrelationshipofZXSDRR8860externalcablesis

describedinT able12.

TABLE12ZXSDRR8860EXTERNALCABLECONNECTIONRELATIONSHIP

Name

PowercableConnectstheZXSDR

Connection

Relationship

R8860powerinterface

(DCIN)tothepower

supplyequipment

interface

Description

Oneendisthe

aviationplugandthe

otherendisreserved

forpowercablemade

onsite.Thelengthof

cableisbasedonthe

engineeringsurvey.

ConfidentialandProprietaryInformationofZTECORPORATION67

Page 76

ZXSDRR8860InstallationManual

Name

Connection

Relationship

Groundingcable

ConnectsoneZXSDR

R8860groundboltto

thecopperbar

OpticalFiberTherearetwotypes

ofZXSDRR8860fiber:

BBUconnection

/ZXSDRR8860

cascading.

Environment

monitoringcable

ConnectstheZXSDR

R8860environment

monitoringinterface

MONtothe

externalmonitoring

componentsorthe

drycontact.

AISGcontrolcableConnectstheZXSDR

R8860debugging

interface(AISG)

tothecontrol

interfaceof

electrical-adjustment

antenna.

Frequencypoint

extensioncable

Interconnects

theZXSDRR8860

RXin/RXout

interfaces.

Antenna,feederand

jumper

ConnectstheZXSDR

R8860tothemain

feeder.

Description

Thegroundingcableis

madeupofstrandsof

flame-retardantwire.

Thecrosssectional

areaofZXSDRR8860

groundingcableis

10mm

2

.The

colorofgrounding

cableisyellowand

green.Copperlugs

arecrimpedatboth

endsoftheZXSDR

R8860grounding

cable.

Therearetwotypesof

ZXSDRR8860optical

fiber:oneusedin

BBUconnectionand

theotherusedin

cascadingbetween

ZXSDRR8860s.

Aendofthe

environment

monitoringcable

isPINdesign.Bend,

with3mlengthin

total,needsmaking

basedontheon-site

engineering.

AISGisusedfor

controlofthe

electrical-adjustment

antenna.

Thefrequencypoint

extensioncable

usuallyadoptsthe

finished1/2″jumper

with2mlength.

Thejumpercanbe

self-madebased

onthereal-time

conditiononsite.

AandBends

ofjumperareN

connectors(male).

TheRFjumperusually

adoptsthefinished

1/2″jumperwith2m

length.Thejumper

canbeself-made

basedonthereal-time

conditiononsite.

TheendofjumperisN

connector(male)and

theotherendisDIN

connector(female).

68ConfidentialandProprietaryInformationofZTECORPORATION

Page 77

Chapter4ExternalCableInstallation

ExternalCableInstallation Flow

Figure52liststheinstallationowofexternalcable.Thisowcan

beadjustedbasedonthereal-timecondition.

