Page 1

SD-324

Sporlan Kelvin II

Refrigeration Controller

User’s Manual, November 2009

Page 2

Page 1

1

24 VAC

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

19

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

24 VAC

N/C

N/C

N/C

N/C

N/C

Ground

RS-485 A+

RS-485 B-

N/C

N/C

N/C

Load

Line

N/C

N/C

N/C

N/C

N/C

N/C

T3-

T3+

T2-

T2+

T1-

T1+

PWR

Room

Tout

RS485

Valve

LL Sol

N/C

Pressure

Aux

SER, SEI, SEH ESX

Red Black

Green Red

White Yellow

Black Orange

N/C Gray

Black

Green

White

+5VDC

Ground

Sense

Description

The Kelvin II is a standalone superheat controller. The Kelvin

II may be connected with a MODBUS master or a Network

Master to give remote access to pressure and temperature

readings in addition to viewing and editing the controller’s

setpoints. The user can also take advantage of the easy to use

local display or a Remote Display to accomplish the same

tasks.

1. Kelvin II Configuration

Specifications

n Input Voltage: 24 VAC (± 10%), 40 VA minimum to board

with external transformer

n Operating ambient temperature: -40°F to 120°F

n LED: One Power LED

n Communications: 1 RS485 Port, 1 USB port

(Not operational)

n 4 Digit 7 segment display

n Inputs:

– Optical Encoder (Knob)

– One Pressure Input

– Three Temperature inputs

n Valve Control of all Sporlan Electric Expansion Valves

“EEV”

