Page 1

U

D

y

F

INSTALLATION

AND OPERATING INSTR

CTIONS

ispla

reezers

Zero Zone, Inc. 110 N. Oakridge Dr. North Prairie, WI 53153-9792

1-800-247-4496 FAX: 1-262-392-6450 www.zero-zone.com

Page 2

TABLE OF CONTENTS

SUBJECT

GENERAL INFORMATION 2

INTRODUCTION 2

INSPECTION 2

LOCATION 2

INSTALLATION 2-6

LEVELING 2-3

JOINING FREEZERS 4

DRAIN LINE 5-6

CART BUMPER 6

REFRIGERATION 7-8

GENERAL 7

REFRIGERANT PIPING 7

TEMPERATURE CONTROL 8

TEMPERATURE CONTROL ADJUSTMENT 8

LEAK CHECK-EVACUATION-CHARGING 8

ELECTRICAL 8-9

DEFROSTING 9-11

GENERAL 9

ELECTRIC DEFROST 9

GAS DEFROST 10

LIMIT THERMOSTAT 10-11

USER INFORMATION 11-12

CLEANING 11

SHELF LOCATION 11

LOADING THE FREEZER 11

LIGHT SWITCH 12

LIGHTING 12

SERVICE 12-13

CART BUMPER 12

EVAPORATOR 12

EXPANSION VALVE 12

DEFROST HEATER ELEMENT 13

RMZC30XL HEATER ELEMENT REMOVAL 13

EVAPORATOR FANS 13

RMZC30XL FAN REMOVAL 13

ELECTRICAL SCHEMATICS 14

- 1 -

REVISION A

10/30/02

Page 3

GENERAL INFORMATION

Introduction

The information contained in this manual pertains to

the following Maximizer display freezer: RMZC30XL.

This case is used for merchandising frozen food or ice

cream. The RMZC30XL has 30-inch wide doors and

utilizes the revolutionary new S-coil. Zero Zone, Inc.

of level conditions will result in reduced performance,

and will make the installation more difficult.

When located next to a wall, or backed up to another

case line-up, the cases should be positioned to allow

a minimum (4) inch space behind the back of a unit.

This will allow necessary air to circulate behind the

unit.

has made every effort to produce refrigeration

equipment of the highest quality using state-of-the-art

components.

This display freezer was designed to operate in an air-

conditioned store where the temperature is

maintained at 75°F or lower and the relative humidity

is 55% or lower.

Inspection

This display freezer was carefully factory tested,

inspected and properly packaged to ensure delivery in

the best possible condition. The equipment should be

uncrated and checked for damage immediately upon

delivery.

ALL CLAIMS REGARDING SHIPPING DAMAGES MUST

BE FILED WITH THE CARRIER/TRANSPORT COMPANY.

DO NOT FILE CLAIMS WITH ZERO ZONE, INC.

(The carrier/transport company will supply the

necessary report and claim forms.

Location

This freezer must not be installed where it will be

exposed to direct sunlight or near a source of radiant

heat.

INSTALLATION

DISCLAIMER,

Installation of the case; including proper footings &

stable support, leveling, drain plumbing,

refrigeration and electrical tie-ins, application of

local building codes, etc. are in whole the

responsibility of the store and the contractor/s

performing these jobs. Zero Zone, Inc. will not

accept responsibility for improper installations.

Leveling

Refrigeration equipment must be installed level and

plumb to allow efficient operation of the refrigeration

coils and complete drainage of defrost condensate

(water). Since a level area is seldom available, the

following steps are recommended to insure a level

installation.

