Page 1

TranzStor

8X

FIELD-READY

User Manual

Z Microsystems

Page 2

REGULATORY

WARNING

TO PREVENT FIRE OR SHOCK HAZARDS, DO NOT EXPOSE THIS UNIT TO R AIN OR

MOISTURE. ALSO, DO NOT USE THIS UNIT’S POLARIZED AS PLUG WITH AN EX TENSION

CORD RECEPTACLE OR OTHER OUTLETS UNLESS ALL THR EE PRONGS CAN BE FULLY

INSERTED

1. Use the power c able

supplied with the product

to help prevent interference with radio and television reception. The use

of cables and adapters

may cause interference

with electronic equipment

in the vicinity of this unit.

2. Changes or modifi cations not expressly

approved by Z Microsystems could void user’s

warranty.

TranzStor

8X

CAUTION

RISK OF ELECTRIC SHOCK - DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK DO NOT REMOVE COVER (OR

BACK OF UNIT). NO USER SERVICEA BLE PARTS INSIDE . REFER SERVICING TO QUALIFIED PERSONNEL.

This symbol warns the user that insulated voltage within the unit may have suf fi cient

magnitude to cause electric shock. Therefore, it is dangerous to make any kind of

contact with any part inside this unit.

This symbol alerts the user that impor tant literature concerning the operation and

maintenance of this unit has been inc luded. Therefore it should be read carefully in

order to avoid any problems.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

2

Page 3

TABLE OF CONTENTS

SECTION PAGE

Introduction ........................................................................................................ 4

About This Manual ............................................................................................ 4

Safety Precautions ............................................................................................ 4

Product Description ........................................................................................... 5

Installation ......................................................................................................... 6

Shipment Contents ............................................................................................ 6

Required Tool .................................................................................................... 8

Preparations ...................................................................................................... 8

Installation Precautions ..................................................................................... 8

Rail Installation .................................................................................................. 9

8X RAID Installation .........................................................................................11

Cable Connections ...........................................................................................12

Operations ........................................................................................................ 13

Powering up TranzStor 8X ...............................................................................13

Establish Serial Co nnection .............................................................................13

Verify Channel Settings ...................................................................................14

Begin Quick Install Wizard ...............................................................................15

Add New Logical Drive .....................................................................................17

Status Indicators ............................................................................................. 20

TP7 Description ................................................................................................21

Inserting the TP7 ............................................................................................. 22

Removing the TP7 .......................................................................................... 23

Removing the Door ......................................................................................... 24

Replacing the Door ......................................................................................... 25

Maintenance ................................................................................................... 26

Cleaning the TranzStor 8X .............................................................................. 26

Replacing the Fan Assembly .......................................................................... 27

Troubleshooting ............................................................................................... 28

Confi guring the Channels After Reset ............................................................ 28

Drive Failures .................................................................................................. 34

Schematics for TranzStor 8X .......................................................................... 39

Appendix ..........................................................................................................41

Specifi cations ...................................................................................................41

Replacements ..................................................................................................42

Warranties ...................................................................................................... 43

Customer Support ........................................................................................... 49

Customer Feedback ........................................................................................ 50

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

3

Page 4

INTRODUCTION

ABOUT MANUAL

This Manual is also available on the Z Microsystems website (ww w.zmicro.com). We

recommend you read this manual carefully and follow the instructions in the Installation

chapter for verifi cation of system functions and control settings.

SAFETY PRECAUTIONS

DANGER:

To avoid shock hazard:

Do not penetrate the 8X with any

•

screw longer than .18”. Damage will

occur.

Do not connect or disconnect the 8X

•

during an electrical storm.

e power cord plug must be connected

•

to a properly wired and grounded

power outlet.

Any equipment to which the 8X will

•

be attached must also be connected to

properly wired and grounded power

outlets.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

4

Page 5

INTRODUCTION

PRODUCT DESCRIPTION

From the TranzStor family of low-profi le, platform-independent network storage solutions comes the TranzStor 8X SC (SCSI Controller). Featuring an Ultra 160 (or Ultra 320)

SCSI to SCSI RAID controller and 8 hot-swappable TranzPak 7 hard drive modules. The

TranzStor 8X SC RAID array provides data intensive, mission critical applications with the

high-end availability, performance and fault-tolerance they require.

Packed in a tough, lightweight, compact aluminum enclosure, this fail proof hot-plug storage installs easily into any industry standard 7” (4U) RETMA rack or transit case slot. Designed specifi cally to work under extreme conditions, this ultra-rugged low-profi le modular

system utilizes hot-pluggable and removable TranzPak 7 hard drives to of fer portability in

complex deployed computing environments. Each TranzPak 7 drive holds up to 400 GB

of storage capacity and features an extruded aluminium body and a die cast cam locking

front panel, solid protection for your deployed media investment.

5

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 6

INSTALLATION

INSTALLATION

This portion of the Operations chapter is for quick reference only. For a more detailed

description of RAID confi gurations, see the Controller Manufacturer’s user manual.

