Page 1

Page 2

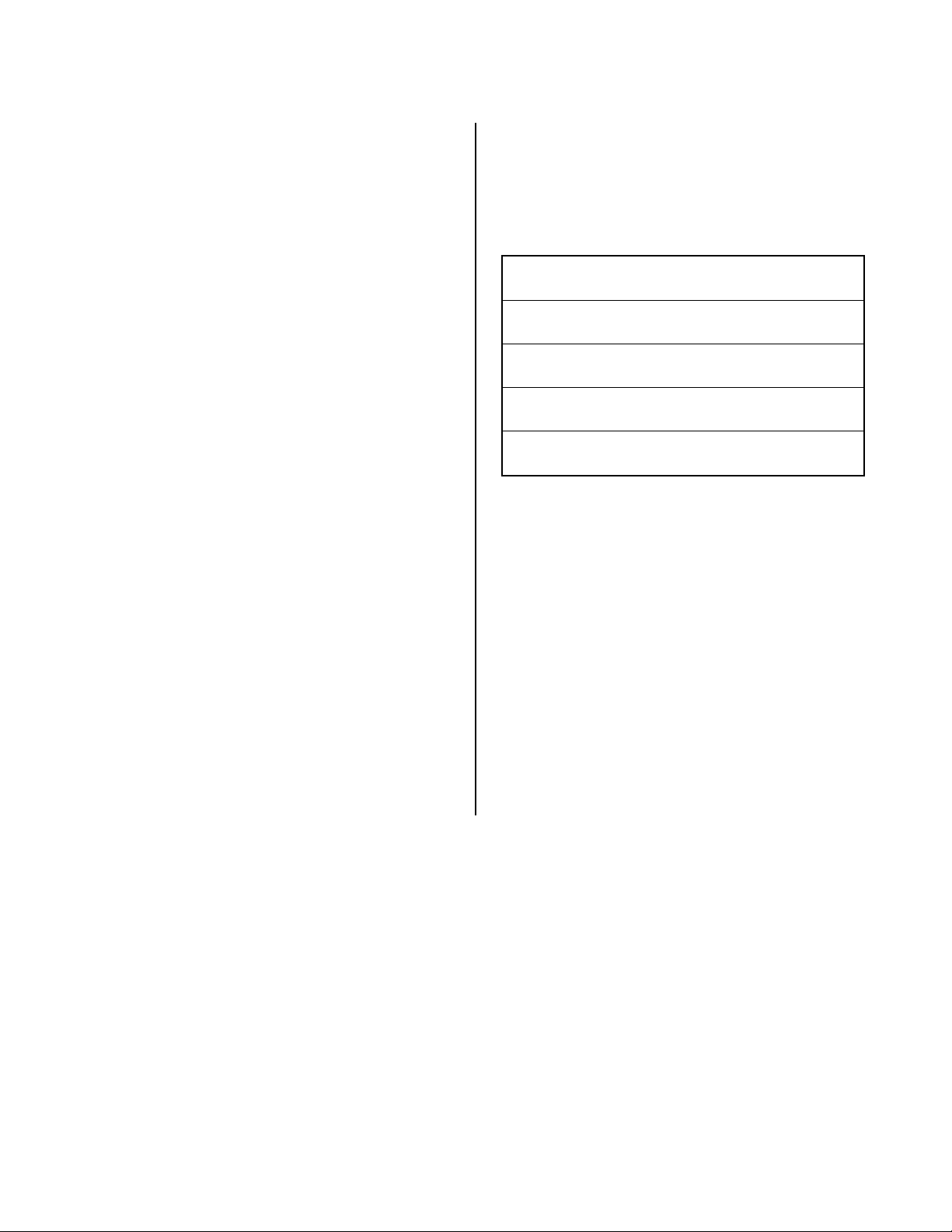

TABLE OF CONTENTS

S

UBJECT

GENERAL INFORMATION ........................................................................... 1

INTRODUCTION ........................................................................................................

INSPECTION ..............................................................................................................

LOCATION ................................................................................................................

INSTALLATION.............................................................................................................

1

1

1

1

OPERATION.................................................................................................. 1

OPERATION ..............................................................................................................

DRAINS .............................................................................................................…….

REFRIGERATION ........................................................................................................

