TECHNICAL DATA SHEET

Date of issue: 01.01.2014 | Update: 03.01.2018 | Version: 2.00

Set the Standards

Z-ABS is a versatile and economic material which perfec-

tly matches the needs of users who begin their work

with 3D printing as well as professionals who want to

make savings on in-house prototyping. With a wide

selection of post-processing methods, either mechanical

or chemical, Z-ABS becomes well-suited not only for

producing affordable prototypes, but also for creative

applications, such as conceptual models, gadgets or

figurines. Z-ABS is something you seek for if you need to

3D print low-cost, attractive-looking objects or prototypes with functional requirements.

Mechanical Properties Metric English Test Method

Tensile Strength 30.46 MPa 4420 psi ISO 527:1998

Breaking Stress 25.89 MPa 3760 psi ISO 527:1998

Elongation at max Tensile Stress 4.52% 4.52% ISO 527:1998

Elongation at Break 11.08% 11.08% ISO 527:1998

Bending Stress 46.30 MPa 6720 psi ISO 178:2011

Flexural Modulus 1.08 GPa 157 ksi ISO 178:2011

Izod Impact, Notched 8.93 kJ/m

2

4.25 ft-lb/in

2

ISO 180:2004

Thermal Properties Metric English Test Method

Glass Transition Temperature 107.89° C 226° F ISO 11357-3:2014

Other Properties Metric English Test Method

11.75 g/10 min

Melt Flow Rate ISO 1133:2006

Specific Density 1.195 g/cm

Load 10 kg

Temperature 220° C

3

0.0259 lb/10 min

Load 22 lb

Temperature 428° F

9.97 lb/gal ISO 1183-3:2003

Shore Hardness (D) 69.2 69.2 ISO 868:1998

www.zortrax.com

TECHNICAL DATA SHEET

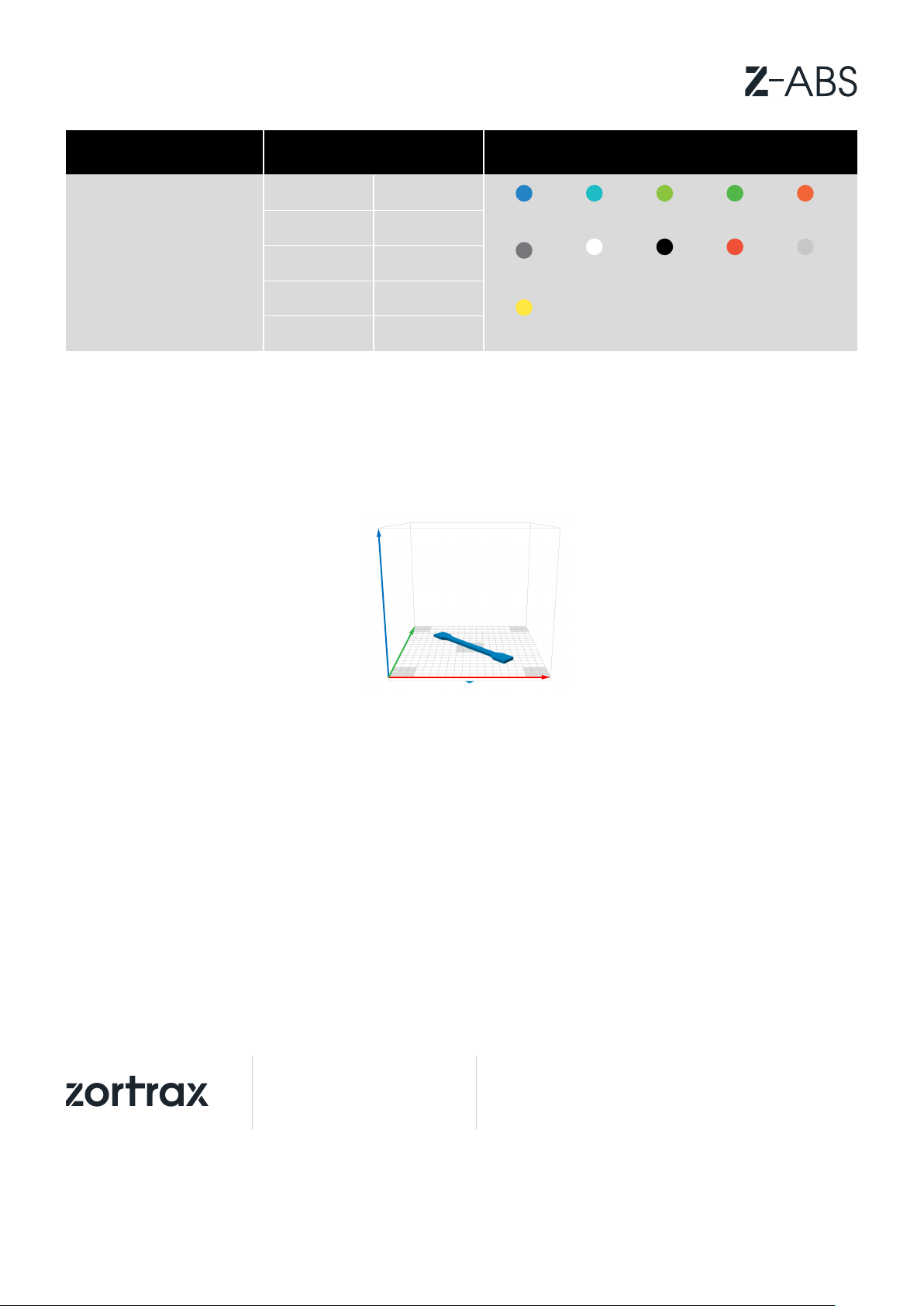

Compatible with Layer Thickness Range Available Colors

ZORTRAX M200 0.09 mm

0.14 mm

0.19 mm

0.29 mm

0.39 mm 0.0154 in

0.0035 in

0.0055 in

