zortrax Apoller User Manual

Device User Guide

Apoller

Table of content

Introduction 3

Intended Use of the Zortrax Apoller 3

General Safety Information 4

Workplace Health and Safety 7

Additional Safety Information 10

Learn More About the Zortrax Apoller 11

How does the Zortrax Apoller Work? 11

What’s in the Box 12

Main Components 13

Zortrax Apoller Technology Glossary 14

First Use Preparations 17

Navigating through the Menu 27

Light Signals and Operating Modes 30

Adding the Solvent 31

Changing the Solvent 33

Starting the Process 39

Preparing for Transport 45

Materials Prone to Smoothing Process in the Zortrax Apoller 51

Basic Maintenance 52

Support and Troubleshooting 55

Error Messages 56

Specification 59

Recycling 61

Certification 61

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

3

Introduction

Read this User Guide carefully and thoroughly before operating the Zortrax Apoller for the

first time. The User Guide includes basic information about the device, safety guidelines

and advice on preparing the machine for the first smoothing process and basic mainte-

nance work. Ignorance and non-compliance with these instructions may result in property

damage, injuries, device failures or lower performance. It is also necessary to ensure that

every user who operates the device knows, fully understands and follows the instructions

provided in this User Guide.

The Manufacturer makes every effort to ensure that the device is safe in transportation,

installation, usage, storage and disposal. However, due to the lack of direct and ad hoc

control as well as other conditions influencing the device and those that are beyond the

Manufacturer’s knowledge, the Manufacturer is not responsible for damage, injuries, fa-

ilures and costs resulting from improper transportation, installation, usage, storage and

disposal.

Intended Use of the Zortrax Apoller

The Zortrax Apoller is a post-processing device which smoothes down layers characte-

ristic for items 3D printed in the LPD/FDM technology. This effect is achieved through

vaporization of solvents that react with the thermoplastic used for 3D printing.

Users are responsible for qualifying and determining the intended use of smoothed mo-

dels. The Manufacturer takes no responsibility for any use of the objects, especially when

those objects constitute a part of safety equipment or strictly regulated medical, military

or space science equipment.

Due to the size and specificity, the device is not intended for use by minors and people

with reduced manual, motor and psychomotor skills. The Manufacturer recommends pro-

viding assistance and guidance to people with disabilities, minors and older adults who

wish to operate the device.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

4

General Safety Information

This User Guide contains safety guidelines that should be followed during operation of

the Zortrax Apoller. It also mentions situations which require special attention and warnin-

gs against negligence and misuse which could cause damage or injuries.

It is important to read Safety Data Sheets for materials available at: https://zortrax.com/

filaments/. To avoid any kinds of device failures, it is essential to update the firmware. Visit

https://zortrax.com regularly to learn about the latest updates.

Safety signs used in the User Guide:

Symbol Description

A warning to strictly follow the instructions included in the User Guide

to ensure safety and full functionality of the device.

Information especially useful during installation and operation of the

device.

Information regarding explosion protection especially useful during

installation and operation of the device.

The Zortrax Apoller operates at high temperatures with the use of

explosive vapors and irritant chemicals, therefore, be particularly care-

ful when handling the device.

It is extremely important to avoid situations that may lead to burns or

interference in the device’s proper functioning. Do not inhale vapors

that remain in the chamber after opening the door.

Do not leave the machine unattended during the smoothing process

- check it periodically for proper functioning to avoid potential failures.

Turn off the device once the process is finished.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

5

Monitor your device for wear and tear regularly. Contact Support Cen-

ter available at: https://support.zortrax.com for assistance while repla-

cing worn components.

Keep the device away from heat sources, flammable materials, equip-

ment emitting radiation, fire, humidity, water and other liquids.

Keep the device out of reach of children and animals. Do not shake or

drop the device as it may cause breakdowns.

The device is not intended for use in potentially explosive atmospheres.

While operating the device, wear safety gloves and glasses.

On the basis of the conducted risk assessment (including the risk of explosion), the Ma-

nufacturer concludes that the Zortrax Apoller conforms to the provisions of the Directive

2006/42/EC.

Due to the nature of the technological process, the device has been designed and produ-

ced in such a way to prevent the risk of explosion caused by the machine itself and by the

vapors of ammable liquids used during its operation. The sucient level of protection

has been achieved through the adoption of the Directive 2014/34/EU of the European

Parliament and of the Council of 26 February 2014 on the harmonization of the laws of

the Member States relating to equipment and protective systems intended for use in

potentially explosive atmospheres (ATEX).

