MATERIAL DATA SHEET

Date of issue: 16.11.2015 | Update: 20.09.2016 | Version: 1.02

Material Data Sheet: Z-PCABS

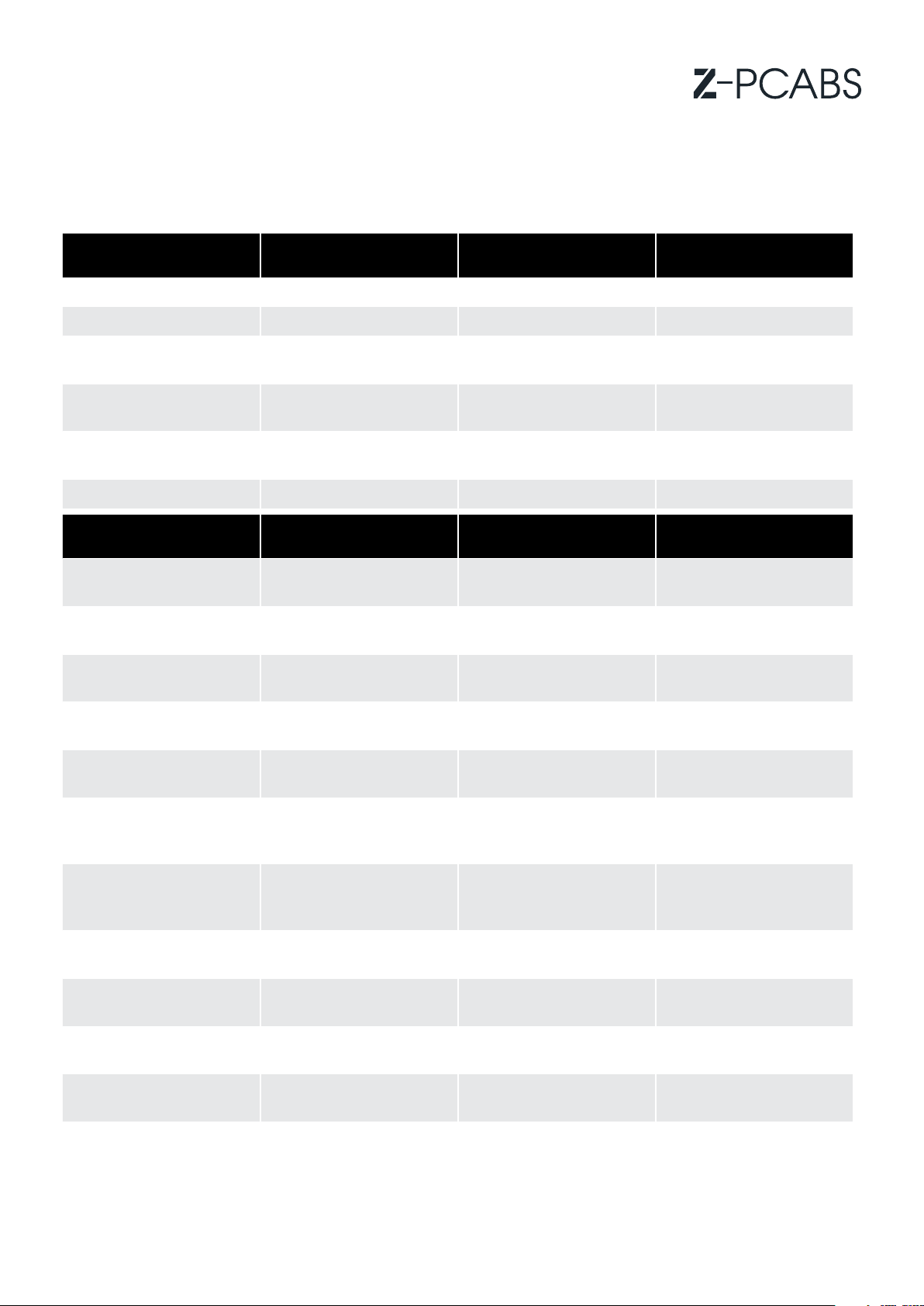

Physical Properties Metric English Comments

Specific Gravity 1.14 g/cm

Density 1.14 g/cm

Moisture Absorption 0.1% 0.1%

Water Absorption 0.1%. 0.1%

Mold Shrinkage, flow 0.5 – 0.7 % 0.5 – 0.7 %

Melt Flow Rate 8.5 g/10 min

3

3

9.514 lbs/gal ASTM D792

9.514 lbs/gal ISO 1183

23°C / sat

23°C / 50% RH

3,2mm (0.125 inch) [5]

