Page 1

INSTALLATION, OPERATION

AND TROUBLESHOOTING

MM9000 - CLEAR COMMAND USER MANUAL

MARINE PROPULSION SYSTEMS

Page 2

2 EN 3340.758.003a - 2014-11

COPYRIGHT

Released by After Sales dept.

Data subject to change without notice. We decline all responsibility for the use of non-original components or accessories wich

have not been tested and submitted for approval.

ZF reserves all rights regarding the shown technical information including the right to le industrial property right applications and the industrial property rights resulting from these in Germany and abroad.

© ZF Friedrichshafen AG, 2014.

Page 3

3

EN 3340.758.003a - 2014-11

TABLE OF CONTENT

MM9000 ClearCommand User Manual

Table of Contents

Table of Contents

Installation, Operation and Troubleshooting Manual

SW15623.OE

ClearCommand User Manual.......................................................... 1

Table of Contents................................................................................. 3

List of Figures....................................................................................... 7

List of Tables ...................................................................................... 13

Revision List ....................................................................................... 15

Preface ............................................................................................... 17

1 Introduction........................................................................................ 21

1.1 Basic Theory of Operation ...............................................................................................................21

1.2 System Features ..............................................................................................................................26

2 Operation ........................................................................................... 27

2.1 DC Power On ...................................................................................................................................27

2.2 Taking Command.............................................................................................................................27

2.3 Basic Operation ...............................................................................................................................28

2.4 Start Interlock (if used)....................................................................................................................29

2.5 Station Transfer ...............................................................................................................................30

2.6 Proportional Pause ..........................................................................................................................30

2.7 Warm-up Mode................................................................................................................................31

2.8 High/Low Idle ..................................................................................................................................32

2.9 One Lever Mode (Twin Screw) ........................................................................................................33

2.10 Engine Synchronization (Twin Screw).............................................................................................35

2.11 Control System’s Configurability .....................................................................................................37

2.12 Audible Tones ..................................................................................................................................39

2.13 Push Button Set Up .........................................................................................................................41

2.14 Visual System Diagnostics, Set Up And Status Indication ..............................................................41

2.15 Pluggable Connections....................................................................................................................42

2.16 Optional Features Operation ...........................................................................................................43

3 Plan the Installation ........................................................................... 45

3.1 System Requirements......................................................................................................................45

3.2 Installer Supplied Tools And Parts...................................................................................................50

3.3 DC Power Source ............................................................................................................................51

Page 4

4 EN 3340.758.003a - 2014-11

TABLE OF CONTENT

MM9000 ClearCommand User Manual

Table of Contents

4 Installation .........................................................................................53

4.1 Processor.........................................................................................................................................53

4.2 Control Head(s) ...............................................................................................................................53

4.3 Wire Harness Installation ................................................................................................................53

4.4 Hard-Wired Cable ............................................................................................................................58

4.5 Engine Stop Switches......................................................................................................................73

4.6 Push-Pull Cable Connections...........................................................................................................74

5 Set up Procedure ............................................................................... 77

5.1 Processor Components Used In Set Up ..........................................................................................77

5.2 Activating Set Up Mode...................................................................................................................80

5.3 Storing Values To Memory ..............................................................................................................80

5.4 Set Up Function Codes And Values .................................................................................................80

5.5 Field Service Test Unit (Break-out Box) and Multimeter Use..........................................................85

5.6 System Programming And Adjustments..........................................................................................86

5.7 Function Code E1 – Throttle in Neutral ...........................................................................................91

6 Dock Trials ....................................................................................... 113

6.1 Control Heads (Engines Stopped) .................................................................................................113

6.2 Start Interlock (Engines Stopped) .................................................................................................113

6.3 Engine Stop Switches....................................................................................................................113

6.4 Push-Pull Cables ............................................................................................................................113

6.5 High Idle ........................................................................................................................................113

6.6 Control Head Servo Command ......................................................................................................114

6.7 Control Head Solenoid Command .................................................................................................114

6.8 Throttle Pause Following Servo Shift ............................................................................................114

6.9 Throttle Pause Following Solenoid Shift .......................................................................................114

6.10 Trolling Valve .................................................................................................................................115

7 Sea Trials..........................................................................................117

7.1 Full Speed Setting - Servo Throttle................................................................................................117

7.2 Full Speed Setting - Electronic Throttle.........................................................................................117

7.3 Proportional Pause ........................................................................................................................117

7.4 Synchronization Test (Twin Screw Only).......................................................................................119

7.5 Sea Trial Report .............................................................................................................................124

F-226 9000 Series Sea Trial Report ................................................................................. 125

8 Control Options................................................................................ 131

8.1 External Alarm Capability ..............................................................................................................131

Page 5

5

EN 3340.758.003a - 2014-11

TABLE OF CONTENT

MM9000 ClearCommand User Manual

Table of Contents

8.2 Clutch Pressure Interlock ..............................................................................................................132

8.3 Station Expander (SE) ....................................................................................................................133

8.4 9001 Actuator Trolling Valve Control.............................................................................................134

9 Periodic Checks and Maintenance ..................................................135

9.1 Control Heads ................................................................................................................................135

9.2 Processor.......................................................................................................................................135

9.3 Power Supply.................................................................................................................................135

10 Troubleshooting ............................................................................... 137

10.1 General ..........................................................................................................................................137

10.2 Troubleshooting Questions............................................................................................................143

10.3 Troubleshooting Problem Resolution ............................................................................................144

10.4 Troubleshooting Diagnostic Menu ................................................................................................145

10.5 Troubleshooting Audible Tones .....................................................................................................148

10.6 Troubleshooting Station Transfer ..................................................................................................154

10.7 Troubleshooting Stuck Transfer Button.........................................................................................156

10.8 Error Codes....................................................................................................................................156

10.9 Basic Problem Causes And Solutions............................................................................................160

10.10 Problems Without Error Codes......................................................................................................172

10.11 Synchronization Troubleshooting ..................................................................................................175

10.12 Troubleshooting Wire Harnesses ..................................................................................................179

10.13 Processor Pigtails ..........................................................................................................................193

11 Appendix A - System Components and Specifications.................... 197

MMC-280 400 Series Control Head Variations................................................................ 199

MMC-329 MC2000 Series Standard Control Head Variations......................................... 205

MMC-307 700 Series Standard Control Head Variations ................................................ 209

MMC-279 400 Series Weather Mount Enclosure ............................................................ 215

Deutsch Connector Assembly.......................................................................................... 217

S-214 Automatic Power Selector Model: 13505 ............................................................. 219

Drawing 11488 DC Power Source Kit .............................................................................. 221

MMC-287 Grounding (Bonding) ...................................................................................... 231

MMC-288 References and Parts Source ......................................................................... 233

SER-161 Engine Tach Sender Req. .................................................................................. 235

MMC-289 Morse Clutch and Throttle Kit......................................................................... 237

MMC-290 Universal Mounting Kit ................................................................................... 239

MMC-345 43C Cable Conversion Kit ...............................................................................241

Page 6

6 EN 3340.758.003a - 2014-11

TABLE OF CONTENT

MM9000 ClearCommand User Manual

Table of Contents

MMC-343 Station Expander User Instructions ................................................................ 243

12 Appendix B - QFA & DVTP................................................................ 257

ENG-127 9000 Series Micro/ClearCommand Servo Throttle - Servo Clutch Qualitative Failure

Analysis, Design Verification Test Procedure and Periodic Safety Test .......................... 259

ENG-143 9000 Series ClearCommand Throttle - Solenoid Clutch Qualitative Failure Analysis,

Design Verification Test Procedure and Periodic Safety Test .........................................263

ENG-144 9000 Series Electronic Throttle - Servo Clutch Qualitative Failure Analysis, Design

Verification Test Procedure and Periodic Safety Test ..................................................... 267

ENG-145 9000 Series Servo Throttle - Solenoid Clutch, Qualitative Failure Analysis & Design

Verification Test Procedure ............................................................................................. 271

13 Appendix C - Sales and Service Information ................................... 275

MMC-123 Factory Authorized Sales & Service - North America ..................................... 277

MMC-151 Factory Authorized Service Centers - North America..................................... 283

MMC-172 Factory Authorized Sales & Service Centers - International........................... 295

MMC-165 Warranty ......................................................................................................... 303

MMC-163 Warranty Registration..................................................................................... 305

MM13927 Field Service Test Unit .................................................... 307

14 Appendix D - System Drawings ....................................................... 323

Drawing 12284 ClearCommand All Configuration Twin Screw System Drawing .............. 325

Page 7

7

EN 3340.758.003a - 2014-11

LIST OF FIGURES

MM9000 ClearCommand User Manual

List of Figures

List of Figures

Figure 1-1: Basic 9120 or 9122 ClearCommand System Diagram .......................................................................... 22

Figure 1-2: Basic 9121 ClearCommand System Diagram ....................................................................................... 23

Figure 1-3: Basic 9210 ClearCommand System Diagram ....................................................................................... 24

Figure 1-4: Basic 9211 ClearCommand System Diagram ....................................................................................... 25

Figure 1-5: Basic 9221 ClearCommand System Diagram ....................................................................................... 26

Figure 2-1: Station taking Command .....................................................................................................................27

Figure 2-2: Control Head Detents ..........................................................................................................................28

Figure 2-3: Control Head 20 Degree Troll Range - Type 1 ...................................................................................... 29

Figure 2-4: Control Head 35 Degree Troll Range - Type 2 ...................................................................................... 29

Figure 2-5: Control Head 45 Degree Troll Range - Type 3...................................................................................... 29

Figure 2-6: Control Head 55 Degree Troll Range - Type 4...................................................................................... 29

Figure 2-7: Remote Stations Before Transfer of Command.....................................................................................30

Figure 2-8: Remote Station Transfer after Transfer of Command............................................................................30

Figure 2-9: Control Head Warm-Up Mode ............................................................................................................. 31

Figure 2-10: Control Head Normal Operating Mode...............................................................................................31

Figure 2-11: High/Low Idle Mode Selection........................................................................................................... 32

Figure 2-12: Step A) One Lever Operation Mode ................................................................................................... 33

Figure 2-13: Step B) One Lever Operation Mode ................................................................................................... 34

Figure 2-14: Circuit Board Shield Layout................................................................................................................ 41

Figure 2-15: Standard Processor Pluggable Connections View ..............................................................................42

Figure 3-1: Processor Dimensions.......................................................................................................................... 45

Figure 4-1: Harness Plug Keying............................................................................................................................53

Figure 4-2: Start Interlock Connections..................................................................................................................54

Figure 4-3: Twin Screw Serial Harness Connections ..............................................................................................56

Figure 4-4: Liquid Tight Installation........................................................................................................................ 58

Figure 4-5: Standard Enclosure Cable Holes ..........................................................................................................58

Figure 4-6: Standard Circuit Board Hard-Wired Termination Points........................................................................59

Figure 4-7: 9120 and 9121 Enclosure Cable Holes ................................................................................................ 60

Figure 4-8: 9122 Enclosure Cable Holes ................................................................................................................ 61

Figure 4-9: 9210 and 9211 Enclosure Cable Holes ................................................................................................62

Figure 4-10: 9221 Enclosure Cable Holes ..............................................................................................................63

Figure 4-11: 9000 Series Circuit Board Hard-Wired Termination Points .................................................................64

Figure 4-12: Seven-Conductor Control Head Cable Shield Wire and Heat-Shrink................................................... 65

Figure 4-13: Clamp Views .....................................................................................................................................65

Figure 4-14: Terminal Strip Cable Connections...................................................................................................... 65

Figure 4-15: Two-Conductor Start Interlock Cable ................................................................................................. 66

Figure 4-16: Two-Conductor Power Cable .............................................................................................................67

