Page 1

OPERATING INSTRUCTIONS

ZF-DUOPLAN

2-Speed Gearbox

2K250 / 2K300

Page 2

Copyright © ZF Friedrichshafen AG

This document is protected by copyright.

Complete or partial reproduction or distribution of this document is not

permitted without the approval of ZF Friedrichshafen AG. Infringements lead

to civil and criminal prosecution.

Page 3

Contents

EN 4161.758.102q – 2017-09 3

1 Preface ................................................................................................................................... 5

1.1 Validity and field of application ..................................................................................................... 5

1.2 Consumables ............................................................................................................................... 5

2 Safety ..................................................................................................................................... 6

2.1 Signal words and symbols ............................................................................................................ 6

2.2 General safety instructions ........................................................................................................... 6

2.3 Product-specific safety instructions .............................................................................................. 8

3 Application and Design .......................................................................................................... 9

3.1 Application ................................................................................................................................... 9

3.2 Features ....................................................................................................................................... 9

3.3 Design ........................................................................................................................................ 10

3.4 Technical data ............................................................................................................................ 11

3.5 Installation positions ................................................................................................................... 12

4 Initial Installation ................................................................................................................. 13

4.1 Radial run-out, axial run-out and linear tolerances of drive motor ............................................... 13

4.2 Balancing ................................................................................................................................... 14

4.2.1 Semi-key balancing .................................................................................................................... 14

4.2.2 Full-key balancing ...................................................................................................................... 14

4.2.3 Motor shafts/Hubs without keyways ........................................................................................... 15

4.3 Adaptation, motor/gearbox ........................................................................................................ 16

4.3.1 Open design............................................................................................................................... 16

4.3.2 Closed design with hub bearing and shaft sealing ring ............................................................... 17

4.3.3 Closed design (with shaft seal) ................................................................................................... 18

4.3.4 Open design with adapter ring ................................................................................................... 19

4.3.5 Closed design with hub bearing, shaft sealing ring and keyless hub ........................................... 20

4.3.6 Mounting the gearbox ................................................................................................................ 21

4.3.7 Version with pulley drive ............................................................................................................ 22

4.3.8 Closed design with hub bearing, shaft sealing ring and clamping hub ........................................ 23

4.4 Output ........................................................................................................................................ 25

4.4.1 Version with belt output ............................................................................................................. 25

4.4.2 Version with coaxial output ........................................................................................................ 25

4.4.3 Version with TSC ........................................................................................................................ 25

4.5 Electrical connection, gearchange .............................................................................................. 25

4.5.1 Shift unit .................................................................................................................................... 25

4.5.2 Shift logic ................................................................................................................................... 28

Page 4

Contents

4 EN 4161.758.102q – 2017-09

4.6

Lubrication ................................................................................................................................ 29

4.6.1 Splash lubrication ...................................................................................................................... 29

4.6.2 Recirculating lubrication ............................................................................................................ 29

4.6.3 Connections for lubrication ........................................................................................................ 31

5 Initial Operation ................................................................................................................... 34

5.1 Initial inspection ........................................................................................................................ 34

5.2 Checking setting dimension of sun gear .................................................................................... 34

6 Maintenance ........................................................................................................................ 34

6.1 Oil change ................................................................................................................................. 34

7 Repair .................................................................................................................................. 35

7.1 Gearbox fault checklist .............................................................................................................. 35

7.2 Gearbox – disassemble ............................................................................................................. 36

7.3 Input hub with parallel key ........................................................................................................ 36

7.4 Disassembly of gearbox with clamping hub ............................................................................... 37

8 Frequently Asked Questions (FAQ) ...................................................................................... 38

Page 5

Preface

EN 4161.758.102q – 2017-09 5

1 Preface

In addition to the ZF documentation, observe the

provisions of the body manufacturer.

1.1 Validity and field of application

This documentation applies to the following ZF

products:

2K250

2K300

1.2 Consumables

Product Name/Specification Quantity

(approx.)

[dm

3

]

Application Comment

Grease

Shell Avania WR2

Fuchs Renolit CXEP2

Esso Beacon EP2

General assembly

aid

Gearbox oil

HLP 68 according to

ISO VG 68

2K250

B5: 1.5

V1: 1.2

2K300

B5: 2.8

V1: 1.5

Gearbox oil for

splash lubrication

depending on

installation position

Can also be used for

recirculating lubrication

and recirculating

lubrication with heat

exchanger

Gearbox oil

HLP 46 according to

ISO VG 46

Gearbox oil for

recirculating

lubrication

Can also be used for

recirculating lubrication

with heat exchanger

Gearbox oil

HLP 32 according to

ISO VG 32

Gearbox oil for

recirculating

lubrication with

heat exchanger

Gearbox oil HLP 22 according to

ISO VG 22

Gearbox oil for

recirculating

lubrication with

heat exchanger

and integrated

lubricating oil

system

Bonding agent

(liquid seal)

Loctite 574 Sealing end cover

in hub

End washer 40 DIN 470 1 Hub sealing Replace after hub

disassembly

Page 6

Safety

6 EN 4161.758.102q – 2017-09

2 Safety

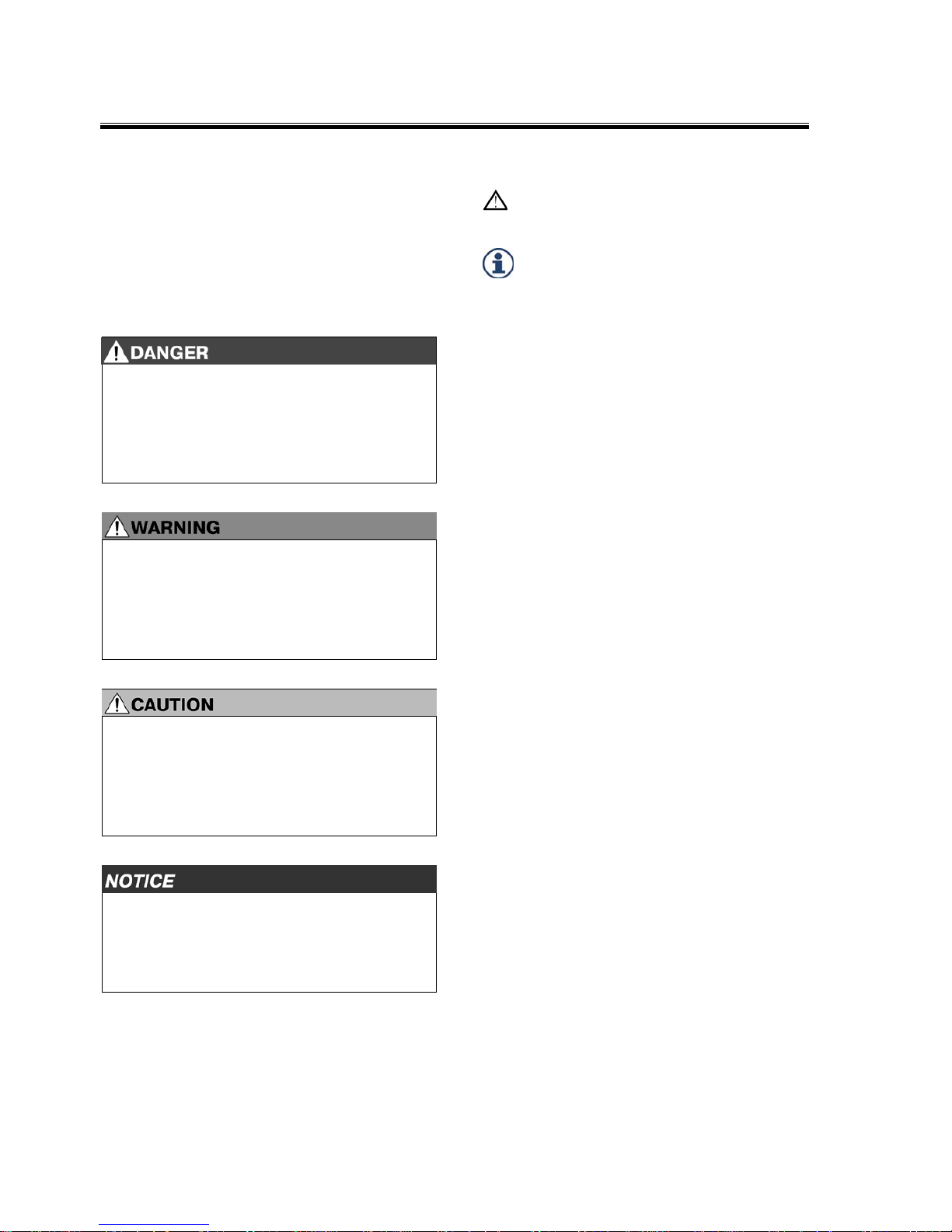

2.1 Signal words and symbols

This document contains specifically highlighted

safety instructions which are marked with one of

the following signal words depending on the

severity of the danger.

DANGER

The signal word DANGER indicates a dangerous

situation that, if not prevented, will lead to a

severe injury or death.

Information as to how the hazard can be

p

r

evented.

WARNING

The signal word WARNING indicates a

dangerous situation that, if not prevented, can

lead to a severe injury or death.

Information as to how the hazard can be

p

r

evented.

CAUTION

The signal word CAUTION indicates a

dangerous situation that, if not prevented, can

lead to a slight or moderate injury.

Information as to how the hazard can be

p

r

evented.

The signal word NOTICE indicates a situation

that, if not prevented, can lead to property

damage.

Information as to how the property damage

can be prevented.

The following symbols are additionally used:

This symbol refers to additional, safetyrelevant information.

This symbol indicates information

concerning special workflows, methods,

application of auxiliary materials, etc.

2.2 General safety instructions

Read all safety instructions and information.

Failure to comply with safety instructions and

information may lead to property damage, serious

injuries or death.

Intended use

The ZF product is exclusively intended for the

application as defined in the contract and as

agreed on at the time of delivery. Any other or

more extensive form of use does not comply with

this definition of intended use. The intended use

includes compliance with this documentation and

other applicable documents, in order to avoid

malfunctions and damage in operation.

The ZF product is designed and produced in line

with state-of-the-art technology. The ZF product is

safe to operate in its delivery status. However, the

ZF product may pose dangers if improperly used

by unauthorized, untrained and uninstructed staff

or if not used according to its intended use.

Figures might deviate from the ZF product and are

not drawn to scale. No conclusions can be drawn

with regard to size and weight.

Assembly, commissioning, maintenance and

repair

Only perform assembly, commissioning,

maintenance and repair work according to this

documentation and other applicable documents.

Page 7

Safety

EN 4161.758.102q – 2017-09 7

Observe the following points:

Employ authorized, trained and instructed staff.

Observe technical provisions.

Only use genuine ZF spare parts.

Only use genuine ZF accessories.

Only use genuine ZF special tools.

Unauthorized changes and modifications lead to

the expiry of the operator's license, warranty or

guarantee.

In case of damage, contact ZF and have the

following information on the product to hand:

Type

Parts list [BoM] number

Serial number

Operating hours

Description of damage

Observe safety instructions, valid safety regulations

and legal requirements to prevent malfunctions

and damage.

The country-specific safety regulations, accident

prevention regulations and environmental

protection provisions also apply.

Wear workwear in accordance with safety

requirements for all work. Depending on the work,

also wear personal protective equipment.

After completing the work, check correct function

and functional security.

Handling of ZF product

Unauthorized changes and modifications may

impair functional security.

Changes, modifications and applications are only

permitted with the written approval of ZF

Friedrichshafen AG.

Observe the following when working on the ZF

product:

Secure workspace.

Only carry out work at the unit when in a

voltage-free state.

Protect unit against being started accidentally.

Attach information sign in a clearly visible

position.

Perform work when motor is switched off.

Protect motor against being started accidentally.

Attach information sign in a clearly visible

position.

Do not stand beneath a suspended load.

Do not work on a suspended load.

Only use permitted means of transport and

lifting devices with sufficient load-bearing

capacity.

Close open pipelines and hoses and avoid

damage.

Observe tightening torques.

Protect cables against mechanical damage.

Noise

Noise may cause irreversible damage to hearing.

The perception of acoustic signals, warning calls

or sounds warning of impending danger is

impaired by noise.

Observe the following when working on the ZF

product:

Avoid noise.

Wear ear protection.

Operating supplies and auxiliary materials

Operating supplies and auxiliary materials may

cause permanent damage to health and

environmental damage.

