Zesto CG4032DD User Manual

REF #0908w-53

OWNER'S , SERVICE & INSTRUCTION MANUAL

SLEDOMNEVOROYEVNOCSAG

8103GC8104GC

4263GC2363GC

4284GC2384GC

4206GC2306GC

DD2304GCDD2356GC

IMPORTANT INSTRUCTIONS FOR OVEN

INSTALLATION, OPERATION AND MAINTENANCE

GAS: MINIMUM PRESSURE AT THE OVEN, NATURAL GAS SHOULD BE 6" W.C.

PROPANE GAS SHOULD BE 11.5" W.C. OVENS ARE EQUIPPED WITH 3/4" NPT

SUPPLY LINE. RECOMMENDATION: FLEXIBLE 3/4" GAS CONNECTOR WITH RESTRAINING DEVICE (SUPPLIED BY OTHERS).

ELECTRICAL:

CG 3018 & CG 4018

120v 15 AMP NEMA 5-15R WALL RECEPTICLE REQUIRED

CG 3624, CG 3632, CG 4824, CG 4832, CG 6024, CG 6032

120v 20 AMP NEMA 5-20R WALL RECEPTICLE REQUIRED

CG 4032DD & CG 6532DD

208v / 240v SINGLE PHASE 15 AMP. DIRECT LINE

FOOD EQUIPMENT MANUFACTURING INC.

MANUFACTURIER D'EQUIPEMENT EN ALIMENTATION INC.

6450 HUTCHISON, MONTREAL, QUEBEC, H2V 4C8 TEL(514)278-4621 FAX(514)278-4622

e-mail: info@zesto.ca www.zesto.ca

1

REF #0908w-53

NOTICE: WHEN THIS APPLIANCE IS INSTALLED WITH CASTERS, IT MUST

BE INSTALLED WITH THE CASTERS SUPPLIED, A CONNECTOR

COMPLYING WITH EITHER ANSI Z21.69 OR CAN/CGA-6.16. AND A

QUICK-DISCONNECT DEVICE COMPLYING WITH EITHER ANSI Z21.41 OR

CAN 1-6.9. IT MUST ALSO BE INSTALLED WITH A RESTRAINING MEANS

TO GUARD AGAINST TRANSMISSION OF STRAIN TO THE CONNECTOR ,

AS SPECIFIED IN THE APPLIANCE MANUFACTURER'S INSTALLATION

INSTRUCTIONS.

IN THE COMMONWEALTH OF MASSACHUSETTS THIS APPLIANCES MUST

BE INSTALLED UNDER AN EXHAUST HOOD AND MUST BE INTERLOCKED

WITH THE GAS SYSTEM AND COMPLY WITH STATE PLUMBING CODES

AND INSTALLED BY A LICENSED PLUMBER OR GAS FITTER.

IMPORTANT FOR YOUR SAFETY

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

WARNING

This appliance is only for professional use and shall be used only by

qualified people. All parts that have been protected by the manufacturer

or his agent must not be adjusted by the end user.

Improper installation, adjustment, service or maintenance can cause

property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing this equipment.

WHAT TO DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch; do not use any

phone in your building.

· Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

· If you cannot reach your gas supplier, call the fire department.

FOR YOUR SAFETY

Do not store or use gasoline or flammable vapors or

liquids in the vicinity of this or any other appliance.

IN THE EVENT OF A POWER FAILURE DO NOT ATTEMPT

TO OPERATE THIS DEVICE. SHUT OFF POWER.

2

REF #0908w-53

STNETNOCFOELBAT

4

...................................................................LARENEG

.................................................................ytilibisnopseRs'resahcruP4

...........................................................NOITALLATSNI

italitneV4

S5

................................................................................................no

.................................................................................................gnivieceR5

...................................................................................................noitacoL5

....................................................sdradnatSdnasedoCnoitallatsnI5

...............................................................................................gnipiPsaG5

......................................................................................snevOgnikcat

............................................................................nevOcisaBgnillatsnI 7-6

...............................................................NOITAREPO

.............................................................................lortnoCerutarepmeT8

...

