Page 1

COMMAND

CONSOLE

FIELD-READY

14

User Manual

Doc# 27-0001UM Issued 7/99 Rev. 1.2

Z Microsystems

Page 2

Regulatory

FCC INFORMATION

1. Use the power and

video cables supplied

with the Command

Console to help

prevent interference

with radio and

television reception.

The use of cables

and adapters may

cause interference

with electronic

equipment in the

vicinity of this unit.

2. This equipment has

been tested and

found to comply with

the limits for Class

A digital devices,

pursuant to certain

limits imposed by

Part 15 of the FCC

rules. These limits are designed to provide

reasonable protection against harmful

interference in when equipment is operated in

COMMAND

CONSOLE

14

commercial

environments. This

equipment generates,

uses and can radiate

radio frequency

energy, and, if not

installed and used in

accordance with the

instruction manual,

may cause harmful

interference to radio

communications.

3. Operation of this

equipment in a

residential area is

likely to cause

interference in which

case the user will be

required to correct the

interference at his

own expense.

Changes or modifications not expressly

approved by Z Microsystems could void

users authority to operate the equipment

Doc# 27-0001UM Issued 7/99 Rev. 1.2

2

Page 3

Contents

STARTING POINT 4

Shipment Contents 4

User Manual 4

System Requirements 4

Product Description 5

PREPARATION 6

INSTALL RAILS 7

INSTALL CONSOLE 8

FINAL ADJUSTMENTS 9

CABLES 9

SETUP 11

Closing Console 12

OPERATION 13

MONITOR ADJUSTMENTS 14

REFERENCE 18

TROUBLESHOOTING 20

SPECIFICATIONS 22

APPENDICES 23

SUPPORT 24

Further Help 24

Replacing Parts 25

Providing Feedback 25

Y2K Compliance 26

DRAWINGS 27

HARDWARE INSTALLATION 29

Doc# 27-0001UM Issued 7/99 Rev. 1.2

3

Page 4

SHIPMENT CONTENTS

The Command Console shipping box

contains the following:

The Command Console Unit

Video Signal Cable

AC/DC Power Supply Brick with

attached DC cable

AC Power Cable

Setup Diskette

User Manual

Remember to save your original

shipping container and packing

material to transport or ship the

Command Console.

The User Manual comes in two

formats: printed hardcopy or CDROM. This Manual is also available

on the Z Microsystems website

(www.zmicro.com).

We recommend you read this manual

as follows:

Carefully follow the instructions in the

Installation and Testing chapter for

hookup and initial control settings.

Refer to the Operation chapter for a

complete description of all the user

controls, and the Maintenance and

Troubleshooting chapters for care and

correcting any unforeseen problems

with the system. The Appendices and

References chapters are provided for

quickly finding technical information

about the Command Console.

SYSTEM REQUIREMENTS

The Command Console works with

any computer system that provides

industry standard screen formats from

640 x 480 to 1024 x 768, with up to

75 Hz vertical sync. See the Specifications Table of this Manual for a

complete listing of all resolutions

supported.

The Command Console requires a

computer with a suitable onboard

subsystems for Video Adapter Card

that can support XGA 1024 x 768,

SVGA 800 x 600, or VGA 640 x 480

at 60 Hz

Doc# 27-0001UM Issued 7/99 Rev. 1.2

4

Page 5

PRODUCT DESCRIPTION

The Command

Console provides

a liquid crystal

display, a desk

work surface and

storage for any

size keyboard

and mouse in a

3.5" high (2U)

standard 19"

rack or transit

case.

The lightweight and durable aluminum construction provides exceptional

strength in field applications.

The high quality LCD screen provides

full color and features up to 1024 x

768 pixel resolution.

The LCD screen has a backlight

control that reduces power and

extends the life of the monitor.

The side-viewing angle is up to 160

degrees. It can be easily adjusted to

Specially designed locks on

each side of the

Command

Console hold the

compact folded

unit securely in

place during

storage.

Release of the

two Z-Locks on

the front sides of

the Console

allow it to slide

out and the LCD

display to quickly

swing up into a

reading position

any vertical-viewing angle up to 100

degrees. The display works effectively

with any workstation.

An electrostatically-applied and

baked-on finish is used for extreme

durability for shipboard, airborne,

field deployments, and industrial or

lab applications where weight and

size are very critical.

By lifting up the

desktop, the

keyboard and

mouse can be

easily removed

and set on top.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

5

Page 6

Starting Point

TOOLS REQUIRED

DANGER: To avoid shock hazard:

Do not remove the covers around

the Command Console.

Do not connect or disconnect the

Command Console during an

electrical storm.

The power cord plug must be

connected to a properly wired

and grounded power outlet.

Any equipment to which the

Command Console will be

attached must also be connected

to properly wired and grounded

power outlets.

Required Tools and Equipment

Flathead screwdriver with about 10"

shaft.

Phillips screwdriver with about 10"

shaft.

Computer Setup Diskette

PRECAUTIONS

NOTE: For the fastest and easiest

installation of the

Command Console, follow

these steps in the sequence

they are presented.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

In preparation to install the Command Console, take the following

precautionary steps:

Turn off the electrical power to your

computer.