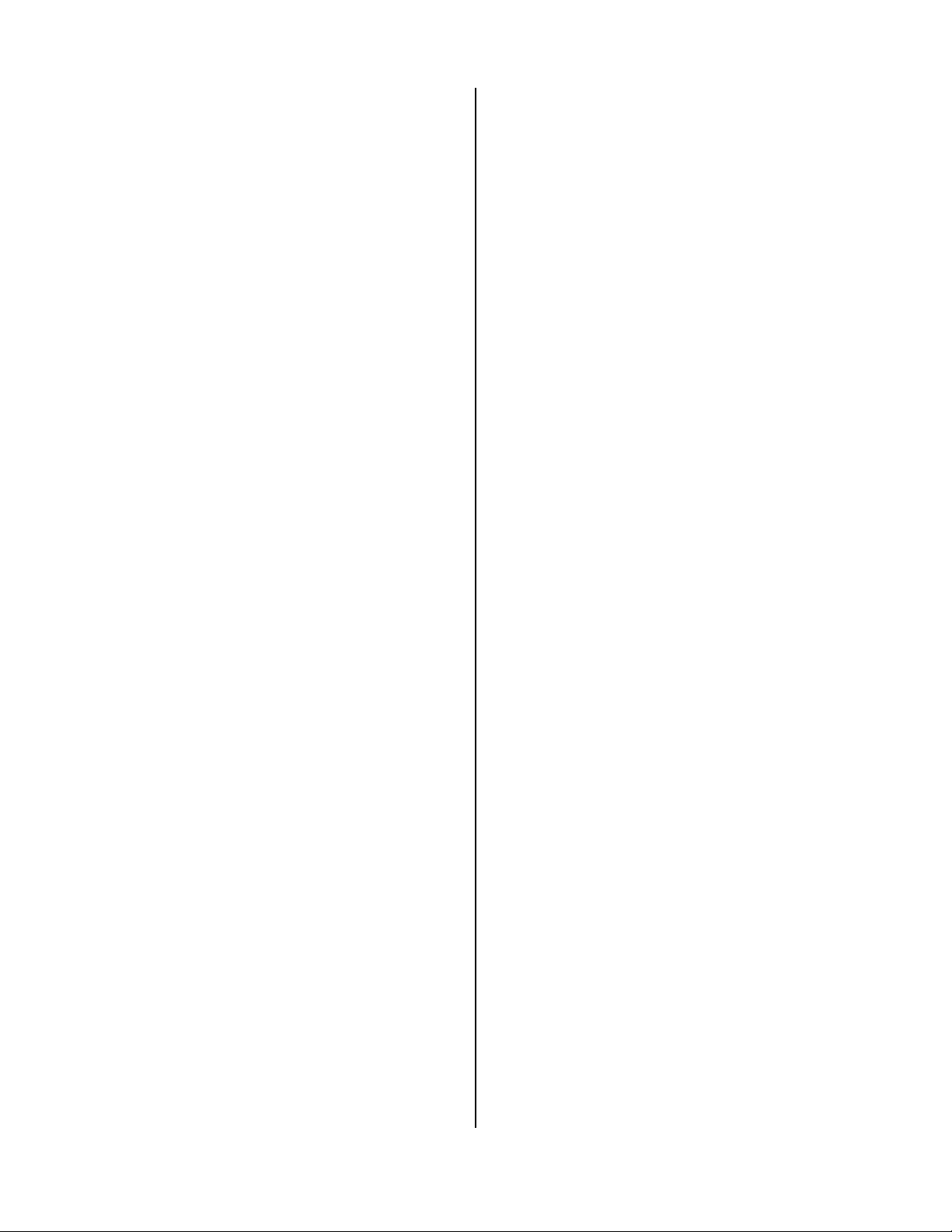

1. Carefully, measure off and mark on floor with the

dimensions of the case line-up. (Check blueprints

– See Figure 1A)

2. Snap a chalk line at the locations for the front and

back positions of the base rails.

Be certain that the floor under the installation is of

sufficient strength to support a fully loaded case. Out

- 2 -

REVISION A

10/30/02

Page 4

7. Place the required number of shims (supplied) at

each joint (front and back) to equal the highest

FIGURE 1A

MARKING AND LAYOUT

3. Mark locations of all joints (front and back).

4. Using a transit or laser, find the highest point

along both base rail position lines. Using the high

point as a reference, mark the difference directly

on the floor to each joint (front and back).

5.

If a transit or laser is not available, a water level

can be used to mark reference elevation points.

Water levels can be purchased from a contractor

supply house or hardware store for a minimal

cost.

6. A string level can also be used to mark elevation

points. The string level should only be used on

short line-ups to avoid problems with string sag.

point. Tape all shims in

place (See Figure 1B).

3/8"

FIGURE 1B

LEVELING AND SHIMMING

8. Be sure to place shims under all the bases where

required. Do not leave a base unsupported.

9. Using a spirit (bubble) or laser level check the

installation as you go. The case

from front to back and side to side. Install

case

at the highest point first, if part of a line-up.