0.0075 in

0.0114 in

cool

grey

yellow

blue

pure

white

android

green

pure

black

greenblue sky

red

orange

warm

grey

The data presented in this document are intended for information and comparison purposes only. They should

not be used for project specifications or its quality evaluation. The material’s actual properties depend on the

printing process conditions, the design structure and its purpose, test conditions, etc.

Samples of Z-ABS used to carry out the tests were built on Zortrax M200.

The general print parameters utilized are noted below:

Z-SUITE: v2.2.0.0

Layer thickness: 0.19 mm;

Z

Quality: High;

Seam: Normal;

Infill: Solid,

Fan Speed: Auto;

Surface Layers:

Y

- Top: 7 (default);

- Bottom: 4 (default);

X

Product specifications are subject to change without notice.

Each user is responsible for complying with product safety standards, its intended use as well as the law and waste

disposal (and recycling) rules for electrical and electronic equipment. Zortrax does not make any express or implied

warranties, including but not limited to implied warranties of merchantablitiy or fitness for a particular purpose.

Zortrax S.A.

Lubelska 34

10-409 Olsztyn, Poland

NIP: 7393864289

REGON: 281551179

©2017 Zortrax S.A. All rights reserved. ‘Zortrax’, ‘Zortrax M200’, ‘Zortrax M300’, ‘Zortrax Inventure’, ‘Zortrax DSS’, ‘Z-ABS’, ‘Z-ASA Pro’,

‘Z-ESD’, ‘Z-GLASS’, ‘Z-HIPS’, ‘Z-PCABS’, ‘Z-PETG’, ‘Z-PLA’, ‘Z-PLA Pro’, ‘Z-SEMIFLEX’, ‘Z-SUPPORT’, ‘Z-SUPPORT Plus’, ‘Z-ULTRAT’,

‘Z-ULTRAT Plus’, ‘Z-SUITE’ are trademarks of Zortrax.

Contact

Office: office@zortrax.com

Sales Department: sales@zortrax.com

Support: support@zortrax.com

www.zortrax.com

Loading...

Loading...