Observe the following when selecting operating

supplies and auxiliary materials:

Health risks

Environmental compatibility

Material safety data sheets

Observe the following when handling operating

supplies and auxiliary materials:

Store operating supplies and auxiliary materials

in suitable and correctly labeled containers.

Seek medical help in case of injuries due to hot,

cold or caustic operating supplies or auxiliary

materials.

Observe the following to protect the environment:

Collect leaking operating supplies and auxiliary

materials in containers of a sufficient size.

Observe disposal regulations.

Observe material safety data sheets.

Page 8

Safety

8 EN 4161.758.102q – 2017-09

2.3 Product-specific safety instructions

Remove any traces of old seals or gaskets from

mating faces. Burrs or other similar rough

surfaces are to be carefully removed with an oil

stone.

Carefully cover opened gearboxes to prevent

the entry of foreign matter.

Page 9

Application and Design

EN 4161.758.102q – 2017-09 9

3 Application and Design

3.1 Application

The DUOPLAN 2-speed gearbox by ZF is mainly

used in machine tool drives.

As a result of the different installation positions,

the gearbox can be used, for example, for turning

machines (horizontal B5) or machining centers

(vertical V1). In addition, the gearboxes are used in

various equipment in which an increase in torque

or a reduction in speed is needed.

The gearboxes have a coaxial output and are

suited to the high speeds encountered in machine

tool engineering.

3.2 Features

2-speed gearbox for AC and DC main spindle

drives in machine tools

Compact thanks to to planetary design

Flange-mountable to all AC, DC and standard

motors

High running smoothness and low-noise

operation thanks to helical gearing

Low torsional backlash

Easy to install

High radial forces permitted on output

Combined axial and radial force thanks to

flexible output bearings

High efficiency

Electromechanical gearchange

Page 10

Application and Design

10 EN 4161.758.102q – 2017-09

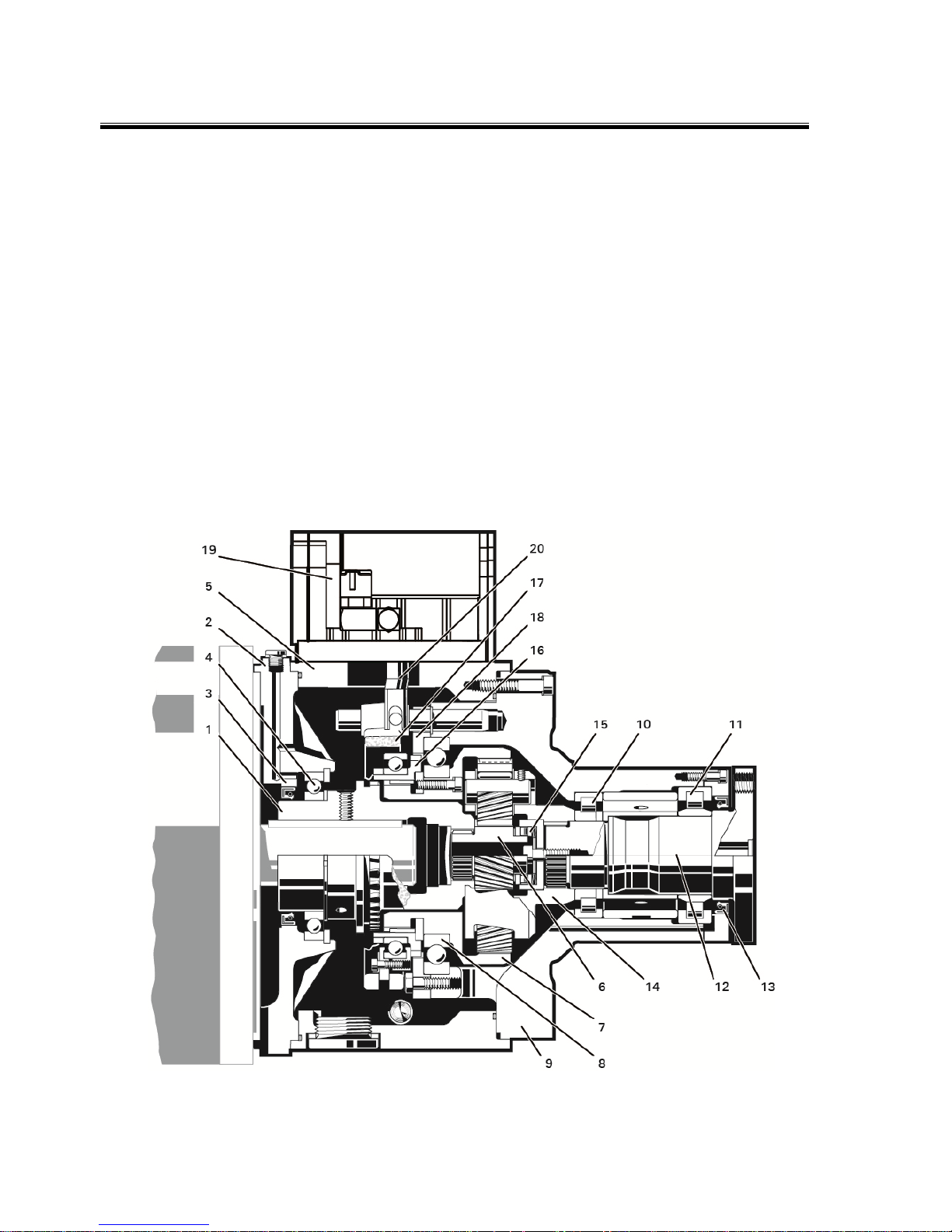

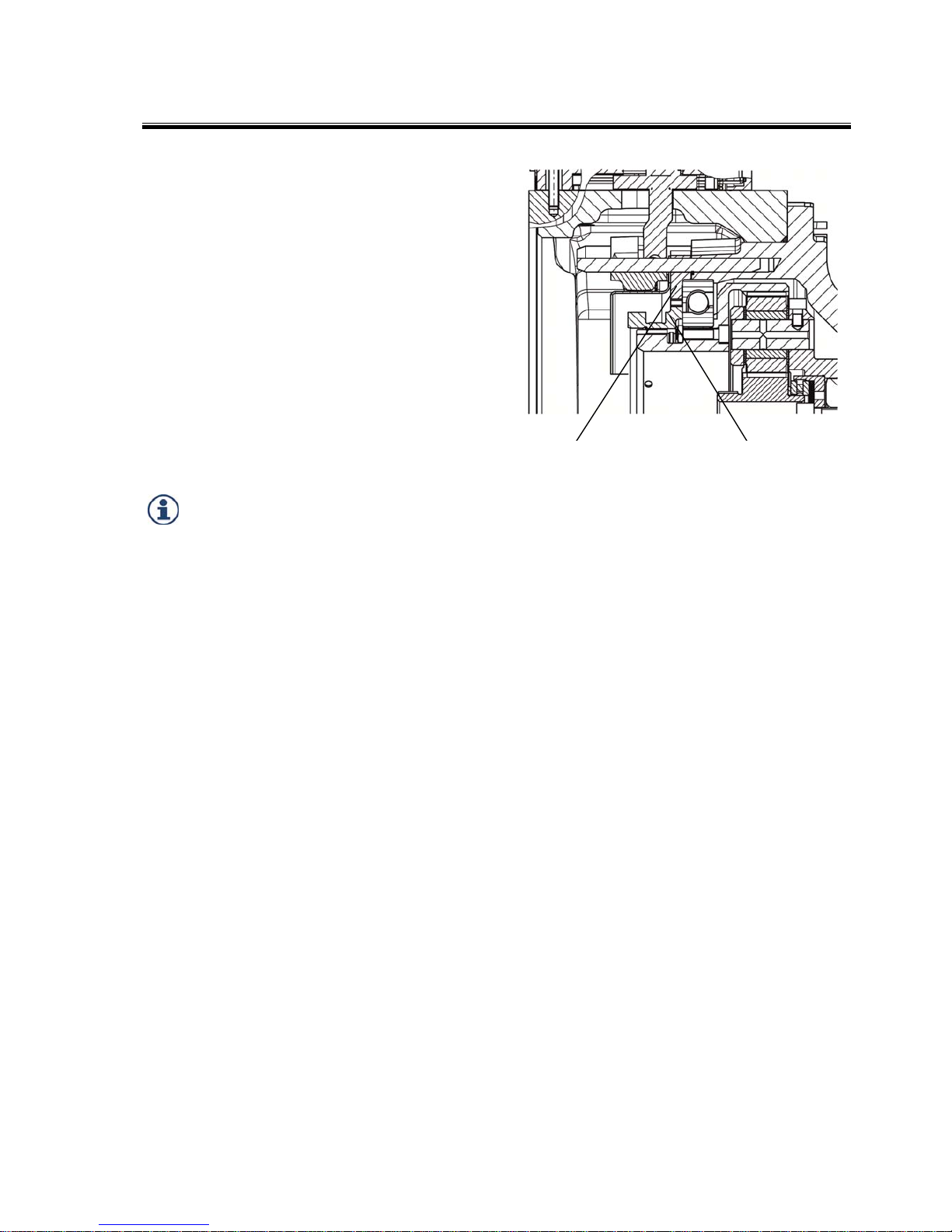

3.3 Design

The gearbox primarily comprises the following

assemblies:

Connecting parts:

Input hub (1)

Where required, adapter plate (2) with radial

shaft seal (3) and hub bearing (4)

Housing:

Gearbox housing (5)

Input:

Sun gear (6)

Ring gear (7)

Ring gear bearing (8)

Output:

Bearing housing (9)

Output bearing (10, 11)

Output shaft (12)

Radial shaft seal (13)

Planet carrier (14)

Axial bearing with cup springs (15)

Shift mechanism:

Sliding sleeve (16)

Shift fork (17)

Brake disk (18)

Shift unit:

Shift unit (19)

Selector finger (20)

Page 11

Application and Design

EN 4161.758.102q – 2017-09 11

S

2

a

1

e

2

d

b

h

l

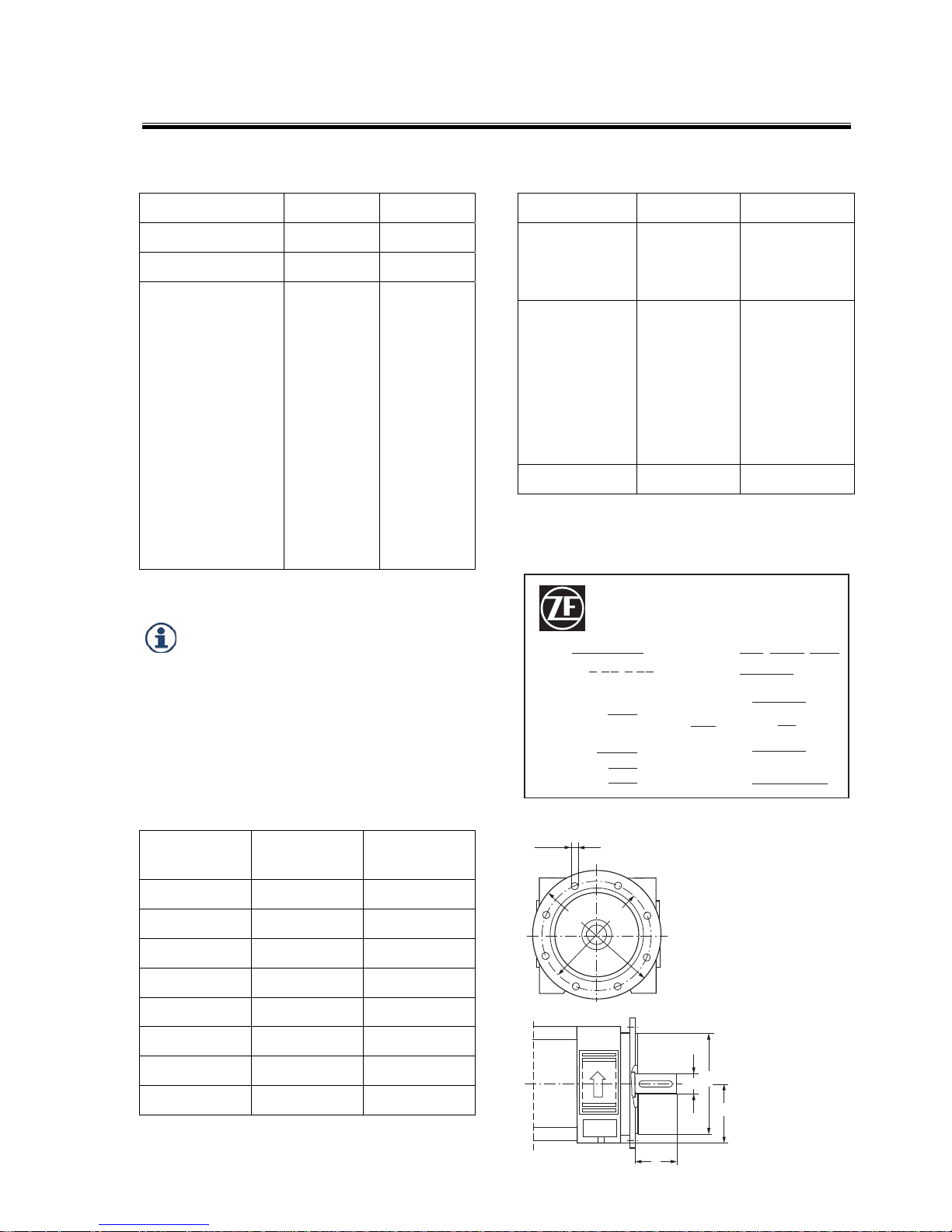

3.4 Technical data

2K250 2K300

Nominal power max. 39 kW max. 47 kW

Nominal speed 1,500 rpm 1,500 rpm

Max. speed

when ratio i1

in direct drive i=1

(with gearbox oil

cooling and

integrated

lubricating oil

system).

