Page 1

SMCP26FL Series

SMCP26PC Series

elf-Contained

Coolers

ZERO ZONE

Zero Zone, Inc. • 110 N. Oakridge Dr. • North Prairie, WI 53153-9792

1-800-247-4496 • FAX: 1-414-392-6450 • www.zero-zone.com

C

CRMA

Certified

S

S

SMCP26 Series

INSTALLATION

and

OPERATING INSTRUCTIONS

for

06995M21000129

Page 2

TABLE OF CONTENTS

SUBJECT

GENERAL INFORMATION…......................................................................... 1

INTRODUCTION.......................................................................................................... 1

INSPECTION................................................................................................................ 1

LOCATION.................................................................................................................. 1

INSTALLATION.............................................................................................. 1

ELECTRICAL................................................................................................................ 1

START-UP.............................................................................................................……. 1

USER INFORMATION................................................................................................ 2

CLEANING………………...……………….................................................................. 2

SHELF LOCATION....................................................................................................... 2

LANE DIVIDERS – (SHELF ACCESSORIES)................................................................. 2

SHELF GLIDES – (SHELF ACCESSORIES)...........…..................................................... 2

PRE CUT SALAD RACK – (SHELF ACCESSORIES)..................................................... 2-3

FLORAL SHELVES – (SHELF ACCESSORIES).........……….......................................... 3

TEMPERATURE CONTROL.......................................................................................... 3

LOADING THE COOLER............................................................................................ 3

LIGHT SWITCH………….............................................................................................. 3

COIL DE-ICING...…….............................................................................................. 3

SERVICE..................................................................................................…..................... 3

EVAPORATOR.................................................................................................................. 3-4

EXPANSION VALVE......................................................................................................... 4

EVAPORATOR FANS….………………...…................................................................ 4

LIGHTS………………................................................................................................... 4

ALTERNATE LIGHTING – T-8....................................................................................... 4

COMPRESSOR ACCESS PANEL (GRILL)................................................................... 4

COMPRESSOR…………………………...................................................................... 4

LIGHT BALLAST……………......................................................................................... 5

SIGNAGE…………………….…..……….................................................................... 5

CIRCUIT PROTECTION…………..……………..…….................................................. 5

PREVENTATIVE MAINTENANCE..........................................................….................. 5

SPECIFICATION SHEET………..........................................................…..................... 6

WIRING DIAGRAMS..………............................................................…..................... 7-8

WARRANTY……….…..………..........................................................…..................... 9

SMCP26

Page 3

GENERAL INFORMATION

Introduction

rays of the sun or near a source of radiant heat.

Locate on a floor with sufficient strength because if the

building floor sags, the cooler doors could bind. The

cooler must be level and plumb for proper operation.

The information contained in this manual pertains to

Zero Zone 2- and 3-door self-contained coolers used

for refrigerated food, pre-cut salads, or floral merchandising. Zero Zone has made every effort to

produce refrigeration equipment of the highest quality

using state of the art components and modern manufacturing techniques. Read these instructions carefully

and completely before attempting to install Zero Zone

equipment. Refer to all National, State, and local

electrical, health and HVACR code requirements

before installation. These display coolers are designed to operate in an air-conditioned environment

where the air temperature is maintained at 75°F or

lower and the relative humidity does not exceed 55%.

Inspection

These display coolers were factory-tested, inspected

and properly packed to ensure delivery in the best

possible condition. The equipment should be checked

for damage before and after unloading. It should be

uncrated immediately after unloading and further

checked for damage.

ALL CLAIMS FOR DAMAGES MUST BE FILED WITH

THE TRANSPORTATION COMPANY – NOT WITH

ZERO ZONE. THE CARRIER WILL SUPPLY NECESSARY

REPORT AND CLAIM FORMS.

Once uncrated, verify that the available electrical

supply corresponds with that specified on the cooler’s

rating plate. The rating plate can be found on the

ceiling of the cooler above the left-hand door.

Location

A minimum of a 4” space between the back of the

cooler and surrounding wall and shelving must be

maintained for proper case airflow.

INSTALLATION

Electrical

The cooler lights, fans, door heaters, and compressor

operate on 115 volt, 1 phase, 60 Hz. Wiring should be

sized according to the amperage rating stamped on

the nameplate, which is located on the ceiling of the

left-hand door. The standard amperage rating is 20

amps for a 2-door and 25 amps for a 3-door.