FIGURE52EXTERNALCABLEINSTALLATIONFLOW

ConfidentialandProprietaryInformationofZTECORPORATION69

Page 78

ZXSDRR8860InstallationManual

InstallingPowerCable

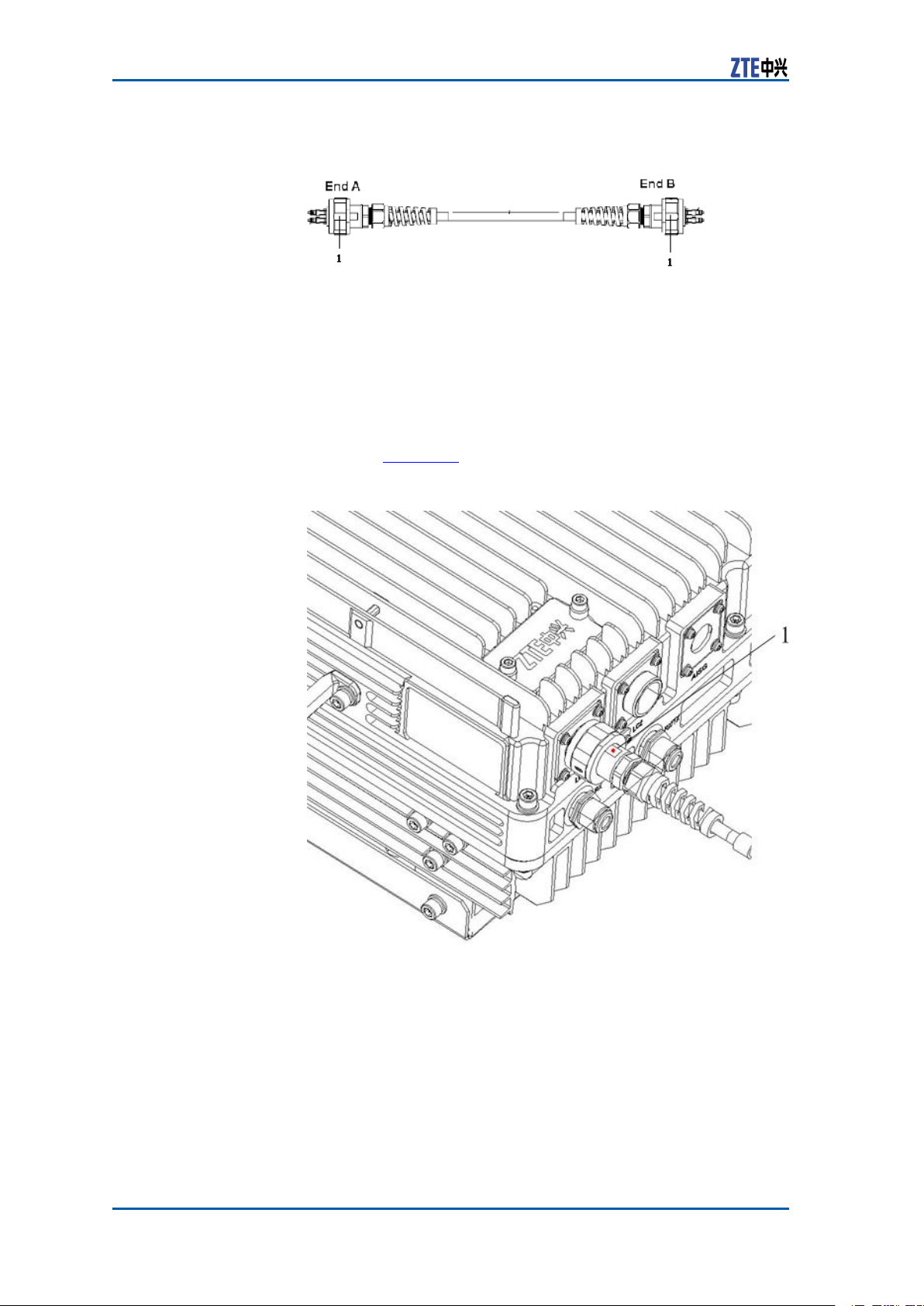

ContextTheZXSDRR8860cabinetadopts-48VDCforpowersupply .End

AistheaviationplugandEndBisreservedforself-madepower

cableonsite.Thelengthofpowercableisaccordingtotheengineeringsurvey.

ZXSDRR8860F

FIGURE53POWERCABLESTRUCTURE

Table13describesthecolorsandspecicationsofinsidecoreca-

ble.

TABLE13COLORANDSPECIFICATION

igure53showsthestructureofpowercable.

Color

Blue

Black

Note:

1.Ifthetwo-corecableisadopted,thebluecorecablestands

for-48Vandtheblackcorecablestandsfor-48VGND;

2.Ifthefour-corecableisadopted,thetwobluecorecables

connectedinparallelstandfor-48Vandtheblackcorecables

connectedinparallelstandfor-48VGND.

Steps1.ConnectEndAofpowercablewithDCINinterfacelocatedat

thebottomofZXSDRR8860.

2.StriptheprotectivecoatofEndBandconnectitwiththeDC

inputpowersourceaccordingtocolorsoftheinsidecorecable.