should be level

the

- 3 -

REVISION A

10/30/02

Page 5

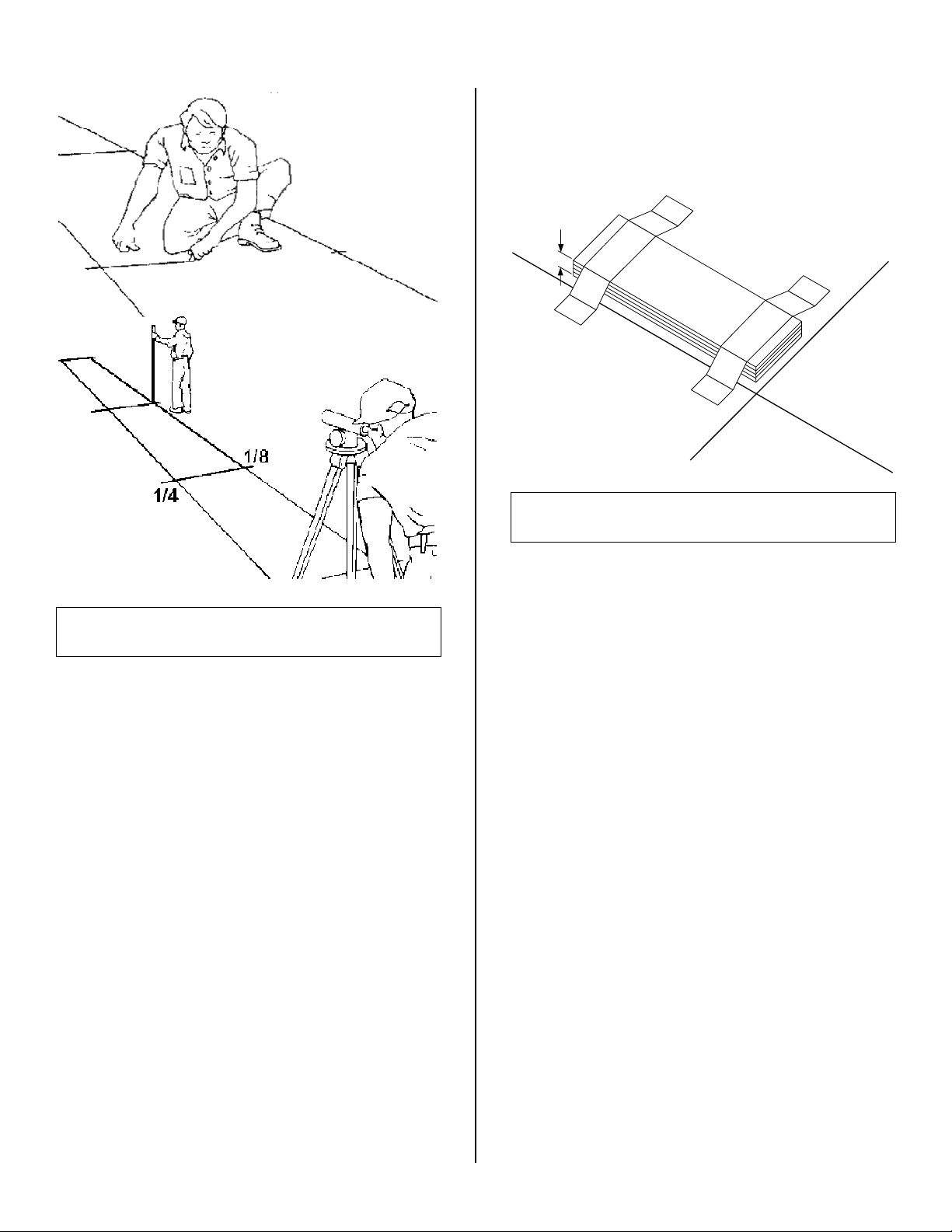

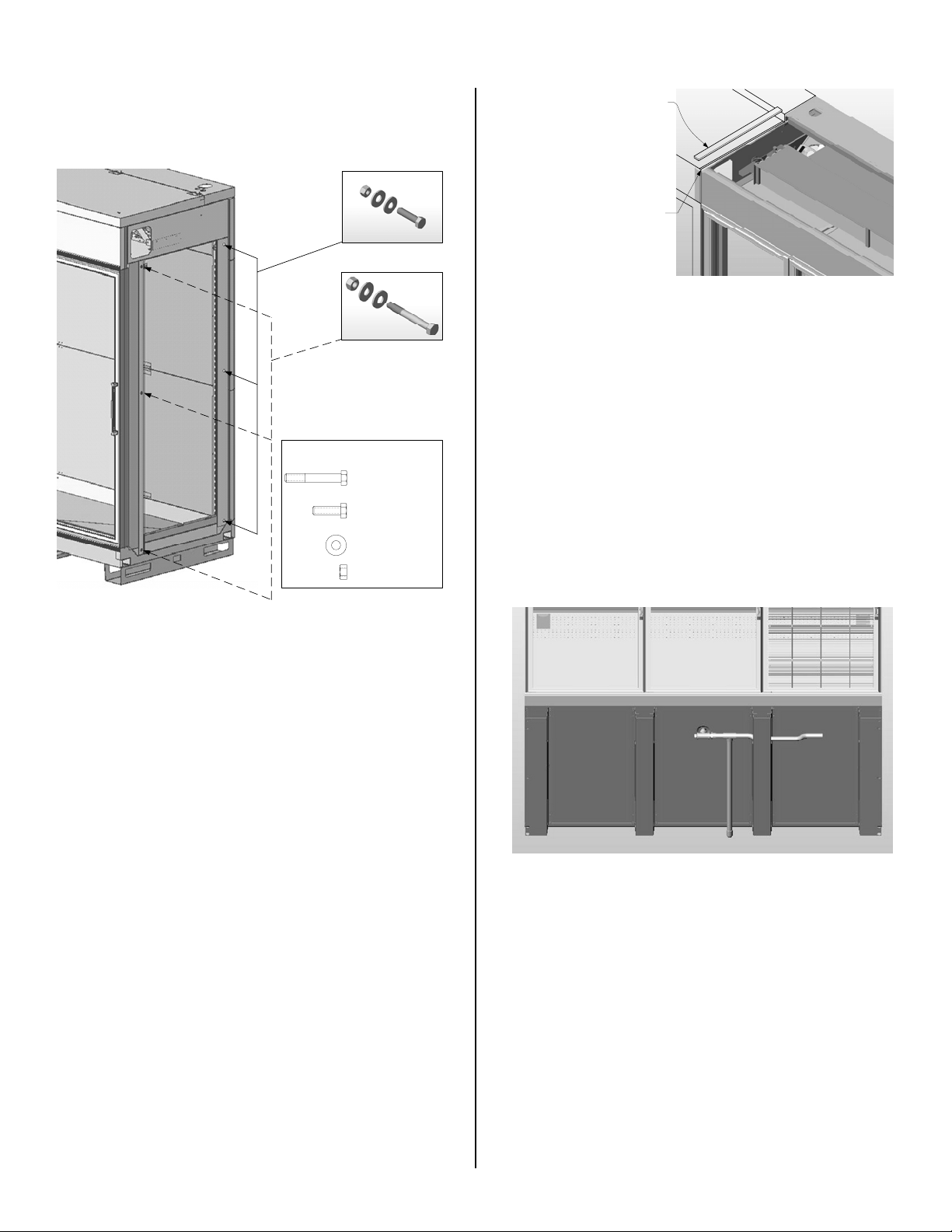

Joining Freezers

This reach-In freezer has been engineered for

continuous line-up. This means that any number of

cases can be joined together to create the desired

length. Reach-In freezers are built on permanent steel

skids to promote easy installation. The cases can be

moved by using case jacks, with a fork truck

(Telehandler) or with Johnson Bars.