All internal wiring has been completed at the factory.

Two-door cases have a three-prong 20-amp 115-volt

appliance cord. Three-door units have a three-prong

25-amp 115-volt power connection that is made to the

leads in the back of the ballast box located in the right

side of the compressor compartment. A three prong

20-amp appliance cord is optional on 3-door cases.

The cord connected units should be plugged into a

dedicated 20-amp outlet.

The 3-door units’ fans, lights and anti-condensate

heaters are protected by a 20-amp circuit breaker.

The breaker is mounted in the electric box located in

the front of the case behind the grill. When a cord is

supplied, the unit does not have a 20-amp circuit

breaker.

Note: All wiring installations must comply with the

National Electrical Code and all local codes.

The Zero Zone upright reach-in coolers are ideal for

remodels, end cap displays or wherever space is at a

premium. These coolers must not be installed in a

location where they would be exposed to the direct

Start-Up

For the 2-door cord connected units the on/off switch

must be switched on after the cord is connected. The

on/off switch is mounted on the

SMCP26

Page 4

electric box located in the front of the case behind the

grill. For the 3-door cooler, energizing the electric

circuit will start the case.

USER INFORMATION

Cleaning

The cooler should be thoroughly cleaned before startup and routinely thereafter to maintain a sanitary

appearance. Use mild detergent and warm water

(never an abrasive cleaner) to wipe out the inside of

the cooler. Wash down all glass doors with a quality

glass cleaner. The cooler will remain bright and

sparkling with just a few minutes of cleaning each

week.

Note: Do not use high-pressure water or steam to

clean the interior.

Shelf Glides – (Shelf Accessories)