n 3 amp Solid State Relay for Liquid Line Solenoid Kelvin II

w/o Local Display

n 1 amp Solid State Relay for Liquid Line Solenoid Kelvin II

w/Local Display

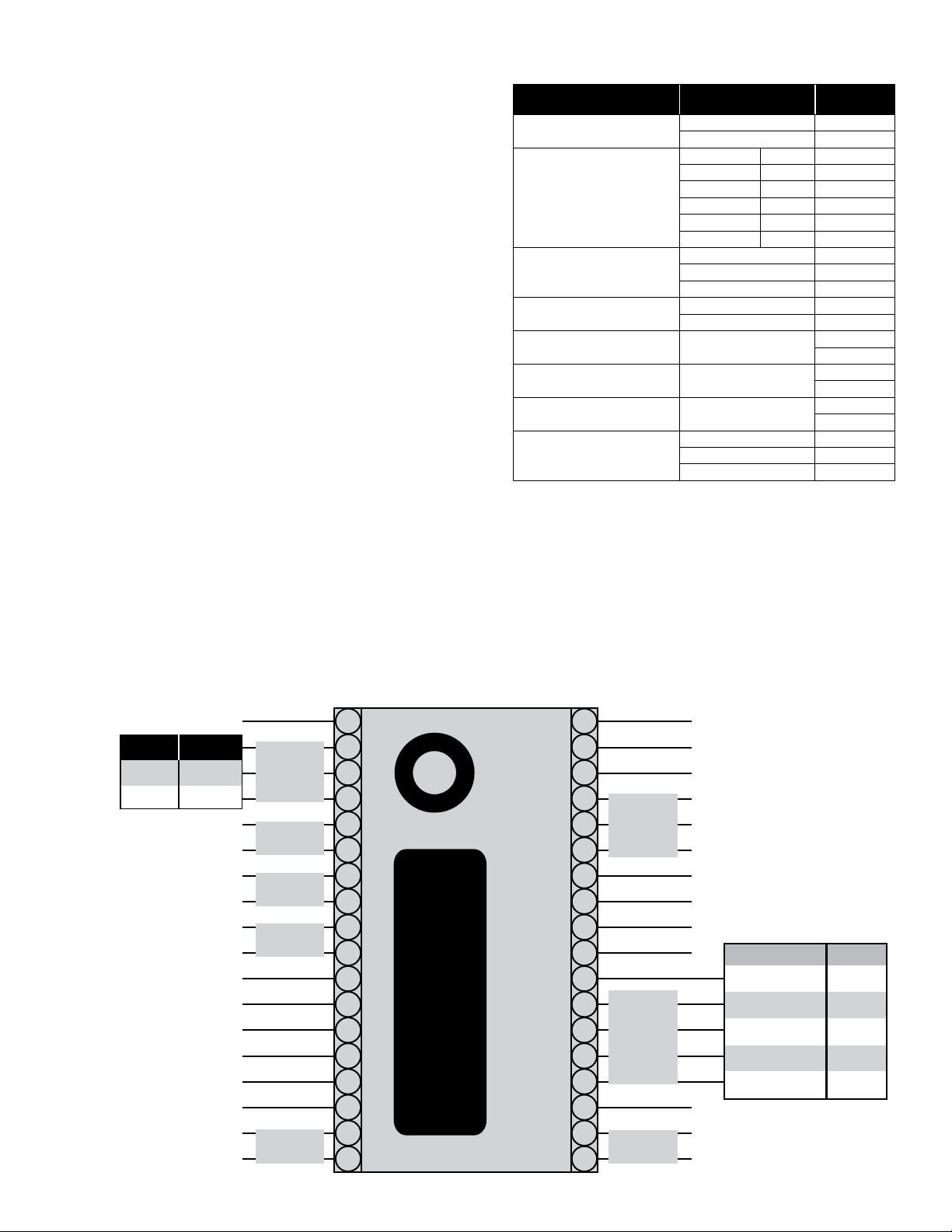

2. Kelvin II Connections

The Kelvin II has screw terminals on the each side of the

controller. The controller should be wired as follows and as

shown in Figure 1.

Figure 1

Item Wire (line)

Power

Valve

RS-485

Liquid Line Solenoid

Auxiliary Temperature Sensor

(Displayed menu item: S-3)

Room Temperature Sensor

(Displayed menu item: CtP)

Coil Out Temperature Sensor

(Display option: tout)

Pressure Transducer

(Displayed menu item: SucP)

24VAC 1

24 VAC 2

SEI, SER, SEH ESX —

N/C Gray 4

Black Orange 5

White Yellow 6

Green Red 7

Red Black 8

Ground 13

A+ 14

B- 15

Line 19

Load 20

T3

T2

T1

Sense (WHITE) 33

Ground (GREEN) 34

+5 VDC (BLACK) 35

Kelvin II

connect point

27

28

29

30

31

32

3. Kelvin II Display

Upon the rst power-up from Sporlan, the Kelvin II will enter the setup menu. This menu allows the user to set some

critical setpoint values, seen in Table 1, before the controller

will operate. These critical values can be set via the local or

remote displays, MODBUS, or Network Master. (Note: Only

the Valve Type and Refrigerant have to be set via MODBUS

or Network Master for the controller to operate) Once these

values are entered the Kelvin II will then begin its control. If

the setup menu is displayed on the local or remote displays

Page 3

Page 2

and the user sets these values via MODBUS then the Kelvin

II will automatically leave the setup menu.

