Zesto CE4032DD Operators Manual

REF #0907-53

OWNER'S , SERVICE & INSTRUCTION

MANUAL

SNEVOROYEVNOCCIRTCELE

8142/6142ECX

LEDOM

8104ECX

DH8103/8103ECX

2363/4263ECX

2384/4284ECX

2306/4206ECX

IMPORTANT INSTRUCTIONS FOR

OVEN INSTALLATION, OPERATION AND

MAINTENANCE

FOOD EQUIPMENT MANUFACTURING INC.

MANUFACTURIER D'EQUIPEMENT EN ALIMENTATION INC.

6450 HUTCHISON, MONTREAL, QUEBEC, H2V 4C8 TEL(514)278-4621 FAX(514)278-4622

e-mail: info@zesto.ca www.zesto.ca

1

REF #0907-53

NOTICE

A permanently connected appliance provided with casters

or wheels on all legs of the appliance shall be provided with

a means for securing the appliance to the building structure

to limit the movement of the appliance so that stress is not

transmitted to the electrical supply conduit complying

with either UL 197 or ISBN 0-7629-0856-4

IMPORTANT FOR YOUR SAFETY

Improper installation, adjustment, service or maintenance can cause

property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing this equipment.

FOR YOUR SAFETY

liquids in the vicinity of this or any other appliance.

CAUTION

Electical disconect breaker should be installed on

each oven section with a minimum 3mm spaced

contact. Disconect the power supply before any

Do not store or use gasoline or flammable vapors or

CAUTION

Risk of electric shock. Do Not Obstruct Access

to this Panelboard. No Storage in this Area

repairs or maintainance work is perfomed on oven.

IN THE EVENT OF A POWER FAILURE DO NOT A TTEMPT

TO OPERATE THIS DEVICE. SHUT OFF POWER.

2

REF #0907-53

STNETNOCFOELBAT

4

...................................................................LARENEG

.................................................................ytilibisnopseRs'resahcruP4

4

...........................................................NOITALLATSNI

alitneV4

................................................................................................noit

...gnivieceR5

..........noitacoL5

..............................................................................................

.........................................................................................

....................................................sdradnatSdnasedoCnoitallatsnI5

..

....................................................................................snevOgnikcatS5

....

........................................................................nevOcisaBgnillatsnI 6-5

...............................................................NOITAREPO

.............................................................................lortnoCerutarepmeT7

...

......................................................................................lortnoCdeepS8

.........................................................ECNANETNIAM

..gninaelC 01-9

leB11

.................................................................................................

....................................................................gninaelcroflavomert

......ELPUOCOMREHT&RIA-STNEMTSUJDA

............................................................noitubirtsiDriAfotnemtsujdA 51-21

....

.....................................................................................elpuocomrehT51

8-7

11-9

51-21

............................................ECIVRESLACINHCET

......................................................................metsysgnitaehlacirtcelE 71-

61

MraeG81

...............................................................................................roto

...........................................................rotoMrewolBgnitalucriCtaeH91

.........

.......................................................................)laixA(naFgnilooC02

.................................................SMARGAIDGNIRIW

.............................................GNITOOHSELBUORT

....................................................TRAHCGNIKOOC

...............................................................YTNARRAW

3

02-61

b12-a12

22

32

42

REF #0907-53

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL: Read these instructions and keep them for future reference. Before installing the oven, consult your

local building authority and obtain a building permit if necessary. Do not modify or alter the construction of the oven

or any of its components. Install the oven as described in these instructions. Use only ZESTO components.

Failure to do so will void the Certification approvals and the warranty of this oven.

PURCHASER’S RESPONSIBILITY

1. To see that the electric services for the oven are installed on site in accordance with the manufacturer’s

specifications.

2. To unload, uncrate and install the oven in its proper location in accordance with the Installation Operation

Manual.

3. To see that the electric services are connected properly by a qualified licensed ELECTRICIEN or installer of

your choice. All such connections must be in accordance with applicable Code requirements.

4. Do not attempt to operate the oven until connection of utility service has been fully inspected by an authorized

service technician.