Figure 4-17: Four-Conductor Serial Communication Cable.....................................................................................67

Figure 4-18: AC Type Tachometer Cable ............................................................................................................... 68

Figure 4-19: Open Collector Tachometer Cable ..................................................................................................... 69

Page 8

8 EN 3340.758.003a - 2014-11

LIST OF FIGURES

MM9000 ClearCommand User Manual

List of Figures

Figure 4-20: Clutch Cable Heat Shrink in Processor ............................................................................................... 69

Figure 4-21: Clutch Cable Plug Termination Connections....................................................................................... 70

Figure 4-22: Clutch/Troll Cable Heat Shrink in Processor .......................................................................................70

Figure 4-23: Clutch Cable Plug Termination Connections.......................................................................................71

Figure 4-24: Clutch Cable Heat Shrink in Processor ............................................................................................... 72

Figure 4-25: Clutch Cable Plug Termination Connections....................................................................................... 72

Figure 4-26: Engine Shield ....................................................................................................................................73

Figure 4-27: Processor Cable Clamp Rotation........................................................................................................ 74

Figure 4-28: Push-Pull Cable Interior Connection ................................................................................................... 74

Figure 4-29: Throttle Push-Pull Idle Orientation to Selector Lever...........................................................................75

Figure 4-30: Shift Push-Pull Cable Neutral Connection at Transmission.................................................................. 75

Figure 5-1: Typical Processor Cover....................................................................................................................... 77

Figure 5-2: Processor Shield Push Button and Display LED Locations .................................................................... 78

Figure 5-3: Display LED at Normal Operation......................................................................................................... 78

Figure 5-4: Display LED Designations .................................................................................................................... 78

Figure 5-5: Circuit Board Push Buttons .................................................................................................................. 79

Figure 5-6: Display LED Error Menu Example......................................................................................................... 79

Figure 5-7: Display LED Four Digit Value................................................................................................................79

Figure 5-8: Service Field Test Unit and Multimeter................................................................................................. 85

Figure 5-9: E1, E2, E3, E4, E6, L4 Processor, Test Unit, and Multimeter Connections ............................................ 86

Figure 5-10: L2, L3, C6, and C7 Processor, Test Unit, and Multimeter Connections ...............................................86

Figure 5-11: Display LED Function A0 Set Up Activated.........................................................................................87

Figure 5-12: Display LED Function A1 Set Up Activated.........................................................................................88

Figure 5-13: Display LED Function A2 Set Up Activated......................................................................................... 88

Figure 5-14: Display LED Function A3 Set Up Activated......................................................................................... 89

Figure 5-15: Display LED Function A4 Set Up Activated.........................................................................................89

Figure 5-16: Display LED Function E5 Set Up Activated......................................................................................... 90

Figure 5-17: Display LED Function E6 Set Up Activated......................................................................................... 90

Figure 5-18: Display LED Function E1 Set Up Activated......................................................................................... 91

Figure 5-19: Display LED Function E4 Set Up Activated......................................................................................... 91

Figure 5-20: Display LED Function E7 Set Up Activated......................................................................................... 92

Figure 5-21: Throttle Push-Pull Cable Orientation................................................................................................... 92

Figure 5-22: Example: Throttle Push-Pull Cable Fully Retracted Position for Idle.....................................................93

Figure 5-23: Display LED Function E0 Set Up Activated......................................................................................... 93

Figure 5-24: Display LED Function E2 Set Up Activated......................................................................................... 93

Figure 5-25: Throttle Push-Pull Cable Full Throttle Position ....................................................................................94

Figure 5-26: Display LED Function E3 Set Up Activated......................................................................................... 94

Figure 5-27: Display LED Function E0 Set Up Activated......................................................................................... 95

Figure 5-28: Display LED Function E2 Set Up Activated......................................................................................... 95

Figure 5-29: Display LED Function E3 Set Up Activated......................................................................................... 96

Figure 5-30: Display LED Function C0 Set Up Activated.........................................................................................96

Figure 5-31: Display LED Function C1 Set Up Activated.........................................................................................97

Page 9

9

EN 3340.758.003a - 2014-11

LIST OF FIGURES

MM9000 ClearCommand User Manual

List of Figures

Figure 5-32: Display LED Function C2 Set Up Activated.........................................................................................97

Figure 5-33: Display LED Function C3 Set Up Activated.........................................................................................98

Figure 5-34: Display LED Function C4 Set Up Activated.........................................................................................99

Figure 5-35: Clutch Push-Pull Cable Orientation ..................................................................................................100

Figure 5-36: Display LED Function C5 Set Up Activated.......................................................................................100

Figure 5-37: Clutch Push-Pull Cable Ahead Position ............................................................................................ 101

Figure 5-38: Display LED Function C6 Set Up Activated.......................................................................................101

Figure 5-39: Clutch Push-Pull Cable Astern Position ............................................................................................102

Figure 5-40: Display LED Function C7 Set Up Activated.......................................................................................102

Figure 5-41: Display LED Function C5 Set Up Activated.......................................................................................103

Figure 5-42: Display LED Function C6 Set Up Activated.......................................................................................103

Figure 5-43: Display LED Function C7 Set Up Activated....................................................................................... 104

Figure 5-44: Display LED Function L0 Set Up Activated. ...................................................................................... 105

Figure 5-45: Control Head 20 Degree Troll Range - Type 1 .................................................................................. 105

Figure 5-46: Control Head 35 Degree Troll Range - Type 2 .................................................................................. 105

Figure 5-47: Control Head 45 Degree Troll Range - Type 3..................................................................................105

Figure 5-48: Control Head 55 Degree Troll Range - Type 4 .................................................................................. 105

Figure 5-49: Display LED Function L1 Set Up Activated ....................................................................................... 106

Figure 5-50: Display LED Function L1 Set Up Activated ....................................................................................... 107

Figure 5-51: Display LED Solenoid Function L2 Set Up Activated......................................................................... 107

Figure 5-52: Display LED Servo Function L2 Set Up Activated.............................................................................. 107

Figure 5-53: Display LED Solenoid Function L3 Set Up Activated.........................................................................108

Figure 5-54: Display LED Servo Function L3 Set Up Activated.............................................................................. 108

Figure 5-55: Display LED Solenoid Function L4 Set Up Activated......................................................................... 109

Figure 5-56: Display LED Function L6 Set Up Activated ....................................................................................... 110

Figure 5-57: Display LED Function L6 Set Up Activated .......................................................................................110

Figure 8-1: External Alarm Connections Processor Hard-Wired Example .............................................................131

Figure 8-2: External Alarm Connections Processor Hard-Wired Example .............................................................131

Figure 8-3: Clutch Pressure Switch with Processor Harness Diagram................................................................... 133

Figure 8-4: Clutch Pressure Switch with Processor Hard-Wired Diagram .............................................................133

Figure 10-1: 9120 and 9122 Basic Twin Screw, Two Station Diagram ................................................................. 137

Figure 10-2: 9121 Basic Twin Screw, Two Station Diagram................................................................................. 138

Figure 10-3: 9210 Basic Twin Screw, Two Station Diagram................................................................................. 139

Figure 10-4: 9211 Basic Twin Screw, Two Station Diagram.................................................................................140

Figure 10-5: 9221 Basic Twin Screw, Two Station Diagram................................................................................. 141

Figure 10-6: Display Function Code List...............................................................................................................146

Figure 10-7: Display Troubleshooting Function .................................................................................................... 146

Figure 10-8: Display Troubleshooting Function Blinking....................................................................................... 146

Figure 10-9: Example Display of Applied Battery Voltage..................................................................................... 146

Figure 10-10: Example Display of Tach Sensor Frequency ...................................................................................146

Figure 10-11: Example Display Control Head Lever Current Positions .................................................................. 147

Figure 10-12: Example Display Control Head Transfer Button Status View ...........................................................147

Page 10

10 EN 3340.758.003a - 2014-11

LIST OF FIGURES

MM9000 ClearCommand User Manual

List of Figures

Figure 10-13: Example Display Software Revision Level View .............................................................................. 147

Figure 10-14: Display Examples of Remote Stations ............................................................................................ 149

Figure 10-15: Display Examples of Remote Stations A/D Value............................................................................150

Figure 10-16: Display Station A/D’s No Station Transfer Button Depressed.......................................................... 155

Figure 10-17: Example Display Station A/D’s Transfer Button Depressed for Stations 1 - 4 .................................. 155

Figure 10-18: Display Station A/D/s Transfer Button Depressed for Station 5.......................................................155

Figure MMC-280-1: Part Numbering Configurations ........................................................................................... 199

Figure MMC-280-2: Detents Available ................................................................................................................. 199

Figure MMC-280-3: Dimensions.......................................................................................................................... 200

Figure MMC-280-4: Terminal Connections .......................................................................................................... 201

Figure MMC-280-5: AFT Facing Control Head ..................................................................................................... 201

Figure MMC-329-1: Part Numbering Configurations Detents Available ................................................................ 205

Figure MMC-329-2: Dimensions.......................................................................................................................... 206

Figure MMC-329-3: Terminal Connections ..........................................................................................................207

Figure MMC-329-4: AFT Facing Control Head ..................................................................................................... 207

Figure MMC-307-1: Part Numbering Configurations ............................................................................................ 209

Figure MMC-307-2: Detents Available................................................................................................................. 209

Figure MMC-307-3: Dimensions .......................................................................................................................... 209

Figure MMC-307-4: Dual Control Head Connections ...........................................................................................211

Figure MMC-307-5: Aft Facing Control Head.......................................................................................................211

Figure MMC-343-1: Station Expander..................................................................................................................244

Figure MMC-343-2: Station Expander Harness Connector Locations ..................................................................246

Figure MMC-343-3: Harness Plug Connectors ..................................................................................................... 246

Figure MMC-343-4: Station Expander Dimensions............................................................................................... 247

Figure MMC-343-5: Station Expander Display LED and Arrow Push Buttons........................................................ 249

Figure MMC-343-6: Display LED at Normal Operation ......................................................................................... 250

Figure MMC-343-7: Display LED Designations..................................................................................................... 250

Figure MMC-343-8: Error Menu Example ............................................................................................................251

Figure MMC-343-9: Display LED Four Digit Value ................................................................................................ 251

Figure MMC-343-10: Display Normal Operating Condition .................................................................................. 251

Figure MMC-343-11: Display Function Menu Activated ....................................................................................... 252

Figure MMC-343-12: Display with Set up Activated.............................................................................................252

Figure MMC-343-13: Display with A0 - Station Expander Identification Set Up Activated .................................... 253

Figure MM13927-1: .Service Field Test Unit (Break-out Box)...............................................................................311

Figure MM13927-2: CruiseCommand Connector Locations .................................................................................311

Figure MM13927-3: Example of CLEARCommand Pigtail Locations..................................................................... 312

Figure MM13927-4: Throttle Connection (DC Voltage) ........................................................................................313

Figure MM13927-5: Throttle Connection (Current mA)........................................................................................314

Figure MM13927-6: Throttle Connection (PWM with DC Voltmeter).................................................................... 315

Figure MM13927-7: Throttle connection (PWM with Duty Cycle Meter) .............................................................316

Figure MM13927-8: Throttle Connection (Frequency Hz).....................................................................................317

Figure MM13927-9: Clutch Connections Neutral Solenoid...................................................................................317

Page 11

11

EN 3340.758.003a - 2014-11

LIST OF FIGURES

MM9000 ClearCommand User Manual

List of Figures

Figure MM13927-10: Clutch Connections Ahead Solenoid..................................................................................318

Figure MM13927-11: Clutch Connections Astern Solenoid.................................................................................. 319

Figure MM13927-12: Troll Connections Troll On/Off Solenoid ............................................................................. 319