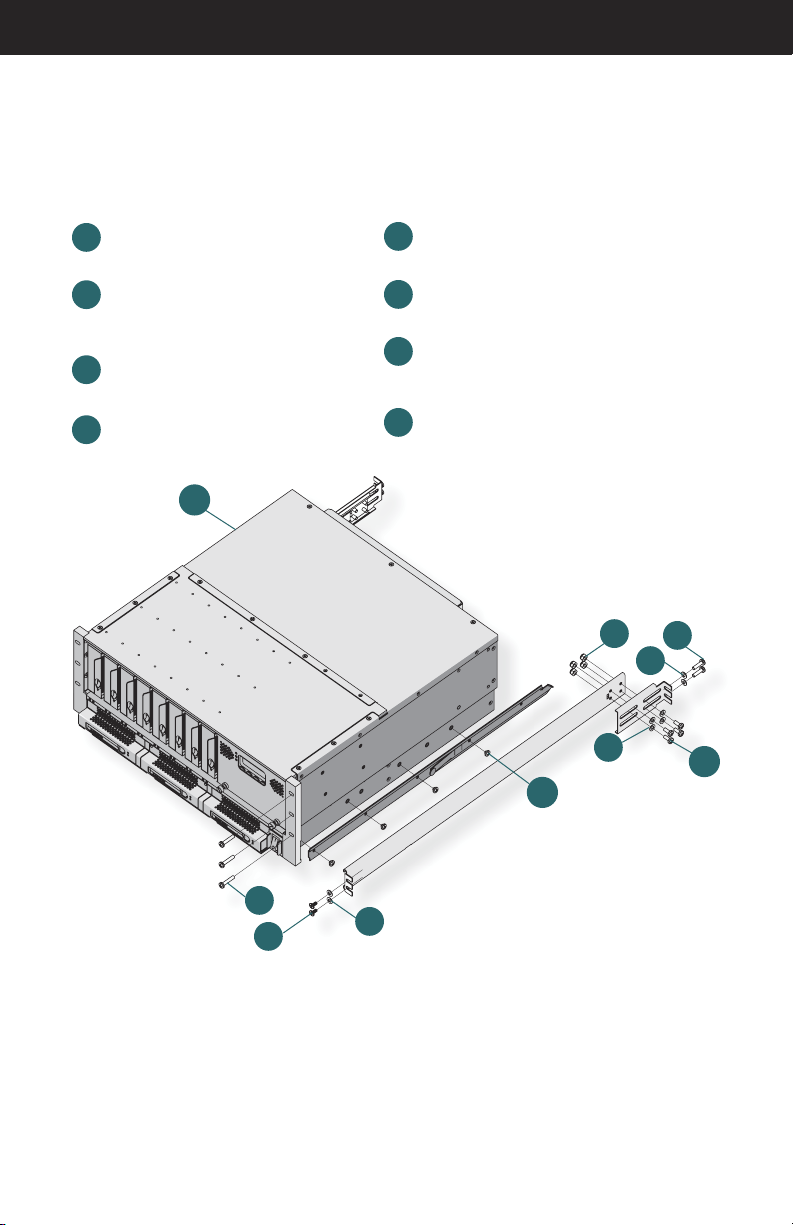

Shipment Contents:

(8) Nut, Locking, 10-32, SS, 01-

8X Raid Enclosure (Power Sup-

a

plies and TP7s installed)

e

92151

(6) Screw, SEM, Phillips, 10-32

b

x 1.00”, SS,

01-92220

(4) Screw, Pkh, Phillips, 10 -32 x

c

0.375Lng, SS, 01-92087

(16) Washer, 10 Flat SS, 01-

d

91872

a

(4) Screw, 10-32 x 0.75 Pan Phil-

f

lips, 01-92112

(8) Screw, 10-32 x 0.50 Pan Phil-

g

lips SS ISEM,

01-91622

(8) Screw, 10-32 x 0.1875 Pan SS,

h

01-91827

h

e

f

d

d

g

b

c

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

d

6

Page 7

INSTALLATION

Null Modem Cable (DB9F to DB9F)

i

j

IEC Power Cable

k

Rack Slides

l

SCSI LVD/SE External Terminators

(Quantities will vary depending on

RAID Controller Model)

i

Raid Controller Manual

m

n

Warranty & Service Plan

o

8X User Manual

p

Electronic Documentation

j

k

l

n

m

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

p

o

7

Page 8

INSTALLATION

REQUIRED TOOLS

• Phillips Head Screwdriver

• 3/8” ratchet

PREPARATIONS

In preparation to install the 8X, take the

following precautionary steps:

Turn off the electrical power to the host

computer.

INSTALLATION

PRECAUTIONS

When mounting the 8X, there is a

maximum of .18” screw penetration on the

underside and side screw hole locations.

