Page 1

INSTALLATION & SERVICE MANUAL

Quik Load doors and frames

May 2008

Page 2

Table of contents

3-5. Warranty

6. Serial plates

7. Frame inst allation

8. Door Installation

9. Door removal

10. Reversing the door swing

11. Replacing the door heater

12. Removing and replacing the torque rod

13. Gasket and handle replacement

14. Replacing a frame heater

15. Anti-sweat heater information

16. Blank

17. Replacing light fixtures

18-19. Ballast/power su pply replacement and lighting schematics

20. Exploded View – Door

21. Exploded Vie w – Fr ame T8

22. Exploded Vie w – Fr ame Gelcore

23. Exploded View – Frame Crossfire

24. Care and cleaning information

Page 3

6/25/08 - Rev. A Page 3

SCHOTT Gemtron Food Display

WARRANTIES AND GENERAL TERMS AND CONDITIONS

CONDITIONAL ACCEPTANCE OF ORDER: SCHOTT Gemtron Corporation’s (“SCHOTT

Gemtron”) acceptance of customer’s order and therefore, the formation of a valid contract for

sale, is EXPRESSLY CONDITIONED on Customer’s acceptance of the general terms and

conditions as set forth herein and any additional terms and conditions indicated on the face of

SCHOTT Gemtron’s Conditional Acceptance of Order or quotation. Customer will be deemed to

have accepted these general terms and conditions and any general terms an d conditions

indicated on the face of SCHOTT Gemtron’s Conditional Acceptance of Order or quotation unless

customer shall object thereto in writing within five days from receipt of SCHOTT Gemtron’s

Conditional Acceptance of Order or quotation or upon acceptance of all or any parts of the goods

ordered, whichever occurs first.

ADDITIONAL TERMS AND CONDITIONS: The terms and conditions as set forth on SCHOTT

Gemtron’s Conditional Acceptance of Order, quotation, or price lists shall be considered

additional terms and conditions of this sale. SCHOTT Gemtron and the purchaser acknowledge

that all of the terms and conditions applicable to this sale reflect an acceptable allocation of the

rights and obligations of the parties to this sale.

SHIPMENT OF GOODS / RETURN OF GOODS: Every effort will be made to ship the goods on

the scheduled shipment date and to maintain production schedules consistent therewith.

SCHOTT Gemtron will not be liable, however, for any claims arising from the failure to meet any

scheduled shipping dates. If Buyer refuses shipment of any standard catalog products under an

acknowledged order and those products are consistent with that order and are not delivered

damaged or defective, then Buyer will be responsible for:

1. Return shipment of the products to SCHOTT Gemtron in original shipping containers;

2. Return freight to SCHOTT Gemtron prepaid by Buyer; and

3. A restocking charge to be determined by SCHOTT Gemtron of not less than twenty-five

percent (25%) of the sales price. Buyer assumes the risk of any return shipment damage or loss,

the cost of which will be assessed by SCHOTT Gemtron and added to the restocking charge. No

custom products or custom sizes of catalog items may be returned to SCHOTT Gemtron fo r

credit unless those products are not consistent with an acknowledged order or they are defective.

If they are defective, SCHOTT Gemtron reserves the right to correct the defect at the ship-to

location.

TERMS OF CREDIT: All credit terms are net 30 days from date of invoice. Any deductions from

the net invoice amount must be approved by an authorized representative of SCHOTT Gemtron.

If credit is extended to Buyer, SCHOTT Gemtron reserves the right to revoke such credit if Buyer

fails to make timely payment for any goods delivered. SCHOTT Gemtron reserves the right to

require payment or other assurances which it deems necessary prior to the shipment of any

goods, if, in SCHOTT Gemtron's opinion, exercised in SCHOTT Gemtron's subjective, good faith

judgment, the Buyer's financial condition has deteriorated or the risk of non-payment has

otherwise increased. Credit is subject to approval upon receipt of completed credit application.

Any goods shipped prior to credit approval shall be shipped "Cashiers Check", or pre-payment. A

$50.00 charge will be applied for each returned check. Goods may not be returned for credit

unless prior authorization and an authorization number have been granted by SCHOTT G emtron.

A 1-1/2% per month charge will be assessed on past due amounts.