Figure MM13927-13: Troll Connections (Proportional Solenoid) ......................................................................... 320

Figure MM13927-14: 2-Speed Connections ........................................................................................................321

Page 12

12 EN 3340.758.003a - 2014-11

Page 13

13

EN 3340.758.003a - 2014-11

LIST OF TABLES

MM9000 ClearCommand User Manual

List of Tables

List of Tables

Table 4-1: ClearCommand Processor Optional Hard-Wiring Cable List................................................................... 60

Table 4-2: Processor Circuit Board Terminal Strip Color Coded Connections for Remote Stations .......................... 66

Table 4-3: Processor Circuit Board Terminal Strip Color Coded Connections for Serial Communication .................. 68

Table 4-4: Processor Circuit Board Terminal Strip Color Coded Connections for Tachometer..................................69

Table 4-5: Clutch Termination Table ......................................................................................................................70

Table 4-6: Clutch/Troll Termination Table............................................................................................................... 71

Table 4-7: Clutch Termination Table ...................................................................................................................... 72

Table 4-8: Throttle Termination Table ....................................................................................................................73

Table 5-1: Function Codes.....................................................................................................................................80

Table 5-2: Processors Function Code Defaults .......................................................................................................83

Table 5-3: Solenoid Error Status Enable...............................................................................................................111

Table 6-1: Shaft RPM at Idle ................................................................................................................................ 115

Table 6-2: Shaft RPM at Idle ................................................................................................................................ 116

Table 7-1: Shaft RPM at Idle ................................................................................................................................ 120

Table 7-2: Troll Valve Adjustments.......................................................................................................................121

Table F-226-1: Vessel Information ....................................................................................................................... 125

Table F-226-2: Processor Information ..................................................................................................................125

Table F-226-3: Power Supply............................................................................................................................... 126

Table F-226-4: Dock Trials...................................................................................................................................126

Table F-226-5: Record at Dock ............................................................................................................................ 126

Table F-226-6: Sea Trials ..................................................................................................................................... 127

Table F-226-7: Record during Sea Trial................................................................................................................127

Table F-226-8: Processor Parameters Record ...................................................................................................... 127

Table 9-1: Fully Charged Battery..........................................................................................................................136

Table 10-1: ClearCommand Processor Push-Pull Reference .................................................................................142

Table 10-2: Examples of Components (Internal/External).....................................................................................145

Table 10-3: Control Head Lever A/D Counts.........................................................................................................155

Table 10-4: Clutch Solenoid Control System Error Codes ..................................................................................... 156

Table 10-5: Troll Solenoid Control System Error Codes ........................................................................................ 156

Table 10-6: Basic Control System Error Codes ..................................................................................................... 157

Table 10-7: Servo 1 Error Codes .......................................................................................................................... 159

Table 10-8: Servo 2 Error Codes .......................................................................................................................... 159

Table 10-9: Basic Control System Problem Causes and Solutions ........................................................................160

Table 10-10: Servo 2 Throttle Problem Causes and Solutions............................................................................... 169

Table 10-11: Servo 1 Clutch Problem Causes and Solutions ................................................................................169

Table 10-12: Servo 2 Troll Problem Causes and Solutions....................................................................................170

Table 10-13: Servo 2 Troll Problem Causes and Solutions....................................................................................171

Table 10-14: Wire Harness - Serial Communication (p/n 13316-XX)....................................................................179

Table 10-15: Wire Harness - Serial Communication Multi-Screw (p/n 15544-XX) ................................................ 180

Table 10-16: Wire Harness - Serial Communication / CANtrak (p/n 70422-XX).................................................... 181

Page 14

14 EN 3340.758.003a - 2014-11

LIST OF TABLES

MM9000 ClearCommand User Manual

List of Tables

Table 10-17: Wire Harness - Throttle, Voltage (IVECO, Cummins) (p/n 13432-XX)............................................... 181

Table 10-18: Wire Harness- Throttle, Current (MAN, MTU) (p/n 13494-XX)........................................................ 182

Table 10-19: Wire Harness - Throttle, Voltage (Cummins Plug), (p/n 13565-XX).................................................. 182

Table 10-20: Voltage Throttle Harness Pin-Out (p/n 14148-XX) ........................................................................... 183

Table 10-21: Wire Harness - Throttle (Pulse width modulation [PWM]), (p/n 13533-XX) .....................................183

Table 10-22: Voltage Throttle Harness Pin-Out (p/n 71262-XX) ........................................................................... 184

Table 10-23: Cable, throttle, MAN EDC (p/n 14421-XX) ...................................................................................... 184

Table 10-24: Wire Harness - Throttle Current w/ Mag Pickup, Man (Non-Common Rail) (p/n 14363-XX)............. 185

Table 10-25: Wire Harness - Clutch, Ahead, Astern (p/n 15719-XX)....................................................................186

Table 10-26: Wire Harness - Ahead / Astern Troll on/off Command (p/n 15725-XX) ............................................ 186

Table 10-27: Wire Harness - Clutch with Troll Command (p/n 15732-XX)............................................................ 187

Table 10-28: Wire Harness- Clutch, Ahead, Astern, Troll Command, Troll On-Off (p/n 70390-XX) .......................188

Table 10-29: Wire Harness- Clutch, Ahead, Astern, ZFF Transmission (p/n 70673-XX)........................................189

Table 10-30: Power, Start Interlock Harness Pin-Out (p/n 13756-XX) ..................................................................189

Table 10-31: Wire Harness - Power, SI & Clutch Pressure Switch (p/n 13552-XX) ...............................................190

Table 10-32: Wire Harness - Power, SI, Clutch Pressure Switch & Alarm (p/n 13631-XX) .................................... 190

Table 10-33: Wire Harness- Power Use W/existing St Intlk Only (p/n 15023-XX).................................................191

Table 10-34: Wire Harness - Control Head One Connector (p/n 13557-XX) .........................................................191

Table 10-35: Wire Harness - Control Head Two Connectors (p/n 14261-XX) ....................................................... 192

Table 10-36: Wire Harness - Serial Communication, Processor Lead (p/n 15705-XX) ..........................................193

Table 10-37: Wire Harness - Throttle, Processor Lead (p/n 15703-XX).................................................................194

Table 10-38: Wire Harness - Solenoid Clutches, Processor Lead (p/n 15701-XX).................................................194

Table 10-39: Power, Start Interlock, Clutch Oil Pressure Switch, and Alarm Pigtail Pin-Out (p/n 15710-XX)......... 195

Table 10-40: Wire Harness - Control Head, Processor Lead (p/n 15706-XX).......................................................196

Table 10-41: Wire Harness - Mag Pickup, Processor Lead (p/n 15704-XX) .......................................................... 196

Table MMC-343-1: Functions List ........................................................................................................................ 252

Table MMC-343-2: Troubleshooting Functions .................................................................................................... 253

Page 15

15

EN 3340.758.003a - 2014-11

REVISION LIST

MM9000 ClearCommand User Manual

Revision List

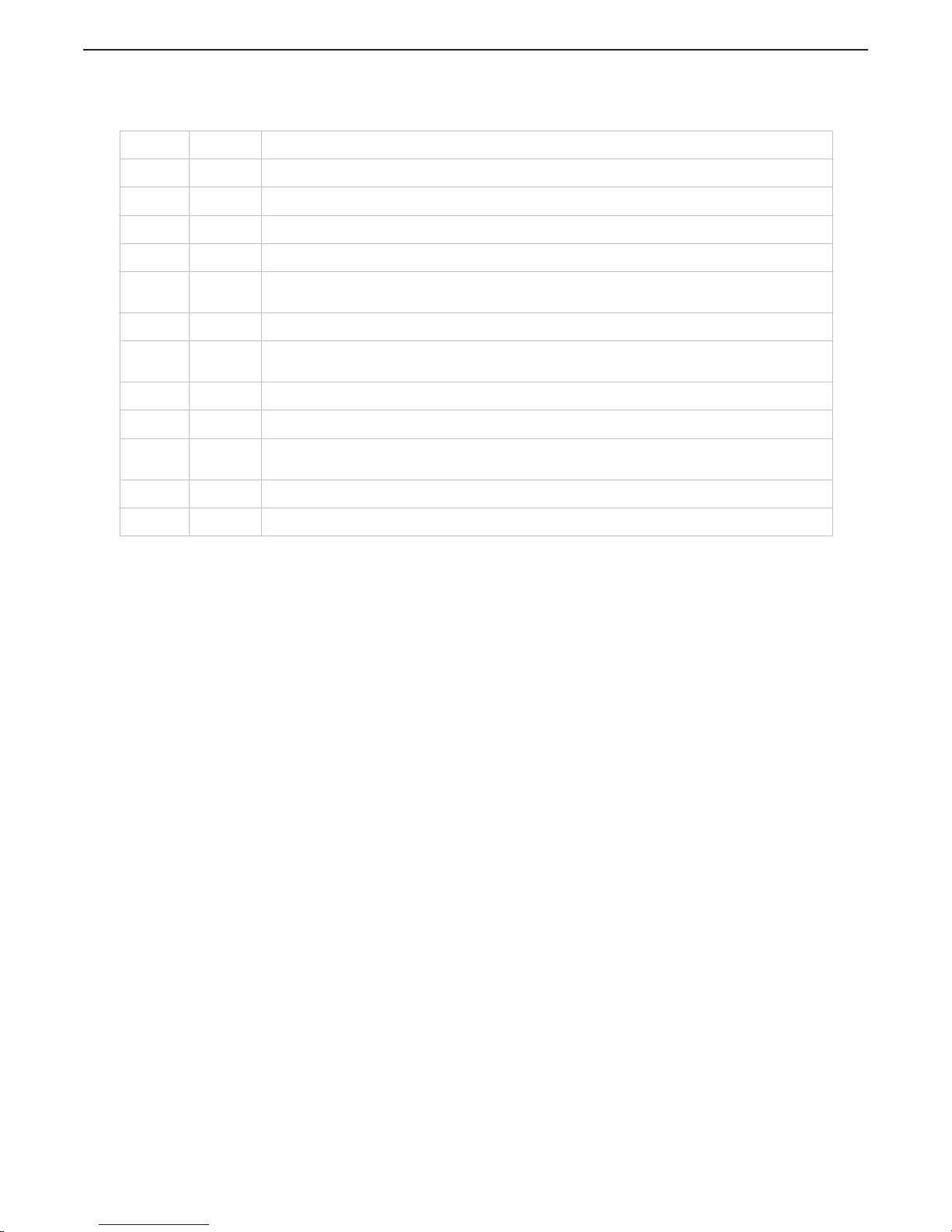

Revision List

Revision Date Revision Description

Rev - 11/03 Revision - was a PRELIMINARY manual printed to support Production.

Rev A 4/03 Released and Signed Off.

Rev B 6/04 Updated with most current Forms and Manual Modules.

Rev C 8/04 Included ELR 1167 and 1150

Rev C.1 2/08

Replaced Field Service Test Unit (MM13927) manual with current revision (reformatted).

Replaced forms MMC-172 International FASSC List, MMC-165 Warranty Policy with current revision.

Rev C.2 5/08 Replaced MMC-280 & MMC-329 Control Head Variations current revision.

Rev C.3 1/09

Replaced MMC-165 - Rev G 1/09 Electronic Propulsion Systems Limited Warranty

Replaced MMC-123, MMC-151, MMC-172 - Factory Authorized Sales & Service Center Lists

Rev C.4 04/09 Replaced MMC-123, MMC-151, MMC-172 - Factory Authorized Sales & Service Center Lists

Rev C.5 09/09 Reviewed and replaced all external forms and documents with current revisions.