See Chap. 4.6.3.3

"Connections for

integrated

lubrication oil system

and maximum

speed"

6,300 rpm

10,000 rpm

6,300 rpm

10,000 rpm

When using engine brakes/counterflow to

brake the spindles (e. g. emergency stop)

ensure that the moments of inertia do not

exceed the admissible output torques.

Braking times must be adjusted

accordingly.

Standard installation dimensions (in mm)

according to EN 50347: 2001

Two-stage

gearboxes

2K250

FF300

2K300

FF350

Motor size 132 160

h 132 160

d 42/48/55 48/55/60

l 110-0.2 110-0.2

b 250 300

e2 300 350

a

1

– –

s2 18 18

2K250 2K300

Input nominal

torque

max. 250 Nm max. 300 Nm,

when i = 5.50

max. 250 Nm

Output torque,

max. for

i = 1.00

i = 3.07

i = 4.00

i = 5.50

250 Nm

768 Nm

1,000 Nm

1,375 Nm

300 Nm

921 Nm

1,200 Nm

1,375 Nm

Weight approx. 68 kg approx. 86 kg

Model plate (standard)

(mounted on gearbox housing)

ZF FRIEDRICHSHAFEN AG

MADE IN GERMANY

TYPE PARTS LIST

RATIO SERIAL-NO.

BACKLASH

MAX.

INPUT TURN RPM

POWER MAX.

AT RPM KW

INPUT

TORQUE NM

OIL GRADE

OIL

QUANTITY

SHITING V

UNIT W

i , - ,

MIN.

Page 12

Application and Design

12 EN 4161.758.102q – 2017-09

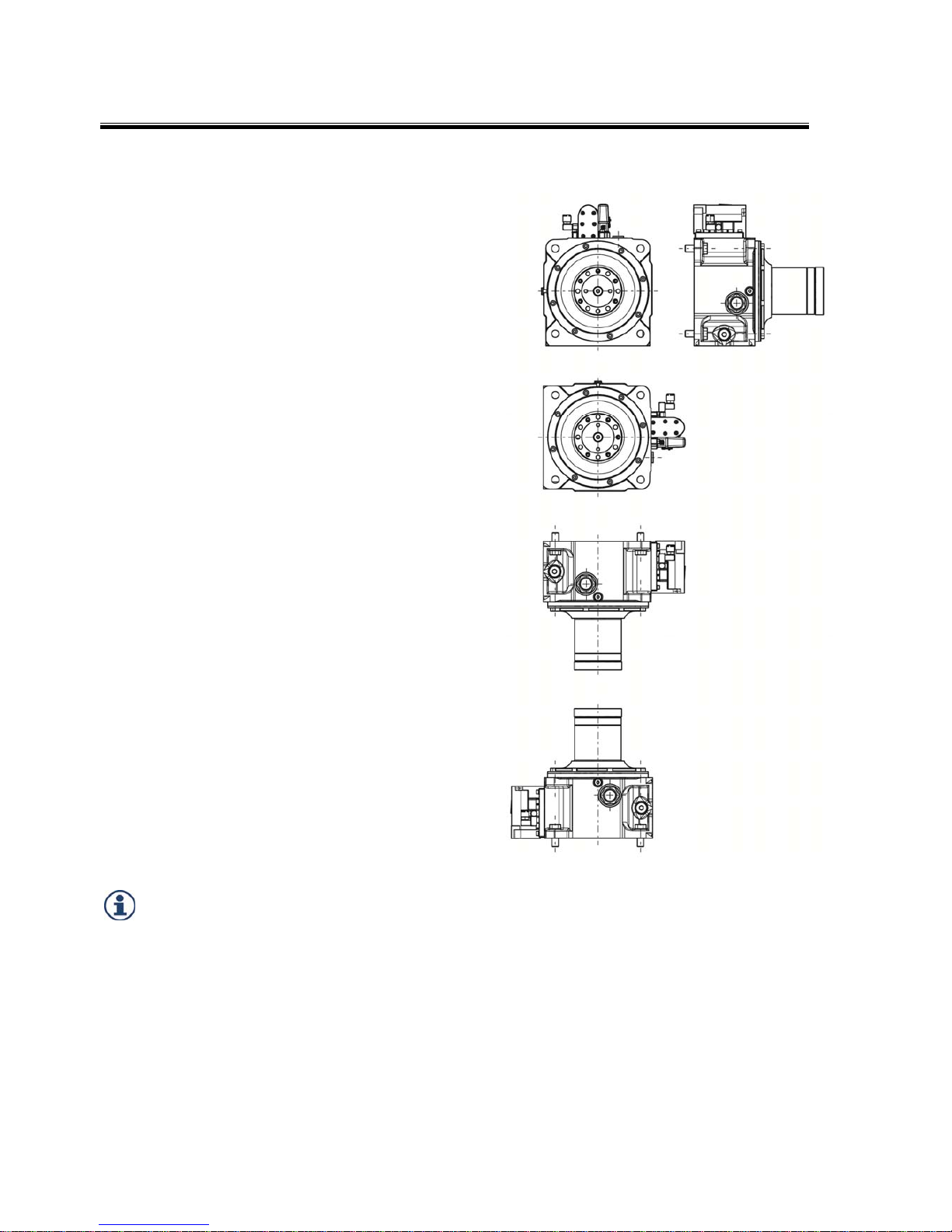

3.5 Installation positions

Horizontal B5

Horizontal B5

Shift unit on right

Gearbox rotated around longitudinal axis

(looking at output)

Vertical V1

Vertical V3

Possible damage to gearbox due to oil

leaks.

Fit breather at top in all installation

positions.

Page 13

Initial Installation

EN 4161.758.102q – 2017-09 13

4 Initial Installation

4.1 Radial run-out, axial run-out and linear

tolerances of drive motor

To ensure trouble-free operation, the motor to be

connected must comply with the specified

tolerances.

Radial run-out, axial run-out and linear tolerances

of mounting flange of electric motor:

Gearbox

type

Tolerance

A B C

L

2K250 /

2K300

0.025 0.063 0.063 -0.200

Tolerances A, B, C according to DIN 42955R

Please note the restricted tolerance of the shaft

length "L" compared to DIN.

The gearbox function will be impaired by

incorrect tolerances.

Comply with tolerance of shaft length "L".

Compliance with tolerance, especially of shaft

length "L", is important for smooth gearbox

functions. If undersized, compensate the

insufficient length using shim rings when

mounting on the motor. If oversized, the shaft

must be machined to the correct length.

Note the permissible axial forces on the motor

shaft. Also refer to ZF-DUOPLAN catalog

(4161.750.102), Chapter Performance data.

Take into account the motor shaft elongation

caused by heating in motors with fixed bearing on

the B-side (opposite the motor output shaft).

ABC

L

001064

Page 14

Initial Installation

14 EN 4161.758.102q – 2017-09

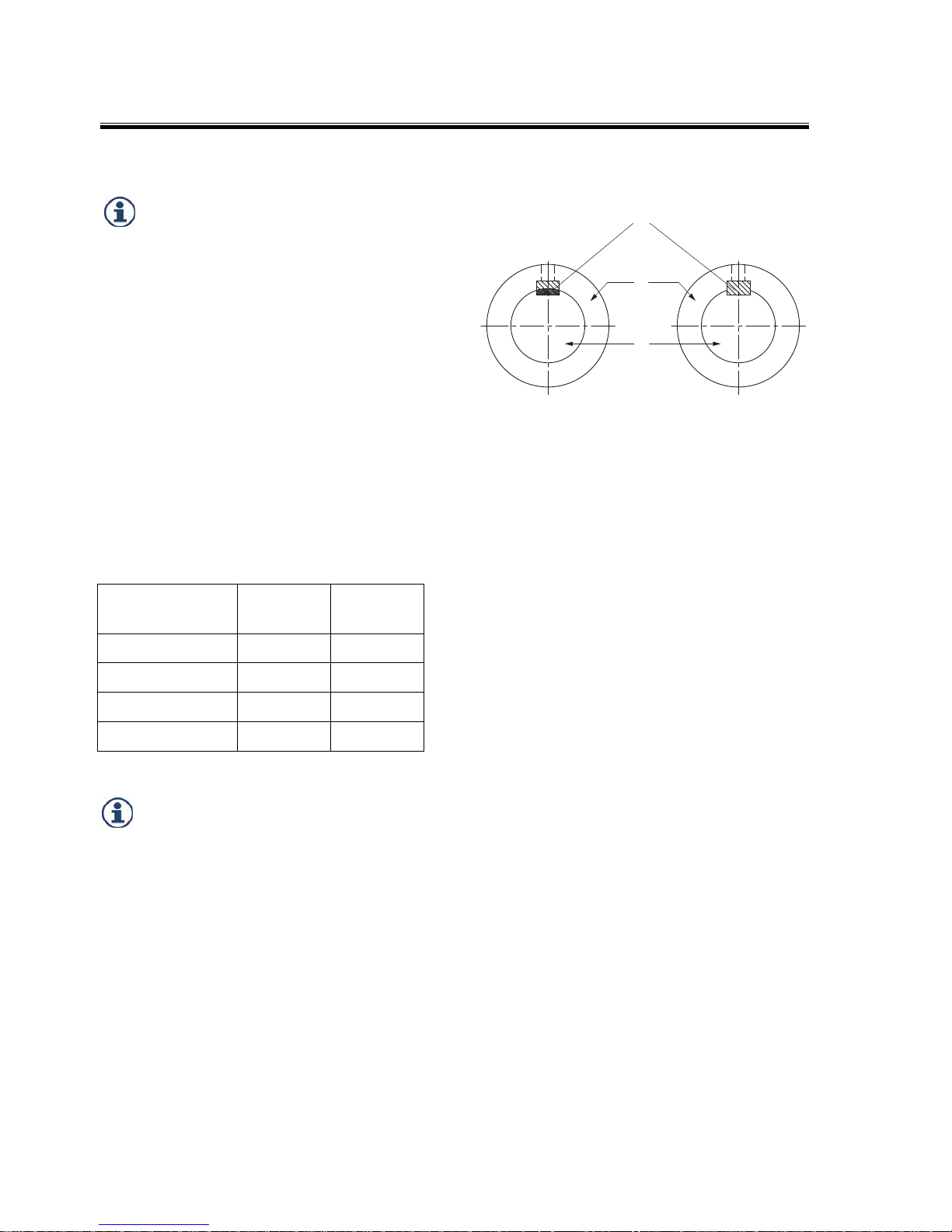

Semi-key balancing Full-key balancing

4.2 Balancing

If using motors with parallel keys, note

the balancing type.

The hubs (2) are delivered with a keyway (1) to

transmit power from the motor shaft (3) as

standard.

There are two balancing types for motor and

gearbox: semi-key and full-key. They are described

in more detail in DIN ISO 8821.

Note that the hub is balanced using the same

balancing type as the motor.

When ordering, it is therefore very important that

you state the motor along with the associated

dimensions and balancing type.