According to the ATEX 2014/34/EU Guidelines (First edition - April 2016), all essential

objectives of the Low Voltage Directive 2006/95/EC have been covered by the Directive

2014/34/EU (Annex II 1.2.7).

EN 1127-1:2009 Explosive atmospheres - Explosion prevention and protection - Part 1:

Basic concepts and methodology

ISO 80079-36:2016-07 Explosive atmospheres - Part 36: Non-electrical equipment for

explosive atmospheres - Basic method and requirements

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

6

ISO 80079-37:2016-07 Explosive atmospheres - Part 37: Non-electrical equipment for

explosive atmospheres - Non-electrical type of protection constructional safety “c,” control

of ignition sources “b,” liquid immersion “k.”

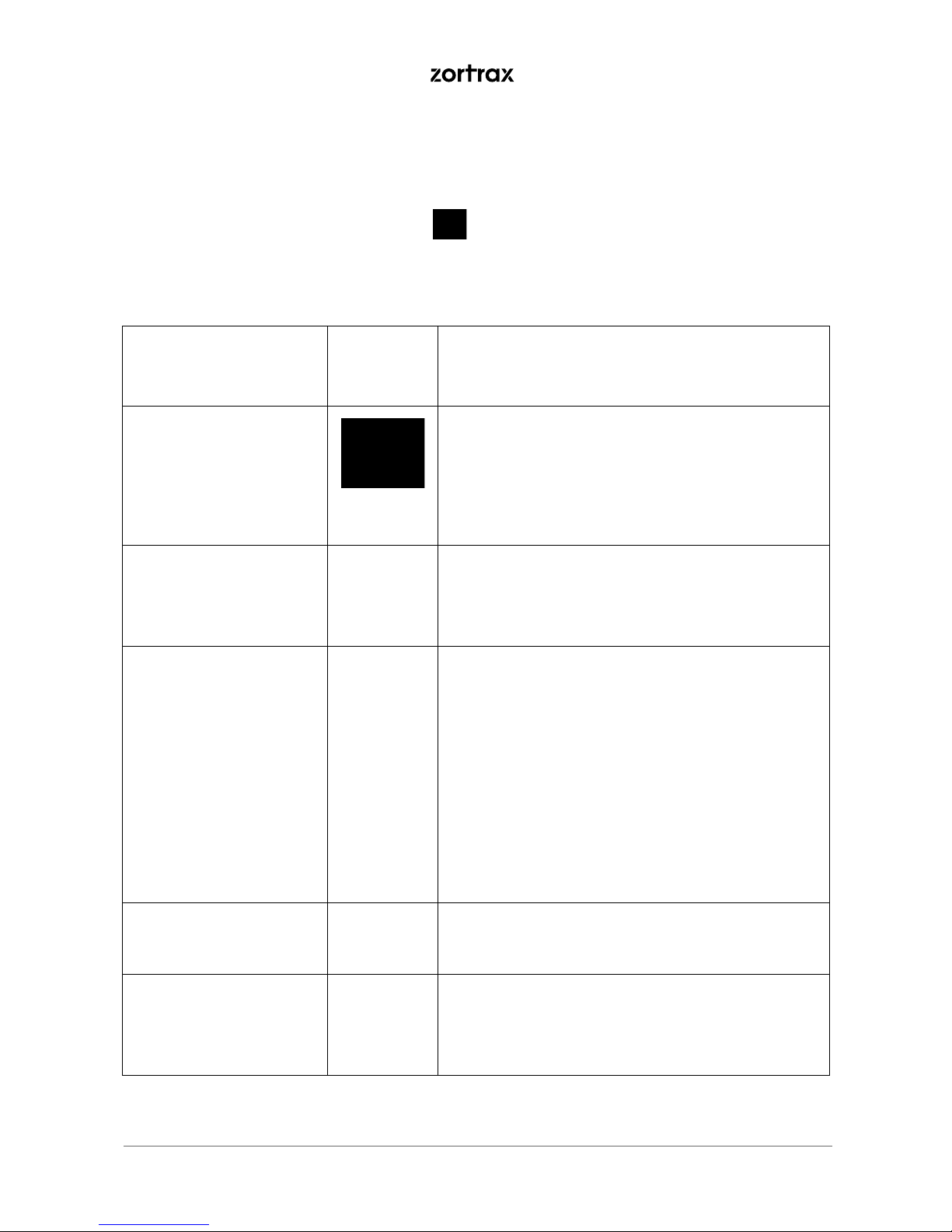

The Zortrax Apoller has been marked:

II 1/- G Ex h IIA T2 Ga/-

The restrictions of the device’s use in accordance with symbols present in the above mar-

king and on the nameplate of the device:

Name ATEX

Marking

Explanation

Explosion protection

mark

Symbol of equipment for use in explosive at-

mospheres.