SCHOTT Gemtron Food Display • 2840 Nebo Road, Madisonville, KY 42431

Toll Free: 800.326.2717 • Phone: 270.821.2864 • Fax: 270.326.3624

FWTC1011

Page 1 of 4

Page 4

6/25/08 - Rev. A Page 4

LIMIT ON REMEDIES IN EVENT OF FAILURE: In the event any SCHOTT Gemtron product fails

to perform as warranted, SCHOTT Gemtron’s sole responsibility and PURCHASER’S SOLE AND

EXCLUSIVE REMEDY under any warranty, contract, negligence or other claim of liability shall be

limited to a refund of SCHOTT Gemtron’s original selling price or, at SCHOTT Gemtron’s option,

furnishing the purchaser with another product without charge F.O.B. Madisonville, Kentucky. In

no event shall SCHOTT Gemtron be liable for cost incurred in the removal of failed products, the

installation of replacement products, OR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

INCURRED AS NON-PERSONAL INJURY LOSSES. In the event a product is replaced pursuant

to any applicable SCHOTT Gemtron warranty, the replacement product is warranted only for the

remainder of the warranty period applicable to the original product. SCHOTT Gemtron shall not

be liable for any allegedly defective product unless SCHOTT Gemtron first has the right to inspect

such product and verify the defective condition.

CLAIMS BY BUYER: All claims by Buyer against SCHOTT Gemtron, including claims for alleged

shortages, must be made in writing and delivered to SCHOTT Gemtron within 30 days of receipt

of the goods. SCHOTT Gemtron shall thereupon be afforded a reasonable opportunity to inspect

the goods. All claims not made in the time period and manner specified above shall be deemed

waived. All actions, claims or defenses by Buyer shall be deemed waived unless commenced or

asserted within 6 months of receipt of the goods.

WARRANTY: The following shall be the sole and exclusive warranty for products sold by

SCHOTT Gemtron Food Display with the exception of the SCHOTT Gemtron Food Display

Limited Warranty (Form No. W1010): SCHOTT Gemtron warrants to Customer that all Products

will conform to and perform in accordance with the applicable current specifications issued by

SCHOTT Gemtron. This warranty shall not apply to any Product that shall have been subject to

misuse, abuse, accident, disaster, or which has been used co ntrary to current instructions.

THE FOREGOING WARRANTIES ARE THE SOLE WARRANTIES, EXPRESS OR IMPLIED,

GIVEN BY SCHOTT GEMTRON IN CONNECTION WITH THE PRODUCTS, AND SCHOTT

GEMTRON DISCLAIMS ALL OTHER WARRANTIES, INCLUDING WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NON-INFRINGEMENT

OF THIRD PARTY RIGHTS.

SCHOTT Gemtron assumes no liability for consequential damages, anticipated or lost profits,

incidental damages, loss of time, or other losses incurred by Customer or any third party in

connection with the Products.

SUITABILITY OF PRODUCTS: Purchaser shall be solely responsible for determining the

suitability for use of the products purchased from SCHOTT Gemtron. Representations by

employees or agents of SCHOTT Gemtron (other than the warranties specified herein)

concerning the suitability of SCHOTT Gemtron’s products are not authorized by SCHOTT

Gemtron and may not be relied upon by the purchaser.

PERMISSIBLE VARIATIONS, STANDARDS AND TOLERANCES: Except in the particulars

specified by purchaser and expressly agreed to in writing by SCHOTT Gemtron, all material shall

be produced in accordance with SCHOTT Gemtron’s standard practices. All material, including

that produced to meet an exact specification, shall be subject to tolerances and variations

consistent with usages of the trade and regular factory practices concerning dimensi on, weight,

straightness, section, composition and mechanical properties, normal variations in surface,

internal conditions and quality, and deviations from tolerances and variations consistent with

practical testing and inspection methods.

SCHOTT Gemtron Food Display • 2840 Nebo Road, Madisonville, KY 42431

Toll Free: 800.326.2717 • Phone: 270.821.2864 • Fax: 270.326.3624

FWTC1011

Page 2 of 4

Page 5

6/25/08 - Rev. A Page 5

CHANGES IN ORDER: SCHOTT Gemtron reserves the right to void any quotation for price or

terms in the event the customer to whom such quotation is made changes his order with respect

to any factor reflected in price or other terms originally ordered or quoted.

CHANGES BY SCHOTT GEMTRON: SCHOTT Gemtron reserves the right to change design,

colors and specifications of any goods without notice to Buyer.

DEFAULT: If Buyer defaults on the purchase of any goods or if a petition in bankruptcy is filed by

or against Buyer, SCHOTT Gemtron, in addition to other remedies, may repossess any goods

which were previously delivered and for which payment has not been received and may refuse to

make further shipment of goods. Buyer agrees to pay SCHOTT Gemtron's costs and expenses of

collection or repossession including the maximum attorney's fee permitted by law.

WE ASSUME NO RESPONSIBILITY FOR BREAKAGE IN TRANSIT: Breakage on arrival

should be noted on Bill of Lading and a claim filed PROMPTLY with carrier.

PREVAILING PRICE: Unless specifically indicated otherwise in writing, all orders are deemed to

be at the price prevailing at the date of shipment.