HIGH PRESSURE CUT-OUT..........................................................................................

TEMPERATURE CONTROL ………………..................................................................

THERMOMETER .........................................................................................................

ELECTRICAL ..............................................................................................................

DEFROST ....................................................................................................................

USER INFORMATION

CLEANING ................................................................................................................

SHELVING ………......................................................................................................

LOADING ………......................................................................................................

…................................................................................................

1

2

2

2

2-3

3

3

3

3

3

3

3-4

SERVICE ...................................................................................................... 4

EXPANSION VALVE ..................................................................................................

LAMPS .......................................................................................................................

ALARMS …….............................................................................................................

4

4

4

FIGURES ...................................................................................................... 5-8

FIGURE 1 SUMMARY OF PARAMETERS....…..............................…………………...

FIGURE 2 CHANGING PARAMETERS...………………........................................….

FIGURE 3 DESCRIPTION OF THE MAIN ALARM SIGNALS…..................................

5

6-7

8

WIRING DIAGRAMS..................................................................................... 9-12

FIGURE 4 OMC-LB………………..............................................................................

FIGURE 5 OMC-36 & 48.............................................................…………………....

FIGURE 6 OMC-72....................................................................…………………......

FIGURE 7 OMCSL48.….............................................................…………………......

OMC-LB SPECIFICATION SHEET..................................................................

OMC SPECIFICATION SHEET.......................................................................

9

10

11

12

13

14

OMC-SL-48 SPECIFICATION SHEET……………………………………………. 15

WARRANTY................................................................................................... 16

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 3

GENERAL INFORMATION

Introduction

The information contained in this manual

pertains to the self-contained open display

merchandisers: OMC-LB, OMC-36, OMC-48,

OMC-72, and OMCSL48. These merchandisers

are ideal for showcasing prepackaged food

products in a safe manner. These display

coolers were designed to operate in an airconditioned store where the temperature is

maintained at 75°F or lower and the relative

humidity is 55% or lower.

Inspection

These display coolers were carefully factorytested, inspected and properly packed to

ensure delivery in the best possible condition.

The equipment should be uncrated and

checked for damage immediately upon

delivery. ALL CLAIMS FOR DAMAGES MUST BE

FILED WITH THE TRANSPORTATION COMPANY NOT WITH ZERO ZONE. The carrier will supply

necessary report and claim forms.

Location

Position the OMC-LB and OMC units at a

minimum of 3-1/2” from walls and other objects

that may impede the circulation of air around

the exterior of the case. The wall bumper stops

supplied for the rear of the OMC-LB and OMC

coolers must always remain attached. The

OMCSL48 is designed for placement within a

lineup of gondola shelving and does not require

wall bumper stops.

Do not locate this equipment where it will be

exposed to the direct rays of the sun or near a

source of radiant heat.

Do not install the display case near doors or

areas exposed to air currents.

Do not stack cartons or packaging around the

unit that might restrict air circulation to and from

the air-cooled condensing unit.

FAILURE TO OBSERVE THIS MAINTENANCE

PROCEDURE COULD CAUSE A SIGNIFICANT

DECREASE IN REFRIGERATION PERFORMANCE

AND INCREASED RUNNING COSTS.

Installation

OMC-LB, OMC-36, OMC-48 and OMC-72

merchandisers must be taken off of the shipping

skid and plugged into the proper electrical

receptacle. Additionally, because of its shallow

profile, the OMCSL48 must be anchored to the

shelving uprights or similar support using the

brackets shipped with the unit.

OPERATION

Operation

Table 1 on page 4 lists the case model with

power and electrical receptacle requirements.

The power switch on the OMC and OMC-LB is

located behind the lower front air grill. On the

OMCSL48 the power switch is located behind

the light box, accessible over the top of the

cabinet. The power switch should be off before

plugging or unplugging the case. Initially, the

evaporator and condenser fans (one on the

OMC-LB & OMC-72) will run without the

refrigeration compressor(s). After a delay of two

minutes, the compressor(s) will start and the

case will begin to cool.

All stock must enter the cabinet pre-chilled.

Do not operate with lower rear vent panel

removed. This panel has been specifically

designed to disperse moisture from the drain

tank.