Note: Read the equipment category explana-

tion.

Equipment group II Equipment intended for use in explosive at-

mospheres other than underground mining

works.

Equipment category 1/- G Equipment is not intended for use in potential-

ly explosive atmospheres.

Due to the nature of the technological pro-

cess, the device has been designed and pro-

duced in such a way to prevent the risk of

explosion caused by components in contact

with the process medium or vapors of flam-

mable liquids used for operation.

Type of protection Ex h Constructional safety according to normative

requirements.

Group IIA Classification by the type of medium used for

operation and by the presence of flammable

gases: explosion subgroup IIA (propane).

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

7

Temperature class T2 Equipment operates with the use of flamma-

ble liquids of auto-ignition temperature > 300°

С [572° F].

Note: The restrictions of the liquid’s use are

included in this User Guide.

The Zortrax Apoller does not pose a threat to health and safety of people when: properly

installed and maintained, and used according to its intended purpose (following this User

Guide) or under foreseeable conditions.

Workplace Health and Safety

All maintenance activities as well as device operation require wearing neoprene safety

gloves included in the Starter Kit. Wearing safety gloves is also advised while removing the

print from the platform after the smoothing process.

Keep the workplace clean and well-lit. Disorder and lack of lighting in the workspace could

lead to accidents.

The vapors released during the smoothing process do not pose a hazard - the device

is tight. However, the room dedicated for operating the device should be properly and

regularly ventilated.

Food and beverages should be kept away from both the device and 3D printed objects.

All measures regarding health and safety provided in this User Guide as well as in separa-

te regulations should be implemented while operating the Zortrax Apoller.

The device should be configured according to its intended purpose. Improper configu-

ration may cause defective operation which may lead to damage of the device or an ac-

cident.

If the device begins to operate in an unidentified way, safely unplug it from the power

source and immediately contact the Manufacturer through the support form at: http://

support.zortrax.com/support-form/.

Before and during each smoothing process it is extremely important to observe all safety

rules. Do not disregard any of the rules included in the User Guide, even if you have

carried out multiple smoothing processes. Careless use of the device may cause serious

injuries in a very short time.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

8

Electrical Safety

Use only the original power cable supplied with the device. Do not damage, cur or repair

the cable. A damaged cable should be immediately replaced with a new one. The cable

should be used according to its intended purpose and should be protected from heat,

oils, sharp edges and moving components of the device. A damaged cable increases the

risk of an electric shock.

Protect the device against rain and humidity. Be careful not to spill the liquid outside the

filler. Liquids spilled into the device increase the risk of an electric shock.

To ensure the highest safety standards, including protection against short circuit, overload, over voltage and device overheating, do not attempt to modify the device and do not

use replacement parts other than those recommended by the Manufacturer.

Before plugging the power cable into the outlet, make sure that the power supply voltage

in the outlet matches the required value provided on the nameplate at the back of the

device. Avoid overloading the outlet with too many devices.

The device must be well-grounded. Always make sure that the ground complies with local

and national regulations.

Repair work can only be carried out by the Manufacturer or the Manufacturer’s Authorized

Service.

All maintenance activities should be carried out when the device is off and unplugged.

Always follow the instructions included in this User Guide.

Mechanical Safety

All mechanical components in the Zortrax Apoller are covered and protected against the

possibility of touching. However, you should not block the device’s ventilation openings or

put any objects in them.

Tools and accessories delivered with the device should be used with special care only for

intended purposes. Improper use may cause serious injuries.

While following post-processing procedures, wear safety gloves and glasses to avoid in-

juries that may be caused by sharp edges and fragile elements of models.

If it is particularly difficult to remove a print from the platform after the smoothing pro-

cess, at first take out the platform and remove the print outside the device using a spatula.