Verify the Command Console power

switch is off. If the Console is off, the

light will not be illuminated.

6

Page 7

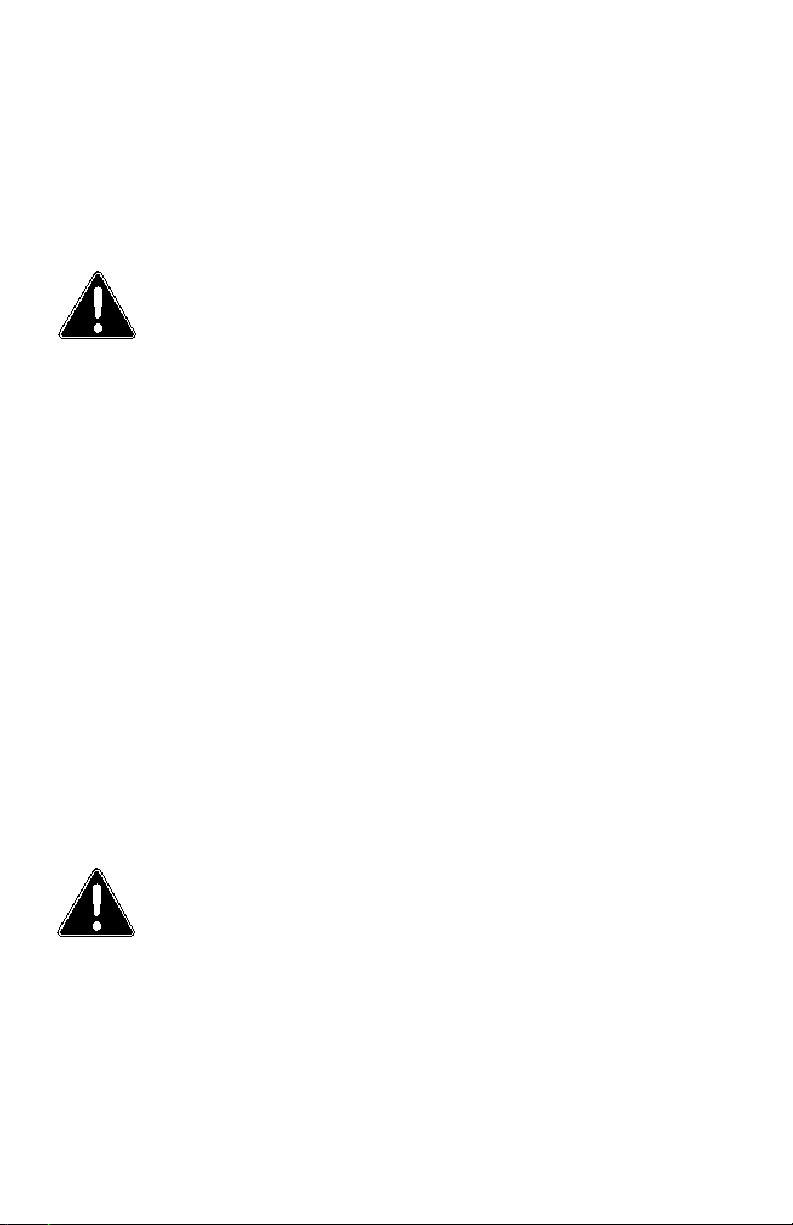

SLIDE REMOVAL

Install Rails

With the Console sitting

on a workbench with the

front facing towards

you, press down to

release the Z-Locks on

each side of the front of

the Console to slide the

side rails back.

The slide rail will reach

a stop about half way

back.

This is a safety stop to

prevent the Console

sliding out too far while

mounted to the rack.

Simultaneously press in

the safety catches on

each slide rail and slide

the side rails all the way

off the back of the

Console.

The slides should now

be separated from the

Console.

Each slide unit includes

the slide rail, with the

front Z-lock mount and

the rear mount.

INSTALL THE SLIDES IN THE CABINET FRAME

On the front of the

cabinet frame, use three

Phillips screws ((V) see

page 30 - Install

hardware ) on each side

to secure the right and

left Z-Lock mounts.

DO NOT tighten these

screws to allow for

adjustment of the

Console within the

cabinet frame.

On the rear of the

cabinet frame, use the

three Phillips screws ((W)

see page 30 - Install

hardware) to loosely

secure the right and left

rear slide mount to the

cabinet frame.

DO NOT tighten these

screws fully at this time.

On the slide rails, using

a slot screwdriver,

loosen off the slide

extension rail screw ((U)