1

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 4

Drains

It is important that the condensate drainage

system be kept clear of any obstructions.

Obstructions can be in the form of foreign

objects such as loose stock items, dislodged

price tags, product labels, etc. Because this

cabinet circulates refrigerated air, the entrance

of environmental borne dust particles is

inevitable. These particles can accumulate in

the drainage system and eventually form

sludge.

Condensate water drains into a tank, which is

designed to evaporate the water. To remove

the tank, switch off the power supply, remove

the lower front air grill, unplug the electrical

socket and slide the tank out the front of the

cabinet.

WHEN CLEANING, THE TANK SHOULD NOT BE

IMMERSED IN WATER, AS ELECTRICAL

COMPONENTS COULD BE DAMAGED

It is recommended that the condensate

drainage system be thoroughly cleaned on a 6month basis. The need for this may be more

frequent, depending on environmental

conditions.

Refrigeration

All OMC cases are supplied with a selfcontained refrigeration system. The units are

factory charged with POE oil and R404a

refrigerant.

Refrigerant charges are as follows:

OMC-36 3.86 lbs

OMC-48 4.40 lbs

OMC-72 (2) 3.86 lbs ea.

OMC-LB 3.86 lbs.

OMCSL48 5.00 lbs.

All valves and adjustments to the refrigeration

system have been preset for operation by the

factory. No additional adjustments are

necessary once the case is installed.

To protect the compressor from damage, the

condensing unit is supplied with a low-pressure

safety cut out and a high-pressure safety cut

out. The low-pressure cut out is self-resetting and

has a non-adjustable setting of 5 PSIG. The highpressure cut out is manually reset (see service

section), and has a non-adjustable setting of

410 PSIG.

High Pressure Cut-Out

On the OMC and OMC-LB, the high pressure

cut-out is located adjacent to the condenser

coil, behind the lower front air grill. To access

the control, remove the lower front air grill by

lifting up and away from the cabinet. To reset,

press the red button on the control. The highpressure control is set at 410 PSIG located in the

discharge line. On the OMCSL48, the control is

located on the side of the electrical box on top

of the cabinet behind the light box. This is

accessible from the top of the cabinet.

Temperature Control

A microprocessor controller is mounted behind

the lower front air grill and is accessed by

removing the air grill on the OMC-LB, 36, 48 and

72. The controller for the OMCSL48 is located on

the electrical box behind the light box,

accessible over the top of the cabinet.

This controller has many functions including a

temperature control and a defrost control. It

has been factory set for your application and

has different factory settings for various product

applications.

If you want to change the case operating

temperature, a qualified refrigeration technician

will be able to change the set points. There are

different operating temperatures depending on

which product is to be displayed in the case.

There are three general product operating

temperature options offered in

descriptions include; Meat, General Purpose

(Factory Setting), and Fresh Cuts.

includes all the preprogrammed parameters of

the twin probe temperature control.

provides instructions for changing these and

2

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

Figure 1

. The

Figure 1

Figure 2

also

03035

Page 5

other parameters in the case. Figure 3 lists

descriptions of the main alarm signals.

Thermometer

The thermometer is mounted at the left-hand

lower front of the case. This allows the customer

and operator to read refrigerated air

temperature. Allow a minimum run time of 1

hour to achieve accurate temperature

readings.

Electrical

Figures 4-8 show typical wiring diagrams. The

light switch for the sign of the OMC and

OMCSL48 cases is on top of the unit. The light

switch for the OMC-LB case is located on the

bottom of the light box.

Defrost

The OMC case has an automatic defrost

control, which has been factory set. The defrost

cycle is every 4 hours and terminates on

temperature. The case uses off cycle air defrost.

The compressor is turned off and the evaporator

fans continue to run to melt frost from the coil.

The condenser fans (1 fan on OMC-LB and 72)

run during defrost except the OMCSL48

condenser fan, which does not run during

defrost.

USER INFORMATION

Cleaning

The condenser fins on the OMC, OMC-LB and

OMCSL48 cases must be cleaned a minimum of

every 3 months.

Remove the lower front air grill by lifting up and

away from the cabinet. Remove dust and lint

using a brush or vacuum cleaner. Replace grill.