Rev C.6 05/11

Reformatted to FrameMaker9, Updated Software number, Revised preface per ELR00113, updated

all external documents with current revision level, Revised per ELR00048

Rev C.7 09/11 Added MMC-343, changes made per ELR00144

Rev C.8 01/13 Changed name to ZF Marine Propulsion Systems Miramar, LLC

Page 16

16 EN 3340.758.003a - 2014-11

Page 17

17

EN 3340.758.003a - 2014-11

PREFACE

MM9000 ClearCommand User Manual

Preface

Preface

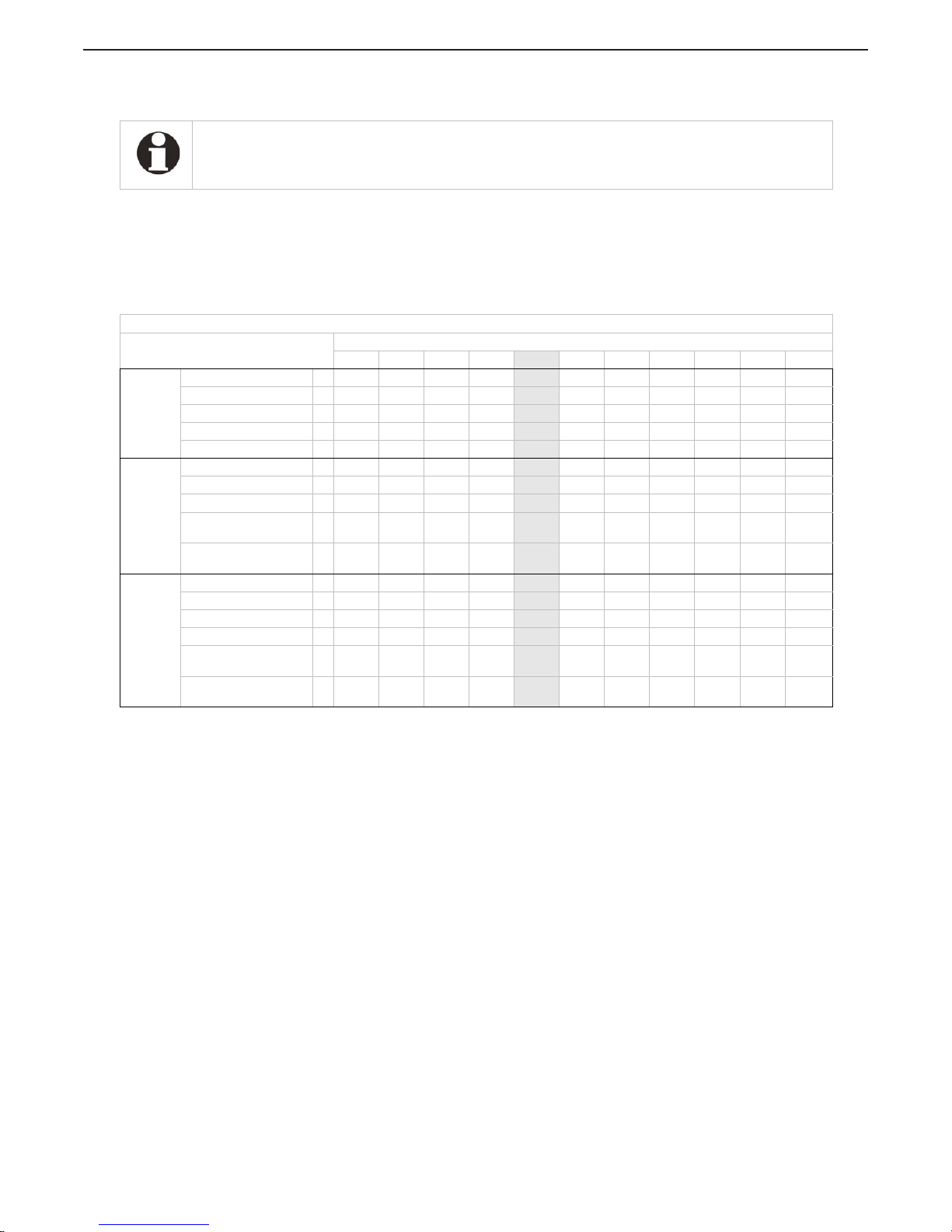

ClearCommand Processor List

The processors for the systems listed below have software which includes several featured options.

Information about these options is contained in this manual, along with all standard instructions for 9000

series Processors. All vessels with ClearCommand Processors will not necessarily use all the featured options.

Decide on their utility based upon your application.

Below is an example of the 9000 Series Part Numbering system. This is just a guide, there are more options

available than shown below.

For example a 91212 is a ClearCommand Processor with Mechanical Engine, Solenoid Clutch, Mechanical

Troll and 2 stations. Each number in the part number signifies a different quality of the processor that fits your

needs. The last number in each Processor part number is the number of stations that are being used.

Available Options for the Processors Covered in this Manual

• Dynamic Positioning Interface

• Station 4 / Joystick Interface

• CANtrak Display

• Engine Room/Remote Switch (Station 1 only)

• Station 2 Lockout

• Speed Boost — Loaded w/Software

• Fixed Neutral Delay — Loaded w/Software

IMPORTANT: Keep this manual in a safe place for future reference. It contains essential information about the

installation and operation of the ZF Marine Propulsion Systems Miramar control system for your vessel.

9000 Series Part Numbering / Identification Guide

Part Number

90010 91000 91102 91202

91212 92000 92102 92112 92212 95232 96232

Engine /

Throttle

None 0 X

Mechanical 1 XXXX

Electrical 2

XXXX

Premium Mechanical 5

X

Premium Electrical 6

X

Gear /

Clutch

None 0 XX

X

Mechanical 1 X

XX

Solenoid 2 X

X XX X

Mechanical Gear /

Solenoid 2 Speed

3

Solenoid Gear /

Solenoid 2 Speed

4

Troll

None 0 XXX

XX

Mechanical 1 X

XX

Solenoid 2

Autotroll 3 XX

Mechanical Governed

Troll

5

Solenoid Governed

Troll

6

Page 18

18 EN 3340.758.003a - 2014-11

PREFACE

MM9000 ClearCommand User Manual

Preface

Conventional Symbols Used in the Manual

Throughout this manual special attention should be paid to the following symbols.

Important Information

WARNING: Personal Injury may result if this message is disregarded.

CAUTION: Damage to equipment may occur if this message is disregarded.

IMPORTANT: Contains essential Information about a topic.

NOTE: Contains noteworthy information that may help to clarify a topic.

WARNING: Personal Injury could occur if the following steps are not followed exactly.

CAUTION: On Control Systems with more than one Processor, ZF Marine Propulsion Systems Miramar highly

recommends that ALL UNITS utilize the same software revision for each Processor.

CAUTION: Electro-static discharge can damage this equipment. Personnel working on this equipment must be

grounded to the chassis with an Anti-static Wrist Strap.

CAUTION: Disconnect the Power from the Processor whenever welding is being done on the vessel. Failure to

do so can cause permanent damage to the Processor.

CAUTION: This equipment is designed to work with other ZF Marine Propulsion Systems Miramar designed

equipment. DO NOT operate this equipment with any other manufacturers equipment unless approved so in

writing by ZF Marine Propulsion Systems Miramar Engineering Department.

Page 19

19

EN 3340.758.003a - 2014-11

PREFACE

MM9000 ClearCommand User Manual

Preface

Optional Features Information

How to Use the Manual

This manual is written describing all possible options available for this processor. Your vessel may not require

all of these options. Refer only to the sections that apply to your vessel. If you wish to use one of the available

options listed, please contact a technician from ZF Marine Propulsion Systems Miramar Sales & Service

Organization (SSO). For more information on an SSO in your area, please see Section 13: Appendix C - Sales

and Service Information.

WARNING: If the Dynamic Positioning (DP) Interface option is being used, it is the operator’s responsibility to

operate the vessel per the DP system manufacturer’s requirements. Please call your ZF Marine Propulsion

Systems Miramar representative for any questions with any installation/operational questions prior to Sea

Trials.

WARNING: If the DP/JS Interface option is being used, it is the operator’s responsibility to operate the vessel

per the DP system manufacturer’s requirements. Please call your ZF Marine Propulsion Systems Miramar

representative for any questions with any installation/operational questions prior to Sea Trials.

CAUTION: The DP pigtail MUST NOT be used to connect any other device such as a remote station Control

Head. Failure to meet this requirement will nullify the Processor warranty, cause an unsafe operating condition

and/or damage the Processor.

CAUTION: If the DP option is being utilized with a multi-screw application, ALL Processors MUST HAVE the DP

pigtail connected to the DP System. Failure to comply with this requirement could cause an unsafe operating

condition with possible severe personal injury and/or property damage.

CAUTION: If the DP option with Troll is being utilized with a multi-screw application, the Dynamic Positioning

System is responsible for any transmission damage that may occur due to Trolling with one screw and

operating with the clutch fully engaged on another screw (i.e., “dragging” a screw through the water).

CAUTION: Misapplication of the Speed Boost feature can damage the transmission or other equipment. Before

using Speed Boost, the transmission representative must be consulted about its use, and any limitations on

clutch engagement as a function of engine speed. The person(s) implementing Speed Boost have the

responsibility for ensuring it is properly adjusted and for any damage that might occur.

NOTE: ZF Marine Propulsion Systems Miramar is not liable for any damage incurred if these notices are not

followed exactly.

Page 20

20 EN 3340.758.003a - 2014-11

Page 21

21

EN 3340.758.003a - 2014-11

INTRODUCTION

MM9000 ClearCommand User Manual

Introduction

1 Introduction

This manual is written to document every possible system option.

Your system may not include every available option for single or twin screw reverse reduction gear

applications.

Only those sections that apply to your specific installation are relevant to your vessel.

If additional options described within this manual are desired, contact your dealer for availability/

compatibility with your system.

1.1 Basic Theory of Operation

The ClearCommand Marine Propulsion Control System (hereafter referred to as ClearCommand or System) is

electronic and requires a 12 or 24 VDC power supply, one Processor per engine/clutch and one Control Head

per remote station. The ClearCommand commands the vessel’s throttle and shift using a single Control Head

lever.

One electric cable per Control Head lever connects the remote station(s) to the Processor(s). Only one remote

station will have command at a given time and the Station-in-Command is indicated by a red light located on

the Control Head. Station transfer is accomplished by pressing the Control Head mounted transfer button.

1.1.1 9120 Processor (Throttle-Servo 2, Shift-Solenoid) or 9122 Processor (Throttle-Servo 2,

Shift-Solenoid, Troll-Solenoid).

The 9120 or 9122 System is designed for pleasure and light commercial marine vessels that require

remote control of:

9120

• mechanically actuated engines

• solenoid activated clutches

9122

• mechanically actuated engines

• solenoid activated clutches

• solenoid activated trolling valves

The 9120 or 9122 Processor is typically mounted in the engine room area and is connected

mechanically to the vessel’s main engine throttle selector lever with standard 33C type push-pull

cables.

The 9120 Processor controls the electrical Ahead and Astern Shift Solenoids at the transmission, via

electric cable.

Page 22

22 EN 3340.758.003a - 2014-11

INTRODUCTION

MM9000 ClearCommand User Manual

Introduction

The 9122 Processor controls the electrical Transmission and Trolling Valve Solenoids for shift and

trolling functions, via electric cable.

Figure 1-1: Basic 9120 or 9122 ClearCommand System Diagram

IDLEFULL

33C PUSH-PULL CABLE

IDLE

FULL

THROTTLE

STBD

STATION 2

STATION 1

PORT

12296-

SERIAL COMMUNICATION

10 AMP CIRCUIT BREAKERS

(BY OTHERS)

COMMON

GROUND

COMMON

GROUND

+

-

+

-

APS

CLUTCH PRES.