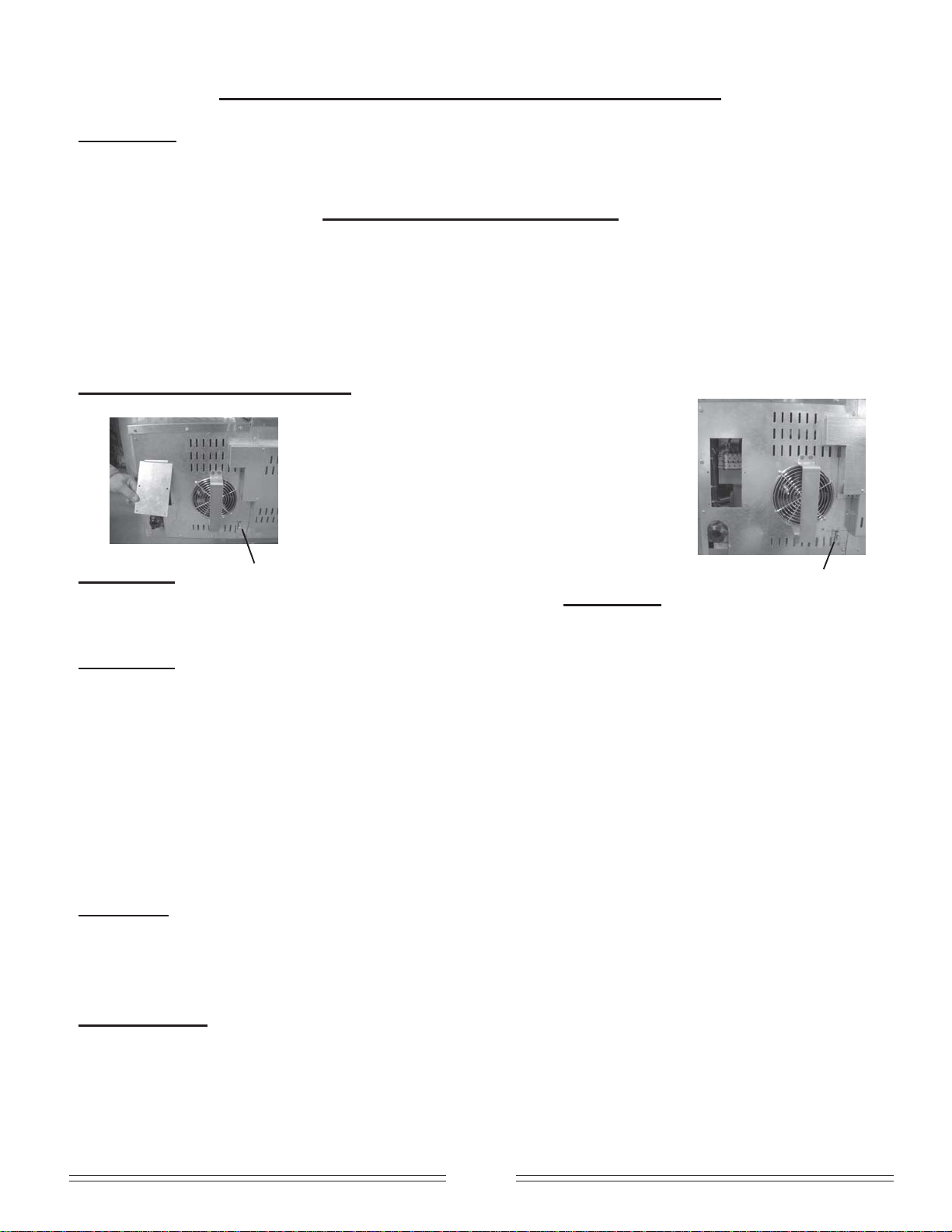

INSTALLATION W ARNING:

Input voltage and phasing must

match the units voltage & phasing.

Remove back panel and pass the

service line through the rear of the

unit and connect to the teminal block.

WARNING:ADEQUATE MEANS MUST BE PROVIDED TO LIMIT THE MOVEMENT OF

CASTERED APPLIANCES. A RESTRAINING DEVICE IS REQUIRED FOR ALL TYPES OF

MOVEABLE APPLIANCES.

WARNING:

* INST ALLATION AND REP AIR SHOULD BE DONE BY A QUALIFIED SERVICE PERSON.

THE APPLIANCE SHOULD BE INSPECTED BEFORE USE AND A T LEAST ANNUALLY

BY A QUALIFIED SERVICE TECHNICIAN. MORE FREQUENT CLEANING MA Y BE

REQUIRED DUE TO OVEN GREASE VAPORS, DUST, ETC. IT IS IMPERATIVE THAT

CONTROL COMP ARTMENTS, BURNERS AND CIRCULA TING AIR PASSAGEW A YS OF

THE OVEN BE KEPT CLEAN.