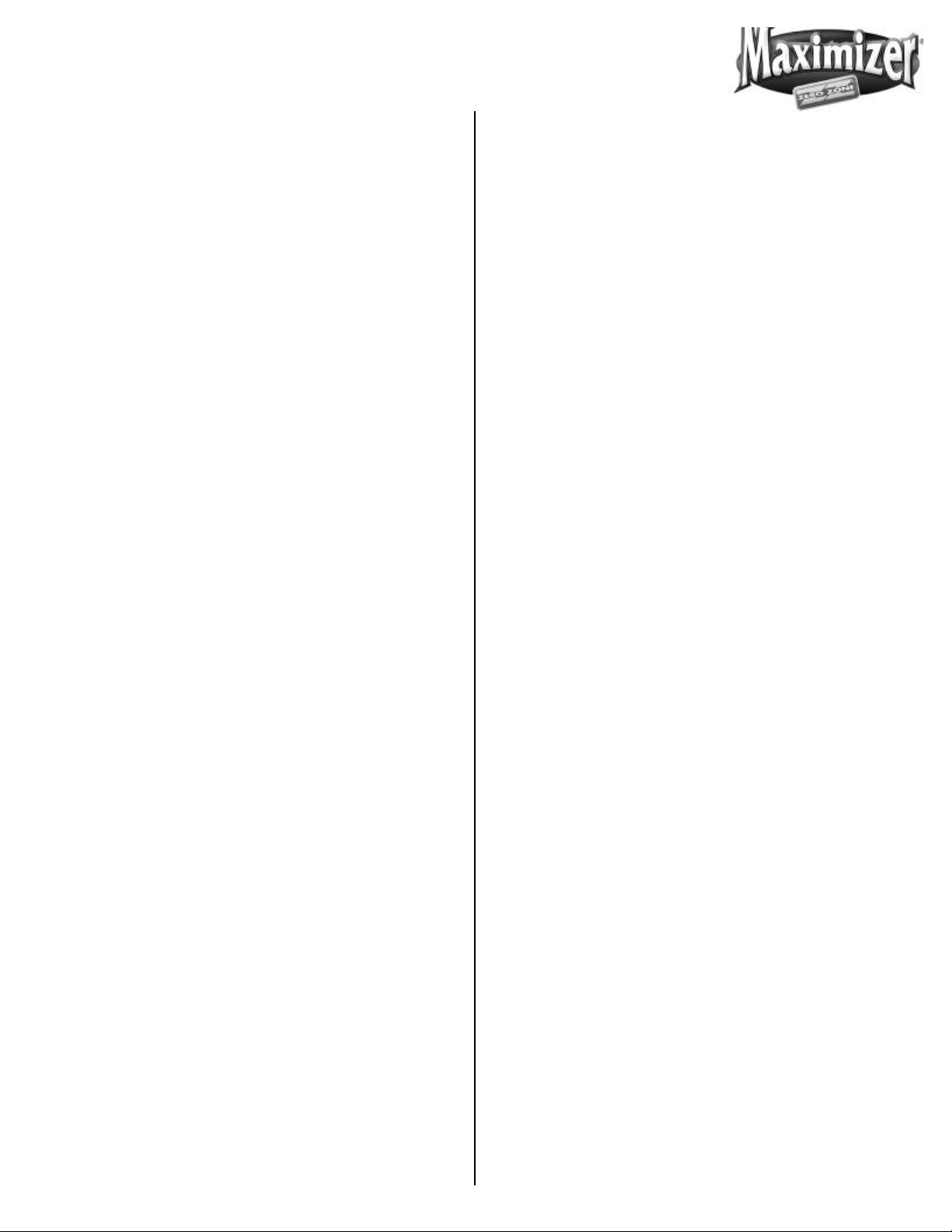

Figure 1. Lane Divider

Shelf glides are available for use with lane dividers.

This helps the product gravity feed to the front of the

case.

Shelf Location (See Specifications)

The shelves are adjustable in ½ inch increments and

may be located in any position for best display. Due to

the air discharge arrangement, it is suggested that the

uppermost shelf be placed 10 to 11 inches down from

the ceiling and the remaining shelves approximately

10-1/2 inches apart at the front of the cooler.

BE SURE SHELF CLIPS OR BRACKETS ARE COMPLETELY SEATED BEFORE INSTALLING THE SHELF.

Lane Dividers – (Shelf Accessories)

Lane Dividers with 2-7/8 inch or 3-1/4 inch wide lanes

are available for use on the shelves. The rear of the

lane divider has the shelf hooks inset from the end.

The rear of the shelf should be set lower than the front

so that the shelf slants downward at the rear. The

lane divider is installed by hooking the rear hooks

under the large shelf wire. Flex the lane divider and

hook the wire under the large front shelf wire (See

Figure 1).