To install Reach-Ins, perform the following steps:

1. Set the first Reach-In into the desired position and

level it. Run two (2) 3/8 inch diameter beads of

Butyl caulk 1/2 inch in from both the inner and

outer surfaces of the case end. (See Figure 2A)

2. Push the second Reach-In against the end of the

first. Level the second Reach-In. Remove the left

and right end floor covers and the rectangular

pocket hole covers, accessing the holes in the end

panels of each freezer as shown (Figure 2A).

Install tee strips between the doorframes at case

joints (See Figure 2B) Use the special screws and

nuts provided.

APPLY TWO (2)

CONTINUOUS 3/8"

DIAMETER BEADS

OF BUTYL CAULK

ALONG THE

PERIMETER OF BOTH

MATING ENDS

(AS SHOWN)

THOUGH SHOWN IN

BLACK, THE COLOR OF

THE BUTYL CAULK

MAY BE WHITE OR

CREAM DEPENDING

UPON THE COLOR OF

THE CASES TO BE

ALSO APPLY A SHORT

BEAD OF CAULK TO

EACH JOINT WHERE

THE INSULATED

PANELS MEET AT A

SEAM. THREE (3)

POCKET COVERS,

THREE (3) PER END

JOINED

PLACES

FIGURE 2B

INSTALLING TEE STRIPS

3. Start the joining bolts, but do not tighten them.

Begin tightening the bolts at the top rear, working

down the back of the case and up the front

FIGURE 2A

CAULKING THE CASES

making sure that the front faces of the cases are

flush (See Figure 2C). Pay attention to the

alignment of the doorframes.

- 4 -

REVISION A

10/30/02

Page 6

1-1/2" LONG HEX HD CAP

SCREWS AT REAR

ROOF GASKET MATERIAL (WHITE OR BLACK)

PEEL THE DOUBLE STRIP OFF THE BACK OF

THE GASKET AND APPLY IT SUCH THAT AN

EQUAL AMOUNT OF GASKET IS LOCATED

ON BOTH CASES. START THE GASKET AT

THE JOINT WHER E THE ROOF PANEL MEETS

THE HINGE PANEL AND RUN IT FORWARD

TO THE FRONT OF THE CASE.

1-1/2" WIDE x 3/16" THICK

APPLY THE GASKET SUCH THAT IT

COVERS THE SEAM COMPLETELY

BETWEEN THE TWO CASES

(DO NOT RUN THE GASKET DOWN THE

FRONT PANEL)

FIGURE 2D

3" LONG HEX HD CAP SCREWS

AT FRONT

INSTALLING ROOF GASKET

Drain Line

FASTENERS REQ'D TO JOIN A

ZERO ZONE® RMZCXL CASE

(3) 3/8"UNC x 3" LONG

HEX HD CAP SCREW.

PART No. 64-0025

(3) 3/8"UNC x 1-1/2" LONG

HEX HD CAP SCREW.

PART No. 64-0080

(12) 3/8" FLAT WASHERS

PART No. 64-0034

(6) 3/8"UNC HEX NUTS

PART No. 64-0064

The drain is located at the center of the freezer in the

floor pan. The drain can be reached by removing the

center floor covers. The 1 inch PVC drain outlet is

located at the center front of the freezer behind the

kick plate. Figure 3A shows this location (the case is

tilted backward to clearly illustrate).

FIGURE 2C

INSTALLING JOINING BOLTS

4. Each case joint at the top requires a 1-1/2 inch

wide roof gasket to merge the seam between the

two (2) cases. Installation of this gasket is very

important. Place the gasket back to where the

hinge panel begins and run it all the way forward

to the edge of the front panel. Cut it flush with the

front panel. (See Figure 2D)

FIGURE 3A

DRAIN LOCATION

Install a tee to the outlet pipe. Next, connect the line

that returns to the rear of the case to connect the

defrost drain line. Then connect PVC drain trap to the

tee. The drain line must be pitched a minimum of (1)

inch per lineal foot. Connect the flexible defrost drain

- 5 -

line to the barbed end of the lower drain assembly.

Using the hose clamp, secure the flexible tubing to the

barbed fitting. The tee, drain trap, and plug are

REVISION A

10/30/02

Page 7

supplied standard with the case. The drain assembly

is supplied such that it can be routed to either the right

or left of the case. Dry fit all your drain parts first to

ensure they are located properly. (See Figure 3B)

DO NOT FORGET TO GLUE THE SLIP FIT PVC PARTS

TOGETHER USING PVC CEMENT.