3.MakewaterproofprotectionofEndB.

4.Attachlabelsatbothendsofthepowercable.

5.Fixthepowercable.

ENDOFSTEPS.

Specification

-48V

-48VGND

70ConfidentialandProprietaryInformationofZTECORPORATION

Page 79

Chapter4ExternalCableInstallation

InstallingGroundingCable

ContextThegroundingcableismadeupofstrandsofame-retardantwire.

ThecrosssectionalareaofZXSDRR8860groundingcableis10

2

mm

lugsarecrimpedatbothendsoftheZXSDRR8860groundingcable,asshowninF

FIGURE54GROUNDINGCABLESTRUCTURE

Steps1.Coverandxacopperlugontheagroundingboltofthe

.Thecolorofgroundingcableisyellowandgreen.Copper

igure54.

ZXSDRR8860cabinet,asshowninFigure55.

FIGURE55ZXSDRR8860GROUNDINGBOLT

1.Groundingbolt

ConfidentialandProprietaryInformationofZTECORPORATION71

Page 80

ZXSDRR8860InstallationManual

2.Connecttheothercopperlugtotheearth-networkingcopper

barandxitwithabolt,asshowninFigure56.

FIGURE56EARTH-NETWORKCOPPERBAR(UNIT:MM)

3.Attachthelabelonthegroundingcable.

4.Measurethegroundingresistanceandmakesureitlessthan

5Ω.

ENDOFSTEPS.