......................................................................................lortnoCdeepS9

.........................................................ECNANETNIAM

...gninaelC 11-01

................................................................................................

....................................................................gninaelcroflavomertleB21

......ELPUOCOMREHT&RIA-STNEMTSUJDA

............................................................noitubirtsiDriAfotnemtsujdA 61-31

.....................................................................................elpuocomrehT61

....

7-4

9-8

21-01

61-31

3

............................................ECIVRESLACINHCET

...............................................................................metsysrenruBsaG 12

............................................................................trahCelbuorTrenruB 32-22

...............................................................................................rotoMraeG42

...........................................................rotoMrewolBgnitalucriCtaeH52

................................................................................)laixA(naFgnilooC62

-71

.................................................SMARGAIDGNIRIW

.............................................GNITOOHSELBUORT

....................................................TRAHCGNIKOOC

...............................................................YTNARRAW

82

92

03

62-71

b72-a72

REF #0908w-53

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Read these instructions and keep them for future reference. Before installing the oven, consult your local

building authority and obtain a building permit if necessary. Do not modify or alter the construction of the

oven or any of its components. Install the oven as described in these instructions. Use only ZESTO

components. Failure to do so will void the Certification approvals and the warranty of this oven.

PURCHASER’S RESPONSIBILITY

1. To see that the electric services for the oven are installed on site in accordance with the manufacturer’s

specifications.

2. To unload, uncrate and install the oven in its proper location in accordance with the Installation

Operation Manual.

3. To see that the electric services are connected properly by a qualified installer of your choice. All such

connections must be in accordance with applicable Code requirements.

4. To arrange for inspection and operation check-out by an authorized service technician as described

below.

5. Do not attempt to operate the oven until connection of utility service has been fully inspected by an

authorized service technician or a Zesto service representative.

6. The warranty shall not apply if the ovens are started up and operated prior to the utilities and oven

being inspected and checked out by an authorized service technician or a Zesto service representative.

INSTALLATION

WARNING:

* INST ALLATION AND REPAIR SHOULD BE DONE BY A QUALIFIED SERVICE

PERSON. THE APPLIANCE SHOULD BE INSPECTED BEFORE USE AND AT

LEAST ANNUALLY BY A QUALIFIED SERVICE TECHNICIAN. MORE FREQUENT

CLEANING MAY BE REQUIRED DUE TO OVEN GREASE VAPORS, DUST, ETC.

IT IS IMPERATIVE THAT CONTROL COMPARTMENTS, BURNERS AND

CIRCULATING AIR PASSAGEW AYS OF THE OVEN BE KEPT CLEAN.

* DO NOT MODIFY THIS APPLIANCE.

* DO NOT BLOCK THE AIR REGISTERS ON THE OVEN AS THIS WILL CAUSE

THE OVEN TO OVERHEAT.

WARNING: DO NOT USE THIS APPLIANCE IF ITS CONTROL HAS BEEN UNDER

WATER. IMMEDIATELY CALL A QUALIFIED SERVICE TECHNICIAN T O INSPECT

THE APPLIANCE AND TO REPLACE ANY PART OF THE CONTROL SYSTEM

WHICH HAS BEEN UNDER W ATER.

WARNING:ADEQUATE MEANS MUST BE PROVIDED TO LIMIT THE MOVEMENT

OF CASTERED APPLIANCES. A RESTRAINING DEVICE IS REQUIRED FOR ALL

TYPES OF MOVEABLE APPLIANCES.

VENTILATION:

1. Ventilation hood should extend 6" (15cm) minimum past the oven on the front and back and 6"

(15cm) minimum past each side of the conveyor belt and hung 6’6" (198cm) above the floor surface.

2. Exhaust - Approximately 2000 CFM required for double stacked ovens.

Approximately 1500 CFM required for single oven.

Make-up air should be 65% - 80% of the exhaust air rating.