MAKE SURE ALL PVC SLIP

FIT JOINTS ARE GLUED,

USING PVC CEMENT

THIS PORTION OF THE

DRAIN IS FIXED WITHIN

THE FLOOR OF THE CASE

THIS GROUP OF DRAIN

PARTS CAN BE FLIPPED

TO THE OPPOSITE SIDE TO

FACILITATE A LEFT-HAND

DRAIN IF NECESSARY

FIGURE 3B

DRAIN ASSEMBLY

Cart Bumper

The cart bumper should be installed at the bottom

front of the case. (See Figure 4A) The assembly is

BUMPER

SPLICE

CART BUMPER

& BUMPER

SUPPORT RAIL

KICK RAIL

FIGURE 4A

BUMPER JOINING STRIP

USING THE HOLE

PROVIDED, RIVET

THE SPLICE TO THE

TOP EDGE OF THE

FRONT PANEL USE

THIS TO COVER THE

UPPER SEAM

BETWEEN THE TWO

(2 ) CASES.

adjustable to compensate for uneven floors.

Center and hook the bumper assembly on the

hangers provided.

In continuous line-ups, place a kick plate joint strip at

each joint. On case ends, lineup an end kick plate

with the front mounting holes. Fasten the rear of the

end kick plate to the case using TEK screws.

A bumper and top splice joint strip can be installed

over the bumper and the seam between the cases.

(See Figures 4 A and 4B for details)

UPPER SPLICE

APPLY (3) DABS OF

CAULK/ADHESIVE

TO THE FACE (NEAR

THE EDGE) OF THE

UPPER PANEL

FIGURE 4B

UPPER JOINING STRIP

- 6 -

REVISION A

10/30/02

Page 8

REFRIGERATION

General

Unless otherwise specified, the liquid and suction line

connections are made on the outside of the case at

the top/rear of the case. If the case is an electric

defrost, the connections will be on the left end of the

case. If the case is hot gas defrost, the connections

will be on the right end of the case.

Alternate locations are available depending on how

the case was ordered from the factory. After all the

connections have been made, all refrigeration egress

holes (through the case) must be sealed completely.

The holes should be filled using expanding urethane

foam (i.e. Great Stuff®); and then covered with a layer

of Perma-gum Strip Caulk to prevent moisture

infiltration.

Refrigerant Piping

Correct refrigeration line sizing and installation is

essential for proper system operation. The following

tables (Table 1) list R502, R404A, R507, and R-22 line

sizes for different combinations of frozen food and ice

cream freezers. This information is also available by

contacting Zero Zone, Inc. A P-trap must be installed

at the bottom of all vertical suction risers.

When two or more freezer sections are connected to

The compressor should be installed as close as

possible to the freezers to reduce pressure drop. If the

compressor is located above the freezer, check the

refrigerant line size tables (Table 1) of this manual to

determine the riser line size. Or contact Zero Zone,

Inc. directly for correct sizing information. Install a trap

at the bottom of the riser. Use a flexible connection

(vibration eliminator) between the suction line and

compressor.

The suction and liquid lines may be joined together to

form an external heat exchanger. Insulate the

refrigerant tubing for at least 20 feet from the freezer

outlet.

The best location for the liquid line drier is inside the

freezing compartment. However, it may be installed

near the compressor for easy maintenance. Install a

moisture indicating sight glass at the outlet

drier.

end of the

one compressor, the main liquid and suction line for

the group should be run through the freezers and

brought out through the refrigeration outlet of one

freezer only. Standard installation procedures

recommend one riser per circuit, per system, for hot

gas defrost setup. This is available as a factory

installed option. A piping chase allows the refrigerant

lines to be run case to case out of the upper left or

right of the end frames.

- 7 -

Temperature Control

REVISION A

10/30/02

Page 9

A low pressure or temperature control can be used to

The sensing bulb/probe is located under the coil cover

control freezer

temperature. The control should be

selected with adequate contact capacity for the

switching load. In rack systems, an evaporator

pressure-regulating valve may be used to control the

evaporating temperature.

CONDENSING UNIT PRESSURE SETTINGS

FROZEN FOOD

PRESSURE (psig)

R-22 R502 R404A R507

CUT IN 21 23 30 31 -2

CUT OUT 11 16 18 18 -8

ICE CREAM

PRESSURE (psig)

R-22 R502 R404A R507

CUT IN 15 21 22 23 -10

CUT OUT 6 11 12 13 -16

RETURN AIR

TEMPERATURE (ºF)

RETURN AIR

TEMPERATURE (ºF)

FIGURE 5A

TEMPERATURE CONTROL

RACK EPR SETTINGS

(SATURATED COIL TEMPERATURE)

MODEL NUMBER FROZEN FOOD ICE CREAM

RMZC30XL -15º F -23º F

FIGURE 5B

RACK EPR SETTINGS

The settings (See Figures 5A and 5B) are approximate

due to variations in gauge accuracy, differences in

compressor efficiency, line pressure drop and super

heat settings. Before making adjustments for store or

stocking conditions, NOTE: (make sure the

heat

is set between 6º F and 10º F).

super-

Temperature Control Adjustment

When factory installed, the temperature control is

located toward the top right end of the freezer inside

the freezer compartment and in front of the

honeycomb (discharge air) case (in front of the coil).

- 8 -

inside the cabinet. It should be wired in series with the

low-pressure (L.P.) control. The wiring diagram (Figure

NN) shows use

of the thermostat in a pump down

system. (Figure NN) shows a standard type of

temperature control

.

Leak Check-Evacuation-Charging

After all of the refrigeration piping and system

components have been assembled, the entire system

must be pressurized and checked for leaks. Use

nitrogen and refrigerant vapor to check for leaks. A

Halide leak detector or an electronic leak detector is

recommended.