Motor output shafts with standard parallel key

according to EN 50347: 2001

Shaft diameter Parallel ke

y

Parallel key

length

42 mm A12x8 90 mm

48 mm A14x9 90 mm

55 mm A16x10 90 mm

60 mm A18x11 125 mm

In the case of motor shafts with open

keyway ends, glue the parallel key into the

groove in order to avoid axial migration of

the parallel key and/or the hub.

Clamping hubs are used for motors without

parallel keys. A balancing type is not required.

4.2.1 Semi-key balancing

With semi-key balancing, the keyway is filled by

balance compensation corresponding to

approximately half a parallel key, shape B by

default. This is based on the original parallel key,

shape, length and position used by the motor

manufacturer and is defined as a counterweight.

Since in semi-key balancing – in contrast to fullkey balancing – the joint passes through a shared

component, imbalance can arise after assembly

due to tolerance factors.

As a result, it is recommended that rebalancing

should be performed after the joined parts have

been assembled.

4.2.2 Full-key balancing

With full-key balancing, the motor shaft is

balanced with a full parallel key whereas the hub

is balanced without one. The parallel key, shape,

length and position are not important in this case.

1

2

3

Page 15

Initial Installation

EN 4161.758.102q – 2017-09 15

4.2.3 Motor shafts/Hubs without keyways

Clamping hubs are available for motor shafts with

diameters of 42 mm, 48 mm, 55 mm and 60 mm.

1 Hub

2 Motor shaft

Page 16

Initial Installation

16 EN 4161.758.102q – 2017-09

4.3 Adaptation, motor/gearbox

The motors must have a flange-mounting design

for mounting the gearbox.

The gearbox housing is fitted to the motor by

means of the centering adapter on the bearing

housing. This is standard.

A foot fastener is also available on the gearbox

housing for 2K250 and 2K300.

Depending on the motor version, different gearbox

variants are used. The gearbox mounting differs

accordingly.

Reference dimensions for hub position

Gearbox type Dimension D in mm

2K250 125.0-0.2

2K300 125.0-0.2

In the case of motors with fixed bearing on the

B-side, the dimension is D = 124.5-0.2.

If using spacer disks, shim rings of various

thicknesses are also supplied. These are used to

compensate for motor shaft length tolerances and

therefore to comply with control dimension "D".

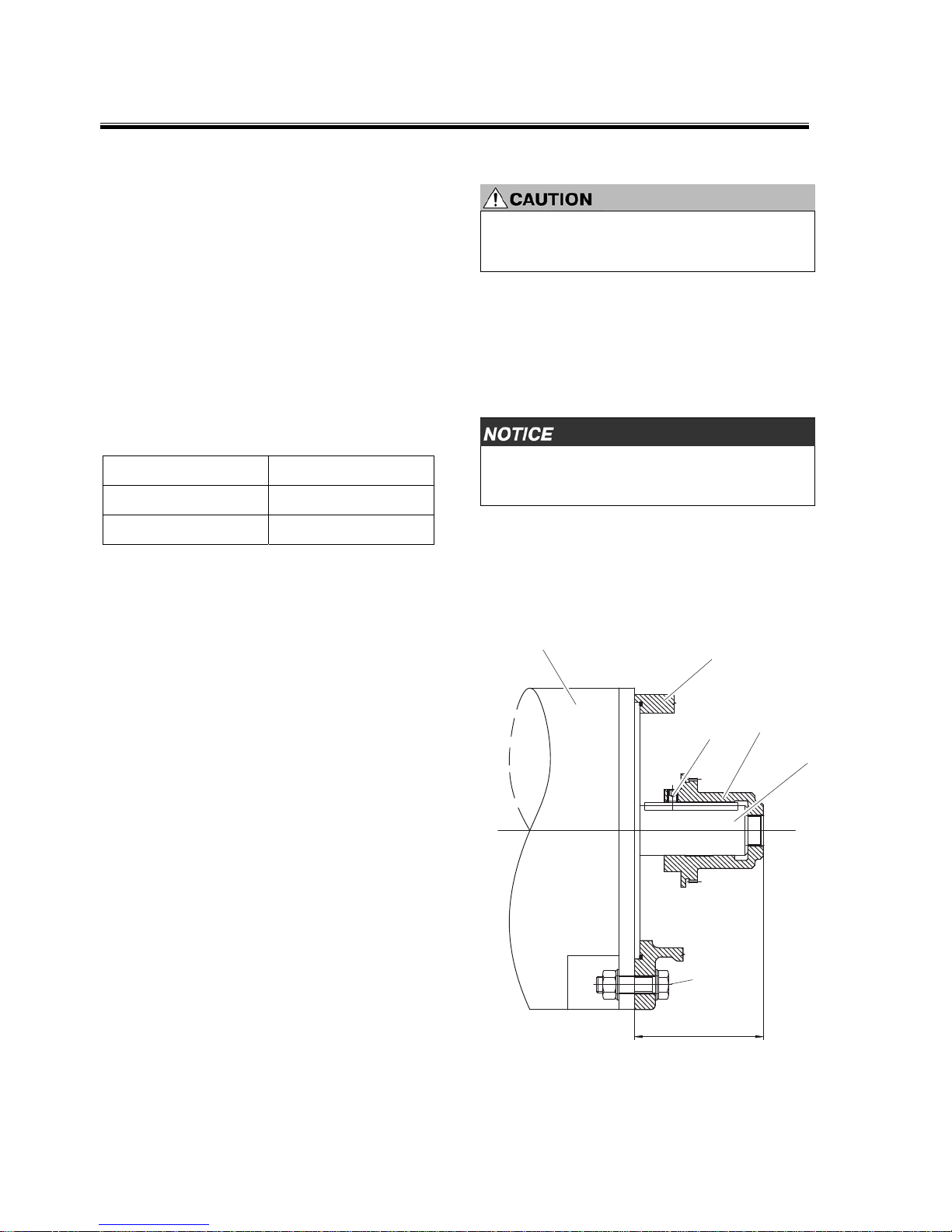

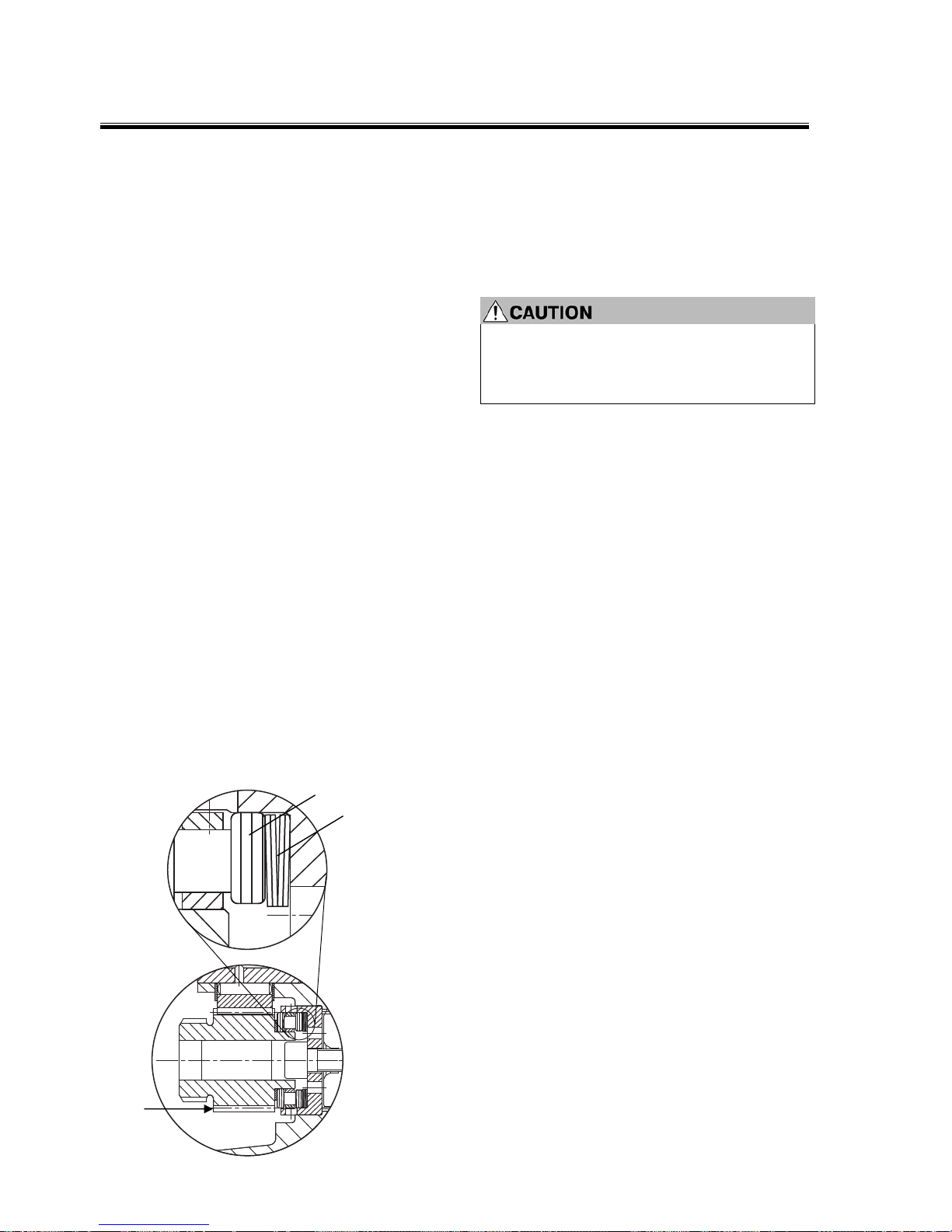

4.3.1 Open design

Open design describes the gearbox without

adapter plate, but with a seal to prevent gearbox

oil ingress on the motor output shaft (2).

The input hub (1) is delivered loose with the

gearbox. Clean the fitting surfaces of motor (3)

and input hub. Check the motor shaft and, if

necessary, correct in terms of concentric running,

axial run-out and length according to Chap. 4.1.

If undersized, use shim rings to compensate. If

oversized, shorten motor shaft. A little grease must

also be applied to the motor shaft.

Risk of burns due to contact with hot surfaces.

Slight to moderate injury possible.

Wear protective gloves.

After cleaning the fitting surfaces, the input hub

must be heated to approx. 120 °C from the

opening and slid onto the motor shaft until the

stop is reached, using shim rings if required.

Then check reference dimension "D".

Risk of motor shaft damage if input hub is not

heated sufficiently.

Heat input hub to approx. 120 °C.

Tighten the set screw (9) and secure it to prevent

it from turning, refer to Chap. 4.3.6.