4

REF #0908w-53

RECEIVING:

Immediatly after receiving the oven, check for possible shipping damages. If this oven is found to be damaged,

save the packaging material and contact the carrier within 15 days of delivery. Prior to installation, verify that

the electrical service and type of gas (natural or propane) agree with the specifications on the oven data plate,

located on right front side service panel. Do not use the door or the handle to lift oven.

LOCATION:

Verify that the doors and access routes into kitchen area are checked for clearance. (When crate is

turned on its side, the oven will pass through a 864mm [34"] door opening). The equipment area

must be kept free and clear of combustibles. Maintain clearances from combustible or

noncombustible construction of at least 76mm (3") from the side and 76mm (3") from the back of the

oven. The installation location must allow adequate clearances for servicing and proper operation.

INSTALLATION CODES AND ST ANDARDS:

This oven complies with the National Standards of Canada and the United States and is certified by the

Warnock Hersey Inchcape Services and ETL under the standards of (CGA) Canadian Gas Association, (AGA)

American Gas Association and National Sanitation Foundation (NSF). In Canada the installation must conform

with local codes or, in the absence of local codes, with the current CAN/CGA B149 Installation Code.The oven,

when installed, must be electrically grounded in accordance with the local codes or, in the absence of local

codes, with the current Canadian Electrical Code: CSA C22.1. In the United States, installations must conform

with local codes or, in the absence of local codes, with the National Fuel Gas Code; ANSI Z223.1 (latest

edition).

The oven, when installed, must be electrically grounded in accordance with local codes or, in the absence of

local codes, with the National Electrical Code; ANSI/NFPA 70 (latest edition). A seperate 20 amps/110v wall

recepticle must be provided for each oven. For stacked ovens, each oven must be considered as a separate

oven.

GAS PIPING:

CAUTION: The available gas pressure should be within the limits shown in the SPECIFICATIONS section.

Excessive pressure will damage Combination Valve and Regulator. If the supply pressure exceeds the

14.0" w.c. maximum, a suitable intermediate main regulator must be installed ahead of the Main Manual

Shut-Off Valve.

• The burner gas supply piping should branch off from the main line as close to the gas meter as possible. Do not

connect to the bottom of an horizontal section. Use new black pipe and malleable fittings free of cutting and threading

burrs or defects.

• Provide a sediment trap, a union and 3/8" pressure tap in piping close to the burner .

• Use pipe joint compound approved for use with Liquid Petroleum Gases.

• Piping must comply with local codes.

• To obtain the maximum firing rate of 300 MBH, the NATURAL and PROP ANE gas supply piping must be sized to

provide a minimum of 4.0" W.C. pressure to the inlet of the combination valve when the burner and all other gas

utilization equipment are on. For a firing rate of 225 MBH or less, 3.5" w.c. inlet pressure is suf ficient.

• When selecting the burner supply pipe size per Table 2, the permissible pressure drop must be based on the pressure

available at the inlet to the supply pipe branch line when all other gas utilization equipment is on.

• If the burner piping must be rearranged because of space limitations, be sure to carry out the general arrangement.

Install the Combination valve in any position except up-side down.

• When the burner is installed in jacketed equipment, it is recommended that the combination valve be left adjacent to

the burner within the vestibule and the Main Manual Shut-Off Valve be installed outside.

5

REF #0908w-53

NOTE: If there is more than 1.0" w.c. differential in the inlet pressure to the burner compared to when

all other gas utilization equipment is off, refer to COMBINATION GAS VALVE last paragraph.

CAUTION: Because it is difficult to accurately control pressure during supply pipe leak test, it

is recommended that the Combination Valve be disconnected. Exposing the combination

valve to a pressure over ½ psig (14.0" w.c.) will damage the valve and void all warranties.

DANGER! Explosion hazard.

Do not use oxygen for pressure testing.

An explosion could occur during initial start-up.