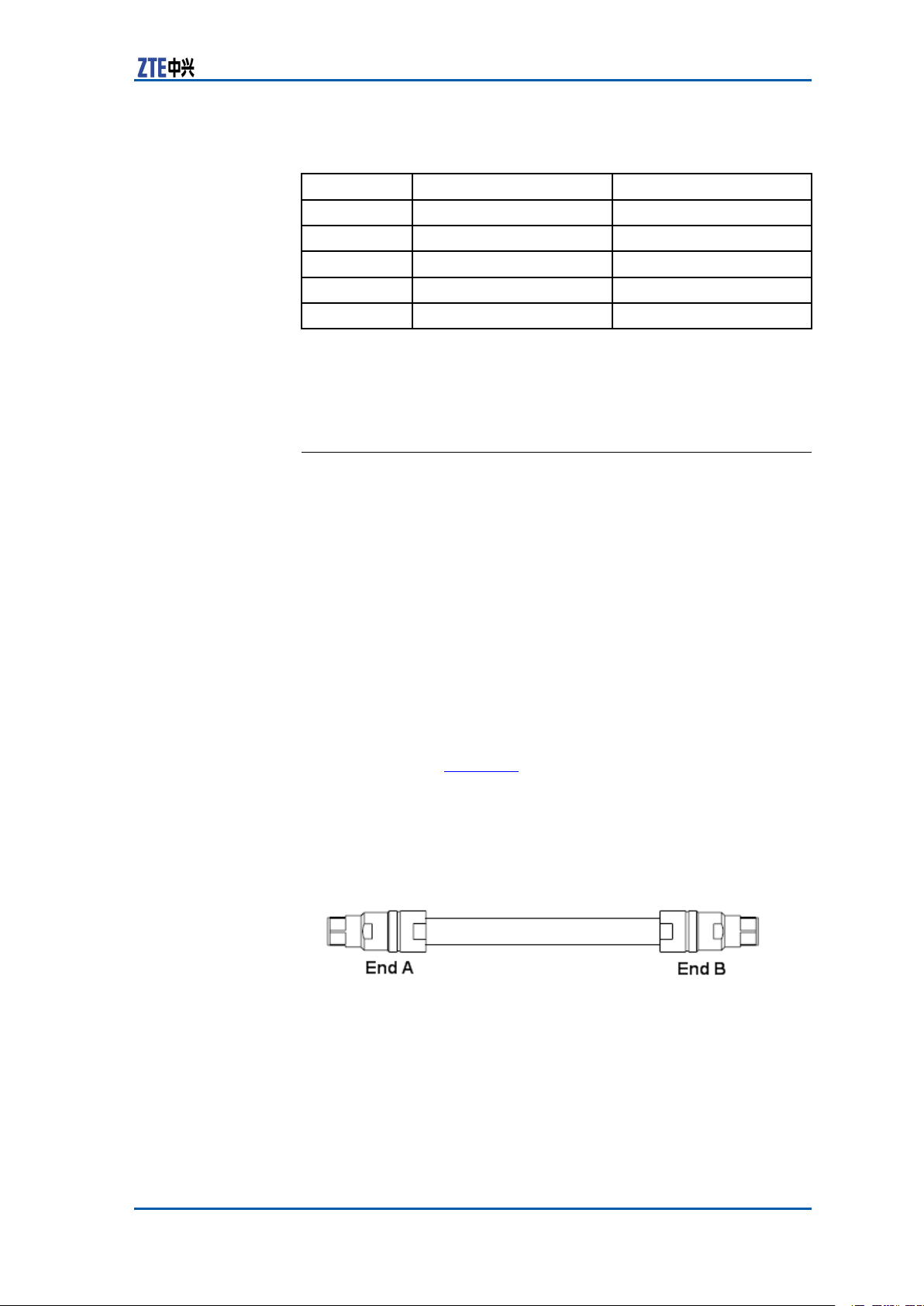

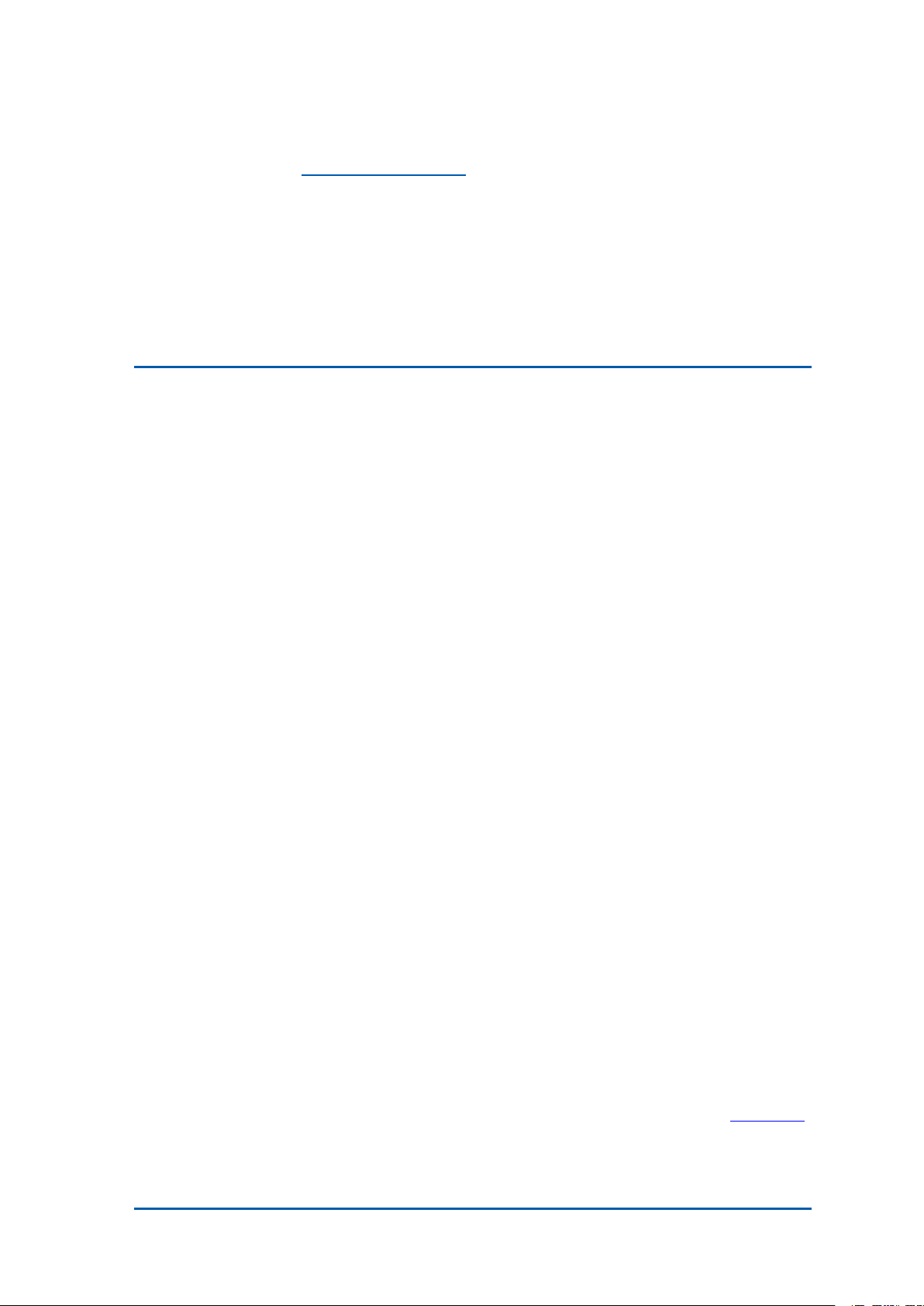

InstallingFiberbetween BBUandRRU

PrerequisiteTheZXSDRR8860cabinetmustbeinstalledandxedsuccessfully.

ContextFigure57showsberconnectionbetweenZXSDRR8860andBBU.

FIGURE57FIBERCONNECTIONBETWEENZXSDRR8860ANDBBU

1.OutdoorSealComponent

WhileconnectingaBBUtoZXSDRR8860,makesurethatthebase-

bandRFberinterface(LC1/2)oftheZXSDRR8860isconnected

totheopticalinterfaceconnectoroftheBBU.

72ConfidentialandProprietaryInformationofZTECORPORATION

Page 81

Chapter4ExternalCableInstallation

Steps1.Attachlabelsatbothendsoftheber .

2.AdjustthesideofEndAwiththecolormarkandinsertthe

ZXSDRR8860berinterface,andscrewdownthenuts,as

showninF

FIGURE58OPTICALFIBERINSTALLATION

igure58

1.Colormark

3.ConnectEndAofthebertothebasebandRFberinterface

(LC1/2)oftheZXSDRR8860.

4.ConnectEndBoftheber ,whichisaDLCconnector ,tothe

BBUopticalconnector .

5.ScrewdowntheoutdoorsealcomponentatEndAforwaterproong.

ENDOFSTEPS.