FINAL ACCEPTANCE OF ORDERS: All orders are subject to final acceptance at SCHOTT

Gemtron’s office in Madisonville, Kentucky. Conditional acceptance is evidenced by SCHOTT

Gemtron’s Conditional Acceptance of Order or shipment of the ordered products and final

acceptance is effective according to the provisions herein.

CHANGE OF TERMS: Prices, terms and conditions of sale are subject to change without notice.

PRICE QUOTATIONS: All prices are quoted in U.S. dollars.

PAYMENT OF TAXES: Any federal, state or municipal tax imposed by virtue of the sale

hereunder shall be added to the invoice and paid by the purchaser without discount.

FORCE MAJEURE. Except for the payment of money, neither party shall be held responsible for

any delay or failure in performance of any part of this Agreement to the extent that delay or failure

is caused by causes beyond its control (“Force Majeure Conditions”), including, but not limited to,

fire, flood, explosion, war, strike, embargo, government requirement, civil or military authority, act

of God, act or omission of carriers or other similar causes. If any Force Majeure Condition occurs,

the party delayed or unable to perform (“Delayed Party”) shall give immediate notice to the other

party (“Affected Party”), and the Affected Party, upon giving prompt notice to the Delayed Party,

shall be excused from performance under this Agreement for the duration of the Force Majeure

Condition, provided, however, that the Affected Party shall take all reasonable steps and

cooperate with the Delayed Party to avoid or remove the cause of non-performance and shall

resume performance hereunder with dispatch when the cause is removed; and provided further

that if the Delayed Party cannot within sixty (60) days remove the cause of non-performance, the

Affected Party may terminate this Agreement.

NON-WAIVER:Waiver by SCHOTT Gemtron of a breach of any of the terms and conditions of

this sale shall not be construed as a waiver of any other breach. The mere passage of time shall

not constitute a waiver under the terms and provisions of this sale.

WAREHOUSING: Prices in our price lists are for quantities ordered for production and shipment

at one time. The warehousing charge of 1-1/2% per month will be applied to invoices covering

material which has not been picked up or released for shipment within thirty days after notification

that the order is ready.

SCHOTT Gemtron Food Display • 2840 Nebo Road, Madisonville, KY 42431

Toll Free: 800.326.2717 • Phone: 270.821.2864 • Fax: 270.326.3624

FWTC1011

Page 3 of 4

Page 6

6/25/08 - Rev. A Page 6

CANCELLATIONS: Cancellation of any acknowledged order from SCHOTT Gemtron must be

approved in writing by SCHOTT Gemtron Food Display in Madisonville, Kentucky. SCHOTT

Gemtron shall be entitled to receive, upon demand, liquidated damages of not less than 10

percent (10%) of the purchase price of the order, plus the cost of all materials and work furnished

or done upon time of the cancellation by the purchaser.

SEVERABILITY: If any provision of the terms and conditions specified herein shall be deemed

invalid or unenforceable, the remaining terms and conditions shall be construed as though such

provision does not appear herein and shall be otherwise fully enforceable.

MODIFICATION: No distributor, representative, agent or employee has the authority to alter or

change any product warranty, either orally or in writing.

