MATERIAL DATA SHEET

Date of issue: 01.08.2014 | Update: 13.12.2016 | Version: 1.06

Material Data Sheet: Z-ULTRAT

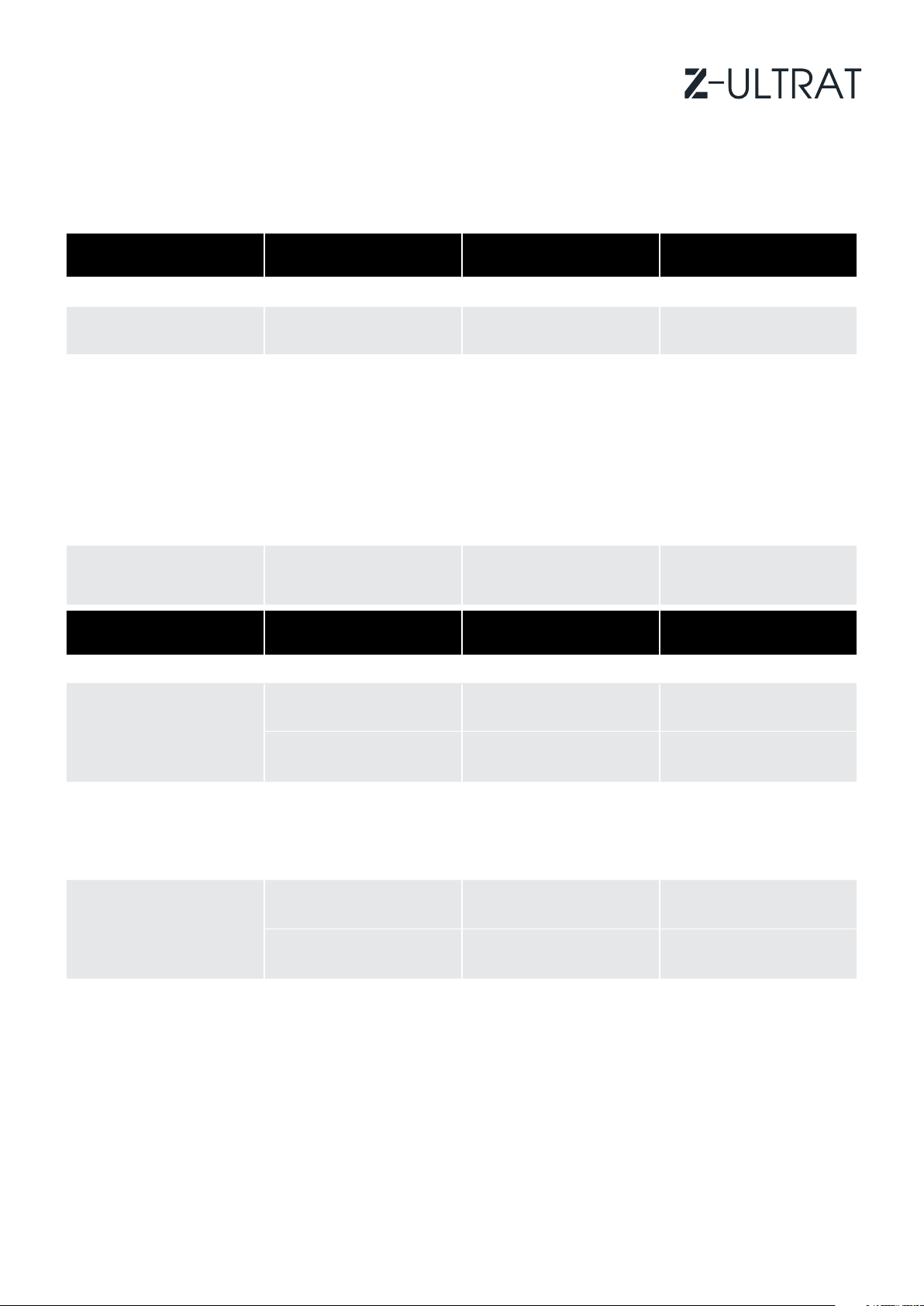

Physical Properties Metric English Comments

Density 1.04 g/cm

Mold Shrinkage,

Flow

0.5 - 0.8%

Thickness 3.20 mm Thickness 0.126 in

11.7 g/10 min

Load 3.80 kg,

Temperature 230 °C

12 g/10 min

Melt Flow

Temperature 220 °C

Load 5 kg,

42 g/10 min

Load 10 kg,

Temperature 220 °C

3

8.679 lbs/gal ISO 1183

0.5 - 0.8%

0.0257 lb/10 min

Load 8.38 lb,

Temperature 446 °F

0.0265 lb/10 min

Load 11 lb,

Temperature 428 °F

0.0926 lb/10 min

Load 22 lb,

Temperature 428 °F

ASTM D1238

1720

Melt Viscosity

Temperature 240 °C

1000 sec

-1

,

Temperature 464 °T

Mechanical Properties Metric English Comments

Hardness, Rockwell R 113 113

46 MPa

5 mm/min

1720

1000 sec-1,

6600 psi

0.2 in/min

ASTM D3825

ASTM D638

Tensile Strength, Yield

46 MPa

50 mm/min

6600 psi

1.96 in/min

ISO 1183

ISO 527

Tensile Strength, Break

Elongation at Yield

Elongation at Break

35 MPa 5000 psi

5 mm/min

0.2 in/min

35 MPa 5000 psi

50 mm/min

2 %

2.3 %

18 %

40 % 40 %

1.96 in/min

2 %

2.3 %

18 %

5 mm/min;