* DO NOT MODIFY THIS APPLIANCE.

* DO NOT BLOCK THE AIR REGISTERS ON THE OVEN AS THIS WILL CAUSE THE OVEN

TO OVERHEA T.

WARNING: DO NOT USE THIS APPLIANCE IF ITS CONTROL HAS BEEN UNDER WATER.

IMMEDIA TELY CALL A QUALIFIED SERVICE TECHNICIAN TO INSPECT THE APPLIANCE

AND TO REPLACE ANY PART OF THE CONTROL SYSTEM WHICH HAS BEEN UNDER

W ATER.

VENTILATION:

1. Ventilation hood should extend 6" (15cm) minimum past the oven on the front and back and 6" (15cm)

minimum past each side of the conveyor belt and hung 6’6" (198cm) above the floor surface.

2. Exhaust - Approximately 2000 CFM required for double stacked ovens.

Approximately 1500 CFM required for single oven.

Make-up air should be 65% - 80% of the exhaust air rating.

4

REF #0907-53

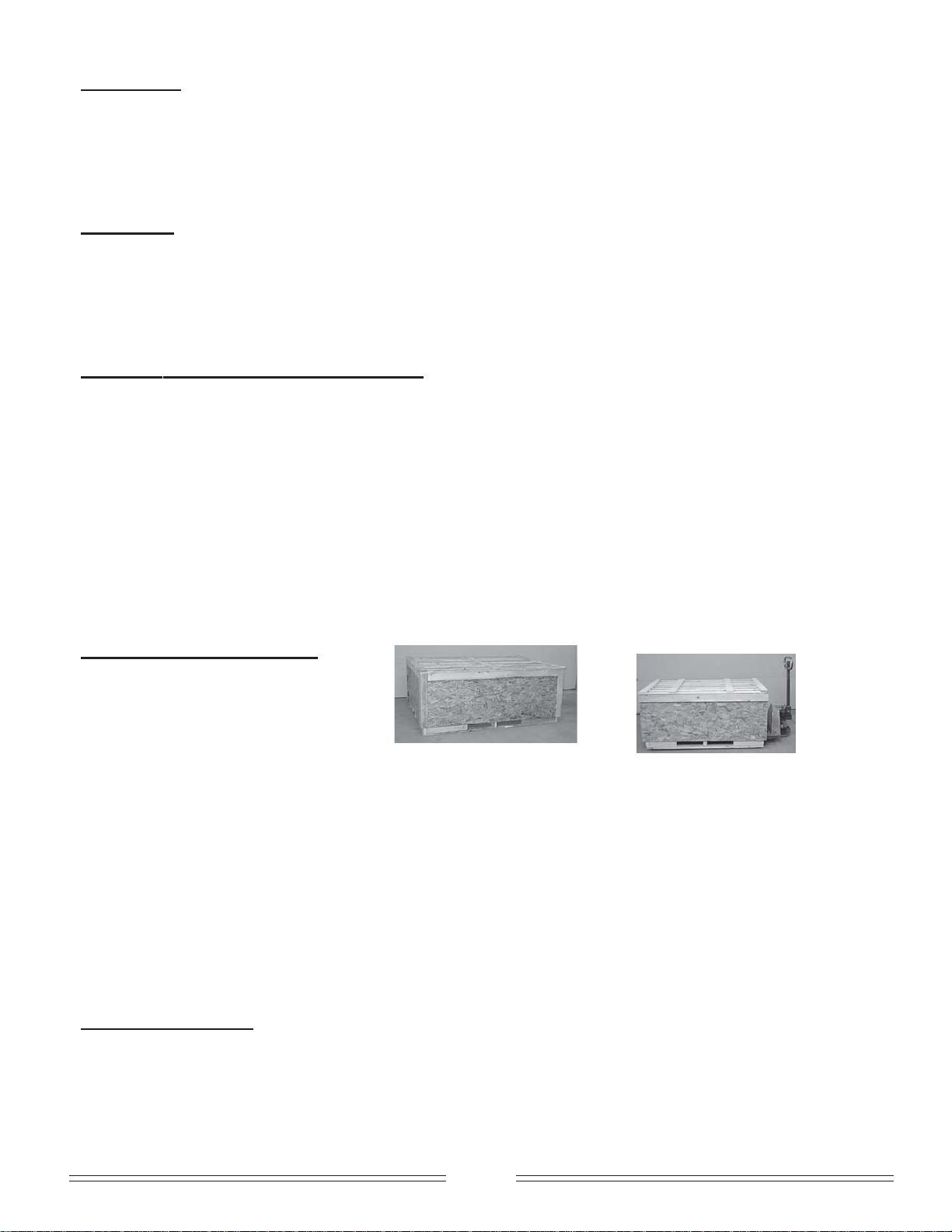

RECEIVING:

Immediatly after receiving the oven, check for possible shipping damages. If this oven is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery. Prior to

installation, verify that the electrical service and type of gas (natural or propane) agree with the

specifications on the oven data plate, located on right front side service panel. Do not use the door

or the handle to lift oven.

LOCATION:

Verify that the doors and access routes into kitchen area are checked for clearance. (When crate is

turned on its side, the oven will pass through a 864mm [34"] door opening). The equipment area

must be kept free and clear of combustibles. Maintain clearances from combustible or

noncombustible construction of at least 76mm (3") from the side and 76mm (3") from the back of the

oven. The installation location must allow adequate clearances for servicing and proper operation.

INSTALLATION CODES AND ST ANDARDS:

This oven complies with the National St andards of Canada and the United States and is certified by the

Warnock Hersey Inchcape Services and ETL under the st andards of UL 197 (ANSI / UL STD.) and National

Sanitation Foundation (NSF). In Canada the installation must conform with local codes or , in the absence of

local codes, with the current CAN/CGA B149 Inst allation Code.

The oven, when installed, must be electrically grounded in accordance with the local codes or , in the absence

of local codes, with the current Canadian Electrical Code: CSA C22.2 Number 109. In the United States,

installations must conform with local codes, with the current UL 197 (ANSI / UL STD.).

The oven, when installed, must be electrically grounded in accordance with local codes or , in the absence of

local codes, with the American National Electrical Code; ANSI/NFPA 70 (latest edition).

A seperate electrical switch box must be provided for each oven. For stacked ovens, each

oven must be considered as a seperate oven.