SCHOTT Gemtron Food Display • 2840 Nebo Road, Madisonville, KY 42431

Toll Free: 800.326.2717 • Phone: 270.821.2864 • Fax: 270.326.3624

Email: info@gemtronfooddisplay.com

FWTC1011

Page 4 of 4

• www.gemtronfooddisplay.com

Page 7

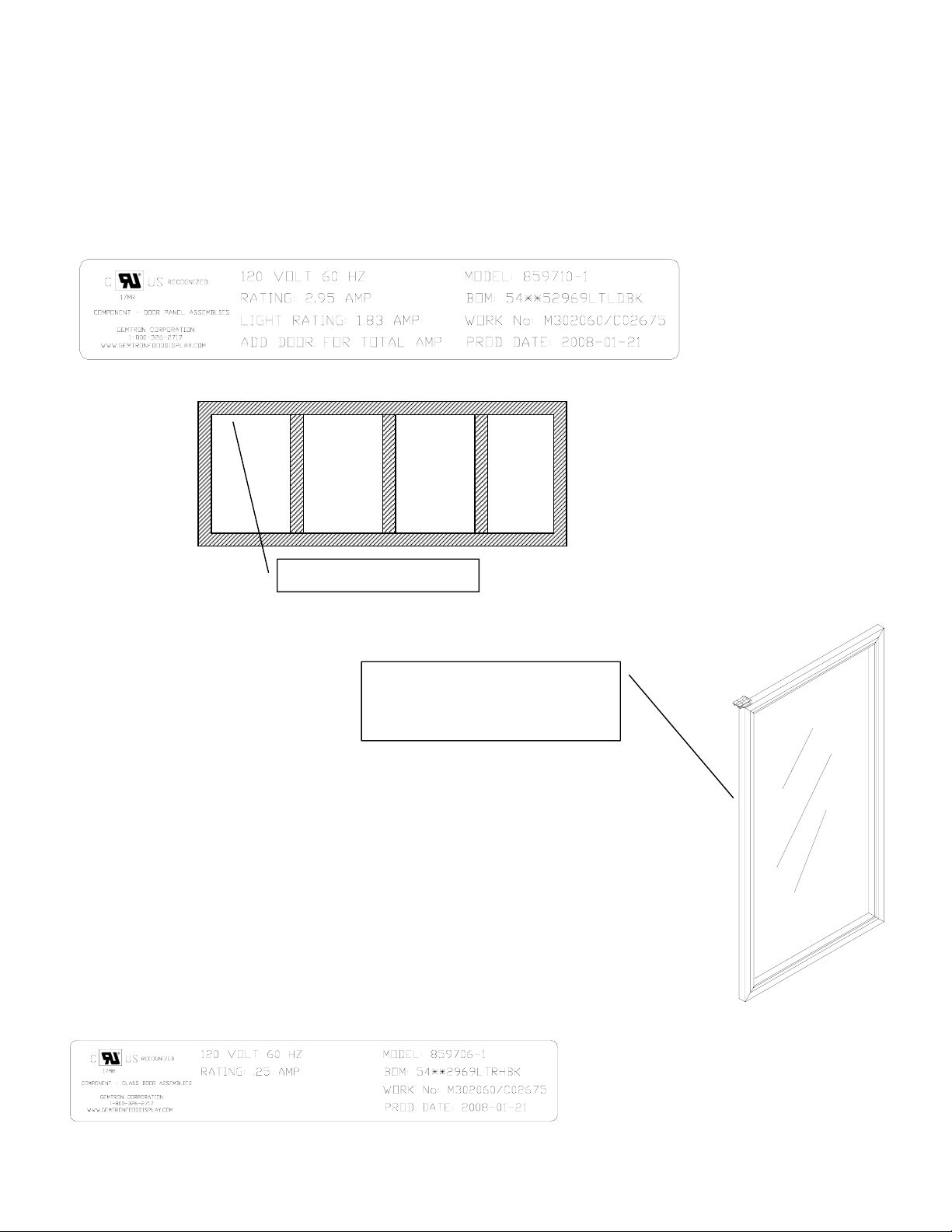

Serial plate

To assist our customer with technical information or ordering spare parts, frames and doors

have a serial plate which informs about Type number, manufacture date, order number and

electric ratings.