The platform is made of glass, therefore, be particularly careful during the assembly and

disassembly process.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

9

Risk of Burns

There is no risk of burns as all heating modules and components which operate at high

temperatures are covered and protected against the possibility of touching.

Constructional modifications of the device’s operating temperature are not permitted as

it may cause serious injuries or bring damage to the device.

Service

Repairs of the device can only be carried out by the Manufacturer or the Manufacturer’s

Authorized Service.

Safe Storage and Transport Guide

Zortrax devices must be stores between 0 and 35° C [32 - 95° F]. The storage space should

be free of moisture and other extreme conditions.

Transport Instructions:

When stacking several devices on a pallet, follow the instructions on the packaging. One

device may weigh more than 30 kg [66 lb]. It is therefore advisable to provide safe pallet

storage but not higher than 1.7 m [5’7”]. The packages must not project beyond the outli-

ne of the pallet. Packages stacked on the pallet should be then bound together and wrap-

ped in foil. The pallet prepared as above can be then forwarded to the shipping company.

Pallet stacking and destacking should be carried out by two people. The package with the

device should be lifted or moved using special handles. The device should not be carried

by one person as it may cause injuries.

Electromagnetic Compatibility (EMC)

Each Zortrax device complies with Part 15 of the FCC rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause un-

desired operation.

This equipment generates, uses, and can radiate radio frequency energy, and if not instal-

led and used in accordance with this instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference which should be removed by the user at his own expense.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

10

Additional Safety Information

- For smoothing processes use only dedicated solvents in a concentration above 99%

(acetone or butanone [MEK]).

- Do not block the ventilation openings. Keep the device 30 cm [12 in] from any objects

that could block the openings.

- The solvent level must not exceed the MAX mark on the solvent level indicator.

- Keep the chamber door gasket clean. Clean gasket facilitates the device’s tightness

during the smoothing process.

- The filler cap must be tightly closed. The device will detect a lack of tightness and display

a notification.

- Keep the solvent tray inside the device clean.

- The device must be placed on a stable surface, away from sources of fire and heat.

- The device can only operate at room temperature (15 - 30° C [59 - 86° F]). Otherwise, it

will not be possible to run it.

- Do not ignore notifications displayed on the screen.

- Do not pour solvent directly into the tray inside the device.

- Only 3D printed models can be placed in the chamber.

- 3D printed models can only be placed on the glass platform or suspended on the hooks

in the grid.

- All containers with solvents must be tightly closed and stored in a specially designated

place, away from children and animals.

- Smoothing process can only be carried out using models 3D printed with dedicated

thermoplastics.

- Do not smooth models that exceed the dimensions of the workspace as it may cause

device malfunction.

- Do not pull the chamber door handle when the device is running.

- The smoothing process must be configured according to the type of solvent poured

into the tank.

- The solvent tank must be filled using the specially designed set delivered with the device.

- Once the smoothing process is stopped after the solvent has been supplied to the tray,

the device begins the condensation procedure.

- Serious failures, including power supply failure, block the chamber door, making it impossible to open.

- It is strictly prohibited to repair the device independently.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

11

Learn More About the Zortrax Apoller

The Zortrax Apoller is a device which post-processes models 3D printed in the LPD/FDM

technology. It operates in a system called Smart Vapor Smoothing (SVS), thanks to which

vapors of a chemical substance circulate inside the chamber to smooth down the surface

of 3D printed items. Depending on the material type used for printing, the device uses

either acetone or butanone (MEK). Vapors of the solvent circulate in the chamber in such

a way that the smoothing effect is even and at the same time the model does not get da-

maged. The device is capable of post-processing multiple models during one smoothing

process. For environmental and safety reasons, the solvent vapors are effectively retrac-

ted and condensed in the chamber so that the liquid can be regained and used for the

next smoothing processes.

How does the Zortrax Apoller work?