3

6

9

1

2

11

D

Page 17

Initial Installation

EN 4161.758.102q – 2017-09 17

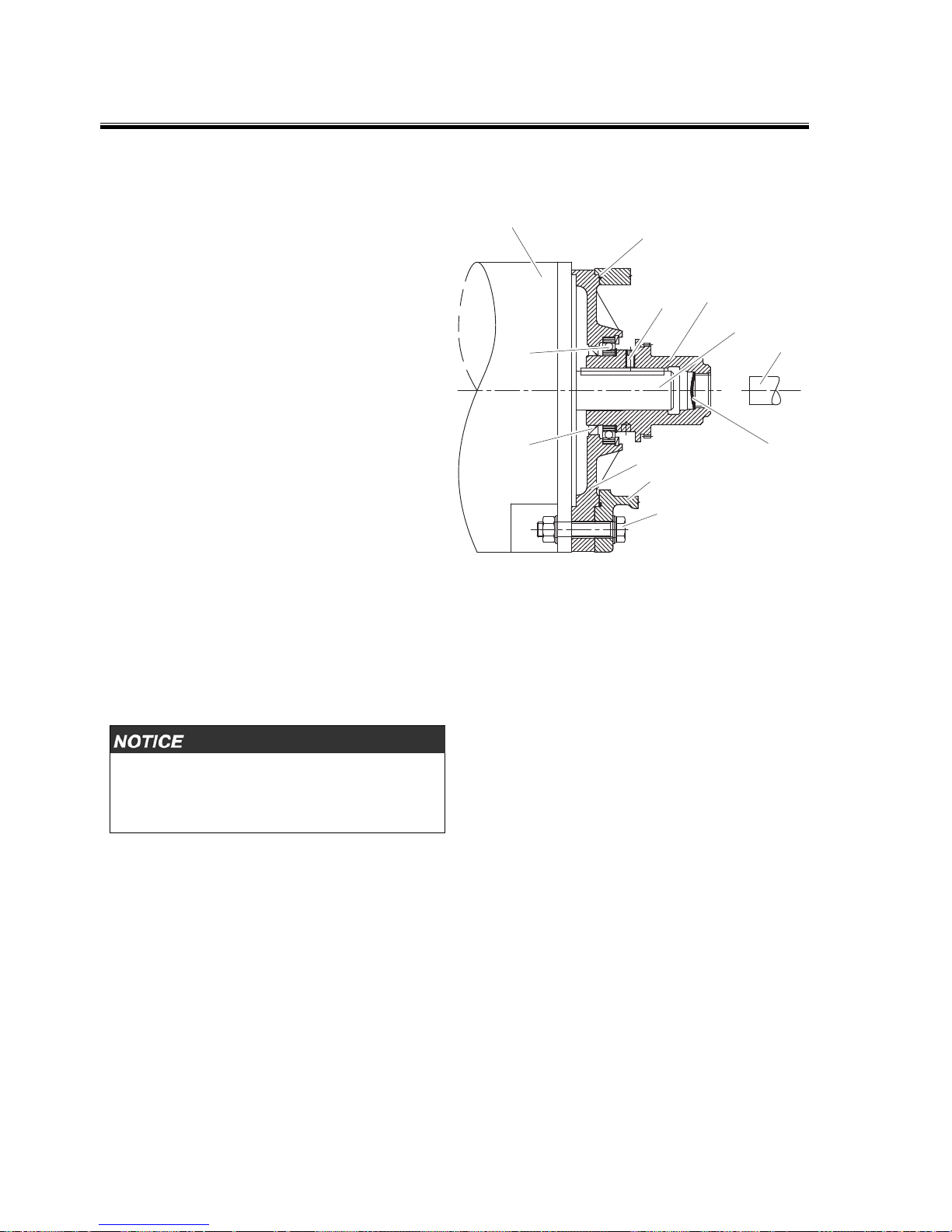

4.3.2 Closed design with hub bearing and

shaft sealing ring

Variant with ball bearing (4), containing additional

bearing mounting for input hub (1), to prevent

axial migration of the input hub.

For assembly, separate input hub (1) with adapter

plate (5) from gearbox housing (6). Clean the

fitting surfaces of motor (3) and input hub. Check

the motor shaft (2) for concentric running and

axial run-out according to Chap. 4.1. A little grease

must also be applied to the motor shaft.

Risk of burns due to contact with hot surfaces.

Slight to moderate injury possible.

Wear protective gloves.

After cleaning the fitting surfaces, the input hub

must be heated to approx. 120 °C from the

opening and slid onto the motor shaft until the

stop is reached.

Control dimension "D" is set ex works.

Risk of motor shaft damage if input hub is not

heated sufficiently.

Heat input hub to approx. 120 °C.

During assembly, it must be possible to easily slide

the input hub onto the motor shaft up to the point

where the adapter plate makes contact with the

motor flange.

Do not use adapter plate to slide hub onto

motor shaft.

Check by ensuring that the adapter plate is making

contact but can be freely rotated. This ensures that

there is no hub bearing preload.

Tighten the set screw (9) and secure it to prevent

it from turning, refer to Chap. 4.3.6.

The radial shaft sealing ring in the drive motor

must be removed on the output end when the

closed design is used.

3

10

9

1

2

5

6

11

D

7

4

Page 18

Initial Installation

18 EN 4161.758.102q – 2017-09

4.3.3 Closed design

(with shaft seal)

This variant contains an adapter plate (5) with

shaft sealing ring (7), making the gearbox a

compact, self-contained unit.

Adapter plate and input hub (1) are delivered

separately and loose. Clean the fitting surfaces of

motor (3) and input hub. Check the motor shaft for

concentric running and axial run-out according to

Chap. 4.1. A little grease must also be applied to

the motor shaft.

Risk of burns due to contact with hot surfaces.

Slight to moderate injury possible.

Wear protective gloves.

After cleaning the fitting surfaces, position the

adapter plate with radial shaft seal on the motor

housing. The input hub must be heated to approx.

120 °C from the opening and slid onto the motor

shaft until it reaches the stop, i.e. spacer disk (12)

with shim rings (13).

Then check control dimension "D" and vary using

shim rings if required.

Risk of motor shaft damage if input hub is not

heated sufficiently.

Heat input hub to approx. 120 °C.

Tighten the set screw (9) and secure it to prevent

it from turning, refer to Chap. 4.3.6.

Thoroughly grease the radial shaft seal and

input hub before assembly. During

assembly, it is essential that the radial shaft

seal's sealing lip is positioned correctly and

that the direction of sealing is correct.

3

10

9

1

2

5

6

11

D

7

12

13

Page 19

Initial Installation

EN 4161.758.102q – 2017-09 19

4.3.4 Open design with adapter ring

The adapter ring allows adaptation to different

connecting dimensions. Sealing is required on the

motor output shaft.

Adapter ring (5) and input hub (1) are delivered

loose. Clean the fitting surfaces of motor (3) and

input hub. Check the motor shaft (2) for concentric

running and axial run-out according to Chap. 4.1.

A little grease must also be applied to the motor

shaft.

Risk of burns due to contact with hot surfaces.

Slight to moderate injury possible.

Wear protective gloves.

After cleaning the fitting surfaces, position the

adapter ring on the motor housing. The input hub

must then be heated to approx. 120 °C from the

opening and slid onto the motor shaft (2) until it

reaches the stop, i.e. spacer disk (12) with shim

rings (13).

Then check control dimension "D" and vary using

shim rings if required.

Risk of motor shaft damage if input hub is not

heated sufficiently.

Heat input hub to approx. 120 °C.

Tighten the set screw (9) and secure it to prevent

it from turning, refer to Chap. 4.3.6.

3 5

10

6

9

1

2

11

11

D

12

13

Page 20

Initial Installation

20 EN 4161.758.102q – 2017-09

4.3.5 Closed design with hub bearing,

shaft sealing ring and keyless hub

When mounting on motor with smooth motor

shaft without parallel key, ring clamping elements

and pressure pieces must be used between motor

shaft and input hub for torque transmission. A

centric screw thread in the motor output shaft is

absolutely essential.

Clean the fitting surfaces for motor (1), motor shaft

(10) and input hub (9).

Check the motor shaft (10) for concentric running

and axial run-out according to Chap. 4.1.

Loosely preassemble the counter-holder (4), ring

clamping elements (5+6), bush (12), pressure

piece (7) and screw connection with a thread-lock

(8). Pay attention to the position of the ring

clamping elements. First install the inner (6) and

then the outer (5) ring clamping elements in the

package on the motor shaft.

Depending on the version, slide input hub onto

motor shaft with or without adapter plate (2).

Attach the ring clamping elements by hand with

the help of the screw connection. Tightening the

screw connection causes the hub (and the adapter

plate, if fitted) to move axially towards the motor.

Take this into consideration by using a lead

dimension of +0.4 mm with 3 ring clamping

elements and a lead dimension of +0.6 mm with

4 ring clamping elements respectively.

Tighten screw connection (8) to 300 Nm for M16

and to 510 Nm for M20.

Note maximum permissible tightening torque for

thread in motor shaft. In adaptations without

coolant flow, use screws of strength class 10.9.

Check dimension D and concentric running of hub.

Additional internal sealing is no longer needed if

using ring clamping elements. The number of ring

clamping elements and bushes may vary

depending on the motor.

If using screw connections with a hole for the

coolant to flow through, be aware of O-rings and

grease them before assembly.

To prevent twisting of the motor shaft and input

hub when tightening, the input hub must be

blocked. This can be done using ZF special tool

1X46.188.387.

D

6

5

7

9 8

11 10

3 4

21

Do not grease: motor shaft (10) and input

hub bore (9).

Apply a little oil: cone-shaped face of ring

clamping elements (5+6).

The counter-holder is supported on the shoulder of

the motor shaft. Ensure a large contact surface.

In the closed version without hub bearing, the seal

running surface for the radial shaft seal on the

input hub is to be greased before assembly. Note

position of sealing lip when sliding on input hub.

When using the closed design with hub

bearing (11) and radial shaft seal (3), do

not use adapter plate to slide input hub

onto motor shaft. Once the screw

connection has been tightened, the adapter

plate must make contact with motor

housing and still be free to rotate. The hub

is then mounted free from pretension.

Page 21

Initial Installation

EN 4161.758.102q – 2017-09 21

4.3.6 Mounting the gearbox

The M8 set screw (9) must be screwed in and

tightened to 18 Nm until firmly home on the

parallel key. Apply liquid seal to the set screw

before installation.

During assembly, ensure that the O-ring (10) is

positioned correctly. The O-ring is delivered loose

with the gearbox and is inserted in the sealing ring

groove in the housing (6) with grease.

Check position of gearbox shift mechanism. The

sliding sleeve must be in gear 1 shift position

("slow" stage).

Take the gearbox and place it on the motor flange.

Carefully connect the sun gear to the input hub.

The external spline of the sun gear must be

fed into the internal spline of the hub.

This process can be simplified by turning the

gearbox output slightly to the left/right.

Gearbox housing, adapter plate and motor are

secured to one another with four or eight hexagon

bolts (11).

Fill the gearbox with oil and/or connect the

recirculating lubrication and power supply. The

breather outlet must be mounted at the top in all

installation positions. The breather is screwed in to

position B5 ex works.

The gearbox is now ready for use.

The gearboxes can be operated under the same

degrees of protection as those in effect for AC

and DC motors.

During installation ensure that the cooling air of

the motor can flow freely in and out.

Before initial operation of the electric motor/

gearbox drive assembly, check that the gearbox

output can be turned by hand.

For drive assemblies which are fastened to the

gearbox flange or gearbox housing, the motor can

be supported on the B-side free from distortion.

Gear 1 shift position:

A Brake disk

B Sliding sleeve

A

B

Page 22

Initial Installation

22 EN 4161.758.102q – 2017-09

4.3.7 Version with pulley drive

The pulley will be centred on the outer diameter of

the drive flange (K6 tolerance), friction-locked in

place and secured using screws, whereby the

permitted torque must be taken into account.

The pulley must have a balance rating of 6.3, as

per VDI Directive 2060, in order to ensure low

vibration operation.

It is mandatory to lubricate the bearings fitted in

the pulley drive with 0.5 – 1.0 l/min via oil

connector ‘S’ in the drive housing.

Note maximum tensile force of belts

(refer to Chap. 4.4.1).

The average belt power must lay in between the

bearings. During assembly, it must be possible

to easily slide the belt pulley onto the input

flange, heat the belt pulley if necessary.