see page 30 - Install

hardware ). Repeat on

each side.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

7

Page 8

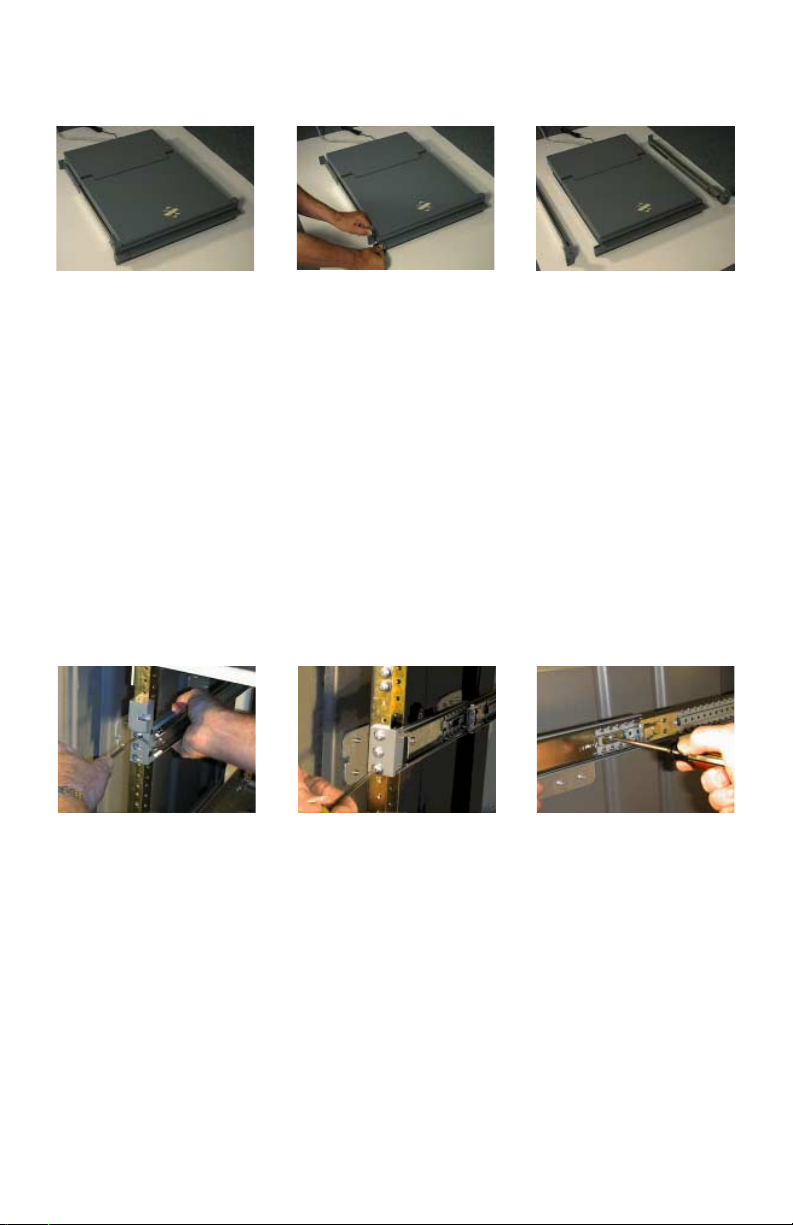

Install Rails

Go back on the rear of

the cabinet frame, and

fully tighten the three

Phillips screws ((W) see

page 30 - Install

hardware) holding the

slide extension rail to

the cabinet frame.

Make sure you hold the

slide mounts hard

against the rack rail.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

8

Page 9

Install Console

INSTALL THE COMMAND CONSOLE IN THE SLIDES

Pull the two Console

slides out until they lock.

Hold the Console by

each side, with the front

toward you.

Feed the four cables

coming out of the

Console back through

the cabinet frame.

Guide the Console into

the slides and slide the

Console in until it stops.

Simultaneously press in

the catches on each

slide and slide the

Console all the way into

the cabinet frame.

The Console should

slide in and out easily.

TEST INSTALLATION AND MAKE ADJUSTMENTS

Slide the Console in

and out several times.

The Console should

easily close completely.

Because of variances in

cabinet frames, there

may need to be some

adjustments of the

Console slide system for

best fit and movement

of the Console in and

out.

To be sure the slide and

mount assembly are

aligned properly, slide

the Console in and out

several times.

If the Console binds

during sliding, do the

following:

Doc# 27-0001UM Issued 7/99 Rev. 1.2

9

Page 10

Install Console

FINAL ADJUSTMENTS OF THE COMMAND CONSOLE

Loosen the screws on

each of the front Z-Lock

mounts.

Slide the Console

partially out.

Use a flathead screw

driver to slightly move

the Z-Locks out away

from the Console.

Tighten all the screws on

the front Z-Lock mounts.

Slide the Console in and

out to see if it moves

smoothly.

Go back to the rear of

the rack and fully

tighten the slide

extension rail screw ((U)

see page 30 - Install

hardware ).screws.