START INTERLOCK

ALARM

START INTERLOCK

CLUTCH PRES.

ALARM

TACH 1 TACH 1

AHEAD/ASTERN

TROLL COMMAND

TROLL ON/OFF

AHEAD/ASTERN

TROLL COMMAND

TROLL ON/OFF

33C PUSH-PULL CABLE

THROTTLE

Page 23

23

EN 3340.758.003a - 2014-11

INTRODUCTION

MM9000 ClearCommand User Manual

Introduction

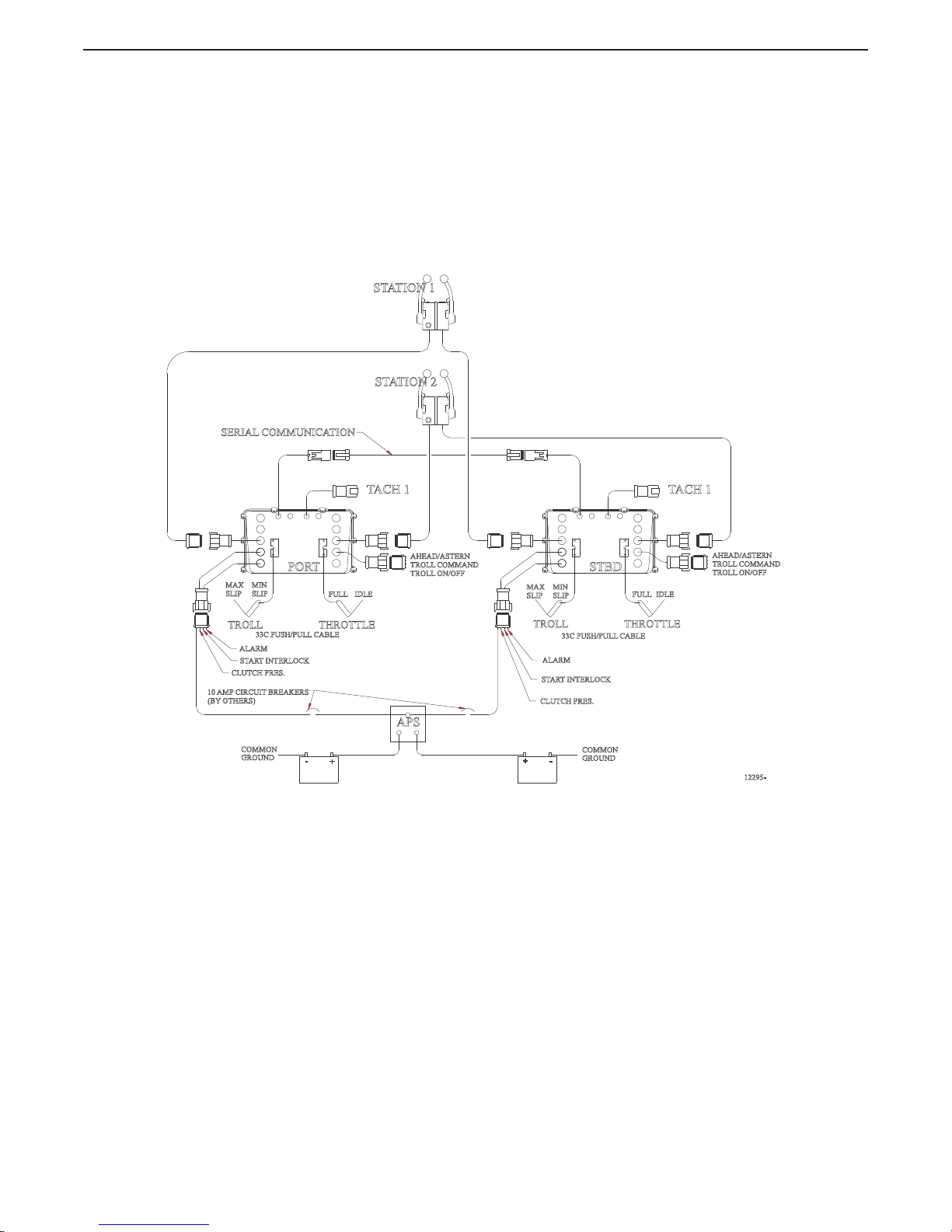

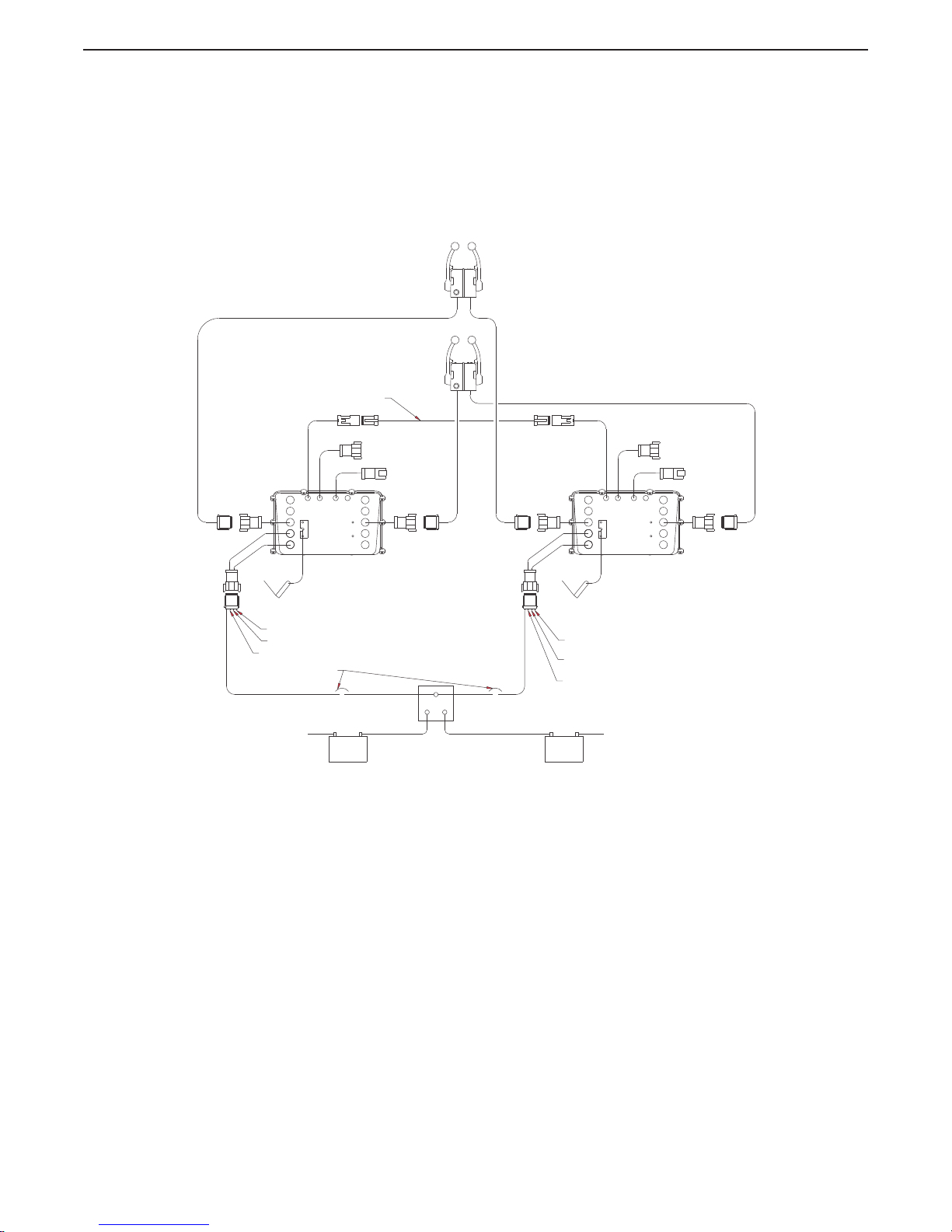

1.1.2 9121 Processor (Throttle-Servo 2, Shift-Solenoid, Troll-Servo 1)

The 9121 System is designed for pleasure and light commercial marine vessels that require remote

control of:

• mechanically actuated engines

• solenoid activated clutches

• mechanical trolling valves.

The Processor is typically mounted in the engine room area and is connected mechanically to the

vessel’s main engine throttle selector lever and trolling valve with standard 33C type push-pull cables.

The transmission is controlled via electrical cables connected to the Ahead and Astern Shift

Solenoids.

Figure 1-2: Basic 9121 ClearCommand System Diagram

IDLEFULL

33C PUSH/PULL CABLE

33C PUSH/PULL CABLE

IDLE

FULL

THROTTLETROLL

STBD

STATION 2

STATION 1

PORT

12295-

SERIAL COMMUNICATION

10 AMP CIRCUIT BREAKERS

(BY OTHERS)

COMMON

GROUND

COMMON

GROUND

+

-

+

-

APS

CLUTCH PRES.

START INTERLOCK

ALARM

START INTERLOCK

CLUTCH PRES.

ALARM

TACH 1 TACH 1

MAX

SLIP

MIN

SLIP

AHEAD/ASTERN

TROLL COMMAND

TROLL ON/OFF

AHEAD/ASTERN

TROLL COMMAND

TROLL ON/OFF

MAX

SLIP

MIN

SLIP

THROTTLETROLL

Page 24

24 EN 3340.758.003a - 2014-11

INTRODUCTION

MM9000 ClearCommand User Manual

Introduction

1.1.3 9210 Processor (Throttle-Electronic, Shift-Servo 1)

The 9210 System is designed for pleasure and light commercial marine vessels that require remote

control of:

• electronic engine governors

• mechanically actuated clutches

The Processor is typically mounted in the engine room area and is connected to the electronic

governor with a two-conductor, shielded, electric cable.

The transmission is controlled mechanically using standard 33C type push-pull cable.

Figure 1-3: Basic 9210 ClearCommand System Diagram

33C PUSH/PULL CABLE

33C PUSH/PULL CABLE

SHIFT

F

N

RFR

N

STBD

STATION 2

STATION 1

PORT

12294-

SERIAL COMMUNICATION

10 AMP CIRCUIT BREAKERS

(BY OTHERS)

COMMON

GROUND

COMMON

GROUND

+

-

+

-

APS

CLUTCH PRES.

START INTERLOCK

ALARM

START INTERLOCK

CLUTCH PRES.