On the OMCSL48, the face of the condenser is

behind the light box, accessible over the top of

the cabinet, which makes it always available for

routine cleaning. No disassembly is required for

this unit.

FAILURE TO OBSERVE THIS MAINTENANCE

PROCEDURE COULD CAUSE A SIGNIFICANT

DECREASE IN REFRIGERATION PERFORMANCE,

COMPRESSOR DAMAGE AND INCREASED

RUNNING COSTS.

To allow the refrigeration system to operate

efficiently, the OMC and OMC-LB cabinets

should be positioned with a minimum of 3-1/2”

clearance from the rear wall. The wall bumper

stops supplied for the rear of these units must

always be attached to maintain this spacing.

The OMCSL48 does not require a wall bumper

for proper performance.

The cooler should be thoroughly cleaned before

start-up and routinely thereafter to maintain a

clean appearance. Use mild detergent (NEVER

AN ABRASIVE CLEANER) and warm water to

wipe out the inside of the cooler. Clean all glass

with glass cleaner. The cooler will remain bright

and sparkling with just a few minutes of cleaning

each week. The case drain should be regularly

cleared of debris and price tags.

NOTE: Do not use high-pressure water or steam

to clean the interior.

Shelving

All OMC units have adjustable height shelves,

which can be mounted horizontally or angled

downward at front. When replacing shelves,

ensure that the rear of the shelf is locked into the

recess in the shelf bracket.

Loading

When loading the display case, the following

points must be taken into consideration:

Do not exceed the load limit as marked on

•

the case.

When restarting the display case after a

•

prolonged shut down, the case should be

left to operate empty for at least one hour

before loading with pre-cooled product.

3

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 6

Leave space between the stock to allow the

•

refrigerated air to circulate.

The air inlet at the lower front of the case

•

and back wall or front grill discharge should

never be obstructed.

Product with a temperature higher than the

•

display case should not be introduced.

SERVICE

Expansion Valve

All OMC cases have an evaporator coil located

below the bottom coil cover. The OMC and

OMCSL cases also have an evaporator coil

located behind the perforated rear wall. Each

coil has its own expansion valve set for 15-20°F

superheat. Bottom TXV superheat should be

lower than top superheat.

Lamps

The lamps are located behind the sign. Before

servicing the lamps, turn off the lamp switch.

The lamps in the OMC-LB and OMC cases are

accessed by removing the screws on the top of

the case and rotating the sign forward. Rotate

the sign slowly to expose the lights. The lamps

on the OMCSL48 can be serviced by removing

the retaining bracket at the top front of the light

box and sliding the sign up and out of the box

channel.

Alarms

Figure 3

Table 1

OMC-LB: 115V-1 PHASE-60Hz, 20A

Straight 3-blade electrical receptacle

OMC-36: 115V-1 PHASE-60Hz, 30A

Straight 3-blade electrical receptacle

OMC-48: 115V-1 PHASE-60Hz, 30A

Straight 3-blade electrical receptacle

OMC-72: 208/230V – 115V -1 PHASE-60Hz, 30A

NEMA L-14-30 twist lock electrical receptacle

OMCSL48: 115V-1 PHASE-60Hz, 30A

Straight 3-blade electrical receptacle

describes the main alarm signals.

4

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 7

FIGURE 1

SUMMARY OF PARAMETERS - (TWIN PROBE)