InstallingFiberbetween RRUandRRU

PrerequisiteThecascadingZXSDRR8860cabinetsmustbeinstalledandxed

successfully.

ContextFigure59showsberconnectionbetweenZXSDRR8860s.

ConfidentialandProprietaryInformationofZTECORPORATION73

Page 82

ZXSDRR8860InstallationManual

FIGURE59FIBERCONNECTIONBETWEENZXSDRR8860S

1.OutdoorSealComponent

WhileinterconnectingtheZXSDRR8860s,makesurethatthetwo

basebandRFberinterfaces(LC1/2)oftheZXSDRR8860areconnected.

Steps1.Attachlabelsatbothendsoftheopticalber .

2.AdjustthesideofEndAwiththecolormarkandinsertthe

ZXSDRR8860berinterface,andscrewdownthenuts,as

showninFigure60.

FIGURE60OPTICALFIBERINSTALLATION

1.Colormark

3.ConnectEndAoftheopticalbertothebasebandRFber

interface(LC1/2)oftheZXSDRR8860.

4.ConnectEndBoftheopticalbertotheotherbasebandRF

berinterface(LC1/2)oftheZXSDRR8860.

74ConfidentialandProprietaryInformationofZTECORPORATION

Page 83

Chapter4ExternalCableInstallation

5.ScrewdowntheoutdoorsealcomponentatEndAforwaterproong.

ENDOFSTEPS.