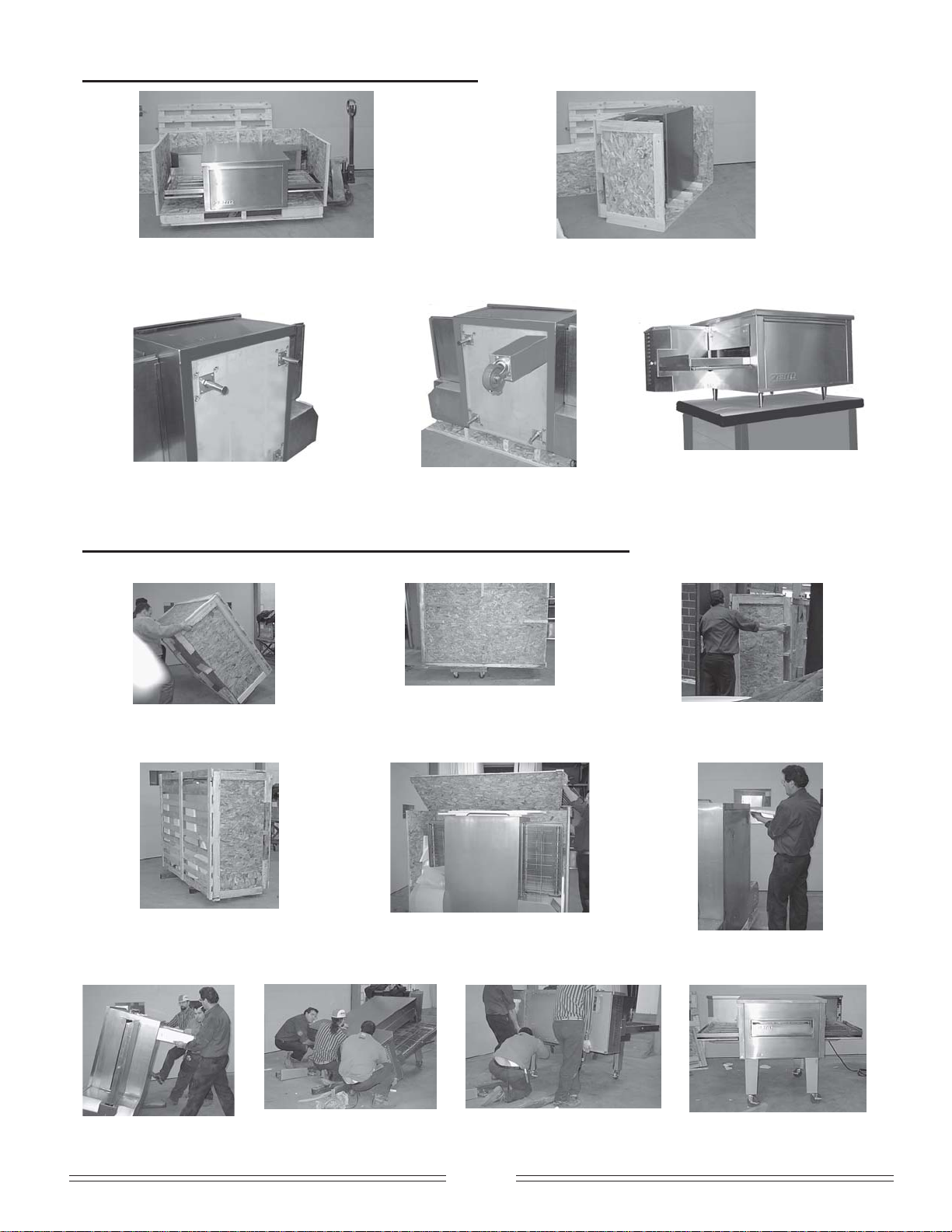

INSTALLING BASIC OVEN:

1) Tilt oven on back side

2) Place oven on 4 wheel dolly

3) Direct oven to location

4) Remove oven from dolly and place on 2 pieces of 4" (100mm) x 4" (100mm) wood

5) Undo crate

6) Fasten front legs to oven

7) Tilt oven forward resting on front legs

8) Lift oven from rear

9) Once oven is lifted fasten back legs to oven

10) Oven is now ready to be placed in operating location

STACKING OVENS:

Follow same procedure as above to uncrate and then lift and place oven on top of bottom one.