Note: A wrench may be

necessary to hold the

nut on the other side.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

10

Page 11

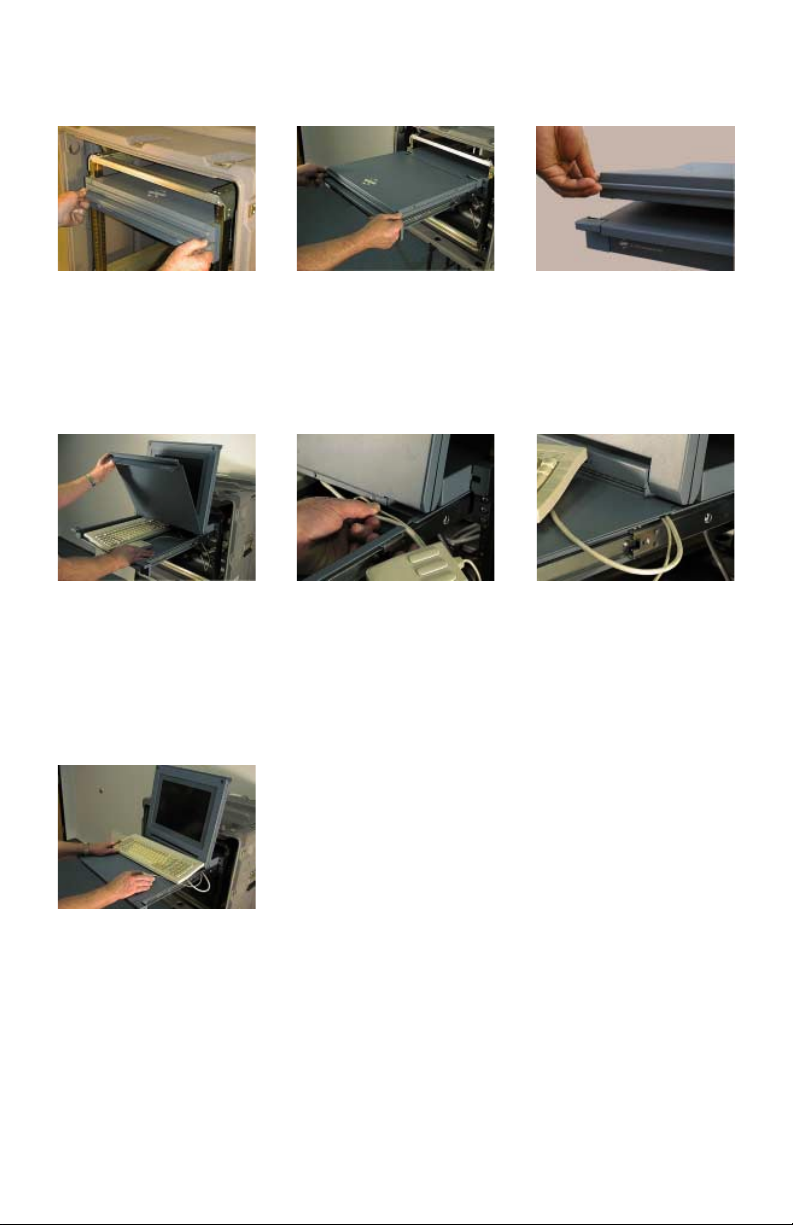

Setup

SETTING UP THE MONITOR KEYBOARD AND MOUSE

With both hands, press

both the Z-Locks down

and

Open the storage tray

top.

Remove the keyboard

and mouse.

Slide the Console all

the way out.

Align the Keyboard and

Mouse cable to pass

through the recessed

access notch.

Using both hands,

gently lift the Console

screen by the top bar.

Close the storage tray

top, then place the

keyboard and mouse on

top of the tray door.

The storage tray door

now becomes a

workstation for the

keyboard and mouse.

There should be ample

cable to both units for

movement around the

workstation.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

11

Page 12

Closing Console

CLOSING DOWN THE MONITOR

Remove the keyboard

and mouse from top.

Open the storage tray

top.

Slide the Console in

with both hands.

Place the keyboard and

mouse inside the tray

along with all cables

and close door.

Press both the Z-Locks

down and slide in the

console until you hear

the positive click from

the lock.

Using both hands,

gently drop the Console

screen by the top bar

until it lays flat.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

12

Page 13

Switch the Console

monitor on by pushing

and releasing the power

switch marked.

Turn on the monitor and

then the computer.