InstallingEnvironment MonitoringCable

PrerequisiteTheZXSDRR8860cabinetmustbeinstalledandxedsuccessfully.

ContextTheenvironmentmonitoringcableprovidesa485interface,used

forZXSDRR8860environmentmonitoring.Inaddition,thecablealsoprovidesfourextensionaccessesforexternaldrycontact

monitoring.

EndAisthe37PINconnector ,andEndBismadebyon-siteengineering.Thetotallengthis3m.Figure61showstheappearance

ofenvironmentmonitoringcable.

FIGURE61ENVIRONMENTMONITORINGCABLE

Theconnector ,connectingtheenvironmentmonitoringcableto

theZXSDRR8860,adopts37–coreaviationjack.Theconnector

accordswiththeGJB599specication.Theconnectorappearance

isasshowninFigure62

FIGURE62AVIATIONJACKAPPEARANCE

Table14describestheconnectorpins.

ConfidentialandProprietaryInformationofZTECORPORATION75

Page 84

ZXSDRR8860InstallationManual

TABLE14CABLEPINDESCRIPTION

PinCore-CableColorSignalDescription

15/16Whiteandblue/blueDrycontact4-/+

17/18Whiteand

19/20Whiteand

21/22Whiteand

23/24Redandblue/blue

25/26Redandorange/ora

Steps1.ConnectEndAtotheMONinterfacelocatedatthebottomof

ZXSDRR8860.

2.ConnectEndBwithexternalmonitoringdevicesordrycontacts.

3.AttachthelabelatEndB.

ENDOFSTEPS.

orange/orange

Drycontact3-/+

Drycontact2-/+

green/green

Drycontact1-/+

brown/brown

RS485receive

RS485transmit

nge

InstallingAISGControl Cable

ContextTheAISGcontrolcableisusedforcontroloftheelectricaladjust-

mentantenna.

Figure63showsthestructureoftheAISGcontrolcable.

FIGURE63AISGCONTROLCABLESTRUCTURE

Table15describestheserialNo.meaningofAISGcontrolcable.

76ConfidentialandProprietaryInformationofZTECORPORATION

Page 85

TABLE15AISGCONTROLCABLEDESCRIPTION

Chapter4ExternalCableInstallation

SerialNo.

1

2TRX_ANT_485_-RS485-

3,4TRX_ANT_28V28V

5,6TRX_ANT_28VGND28VGND

7,8NC

Steps1.ConnectEndAtotheZXSDRR8860debugginginterface

(AISG)andscrewdownthebolt;

2.ConnectEndBtothecontrolinterfaceofelectricaladjustment

antennaandscrewdownthebolt.

ENDOFSTEPS.

Name

TRX_ANT_485_+RS485+

Meaning

Null

InstallingFrequencyPoint ExtensionCable

PrerequisiteThetwoZXSDRR8860cabinetstobecombinedmustbeinstalled

andxedsuccessfully .

ContextAfterthecombinationofcabinets,theZXSDRR8860cansupport

8carriersectorsatmost.

ThetwoZXSDRR8860cabinetsareconnectedthroughtheirconnectinginterfacessuchasRXinandRXoutbytwofrequencypoint

extensioncables.Figure64showsthestructureofthefrequency

pointcable.EndAandEndBareNconnectors(male).

The2M1/2″jumperisoftenusedforthefrequencypointextension

cable.Itmaybepreparedonsiteifnecessary.

FIGURE64FREQUENCYPOINTEXTENSIONCABLE

Steps1.ConnectEndAofthefrequencypointextensioncabletothe

frequencypointextensioninterfaceRXINofoneZXSDRR8860;

2.ConnectEndBtoRXoutoftheotherZXSDRR8860;

ConfidentialandProprietaryInformationofZTECORPORATION77

Page 86

ZXSDRR8860InstallationManual

3.ConnecttheremainingRXin/RXoutinterfacesofthetwocombinedcabinetswiththeotherfrequencypointextensioncable.

ENDOFSTEPS.