5 mm/min;

50 mm/min;

ASTM D638

ISO 527

ASTM D638

50 mm/min;

ISO 527

ASTM D638

ISO 527

www.zortrax.com | 1

MATERIAL DATA SHEET

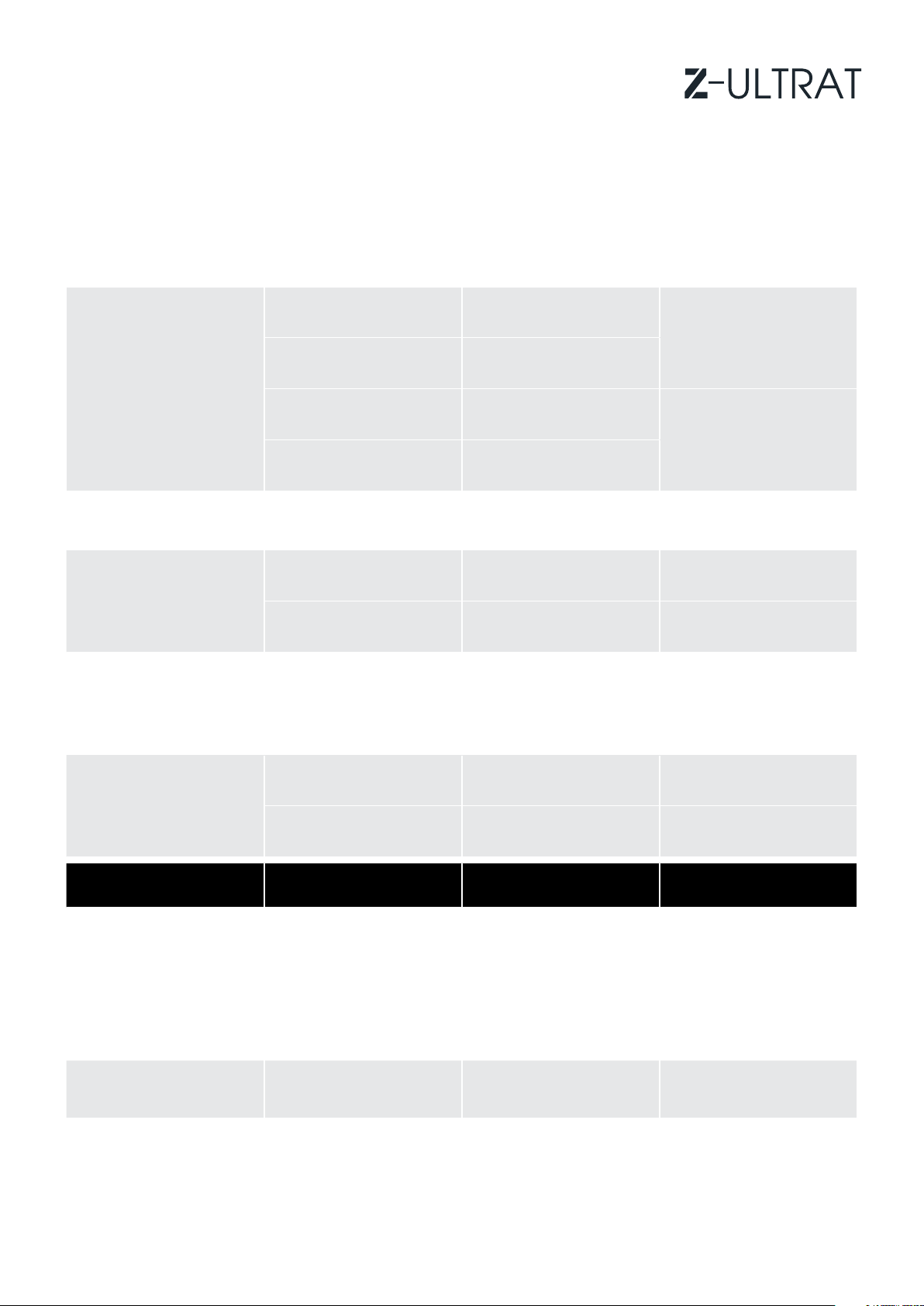

Tensile Modulus

Izod Impact, Notched

Charpy Impact,

V-notch

Flexural Strength, Yield

2.45 GPa

1 mm/min 0.04 in/min

2.48 GPa

5 mm/min

80 J/m

Temperature -30.0 °C

240 J/m

Temperature 23.0 °C

7 kJ/m

80x10x4 mm, Temp -30.0 °C

16 kJ/m

80x10x4 mm, Temp 23.0 °C

18 kJ/m

80x10x4 mm, Span 62 mm

1.3 mm/min, 50 mm span

2 mm/min

355 ksi

360 ksi

0.19 in/min

Temperature -22.0 °F

1.4 ft-lb/in

ISO 527

ASTM D638

ASTM D256

2

2

3.15x0.394x0.157 in,

Temperature -22.0 °F

3.15x0.394x0.157 in,

2

3.15x0.394x0.157 in,

79 MPa

70 MPa

4.4 ft-lb/in

Temperature 73.0 °F

3.33 ft-lb/in

7.61 ft-lb/in

Temperature 73.0 °F

8.57 ft-lb/in

Span 2.44 in

11458 psi

0.05 in/min, 2i n span

10153 psi

0.079 in/min

2

2

2

ISO 180/1A

ISO 179/1eA

ASTM D790

ISO 178

2.62 GPa

1.3 mm/min, 50 mm span

0.05 in/min, 2 in span

380 ksi

Flexural Modulus

363 ksi

0.079 in/min

44 in-lb

185 in-lb

ASTM D3763

ASTM D3763

Instrumented Impact

Total Energy

2.5 GPa

2 mm/min

Temperature -30.0 °C

Temperature 23.0 °C

5 J

Temperature -22.0 °F

21 J

Temperature 73.0 °F

Thermal Properties Metric English Comments

Vicat Softening Point

98.0 °C

98.0 °C

100.0 °C

208.4 °F

208.4 °F

212.0 °F

ASTM D 1525

HBHB

Flame Class Rating

Thickness 1.52 mm Thickness 0.0598 in

ASTM D790

ISO 178

Rate B/50;

Rate B/50;

ISO 306

Rate B/120;

ISO 306

UL94

www.zortrax.com | 2

MATERIAL DATA SHEET

Coefficient of Thermal

Expansion

Deflection Temperature

at 0.45 MPa (66 psi)

Deflection Temperature

at 1.82 MPa (264 psi)

Deflection Temperature

at 0.45 MPa (66 psi)

Deflection Temperature

at 1.8 MPa (264 psi)

Relative Temperature

Index, Electrical

8.82E-05 1/°C

-40.0 °C to 40.0 °C

8.46E-05 1/°C

-40.0 °C to 40.0 °C

8.82E-05 1/°C

-40.0 °C to 40.0 °C

8.46E-05 1/°C

-40.0 °C to 40.0 °C

95 °C

Thickness 3.20 mm

82 °C

Thickness 3.20 mm

89 °C

120x10x4 mm

sp=100 mm

76 °C

120x10x4 mm

sp=100 mm

60 °C 140 °F

4.9E-05 1/°F