ALARM

TACH 1 TACH 1

THROTTLETHROTTLE

SHIFT

Page 25

25

EN 3340.758.003a - 2014-11

INTRODUCTION

MM9000 ClearCommand User Manual

Introduction

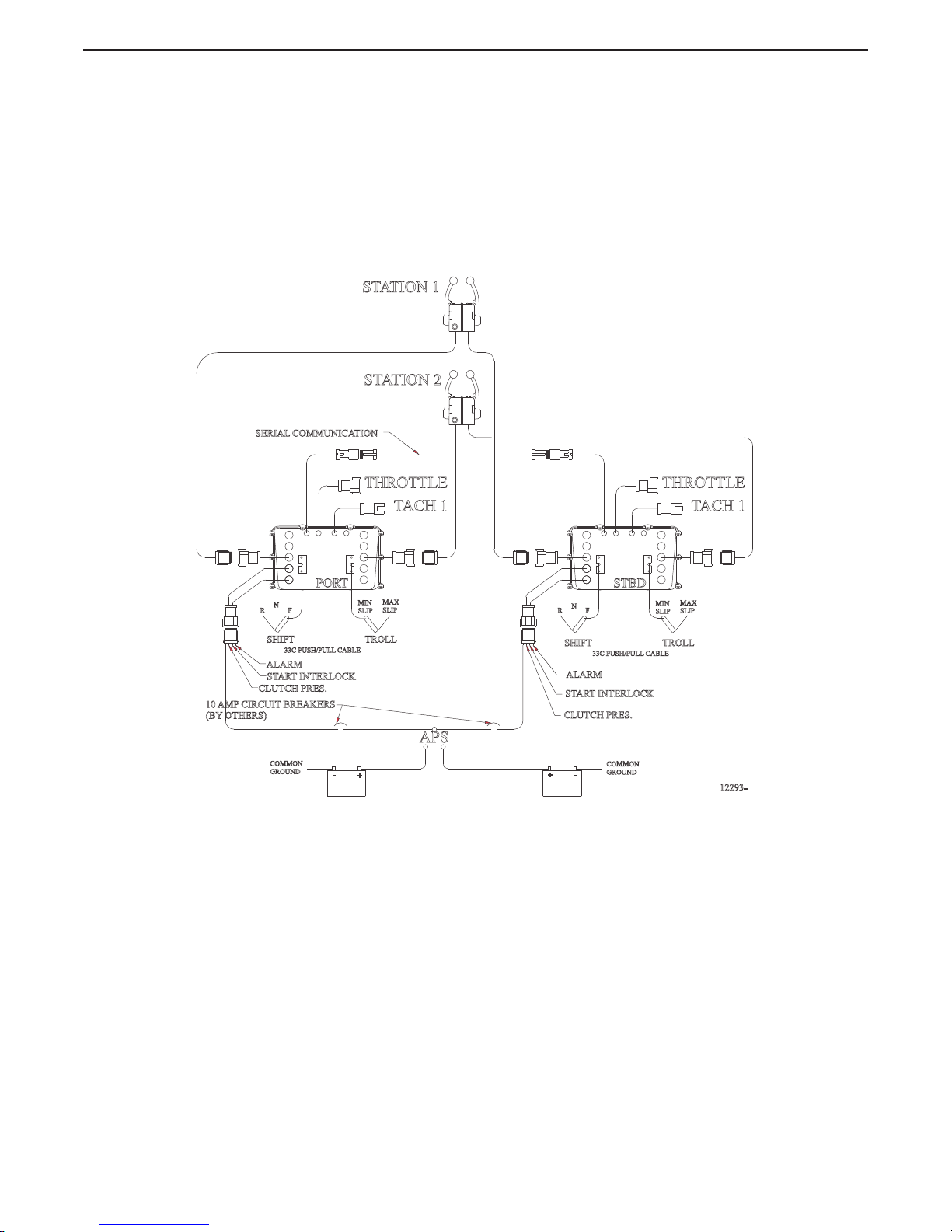

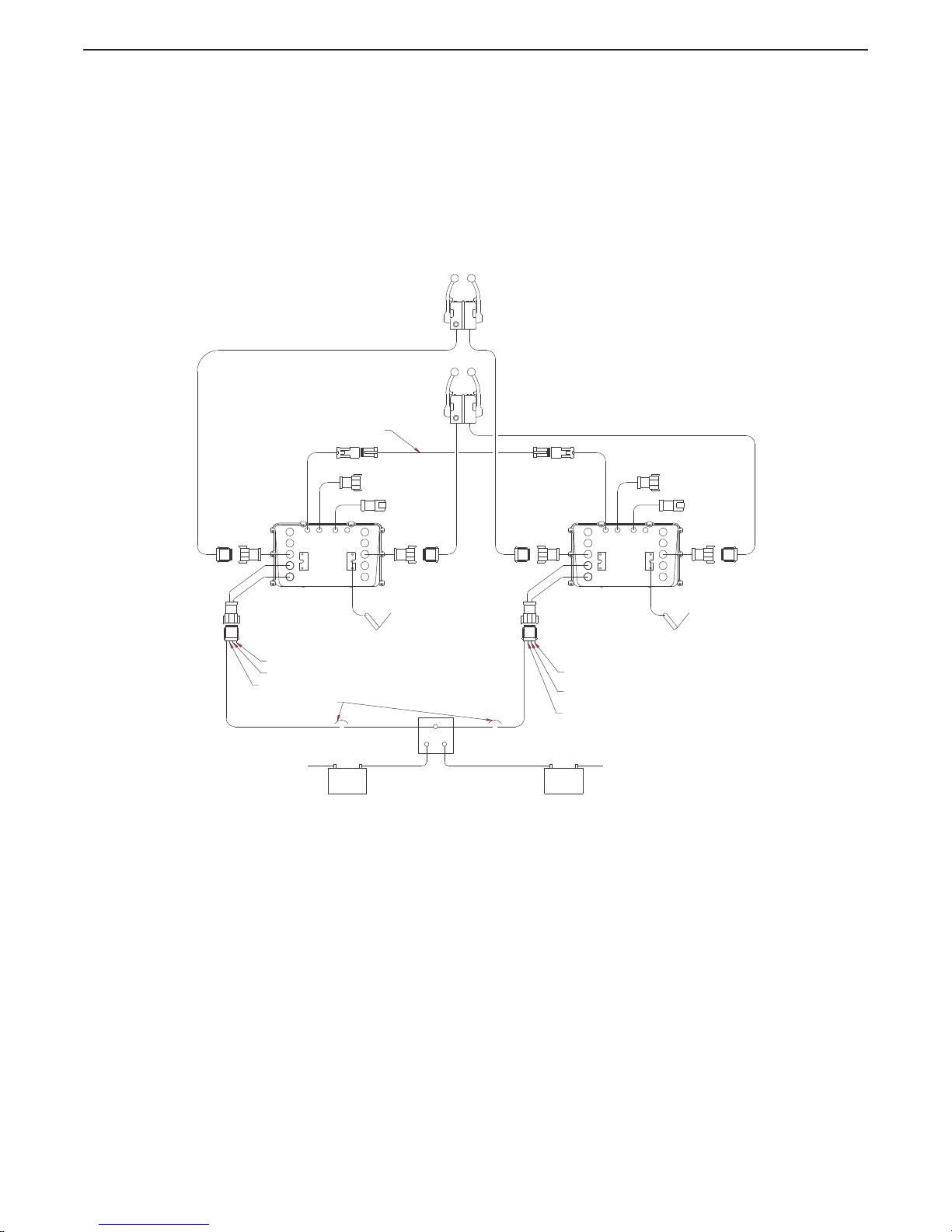

1.1.4 9211 Processor (Throttle - Electronic, Shift - Servo 1, Troll - Servo 2)

The 9211 System is designed for pleasure and light commercial marine vessels that require remote

control of:

• electronic engine governors

• mechanically actuated clutches

• mechanically actuated trolling valves.

The Processor is typically mounted in the engine room area and is connected to the electronic

governor with a two-conductor, shielded, electric cable.

The transmission and trolling valve are controlled mechanically using a standard 33C type push-pull

cable.

Figure 1-4: Basic 9211 ClearCommand System Diagram

33C PUSH/PULL CABLE

33C PUSH/PULL CABLE

TROLLSHIFT

F

N

RFR

N

TROLLSHIFT

STBD

STATION 2

STATION 1

PORT

12293-

SERIAL COMMUNICATION

10 AMP CIRCUIT BREAKERS

(BY OTHERS)

COMMON

GROUND

COMMON

GROUND

+

-

+

-

APS

CLUTCH PRES.

START INTERLOCK

ALARM

START INTERLOCK

CLUTCH PRES.

ALARM

TACH 1 TACH 1

THROTTLETHROTTLE

MIN

SLIP

MAX

SLIP

MIN

SLIP

MAX

SLIP

Page 26

26 EN 3340.758.003a - 2014-11

INTRODUCTION

MM9000 ClearCommand User Manual

Introduction

1.1.5 9221 Processor (Throttle - Electronic, Shift - Solenoid, Troll - Servo 2)

The 9221 System is designed for pleasure and light commercial marine vessels that require remote

control of:

• electronic engine governors

• solenoid activated clutches

• mechanically actuated trolling valves

The Processor is typically mounted in the engine room area and is connected to the electronic

governor with a two-conductor, shielded, electric cable.

The transmission’s Ahead and Astern solenoids are connected via 2 two-conductor cables, and the

trolling valve is controlled mechanically using a standard 33C type push-pull cable.

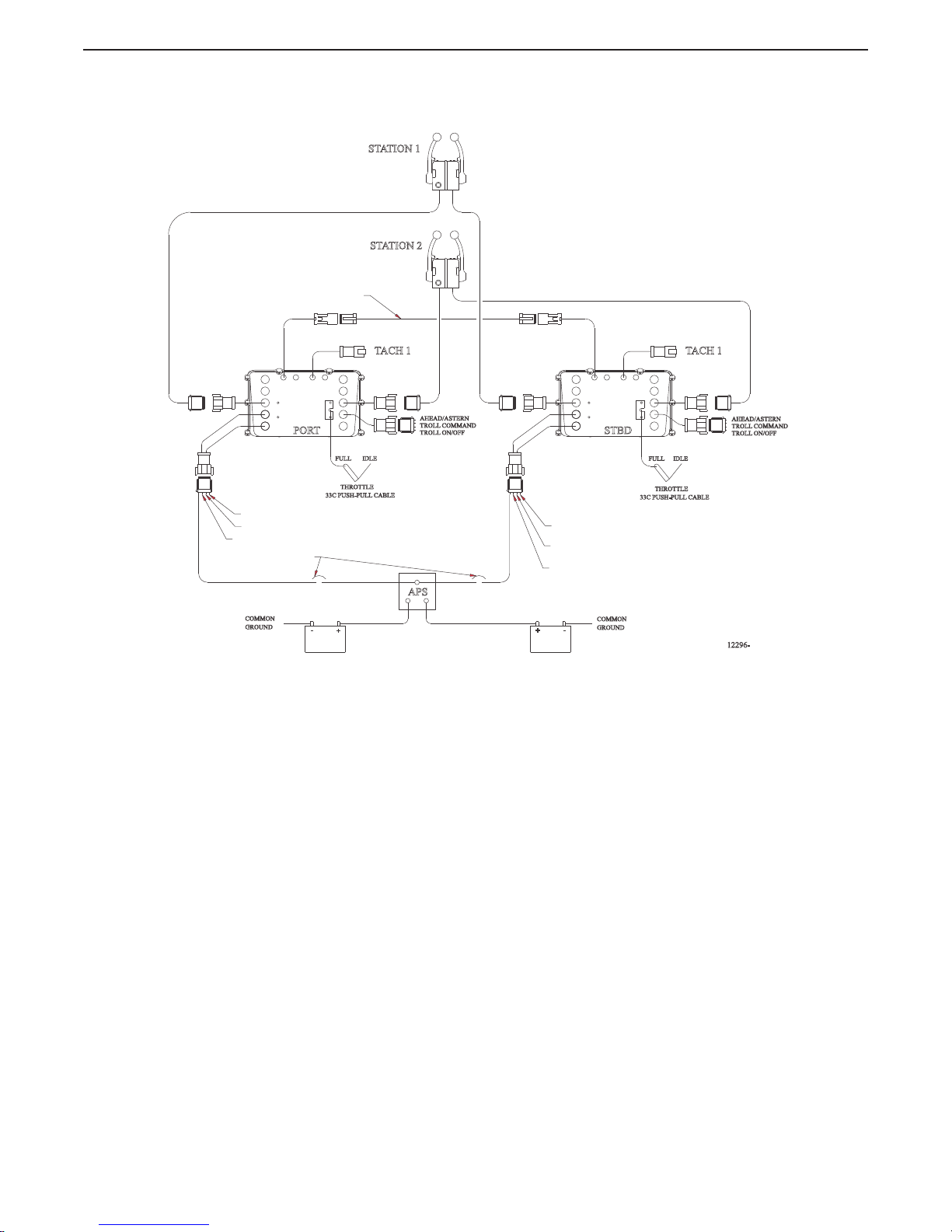

Figure 1-5: Basic 9221 ClearCommand System Diagram

1.2 System Features

1.2.1 Standard Features

• Station-in-Command indication. (Section 2.2: Taking Command)

• Up to five Remote Stations. (Section 2.2: Taking Command)

• Single Control Head lever command of speed and direction. (Section 2.3: Basic Operation)

33C PUSH/PULL CABLE

STBD

STATION 2

STATION 1

PORT

12297

SERIAL COMMUNICATION

10 AMP CIRCUIT BREAKERS

(BY OTHERS)

COMMON

GROUND

COMMON

GROUND

+

-

+

-

APS

CLUTCH PRES.