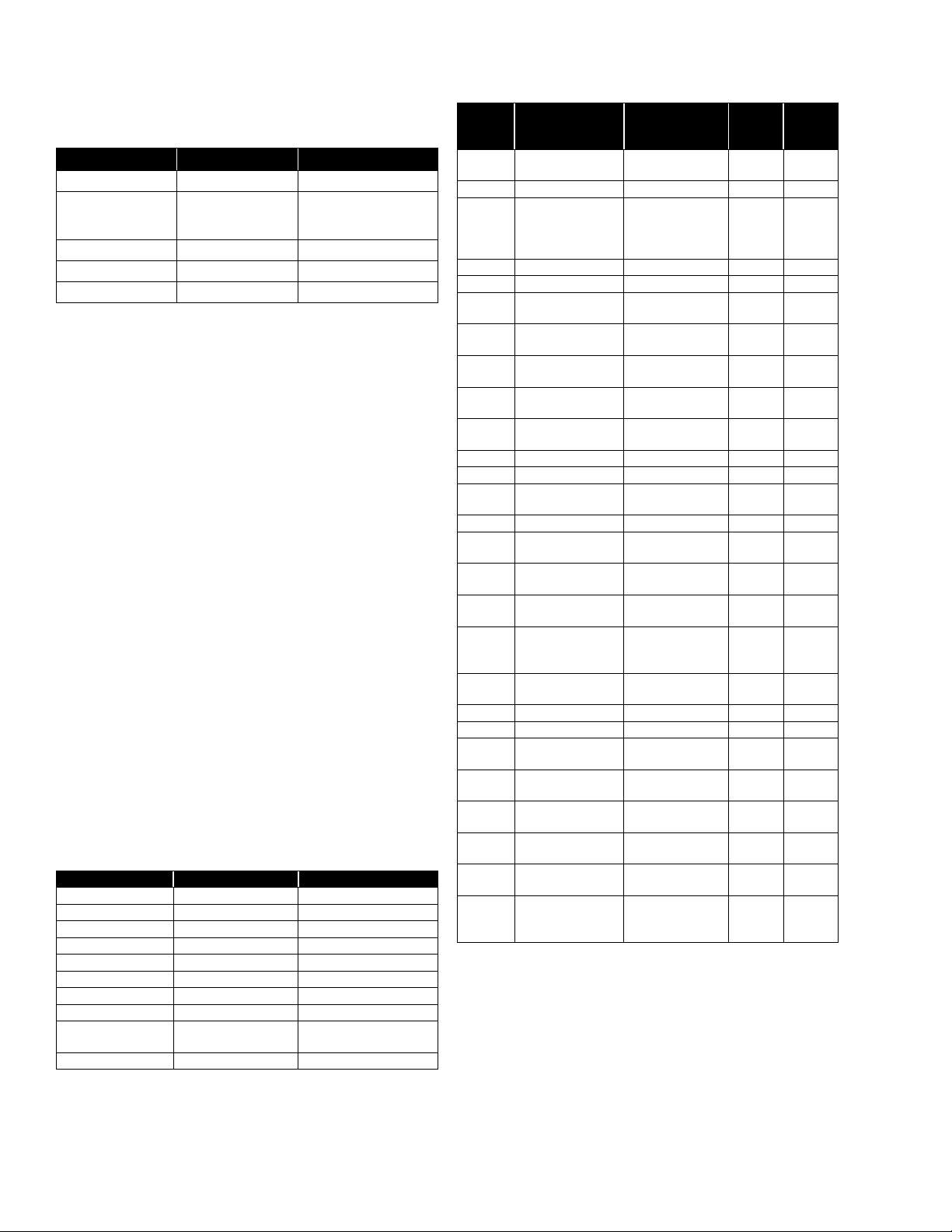

Table 1 Setup Menu

Displayed Menu Item Description Selections

StEP

rEFr

PtYP

un_T

un_P

Valve Type 1596, 3192, 2500, 6384, 400

Refrigerant

Pressure Sensor Type gAUg, AbSL

Temperature Units FAHR, CELS

Pressure Units PSI, BAR

r22, 134A, 402A, 404A,

407A, 407C, 410A, 417A,

r507, 422d, r744, 245F

After setup, the Kelvin II defaults to showing the Superheat

value. The user can then turn the knob to view the other process values of their system. The screen will alternate between

the process values identity and value alternating every 3 seconds. For ease of use, the value that is displayed for a process

value may come in the form of text to eliminate the need of

‘looking up the meaning’. The menu text and meanings for

process values are described in Table 2.

The user may also view/edit the setpoints by pressing the knob

and holding it down for 5 seconds. The user is then prompted

for a password to verify his credentials. The knob should be

rotated up to ‘111’ for the password. If the password is correct the user may change the setpoints to the value he desires

in order to obtain optimum system performance. The menu

text and meanings for setpoint values are described in Table 3.

Setpoints are saved to the controller when the user leaves the

Setpoint menu by pressing the knob when “ESC” is shown.

The setpoint menu has a timeout of 60 seconds for inactivity. When this timeout is reached the controller goes back to

showing the process values and does not save any setpoints

that might have been changed. If the user is in the Manual

Valve Position setpoint then this timeout length is 60 minutes.

As long as the controller does not time out the 60 minutes,

Setpoints are saved to the controller when the user leaves the

Setpoint menu by pressing the knob when “ESC” is shown.

All process values and setpoints are accessible1 through the

local and remote displays.

