Page 1

EC10 & EX16 Quick Start Guide

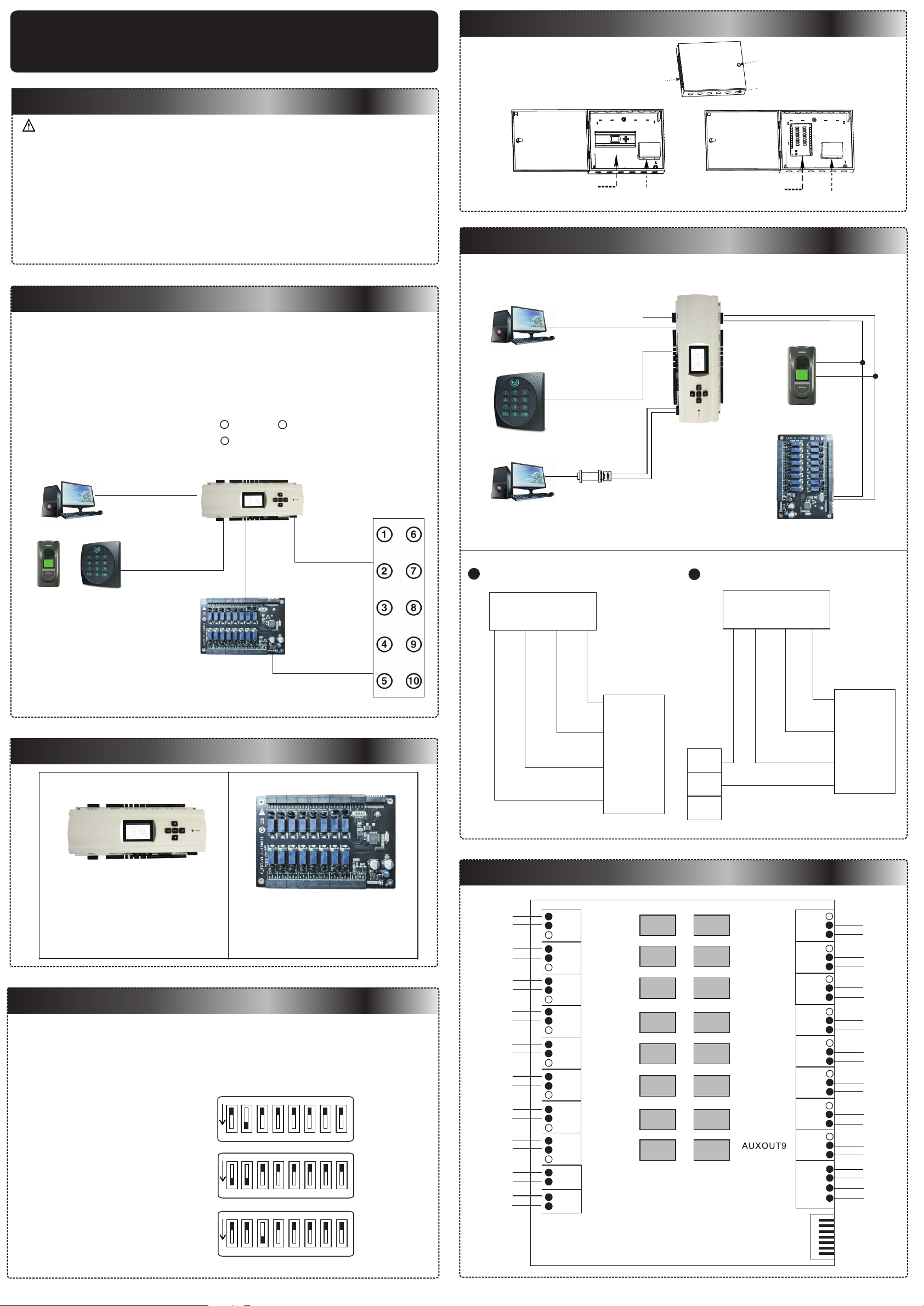

5.Appearance of case

Version:V1. 1 Date:2013. 7

1.Installation Precautions

Pay atten ti on to the fol lo wing safety i tems. Mis -o perations m ay cause huma n danger or

equipment f aults:

1) Befo re installa tion comple tes, do not pow er on the equip ment or perfo rm operatio ns

with elec tr icity.

2) Use dedica ted elevato r ethernet ca ble to connec t the elevato r controlle r and compute r.

Use 2pin co nt roller cabl e for the press b utton on each f loor.

3) Instal l th e card reader w ith a height of 1 .2 to 1.4 met er s.