PROBE PARAMETERS TYPE MIN MAX UNIT DEF LB 36 48 72 SL48

11 Type of probe (0=NCT, 1= PTC) DO NOT CHANGE C 0 1 - 0 0 0000

C Calibration F -4 77 C/F 0 0 0000

2 Measurment stability C 1 15 - 4 4 4444

3 Probe reading speed C 1 15 - 8 8 8888

4 Virtual probe C 0 100 0 0 0000

5 C/F (0=C, 1= F) C 0 1 flag 0 1 1111

6 Decimal point (0=yes, 1=no) C 0 1 flag 0 0 0000

CONTROL PARAMETERS TYPE MIN MAX UNITS DEF LB 36 48 72 SL48

rd Control differential F 0.1 19.9 C/F 2

-Meat - - - - 6.8 6.8 6.8 6.8

-General Purpose (Factory Setting) - - - - 6.8 6.8 6.8 6.8 6.8

-Fresh Cuts - - - - 4.8 5.8 4.8 5.8

r1 Minimum set point allowed C -40 r2 C/F -40 24 24 24 24 24

r2 maximum set point allowed C r1 *19 C/F 90 32 32 32 32 32

r3 Enable defrost end on time alarm(Ed) C 0 1 flag 0 1 1111

r4 Value to increase set point by, when A4 (digital input)=7 C 0 20 C/F 3 0 0000

r5 Enable min and max temperature logging (0= no, 1+yes) C 0 1 flag 0 1 1111

rt Interval of min and max temperature logging F 0 199 hours - - ---rH Max temperature monitored during period rt F -50 90 C/F - - ---rL Minimum temperature monitored during period rt F -50 90 C/F - - ----

COMPRESSOR PARAMETERS TYPE MIN MAX UNITS DEF LB 36 48 72 SL48

c0 Compressor start-up delay after power up C 0 15 min 0 2 2222

c1 Minimum interval between two compressor starts C 0 15 min 0 5 5555

c2 Minimum compressor off-time C 0 15 min 0 2 2222

c3 Minimum compressor on time C 0 15 min 0 2 2222

c4 Duty setting (compressor safety, 0=OFF, 100= ON) C 0 100 min 0 5 5555

cc Duration of continuous cycle C 0 15 hrs 4 0 0000

c6 Alarm cut-off delay after continuous cycle C 0 15 hrs 2 2 2222

DEFROST PARAMETERS TYPE MIN MAX UNITS

do Defrost( 0=electric, 1= hot gas, 2=water/electric by time, 3=hot gas by time) C 0 3 flag 0 0 0000

dI Interval between defrosts F 0 199 hrs 8 4 4444

dt Defrost termination temperature F -40 -199 C/F 4 43 43 43 43 43

dP Max duration of defrost (time protecion) if Dc =0; or defrost time=2.3 F 1 199 min 30 60 60 60 60 60

d4 Defrost on power up (0=no, 1=yes) C 0 1 flag 0 0 0000

d5 Defrost delay after unit power up of multifunction input C 0 199 min 0 180 180 180 180 180

d6 Display override during defrost (0=no, 1=yes) C 0 1 flag 0 0 0000

dd Dripping (drain) time F 0 15 min 2 0 0000

d8 Duration of alarm cut-out after defrost and/or opening of door F 0 15 hrs 1 2 2222

d9 Defrost has priority over compressor protection (0=no, 1=yes) C 0 1 flag 0 0 0000

d Defrost probe reading F 0 - C/F - - ---dC Time basis (0=hours/minutes 1= minutes/seconds C 0 1 flag 0 0 0000

ALARM PARAMETERS TYPE MIN MAX UNIT

A0 Alarm and fan differential C 0.1 20 C/F 0.2 0.4 0.4 0.4 0.4 0.4

AL Low temperature alarm (deviation from set point) F 0 199 C/F 10 4 4444

AH High temperature alarm (deviation from set point) F 0 199 C/F 10 36 36 36 36 36

Ad Temperature alarm delay C 0 199 min 120 120 120 120 120 120

A4 Multifunction input configuration IR32S, Y and C IR32M C 0 7 - 0 1 1111

A5 (must be kept at 0) 0 5 - 0 0 0000

A6 Duty setting for external alarm (0= OFF,100= ON) C 0 100 min 0 0 0000

A7 External alarm delay 9A4=2, Multifunction input C 0 199 min 0 0 0000

FAN PARAMETERS TYPE MIN MAX UNIT

(difference between ambient and evap temp.,2= Fan regulator evap

F0

temp) C 0 2 flag 0 0 0000

Fan turn-off temperature if F0=1: fans are on when evap temp< (ambient

F1

temp-F1-A0) if F0=2 Fans are on if evap temp<(set point+F1-A0) F 0 20 C/F 5 0 0000

F2 Cycle fans with compressor (0=no, 1= yes) C 0 1 flag 1 0 0000

F3 Stop fans during defrost (0=no, 1= yes) C 0 1 flag 1 0 0000

Fd fan delay (After dripping) F 0 15 min 3 0 0000

OTHER SETTINGS TYPE MIN MAX UNIT

Ho Address within network C 0 15 - 0 0 0000

H1 Multifunction output (0=Auxilary, 1=Alarm n.c., 2=Alarm n.o.) C 0 1 flag 1 0 0010

