Zortrax M Series User manual

3D Printers User Guide

M Series

2

Table of Contents

Introduction 3

Intended Use of Zortrax Printers 3

General Safety Information 4

Warning and Safety Labels on Zortrax Devices 6

Learn More About Zortrax M Series 8

How does the Zortrax 3D Printer Work? 8

What’s in the Box 9

Main Components 11

Zortrax 3D Printing Technology Glossary 15

First Use Preparations 19

Z-Firmware Installation 27

Navigating through the Zortrax Printer Menu 28

Material Loading 30

Platform Calibration 31

Z-SUITE Installation 33

Starting and Removing a Print 34

Available Materials 39

Basic Maintenance and Service Work 39

Support and Troubleshooting 45

Specifications 49

Recycling 50

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

3

Introduction

Read this User Guide carefully and thoroughly before operating Zortrax products for the first time. The

User Guide includes basic information about the 3D printer, safety and protection guidelines as well

as advice on preparing the machine for the first printing and basic maintenance work. Ignorance and

non-compliance with these instructions may result in property damage, injuries, device failures or lower

quality of 3D prints. It is also necessary to ensure that every 3D printer user knows, fully understands and

follows the instructions provided in this User Guide.

The Manufacturer makes every effort to ensure that Zortrax products are safe in transportation, installation, usage, storage and disposal.

However, due to the lack of direct and ad hoc control as well as other conditions influencing the device

and those that are beyond the Manufacturer’s knowledge, the Manufacturer is not responsible for damages, injuries, failures and costs resulting from improper transportation, installation, usage, storage and

disposal.

Furthermore, the users should take into consideration the risk of possible faults of the device resulting

from material and production defects.

Intended Use of Zortrax Printers

Zortrax devices 3D print in Layer Plastic Deposition (LPD) technology which allows to apply previously

melted material one layer after another on a given surface in order to form a predesigned shape. The

extruder is equipped with three heating points which makes it possible for the liquid material to flow

through the nozzle onto the heated platform without causing blockages in it. Zortrax 3D printers together with Z-SUITE and dedicated materials guarantee achieving high quality prints. However, the users are

responsible for qualifying and determining the intended use of the 3D printed models. The Manufacturer takes no responsibility for any use of the printed objects, especially, when these objects constitute

a part of safety equipment or strictly regulated medical, military or space science equipment.

Due to the size and specificity, Zortrax devices are not intended for use by children under the age of 14

and by people with reduced manual, motor and psychomotor skills. The Manufacturer recommends providing assistance and guidance to people with disabilities and older adults who wish to operate Zortrax

printers.

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

4

General Safety Information

This User Guide contains important safety directions that should be followed during installation and operation of Zortrax 3D printers. It also mentions situations which require special attention and includes

warnings against negligence and misuse that could cause damages or injuries.

Always read safety data sheets available at: https://zortrax.com/materials/zortrax-m-series/. They are

a source of basic information and safety procedures for the equipment you bought. It is essential to up-

date the firmware so as to avoid any kind of failures. Visit our website: https://zortrax.com/ regularly to

see the latest news and updates.

Zortrax 3D printers operate at high temperatures and have easily accessible movable components,

therefore, you must be particularly careful when handling or operating the devices. While operating

the printer, it is extremely important to avoid situations that may lead to burns or interference in proper

functioning.

Do not leave the machine unattended during the print job - check it periodically for proper functioning in

order to avoid potential accidents or breakdowns. Turn off the printer once the print job is finished.

Monitor your device for wear and tear regularly. Contact our Support Center at: http://support.zortrax.

com/ for assistance while replacing worn or broken parts.

Keep the printer away from heat sources, fire, flammable materials, humidity as well as water and other

liquids. Place the machine away from any equipment emitting radiation. To prevent any inadvertent use,

keep the device out of reach of children and animals. It is forbidden to shake or drop the printer as it may

cause breakdowns. The equipment is not intended for use in a potentially explosive environment.