Page 23

Initial Installation

EN 4161.758.102q – 2017-09 23

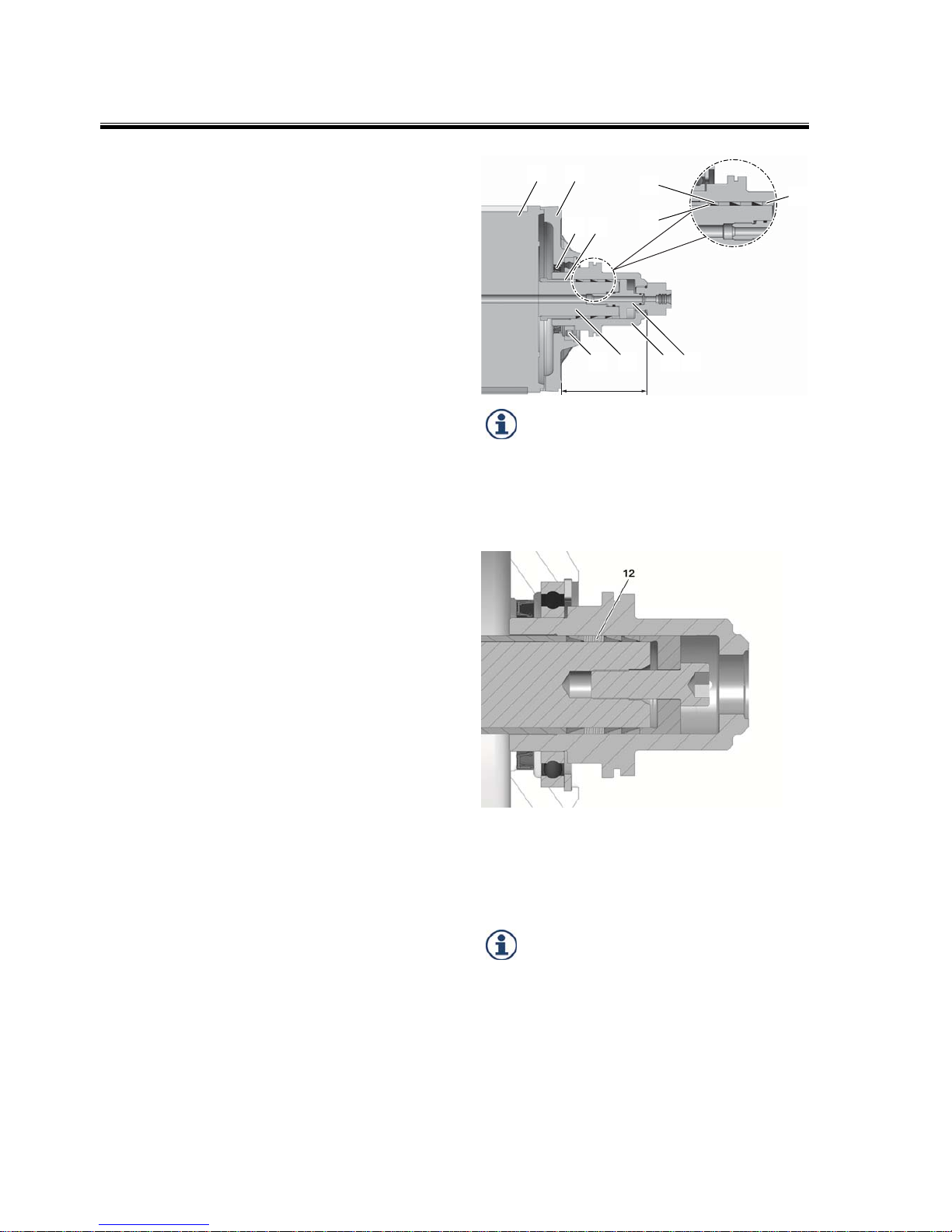

4.3.8 Closed design with hub bearing,

shaft sealing ring and clamping hub

The motor is mounted on the gearbox using

an adapter flange with clamping hub. The

motor shaft is connected to the clamping

hub with a force fit.

The gearbox with clamping hub may only be fitted

on motors with a smooth motor shaft.

1 Adapter plate

2 Motor shaft

3 Motor flange

4 Mounting screw

5 Clamping hub

6 Sleeve

7 Clamping screw

8 Cover plate

9 Output shaft

Mounting gearbox on motor:

First the motor shaft (2), the bore of the clamping

hub (5) and, if present, the sleeve (6) must be

degreased. Then insert the sleeve into the

clamping hub until the stop is reached. The

clamping hub (5) must be positioned so that the

clamping screw (7) can be tightened via the

access bore. The cover plate (8) is removed for

this purpose. The motor shaft (2) is guided

(centered) into the clamping hub (5) until the

motor flange (3) makes contact with the adapter

plate (1). Ensure that the motor shaft does not jam

in the clamping hub. The fixing bores on the motor

flange and adapter plate must match precisely.

The motor is mounted on the gearbox with four

appropriate mounting screws (4), with a screw-in

depth into the adapter plate of 15 to 25 mm.

Tighten clamping screw (7) to 260 Nm with torque

wrench, socket wrench extension and hex socket

insert (WAF 14). If necessary, block the output

shaft (9). Close off the access bore again with

cover plate (8).

Dimension A for extension of hexagon socket

wrench

Adapter plate 2K250, A = 100 mm

Adapter plate 2K300, A = 125 mm

Page 24

Initial Installation

24 EN 4161.758.102q – 2017-09

4.3.8.1 Spindle cooling (TSC) version,

feeding emulsions, hydraulic oils or

air-oil mixtures

Mounting gearbox on motor:

Coat thread of connecting piece (1) with sealing

compound. Screw connecting piece with preassembled and greased O-rings (2) into motor

shaft (3) by hand until stop is reached. Use jaw

wrench (WAF 27) to tighten connecting piece to

130 Nm, blocking motor shaft in the process.

Follow the description provided in Chapter 4.3.8

for the rest of the mounting process.

1 Connecting piece

2 O-rings

3 Motor shaft (hollow shaft)

Installing the rotary union:

Apply grease to both ends of tube (5) and place in

rotary union (4). Carefully guide tube through

greased radial shaft seal (1) into gearbox. Coat the

four cap screws (3) with hex socket (WAF 3) with

sealing compound and tighten to 2.8 Nm with

torque wrench.

1 Radial shaft seal

2 Output shaft

3 Cap screw

4 Rotary union

5 Tube

Page 25

Initial Installation

EN 4161.758.102q – 2017-09 25

4.4 Output

Please note the details relating to the resultant

force in the installation drawings.

4.4.1 Version with belt output

The belt pulley is centered to the outside diameter

of the output flange (tolerance K6), attached and

secured with friction engagement using screws,

while noting the permissible tightening torques.

For low-vibration operation, the belt pulley should

be balanced to quality 6.3 according to VDI

directive 2060.

Possible damage due to bearing overload.

Note maximum tensile force of belts.

To avoid overloading the bearings, note the

maximum tensile force when tensioning the belts.

The average belt power must lay in between the

bearings. During assembly it must be possible to

easily slide the belt pulley onto the output flange,

heat the belt pulley if required.

4.4.2 Version with coaxial output

For the version with coaxial output (stub shaft), the

balancing type should also be noted for the output

(refer to Chap. 4.2). The gearbox is delivered with

full-key balancing.

The parallel key dimensioning can be seen in the

installation drawing. Fix the parallel keys using a

set screw in any case.

4.4.3 Version with TSC

The version with TSC (Through Spindle Coolant)

serves to transmit cooling lubricant, hydraulic oils

or air-oil mixtures

1)

through the gearbox to the

spindle. To ensure liquid transfer during gearbox

under speed differential, a rotary union is needed,

which is subject to wear depending on the load

and the status of the medium. Depending on the

system used, leakage drips can occur when

activating and deactivating. This can be traced

back to design measures in the coolant circuit. A

transparent coolant return allows the status of the

rotary union to be assessed.

The warranty for the rotary union is limited to 12

months.

Information regarding the product, function,

operation and installation of the rotary union can

be found in the operating instructions

4161.758.030 (German)

4161.758.130 (English)

1)

No abrasive or solvent additives are permitted

in the fluids.

4.5 Electrical connection, gearchange

The electrical connection may only be performed

by a qualified electrician.

Possible damage to shift unit due to incorrect

connections.

Connect shift unit as described in Chap. 4.5.1

and 4.5.2.

The gearbox is connected electrically with the

8-pole Harting connector supplied (HAN 8 U). The

plug connection is located on the shift unit.

4.5.1 Shift unit

Technical data:

Power consumption 84 W

Supply voltage 24 V DC ±10%

Max. pickup current 5 A

Nominal current: 3.5 A

Protection class IP64

The required cable lead diameter is 1.5 mm².

Ensure the supply voltage of 24 V DC and the

current consumption of 5 A on the shift unit plug.

Losses due to cable length and transition

resistances are to be taken into consideration.

Scope of supply:

Sleeve housing, screw connection, socket insert

and 8 Harting AWG16 contact bushings. The shift

unit is only available as a complete part.

Page 26

Initial Installation

26 EN 4161.758.102q – 2017-09

Gearbox shift mechanism:

During the gear change, the motor shaft

and/or gearbox output is without load

(unbraked).

Shifting is performed through application of 24 V

on pin 2 and 3. The polarity of the applied 24 V DC

voltage is decisive for the gear stage.

In gear 1 => Pin 2: + / Pin 3: ‒

In gears 2 and 3 => Pin 2: ‒ / Pin 3: +

During the gear change, the main spindle motor

should make the shaft oscillate +5° or -5° at a rate

of 1 to 5 rotation direction changes per second. A

larger pendulum motion may cause damage to the

meshing gears. The gears usually already mesh at

the first rotation direction change, so that the

switchover time is approx. 300 to 400 ms.

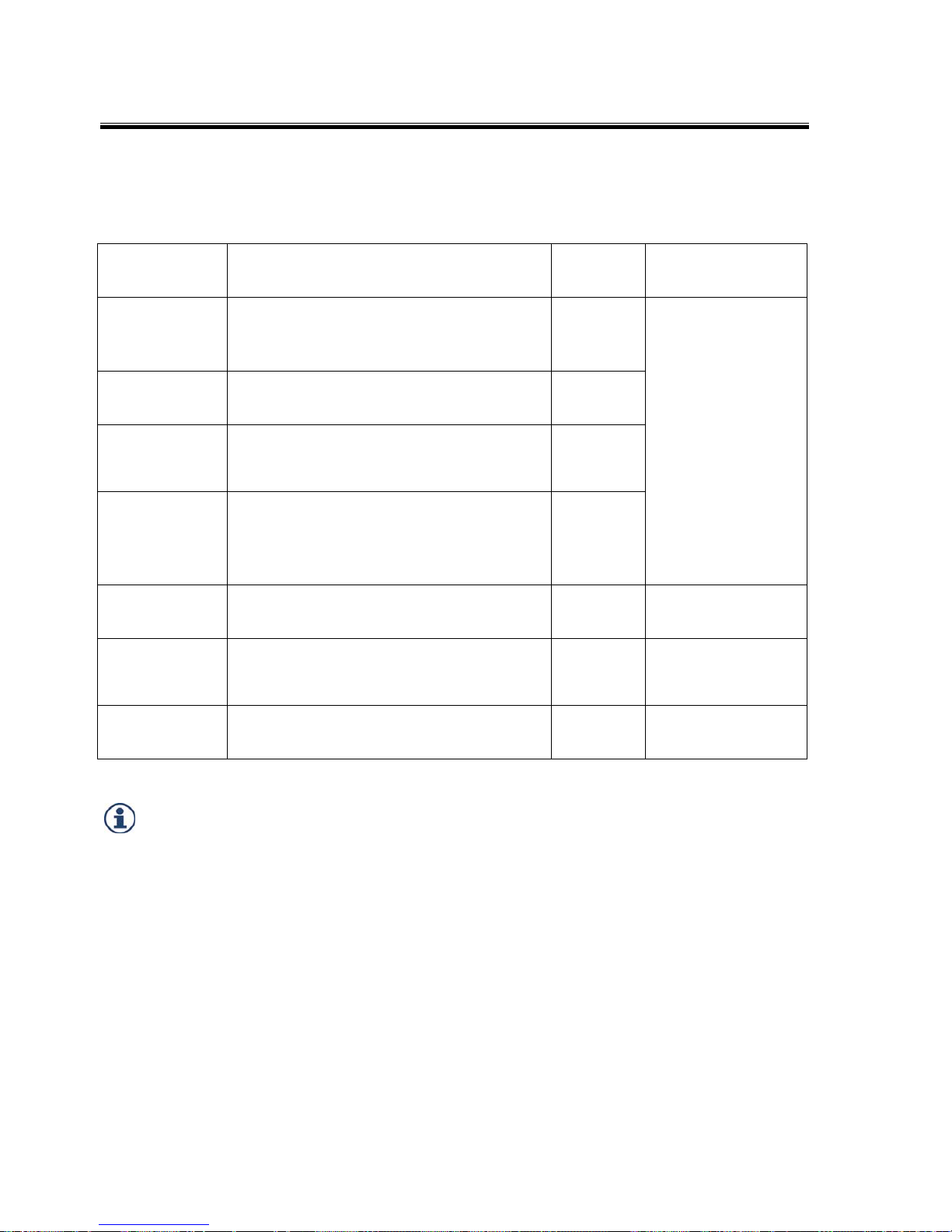

On average, this means: n

Mot

= 5°/s = 5° 60/min =

300°/min = 300/360 rpm = 0.83 rpm.

Conversion

Pendulum speed

pendulum rotary motion

Speed

[rpm]

Angle

[°/min]

Time

[sec]

Angle

[°/sec]

0.25 90 3.33 5

0.50 180 1.67 5

1.00 360 0.83 5

2.00 720 0.42 5

3.00 1,080 0.28 5

4.00 1,440 0.21 5

5.00 1,800 0.17 5

Because of the different masses and associated

drag torques of the spindle, the machine optimum

is to be determined on the basis of shift tests.

The limit switch signals of S1 – gear 1 (contact 4)

and S2 – gear 2 (contact 6) serve to shut off the

shift unit once the gear change is complete.