Frame Serial Plate

Door Serial Plate

Frame Seri al Plate

Door serial plate is located on

the top or on the hinge side of

door

Page 8

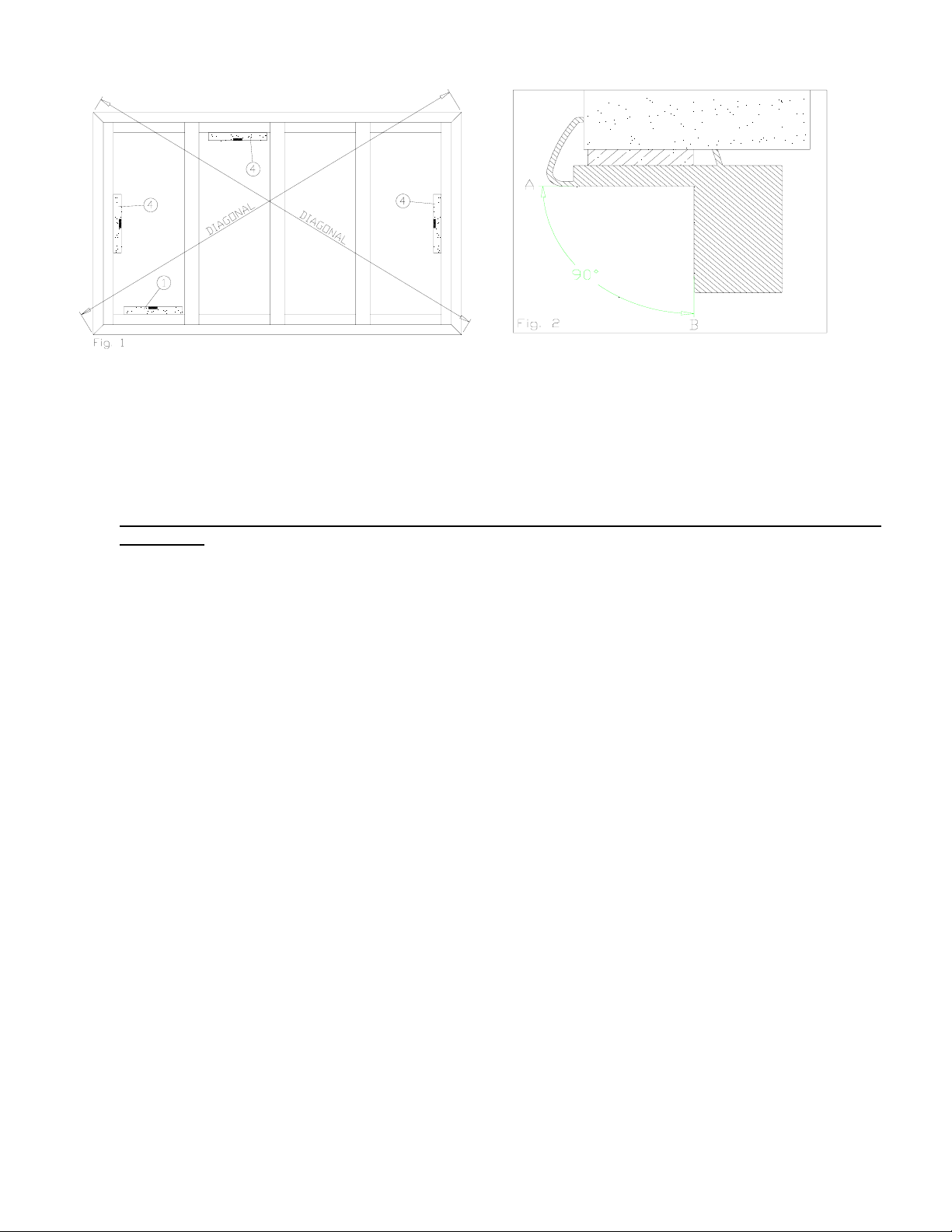

Frame Installation

6/25/08 - Rev. A Page 8

1. Place frame into opening in the panel. Clamp top of frame. Check horizontal alignment with a level (1), then

fasten bottom of frame with mounting screws.

2. Use spacer at the upper horizontal to prevent distortion of frame (Fig 2).

Attention! Make sure that the gap is filled, to keep the profile from bending out. Surface “A” and “B” must be

keep at 90◦.

3. Make sure both diagonals are equally long.

4. Check vertical and horizontal sides with a level (4). Fasten the side profiles and the upper vertical with

mounting screws. Any gaps between the frame and cooler/freezer wall needs to be insulated with sealant to

prevent air leaks.

Page 9

Installing a Door

1. Handling each door carefully, install them into the frame, one at a time by inserting the torque rod-end

into the cavity of the torque adjuster.

2. Tilt the top of the door up and toward the frame, inserting the hinge pin into the Gib, located in the top of

the door frame making sure that the spring clip engages into the upper frame rail.

3. Insert the hold-open bolt through the elongated hold-open slot and into the frame mounting hole. Tighten

with a Phillips-head screwdriver.

4. Adjust the door swing and door squareness by adjusting the torque adjuster. (see Torque and Sag

Adjustment)

NOTE: Do not use power tools to adjust the torque adjuster.

NOTE: Do not over-tighten the hold-open bolt (torque to 45-51 inch pounds). Be certain that the hold-open does

not bind while sliding along the hold-open bolt and adjust as necessary.

1. 2. 3.

Torque and Sag Adjustment

The torque adjuster regulates the door squareness and tension of the door swing.

1. Use the flathead screwdriver, adjust the torque rod tension

by turning the outside screw on the torque adjuster.

• Turn counter-clockwise to increase tension.

• Turn clock-wise to decrease the tension.

2. Adjust the door sag to square it in the frame by turning the screw

that is marked SAG ADJ. (sag adjustment), on the end of the

torque adjuster, until the door slowly closes itself.

• Turn the screw clockwise to lower the handle side of the door.

• Turn the screw counter-clockwise to raise the door’s handle side.

NOTE: Do not use power tools when adjusting the torque adjuster. To check for proper door closing tension, open

the door approximately 1 inch and release the door. The door should self close without any assistance.

Page 10

Removing a Door

6/25/08 - Rev. A Page 10

1. Using a flat-head screwdriver, turn the

adjustment screw on the front of the torque

adjuster clockwise until the door no longer

self-closes.

2. Open the door to access the hold-open

device and remove the mounting bolt from

the frame using a Phillips-head

screwdriver.

3. With the door in a nearly closed position,

insert the top half of the needle-nose pliers

into the grip hole in the hinge pin spring

clip and the bottom half of the pliers

beneath the hinge pin shroud.

4. Squeeze the pliers to pull down the spring

clip, while simultaneously pulling the top

of the door away from the frame and pull

the top of the door out.

5. Lift and remove the door from the torque

adjuster.

NOTE: Exercise caution when handling the door.