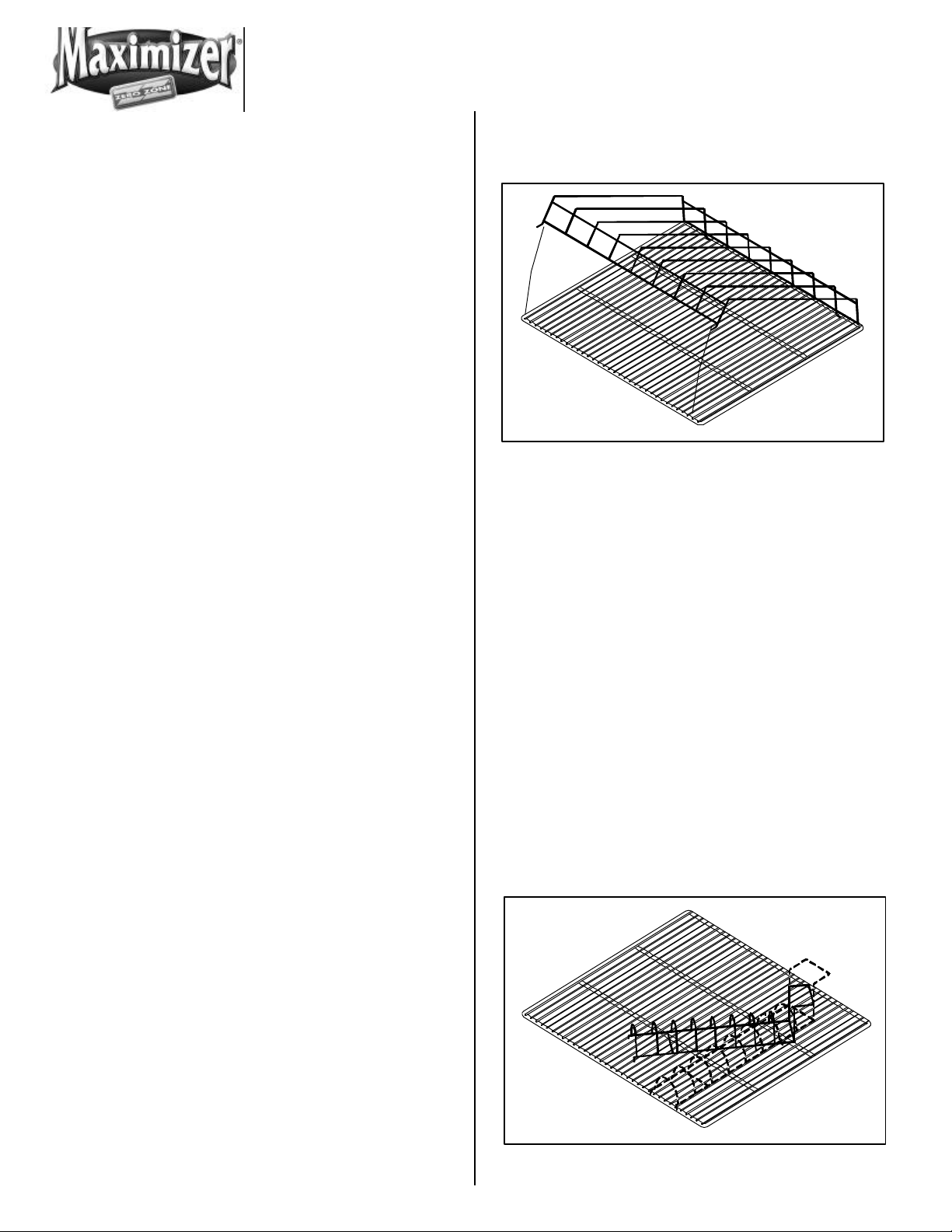

Pre Cut Salad Rack – (Shelf Accessories)

The rear of the rack has two feet that slip under the

shelf wires. The rear of the rack also has a raised wire

stop. The stop is used to provide an air gap between

the product and rear wall.

The rack is installed as follows:

• Set the rack on top of the shelf

• Rotate the rack 45 degrees to the side

• Slide both rear feet under the shelf wires

Figure 2. Salad Rack

SMCP26

Page 5

• Rotate the salad rack back to the original position

while keeping the rear feet under the wires

• Gently squeeze the front of the rack and slide the

two feet between the shelf wires (See Figure 2)

remove the product from the cooler easily. Leave a

1½-inch air gap at the rear of the case. This allows

cool air to travel down the back of the product and

return to the evaporator at the front of the case.

Floral Shelves – (Shelf Accessories)

Glass cantilever floral shelves are available. The

shelves rest on special extra wide shelf brackets.

Cantilever floral bucket shelves are also available. The

bucket shelf bracket is adjustable to allow for shelf

tilting. Before attempting to adjust the shelf bracket,

follow these steps:

• Remove the shelf

• Remove the set screw from the side of the bracket

• Rotate the bracket to the new position

• Install the set screw

• Cantilever shelf standards are factory installed and

must be ordered with a new case

Temperature Control

The cooler temperature is controlled by a low-pressure

control, located in the compressor compartment. The

control is factory-set to maintain a cooler air temperature of 36°F to 41°F. An adjustment knob on top of the

low-pressure control permits fine-tuning of the cooler

temperature.

Products should be placed on the shelves in an orderly

fashion. Whenever possible, leave some room between rows of packages so that chilled air can filter

over and around products.

For proper display, the products should be placed on

edge and slanted to the back so the customer can see

the faces of the packages. Rotate inventory on a

regular basis.

Light Switch

The light switch is located inside the cooler in the

upper right corner of the frame or on the mullion of the

right door. Always turn the lights off when replacing

bulbs.

Coil De-Icing

Periodic de-icing to keep the coil free of excessive frost

for top efficiency is accomplished automatically during

the unit off cycle.

! CAUTION !

To raise the case temperature, turn the adjusting knob

to a higher number. To lower the case temperature,

turn the knob to a lower number. The factory-set

position is at “5”. Maximum cold is “1”.

When properly adjusted the unit should not run continuously. Off cycle time allows the coil to de-ice

automatically. If a coil freeze-up occurs, unsatisfactory

cooler temperatures will result.