InstallingJumper

ContextOneendofRFjumperconnectswiththemainfeederandtheother

endconnectswiththeantennafeederinterfaceofZXSDRR8860

cabinet.BeforeinstallingtheRFjumper ,themainfeederisinstalled.

TheRFjumperadoptsthe1/2″jumperwitha2mlength.The

jumpercanalsobeself-madeaccordingtotheon-sitecondition.

TheinstallationpositionofRFjumperisasshowninFigure65.

FIGURE65RFJUMPERINSTALLATION

PerformthefollowingstepstoinstalltheRFjumper .

Steps1.ConnecttheDINconnector(male)ofRFjumperwiththeDIN

connector(female)ofmainfeeder .

2.ConnecttheDINconnector(male)ofRFjumperwiththeDIN

connector(female)ofZXSDRR8860cabinet.

3.SealtheconnectorswithwaterproofadhesivetapesandPVC

tapes.

ENDOFSTEPS.

78ConfidentialandProprietaryInformationofZTECORPORATION

Page 87

Chapter5

MainAntennaFeeder SystemInstallation

TableofContents:

MainAntennaFeederSystemStructure................................79

MainAntennaFeederSystemInstallationPreparation.............85

MainAntennaFeederSystemInstallationFlow......................86

AntennaInstallation...........................................................87

FeederInstallation.............................................................92

InstallingFeederHermetic-window....................................102

FeederIndoorIngoing......................................................104

PerformingAntennaFeederSystemTest.............................108

PerformingOutdoor-connectorWaterproofProcessing...........109

PerformingFeederHermetic-windowWaterproofProcess-

ing................................................................................111

CabinetJumperInstallationDescription..............................114

VSWRTest......................................................................115

ZXSDRR8860

congurationwith

commonantenna

MainAntennaFeeder SystemStructure

ThetypicalcongurationsforZXSDRR8860mainantennafeeder

systemdescribedbelowincludes:

�ZXSDRR8860congurationwithcommonantenna

�ZXSDRR8860congurationwithcommonantenna,AISGdual

poweramplier

�ZXSDRR8860congurationwithelectronicadjustmentan-

tenna(1)

�ZXSDRR8860congurationwithelectronicadjustmentan-

tenna(2)

�ZXSDRR8860congurationwithelectronicadjustmentan-

tenna,AISGdualpoweramplier

Inthisconguration,generallyZXSDRR8860installationposition

isnearantennaandtheyareallinstalledonthebuildingtop.

ZXSDRR8860isconnectedtotheantennaby1/2″feederdirectly ,

occasionally5/4″or7/8″feederisadopted,asshowninFigure66.

ConfidentialandProprietaryInformationofZTECORPORATION79

Page 88

ZXSDRR8860InstallationManual

FIGURE66ZXSDRR8860CONFIGUREDWITHCOMMONANTENNA

ZXSDRR8860

congurationwith

commonantenna,

.

Inthisconguration,generallyZXSDRR8860isinstalledonthe

tower .ZXSDRR8860isconnectedtotheantennaby5/4″or

7/8″feeder ,asshowninFigure67.

80ConfidentialandProprietaryInformationofZTECORPORATION

Page 89

Chapter5MainAntennaFeederSystemInstallation

AISGdualpower

amplier

FIGURE67ZXSDRR8860CONFIGURATIONWITHCOMMONANTENNA,

AISGDUALPOWERAMPLIFIER

ConfidentialandProprietaryInformationofZTECORPORATION81

Page 90

ZXSDRR8860InstallationManual

withelectronic

ZXSDRR8860

conguration

adjustment

antenna(1)

Inthisconguration,generallyZXSDRR8860installednearthe

antennaonthebuildingtop.ZXSDRR8860isconnectedtothe

antennaby1/2″feederdirectly ,occasionally5/4″or7/8″feederis

adopted,asshowninF

FIGURE68ZXSDRR8860CONFIGURATIONWITHELECTRONIC

ADJUSTMENTANTENNA(1)

igure68.