Page 11

Reversing the Door Swing

6/25/08 - Rev. A Page 11

1. Using a flat-head screwdriver, loosen the torque adjuster from its mount by turning the center mounting

screw counter-clockwise less than one-half (1/2) of a turn.

2. Remove the torque adjuster, exposing the mounting hole in the bottom frame rail.

3. Locate the mounting hole at the opposite side of the door opening.

4. Using the flat-head screwdriver, carefully pry underneath the plug cap and remove it.

5. Place the torque adjuster on the newly opened mounting hole, aligning the flanged corners of the mounting

tabs.

6. Insert the torque adjuster mounting tabs onto the mounting hole with the hollow end of the torque adjuster

against the door frame.

7. Confirm that the mounting flanges on the bottom of the torque adjuster align with the corner mounting slots

of the mounting hole in the frame.

8. Using a flat-head screwdriver, turn the torque adjuster mounting set-screw clockwise, for 1/2 a turn, to

tighten the mount and lock it in place. Confirm that the torque adjuster mounting is flush with the door

frame.

9. Using a Phillips head screwdriver, loosen and remove the hold-open bolt from the top frame rail.

10. Relocate and install the hold-open shoulder bolts into the opposite hold-open mount of the same door

frame.

11. Open the vertical side access to the hinge pin wire connections in the rail on the hinge side of the door

assembly.

12. Disconnect the Hot, Neutral and Ground wires of the hinge pin from the heater wire circuit and the ground

terminal.

13. Completely remove the hinge pin assembly from the top door rail.

14. Using a plastic mallet and a flat-head screwdriver, remove the torque rod from the bottom of the door

assembly.

15. Swap placement of the Hinge Pin and Torque Rod to the other’s original mounting hole in the door

assembly hinge side rail.

16. Reinstall the hinge pin and the torque rod completely into the ends of the door assembly hinge rail.

17. If necessary, lightly tap on the hinge pin and torque rod with a plastic or rubber mallet until each is fully

seated into the top and bottom of the door.

18. Reconnect the hinge in wires and confirm that all connections are secure.

19. Check and confirm torque rod and hinge pin are correctly and completely installed.

20. Reinstall the door into the frame.

1. 8. 12.

13. 14. 17.

Page 12

6/25/08 - Rev. A Page 12

Door heater replacement

1. Disconnect frame from power source. Remove the

door. Remove the magnetic gasket (A) by starting

on the upper corner and work your way down.

Carefully remove plastic (B) cover with a

screwdriver, starting at the upper corner (Fig. 1). If

plastic cover becomes damaged it has to be

replaced.

2. Refer to Fig. 2 for heater wire location. Remove the

heater from the door rail, and cut the leads at the

hinge pin power connection.

3. Starting at the upper hinge side corner, run the new

heater around the door, pressing the heater into the

aluminum channel the old one was removed from.

4. Connect the new heater to the hinge pin leads as

shown in Fig. 3.

5. Carefully replace the plastic back molding.

Reinstall the gasket (see gasket replacement

instructions). Reinstall the door (see door

installation instructions).

Page 13

Removing and Replacing the Torque Rod

6/25/08 - Rev. A Page 13

1. Carefully place a flathead screwdriver between the door rail and the washer beneath the torque rod. (A)

2. Dislodge the torque rod from the door by pushing on the torque rod or tap it loose using a plastic or rubber

Mallet. (B)

3. Once dislodged pull the torque rod completely out of the door.

4. Reinstall a new torque rod by inserting it into the same hole fully seating it with a plastic or rubber mallet. (C)

A

B C

Page 14

Gasket replacement

6/25/08 - Rev. A Page 14

1. Remove the magnetic gasket (A) by starting on the upper corner and work your way down (Fig. 1).

2. To install a gasket, insert the lip around the inner edge of the gasket into the groove in the plastic on the back of the door

(B), then press the dart on the back of the gasket into the plastic on the back of the door (C) (Fig. 2).

Handle replacement

1. Remove the gasket (A) as much as necessary to access

the cut-outs (B) in the plastic, this will allow access to

the handle mounting screws (C) (Fig. 1).

2. Reinstall gasket (see gasket replacement instructions).

Page 15

Replacing a frame heater

6/25/08 - Rev. A Page 15

1. Disconnect the frame from its power source. Remove the doors, following

the instructions in the “Door removal” section of this book. Refer to

section 7, “Anti-sweat heater wiring diagram” for information on electrical

connection locations and heater part numbers.

2. Remove the plastic profiles covering the defective heater by first removing

the horizontal pieces, then the vertical pieces. Use a screwdriver to

carefully release the profiles (Fig. 2). Caution:

during removal.

3. Cut the defective heater approximately 8 inches from its end, and remove

it from the frame (Fig. 3).

4. Press the new heater into place using your finger. Be careful not to

damage the insulation on the heater. Splice the heaters using line-to-line

connectors (Fig. 4). WARNING! Only an authorized technician should

perform heating cable replacement.