Operation

Doc# 27-0001UM Issued 7/99 Rev. 1.2

13

Page 14

Monitor Adjustments

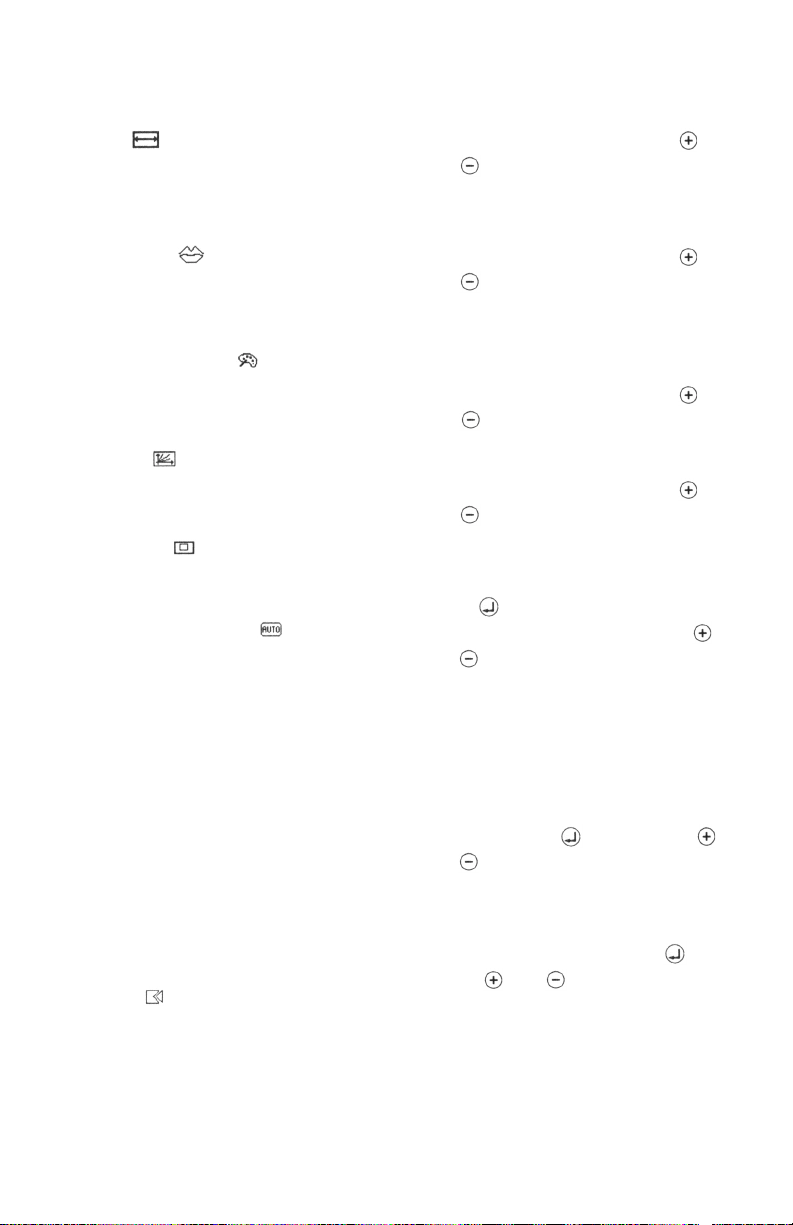

ON-SCREEN DISPLAY

The LCD monitor features an OnScreen Display (OSD) with menus

designed to make adjusting the

monitor display settings easier. When

highlighted, the icons illustrate the

control function to assist in identifying

which control needs adjustment.

Before activation of the OSD menu,

the Enter button

automatically adjust the display to the

proper size and horizontal and

vertical position. The monitor must be

set to one of the 15 factory preset

timing modes to utilize this feature.

The OSD menu activates automatically when the Enter button on the

rear of the monitor is pressed. The

OSD remains centered on the screen

while the adjustments are made. Use

either the or button to move the

highlight to the control to be selected.

A submenu or the control with a status

bar will appear. From the factory

can be used to

preset, the status bar indicates in

which direction the adjustments are

being made. Use the or button

to adjust the control. In addition, a

second control icon will appear

allowing to toggle between the two

controls.

The contrast and brightness can also

be adjusted by simply pressing either

the or button.

When you have finished making

adjustments, press the button to

save the setting and exit back to the

main menu. If the buttons are left

untouched for 15 seconds, the settings

will be automatically saved and

exited. While in the main menu,

pressing the button will save and

exit the OSD.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

14

Page 15

Monitor Adjustments

MENU DESCRIPTIONS

AUTO ADJUSTMENT

NOTE: This item must operate on

full screen image. If it does

not, it is possible to operate

abnormally.

CONTRAST

BRIGHTNESS

H-POSITION

(HORIZONTAL POSITION)

V-POSITION

(VERTICAL POSITION)

TUNING & FINE TUNING

Select this control to adjust the size

and position automatically. It takes a

maximum of 10 seconds to complete.

This control allows adjustments to the

black level of the display screen.

Selection of this control allows making

adjustments to the luminosity level of

the display screen.

Use this control and then use the

and buttons to center the image

horizontally on the screen.

Select this control and then use the

and buttons to center the image

vertically on the screen.

Select these controls, then use the

and buttons until the screen

images looks focused, crisp and

sharp.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

15

Page 16

Monitor Adjustments

MENU DESCRIPTIONS

H-SIZE

LANGUAGE

COLOR CONTROL

GAMMA

MOVE OSD

AUTO CALIBRATION

Select this control, then use the

and buttons to expand or

decrease the image width to horizon-

tally fill the display screen.

Select this control, then use the

and buttons to choose from:

English, German (Deutsch), Spanish

(Espanol), Italian (Italiano) or French

(Francais).

Select this control, then use the

and buttons to individually adjust

R, G or B color.

Select this control, then use the

and buttons, which allows

adjustment of the natural color tone.

Select this control, then use the ENTER

button

to move the OSD menu. Use the

and buttons to move the OSD

menu.

to select in which direction

CALIBRATION

VGA GRAPHICS

RECALL

Doc# 27-0001UM Issued 7/99 Rev. 1.2

This function requires the 3.5 diskette

provided with the Command Console.

When the Auto Calibration program

diskette is used, select this menu using

the ENTER button

and buttons to the setting ON.

When the 640x480 or 720x400

displays are displayed, select this

menu using the ENTER button,

use the

ON or OFF.

If the menu is operated, then the

current modes settings are all erased

and returned to the factory settings.

16

and buttons to set

, then use the

then

Page 17

Monitor Adjustments

AUTO CALIBRATION PROGRAM

This program cooperates with FPMC

firmware which automatically adjusts

and saves the panel settings, which

will fit each support mode. It takes

about 50 seconds for auto adjustment.

NOTE: In order to make it work

correctly, first set ON in

the OSD menu of the AUTO

CALIBRATION item.