If the system is sealed, evacuate with a deep

vacuum pump. Triple evacuation to a

minimum of 500 microns and nitrogen sweep

is recommended. After the system has been

thoroughly evacuated of all moisture and noncondensable gas, charge the system with the

proper refrigerant, using “ hi-side/low-side”

charging techniques.

ELECTRICAL

Figure 13 shows the typical wiring diagram for a

freezer equipped with electric defrost. Figure 14

shows the typical wiring diagram for a freezer

equipped with hot gas defrost. Each case is provided

with a wiring diagram located near the electric box

that shows the exact wiring of the case.

There are many control options available for multiple

case defrost systems. Wiring diagrams and

instructions can be obtained by calling Zero Zone`s

Service Department.

REVISION A

10/30/02

Page 10

External wiring should be sized according to the

generally have the pressure switch built into the time

amperage rating stamped on the serial plate. The

serial plate is located on the ceiling inside the left-

hand door. All internal wiring has been done at the

factory. It has been terminated in the electrical box

located

at the top and rear on the right end of the

case. A terminal block has been used to simplify field

connections.

The line side of the contactor/relay is energized with

115 volts at all times. The 115-volt loads in the freezer

are energized at all times except during defrost and

during post-defrost pulldown. For electric defrost the

208/230 volt defrost element is OFF at all times except

during defrost. The time clock is in operation at all

times. The drain line heater is wired at 115-volt and is

on at all times. If a Hot Gas Solenoid and/or a roof

mounted anti-sweat kit are installed, these too will run

clock. A time clock can be purchased from Zero Zone

or from a local refrigeration supply house.

Temperature termination of defrost is strongly

recommended on Zero Zone cases.

BLUE

YELLOW

OPEN ON FALL

OPEN ON RISE

YELLOW

BLUE

RED

RED

DEFROST

TERMINATION

STAT (50-55ºF)

SETTINGS

RED/YELLOW CLOSE ON RISE

RED/BLUE CLOSE ON FALL

DIFFERENCIAL SLIDER CONTROL

(LOCATED BEHIND COVER)

LINE TO PROBE

at all times on 115-volt.

Note: All wiring must comply with the National

Electrical Code and all local codes.

DEFROSTING

General

Periodic defrosting to keep the coil free of frost is

accomplished automatically by a time clock used in

conjunction with an electric, hot gas, or reduced

temperature gas injection defrost system. The most

reliable and efficient defrost system for a single case

uses a time

termination device. Time clocks can be purchased

that terminate on coil temperature or case coil

pressure. These clocks have the ability to match the

defrost time to the frost load on the coil. Coil

temperature is sensed by the defrost temperature

termination thermostat supplied as standard on all

Zero Zone freezers. Pressure terminating clocks

clock that incorporates a defrost

FIGURE 6

JOHNSON TYPE CONTROL

Electric Defrost

When the pin in the 24 hour dial reaches the TIME

arrow, the clock will trip and the defrost cycle will start.

At that time, the clock will stop the compressor,

energize the 208/230 volt defrost heater, and

energize the normally closed 208/230 volt contactor

or relay. This de-energizes the 115-volt fans, lights,

and door set anti-sweat heaters.

After the defrost period, the compressor will operate.

When the coil temperature drops below +5°F, the fan,

light and anti-sweat heater limit thermostats will close,

starting the fans, lights and anti-sweat heaters.

- 9 -

REVISION A

10/30/02

Page 11

Gas Defrost

Several types of gas defrost methods in conjunction

with time actuated, time or temperature terminated

defrost timers can be used to defrost the evaporator.

The refrigeration system designer and installer are

responsible for correct line sizing for effective gas

defrost and liquid return from the freezers. Sizing and

component selection depend on the type of defrost,

size, and location of high side refrigeration system.

Zero Zone freezers equipped for hot gas defrost

consist of a side port, distributor and check valve for

coil defrost, and a check valve and serpentine coil

attached to the bottom of the pan to ensure pan and

drain defrost.

Liquid and suction line connections are made outside

the case, through the refrigeration access hole located

at the top right rear corner of the freezer.

The timer starts the gas defrost cycle by energizing a

solenoid, reversing valve, or directional valve. The gas

is injected from the source into the suction line of the

evaporator to be defrosted. The gas flows into the

serpentine coil attached to the floor of the case and

into the evaporator. Condensed liquid leaves the

evaporator through the side port distributor, through a

check valve into the liquid line.

the serpentine passes through a check valve into the

liquid line. Refer to the defrost frequency and

termination recommendations that follow on (Figure

9).

TEMPERATURE AND PRESSURE TERMINATION

REDUCED

FREQUENCY 1 1 1

TEMPERATURE 55º F 55º F 55º F

TEMPERATURE

GAS DEFROST

Liquid condensed in

HOT

GAS

DEFROST

ELECTRIC

DEFROST

PRESSURE

FAIL-SAFE

TIME (minutes)

DRAIN/DRIP

TIME (minutes)

TIME ONLY TERMINATION (not recommended)

TIME (minutes) 14-22 12-20 40-45

DRAIN/DRIP

TIME (minutes)

SATURATED SUCTION PRESSURE

EQUAL TO 50º F

40 30 60

3-5 3-5 0

3-5 3-5 0

FIGURE 9

DEFROST FREQUENCY & TERMINATION

Temperature Termination Required

Refrigeration technician should recheck coil

condition after one week of operation to be certain

that the frequency and duration of defrost is

adequate for the particular store and locality. For

example, if defrost voltage is below 200 volts,

additional fail-safe time may be required.