5. To replace the plastic profiles (covers), begin with the vertical covers then

move on to the horizontal ones. To replace the plastic profile s on the

mullions, begin by hooking the plastic cover on the right side of the

mullion (Fig. 5A). Replace the metal cover, ensuring that it fits properly

under the plastic cover (Fig. 5B). Then install the left plastic cover on to

the mullion, using a rubber mallet to get it into position (Fig. 5C). If

getting the cover into position is difficult, try hammering on both sides of

the mullion. Be careful not to damage the plastic.

6. To replace the vertical and horizontal covers, begin by installing the

plastic cover on to the metal cover (Fig. 6A). Install the metal cover on to

the frame (Fig. 6B). Use a rubber mallet to position the plastic cover on to

the frame (Fig. 6C). For the covers to lock to the frame properly, the metal

must be inserted into the plastic correctly (Fig. 7)

7. Reinstall the doors following the “Door installation” instructions, and

reconnect the frame to its power source.

Do not damage the plastic

Fig.2

Fig. 3

Fig. 4

Fig. 5

Fig. 6 Fig. 7

Page 16

Blank – Page 16

Page 17

Replacing Lighting

6/25/08 - Rev. A Page 17

T8 lighting

1. Disconnect the frame from its power source.

2. Press together lamp cover and twist outwards.

3. Twist light tube 90◦ clockwise or counter

clockwise and remove it.

4. Install new light tube and reinstall lamp cover.

Attention! It is important that the lamp cover fits

tightly against the frame. If air leaks in, light tube

efficiency decreases.

Gelcore LED lighting

1. Disconnect the frame from its power source.

2. Use your thumb to press down on one side of

the mounting clip.

3. Twist the LED fixture out of the mounting clip.

4. The new LED fixture will snap into the existing

mounting clip.

Crossfire LED lighting

1. Disconnect the frame from its power source.

2. Remove the mounting screws at the top and

bottom of the LED fixture.

3. The new LED fixture will mount using existing

screws and mounting holes.

Page 18

Replacing a T8 ballast or

6/25/08 - Rev. A Page 18

Gelcore LED power supply

1. Disconnect the frame from its power source.

2. Remove the ballast/power supply cover (A)

located on the side of the mullion. Then

remove the ballast/power supply (B).

3. If quick connect plugs (C) are present, use

them to disconnect the wiring and replace the

ballast/power supply. If the plugs are not

provided, the wires must be cut at a length you

can comfortably connect the new power

supply. (see LED and T8 wiring diagrams for

detailed information on ballast/power supply

wiring)

4. Reinstall the ballast/power supply (B) and

cover (A). Reconnect the frame to its power

source.

Note: The power supply for Crossfire LED lighting is

built into the LED light fixture.

Page 19

6/25/08 - Rev. A Page 19

Note: The power supply for Crossfire LED lighting is built into the LED light fixture.

Page 20

Exploded view – Quik Load Door

6/25/08 - Rev. A Page 20

1. Corner Block

2. Door Rail

3. Heater Wire

4. Insulated Glass Unit

5. Plastic Back Molding

6. Hinge Pin

7. Cable Bushing

8. Torque Rod Assembly

9. Access Cover

10. Handle

11. Hold Open

12. Spacer

13. Screw

14. Backer Plate

15. Shoulder Bolt

16. Gasket

Note: For specific part numbers,

provide serial plate information.

Page 21

Exploded view – T8 frame

6/25/08 - Rev. A Page 21

• 1 Top lamp bracket

• 2 Lamp socket

• 3 Tube guard end cap

• 4 Tube guard

• 5 Lens

• 6 9 pin electrical connector

• 7 Width vinyl

• 8 Width contact plate

• 9 Quik Load torque adjuster

• 10 Ballast cover plate

• 11 Cover Plate Screw

• 12 Mounting hole plug

• 13 Ballast

• 14 Mullion contact plate

• 15 Mullion side vinyl

• 16 Vertical vinyl

• 17 Vertical contact plate

• 18 Light switch

• 19 Receptacle (NTH & LT only)

• 20 Gib

• 21 Hole plug (torque adjuster)

• 22 Lamp

• 23 Bottom lamp bracket

• 24 Lens spring clip

• 25 Lamp bracket mounting screw

Note: For specific part numbers, provide

serial plate information.