Table 2 Process Value Menus

Displayed Menu Item Description Range

SuPH

SucP

tSAt

tout

CtP

PoSn

S-3

rELA

StAt

ALS

Superheat 0 to 165°F, 0 to 91.6°C

Suction Pressure

Saturation Temperature -60 to 150°F, -51.1 to 65.6°C

Suction Temperature -60 to 150°F, -51.1 to 65.6°C

System Temperature -60 to 150°F, -51.1 to 65.6°C

Valve Position 0 to 100% Open

Auxiliary Temperature

Solenoid Status dEng, Eng

System Cycle Status

Alarm Status

4

0 to 150 PSI, 0 to 10.34 Bar

2

-60 to 150°F, -51.1 to 65.6°C

Current cycle and manual

3

valve position state

noAL or all active alarms

Table 3 Setpoint Menu

Displayed

Menu

Item

ESC

SHSP

rEFr

d_On

dOFF

d_St

CtSP

H_oP

C_in

Cout

HiCP

SUPS

-P-

-I-

-d-

StEP

SPoS

nEt

Addr

un_P

un_T

PtYP

CaLP

CLt1

CLt2

CLt3

CAdr

Description Range

Escape and save

settings

Superheat Setpoint 0 to 45°F, 0 to 25°C 8

Refrigerant

Delay On 0 to 60 seconds 0

Delay Off 0 to 60 seconds 0

Delay Percent Open

of Valve

Cut-out Suction

Pressure

Maximum Operating

Pressure

Cut-in Temperature

Cut-out Temperature

Max Valve Capacity 20 to 100% 100

Supermarket Setting OFF, ON OFF

Proportional

Coefficient

Integral Coefficient 0 to 100 25

Derivative

Coefficient

Valve Type

Manual Valve

Position

Network Type

(MODBUS or

Network Master)

MODBUS/Network

Master Address

Pressure Units PSI, BAR PSI

Temperature Units FAHR, CELS FAHR

Pressure Sensor

Type

Pressure Sensor

calibration value

Tout calibration

value

Ctp calibration value

S-3 calibration value

Controller Display

Address

— —

r22, 134A, 402A,

404A, 407A, 407C,

410A, 417A, r507,

422d, r744, 245F

0 to 100 percent 0

4

PSI,

0 to 150

4

4

4

Bar

PSI,

Bar

0 to 10.3

0 to 150

0 to 10.3

-60 to 125°F,

-51.1 to 51.6°C

-60 to 124°F,

-51.1 to 51.1°C

0 to 100 40

0 to 100 5

1596, 3192, 2500,

6384, 400

0 to 100% Open

nbUS (MODBUS)

or ProP (Network

Master)

1 to 255 1

AbSL, gAUg gAUg

-5 to 5 PSI,

-0.34 to 0.34 Bar

-5 to 5°F, -2.7 to

2.7°C

-5 to 5°F, -2.7 to

2.7°C

-5 to 5°F, -2.7 to

2.7°C

0 to 99

Default

Setting

404A

0

150

-59

-60

1596

Present

Position

nbUS

0

0

0

0

0 or 1

for local

display

User

Setpoints

4. Kelvin II MODBUS

The Kelvin II can communicate with a MODBUS master.

The Kelvin II will transfer process values and setpoints via

MODBUS.

1 Setpoints can only be viewed and edited when the proper password is entered.

2 The Auxiliary Temperature sensor input has a special Pumpdown feature. If a “short” or switch closure is placed across these terminals, the valve will

shut for pumpdown. The full details of this feature are described in Section 5.

3 The Alarm Status process value is described in Section 6.

4 The maximum value varies based on which refrigerant is selected. (R-410A is 300 PSI, R-744 is 500 PSI and all others are 150 PSI).

Page 4

Page 3

The Kelvin II only supports the RTU transmission mode. The

serial settings are as follows:

n 9600 baud

n 8 data bits

n 1 stop bit

n Even parity

The Kelvin II supports the ‘Read Input Registers’, ‘Read

Holding Register’, ‘Write Single Register’, ‘Read Multiple

Coils’ and ‘Write Single Coil’ function codes. Any other request will result in an exception response. The Kelvin II will

allow a full and partial block read of the Input and Holding

registers and Coils.

4.1. Scaling

In order to preserve precision, scaling was implemented when

using Bar or Celsius for units. PSI and Fahrenheit units are

both in whole numbers and have no scaling. The tables of the

MODBUS memory map below reect this implementation.

The Celsius values that are transferred via MODBUS are 10X.

For example, if Celsius is chosen for the temperature units

then 45°C is transferred for the Superheat. The actual Superheat is 4.5°C. If the user desired to change a setpoint they

should keep this in mind when they enter a value.

The Bar values that are transferred via MODBUS are 100X.

For example, if Bar is chosen for the pressure units then 1034

Bar is transferred for the Maximum Operating Pressure. The

actual Maximum Operating Pressure is 10.34 Bar. If the user

desired to change a setpoint they should keep this in mind

when they enter a value.