START INTERLOCK

ALARM

START INTERLOCK

CLUTCH PRES.

ALARM

TACH 1 TACH 1

THROTTLETHROTTLE

TROLL

MAX

SLIP

MIN

SLIP

TROLL

33C PUSH/PULL CABLE

MAX

SLIP

MIN

SLIP

Page 27

27

EN 3340.758.003a - 2014-11

OPERATION

MM9000 ClearCommand User Manual

Operation

2 Operation

2.1 DC Power On

When DC power is turned ON to the Processor:

• A short steady tone, followed by an intermittent tone, will sound at all Remote Stations indicating that

no station has command.

• The Start Interlock relay contact will remain open, preventing engine start.

• Throttle:

Servo:

The throttle servo will drive to Idle.

Electric:

The throttle signal will be commanded to Idle.

• Shift:

Servo:

The Shift servo will drive to Neutral.

Solenoid:

The Ahead and Astern shift solenoids will be de-energized, commanding Neutral.

• Tro ll:

Servo:

The trolling valve servo will drive to lock-up.

Solenoid:

The trolling valve solenoids are commanding lock-up.

2.2 Taking Command

To take command at any one of the up to five Remote Stations:

• Ensure all Control Head’s lever(s) at that Station are in the Neutral detent (vertical position)

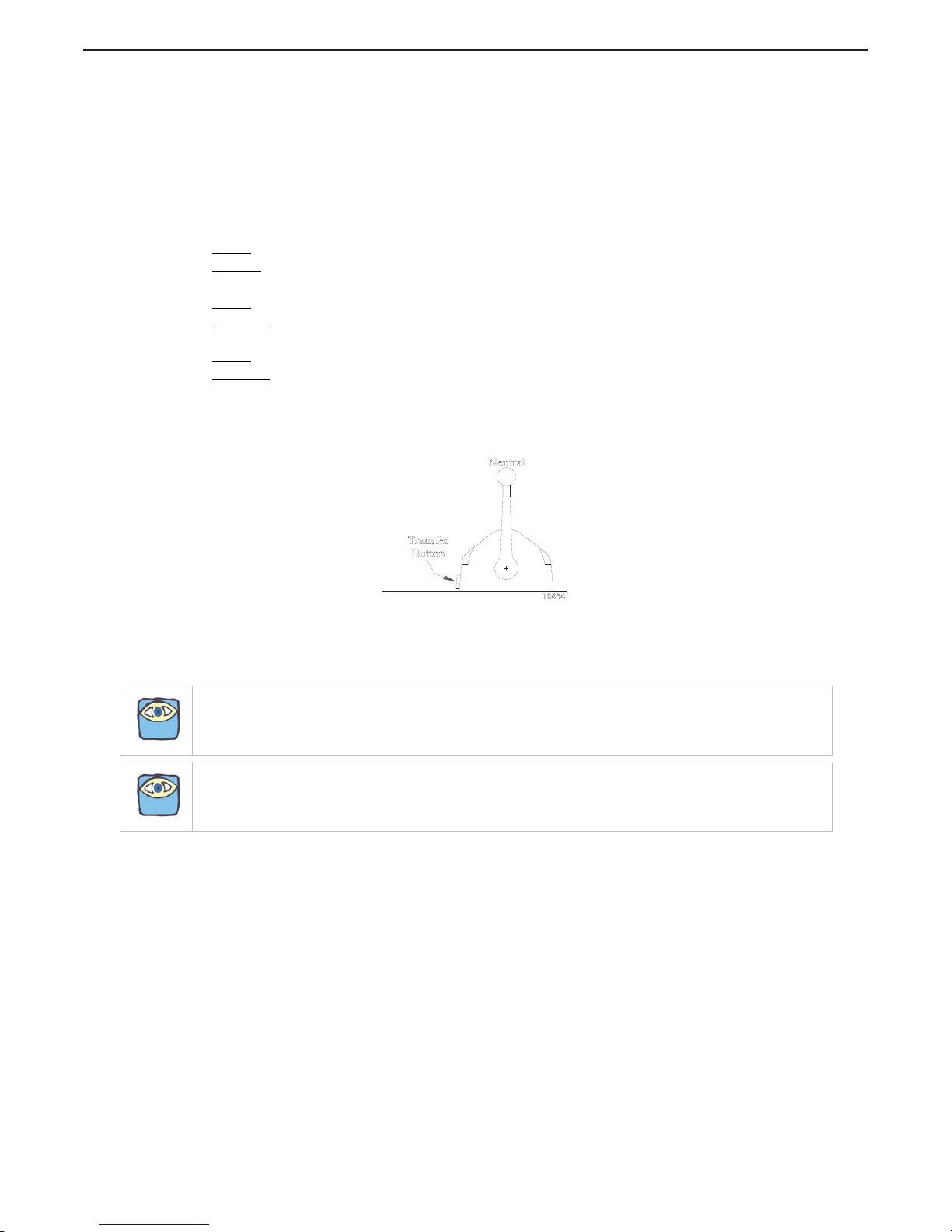

Figure 2-1: Station taking Command

• Depress the transfer button for 1/2 second.

The Slow Repetitive tone will stop at all Stations, and the red LED indicator light will turn ON at the Control

Head of the Station that had assumed command of the Control System.

NOTE: If Start Interlock is used: Once a Station is in command the Start Interlock relay contact will close,

allowing the engine to start.

NOTE: Only one Station can have command at a time.

Neutral

Transfer

Button

10454

Page 28

28 EN 3340.758.003a - 2014-11

OPERATION

MM9000 ClearCommand User Manual

Operation

2.3 Basic Operation

2.3.1 Normal Operating Mode

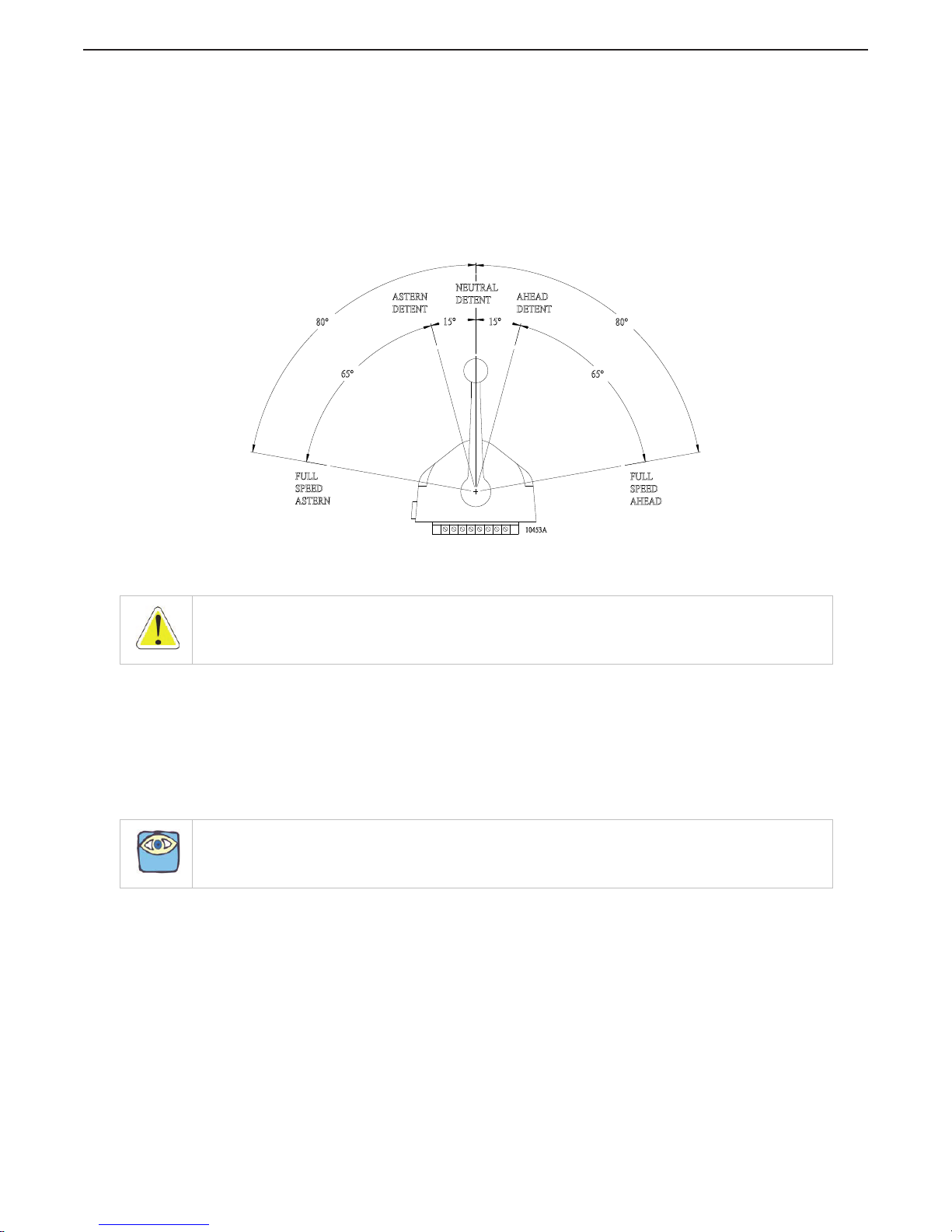

A The Control Head has three detents; Ahead, Astern and Neutral.

B With the Control Head lever positioned in the Neutral (vertical) detent, the Processor will

command Neutral and the throttle at Idle revolutions per minute (RPM).

C Movement of the Control Head’s lever 15 degrees to the Ahead or Astern detent will

command Ahead or Astern clutch engagement, while the engine RPM remains at Idle.

D Further movement of the Control Head lever through the next 65 degrees, will increase the

engine RPM in proportion to the Control Head’s lever position.

Figure 2-2: Control Head Detents

2.3.2 Trolling Valve Operation

The operation is quite different in Systems equipped with Trolling Valves. Troll Mode is a feature that

must be turned On and Off at the Control Head. On initial power-up, Troll Mode is disabled.

A The Control Head has three detents; Ahead, Astern and Neutral. To turn ON Troll Mode, place

the Control Head lever in any of the above mentioned detents.

• With the Control Head lever positioned in the Neutral (vertical) detent, the Processor will

command Neutral, the trolling valve will be at lock-up and the throttle at Idle rpm.

B Depress and hold the transfer button for two (2) seconds.

• The solid red indicator light on the Control Head will begin blinking rapidly, indicating the

system is now in Troll Mode.

C Once the system has been placed in Troll Mode, movement of the Control Head’s lever 15

degrees to the Ahead or Astern detent will command Ahead or Astern clutch engagement

and the trolling valve commanded to minimum pressure, while the engine RPM remains at

Idle.

WARNING: Personal Injury may result if this message is disregarded.

NOTE: If system is set for Twin Screw operation, ensure all Control Head levers are in the same detent

(Neutral, Ahead or Astern).