NOTE: For the fastest and easiest

installation of the 8X, follow

these steps in the sequence they

are presented.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

8

Page 9

INSTALLATION

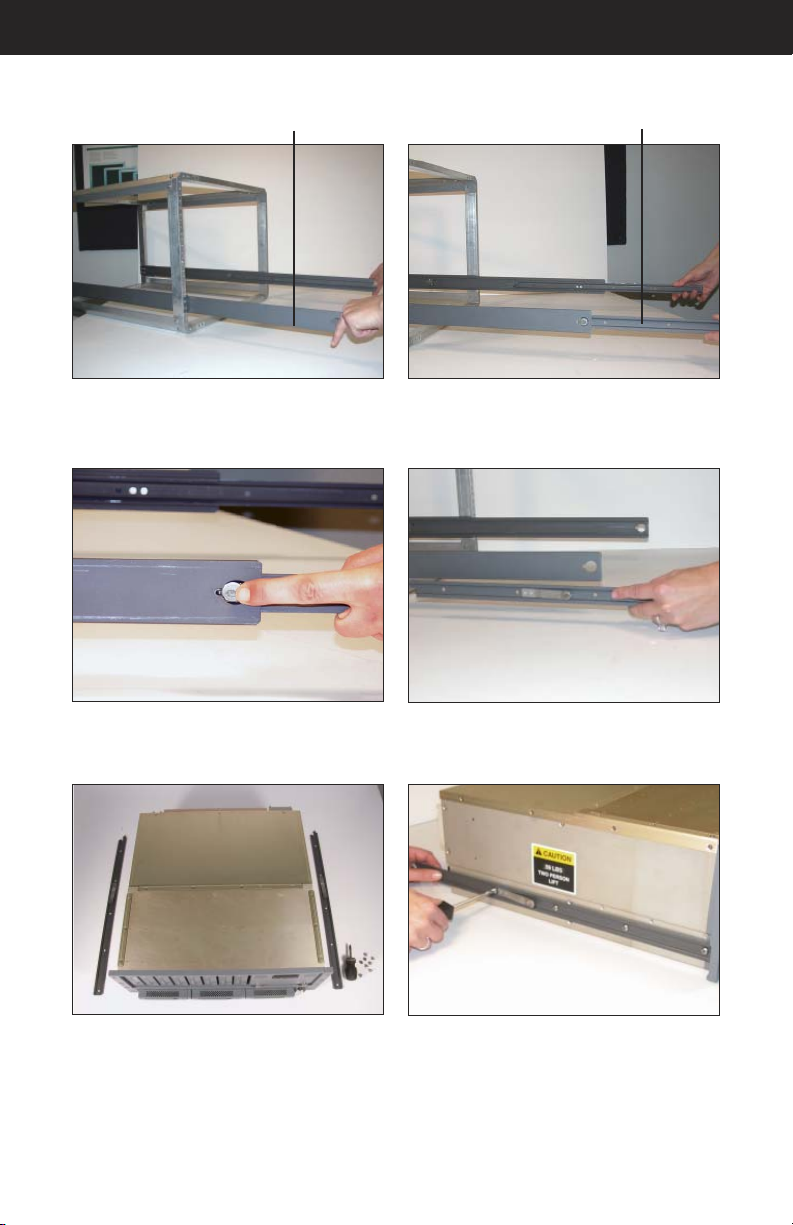

STEP 1: RAIL INSTALLATION

The 8X RAID will arrive with the slides unattached.

To attach the slides to the extension

brackets, use two panhead phillips screws

(part # 01-91622), two fl at washers (01-

91872), and two lock washers (01-92151).

Slide Extension Bracket

Outer Slide Member

Insert the screws through the slots of the

extension bracket and into the holes in

the outer slide member. Secure loosely

with fl at and lock washers. Do not tighten.

Repeat with the second slide assembly.

Secure the rear of the slide assembly to

the rear of the rack using two panhead

Phillips head screws (part #01-91622).

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Positioning the slide assembly on the

inside of the rack, secure the front of the

slide assembly to the front of the rack using

a fl at Phillips head screw (part #01-92087)

in the top position.

Tighten the slide assembly screws using

a Phillips screwdriver and 3 /8” ratchet.

Repeat rail installation for other side.

9

Page 10

INSTALLATION

Middle Slide Member

Once both slide assemblies are installed

in the rack, extend the middle members of

the slide assemblies out of the rack.

Inner Slide Member

Extend the inner members of the slide assemblies out as far as they will go.

Press the slide locking tab on the outer

sides of the slides...

Lay the inner members along either side

of the 8X RAID, placing the pointed end of

the members toward the rear of the unit.

This is how the inner members will be attached to the 8X RAID.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

and remove the inner members of the slide

assemblies.

Attach the inner members to the sides of

the 8X RAID using 10-32 x 3/16” panhead

Phillips head screws (part# 01-91827).

10

Page 11

INSTALLATION

STEP 2: 8X RAID INSTALLATION

CAUTION: When attaching the inner

members of the slide assemblies

to the sides of the 8X RAID,

ensure screw penetration

does not exceed 3/16” length.

Damage may result if screw

length exceeds 3/16” length.

Use 10-32 x 3/16” screws only

(part# 01-91827).

Hold the 8X R AID up to the extended

rails with the rear of the 8X RAID to the

rear of the rack. Insert the inner member

(attached to the 8X RAID) into the middle

member of the slide.

Simultaneously press the slide locking tab

in and push the unit all the way back into

the rack.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Slide the unit in until the slide action stops.

Secure the front of the 8X RAID to the rack

with three 8-32 x .75” panhead Phillips

screws on each side. See image above.