H2 Access locking (Keypad and IR remote) C 0 3 - 3 1 1111

H3 code to permit remote programing C 0 199 - 0 0 0000

FACTORY SET POINT (GENERAL PRODUCT)

-Meat - - - - - 27272727

-General Purpose (Factory Setting) - - - - - 2727272727

-Fresh Cuts - - - - - 29272927

F

5

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

DEF LB 36 48 72 SL48

DEF LB 36 48 72 SL48

DEF LB 36 48 72 SL48

DEF LB 36 48 72 SL48

03035

Page 8

FIGURE 2

Temperature Control

For general introduction please see Page 2. The

following is a description of the keys on the

temperature control display.

Up Key:

Increases the displayed value when setting

•

set-point and parameters.

Goes through the parameter.

•

•

If pressed for more than 5 seconds together

with the down key (*): enables/inhibits the

continuous cycle.

Down Key:

Decreases the displayed value when setting

•

set-point and parameters.

Goes through the previous parameter

•

• If pressed for more than 5 seconds: forces a

defrost cycle (only if H1=0).

• If pressed for more than 5 seconds together

with the up key(*): enables/inhibits the

continuous cycle.

(*)

: first push DOWN

NOTE

SEL

SEL Key:

Selects the set-point (see SET-POINT section)

•

Indicates the parameter value (see

•

PARAMETERS SELECTION).

• If pressed for more than 5 seconds together

with the prg key: enters the configuration

menu (see PARAMETERS SELECTION - second

level).

PRG

mute

PRG Key:

Stops the buzzer.

•

• If pressed when the control starts: resets the

default parameters (see ALARMS AND

SIGNALS).

• If pressed for more than 5 seconds: enters

the frequent parameters menu (see below).

key, then UP key

• If pressed for more than 5 seconds together

with the sel key: enters the configuration

menu (see PARAMETERS SELECTION - second

level).

Indications On The Display

COMP 1 LED to indicate compressor ON

2 LED’s to indicate Continuous

Cycle ON (**).

DEF defrost ON (H1=1); if H1=0, the LED

is on to indicate “REVERSE”

working mode.

If one or more LED’s blink: see the ALARMS AND

SIGNALS section.

(**) Not present in the controllers with serial

number lower than 10.000.

Functioning

conditions, the display shows the value

measured by the regulation probe. In case of

active alarm, the relative code blinks alternately

with the alarm code.

The following information shows how to change

the set point and differential on your case in the

event that there is a change in the product

displayed.

during normal working

:

Set-Point:

Press the SEL key for one second to display

•

the set-point value;

After two seconds, the set value blinks;

•

Press UP or DOWN to increase or decrease

•

the value;

Press the SEL key to confirm the new value.

•

Control Differential:

Follow the Parameters Modification

•

procedure. Find the “rd” parameter on the

display by pressing UP or DOWN until it

appears on the display.

Press SEL to display the Control Differential

•

parameter value.

Press UP or Down to increase or decrease the

•

value.

Press SEL to confirm temporarily the new

•

value and display its code.

6

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 9

Press PRG to confirm the new value and exit

•

the parameter modification procedure.

The following are parameter setting procedures

and general information.

Parameters:

The parameters have been divided into two

sections: frequent parameters and configuration

parameters:

FIRST SECTION: frequent parameters (type=F in

the table); no password is required to enter.

Press the PRG key for more than 5 seconds

•

(in case of alarm, silence the buzzer first);

The first modifiable parameter code is

•

displayed.

To modify parameters see PARAMETERS

MODIFICATION on the following page:

SECOND SECTION: configuration parameters

(type=C in the table): a password is required to

enter.

Press PRG and SEL simultaneously for more

•

than 5 seconds;

OO is displayed.

•

Press UP and DOWN until 22 is displayed;

•

(password).

Press SEL to confirm;

•

The first modifiable parameter code is

•

displayed.

To modify the parameters see PARAMETERS

MODIFICATION below.

Parameters Modification:

Press UP or DOWN to show the code of the

•

parameter that has to be changed;

Press SEL to display the selected parameter

•

value;

Press UP or DOWN to increase or decrease

•

the value.