Loading The Cooler

The cooler may be loaded with merchandise after the

desired case temperature has been achieved. When

loading the shelves, leave at least 1-1/2 inches between the top of the merchandise and the shelf immediately above it. This allows customers to

ADJUSTING THE CASE TEMPERATURE TO AN EXTREMELY LOW SETTING WILL CAUSE THE UNIT TO

RUN CONTINUOUSLY. IF THIS OCCURS, THE OFFCYCLE DEFROST STAGE WILL NOT OCCUR, RESULTING IN UNSATISFACTORY COOLER OPERATION AND

COIL ICING.

SERVICE

! CAUTION !

DISCONNECT POWER TO THE CASE BEFORE

SERVICING ELECTRICAL COMPONENTS.

SMCP26

Page 6

Evaporator

Lights

The evaporator coil, located at the rear ceiling of the

cooler, is factory assembled with an expansion valve.

To inspect the coil, the coil cover can be removed as

follows. Loosen screws on the underside of the coil

cover until forward edge drops down exposing the

evaporator coil and fan assemblies. While supporting

the cover, unplug the fan electrical connection from

main coil housing. The coil cover can then be removed from the case.

Expansion Valve

A thermostatic expansion valve with adjustable superheat and thermal bulb is mounted to the evaporator

coil. Under certain conditions, it may be necessary to

adjust the super-heat setting for maximum coil effectiveness. To adjust the expansion valve, remove the

coil cover as described for evaporator inspection.

Remove the cap from the bottom of the valve. When

looking up the valve stem, turn the valve stem counterclockwise to open the valve. Turn the valve stem

clockwise to close the valve. Measure the suction line

temperature at the expansion valve-sensing bulb and

compare it to the suction temperature corresponding

to the saturated pressure.

800 milliamp T-12 lamps are standard with these

coolers. There are three lamps in the 2-door coolers

and four lamps in the 3-door coolers. The full height

lamps provide even illumination of the entire case

contents for a better presentation. To ensure maximum component life, always replace with 800

milliamp lamps. Use retainer clips and lamp shields.

To change a lamp, turn off the light switch and remove

the retainer clip located between the socket and end

cap. Carefully push the lamp upward into the springloaded lamp socket to allow the lamp to be removed

Turn the valve stem only ¼ turn at a time and allow

sufficient time for the valve to settle before making any

further adjustments. Replace the valve stem cap after

the valve super-heat has been adjusted.

Evaporator Fans

Air is circulated throughout the cooler with shaft down,

115-volt medium temperature fan motors. These

motors must be operating at all times. The fans are

mounted on the evaporator coil cover. To service the

fans, they are accessed by removal of the coil cover as

described under SERVICE/EVAPORATOR.

Figure 3. Changing A Light Bulb

from the bottom socket. (See Figure 3.) Remove the

end caps and lamp shield for use on the new lamp.

Alternate Lighting – T8

These systems use a lens to direct lamp light output

evenly across the shelves. The bulb used is an Osram

FO32W/41K (4ft). The lens must be removed to access

the lamp. With the lens removed, reach into the fixture

and remove the mylar warning cover. Remove the

lamp socket assembly by carefully pulling away from

the top and bottom retaining

SMCP26

Page 7

clips. Move the foam center seals away from the

electrical connectors. Disconnect the electrical connectors on the top and bottom sockets by depressing

the locking tab and pulling away from the socket.

Detailed information is contained in the door instruction booklet.

check to make sure the circuit breaker is switched to

the “on” position. A red bar below the word “off”

indicates the circuit breaker has tripped. To reset the

breaker, switch it off and then on. If the circuit breaker

continues to trip, contact a technician to repair the

case.

Note: The ballast for this system is located in the door

mullion.

Compressor Access Panel (Grill)

Remove the compressor access panel located at the

front bottom of the cooler by removing the screws at

the bottom ends of the panel. Drop the panel down

and pull out. The panel must be removed before any

service work can be done to the compressor, light

ballasts and pressure control.

Compressor

A 115 volt, 1 phase, 60 Hz, compressor is mounted

below the cooler. The condensing unit is equipped

with liquid line and suction service valves for refrigeration technician service.

Light Ballast

PREVENTIVE MAINTENANCE

1. Clean condenser fins at least once every 6 months

in order to achieve maximum cooling efficiency.

More often if cooler is in a particularly dirty or dusty

location or near an entrance or check out.

2. Keep floor drain pan and condensate drain tube

clear of debris.

The 2-door cooler has one (1) three-lamp ballast.

The 3-door cooler has two (2) two-lamp ballasts. They

are located in the galvanized electric box located at

the right side of the compressor compartment at the

back.