4) Instal l th e elevator ma in controll er and expans ion board on th e elevator li ft car.

5) Instal l th e emergency b utton in the ma nagement ce nter or under t he elevator b utton.

.

2.System Introductions

The EC10 preven ts un authori ze d e levator -u sers from acces sing pre-def in ed restric te d f loors in

the bu ilding. T he EC1 0 (Ele va tor Control panel ) cont ro ls a ccess up t o 10 floors. Also avail ab le i s

the EX16 (E le vator Flo or E xpansion bo ard) which al lows for acce ss control of u p to 16 additio nal

floors. A maximu m three EX16 bo ards can be daisy-ch ained toge ther and collective ly con trol

access of up to 5 8 flo ors. In orde r to gain ac cess to a desired floor, authori zed u se rs mu st firs t

present eithe r a valid fing erprint and/o r RFID car d wh en ent ering the elevato r. For exam pl e, i f an

authorize d us er h as a ccess rights to only floo r and floor , the elevat or w ill not move if that

same user pre sses the elev ator button f or floor .

3

4

EC10 Elevat or Control Pa nel

10

Heat dissipation hole

1

313

10

1016

13131

21

1212

2

1

1

RS-485 EXT

WIEGAND 3 IN5

IN6

OUT5

OUT6

WIEGAND 4

IN8

IN7

OUT7

OUT8

p

Reset

q

IN3

WIEGAND 1

WIEGAND 2

IN4 OUT3

OUT1 OUT2

OUT4

POWER

IN1 IN2

3

1

151101 21 213131101 21 2

1

3

Contr oller P anel

Power S upply

Eleva tor Con tro l

Exten sion Bo ard

6.Wiring an Elevator Control System

Elevator Co ntrol Panel

DC 12V

TCP/ IP c onnect with P C

Wiegand Rea der

RS485-

RS485+

RS485 EXT-

RS485 EXT+

Key hole

Threading hole

Power S upply

Fingerpri nt Reader

TCP/ IP o r RS485

OR

Fingerpri nt

RFID Reader

Wiegand/R S485

Reader

3.Technical Specifications

EC10Technic al Specific ation

RS485

Button- co ntrolled

EX-16 Flo or E xpansion Bo ard

EX16Technic al Specific ation

Button- co ntrolled

Elevator Fl oor Butto ns

Floor Exp an sion Board

Typica l El evator Wi ring Diag ra m EC10/EC16 E levator Wiring Diagr am

Elevator sy stem

Elevator Bu ttons con tr olled line

GND

LED+

LED-

Elevator sy stem

Elevator Bu ttons con tr olled line

LED-

GND

LED+

Elevator

Elevator

Buttons

Controlle d

Panel

NC

Buttons

Controlle d

Panel

COM

Fl oo r bu tt on c on tr ol r el ays: 10

Ca rd c ap ac ity: 30,000

Fi ng erprint capac it y: 3 ,0 00

Ev en t ca pa city: 100,000

Po we r su pp ly: 12V DC 1 A

Co mm unication : TC P/ IP, Rs 48 5

Su pp or ted flo or e xpansion

bo ar d: 3pcs

Floor butto n control rel ays: 16

Communica tion to EC10 pa nel: RS485

Power suppl y: 12V DC 1A

4.EX 16 DIP Switch Settings

DIP swi tc hes 2-4 are u se d to set each E X1 6 Floor Ext en sion Boar d' s unique de vi ce addres s us ing

RS485 commu nication. Please kee p th e EX16 powe re d off bef ore setting t he device add ress. Each

device addr ess needs to be u nique. See ex ample below :