SABIC Method

0.0187 lbs/10 min ASTM D1238

Mechanical Properties Metric English Comments

Tensile Strength at Yield

Tensile Strength at Break

Thickness 3.20 mm

Thickness 3.20 mm

58 MPa

57 MPa

Tensile modulus 2.21 GPa 320 ksi psi

Elongation at Yield 4.9 % 4.9 %

8200 psi

Thickness 0.126 in

8100 psi

Thickness 0.126 in

50mm/min (2 inch/min);

ASTM D638

50mm/min (2 inch/min);

ASTM D638

ASTM D790

50mm/min (2 inch/min);

ASTM D638

ISO 62

ISO 62

1mm/min

Elongation at Break

Flexural Strength

Flexural Modulus

Tensile Strength at Yield

Tensile Strength at Break

125 %

Thickness 3.20 mm

86 MPa

Thickness 3.20 mm

2.39 GPa

Thickness 3.20 mm

50 MPa

Thickness 3.20 mm

45 MPa

Thickness 3.20 mm

Thickness 0.126 in

Thickness 0.126 in

Thickness 0.126 in

Thickness 0.126 in

Thickness 0.126 in

152 %

12470 psi

347 ksi psi

7250 psi

6525 psi

Tensile modulus 2.25 GPa 326 ksi

Elongation at Yield 4 % 4 %

Elongation at Break

>50 %

Thickness 3.20 mm

Thickness 0.126 in

>50 %

50mm/min (2 inch/min);

ASTM D638

1.27mm/min

(0.05 inch/min);

ASTM D790

1.27mm/min

(0.05 inch/min);

ASTM D790

50mm/min (2 inch/min);

ISO 527

50mm/min (2 inch/min);

ISO 527

1mm/min

ISO 527

50mm/min (2 inch/min);

ISO 527

50mm/min (2 inch/min);

ISO 527

www.zortrax.com | 1

MATERIAL DATA SHEET

1.27mm/min

(0.05 inch/min);

ISO 178

1.27mm/min

(0.05 inch/min);