Health and Safety at Work

All service and maintenance activities as well as device operation require wearing safety gloves included

in the Starter Kit. Wearing safety gloves is also advised while removing the finished print from the platform.

The vapors released during the printing process are not hazardous, however, it is important to ensure

proper ventilation in the print room.

Food and beverages should be kept away from both the 3D printers and 3D printed objects.

While operating Zortrax devices, all measures regarding health and safety provided in this User Guide as

well as in separate regulations should be taken into account.

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

5

Electrical Safety

Zortrax M Series 3D printers have been tested for compliance with Low Voltage Directive. In order to ensure the highest safety standards, including protection against short circuit, overload, overvoltage and

printer overheating, do not attempt to modify the printer and do not use electronic replacement parts

other than those recommended by the Manufacturer.

Replace electronic units according to the instructions and be particularly careful while using the tools

supplied with the printer.

Before plugging the power cable into the outlet, make sure that the power supply voltage in the outlet

matches the required value provided on the nameplate at the back of the printer. Avoid overloading the

outlet with too many devices.

The printer must be well-grounded. Always make sure that the ground complies with local and national

regulations.

Use only the original power cable supplied with the printer. Do not damage, cut or repair the cable.

A damaged cable should be immediately replaced with a new one.

All maintenance and repair work should be carried out while the device is off and unplugged. Do not

expose the device to moisture and liquids. Modifications such as soldering of electronic subunits are

forbidden.

Mechanical Safety

Zortrax 3D printers have movable components, such as the drive belts, Z-axis screw, extruder or platform. Therefore, it is forbidden to reach into the printer or put anything inside the printer when it is running, about to start running or at rest. This may lead to serious injuries or damages.

Tools and accessories from the Starter Kit box should be used with special care for intended purposes

only. Improper use may cause serious injuries.

While following post-processing procedures, wear safety gloves and glasses in order to avoid injuries

that may be caused by sharp edges and fragile elements.

Removing the prints from the platform should be dealt with very carefully so as to avoid injuries. Moreover, special care should be taken so as not to damage the small connector placed at the edge of the

platform with the blade of the spatula.

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

6

Risk of Burns

There is a high risk of burns while operating Zortrax printers as the extruder’s temperature may reach

up to 380⁰C [716⁰F]. Do not touch the extruder with bare hands. Be extremely careful during maintenance and repair work of heated units. If it is necessary to touch a heated component, use the pliers

which are specially adapted for this purpose. Cooling of components should not take less than 30 minutes.

The platform’s temperature can reach up to 110⁰C [230⁰C], therefore, special care should be taken

while operating the printer or while removing the finished print.

Do not ignore the warning labels placed on the devices.

Moreover, constructional modifications of the printer’s operating temperature are not permitted as it

may cause serious injuries or bring damage to the device.

Warning and Safety Labels on Zortrax Devices

Hot surface. Allow to cool before touching

Due to design characteristics, the screws securing the Z-axis screw nut cannot be fully tightened

Do not attempt to modify or remanufacture the product

Removing the print from the platform should be handled with extreme care

Wear safety gloves

This warning symbol indicates that special care should be taken when repairing the device. Also, it points out an important step to carry out.

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

7

The printer needs to be placed on a flat and stable surface to ensure proper

quality of the prints.

Hot surface. Do not touch.

Never reach into moving elements.

Safe Storage and Transport Guidance

Zortrax devices must be stored between 0 and 35 ⁰C. The storage space should be free of moisture and

other extreme conditions.

Transport Instructions

When stacking several devices on a pallet, follow the instructions provided on the packaging. One device

may weigh more than 20kg [44lbs]. It is therefore advisable to provide safe pallet storage but not higher

than 1,7m [5’7”]. It should be noted that the packages must not project beyond the outline of the pallet.

Packages stacked on the pallet should be then bound together and wrapped in foil. The pallet prepared

as above can be then forwarded to the shipping company.

Pallet stacking and destacking should be carried out by two people. The package with the device should

be lifted or moved using special handles. In case of M300, the device should not be carried by one person as it may cause injury or other damage to health.