11

Page 12

INSTALLATION

STEP 3: CABLE CONNECTIONS

The picture below shows the rear of a TranzStor 8X RAID unit and the connection points

for these cables. TranzStor 8X confi gurations may vary.

1. Terminate externa l SCSI connectors

2. Connect SCSI Adapter to Host Computer’s SCSI adapter using a 68 pin external SCSI

cable.

3. Connect Serial CTRL A to the Host Computer’s COM 1 port using the modem cable.

4. Connect power cable.

Install LVD/SE Terminators

SCSI Adapter

Serial CTRL A AC Power Plug

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

12

Page 13

OPERATIONS

STEP 4: POWER UP TRANZSTOR 8X

Before powering the TranzStor 8X, make sure all of the connections are tightened securely at the rear of the unit.

Then press the power switch on the front of the 8X.

Power Switch, Front

After turning on the power switch, the controller will beep. Watch the amber activity lights.

All of the drives’ activity LEDs will illuminate briefl y, and then extinguish.

STEP 5: ESTABLISH

SERIAL CONNECTION

From Accessories/Comunications/ select

Hyperterminal. Create description, select

COM Port and fi ll in Port Settings as

follows:

Bits per seconds: 38 400

•

Data bits: 8

•

Parity: None

•

Stop bits: 1

•

Flow control: None

•

13

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 14

OPERATIONS

STEP 6: VERIFY CHANNEL SETTINGS

If you’re not at the “Main Menu”, select “ PC Graphic (ANSI Mode)” and press “Enter”. This

will take you to the “Main Menu”.

Verify that your channel settings match the image below. If your channel settings do NOT

match, you can not continue with the Quick Guide set-up. Please refer to the troubleshooting section of this manual.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

14

Page 15

OPERATIONS

STEP 7: BEGIN QUICK INSTALL WIZARD

Create logical drive.

Select top option. See controller user manual for other R AID options.

Initialization will begin, and will continue for up to two hours, depending on the drive capacity (about 2 hours for a 146 GB drive).

15

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 16

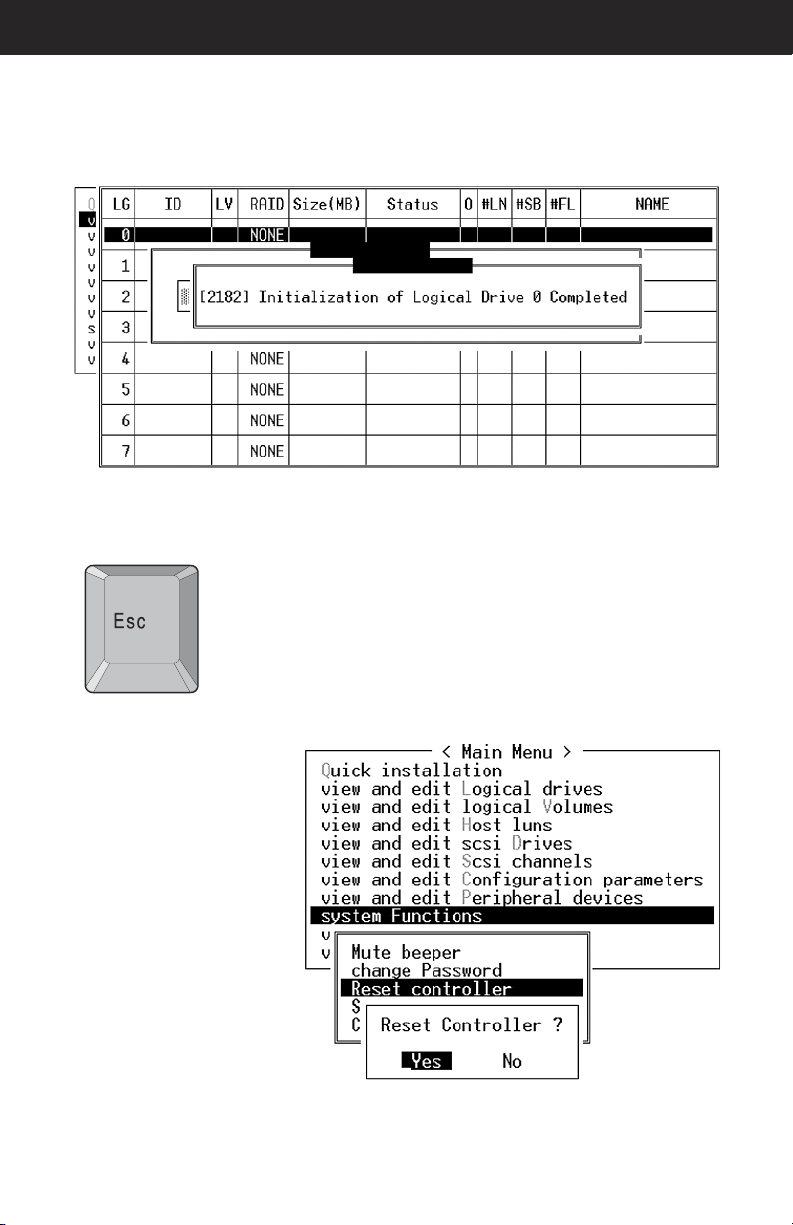

OPERATIONS

Once the initialization is complete, the progress counter will disappear.