Follow these steps to start the Auto

Calibration Program:

1. Insert the Auto Calibration diskette

into the 3.5 disk driver.

2. Drag the Auto Calibration file to

the Windows background on the

computer.

3. Set ON the Auto Calibration in

the OSD menu.

4. Select taskbar properties with Auto

Hide in the Windows OS.

5. Double click the Auto Calibration

icon in the background.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

17

Page 18

Reference

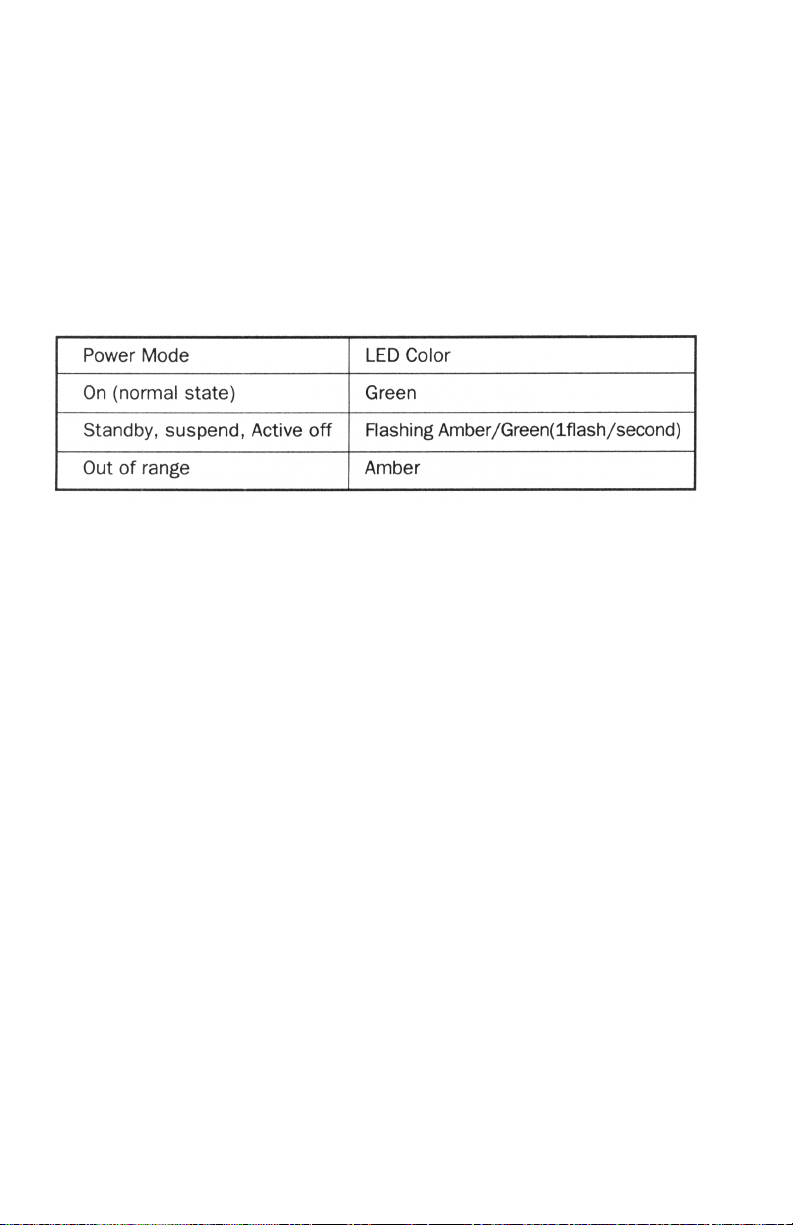

LED INDICATOR

The Power Management feature of the

LCD monitor is comprised of three

stages:

1. On (green)

2. Standby, Suspend or Active Off

(amber/green)

3. Out of Range (amber)

TIMING GUIDE

The monitor is a multi-frequency

monitor. It operates at horizontal

frequencies between 31.25KHz and

60.24KHZ, vertical frequencies

between 56Hz and 75Hz. Because of

its microprocessor-based design, it

offers auto-synchronization and autosizing capabilities. The monitor offers

15 pre-programmed settings that are

listed in the following table.

These preset modes cover most of the

common video modes supported by

popular graphics adapters. However,

each adapters implementation of

these video modes may vary slightly in

timing. If it is necessary to make

minor display adjustments (horizontal

and vertical position and horizontal

position), refer to the On-Screen

Display section of this manual for

instructions.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

18

Page 19

TIMING GUIDE

Reference

The monitor is not limited to these

preset factory-timing modes. In fact,

because the monitor is multi-scanning, it can accept any signal within its

frequency range of 31.25KHz -

60.24KHz horizontal and 56Hz -

75Hz vertical.

If it is desired to use one of the preset

timing modes, refer to the video card

manufacturers installation guide for

instructions on how to make these

changes. The video card controls the

refresh rate. Most video cards provide

software utility or hardware DIP

switches that allow to change the

frequency used for each resolution.

* If using Macintosh, need Mac adapter.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

19

Page 20

Troubleshooting

NO POWER Flip the Power switch ON. The

Power LED turns on.