After the device is turned on, users gain access to the main menu where it is possible to

adjust several settings for the smoothing process: smoothing mode, type of solvent, type

of model’s material and smoothing intensity. Once these settings are selected, the device

removes air from the chamber to ensure tightness and other suitable conditions necessa-

ry for the smoothing process. Next, the device supplies the tray with the required amount

of solvent which then vaporizes as a result of chamber heating and air circulation. The air

circulation system enables even distribution of solvent vapors concentration in the entire

working volume of the device. These vapors have influence on the models’ surface for a

certain period of time, and at the end of the whole process they are condensed. Once the

first stage of condensation is finished, the device warms up the models and the reacted

substance vaporize from their surface. Next, the device starts the final condensation pro-

cedure during which the models are cooled to room temperature. Once the smoothing

process is successfully finished, the models are ready for use.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

12

What’s in the Box

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

13

1. Front view (closed)

2. Front view (open)

Main Components

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

14

3. Right-side view

Zortrax Apoller Technology Glossary

CONDENSATION

a process of solvent vapors condensation, thanks to which it is possible to regain some

part of the solvent. Moreover, condensation ensures safe conditions once the smoothing

process is finished.

DRYING

a gradual process of warming up models and vaporizing a reacted substance from their

surface. Next, the device starts the final evaporation procedure during which the models

are cooled to room temperature.

LPD (LAYER PLASTIC DEPOSITION) / FFF

a 3D printing technology in which a melted material is deposited on a surface. This tech-

nique involves applying onel ayer of material after another in order to accurately form

a computer-designed shape. The printer starts to print from the bottom and builds the

object until it is fully formed. The model and the support structures are created using the

same material.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

15

MATERIALS

specially dedicated Zortrax printing materials which maximize the benefits of 3D printing.

These thermoplastic materials are in the form of filaments wound on a spool.

Each material has different properties and can easily be adapted to a wide range of ne-

eds and applications. Moreover, most of the materials can be mechanically or chemically

post-processed.

MOTHERBOARD

the most important part of Zortrax Apoller to which all components necessary for proper

device operation are connected. It is the main printed circuit board that ensures electrical

flow and communication between particular components of the device. The motherboard

is placed behind the screen inside the machine.

PLATFORM

integral part of Zortrax Apoller on which a user places models that will be subjected to

post-processing. The platform can easily be removed as well as inserted back into the

device.

POWER OUTLET AND MAIN SWITCH

the switch enables turning the device on and off. Next to the switch, there is a

power outlet where you plug the power cable in.

POST-PROCESSING

all mechanical and chemical treatments that influence 3D printed objects’ surface in or-

der to make models look more interesting and attractive. These post-processing me-

thods include, for example, smoothing, sanding, painting or gluing two or more parts

together to create one model.

RAFT

the first few layers of material, which begin the whole printing process. These layers are

always printed before the main object and have a larger area than that object. Once the

printing is done, the raft needs to be removed from the platform together with the rest

of the model. The raft enhances the adhesion of the whole print to the platform and

reduces the risk of warping. Before launching the smoothing process in Zortrax Apoller,

RAFT always has to be removed from the model.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

16

SMART VAPORT SMOOTHING (SVS)

a method of smoothing the surface of 3D printed models that uses advanced algorithms

controlling the concentration of solvent vapors, process temperature, pressure and inten-

sity of vapor circulation. SVS technology helps achieve high quality and repeatability of the

smoothing process, at the same time preserving model’s details intact.

STARTER KIT

a set of tools and protective materials useful while working with the Zortrax Apoller. Each

device is delivered with the full starter set, so that handling or maintaining the machine

becomes easier and more effective.

SUPPORT STRUCTURES

if your model has any overhanging or protruding parts, they have to be supported with

special structures so that they don’t fall down. Without these structures, the model may

lose its predesigned shape. The support is printed with the same material as the model.

Once the printing is done, it is necessary to carefully remove the support by hand or using

pliers. Before launching the smoothing process in Zortrax Apoller, support structures al-

ways have to be removed from the model.

TOUCHSCREEN

the display screen placed at the front of the device, which enables fast and intuitive navi-

gation through the menu. The screen also displays information about the current smo-

othing process and other information concerning the device.

VAPORIZATION

a process of liquid transition to vapors, which will be then atomized in the chamber, and

finally distributed on models.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

17

First Use Preparations

2. Remove the upper and side cushioning.

1. Open the box and remove the metal grid and brochures.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

18

3. Take the device out of the box.

4. Remove the foil.

©2019, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection

19

5. Place the device on a flat and stable surface. Before the first use, make sure that your work area is safe

and well-ventilated. Keep the device away from heat sources, flammable materials and equipment emitting

radiation.

6. Open the chamber door. The door should open easily. If the door is blocked, contact the Authorized

Service. Do not pull the chamber door handle or attempt to remove the the blockage.

Loading...

Loading...