Press the “ESC” key.

Select “System Functions,”

then “Reset the Controller,”

and fi nally “Yes” to reset.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

16

Page 17

OPERATIONS

STEP 8: ADD NEW LOGICAL DRIVE

After the TranzStor 8X system reboots, rescan the SCSI bus on the host computer by

right-clicking on the SCSI controller in the device manager.

NOTE: e following screens are Win2K screens, and may appear diff erently with

diff erent operating systems.

Go to Administrative Tools>Computer Management>Disk Management. Click on “Disk

Management ” to start up Write Signature and Upgrade Wizard. Follow the steps in the

Wizard.

17

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 18

OPERATIONS

The host OS should fi nd a new disk with unallocated space and start up the Create

Volume Wizard automatically. If the Wizard doesn’t start up automaically, right-click on

unallocated disk and select “create volume”.

NOTE: If the Disk symbol is shown as “unallocated” (has a red negative symbol over

the drive symbol), there is no signature written to the drive. To do so, right

click on the disk, and write a signature for the drive in the window that

appears. Click “OK”. e red negative sign will be gone and the drive will

be useable.

The wizard will take

the user through

the remaining

options to create

a logical volume,

assign a new drive

letter and format

the partition with

your fi le system of

choice.

18

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 19

OPERATIONS

Once complete, the new drive can be found in the same fi le location as the fi rst available

drive under “My Computer”.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

19

Page 20

OPERATIONS

STATUS INDICATORS

The drives are numbered one through eight. Each drive has two dedicated status indicator

LEDs just below the drive. The following indicators apply to the drives only:

Green= When the drive is plugged into the

TranzStor 8X, the green light indicates the

drive has power.

Yellow= The yellow light comes on when

the drive is accessed by the controller,

indicating activity on the drive.

Power Activity

System Power Indicator

Drive Status Indicator

Alert Indicator

The System Power Indicator= illuminates when power to the system is detected.

The Drive Status Indicator= illuminates when a drive is active.

The Alert Indicator= illuminates when the system detects an error condition. See the controller manufacturer’s user manual to troubleshoot problems with the controller.

NOTE: For operation of the RAID

Controller, refer to the Infortrend

SR2500F User’s Manual.

20

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 21

OPERATIONS

TP7 DESCRIPTION

Red - SCSI Drive

Sliding Locking catch

Locking handle

High tensile extruded

aluminium alloy thermoconductive body

High tensile diecast aluminium alloy front panel

High tensile diecast aluminium alloy rear panel

Rear Connector

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

21

Page 22

OPERATIONS

INSERTING THE TP7

With the handle in the open position, hold

the TranzPak 7 by the main body and

insert it partially into the docking bay. ( Be

sure that it is sliding on the black guides).

Check that the locking catch is aligned with

the locking indent in the slide rail and press

the handle towards body...

Using your thumb push the TranzPak 7

gently into the bay until you can feel it

touching off on the rear connector.

until it snaps the locking handle in place.

Check that all TranzPak 7 disk modules are

aligned across the face of the 8X.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

22

Page 23

OPERATIONS

REMOVING THE TP7

Slide the locking catch to the right to allow

locking handle to spring open.

Pull handle gently forward to eject the

TranzPak 7 off of the rear connector.

Locking handle springs open.

Continue to gently pull handle to slide

the TranzPak 7 forward. The TranzPak 7

should slide over the grounding contacts

until it is half way out.

Take the TranzPak 7 by the main body and

pull straight out.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

23

Page 24

OPERATIONS

REMOVING THE DOOR ON THE CONTROLLER

To remove the controller door, turn the

thumbscrews on the face of the door

counterclockwise.

The door will come loose.

NOTE: For information regarding

removal of the R AID

Controller, refer to the

Infortrend SR2700F User’s

Manual.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

The door can be removed by lifting it

down and off of the hinge.

24

Page 25

OPERATIONS

REPLACING THE DOOR ON THE CONTROLLER

To install the controller door, seat the

hinges up into the hinge slots at a 45

degree angle.

Rotate the bottom of the door down to

align the thumbscrews with the screw

holes.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Simultaneously press and turn the

thumbscrews on the face of the door

clockwise. Tighten the thumbscrews.

25

Page 26

MAINTENANCE

MAINTAINING THE 8X

WARNING: Be sure to turn off

the power before you perform any

maintenance on the RAID.

CLEANING THE TRANZSTOR 8X

Unplug the 8X from the power outlet before cleaning.

To clean the surface of the 8X, lightly dampen a soft, clean cloth with water or mild detergent and wipe the surface of the 8X gently.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

26

Page 27

MAINTENANCE

REPLACING THE FAN ASSEMBLY

With your fi ngers, turn the two thumbscrews (locations shown above) counter

clockwise until the screws loosen.

Lift the fan assembly away from the TranzStor 8X chassis.

Rotate the fan assembly upward on the

hinge and then down.

To install the new fan assembly, place the

two hinges into the hinge slots (shown in

the next photo) at a 45 degree angle.

The image above shows a hinge being

inserted into the hinge slot.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Seat the assembly down and secure it in

place by simultaneously pressing and turning the thumbscrews clockwise. Tighten

the thumbscrews.