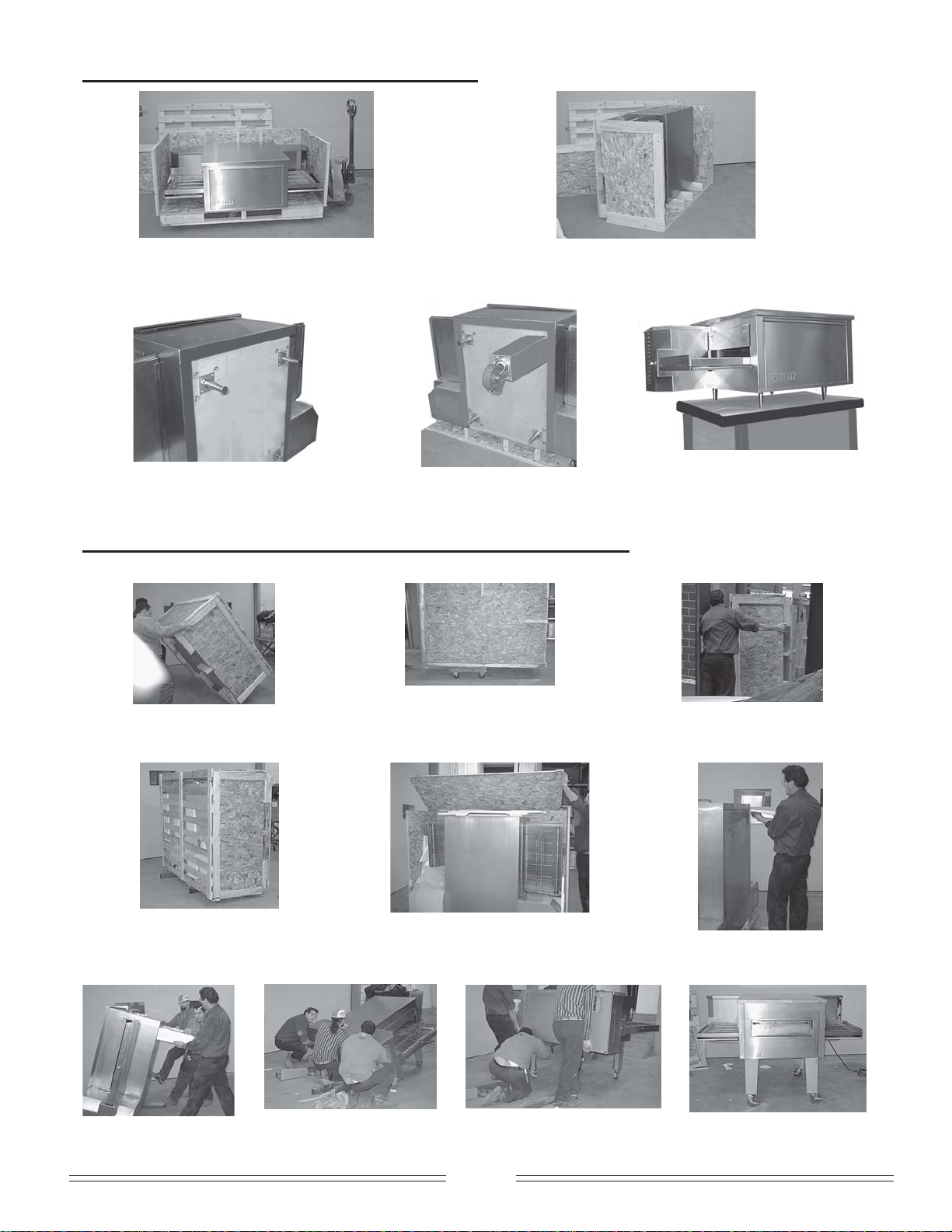

INSTALLING BASIC OVEN:

1) Tilt oven on back side

2) Place oven on 4 wheel dolly

3) Direct oven to location

4) Remove oven from dolly and place on 2 pieces of 4" (100mm) x 4" (100mm) wood

5) Undo crate

6) Fasten front legs to oven

7) Tilt oven forward resting on front legs

8) Lift oven from rear

9) Once oven is lifted fasten back legs to oven

10) Oven is now ready to be placed in operating location

STACKING OVENS:

Follow same procedure as above to uncrate and then lift and place oven on top of bottom

one.

No fasteners are required, the weight of the oven will keep it in place.

5

MODELLE CG/CE 3018, 3018HD, 4018

REF #0907-53

MODELLE CG/CE 3624, 3632, 4824, 4832, 6024, 6032

1) 2) 3)

4) 5)

6)

7) 8) 9) 10)