Electromagnetic Compatibility (EMC)

Each Zortrax printer complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with this instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

8

Learn More About Zortrax M Series

Zortrax M Series includes two 3D printer models – M200 and M300, which together with Z-SUITE and

dedicated materials constitute the whole 3D printing ecosystem. Thanks to these devices, it is possible

to turn digital projects into three-dimensional objects. Zortrax 3D printers can be used in many industries

while designing and prototyping for instance automotive parts, mechanical elements, everyday objects

or decorative elements.

How does the Zortrax 3D Printer Work?

Everything begins with preparing a model. The work on the model can be started in any program which

creates 3D models and generates .stl, .obj, .3mf or .dxf files. These are the standard file formats supported

by most 3D modeling software – the model is saved as a set of three-dimensional triangles (triangle mesh).

The next step is to open the .stl file (or other) in Z-SUITE – the application created specifically for Zortrax

devices. Z-SUITE prepares the model by slicing it into individual layers and saving it as a .zcode. Each layer

represents the extruder’s motion (vertical and horizontal) while building the whole object. Z-SUITE also allows to change and adjust the necessary print settings, such as the size of the model, layer thickness, a type

of infill or what the support structures will look like. The file is then ready to be printed.

Once your model is prepared, save the .zcode onto the hard drive and then onto an SD card. In order to

transfer the model, insert the SD card into the card reader in the printer.

Next, prepare the material which you are going to use to print your model. The full material offer is available

at: https://zortrax.com/materials/zortrax-m-series/.

To start the print, turn on the printer and place the spool with the material on the spool holder at the back

of the printer and load the material into the extruder. Turn the knob to select the model to be printed, push

it to begin the printing process.