No fasteners are required, the weight of the oven will keep it in place.

6

MODELLE CG/CE 3018, 3018HD, 4018

REF #0908w-53

MODELLE CG/CE 3624, 3632, 4824, 4832, 6024, 6032

1) 2) 3)

4) 5)

6)

7) 8) 9) 10)

7

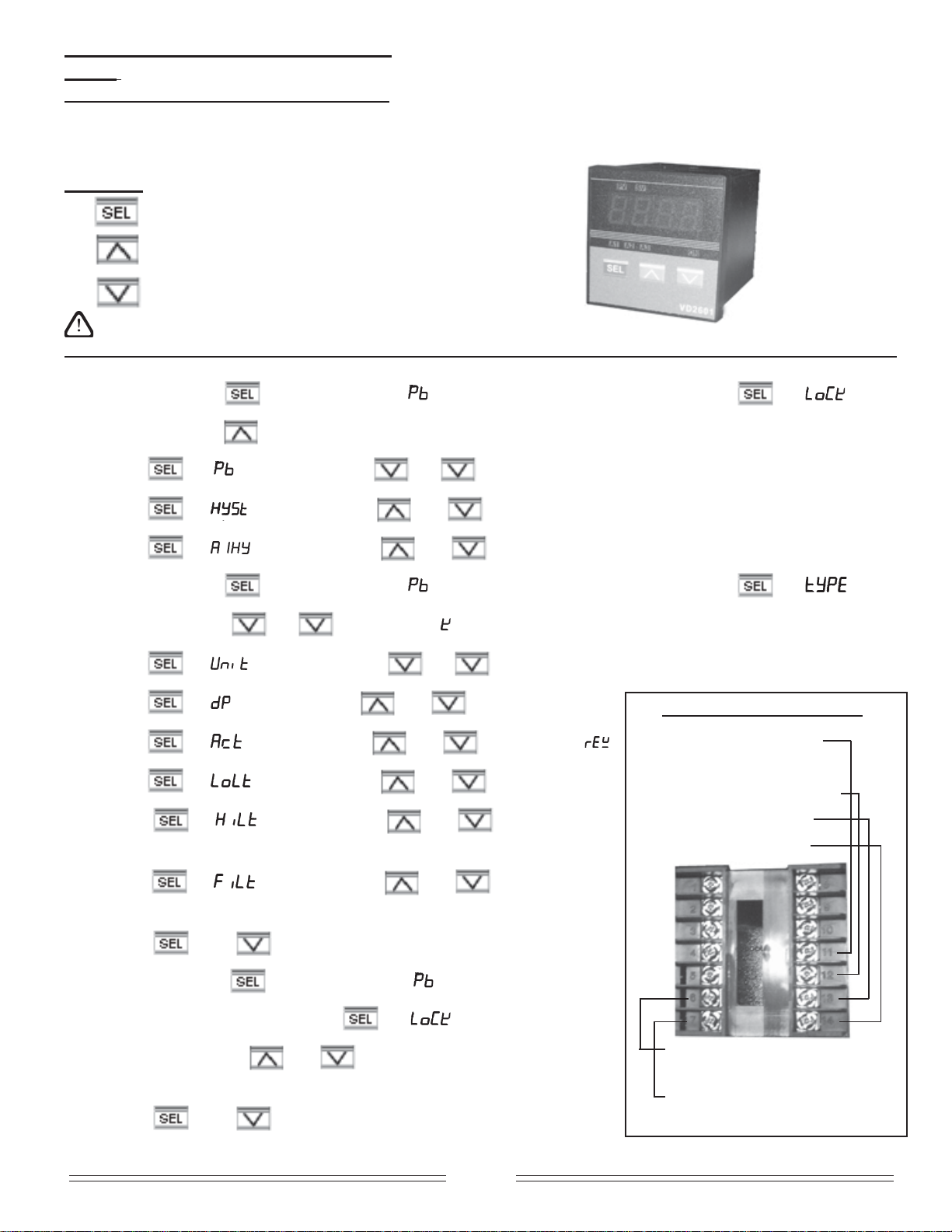

TEMPERATURE CONTROLLER:

NOTE: * DON’T TOUCH THESE ADJUSTMENTS, IT’S ALREADY CALIBRATED

#VD 2001 / 2601 INITIAL POWER-UP: (Part #ZDIVD2001TRIDNA) When power is applied to the

control it will begin operating using the factory set point. The process temperature as measured by

the thermocouple will appear in the digital display and the LOAD (PV) will indicate if the control

output (load) is on.

Key-pad:

- Parameter display / set-point programming.

-Press toRaiseTemperature of Oven.

-Press toLower Temperature of Oven.

WARNING:

To program Controller follow the following steps:(adjustments to be done only by qualified technicien)

1) Press and hold for 5 seconds till appears, then keep pressing togling till

appears. Press till you find 0 100 this unlocks the program.

2) Press till appears press or till you find 0.0.

REF #0908w-53

3) Press till appears press or till you find 2.

4) Press till appears press or till you find 0.

5) Press and hold for 5 seconds till appears, then keep pressing togling till

appears press or till you find (K thermocouple)

6) Press till appears press or till you find Fº or Cº

7) Press till appears press or till you find 0000.

8) Press till appears press or till you find

9) Press till appears press or till you find 0.

10) Press till appears press or

till you find 625Fº or 330Cº.

11) Press till appears press or

till you find 5.0.

12) Press and holding both to exit program.

WIRING CONNECTION

#11 Input Power

#12 Output to

selenoid or SSR

#13 110v black

#14 110v white

13) Press and hold for 5 seconds till appears,

then keep pressing togling till

appears. Press or till you find 0 001

this locks the program.

14) Press and holding both to exit program.