Page 22

Exploded view – Gelcore LED frame

6/25/08 - Rev. A Page 22

• 1 End LED light fixture

• 2 Mullion LED light fixture

• 3 End LED light bracket

• 4 Mullion LED light bracket

• 5 Lamp bracket mounting screw

• 6 9 pin electrical connector

• 7 Width vinyl

• 8 Width contact plate

• 9 Quik Load torque adjuster

• 10 Power supply cover plate

• 11 Cover Plate Screw

• 12 Mounting hole plug

• 13 Power supply

• 14 Mullion contact plate

• 15 Mullion side vinyl

• 16 Vertical vinyl

• 17 Vertical contact plate

• 18 Light switch

• 19 Receptacle (NTH & LT only)

• 20 Gib

• 21 Hole plug (torque adjuster)

Note: For specific part numbers, provide

serial plate information.

Page 23

Exploded view – Crossfire LED

6/25/08 - Rev. A Page 23

• 1 Left LED light fixture

• 2 Mullion LED light fixture

• 3 Right LED light bracket

• 4 -

• 5 -

• 6 9 pin electrical connector

• 7 Width vinyl

• 8 Width contact plate

• 9 Quik Load torque adjuster

• 10 -

• 11 -

• 12 Mounting hole plug

• 13 -

• 14 Mullion contact plate

• 15 Mullion side vinyl

• 16 Vertical vinyl

• 17 Vertical contact plate

• 18 Light switch

• 19 Receptacle (NTH & LT only)

• 20 Gib

• 21 Hole plug (torque adjuster)

Note: For specific part numbers, provide

serial plate information.

Page 24

Care & Cleaning:

6/25/08 - Rev. A Page 24

Gemtron Doors and Frames

Cleaning—Inside

The interiors of doors and frames should be cleaned at least once a year. Unplug the doors and

frames before cleaning. If this is not practical, wring excess moisture out of sponge or cloth when

cleaning around switches, lights, and controls.

Use a warm water and baking soda solution—about a tablespoon (15 ml) of baking soda to a quart

(1 L) of water. This both cleans and neutralizes odors. Rinse thoroughly with water and wipe dry.

When cleaning other parts of the doors and frames—including gaskets and all plastic parts—use the

same solution. After cleaning door gaskets, apply a thin layer of petroleum jelly to the door gaskets at

the hinge side. This helps to keep the gaskets from sticking and bending out of shape. Do not use

cleansing powders or other abrasive cleaners.

Cleaning—Outside

The exteriors of doors and frames can be cleaned with a cloth dampened with a solution of mild

liquid dishwashing detergent and water. Dry with a soft cloth.

Use a household wax, such as Pledge brand or Jubilee brand, to coat the handles. Soil will then easily

wash off with dish detergent and water or a non-abrasive all-purpose cleaner. Glass can be cleaned

with off-the-shelf glass cleaner.

Do not use scouring pads, powdered cleansers, bleach, or cleaners containing bleach because these

products can scratch and weaken the finish.

Gemtron ANTI-FOG/ANTI-FROST

COATED GLASS RECOMMENDED CLEANING

Gemtron’s Anti-Fog/Anti-Frost coating can sometimes become contaminated which degrades the Anti-Fog

performance. The result can be splotchy areas of fog or frost. Even certain cleaners can leave a residue that

blocks the Anti-Fog performance. The solution is to clean the undesirable residue off of the coating. The

best products for cleaning the Anti-Fog coating are degreasers. The preferred degreasing cleaner is

“Greased Lightning”.

Recommended cleaning procedures for Gemtron Anti-Fog/Anti-Frost coating:

Don’ts

• Do not use sealants, gaskets, or other materials containing silicone that can contaminate the coating.

• Do not use tape, glue, stickers, attachments, or magic markers on the anti-fog coating.

• Do not use razor blades or any other mechanical device to remove foreign residue or objects directly

• Do not use abrasive cleaners or materials on the coated glass. Examples of these cleaners or materials

• Do not use cleaners or materials on the coated glass that hinder the anti-fog performance by leaving

Do’s

• Recommended cleaners include: Greased Lightning, Formula 409 Grease & Grime, Formula 409 Grease

• Recommended cleaning is with a soft dry or slightly damp towel, or with one of the degreasing cleaners

from the coated glass.

include Ajax, Brillo, Comet, Scotch Brite, Steel Wool, and Soft Scrub.

residue or damaging the surface. Examples of these cleaners include: Armor All, Tilex, Bleach, Windex

No-Drip, Windex Wipes, Pledge, or any product containing silicone oils or waxes.

& Surface, Fantastic, Mr. Clean, Windex Vinegar, Windex Original, Now, or Mean Green (degreasing

cleaners). Isopropyl alcohol and acetone are also good degreasing cleaners. If you have any question

about the use of a particular cleaner, please contact AFG.

listed above.

Gemtron Food D isplay • 2840 Nebo Road, Madisonville, KY 42431 • To ll-Free: 800.32 6.2717 • Phone:

270.821.2864 • Fax: 270.326.3624

E-mail: info@gemtrondoors.com • www.gemtrondoors

.com

Loading...

Loading...