Press SEL to confirm temporarily the new

•

value and display its code, Repeat the

procedure from the beginning. Press UP or

DOWN.

To exit modifying the parameters with the new

values:

Press PRG to confirm the new values and exit

•

the parameters modification procedure.

To exit without modifying any parameter: Do not

press any key for at least 60 seconds (TIME OUT).

Defrost:

Press the DEF key for more than 5 seconds to

•

force a defrost cycle.

Buzzer Off:

Press the PRG (MUTE) key to silence the

•

buzzer. The alarm code remains until the

alarm condition is eliminated.

Continuous Cycle:

Press UP and DOWN simultaneously for 5

•

seconds to enable/inhibit the compressor’s

continuous cycle. (see CC & oS parameters

in the PARAMETERS TABLE).

7

OMC-LB, OMC-36, OMC-48, OMC-72, OMC-SL-48

03035

Page 10

FIGURE 3

Description of the Main Alarm Signals

The following is a list of the flashing alphanumeric signals that may occur on your temperature

controller and the appropriate troubleshooting options.

FLASHING LED

Initiation of the relative function is delayed for a period while awaiting an external consent or while held

up by another process still in progress. For example, if a defrost is requested during continuous cycle

operation, the defrost will be held up until the continuous cycle is complete, and the appropriate LED

(Def) will flash.

E0 FLASHING: control probe error

Probe not working because the signal has been interrupted or there is a short-circuit.

•

Probe not compatible with the equipment.

•

Parameter /0 does not correspond to unit’s hardware set-up.

•

E1 FLASHING: evaporator probe error – (found in program mode only)

Probe not working because the signal interrupted or there is a short circuit.

•

Probe not compatible with the equipment.

•

Parameter /0 does not correspond to unit’s hardware set-up.

•

AI FLASHING: immediate Multi-function digital input

Suction problem high or low pressure safety open.

•

Check Multi-function input and parameter A4.

•

Ad FLASHING: delayed Multi-function digital input.

Check Multi-function input and parameters A4 and A7.

•

L0 FLASHING: low temperature alarm

The probe has registered a temperature further below the set value than the value given to

•

parameter AL.

Check parameters AL, Ad and A0.

•

The alarm will cease as soon as the temperature returns within the limits selected (see

•

parameter AL).

HI FLASHING: high temperature alarm

The probe has registered a temperature further above the set value than the value given to

•

parameter AH.

8

OMC-LB, OMC-36, OMC-48, OMC-72, OMC48SL

03035

Page 11

FIGURE 4 – (OMC-LB)

9

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 12

FIGURE 5 – (OMC-36 & OMC-48)

10

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 13

FIGURE 6 – (OMC-72)

11

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 14

FIGURE 7 – (OMCSL48)

12

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 15

OMC-LB SPECIFICATION SHEET

Side View

Front View

MODEL

OMC-LB 310 37 3/4 55 1/8 38 1/16 32 3/4 33 5/8 28 1/8 18

MODEL

OM C-LB 20 16 3/4 R404A

WEI GHT

(w/shelves)

CASE DESIGNED TO OPERATE IN AN AMBIENT AIR TEMPERATURE

OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER

OUTSIDE DIMENSIONS

(INCHES)

WH D W H D

ELECTRICAL

INCOMING SUPPLY

115-1 PHASE-60 HZ.

INSIDE DIMENSIONS

(INCHES)

MIN

CIRCUIT

AMPS

All specifications are subject to change without notice.

AMPS

RLA

H.P. REF.

CUBIC

FEET

CAPACITY

U

U

R

R

L

L

C

13

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 16

OMC SPECIFICATION SHEET

Front View

INSIDE DIMENSIONS

(INCHES)

CUBIC

FEET

CAPACITY

MODEL

WEIGHT

(w/shelves)

Side View

OUTSIDE DIMENSIONS

(INCHES)