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

9

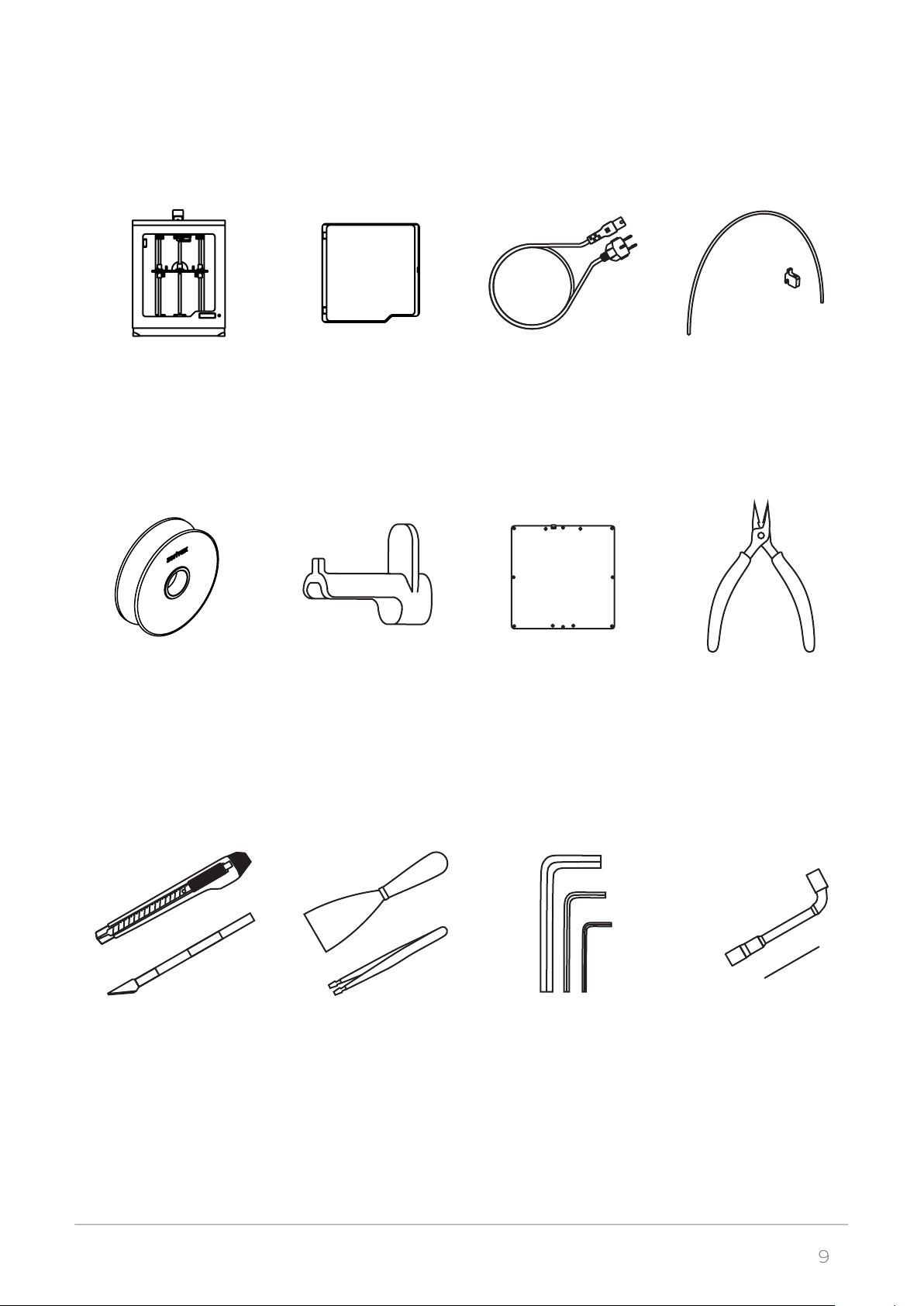

What’s in the box

3D Printer

Zortrax M Series

Material

Spool

Side

Covers*

Spool

Holder

Power

Cable

Perforated

Plate

Material

Guide

Pliers

Cutting Knife

& Scalpel

Spatula

& Tweezers

Allen

Keys

Nozzle Key

&

Nozzle Needle

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

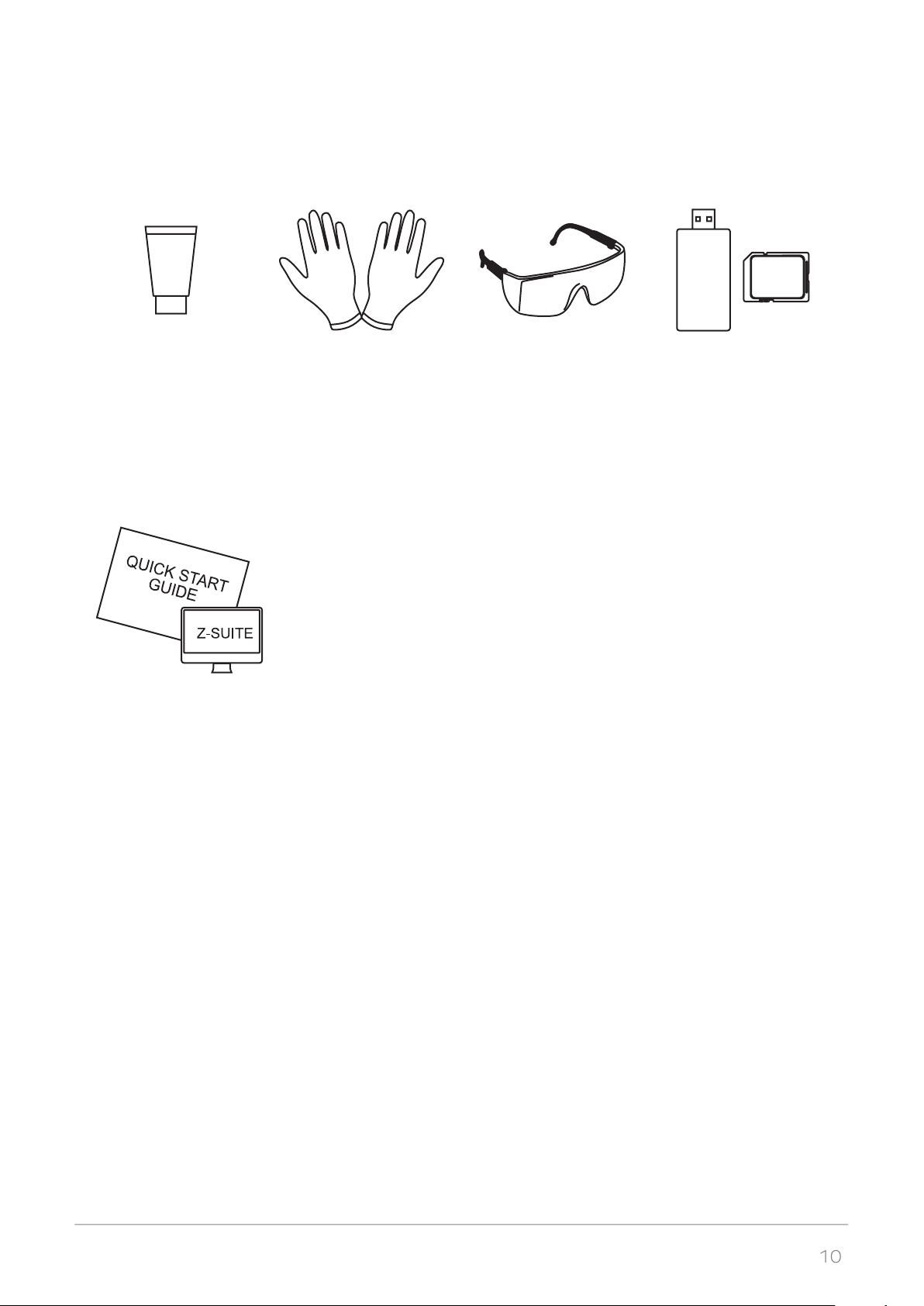

10

Service

Grease

Z-SUITE &

Quick Start Guide

* delivered only with Zortrax M300

Safety

Gloves

Safety

Glasses

SD Card &

SD Card Reader

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

11

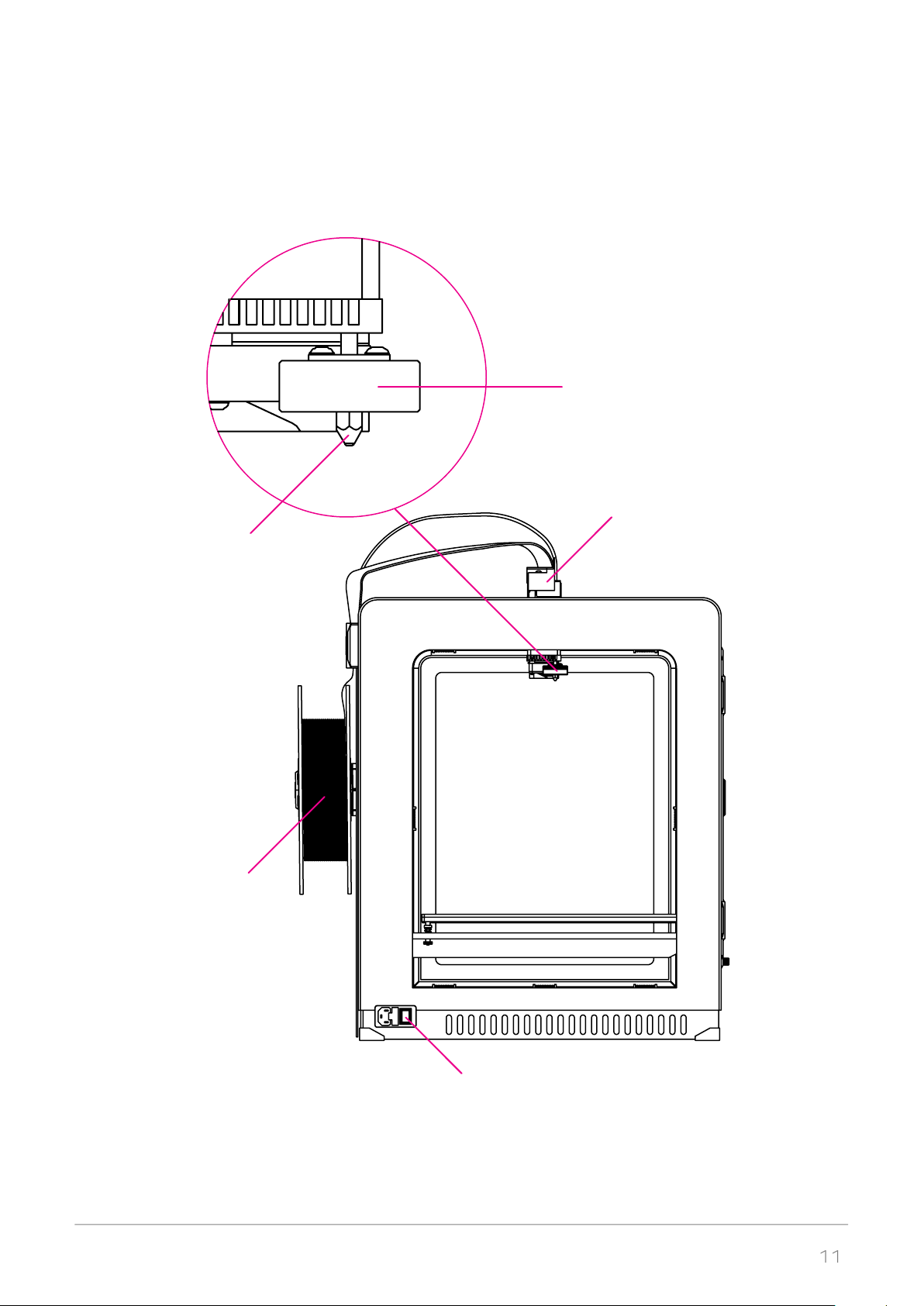

Main Components

Nozzle

Hotend

Extruder