Make sure the A/C power cord is

securely connected to the power

jack and to a power outlet.

Plug another electrical device (like

a radio) into the power outlet to

verify that the power outlet is

supplying the proper voltage.

POWER ON BUT NO SCREEN

IMAGE

FLICKERING

WRONG OR ABNORMAL COLORS

Make sure the video cable attached

from the monitor is tightly secured

to the video output port on the back

of the computer.

Adjust the brightness and contrast.

Not enough power is being

supplied to the LCD monitor.

Connect the LCD monitor to a

different outlet. If a surge protector

is being used, there may be too

many devices plugged in.

See Timing Guide Section of this

manual with a list of refresh rates

and frequency settings showing the

recommended setting for the LCD

monitor.

If any colors (red, green or blue)

are missing, check the video cable

to make sure it is securely connected. Loose pins in the cable

connector could cause a bad

connection.

Connect the LCD monitor to

another computer.

Check the graphics card for proper

sync scheme (or sync polarities) to

match the LCD monitors specifications.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

20

Page 21

Troubleshooting

DOUBLE (SPLIT) SCREEN IMAGE Make sure the graphics card is set

to Non-Interlaced mode.

ENTIRE SCREEN IMAGE ROLL

(SCROLLS) VERTICALLY

CONTROL BUTTONS DO NOT

WORK

NOTE: The LCD contains over

2,359,926 thin-film

transistors (TFTs). A small

number of missing,

discolored or lighted dots on

the screen is an intrinsic

characteristic of TFT LCD

technology and is not a LCD

defect. If a fixed pattern is

displayed for more than 10

hours, its image may

remain on the screen in

overlap mode when

something else is displayed.

Make sure the input signals are

within the LCD monitors specified

frequency range. (Maximum: VESA

1024x768/75Hz, MAC 1024x768/

75Hz)

Connect the video cable securely.

Try the LCD monitor with another

power source.

Press only one button at a time.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

21

Page 22

Specifications

Power 100 - 240 VAC, 47 - 63Hz, 1.2 A Max

Weight 26 lbs.

Colors 262,144

Viewing Angle L/R 45/45 Deg.

Up/Down. 15/35 Deg.

Refresh Rate 1024 x 768 @ 75 Hz Max

Display Area 284.9mm (H) x 213.7 mm (V)

Operating Temp. 0 to +40 Celsius

Storage Temp. -10 to +50 Celsius

22

Doc# 27-0001UM Issued 7/99 Rev. 1.2

Page 23

PIN ASSIGNMENT

Appendix

Doc# 27-0001UM Issued 7/99 Rev. 1.2

23

Page 24

Support

FURTHER HELP

If you are unable to correct the

problem yourself, contact:

NOTE: For image problems, run

AUTO SETUP again before

consulting this section. In

most cases, AUTO SETUP can

fix the problems. See the Auto

Setup section for details.

NOTE: If possible, stay by the

computer. The Z Microsystems

Technical Support Representative may wish to go through

the problem over the

telephone.

NOTE: More help, late-breaking news

and details of the latest

accessories for these products

may be found on the

worldwide web at: http://

www.zmicro.com

Z Microsystems at:

(858) 657-1000

Fax: (858) 657-1001

Website: www.zmicro.com

Before calling, please have available

as much of the following information

as possible:

1. Model and serial number from the

label on the monitor.

2. Purchase P.O.

3. Description of problem.

4. Computer type and model.

5. System configuration (hardware

fitted, etc.).

6. System BIOS version number.

7. Operating System and version

number.

8. Display driver version number.

9. Video Adapter Type.

Doc# 27-0001UM Issued 7/99 Rev. 1.2

24

Page 25

Replacing Parts

If the Z Microsystems Technical

Support Engineer determines that the

product needs to be replaced, a

Customer Service representative will

issue a Return Material Authorization

(RMA) number and return address.

An RMA number is required to return

a product to Z Microsystems, regardless of the reason for the return.

The following information is required

when returning Z Microsystems

products:

1. Model number

2. Serial number

3. Date of purchase

4. Proof of purchase (use the invoice

or packing slip)

5. Customer ship-to address and any

special shipping requirements

6. Specific and detailed description of

the problem

PROVIDING FEEDBACK

Doc# 27-0001UM Issued 7/99 Rev. 1.2

We value feedback on our products,

their performance, any problems and

constructive suggestions. Please send

such productive information in writing

to:

Customer Service

Z Microsystems

5945 Pacific Center Blvd., Suite 509

San Diego, CA 92121-4309

or www.zmicro.com

25

Page 26

Compliance

Y2K COMPLIANCE

Z Microsystems has achieved full Y2K Compliance.

In late 1997, the companys senior management assigned a Y2K Project Team

that consists of a cross-functional representation from information technology,

procurement, manufacturing, test and development, finance, general affairs,

engineering, marketing and facilities organizations to address the Year 2000

issues.

The Assessment/Rectification Phase of the Year 2000 efforts and full compliance

for all mission critical internal systems were accomplished as scheduled by the

end of Q1, 1999. Contingency development and validation of the companys

overall Year 2000 readiness will continue through 1999.

The following strategically important categories have been assessed for Year

2000 readiness:

Suppliers and Service Providers Readiness.