-40.0 °F to 104 °F

4.7E-05 1/°F

-40.0 °F to 104 °F

4.9E-05 1/°F

-40.0 °F to 104 °F

4.7E-05 1/°F

-40.0 °F to 104 °F

4.72x0.394x0.157 in

203.0 °F

Thickness 0.126 in

179.6 °F

Thickness 0.126 in

192.2 °F

sp=3,937 in

168.8 °F

4.72x0.394x0.157 in

sp=3,937 in

ASTM E 831;

flow

ASTM E 831;

xflow

ISO 11359-2;

flow

ISO 11359-2;

xflow

Unannealed;

ASTM D648

Unannealed;

ASTM D648

ISO 75/Be

ISO 75/Ae

UL 746B

Relative Temperature

Index, Mechanical

with Impact

Relative Temperature

Index, Mechanical

without Impact

60 °C

60 °C

140 °F

140 °F

UL 746B

UL 746B

www.zortrax.com | 3

MATERIAL DATA SHEET

The data presented in this document are intended for information and comparison purposes only. They should

not be used for project specifications or its quality evaluation. The material’s actual properties depend on the

printing process conditions, the design structure and its purpose, test conditions, etc.

Samples of Z-ULTRAT used to carry out the tests were made through plastic moulding.

Product specifications are subject to change without notice.

Each user is responsible for complying with product safety standards, its intended use as well as the law and waste

disposal (and recycling) rules for electrical and electronic equipment. Zortrax does not make any express or implied

warranties, including but not limited to implied warranties of merchantablitiy or fitness for a particular purpose.

Zortrax S.A.

Lubelska 34

10-409 Olsztyn, Poland

NIP: 7393864289

REGON: 281551179

©2016 Zortrax S.A. All rights reserved. Zortrax, Zortrax M200, Zortrax M300, Zortrax Inventure, Z-ABS, Z-ULTRAT, Z-HIPS,

Z-GLASS, Z-PCABS, Z-PETG, Z-ULTRAT Plus, Z-Suite are trademarks of Zortrax.

Contact

Office: office@zortrax.com

Sales Department: sales@zortrax.com

Support Center: support@zortrax.com

Entered in the Register of Entrepreneurs of the National

Court Register kept by the District Court in Olsztyn, VIII

Commercial Division of the National Court Register,

under KRS number 0000564079, with a share capital

of PLN 7 462 500 paid in full.

www.zortrax.com | 4

Loading...

Loading...