When using time terminated defrost, temperature

terminated thermostat should be wired in series

with the defrost heater.

Temperature termination thermostats may be

wired in series for multiple evaporator

installations.

Limit Thermostat

Each freezer has factory set limit thermostats (Klixons)

attached to the return bends of the coil on the right

end of the freezer to regulate the operation of the

evaporator fans, freezer lights, and anti-sweat

heaters.

OPERATION OF THE LIMIT THERMOSTATS CAUSES

THE EVAPORATOR FANS, FREEZER LIGHTS, AND

ANTI-SWEAT HEATERS TO REMAIN OFF UNTIL THE

COMPRESSOR IS OPERATING AND THE COIL

TEMPERATURE IS BROUGHT BELOW THE

- 10 -

THERMOSTAT CUT-IN SETTING (+5ºF). SUPERHEAT

REVISION A

10/30/02

Page 12

MUST BE SET CORRECTLY FOR PROPER THERMOSTAT

case temperature and proper control operation. While

OPERATION

When the freezer first operates, the fans and lights

may cycle on and off a few times until coil temperature

stays below +5ºF.

USER INFORMATION

Cleaning

The freezer should be thoroughly cleaned before start-

up and routinely thereafter to maintain a clean

appearance. Use mild detergent and warm water

(never an abrasive cleaner) to wipe out the inside of

the freezer. Wash down all glass doors with glass

cleaner. Clean interior glass reduces fogging and

increases visibility. The freezer will remain bright and

sparkling with just a few minutes of cleaning each

week. Internal components can be cleaned after

removal of access panels. The case drain should be

loading the shelves, leave at least 1-1/2 inch between

the top of the merchandise and the shelf above it so

the customer can remove the

inch space

allows an air curtain on the top of the

merchandise. The 1-1/2

product. Product should not exceed load limits (see

Figure 10).

GENERAL GUIDELINES FOR STOCKING A ZERO ZONE® RMZCXL CASE

1-1/2" GAP BETWEEN THE PRODUCT

AND THE CEILING (TO ALLOW

CLEAR AIRFLOW TO THE REAR DUCT)

1-1/2" GAP BETWEEN THE PRODUCT

AND THE SHELF ABOVE (TO ALLOW

EASY STOCKING AND

UNSTOCKING OF THE PRODUCT)

DO NOT OVER STOCK

THE SHELF WHEREBY PRODUCT

IS NOT RESTING FULLY ON THE

SHELF.

INDIVIDUAL SHELF LOADS

NOT TO EXCEED 275LBS

(125kg)

regularly cleared of debris and price tags.

Note: Do not use high-pressure water or steam to

clean the interior.

Shelf Location

The shelves are adjustable in 1- 1/2inch increments

and may be located in any position for best display

advantage. The shelves also come with a tilt feature

whereby the outer set of hooks can be used on the

shelf brackets to angle the shelf downward. This may

be a desired feature when product needs to roll /slide

ahead for stocking.

Be sure shelf brackets are completely seated

before installing the shelf.

Loading the Freezer

The freezer may be loaded with merchandise after it

has been operated for at least 24 hours with correct

ENSURE ALL SHELVES ARE

SECURELY LOCATED ON

THEIR RESPECTIVE SHELF

BRACKETS

DO NOT BLOCK RETURN

AIR GRILL

FIGURE 10

LOADING A FREEZER

Light Switch

The light switch is located on the mullion by the hinge

side rightmost door. Turn the light switch off during

the initial freezer temperature pull-down to prevent the

freezer lights from cycling off and on. Always turn the

lights off when replacing lamps.

- 11 -

REVISION A

10/30/02

Page 13

effectiveness.

Typical super heat settings are

Lighting

T8 lighting is standard on the RMZC30XL. These

systems use a lens to direct the light output evenly

across the shelves.

In order to access the lamp the lens cover must be

removed. Details of this can be located in the door

instruction booklet.

SERVICE

Cart Bumper

The cart bumper must be removed to gain access to

the drain clean out. Disassemble the bumper and kick

rail by removing the 2 or 3 metal screws located in the

kick rail. The bumper assembly can be lifted up and

removed from the case. The kick plate can be

removed, exposing the drain. (Figure 4A shows the

bumper assembly)

Evaporator

The evaporator coil, located at the top of the freezer, is

factory assembled with distributor and expansion

valve. Additional items (such as hand valves, air

filter/dryers, sight glass, etc.) may be attached to the

system depending upon the options selected. To

inspect the entire coil, open the roof panel and the

front of the coil should be directly visible.

Expansion Valve

Do not adjust the expansion valve, unless you are

qualified to do so. Except where otherwise specified,

an externally equalized thermostatic expansion valve

with pressure limiting charge adjustable super-heat

and thermal bulb is mounted to the evaporator coil.

between 6°F and 10°F

. To adjust the expansion

valve, open the roof panel. To the far left of the coil,

the valve should be visible. Remove the cap from the

bottom of the valve. When looking at the valve stem

end, turn the valve stem counterclockwise to decrease

super heat. Turn the valve stem clockwise to increase

super heat. Measure the

suction line temperature at

the expansion valve-sensing bulb and compare it to

the suction temperature corresponding to the

saturated pressure at the coil.