Material

spool

Power Switch

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

12

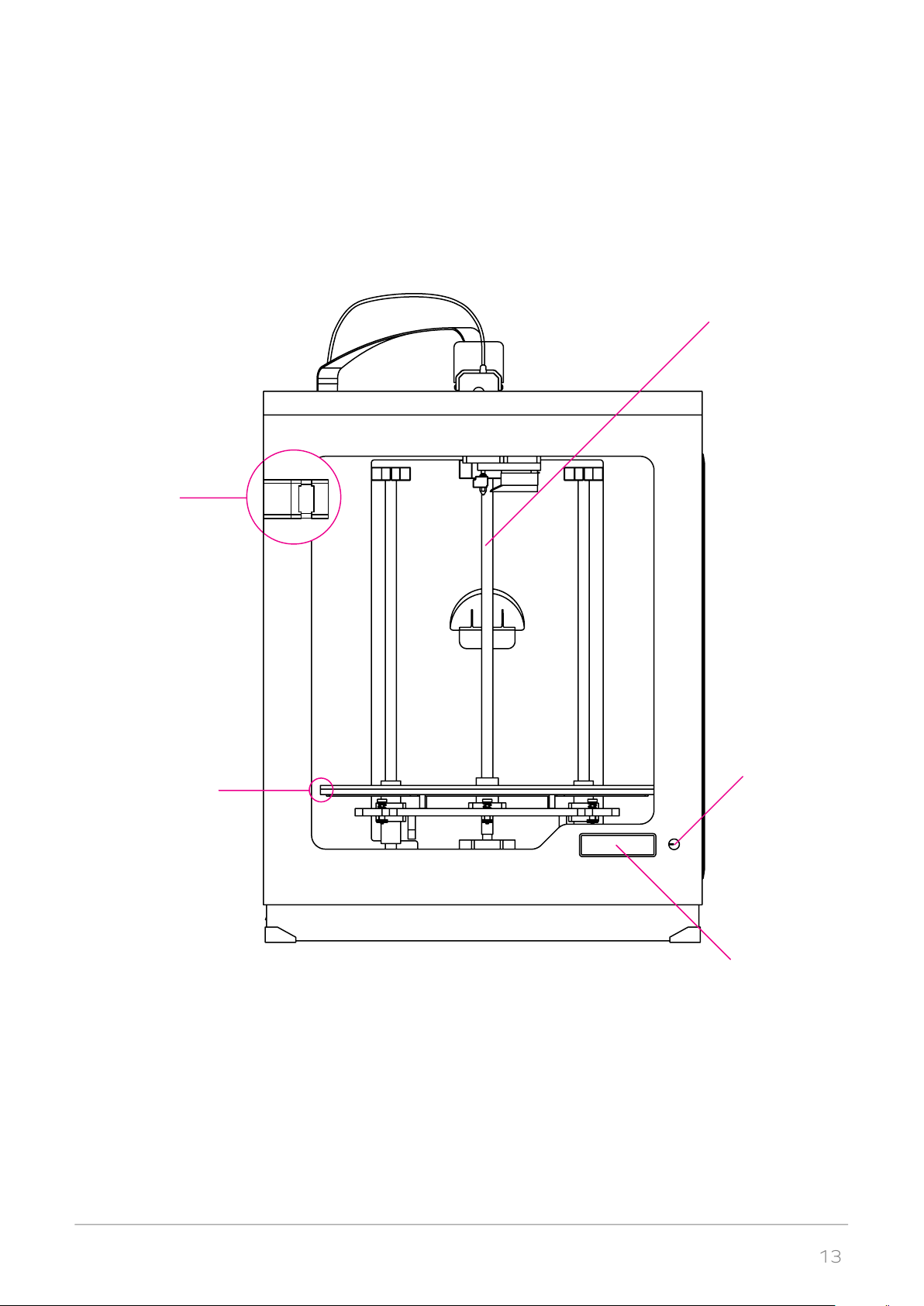

Side Covers

Extruder Cable

Material Guide

Spool Holder

Motherboard Power Supply Unit

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

13

Stepper Motor

Z Axis Screw

Build Platform

Dial

Display

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

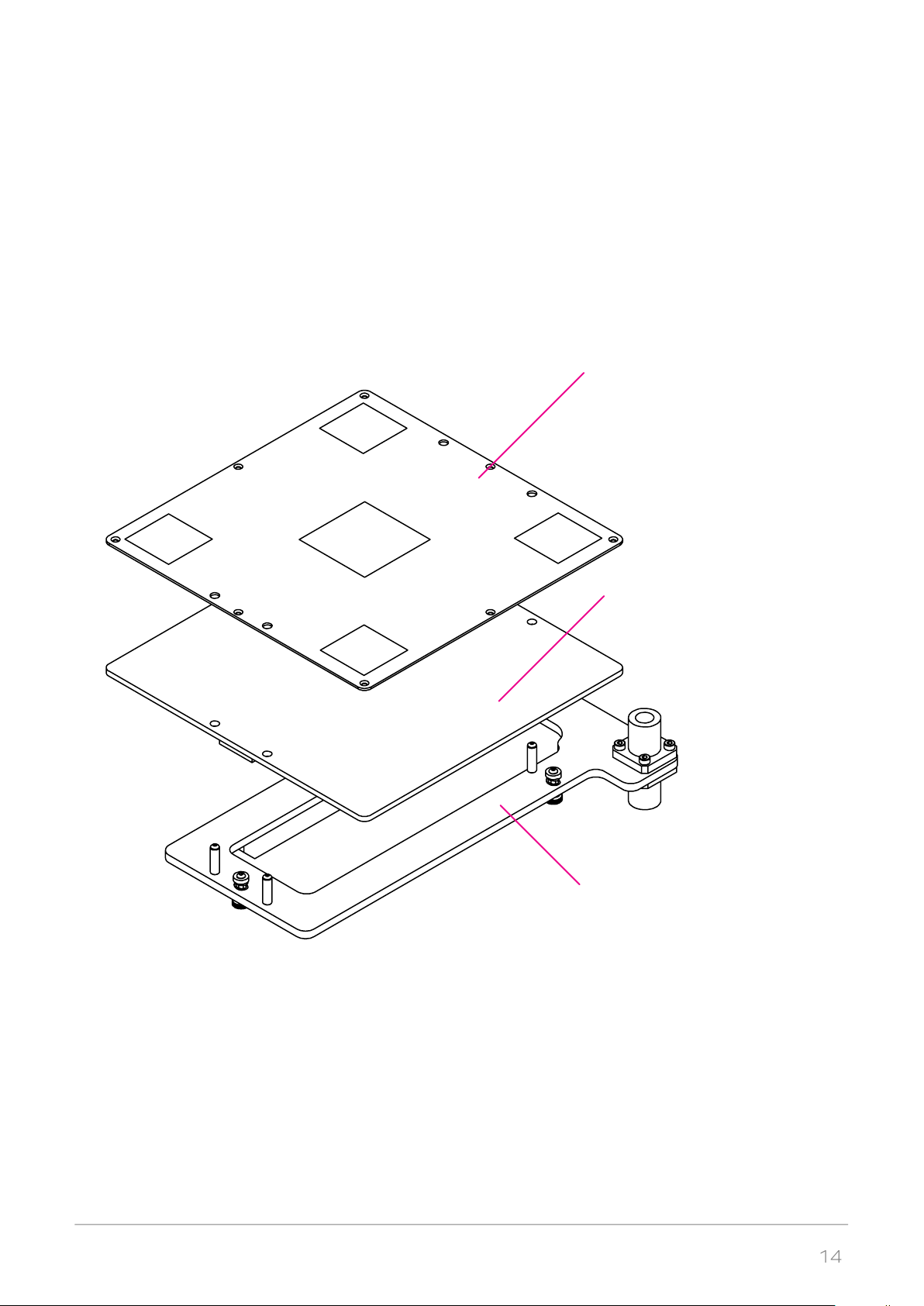

14

Perforated Plate

Heatbed

Heatbed Mount

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

15

Zortrax 3D Printing Technology Glossary

DISPLAY PANEL

a high contrast screen displaying information about the current printing process, the printer’s menu and

other information concerning the printer.