8a

#6 Thermocouple

negative

#7 Thermocouple

positive

REF #0908w-53

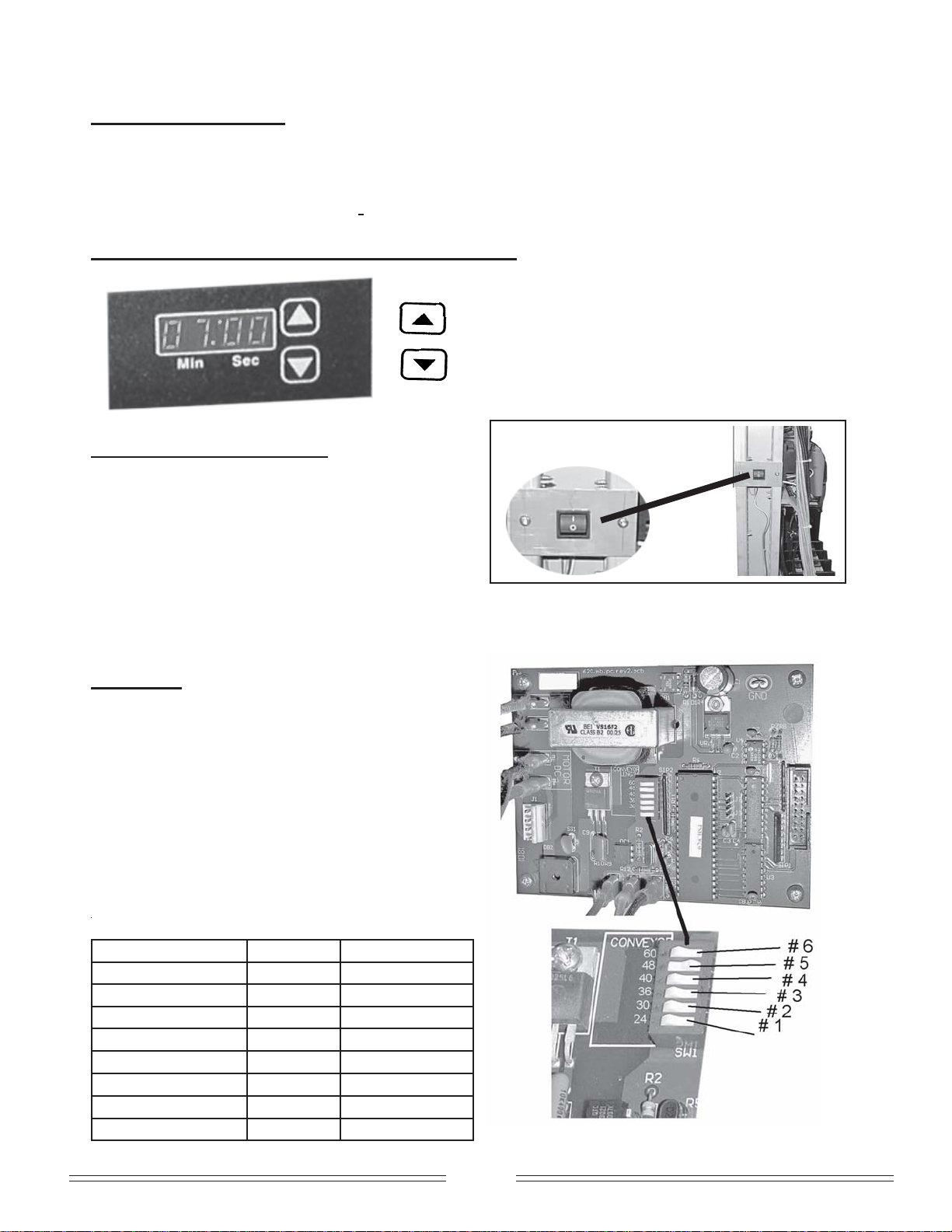

SPEED CONTROL: Model ZRA620

Speed control is made of three different parts: a digital time panel, a reverse switch for belt

direction (for use by serviceman only) and an electronic pcb board.

This control is conected to a tachometer on the back of the gear drive motor which controls

the amount of pulses to regulate

TO REGULATE SPEED OF BELT (1 - 20 minutes)

Press for slower rotation of belt (time)

Press for faster rotation of belt (time)

REVERSAL OF ROTATION:

You can reverse the rotation of the belt simply

by removing the back panel on the control side

of oven, locate the tippette switch and push the

switch to the desired rotation (to be done by

serviceman only).

NOTE: IF DIRECTION IS CHANGED BE

SURE THAT BELT LINKS ARE CHANGED,

LINKS SHOULD ALWAYS BE IN PULLING

DIRECTION (see page 12)

the the speed. This is a closed loop system.

CAUTION:

In case of breakage of the

electronic board do not

touch any component; do

not attempt to repair it.

Service and calibration of

the electronic board require

special instruments and must

be performed by the factory only.

Failure to do so would void the

warranty and the replacement

of the defective electronic board.

sledoMtlebfohtgneLgnitteshctiwspiD

8142,6142EC"84)rebmahc"42(1#

8103EC&GC"65)rebmahc"03(2#

8104EC&GC"66)rebmahc"04(4#

2363,4263EC&GC"27)rebmahc"63(3#

2384,4284EC&GC"48)rebmahc"84(5#

2306,4206EC&GC"69)rebmahc"06(6#

DD2304GC"27)rebmahc"04(4#

DD2356GC"69)rebmahc"06(6#

sledomtnereffidmargorpotsgnitteS

9

REF #0908w-53

Periodically, depending on the amount of use and product you are cooking, the oven belt and

cavity of the oven must be cleaned.