WH D W H D

OMC 36 547 37 3/8 79 1/2 38 3/4 32 3/4 51 3/4 25 18

OMC 48 657 49 79 1/2 38 3/4 44 1/4 51 3/4 25 24

OMC 72 740 72 3/4 79 1/2 38 3/4 68 1/8 51 3/4 25 37

ELECTRICAL

MODEL

INCOMING SUPPLY

OMC 36 30 19.6 3/4 R-404A

OMC 48 30 21.6 1 R-404A

OMC 72 30 19.0 (2) 3/4 R-404A

115-1 PHASE - 60 HZ

115-1 PHASE - 60 HZ

208/230 - 115 - 1 PHASE - 60 HZ

CASE DESIGNED TO OPERATE IN AN AMBIENT OF 75 F OR LOWER

AND RELATIVE HUMIDITY OF 55% OR LOWER

MIN

CIRCUIT

AMPS

AMPS

RLA

H.P. REFRIG.

U

All specifications are subject to change without notice.

R

L

U

R

L

C

14

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 17

OMCSL48 SPECIFICATION SHEET

Side View

WEI GHT

MODEL

OMCSL48 585 47 87 3/4 23 5/8 44 1/4 51 7/8 19 1/8 15.6

OMCSL48 30 24 1 1/2 R404A

w/shelv es

(pounds)

CASE DESIGNED TO OPERATE IN AN AMBIENT AIR TEMPERATURE

OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER

OUTSIDE DIMENSIONS

(INCHES)

WH D W H D

ELECTRICAL

INCOMING SUPPLY

115-1 PHASE-60 HZ.

INSIDE DIMENSIONS

(INCHES)

MIN

CIRCUIT

AMPS

All specifications are subject to change without notice.

AMPS

RLA

H.P. REF.MODEL

CUBIC

FEET

CAPACITY

Front View

U

R

U

R

L

C

L

15

OMC-LB, OMC-36, OMC-48, OMC-72, OMCSL48

03035

Page 18

1. Limited Warranty. ZERO ZONE, INC. (“Seller”) hereby warrants that any products

manufactured by it and sold under this Warranty shall be free for a period of one

year from the date of shipment, from defects in material and workmanship which,

under normal use and service would render such products unusable or

unserviceable. The obligation of Seller under this Warranty shall be limited to the

repair or replacement of any parts that the Seller determines are defective. This

Limited Warranty does not cover labor, freight, transportation or other charges

incidental to replacement or repair. Parts returned to Seller must be returned

freight prepaid and replacement parts will be returned to the Buyer freight

collect.

2. Motor Compressor Extended Warranty. Seller hereby warrants with respect to any

motor compressor sold under this extended Warranty, exclusive of any and all

parts of the condensing unit assembly thereof, that such motor compressor shall

be free from defects in material and workmanship for a period of four (4) years

from the date of the expiration of the one year Warranty provided by the

manufacturer of such motor compressor, if the Buyer purchases said Warranty at

the time of equipment purchase. In the event the motor compressor is not free

from defects in material and/or workmanship during such four-year period, Buyer

must purchase a replacement for the defective motor compressor and obtain

whatever salvage credit may be available from the manufacturer thereof. Upon

receipt by Seller or written notice from Buyer of compressor. Seller will issue a

purchase credit or a refund, at Seller’s option, for the difference between the

compressor replacement cost and the salvage credit. All labor and shipping

charges incurred in connection with such replacement shall be the sole

obligation of the Buyer.

3. Product Not Manufactured by Seller. The written Warranty, if any, provided by the

manufacturer of any part of the refrigeration unit sold by Seller to Buyer, but not

manufactured by Seller, is hereby assigned to Buyer. However, Seller makes no

representation or Warranty regarding the existence, validity or enforceability of

any such written Warranty.

4. LIMITATION AND EXCLUSION OF WARRANTIES. THE WARRANTIES SET FORTH HEREIN

ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES

WHATSOEVER, INCLUDING BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE.

5. Consequential Damages. Notwithstanding anything to the contrary set forth in

this Warranty Certificate, Seller shall not be liable for any incidental or

consequential damages arising out of, or directly or indirectly caused by a

defective part sold by Seller, including but not limited to, costs arising from the

replacement of the part, loss of gas, loss of product, or any damage to person or

property, whether as a result of Seller’s negligence, breach of contract, breach of

Warranty or otherwise.

Model No.________________________ Serial No._______________________

16

OMC-LB, OMC-36, OMC-48, OMC-72

03035

Loading...

Loading...