All major strategic suppliers are assessed to

be Year 2000 compliant. Most of the

companys service providers compliance

efforts will continue through 1999.

Major concerns and efforts will be focused

on the companys shipping companies in

1999.

Z Microsystems Internal Systems

All mission critical internal systems are

determined to be fully Year 2000 Compliant. A few minor Year 2000 Related issues

need to be addressed in 1999.

Z Microsystems Products

All Z Microsystems products are in full

compliance.

The company MIS has taken the lead and worked with the Finance Department

to develop comprehensive Year 2000 Contingency Plans for the company

mission critical application systems to assure the continuity of daily business.

26

Doc# 27-0001UM Issued 7/99 Rev. 1.2

Page 27

Drawings

Doc# 27-0001UM Issued 7/99 Rev. 1.2

27

Page 28

Drawings

Doc# 27-0001UM Issued 7/99 Rev. 1.2

28

Page 29

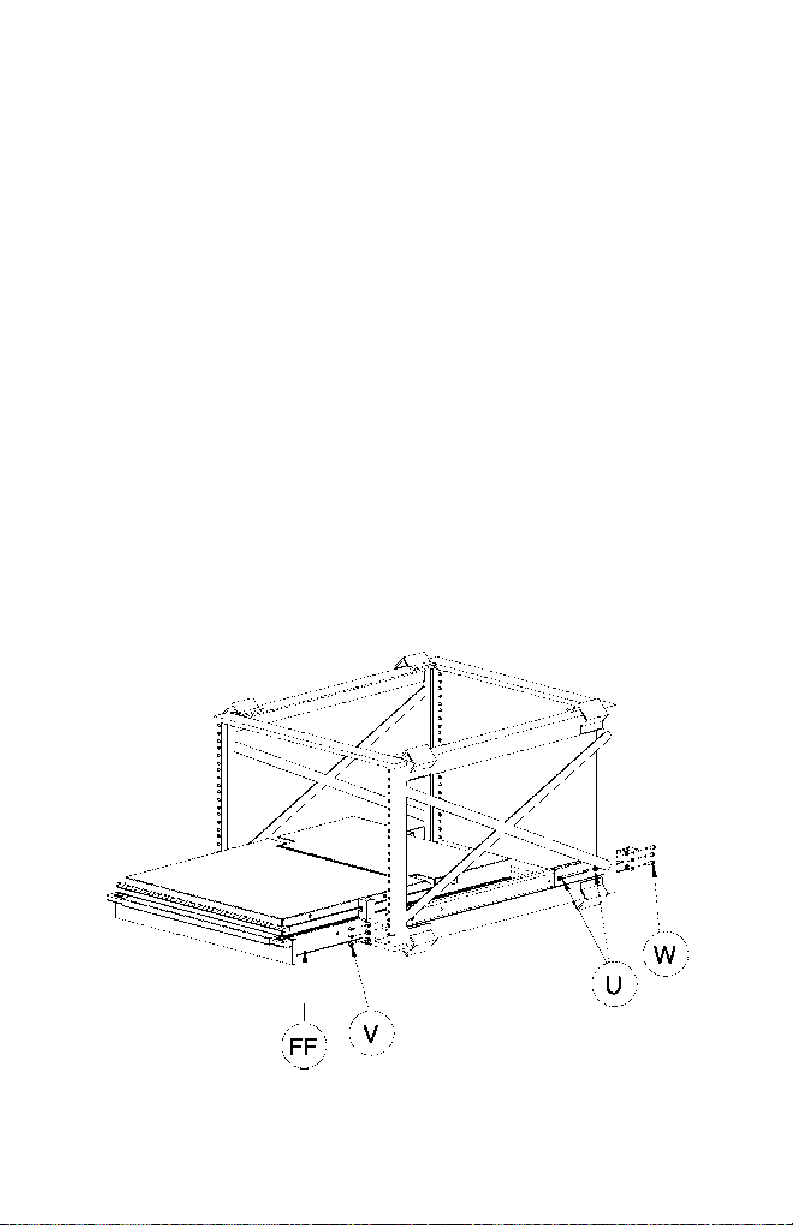

INSTALL HARDWARE

· Install the slide assemblies to the rack by installing three screws (V) to the

front and three screws (W) to the rear.

· Tighten the hex nuts (U) that were installed in the previous page.

· Install the command console (FF) into the rack slides.

U. 01-91802 Nut 8-32 Nylon Hex

V. 01-92087 Scr, 10-32 x .375 Low Hd

W. 01-92097 Scr, 10-32 x .625 Pan Hd

FF. Command Console

Doc# 27-0001UM Issued 7/99 Rev. 1.2

29

Page 30

Doc# 27-0001UM Issued 7/99 Rev. 1.2

Page 31

Doc# 27-0001UM Issued 7/99 Rev. 1.2

Page 32

Doc# 27-0001UM Issued 7/99 Rev. 1.2

Z Microsystems, Inc.

5945 Pacific Center Blvd., Suite 509

San Diego, CA 92121

Phone: (858) 657-1000

Fax; (858) 657-1001

Website: www.zmicro.com

Copyright 1999 Z Microsystems, Inc. All Rights Reserved

Loading...

Loading...