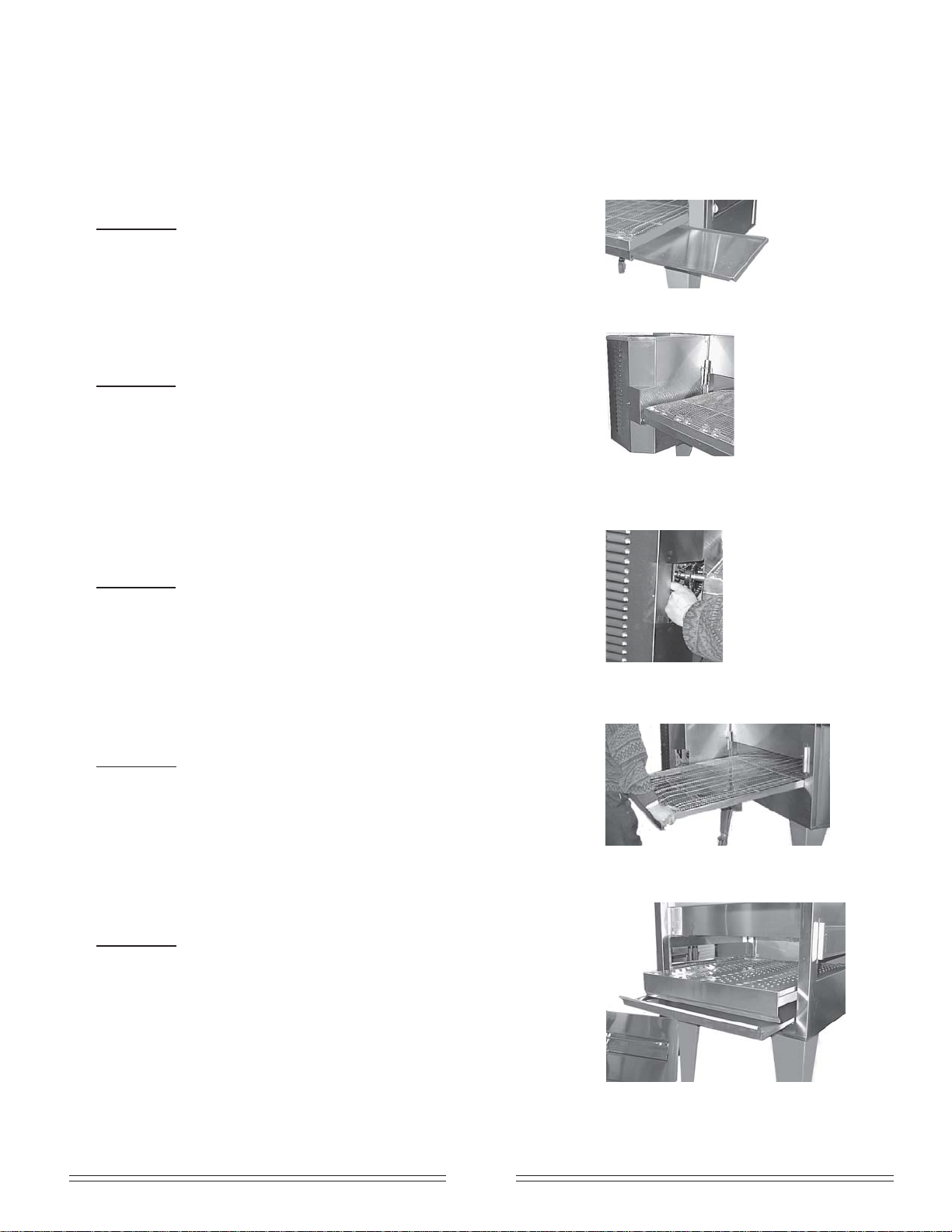

STEP # 1 Remove both exterior crumb trays

daily and wash with soap & water.

STEP # 2 Remove chain cover panel.

STEP # 3 Lift belt and move forward thus

loosening chain from belt shaft

sprocket.

STEP # 4 Now you can remove the belt

by carefully pulling back towards

you.

STEP # 5 Remove bottom crumb tray first, then

bottom air distribution panel and

then the top air distribution panel.

Cavity is now empty.

To clean interior of oven cavity wash with soap and water. If residue is hard

or difficult to clean use a degreaser or abrasive cloth.

10

Loading...

Loading...