To remove the electric box cover, remove the sheet

metal screws from the bottom of the ballast box and

slide the cover upwards to disengage the top flange.

The cover can then be removed for ballast inspection

or replacement.

Circuit Protection

The 3-door unit is equipped with one 20-amp circuit

breaker. The circuit breaker is located in the front of

the electric box. The circuit breaker protects the fan,

door and light circuits. If these circuits fail to work,

SMCP26

Page 8

SMCP26 SPECIFICATION SHEET

(INCHES)

(INCHES)

FEET

AMPS

RLA

Front Elevation

Front Elevation

2SMCP26

3SMCP26

Top View

Shown in Section

Side View

2SMCP26

Top View

Shown in Section

3SMCP26

OUTSIDE DIMENSIONS

MODEL WEIGHT

(w/shelves) W H D W H D CAPACITY AREA SQ. FT.

2SMCP26 640 60 78 5/8 33 1/4 55 59 7/8 29 1/2 43.6 43.5

3SMCP26 856 87 78 5/8 33 1/4 82 59 7/8 29 1/2 61.4 65.3

ELECTRICAL (OPTIONAL)

MODEL INCOMING SUPPLY

2SMCP26 115-1 PHASE-60 HZ. 20 14.02 1/2 R22 2 1/2

3SMCP26 115-1 PHASE-60 HZ. 25 17.6 1/2 R22 2 1/2

INSIDE DIMENSIONS

MIN

CIRCUIT

AMPS

NET CUBIC

NET SHELF

CHARGE

H.P. REF.

Zero Zone Inc. l 110 N. Oakridge Dr.

North Prairie, WI 53153-9792

1-800-247-4496 l FAX: 1-262-392-6450

www.zero-zone.com

All specifications are subject to change without notice.

(LBS.)

SMCP26

Page 9

SMCP26

Page 10

SMCP26

Page 11

1. Limited Warranty. ZERO ZONE, INC. (“Seller”) hereby warrants that any products manufactured by it and sold under this Warranty shall be free for a period of one year from the date

of shipment, from defects in material and workmanship which, under normal use and

service would render such products unusable or unserviceable. The obligation of Seller

under this Warranty shall be limited to the repair or replacement of any parts that the Seller

determines are defective. This Limited Warranty does not cover labor, freight, transportation

or other charges incidental to replacement or repair. Parts returned to Seller must be returned freight prepaid and replacements will be returned to the Buyer freight collect.

2. Motor Compressor Extended Warranty. Seller hereby warrants with respect to any motor

compressor sold under this Warranty, exclusive of any and all parts of the condensing unit

assembly thereof, that such motor compressor shall be free from defects in material and

workmanship for a period of four (4) years from the date of the expiration of the one year

Warranty provided by the manufacturer of such motor compressor, if the Buyer purchases

said Warranty at the time of equipment purchase. In the event the motor compressor is

not free from defects in material and/or workmanship during such four year period, Buyer

must purchase a replacement for the defective motor compressor and obtain whatever

salvage credit may be available from the manufacturer thereof. Upon receipt by Seller or

written notice from Buyer of compressor, Seller will issue a purchase or a refund, at Seller’s

option, for an amount of the salvage credit. All labor and shipping charges incurred in

connection with such replacement shall be the sole obligation of the Buyer.

3. Product Not Manufactured by Seller. The written Warranty, if any, provided by the manufacturer of any part of the refrigeration unit sold by Seller to Buyer, but not manufactured by

Seller, is hereby assigned to Buyer. However, Seller makes no representation or Warranty

regarding the existence, validity or enforceability of any such written Warranty.

4. LIMITATION AND EXCLUSION OF WARRANTIES. THE WARRANTIES SET FORTH HEREIN ARE

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES WHATSOEVER, INCLUDING BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR

A PARTICULAR PURPOSE.

5. Consequential Damages. Notwithstanding anything to the contrary set forth in this Warranty Certificate, Seller shall not be liable for any incidental or consequential damages

arising out of, or directly or indirectly caused by a defective part sold by Seller, including but

not limited to, costs arising from the replacement of the part, loss of gas or product, or any

damage to person or property, whether as a result of Seller’s negligence, breach of contract, breach of Warranty or otherwise.

Model No._________________________ Serial No.______________________

SMCP26

Loading...

Loading...