RS485 Devic e address 2

RS485 Devic e address 3

O

N

1 2 3 4

O

N

1 2 3 4

5 6 7 8

5 6 7 8

K

E

K

E

7. EX16 Elevator Wiring Diagram

18#Outp ut

17#Outp ut

16#Outp ut

15#Outp ut

14#Outp ut

13#Outp ut

12#Outp ut

11#Out put

Backup

Output

DC 12V

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

GND

STAT

GND

+12V

AUXOUT8

AUXOUT7

AUXOUT6

AUXOUT5

AUXOUT4

AUXOUT3

AUXOUT2

AUXOUT1

I N D

POWER

NO

AUXOUT1 6

AUXOUT1 5

AUXOUT1 4

AUXOUT1 3

AUXOUT1 2

AUXOUT11

AUXOUT1 0

EXT

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

+12V

GND

485485+

26#Outp ut

25#Outp ut

24#Outp ut

23#Outp ut

22#Outp ut

21#Outp ut

20#Outp ut

19#Outp ut

12VOutp ut

RS485

RS485 Devic e address 4

O

N

1 2 3 4

5 6 7 8

K

E

EX-1 6

Page 2

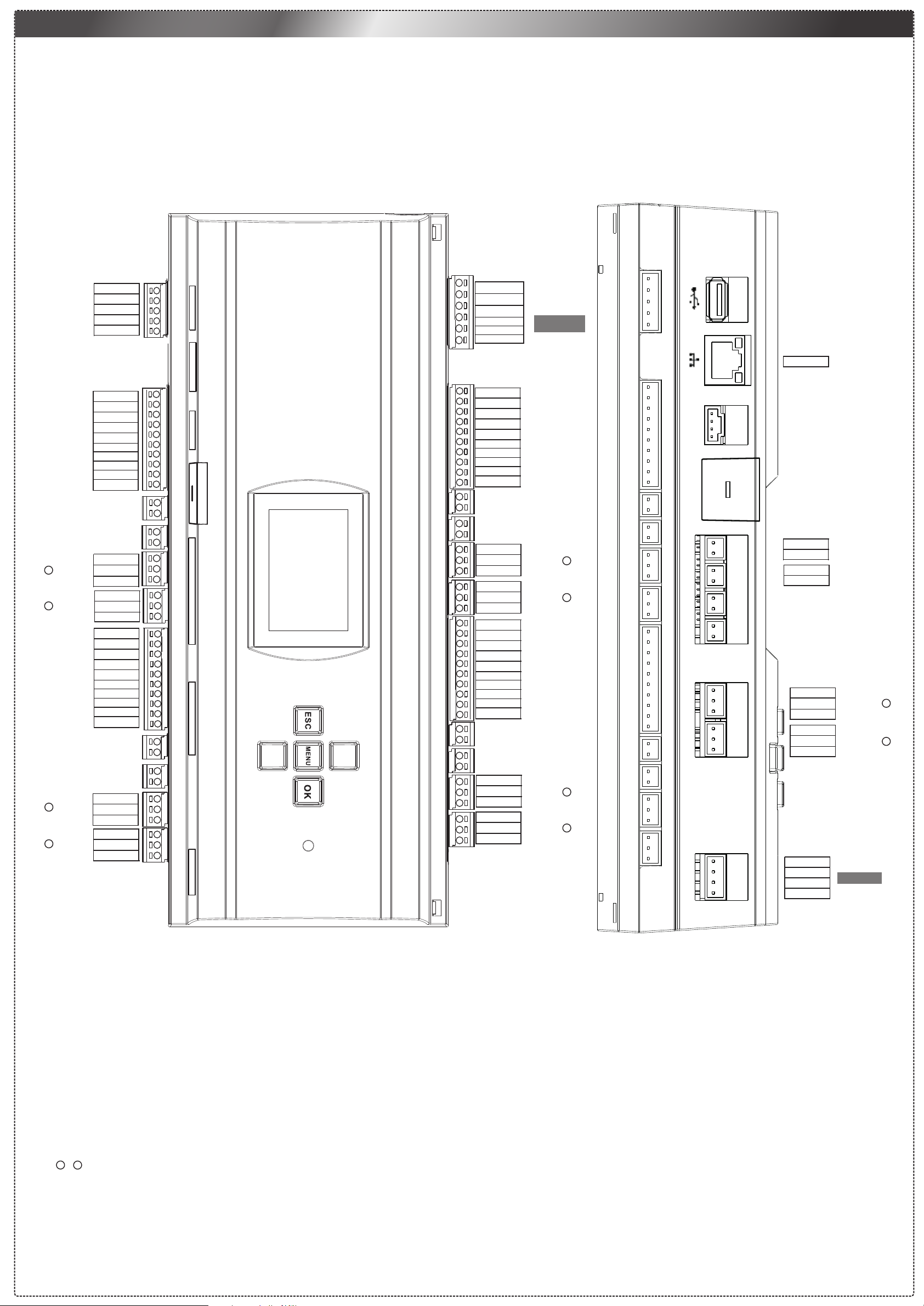

8.EC10 Wiring Terminals Connection

Notes:

1) The backup input is reserved for the elevator control system.

2) Fire linkage and emergency button function require no software settings. These functions are available when the hardware is installed.

3) GPRS, WIFI and functions marked by * are optional. If these functions are required, contact our business representatives or pre-sale technical support.