EXTRUDER

the mechanism which ensures material feeding, heating and extruding as well as cooling of the print.

Its main components include the hotend and the nozzle. The material is melted in the hotend and then

pushed through to the nozzle. The melted thermoplastic is deposited layer by layer to form a previously

designed shape. Additionally, there are two fans on the extruder which cool the whole mechanism and

the print.

EXTRUDER CABLE

a ribbon cable which connects the extruder with the motherboard. It supplies the extruder with electricity and allows to regulate the printing process.

HOTEND

a basic heating system which consists of the aluminium block and the heater & thermocouple. The hotend is responsible for heating and melting the material as well as for providing the proper temperature

of the material during the whole printing process.

KNOB

a round, rotating button used to navigate through the printer’s menu and control its basic settings.

LAYER PLASTIC DEPOSITION (LPD)

the technology in which a melted material is deposited on a given surface. This technique involves applying one layer of material after another in order to form a predesigned shape – an accurate representation of a virtual design. This technology is applied by Zortrax devices – the printer starts to print from the

bottom and builds the object until it is fully formed. The model and the support structures are created

using the same material.

MATERIAL GUIDE

a tube which feeds the material from the spool to the extruder at the proper angle. The material guide in

Zortrax printers has to be attached to the extruder cable and the back of the printer with special buckles.

MATERIALS

specially dedicated Zortrax printing materials which maximize the benefits of 3D printing. These thermoplastic materials are in the filament form wound on a spool. There is a wide choice of materials in the

Zortrax product offer which is available at: https://zortrax.com/materials/zortrax-m-series/. Each mate-

©2017, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following document are registered

trademarks of Zortrax and are subject to legal protection.

Loading...

Loading...