6

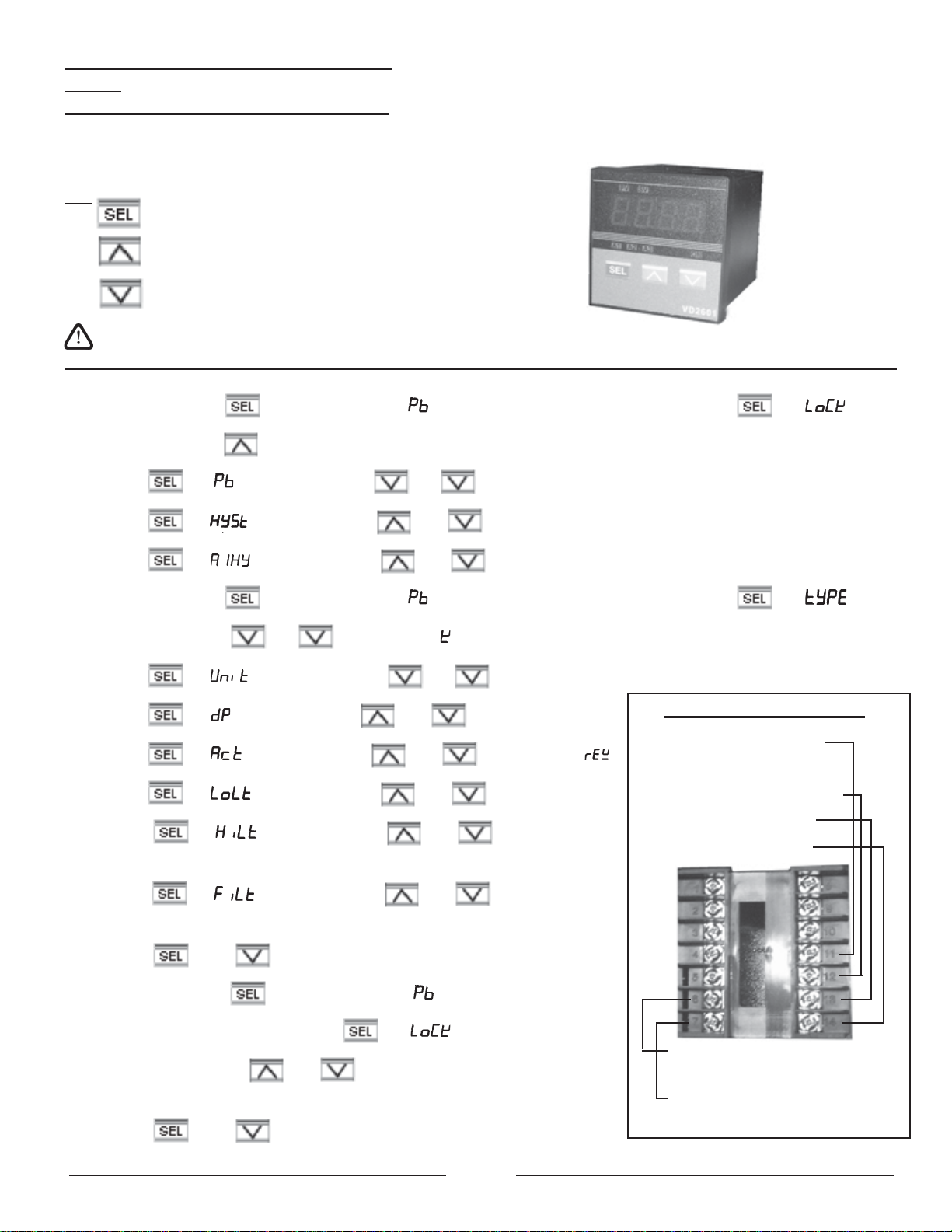

TEMPERATURE CONTROLLER:

NOTE: * DON’T TOUCH THESE ADJUSTMENTS, IT’S ALREADY CALIBRATED

#VD 2001 / 2601 INITIAL POWER-UP: (Part #ZDIVD2001TRIDNA) When power is applied to the

control it will begin operating using the factory set point. The process temperature as measured by

the thermocouple will appear in the digital display and the LOAD (PV) will indicate if the control

output (load) is on.

Key-pad:

- Parameter display / set-point programming.

-Press toRaiseTemperature of Oven.

-Press toLower Temperature of Oven.

WARNING:

To program Controller follow the following steps:(adjustments to be done only by qualified technicien)

1) Press and hold for 5 seconds till appears, then keep pressing togling till

appears. Press till you find 0 100 this unlocks the program.

2) Press till appears press or till you find 0.0.

REF #0907-53

3) Press till appears press or till you find 2.

4) Press till appears press or till you find 0.

5) Press and hold for 5 seconds till appears, then keep pressing togling till

appears press or till you find (K thermocouple)

6) Press till appears press or till you find Fº or Cº

7) Press till appears press or till you find 0000.

8) Press till appears press or till you find

9) Press till appears press or till you find 0.

10) Press till appears press or

till you find 625Fº or 330Cº.

11) Press till appears press or

till you find 5.0.

12) Press and holding both to exit program.

WIRING CONNECTION

#11 Input Power

#12 Output to

selenoid or SSR

#13 110v black

#14 110v white

13) Press and hold for 5 seconds till appears,

then keep pressing togling till

appears. Press or till you find 0 001

this locks the program.

14) Press and holding both to exit program.