4.2. MODBUS Memory Map

Table 4 Memory Map

MODBUS

Function

Code

Read Coils

(0x01)

Read Holding

Register

(0x03)

Mapped

Data

Manual

Valve

Control

Setpoints

Data Map Range

Bit 0 = Manual Valve

Enabled Flag

Bit 1 = Manual Valve

Duration Enabled

Flag

0. Superheat

Setpoint

1. Refrigerant Type

2. Delay On Relay 0 to 60 seconds

3. Delay Off Relay 0 to 60 seconds

4. Delay Steps 0 to 100 % Open

5. Cut-out Suction

Pressure

0 = Disabled,

1 = Enabled.

0 to 45°F, 0 to 250°C

(0.0 to 25.0°C)

0 = r22 1 = 134A

2 = 402A 3 = 404A

4 = 407A 5 = 407C

6 = 410A 7 = 417A

8 = 422A 9 = 422d

10 = r507 11 = r744

12= 245F

5

PSI, 0 to 1034

0 to 150

Bar (0 to 10.34 Bar)

MODBUS

Function

Code

Read Holding

Register

(0x03)

Read Input

Registers

(0x04)

Mapped

Data

Setpoints

Process

Variables

Data Map Range

6. Max Operation

Pressure

7. Temperature

Cut-in

8. Temperature

Cut-out

9. Valve Maximum 20 to 100 %

10. Supermarket

Mode

11. P 0 to 100

12. I 0 to 100

13. D 0 to 100

14. Valve Type

15. Manual Valve

Position

16. Network Type

17. Unit Address 1 to 255

18. Pressure Units 0 = PSI, 1 = BAR

19. Temperature

Units

20. Pressure Sensor

Type

21. Pressure

Calibration Offset

22. Suction

Temperature

Calibration Offset

23. Room

Temperature

Calibration Offset

24. Auxiliary

Temperature

Calibration Offset

0. Superheat

1. Suction

Pressure

2. Saturation

Temperature

3. Suction

Temperature

4. Room

Temperature

5. Valve Capacity

6. Auxiliary

Temperature

7. Relay Status

6

6

0 to 150

Bar (0 to 10.34 Bar)

-60 to 125°F,

-511 to 516 °C

(-51.1 to 51.6 °C)

-60 to 124°F,

-511 to 511 °C

(-51.1 to 51.1 °C)

0 = OFF 1 = ON

0 = 1596 1 = 3192

2 = 2500 3 = 6384

4 = 400

0 to 100 % Open

0 = MODBUS

1 = Network Master

0 = FAHR, 1 = CELS

0 = GauG, 1 = ABSL

-5 to 5°F,

-34 to 34 Bar

(-0.34 to 0.34 Bar)

-5 to 5°F,

-27 to 27°C

(-2.7 to 2.7°C)

-5 to 5°F,

-27 to 27°C

(-2.7 to 2.7°C)

-5 to 5°F,

-27 to 27°C

(-2.7 to 2.7°C)

0 to 165°F,

0 to 916°C

(0 to 91.6°C)

0 to 150 PSI,

0 to 1034 Bar

(0 to 10.34 Bar)

-60 to 150°F,

-511 to 656°C

(-51.1 to 65.6°C)

-60 to 125°F,

-511 to 656°C

(-51.1 to 65.6°C)

-60 to 125°F,

-511 to 656°C

(-51.1 to 65.6°C)

0.0 to 100.0% Open

(0.0 to 100.0)

-60 to 125°F,

-511 to 656°C

(-51.1 to 65.6°C)

0 = Deenergized,

1 = Energized

PSI, 0 to 1034

5 The maximum value varies based on which refrigerant is selected. (410A is 300 PSI, r744 is 500 PSI and all others are 150 PSI).

6 The maximum value varies based on which refrigerant is selected. (410A is 300 PSI, r744 is 500 PSI and all others are 150 PSI).

Page 5

Page 4

MODBUS

Function

Code

Read Input

Registers

(0x04)

Write Single

Coil (0x05)

Write Single

Register

(0x06)

Mapped

Data

Process

Variables

Manual

Valve

Control

Setpoints Same as above.