27

Page 28

TROUBLESHOOTING

TROUBLESHOOTING

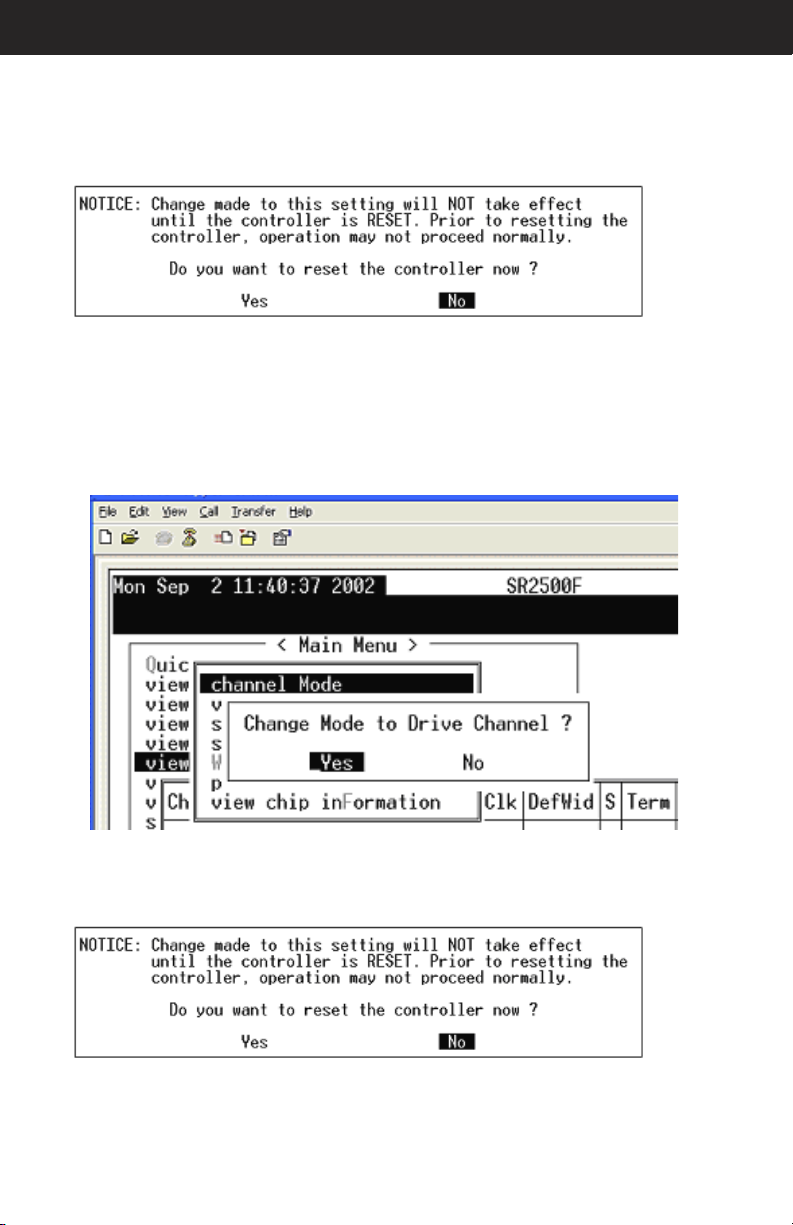

Confi guring the Channels After Accidental Reset

If the controller is reset accidentally to factor y default settings, follow these steps to

recover.

NOTE: Optimal setup for the RAID controller

is 0=Drive, 1=Drive, 2=Host,

3=Host. Only follow these steps if these

parameters are not already setup.

1. Select

“view and edit

channels”.

2. Now select “Chl 0” and then “channel Mode”, and then select “Yes”.

28

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 29

TROUBLESHOOTING

3. At this point you will be asked if you want to reset the controller. Select “No”.

4. Now select “Chl 1” and then “Channel Mode”, and then “Yes”.

5. At this point you will be asked if you want to reset the controller. Select “No”.

29

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 30

TROUBLESHOOTING

6. Now select “Chl 2” and then “Channel Mode”, and then “Yes”.

7. When asked to reset the controller select “No”.

30

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 31

TROUBLESHOOTING

8. Now select “Chl 2” and then “scsi Terminator”, and then “Yes”.

9. When asked to reset the controller select “No”.

31

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 32

TROUBLESHOOTING

10. Now select “Chl 3” and then “channel Mode”, and fi nally “Yes”.

11. When asked to reset the controller select “No”.

32

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 33

TROUBLESHOOTING

12. Now select “Chl 3” and then “scsi Terminator” and then “Yes”.

11. This time, when asked if you want to reset the controller, select “Yes”.

33

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 34

TROUBLESHOOTING

Drive Failures

With a functioning drive, the Attention and Busy LEDs fl ash while the controller is booting

(after the system is powered on). If no amber activity LED is fl ashing when the power is

turned on, please begin the following troubleshooting procedure.

1. If the drive(s) fails during the initial setup of the RAID, turn off power to the RAID and

reboot. Allow the system to come up again and verify that the drives show activity.

2. Ensure the drives are seated securely in the 8X. Remove the failed drive and re -install

it to ensure a good connection.