7a

#6 Thermocouple

negative

#7 Thermocouple

positive

REF #0907-53

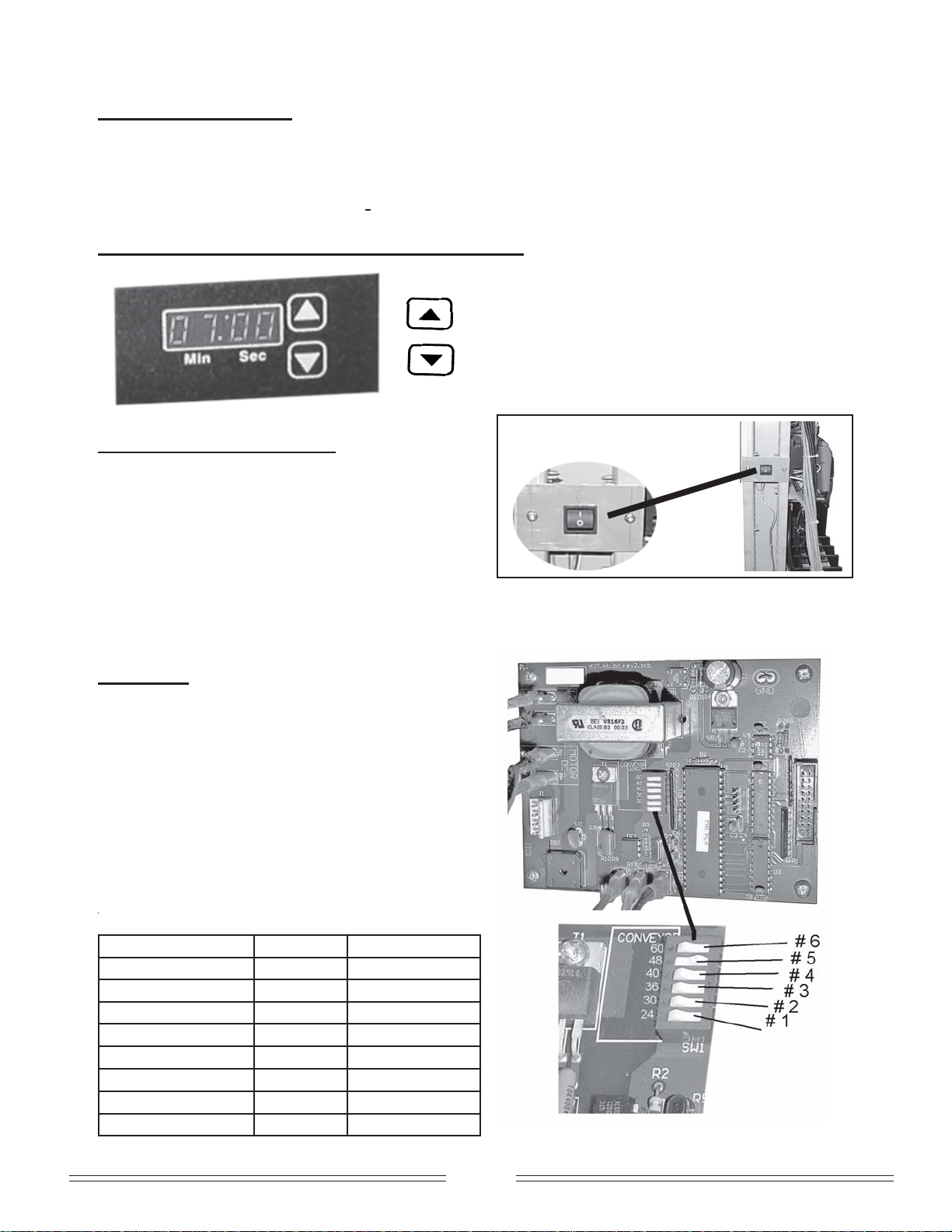

SPEED CONTROL: Model ZRA620

Speed control is made of three different parts: a digital time panel, a reverse switch for belt

direction (for use by serviceman only) and an electronic pcb board.

This control is conected to a tachometer on the back of the gear drive motor which controls

the amount of pulses to regulate

TO REGULATE SPEED OF BELT (1 - 20 minutes)

Press for slower rotation of belt (time)

Press for faster rotation of belt (time)

REVERSAL OF ROTATION:

You can reverse the rotation of the belt simply

by removing the back panel on the control side

of oven, locate the tippette switch and push the

switch to the desired rotation (to be done by

serviceman only).

NOTE: IF DIRECTION IS CHANGED BE

SURE THA T BELT LINKS ARE CHANGED,

LINKS SHOULD ALWAYS BE IN PULLING

DIRECTION (see page 12)

the the speed. This is a closed loop system.

CAUTION:

In case of breakage of the

electronic board do not

touch any component; do

not attempt to repair it.

Service and calibration of

the electronic board require

special instruments and must

be performed by the factory only.

Failure to do so would void the

warranty and the replacement

of the defective electronic board.