After the limit switch signals have been reached,

the shift unit is allowed to be live for a maximum

of 0.5 seconds. The limit switch signals must be

monitored during operation.

The limit switches must only be energized with the

control current (0.1 to 0.5 A), not the changeover

current (5 A).

The changeover current must not be present for

more than 2 seconds.

If the number of resistors is small, a lower control

current may also be used.

The control current for end-position monitoring

must be ensured depending on length, line/

transition resistances and number of connection

points. Increased resistances caused by corrosion

must also be considered after some time.

Switching of inductive loads by means of the

control current requires it to be wired parallel to

the load by a diode.

If the limit switches detect that a gear is no

longer reliably engaged, the control system must

initiate appropriate measures, such as emergency

shutoff etc.

Electromagnetic fields may falsify the signals of

limit position monitoring.

Do not route control lines in parallel with

cables for the voltage supply or shield control

lines.

The shift sequence is to be monitored; if

necessary, a timing element must reverse the gear

change if no limit switch signal (S1/S2) is received

after approximately 2 seconds. Afterwards repeat

the gear change command, the main spindle

motor must not be released.

Rotation direction

changes

Page 27

Initial Installation

EN 4161.758.102q – 2017-09 27

Diagram for shift unit with two shifting positions

(standard) or three shifting positions (with neutral

position):

Gear 1 ==> e.g. 4:1

Gear 2 ==> 1:1

Gear 3 ==> S3 neutral position, idling

(option)

S3

S1 S2

optional

M

34

4

2

1

34

blue

blue

grey

grey

black

blue

black black

green

X8

43526

8

17

The electromechanical gear change is undertaken

by a shift unit on the gearbox, which is driven by a

direct current motor (24 V DC). The gear shift

element is a positively locking, axially movable

shift selector that acts on a sliding sleeve.

The limit positions are monitored by limit position

switches in the shift unit. Monitoring of timing is

provided in the control unit.

When shifting from gear 1 to gear 2 or vice versa,

the motor is to be energized. The rotation direction

is changed by means of pole reversal.

Gearbox with neutral position

The neutral position can only be approached from

gear 1.

As soon as the S3 limit position switch receives

the signal, the direct current motor is to be shut

down by means of a dynamic motor stop (quick

stop).

Under certain operating conditions (e.g. V3

installation position, higher line resistances), a

variable timing element may be needed in the

gearbox control consult ZF.

Page 28

Initial Installation

28 EN 4161.758.102q – 2017-09

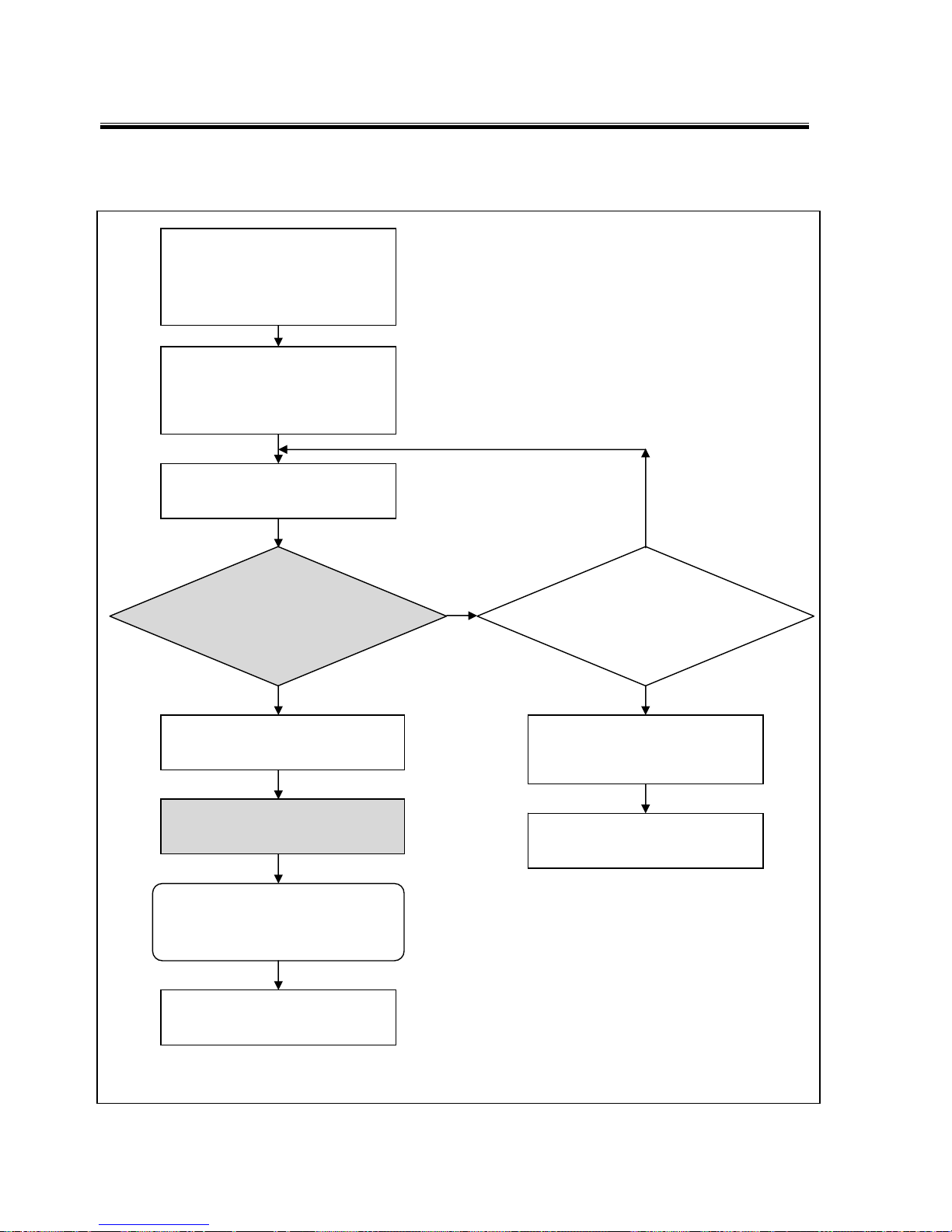

4.5.2 Shift logic

1) Alternatively, the first switching test can be performed without oscillating, but this requires a de-energized main spindle motor or

minor output-end masses.

Decelerate main spindle motor from

operating speed to zero.

Keep controller release (signal)

connected with power converter.

Apply desired oscillating speed to

converter and speed controller

without delay.

1)

Shift unit energized

(pin 2 and 3)

Gear change

must be completed within 2

seconds. (Feedback signal from limit

switch S1, S2 or S3 from the shift

unit)

Shut off desired

oscillating speed.

After 200 ms to max. 500 ms

shift unit OFF.

Gear change

complete.

Number of gear

change attempts > 5

all from the respective starting

position (pole reversal)

Gear change not accomplished:

switch off

main spindle motor.

Check system.

N

N

Y Y

Start main spindle motor

Page 29

Initial Installation

EN 4161.758.102q – 2017-09 29

4.6 Lubrication

4.6.1 Splash lubrication

The B5 standard version of the gearbox has splash

lubrication.

Splash lubrication is suitable for intermittent

operation. Frequent gear shifts, different

speeds and downtimes, such as those

encountered when changing tools, are

assumed.

Possible damage to gearbox due to insufficient

oil quantity and/or running dry.

Fill gearbox oil up to center of oil level gage

glass.

The actual oil level is binding for the amount of oil

to add. The number of liters stated on the model

plate for the relevant gearbox is a reference value.

If the gearbox is installed at an angle, which may

be the case with certain belt tensioning equipment, an oil level tube with calibration mark must

be fitted in place of the oil level gage glass.

Ensure the same oil level as that obtained when

the gearbox is installed horizontally (also refer to

installation drawing).

An oil sensor can occasionally be used to

check the oil level before starting the

machine. The oil sensor can be screwed

into connections D or E (figure, page 31) of

the gearbox housing. (Oil sensor order no.

4161.298.045, Balluff data sheet available

on request)

4.6.2 Recirculating lubrication

Two connecting pieces (hose fittings) with

M42x1.5 and M22x1.5 thread are optional

accessories, order no. 4161.106.016.

Recirculating lubrication enables efficient gearbox

lubrication and cooling. This improves the

gearboxes performance and less heat is

introduced into the machine.

Gearbox failure due to insufficient lubrication.

Gearboxes in the V1 vertical and V3 vertical

installation positions must be operated with

recirculating lubrication.

In the 2K250/2K300 gearboxes, the V1 vertical

and V3 vertical installation positions require

recirculating lubrication. The type of recirculating

lubrication depends on the operating temperature

level required.

Because of the centrifugal forces acting on the oil,

there may be insufficient lubrication at the gearing

if operated continually in direct drive.

Occasionally changing gear (ratio) and then

starting the motor (n

Mot

=1,000 rpm) feeds oil to

the gearing and prevents the gearing from being

loaded on the one side linked to the selected

position.

Some applications require a very low operating

temperature level which can be obtained by

connecting a gearbox oil supply with oil cooling

specifically designed for this purpose. The relevant

gearbox versions are prepared accordingly.

To achieve ideal gearbox cooling without

influencing lubrication, various connectors are

available for recirculating lubrication on the

gearbox depending on the installation position and

mode of operation.

The figures on page 31 show the oil inlet and

outlet points on the gearbox. The precise

measurements can be found on the respective

installation drawings.

After initial operation, the oil level must be in the

center of the oil level gage glass, top up oil if

required.

The pump, oil tank and heat exchanger

components must be positioned below the

gearbox oil level. If the oil return is

connected according to Chap. 4.6.3.2,

limp-home (emergency control)

characteristics are assured.

Page 30

Initial Installation

30 EN 4161.758.102q – 2017-09

The following scenarios are unproblematic:

The oil level in the tank falls during operation as

a result of the gearbox oil in the gearbox

foaming.

The formation of an oil-air emulsion in the oil

return and in the tank.

4.6.2.1 Recirculating lubrication during

V1/B5 operation

For the position of the oil inlets and outlets, refer

to Chap. 4.6.3.2.

The oil inlet is connected in place of the oil drain

plug.

Oil inlet quantity 1.5 to 2 l/min.

One oil level gage glass is removed and replaced

with a screw-in drain pipe (M42x1.5).

In the V3 vertical installation position, the gearbox

oil can be supplied both radially and centrally.

The outlet line should be dimensioned so as to

prevent oil return blockages in the gearbox

(D

i

approx. 20 mm).

4.6.2.2 Recirculating lubrication with heat

exchanger

A heat exchanger is installed in the recirculating

lubrication to achieve an additional reduction in

temperature.

4.6.2.3 Recirculating lubrication with

intermediate tank

For effective oil cooling, the tank volume should be

at least ten times the amount of oil circulated.

To avoid gearbox damage from running dry, ZF

recommends installing an oil level sensor on the

intermediate tank.

Use a 60 μm filter and a safety non-return valve (1)

at the gearbox oil inlet.

This arrangement permits continued operation

using splash lubrication, refer to Chap. 4.6.1.

Downstream of the gearbox, the oil return line

must always be below the oil outlet so that the oil

level in the gearbox cannot rise.