Data Map Range

8. Alarm Status

9. System Cycle

Status

Bit 0 = Manual Valve

Enabled Flag

If Bit set then alarm is

active:

Bit 0 = Suction

Transducer Failure

Bit 1 = Tout Sensor

Failure

Bit 2 = High Superheat

Bit 3 = Low Superheat

If Bit set then mode is

active:

Bit 1 = Setup Mode

Bit 2 = Off Cycle

Bit 3 = Cooling Cycle

Bit 4 = Pump-down Cycle

Bit 5 = Manual Valve

Override Mode

0 = Disabled,

1 = Enabled.

The Manual Valve

duration Bit is read-only.

The max number of

registers written at a

time is

1. The limits can be

seen above in the

‘Read Holding

Register’ definition.

5. Kelvin II Features

5.1. Pumpdown Feature

The Kelvin II will initiate a pumpdown when Auxiliary Temperature sensor terminals are shorted. If desired, this temperature connection could be set up as a dry contact. When a

pumpdown is desired the contact should be closed. The pumpdown will be ended when the short is removed provided that

there are no sensor alarms.

Normally, on the process value screens, the process value

text alternates with its value. When an alarm is activated the

alarm status “-AL-“screen is added to the rotation to make the

user aware that an alarm has been activated. The Alarm Status

menu display item ALS, will show the active alarms shown

in Table 5.

7. Kelvin II Display Networking

The Kelvin II displays can be set up to access other Kelvin II

controllers on the network. The controller’s current ‘CAdr’

value can be determined by pressing down the button on the

display while viewing a process value. To enable the display

network the ‘CAdr’ setting MUST be set to a unique nonzero

value with the RJ-45 connector on the side of the controller

DISCONNECTED.

After ‘CAdr’ has been set, an ‘End’ screen is added just before the ‘SuPH’ process value. Pressing the button on the

display while viewing the ‘End’ screen brings up a menu allowing the selection of other Kelvin II controllers connected

to the display network. Turning the knob allows the selection of other Kelvin II controllers based on their appropriate

‘CAdr’ address. The local controller is listed as ‘LocL’ by a

local display. Note: the remote display always includes the

‘End’ screen since it must be able to view any controller on the

display network.

8. Kelvin II Factory Reset

A factory reset can be performed by holding the button down

on the local or remote displays for 5 seconds when power is

rst applied. If using a local display the display will show

‘FrSt’ while the factory reset is being performed and then

automatically connect to the local controller.

5.2. Manual Valve Position Feature

The Kelvin II has the ability to manually control the valve.

To enable this manual control via the local or remote displays

simply open the setpoint menu and edit the ‘SPoS’ setpoint.

When the value is displayed for this setpoint the user is manually controlling the valve. The valve position can be changed

by rotating the knob clockwise or counterclockwise. There is

an inactivity timer of 60 minutes while in manual control. The

timer is reset each time the user moves the valve. The manual

control of the valve is ended when the user presses the knob to

go back to displaying ‘SPoS’ or a timeout has been reached.

6. Kelvin II Alarms

The Kelvin II has 4 alarms. The following table lists the

possible alarms and the text that is seen on the controller.

The controller’s alarm status can be viewed via MODBUS,

Network Master, and local and remote displays.

Table 5 Alarms

Alarm Text Meaning

NoAL

PSAL

TSAL

HSAL

LSAL

No Alarms active

Pressure Sensor alarm

Tout Sensor alarm

High Superheat alarm

Low Superheat alarm

If using a remote display the display will show ‘FrSt’ and

switch to a menu that allows the selection of the controller

to reset. To perform a factory reset, select the controller with

the appropriate ‘CAdr’ value. The display should show ‘----‘

while the reset is being performed. When nished performing factory resets turn the knob counterclockwise until ‘ESC’

is shown on the display. Pressing the button while ‘ESC’ is

shown on the display exits the factory reset menu and should

automatically connect to a controller on the display network.

Table 6 Replacement Parts

Part Number Description

952560 Kelvin II without display

952561 Kelvin II with local display

952562 Kelvin II Remote panel display

952662 Temperature Sensor Assembly

952795 Well Sensor Kit

953091 Pressure Transducer 150 psig with cable

952995 Pressure Transducer 150 psia with cable

952740

952504

Pressure Transducer 300 psig with cable for

R-410A applications only

Pressure Transducer 500 psig with cable for

R-477 applications only

Page 6

Parker Hannifin Corporation

Sporlan Division

206 Lange Drive • Washington, MO 63090 USA

phone 636 239 1111 • fax 636 239 9130

www.sporlan.com

112009 / SD-324

Loading...

Loading...