AHEAD

DETENT

ASTERN

DETENT

10453A

FULL

SPEED

ASTERN

FULL

SPEED

AHEAD

65°

65°

15°15°

NEUTRAL

DETENT

80°

80°

Page 29

29

EN 3340.758.003a - 2014-11

OPERATION

MM9000 ClearCommand User Manual

Operation

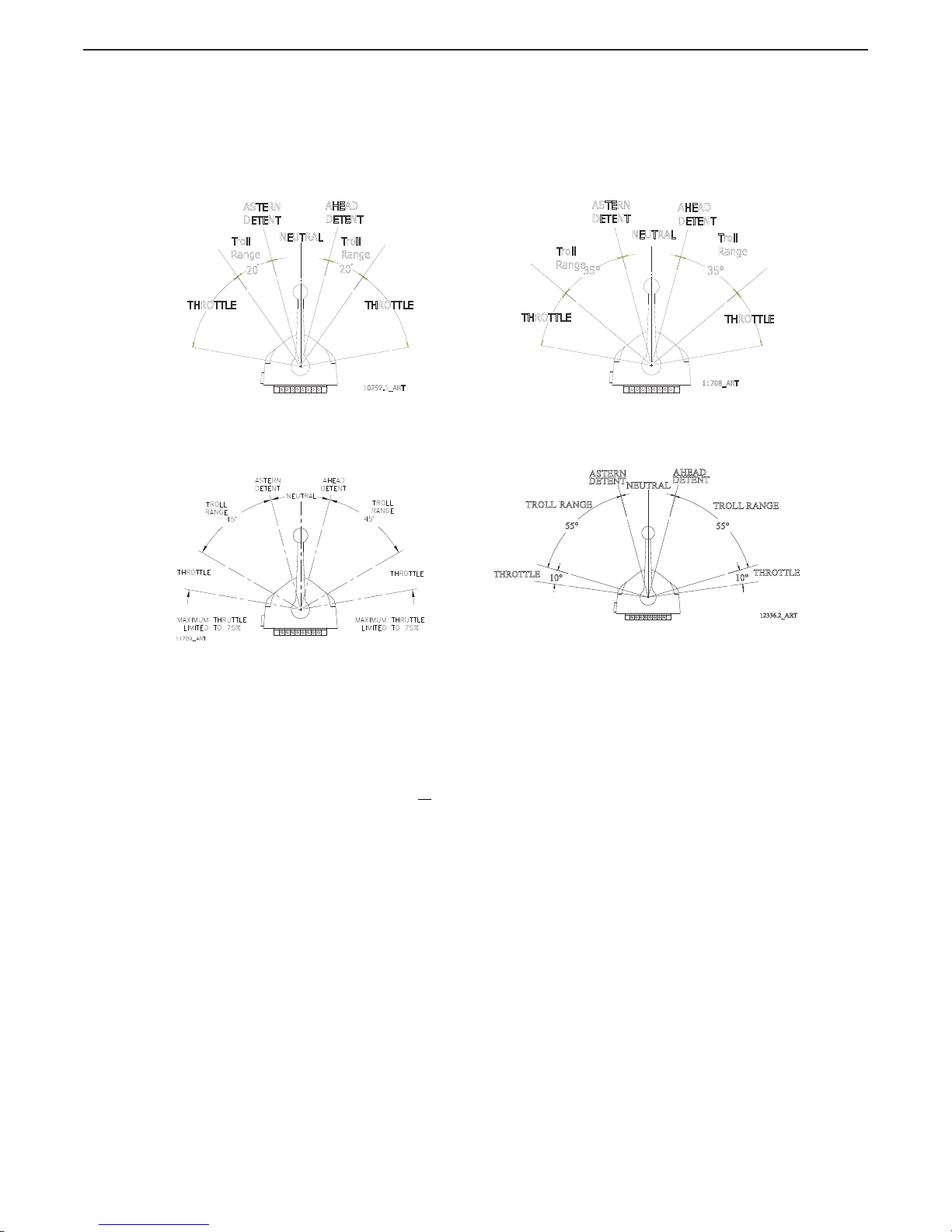

D Further movement through the selectable 25, 35, 45, or 55 degrees, will increase the clutch

pressure to maximum while the throttle remains at Idle.

E Further movement through the next 40, 30, 20, or 10 degrees will increase throttle to full,

except when 45 degrees is selected (where throttle is limited to 75% of full) and 55 degrees

is selected (where throttle is limited to 10% of full).

F To turn Troll Mode OFF, place the Station-in-Command into a detent (Neutral, Ahead, or

Astern).

G Depress and hold the Transfer Button until the red indicator light on the Control Head

becomes lit steady (approximately 2 seconds) then release the button. When the red indicator

light is a steady red, Troll Mode is disabled.

2.4 Start Interlock (if used)

The engine start signal is blocked unless all of the following are true:

• DC power has been turned ON to the Control System.

(Reference Section 2.1: DC Power On)

• A Remote Station is in command. (Reference Section 2.2: Taking Command)

• The Control System is commanding Neutral.

Figure 2-3: Control Head 20 Degree Troll Range - Type 1 Figure 2-4: Control Head 35 Degree Troll Range - Type 2

Figure 2-5: Control Head 45 Degree Troll Range - Type 3

Figure 2-6: Control Head 55 Degree Troll Range - Type 4

AHEAD

DETENT

Troll

Range

ASTERN

DETENT

Troll

Range

10292.1_ART

THROTTLE

20

NEUTRAL

20

THROTTLE

AHEAD

DETENT

Troll

Range

ASTERN

DETENT

Troll

Range

THROTTLE

NEUTRAL

THROTTLE

11708_ART

35°

35°

DETENT

AHEAD

DETENT

ASTERN

12336.2_ART

RANGE

TROLL

RANGE

TROLL

55°

NEUTRAL

55°

10°

10°

THROTTLE

THROTTLE

Page 30

30 EN 3340.758.003a - 2014-11

OPERATION

MM9000 ClearCommand User Manual

Operation

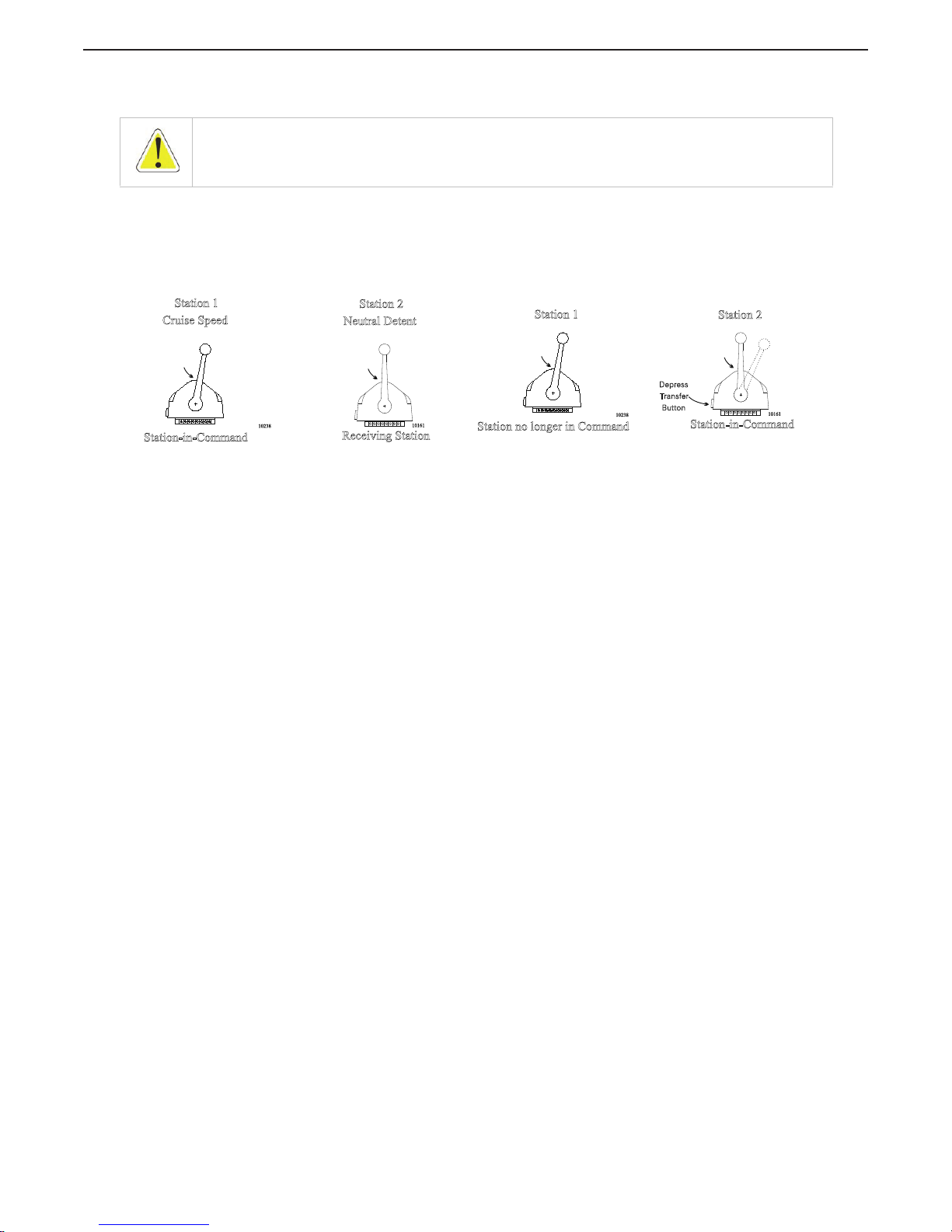

2.5 Station Transfer

Command can be transferred as follows:

A The Station-in-Command’s lever(s) may be left in any position.

B Place the Control Head’s lever(s) of the receiving Station in the Neutral/Idle detent position (refer to

Figure 2-7: Remote Stations Before Transfer of Command)

C At the Station taking command (Receiving Station), depress and hold the transfer button for 1/2

second (refer to Figure 2-8: Remote Station Transfer after Transfer of Command).

• The red LED indicator light at the receiving Station’s Control Head will illuminate, indicating

that the Station has taken command.

• The red LED indicator light will go OFF at the transferring Station’s Control Head, indicating

that the Station no longer is in command.

D The commanded positions of the Throttle and Clutch will remain unchanged for one second after the

red LED lights. This allows the operator time to move the Control Head’s lever(s) to a position

approximately matching the last Station, which will allow the vessel to maintain present speed and

direction.

2.6 Proportional Pause

The proportional pause provides a means of safely reversing the vessel’s direction. A variable pause is

introduced into the clutch command signal to allow time for the engine RPM’s to drop to Idle and for the

vessel’s speed through the water to slow. This pause is set during Section 7: Sea Trials.

WARNING: Personal Injury may result if this message is disregarded.

Figure 2-7: Remote Stations Before Transfer of Command Figure 2-8: Remote Station Transfer after Transfer of

Command

10238

Station-in-Command

Red Indicator

Light “on”

Station 1

Cruise Speed

10161

Receiving Station

Station 2

Red Indicator

Light “off”

Neutral Detent

10238

Station no longer in Command

Red Indicator

Light “off”

Station 1

10161

Station-in-Command

Depress

Transfer

Button

Station 2

Red Indicator

Light “on”

Page 31

31

EN 3340.758.003a - 2014-11

OPERATION

MM9000 ClearCommand User Manual

Operation

2.7 Warm-up Mode

This feature allows the operator to increase the engine’s RPM, while the Clutch remains in Neutral. Warm-Up

Mode is operational only when the Control Head lever is moved in the Ahead direction.

The system is placed into Warm-Up Mode as follows:

A At the Station-in-Command, ensure that the Control Head’s lever is in the Neutral detent position

(refer to Figure 2-9: Control Head Warm-Up Mode).

Figure 2-9: Control Head Warm-Up Mode

B Depress and hold the transfer button.