Installation example B5

1

Page 31

Initial Installation

EN 4161.758.102q – 2017-09 31

4.6.3 Connections for lubrication

4.6.3.1 Connections for initial fill/

oil change

Installation

position

Oil fill Oil drain

B5

I

G, F, H

B5 rotated D

V1 D, E by drawing off

(for version with output shaft)

P (for version with output flange)

V3 H

Page 32

Initial Installation

32 EN 4161.758.102q – 2017-09

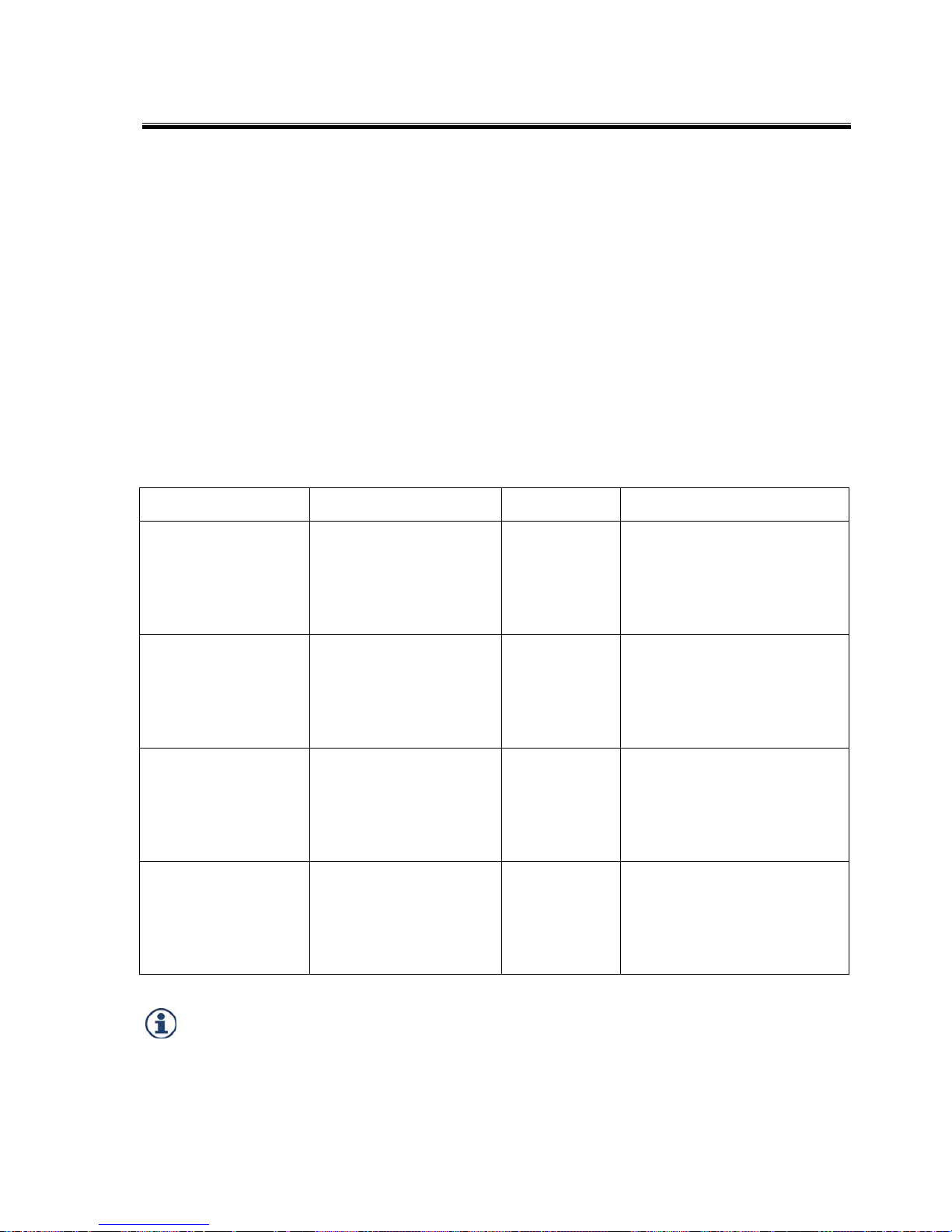

4.6.3.2 Connections for recirculating lubrication in standard applications

Installation

position

Oil inlet connection Max.

pressure

Oil return port

V1

(closed

variant)

M (0.5 l/min) and

T (1.0 l/min)

0.5 bar

0.5 bar

D

Main direction of

rotation

counterclockwise *

E

Main direction of

rotation

clockwise *

V1

(open variant)

T (1.5 l/min) 0.5 bar

B5

(closed variant)

M (0.5 l/min) and

T (1.0 l/min)

0.5 bar

0.5 bar

B5

(open variant)

G (1.5 l/min) main direction of rotation

counterclockwise* or

F (1.5 l/min) main direction of rotation

clockwise*

1.5 bar

B5 rotated

(open on right)

I or F (1.5 l/min) 1.5 bar H

V3

(closed variant)

M (0.5 l/min) and

T (1.0 l/min)

0.5 bar

0.5 bar

H

V3

(open variant)

T or P (1.5 l/min) 1.5 bar H

* As seen facing gearbox output

The principal factor in determining the oil supply volume is always the volume that flows out of the

oil return. In the case of gearboxes with a belt pulley drive, consider the additional lube oil bore "S"

(refer to Chapter 4.3.7).

Page 33

Initial Installation

EN 4161.758.102q – 2017-09 33

4.6.3.3 Connections for integrated lubrication oil system and maximum speed

For applications with a maximum speed of 10,000 rpm and/or a dry sump, the T connection with integrated

lubrication oil system is mandatory. Furthermore, gearbox oil cooling >0.3 kW and a circulating oil volume

>15 liters is required.

All versions include T connection with integrated lubrication oil bore.

When ordering, note the corresponding Machine-Readable Product Designation (MLFB) number for the

integrated lubrication oil system.

The integrated lubrication oil system is only available with the closed variant.

The recommended oil viscosity for integrated lubrication oil system is HLP 22 according to ISO VG 22.

With dry-sump lubrication, HLP 10 according to ISO VG 10 can be used if it can be ensured that the gearbox

oil outlet temperature is below 65 °C at all times.

Installation position Oil inlet connection Max. pressure Oil return connection

V1

(closed variant)

T

(1.5 l/min)

and

M

(approx. 0.5 l/min)

0.5 bar

0.5 bar

D or E

V3

(closed variant)

T

(1.5 l/min)

and

M

(0.5 l/min)

0.5 bar

0.5 bar

H

B5

(dry sump)

T

(1.5 l/min)

and

M

(0.5 l/min)

0.5 bar

0.5 bar

H

B5

(rotated, dry sump)

T

(1.5 l/min)

and

M

(0.5 l/min)

0.5 bar

0.5 bar

D

The principal factor in determining the oil supply volume is always the volume that flows out of the

oil return.

Page 34

Initial Operation/Maintenance

34 EN 4161.758.102q – 2017-09

5 Initial Operation

5.1 Initial inspection

Before initial operation, the correct installation

condition of the gearbox must be checked.

Mechanical fastening

Motor flange-mounting

Gearbox oil connections

Oil supply/oil fill ensured

Electrical connections

Ease of movement (can be turned by hand)

Vertical breather position

5.2 Checking setting dimension of sun

gear

Control dimension "A": 125.1 mm, tolerance

+0.2 mm, measured between housing connection

surface and front side of sun gear. When measuring, press the sun gear towards the output until it

reaches the stop.

The dimension is set correctly ex works.

Check the dimension after inserting the sun gear,

e. g. following disassembly. Dimension "A" is

correct if the spring assembly (2) and shims (1)

are correctly installed in their entirety (see detailed

figure below).

6 Maintenance

6.1 Oil change

Oil change interval: every 5,000 hours of

operation

Risk of burns due to contact with hot oil.

Slight to moderate injury possible.

Wear protective goggles.

Wear protective gloves.

Allow used oil to drain at operating temperature

into a suitable container.

The drain connections differ depending on the

installation position and gearbox version (refer to

Chap. 4.6.3.1).

Fill new gearbox oil at connection I.

The oil level is correct when it reaches the center

of the oil level gage glass with a stationary

gearbox.

The oil level is binding. The number of liters stated

on the model plate is a reference value.

If available, briefly allow oil pump to run after

filling with oil in order to vent, top up oil if

required.

1

2

A

Page 35

Repair

EN 4161.758.102q – 2017-09 35

7 Repair

In the event of gearbox malfunctions, first check

the connected components and their connections.

Carefully document the type of fault so as to assist

manufacturer diagnosis (refer to Chap. 7.1).

Repairs to the gearbox itself may only be

performed by ZF Friedrichshafen AG or by

authorized ZF after-sales points.

7.1 Gearbox fault checklist

If you encounter drive unit faults, please first check

the solutions listed in Chapter 8.

If this does not solve the problem, you will need to

provide the following information for diagnosis at

ZF Friedrichshafen AG or an authorized ZF

aftersales point:

Gearbox data on the model plate:

Typ: . . .

(Type)

Parts list [BoM]: 4161 . . . . .

(Parts list no.)

Serien-Nr.: . . . . .

(Serial no.)

Motor data on the model plate:

Manufacturer: . . .

Type/Size: . . .

Questions for fault diagnosis:

Is oil level gage glass on gearbox dark/black?

Is there a smell of burning oil at the oil

breather?

Gearbox running noise in 1:1 or 4:1 gear ratio,

or only in one rotation direction or in both

rotation directions?

Before the running noise occurred, was the

machine operated in only one gear ratio (1:1)

for an extended period of time?

Did the running noise occur after changing the

machine's cycle or was the machine cycle

unchanged?

Was any maintenance carried out on the

machine before the fault occurred and, if yes,

what did this maintenance work involve?

No gear change or gear loss in the event of a

shift problem?

Does the shift logic conform to ZF

specifications? (Refer to page 28)

What is the shift unit voltage during the shift

sequence?

Page 36

Repair

36 EN 4161.758.102q – 2017-09

7.2 Gearbox – disassemble

(e. g. version with adapter plate, shaft seal and hub

bearings)

Proceed accordingly in the case of other versions.

Switch off the machine

Switch off the power supply

Disconnect the electrical connections

Disconnect the gearbox oil connections,

drain the gearbox oil

Undo the mounting bolts (11)

Pull gearbox (6) off adapter plate (5) and

input hub (1)

7.3 Input hub with parallel key

Undo the set screw (9) used to radially secure the

parallel key.

Use a removing device, e.g. three-arm puller, to

pull off input hub against the motor shaft without

heating the hub:

Press off against a removing aid (12) on the cover

(8). Keep turning the puller until the cover is at

the spacer disc/motor shaft.

The cover plate may cause the input hub to jam

when being pulled off.

Position cover plate (8) centrally on motor

shaft.

Replace end washer 40 DIN 470 after disassembly.

Clean before installing and coat the sealing edge with

liquid seal. Visually check the shaft seal and O-ring

and fit new ones if necessary.

3

10

9

1

2

12

8

5

6

11

7

4

1 Input hub

2 Motor shaft

3 Motor

4 Hub bearing

5 Adapter plate

6 Gearbox

7 Shaft sealing ring

8 Cover plate

9 Set screw

10 O-ring

11 Mounting bolt

12 Removing aid

(cylinder

25x100 mm)

Page 37

Repair

EN 4161.758.102q – 2017-09 37

7.4 Disassembly of gearbox with clamping

hub

Note Chapter 7.2.

Turn motor shaft (2) until clamping screw (7) can

be seen through access bore in adapter plate (1).

Loosen clamping screw.

Loosen mounting screws (4) and pull gearbox off

motor.

1 Adapter plate

2 Motor shaft

3 Motor flange

4 Mounting screw

5 Clamping hub

6 Sleeve

7 Clamping screw

8 Cover plate

9 Output shaft

Page 38

Frequently Asked Questions (FAQ)

38 EN 4161.758.102q – 2017-09

8 Frequently Asked Questions (FAQ)

Error Cause of error Remed

y

Gearbox is loud,

knocking noises

Loose contact on motor speed

sensor. This causes permanent

motor governing.

Speed sensor dirty, no clear

signals sent

Check speed sensor and electrical

lines to motor, clean speed sensor if

necessary.

Check engine management system,

adjust speed control accordingly

(softer setting).

Gearbox is loud,

running noise

Long periods at high cutting speed

in ratio 1:1 followed by change to

machining in ratio 4:1

No gearbox damage

Gearbox running noise normalizes

after several gear changes

Axial bearing incorrectly installed Check installation.

Shims/spring washers on sun gea

r

incorrectly installed

Measure reference dimension "A"

Gearbox is loud,

running noise in ratio

Motor shaft is too long,

axial bearing damaged

Measure reference dimension "A",

correct and install new bearing if

necessary

Gearbox leaking at gearbox

input/output

Defective seals Renew seals, send gearbox to ZF

for inspection if necessary

Gearbox leaking at breathe

r

Oil has aged

Too much oil added during oil

change

Change the oil

Check oil level, adjust to correct

oil volume if required

Machine control does not

receive signals for the shift

position from the shift unit on

the gearbox

Loose contact in plug connection

on gearbox shift unit

Error in the shift unit

Check plug connection and clean

if necessary, secure connectors

using clips.

Send gearbox to ZF for inspection

Gear disengages Limit position switch defective Send gearbox to ZF

Friedrichshafen AG for inspection

Page 39

Page 40

ZF Friedrichshafen AG

88038 Friedrichshafen

Deutschland · Germany

Telefon/Phone +49 7541 77-0

Telefax/Fax +49 7541 77-908 000

www.zf.com

EN 4161.758.102q - 2017-09

Loading...

Loading...