3. Ensure that the power indicators on the front of the 8X are green for the drive(s) that is

failing.

4. If the indicator shows a green light, ensure the drive terminations are secure at the rear

of the 8X.

5. If Steps 1- 4 do not restore activity to the drive, the “Auto Detect Drive Failure” function

should be enabled. Follow these steps:

A. Confi gure the global parameters for the spare drive. To do so, select “view and

edit Confi guration parameters”, and then “Drive-side Parameters”.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

34

Page 35

TROUBLESHOOTING

B. Now select “Auto-Assign Global Spare Drive”. When asked “Enable Auto-Assign

Global Spare?” select “Yes”.

C. Finally, select “Drive Predictable Failure Mode(SMART)” and then “Detect Only”.

When asked “Set Drive SMART Action Mode? ” select “Yes”.

35

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 36

TROUBLESHOOTING

D. Now select “Periodic Auto-Detect Failure Drive Swap Check Time”.

E. Select “5 seconds” from the drop -down menu.

36

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 37

TROUBLESHOOTING

F. When asked “Set Periodic Auto-Detect Failure Drive Swap Check Time?”, select “Yes”.

G. Press “Esc” once to return to the previous menu.

H. Now select “Controller Parameters” followed by “SDRAM ECC”.

37

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 38

TROUBLESHOOTING

I. When asked “Enable SDRAM ECC Functionality?” select “Yes”.

J. When asked “Do you want to reset the controller now?” select “Yes”.

9ES

If the drive is still failing after attempting these troubleshooting steps, call the Z Microsystems’ Customer Service Department for further assistance.

38

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

.O

Page 39

SCHEMATICS

MECHANICAL OUTLINE FOR 8X

WARNING: There is a maximum of .18” screw penetration on the

underside and side screw hole locations. Only use screws provided.

Use of longer screws may result in damage to internal components.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

39

Page 40

SCHEMATICS

2.38

3

6

1.18

4.44

MECHANICAL OUTLINE FOR 8X

1.14

3.772.06

.2

18.19

17.64

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

19.39

18.69

40

18.46

1.75

6.90

1.75

2.58

18.97

Page 41

APPENDIX

SPECIFICATIONS

General Display Specifications

Enclosure

Materials Aluminium 5052 H32, 6061 T6, A380

System Capabilities Eight Storage bays

Storage Capacity Up to 3200 GB (each drive ranges from 73 -400 GB)

Base Options Split-SCSI Bus

Dimension (H x W x D) 6.9” H, 18.97” W, 19.39” D

Net Weight 51 lbs. (with eight TP7 drives @ 2.5 lbs. each)

Power Requirements 90-264 VAC, 1.90A, 47-63 Hz

Environmental*

Operating Temp +5º to + 45º C

Non Operating Temp -20º to + 60º C

Operating Humidity 5% to 95% Non condensing

Non Op. Altitude -1,300 to 40,000 ft.

Operating Altitude -1,300 to 10,000 ft.

Fungus Non Nutrients / contaminants

Rliability

MTTR <20 minutes

Regulatory

Safety UL 1950 (used as a guideline)

EMI FCC Class A

Connectors Micro -D 68 pin SCSI Bus

Quality/Workmanship

MIL-HDBK-454

IPC / ISO 9001:2000 and applicable section of

* Units are designed and built to meet the following environmental levels.

41

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 42

APPENDIX

REPLACING PARTS

If the Z Microsystems Technical Support Engineer determines that the product needs to

be replaced, a Customer Ser vice Representative will issue a Return Material Authorization (RMA) number.

An RMA number is required to return a product to Z Microsystems, regardless of the

reason for the return.

The Z Microsystems Customer Service Department/ RMA Request Form will ask the customer to provide the following information:

You will be given an RMA number and will be asked to send the product to:

Z Microsystems

ATTN.: (RMA#) It is very important to reference the RMA#

5945 Pacifi c Center Dr., Suite 505

San Diego, CA 92121

• model number of the defective product

• serial number of the defective product

• problem with the defective product

• return “ship to” address

• the name and address of the company department to which we will send

the invoice (if product is out of warranty or is different from the “ship to”

address.

• phone number and e-mail address of contact

• purchase order number

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

42

Page 43

APPENDIX

APPENDIX

WARRANTIES

Standard Warranty

-no charge-

Z Microsystems’ one-year Standard Warranty includes a 90-day AirSpare Ser vice Plan.

This means that if any standard Z Microsystems’ product fails within the fi rst 90 days after

shipping, the customer will receive a new replacement.

All non-standard* products are covered for one year under Z Microsystems’ Standard

Warranty that includes free parts and labor. However, the 90-day AirSpare Plan can be

purchased as an additional option for non-standard products.

1-90 days - Z AirSpare Service

• 91-365 days - Free Parts and Labor

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

*a non-standard product is a prototype or a product specifi cally designed or engineered

per a customer’s specifi cation

To return a defective product a customer can call the Z Microsystems Customer Service Department at 1- 858 -657-1000, ext. 232, or fi ll out the RMA Request Form on our

website. Please see the section in this manual titled, “Replacements” for details on how to

replace a part.