ZXSDRR8860

conguration

withelectronic

Inthisconguration,generallyZXSDRR8860isinstallednearthe

topofthetower .ZXSDRR8860isconnectedtotheantennaby

5/4″or7/8″feederisadopted,asshowninFigure69.

82ConfidentialandProprietaryInformationofZTECORPORATION

Page 91

Chapter5MainAntennaFeederSystemInstallation

adjustment

antenna(2)

FIGURE69ZXSDRR8860CONFIGURATIONWITHELECTRONIC

ADJUSTMENTANTENNA(2)

ConfidentialandProprietaryInformationofZTECORPORATION83

Page 92

ZXSDRR8860InstallationManual

ZXSDRR8860

conguration

withelectronic

antenna,AISG

Inthisconguration,generallyZXSDRR8860isinstallednearthe

topofthetower .ZXSDRR8860isconnectedtotheantennaby

adjustment

dualpower

amplier

5/4″or7/8″feederisadopted,asshowninFigure70.

FIGURE70ZXSDRR8860CONFIGURATIONWITHELECTRONIC

ADJUSTMENTANTENNA.AISGDUALPOWERAMPLIFIER

84ConfidentialandProprietaryInformationofZTECORPORATION

Page 93

Chapter5MainAntennaFeederSystemInstallation

MainAntennaFeeder SystemInstallation Preparation

ProperantennainstallationisveryimportanttoZXSDRR8860systemreliableoperation.Beforeinstallation,makesurethatinstallationstaffisqualiedandthefollowingrequirementsaresatised.

Personnel

Requirement

Normally,supervisorsareinchargeofdirectionandsupervision,

whereasinstallationpersonnelcarryouttheinstallation.

�InstallationSupervisor

Therequirementsfortheinstallationsupervisorareasfollows:

�Familiarwithallmaterials,toolsandoperationmethods.

�Theyareinchargeofassigningdifferentworktotheproper

employeewhoisgoodattheoperation,especiallywhile

workingontheirontower .

Note:

Safetyisthemostimportantconsiderationwhenassigning

work.

�InstallationPersonnel

Therequirementsfortheinstallationpersonnelareasfollows:

�Installationemployeesarerequiredtoinstallantennasys-

temskillfullyunderthedirectionofsupervisor .

�Employeesontowermustbequaliedandingoodphysical

state.

�Installationafterdrinkingisforbidden.

Environment

Requirement

Payattentiontofollowingitemsandcheckwhethertheysatisfy

requirementsinengineeringdesign.Normally,theyarecompleted

bythenetworkoperator(carrier).

�Lightningprotectionandgrounding

ZXSDRR8860isusuallylocatedoutdoors.Thegrounding

stakeandoutdoorlightning-protectinggroundingcablesare

installedbytheoperator ,andthesupervisorshouldconrm

lightning-protectinggroundingcablesareinstalledproperly.

�Poleandsupportingrack

Accomplishinstallationofantennasupportingrackandpole

accordingtoprojectdesignrequirement.Thestabilityofthe

supportingrackandpoleshouldbeinaccordancewiththedesignrequirement.

�Feederlayout

Fieldengineersneedtodeterminerouteofmainfeederwith

operatorengineersbeforeinstallation.

ConfidentialandProprietaryInformationofZTECORPORATION85

Page 94

ZXSDRR8860InstallationManual

�Electronicpowerenvironment

�ZXSDRR8860antennaandfeedersystemcannotbeinstalled

tooneartopublicelectricpowercables.

Safety

Precautions

ToolsRequire-

ment

Ensurethefollowingprecautionsbeforeantennainstallation:

�Takenecessarymeasuresforpersonalandequipmentsafety.

�Personnelundertowermustwearsafetyhelmets.

�Personnelontowermustwearsafetybelt.

�Neverclimbtowerwithlooseclothesandwet/slipperyshoes.

�Duringactiveantennaadjustment,wearradiation-shielding

clothingandturnoffpowerampliertoavoidradiationeffects.

�Ifpossible,installinsunnyandwindlessdays.Installationis

forbiddeninrain,strongwind,thunderandlightning.