ISO 178

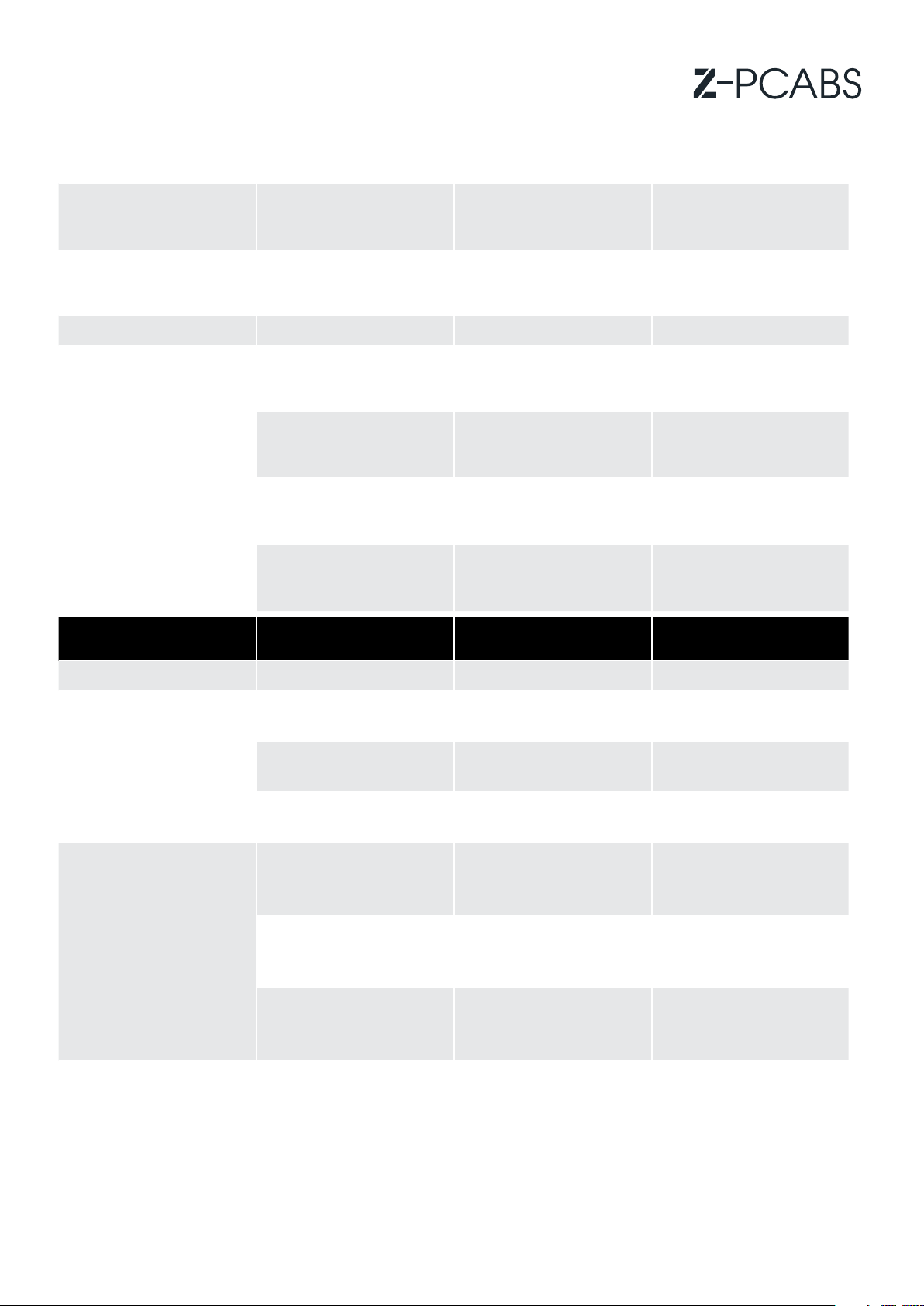

Flexural Strength

Flexural Modulus

85 MPa

Thickness 3.20 mm

2.3 GPa

Thickness 3.20 mm

12325 psi

Thickness 0.126 in

334 ksi

Thickness 0.126 in

Rockwell Hardness 108 108 ASTM D785

9.9 ft-lb/in

Thickness 0.126 in,

Temperature -22 °F

12.1 ft-lb/in

Thickness 0.126 in,

Temperature 73.4 °F

6.4 ft-lb/in

80x10x3 mm,

9.3 ft-lb/in

80x10x3 mm,

Temperature 23.0 °C

ASTM D256

ASTM D256

2

ISO 180/1A

2

ISO 180/1A

Izod Impact, Notched

54 J/cm

Thickness 3.20 mm,

Temperature -30.0 °C

66 J/cm

Thickness 3.20 mm,

Temperature 23.0 °C

35 kJ/m

80x10x3 mm,

Temperature -30.0 °C

50 kJ/m

80x10x3 mm,

Temperature 23.0 °C

2

Temperature -30.0 °C

2

Thermal Properties Metric English Comments

Melting Point 225 °C 437 °F ASTM D3418

B/50

B/50

ISO 306

B/120

ISO 306

Vicat Softening

Temperature

118 °C 244 °F

118 °C 244 °F

122 °C 252 °F

ASTM D1525

1.82 MPa, 3.2 mm

107 °C 225 °F

unannealed

ASTM D648

Heat Distortion

Temperature

124 °C 255 °F

0.45 MPa, 3.2 mm

unannealed

ASTM D648

1.8 MPa, 80x10x4

120 °C 248 °F

sp = 64 mm

ISO 75/Af

-40°C to 40°C, flow ISO

Thermal Expansion

Coefficient

7.2E-05 1/°C 4.E-05 1/°F

-40°C to 100°F, flow

11359-2

ASTM E831

www.zortrax.com | 2

MATERIAL DATA SHEET

The information presented are typical values intended for reference and comparison purposes only. They should

not be used for design specifications or quality control purposes. Final properties of the material can be impacted

(+/-) by part design, end-use conditions, test conditions, etc. Actual values will vary with build conditions. Product

specifications are subject to change without notice.

The performance characteristics of these materials may vary according to application, operating conditions, or

enduse. Each user is responsible for determining that the Zortrax material is safe, lawful and technically suitable

for the inttended application, as well as for identifying the proper disposal (or recycling) method consistent with

applicable environmental laws and regulations. Zortrax makes no warranties of any kind, express or implied including

but not limited to the warranties of merchantability, fitness for a particular use.

Contact Zortrax S.A.

Office: office@zortrax.com

Sales Department: sales@zortrax.com

Support Center: support@zortrax.com

©2015, Zortrax S.A. All rights reserved. Zortrax, Zortrax M200, Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-PCABS, Z-PETG, Z-HIPS, Z-GLASS, Z-Suite,

.zcode are trademarks of Zortrax.

Lubelska 34

10-409 Olsztyn, Poland

NIP: 7393864289

REGON: 281551179

Entered in the Register of Entrepreneurs of the National

Court Register kept by the District Court in Olsztyn, VIII

Commercial Division of the National Court Register,

under KRS number 0000564079, with a share capital

of PLN 7 462 500 paid in full.

www.zortrax.com | 3

Loading...

Loading...