CAP

EXPANSION

VALVE

FIGURE 11

EXPANSION VALVE LOCATION

Turn the valve stem only 1/4 turn at a time and allow

sufficient time (20 to 30 minutes)

for the valve to

settle before making any further adjustments. Replace

the valve stem cap after the valve super-heat has

been adjusted. BE CERTAIN THE VALVE STEM CAP IS

WIPED DRY FIRST.

CAUTION!

DISCONNECT POWER TO THE CASE BEFORE

SERVICING ELECTRICAL COMPONENTS

Defrost Heater Element

Adjust the super-heat setting for maximum coil

- 12 -

REVISION A

10/30/02

Page 14

The heater element is located under the coil. The

electric wire leads are connected in the electrical box

on the top right rear of the case.

RMZC30XL Heater Element Removal

Shut off the power to the case.

of the defrost heater wire from the relay/coil inside the

electrical box.

To remove the defrost element, open the roof of the

case and expose the coil area. At either end of the

coil there is a screw that locks the heater bracket,

relative to the coil. Remove these screws. Once

removed, the heater bracket should slide towards the

front of the case. Once clear of the coil, the heater can

be removed by unscrewing the clips that lock the

heater to the heater bracket. Lift the heater free of the

heater bracket and feed the wires back through the

conduit at the top of the case.

Disconnect the leads

Evaporator Fans

Air is circulated throughout the freezer with 115-volt

low temperature fan motors. These motors must be

all operating at all times except during defrost.

RMZC30XL Fan Removal

Shut off the power to the case.

the case and expose the coil area. At the rear of the

coil, there is a fan shroud. This fan shroud may either

show a hinged cover, or may consist of several slip

covers. Remove any screws that hold down the

covers. Once the cover is opened/removed the fan

motors should now be exposed.

Unplug fan from fan power supply plug located on the

rear face of the fan housing.

Remove the two (2) mounting screws on either side of

the fan bracket and remove the fan assembly from the

fan housing.

Open up the roof of

- 13 -

REVISION A

10/30/02

Page 15

FIGURE 13

ELECTRICAL SCHEMATIC – ELECTRIC DEFROST

- 14 -

FIGURE 14

ELECTRICAL SCHEMATIC – HOT GAS DEFROST

REVISION A

10/30/02

Page 16

- 15 -

REVISION A

10/30/02

Page 17

PRELIMINARY

.

RMZC3OKL SPECIFICATION SHEET

CASE

SIZE

2RMZC30XL

3RMZC30XL

4RMZC30XL

5RMZC30XL

MODEL

NUMBER

2RM ZC30XL

3RM ZC30XL

4RM ZC30XL

5RM ZC30XL

CAPACITY

SPEC1 FICATIONS

CAPACITIES

USABLE

CAPACITY

66

99

131

1

64

FAN

AMPS

0.68

1

.36

1.70

2.04

T-8 LIGHTS

CASE

SIZE

2RMZC30XL

3RMZC30XL

SHELF

25

25

.25

DEPTH

4RMZC30XL

5RMZC30XL

*WEIGHT BASED

WITHOUT

ENDS,

SINGLE

25

ELECTRICAL SPECIFICATIONS

ANTHONY

ANTI-SW EAT

HEATERS

AMPS

4.85

7.05

9.25

10.86

AMPS

1.89

2.50

3.13

3.75

ELM

ANTI-SW EAT

HEATER

AM PS

ANTHONY DOORS

2.43

3.34

4.35

5.37

WEIGHT

POUNDS*

945

1,315

1,76

2,244

ON

UNCRATED CASES

AND FULLY SHELVED.

END

WEIGHT:

65 POUNDS

DEFROST

HEATER

AMPS

208V/1/60HZ.

6.73

10.10

13.46

16.83

IN

1

DRAIN

HEATER

AM PS

4.57

6.25

7.93

9.62

MODEL

NUMBER

2RM ZCJOXL

3RM ZC3OXL

4RM ZC30XL

5RMZC30XL

RMZC30XL

WIOPTIONAL

ELM DOORS

Zero Zone,

Inc.

North Prairie,

1

-800-247-4496

BTUIHR

FOOD

3,550

5.325

7,100

8,875

DEDUCT

275

BTUHRIDOOR

.

1

10

W1

531 53-9792

.

FAX:

www.zero-zone.com

'STANDARD FOR CASE IN A LINE-UP

VOLTAGE: 115 VOLTS 1 PHASE 60 HZ.

BTU/HR ENERGY REQUIREMENTS:

BTUIHR

ICE CREAM

3,870

5,805

7,740

9,675

DEDUCT

325

BTUHRIDOOR

N.

Oakridge

262-392-6450

Dr.

BTUIHR RATING BASED ON T-8 LIGHTING AND PARALLEL RACK

SYSTEM. MULTIPLY BY 1.04 FOR CONVENTIONAL SYSTEM.

CASE DESIGNED TO OPERATE IN

AND RELATIVE HUMIDITY OF 55% OR LOWER.

All

specifications are subject to change without notice.

AN

AMBIENT OF 75OF OR LOWER

RMZC30XL

Loading...

Loading...