43

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Page 44

APPENDIX

Z Extended Warranty

Z Microsystems’ Extended Warranty Plan provides one and t wo year extended warranty

options under which a Standard Warranty is extended from the end of the fi rst year of the

Standard Warranty period.

The One-Year Extended Warranty period will begin on the day the Standard Warranty

expires and the Two-Year Extended Warranty begins when the One-Year Extended Warranty expires.

1-90 days - Z AirSpare Service

91-365 days - Free Par ts and Labor

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

2nd year - Free Parts and Labor

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

3rd year - Free Parts and Labor

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

44

Page 45

APPENDIX

Z Preferred Warranty

Z Microsystems provides a Preferred Service Plan under which Z Microsystems will repair

or replace and return a defective product to the customer within one week of Z Microsystems’ receipt of the defective product.

1-90 days - Z AirSpare Service

91-365 days - Free Par ts and Labor

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

• Guaranteed One Week Turnaround

2nd year - Free Parts and Labor

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

• Guaranteed One Week Turnaround

3rd year - Free Parts and Labor

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

• Guaranteed One Week Turnaround

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

45

Page 46

APPENDIX

Z Airspare Warranty

Z Microsystems provides an AirSpare Service Plan that will replace a defective product,

within the fi rst year of the warranty period, with a new product the following business day.*

The AirSpare Service Plan does not cover special order items. A product may be deemed

a special order item at the discretion of the Customer Service Depar tment. Z Microsystems, at its discretion, may offer the AirSpare Service Plan to a customer who purchases

a special order item at the one-year rate.

*Z Microsystems cannot guarantee next day deliver y if contacted after 2:00 PM Pacifi c

Time. Calls on Fridays or before holidays will receive a new product the following business day.

1st Year - 24 hour replacement

• 9-5 EST telephone technical assistance

• Online technical help

• Email product updates

2nd Year - 24 hour replacement

• 9-5 EST telephone technical assistance

• Online technical help

• email product updates

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

46

Page 47

APPENDIX

Z On-Site Service

Z Microsystems also provides on site service and consultation to customers who require Z

Microsystems’ technical exper tise.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

47

Page 48

APPENDIX

Disclaimer

Z Microsystems warrants that every product is free from defects in materials, workmanship and conforms to Z Microsystems’ stringent specifi cations.

Z Microsystems calculates the expiration of the warranty period from the date the product

is shipped. This means that the ship date on your invoice is your product ship date unless

Z Microsystems informs you otherwise. During the warranty period, Z Microsystems will

provide warranty service under the type of warranty purchased for the product.

Replacement parts will assume the remaining warranty of the parts they replace. If a

product does not function as warranted during the warranty period, Z Microsystems will

repair or replace the part (with a product that is as a minimum functionally equivalent)

without charge.

If the product is transferred to another user, the warranty service is available to that user

for the remainder of the warranty period.

Z Microsystems’ warranties are voided if the covered product is damaged due to an accident or abuse. The warranty is voided if the product is shipped in suffi cient packaging.

Under no circumstances is Z Microsystems liable for any of the following:

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This warranty gives

you specifi c legal rights and you may also have other rights that vary from jurisdiction to

jurisdiction.

Warranty does not take effect until full payment is received by Z Microsystems.

1. Third-par ty claims against you for losses or damages,

2. Loss of, or damage to, your records or data, or

3. Economic consequential damages (including lost profi ts or savings) or

incidental damages, even if Z Microsystems is informed of their possibility.

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

48

Page 49

APPENDIX

CUSTOMER SUPPORT

NOTE: For image problems, run

AUTO SETUP again before

consulting this section. In most

cases, AUTO SETUP can fi x

the problems. See the Auto

Setup section for details.

NOTE: If possible, stay by the computer.

e Z Microsystems Technical

Support Representative may

wish to go through the problem

over the telephone.

If you are unable to correct the problem

yourself, contact:

NOTE: More help, late-breaking

news and details of the

latest accessories for these

products may be found on the

worldwide web at:

http://www.zmicro.com

49

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

Z Microsystems at:

(858) 657-1000

Fax: ( 858) 657-1001

Website: www.zmicro.com

Before calling, please have available as

much of the following information as possible:

1. Model and serial number from the

label on the monitor

2. Purchase P.O.

3. Description of problem

4. Computer type and model

5. System configuration (hardware fitted, etc.)

6. System BIOS version number

7. Operating System and version

number

8. Display driver version number

9. Video Adapter Type

Page 50

APPENDIX

CUSTOMER FEEDBACK

We value feedback on our products, their per formance, problems found, and welcome all

constructive suggestions. Please send such productive information in writing to:

Customer Service

Z Microsystems

5945 Pacifi c Center Blvd., Suite 505

San Diego, CA 92121

or www.zmicro.com

Doc # 27-00 30UM Rev 1.0 Issued 12 /04

50

Page 51

Z Microsystems, Inc.

5945 Pacifi c Center Blvd., Suite 505

San Diego, CA 92121

Phone: (858) 657-1000

Fax: ( 858) 657-1001

Website: www.zmicro.com

Copyright 2005 Z Microsystems, Inc. All Rights Reserved

Loading...

Loading...