4) " # " indicates f loor , " 1# o ut put" in dicates t ha t it is conne ct ed to the fir st f loor butt on , the first e xp ansion bo ar d is connec te d to the 11t h fl oor butto n.

12V Power Input

Shield Wire

AC Fail Detection

*

Battery Fail Detection

*

12V Power Output

Wiegand Input

Sheild Wire

Green

Output

{

Controlled Reader Hold

*

Card Present

*

Red

Beep

+12V

{

GND

Shield

AC Fail

Battery Fail

VCC 12V

{

GND

D0

{

D1

Shield

LED_G

LED_R

BEEP

Hold

Card_present

1

POWER

5

1

WIEGAND 1

10

1 2 1 2 1

IN1 IN2

Front View

6

RS-485 EXT

1

10

WIEGAND 3

1

IN5

Data_Tx-

Data_Tx+

GND

Data_RxTxData_RxTx+

Shield

Card_present

Hold

BEEP

LED_R

LED_G

Shield

D1

D0

GND

VCC 12V

RS 422 Send

}

*

Extension Board

*

or SR 485 Reader

}

*

Shield Wire

Card Present

*

Controlled Reader Hold

*

Beep

Red

Green

Shield Wire

Wiegand Input

}

12V Power Output

}

Output

Front Side View

*

TCP/IP Comm.

RS-232

TCP/IP

1 4

1# Output

1

2

2# Output

12V Power Output

Wiegand Input

Shield Wire

Green

Output

Red

{

Beep

Controlled Reader Hold

*

Card Present

*

3

3# Output

4# Output

4

NO

COM

{

NC

NO

COM

{

NC

VCC 12V

{

GND

D0

{

D1

Shield

LED_G

LED_R

BEEP

Hold

Card_present

NO

COM

{

NC

NO

COM

{

NC

OUT1 OUT2

3

1

3

1

WIEGAND 2

10

1 2 1 2

IN3

IN4 OUT3

1

3

1

OUT4

3

q

Reset

p

IN6

1212

3

OUT5

1

3

OUT6

1

10

WIEGAND 4

21

IN7

1

2

IN8

1

3

OUT7

1

3

OUT8

1

NC

COM

NO

NC

COM

NO

Card_present

Hold

BEEP

LED_R

LED_G

Shield

D1

D0

GND

VCC 12V

NC

COM

NO

NC

COM

NO

5# Output

}

6# Output

}

Card Present

*

Controlled Reader Hold

*

Beep

Output

Red

}

Green

Shield Wire

Wiegand Input

}

12V Power Out

7# Output

}

8# Output

}

IN9

5

6

7

8

2

IN10

1 21 21 21

IN12IN11

OUT9

1

3

OUT10

1

3

1 4

RS-485

Analog_input

GND

Analog_input

GND

NO

COM

NC

NO

COM

NC

Shield

RS 485RS 485+

GND

Fire Linkage Input

Emergency button Input

9# Output

10# Output

Shield Wire

RS485 Comm.

}}

RS485 Ground

10

*

*

*

9

Notice:

1. Open the elevator press button panel when connecting to the elevator button. Ask the supplier to provide the floor button control circuit. If the supplier can not provide the circuit, exclude the incorrect circuit one

by one and ensure the correct connections.

2 . EC10 connects to the computer using TCP/IP or RS485.

3. EC10 suppo rts ZK fing er print rea de rs (model FR1 200) and RFID c ard readers ( model KR seri es).

4 . EC10 controls access up to 10 , EX16 floors controls access up to 16 floors. An EC10 carries a maximum of 3 expansion boards. Total 58 floors can be controlled when combining EC10 with EX16.

5. The RS 48 5 device ad dr ess of the fi ng erprint r ea der (mode l FR 1200) mus t be 1 . The RS4 85 d evice add re ss of the EX1 6 fl oor exten si on board mu st s tart from 2 .

6. Wiegand re ader can conn ect to the elev ator main con troller Wie gand 1#~ 4#.

7. IN9 func ti ons as fire l in kage signal i nput. When fi re linkage si gnal works, e levator con trol system s tops workin g and the eleva tor retains t o original st atus. (Fire l inkage must b e passive dry c ontact sign al)

8. IN10 fun ct ions as an emer gency butto n. When it is pre ssed, the w ho le elevator i s not control led by elevat or controll er. At this momen t, up and down bu ttons are ava ilable. Whe n the emergen cy button is

not pressed , the elevato r retains to th e original st atus.

1

10

9. ~ Output t er minals co nn ect to floo r pr ess butto n.

Loading...

Loading...