sledoMtlebfohtgneLgnitteshctiwspiD

8142,6142EC"84)rebmahc"42(1#

8103EC&GC"65)rebmahc"03(2#

8104EC&GC"66)rebmahc"04(4#

2363,4263EC&GC"27)rebmahc"63(3#

2384,4284EC&GC"48)rebmahc"84(5#

2306,4206EC&GC"69)rebmahc"06(6#

DD2304GC"27)rebmahc"04(4#

DD2356GC"69)rebmahc"06(6#

sledomtnereffidmargorpotsgnitteS

8

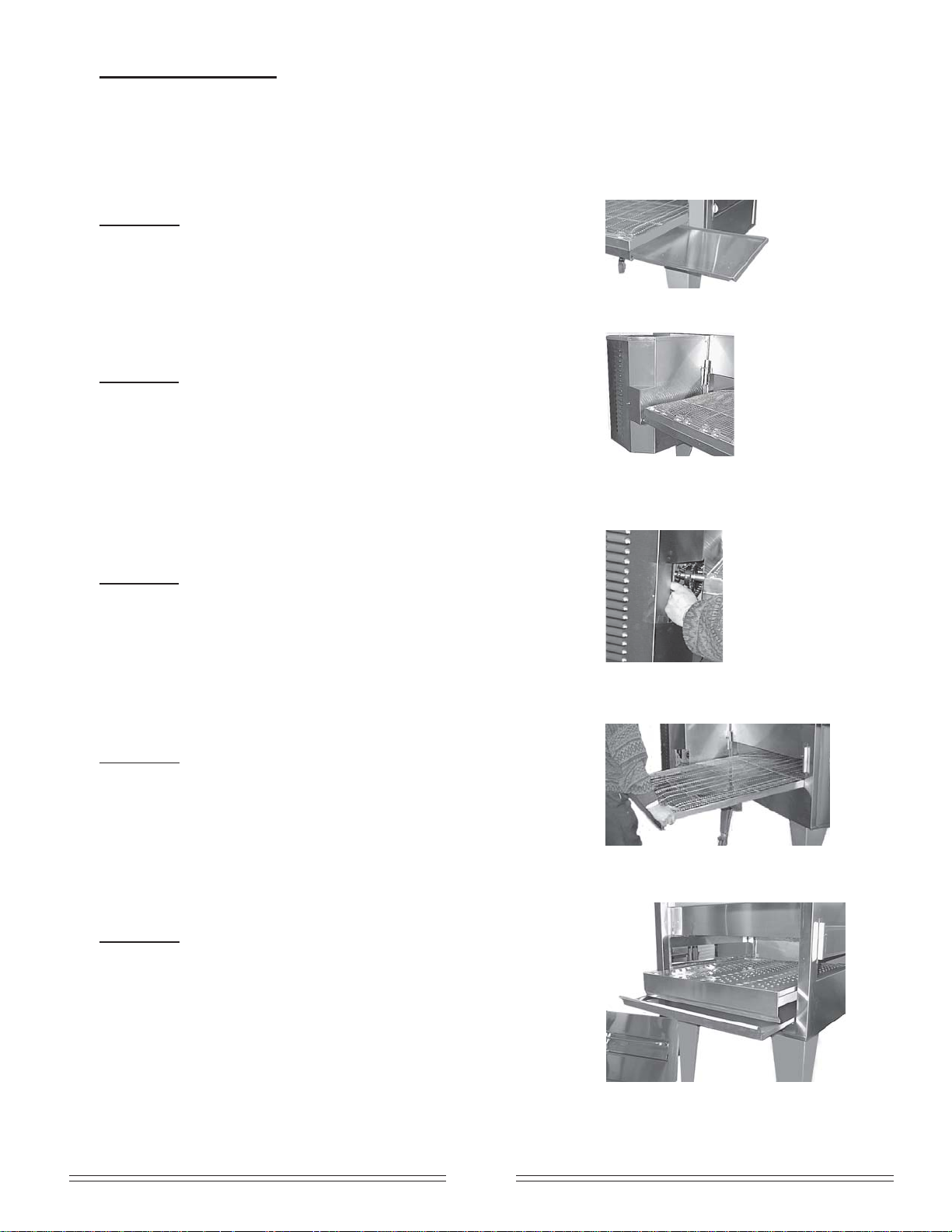

MAINTENANCE:

REF #0907-53

Periodically, depending on the amount of use and product you are cooking, the oven belt and

cavity of the oven must be cleaned.

STEP # 1 Remove both exterior crumb trays

daily and wash with soap & water.

STEP # 2 Remove chain cover panel.

STEP # 3 Lift belt and move forward thus

loosening chain from belt shaft

sprocket.

STEP # 4 Now you can remove the belt

by carefully pulling back towards

you.

STEP # 5 Remove bottom crumb tray first, then

bottom air distribution panel and

then the top air distribution panel.

Cavity is now empty.

To clean interior of oven cavity wash with soap and water. If residue is hard

or difficult to clean use a degreaser or abrasive cloth.

9

Loading...

Loading...