Page 1

D

D

isplay

Freezers

ZERO ZONE

Zero Zone, Inc. • 110 N. Oakridge Dr. • North Prairie, WI 53153-9792

1-800-247-4496 • FAX: 1-414-392-6450 • www.zero-zone.com

RMZP30 Series

RMZP24 Series

C

CRMA

Certified

RMZC30 Series

INSTALLATION

and

OPERATING INSTRUCTIONS

for

06995M21000129

Page 2

TABLE OF CONTENTS

SUBJECT

GENERAL INFORMATION ............................................................................. 1

INTRODUCTION ........................................................................................................... 1

INSPECTION ................................................................................................................. 1

LOCATION .............................……………................................................................... 1

INSTALLATION .........................................….................................................. 1

LEVELING ...................................................................................................................... 1

JOINING FREEZERS .......................................................…........................................... 3

DRAIN LINE ...............................................…............................................................... 3

CART BUMPER ............................................................................................................ 3

REFRIGERATION ........................................................................................... 3

GENERAL ......................................................…........................................................... 3

REFRIGERANT PIPING .........................................................................….................... 5

TEMPERATURE CONTROL ........................................................................................... 5

TEMPERATURE CONTROL ADJUSTMENT ........................................…................ 5

LEAK CHECK-EVACUATION-CHARGING ..............................................…................ 5

ELECTRICAL ..................................................................................…............. 6

DEFROSTING ................................................................................................. 6

GENERAL ..........................................................................…....................................... 6

ELECTRIC DEFROST ...............................................….................................................. 7

GAS DEFROST ....................................……………....................................................... 7

LIMIT THERMOSTAT ..........................................................…........................................ 7

USER INFORMATION .................................................................................... 8

CLEANING ......................................................…......................................................... 8

SHELF LOCATION ........................................................................................................ 8

LOADING THE FREEZER .............................................................................................. 8

LIGHT SWITCH .............................................................................................................. 8

SERVICE ........................................................................................................ 8

CART BUMPER ............................................................................................................. 8

EVAPORATOR ............................................................................................................. 8

EXPANSION VALVE ..................................................................................................... 8-9

DEFROST HEATER ELEMENT ........................................................................................ 9

RMZC/P30 HEATER ELEMENT REMOVAL .......................................…...................... 9

RMZP24 HEATER ELEMENT REMOVAL ....…………........................…....................... 9

EVAPORATOR FANS ................................................................................................... 9

RMZC/P30 FAN REMOVAL ....................................................................................... 9

RMZP24 FAN REMOVAL ...…..................................…............................................... 9

LIGHTS ..............................................................................................…………………. 9-10

RMZC30, RMZP30, RMZP24

Page 3

BALLASTS ..............................................................…......................…………………… 10

ALTERNATE LIGHTING - T8 ..............................................................…........................ 10

TABLES

TABLE 1 RMZC/P30 LINE SIZE -14 F R502, R404a, R507 ........……........…............... 11

TABLE 2 RMZC/P30 LINE SIZE -20 F R502, R404a, R507 ..................….................... 12

TABLE 3 RMZC/P30 LINE SIZE -14 F R22 ...............…...............….............................. 13

TABLE 4 RMZC/P30 LINE SIZE -20 F R22 ...................….....................….................... 14

TABLE 5 RMZP24 LINE SIZE -14 F R502, R404a, R507 ...................…........................ 15

TABLE 6 RMZP24 LINE SIZE -20 F R502, R404a, R507 .............................….............. 16

TABLE 7 RMZP24 LINE SIZE -14 F R22 ...................................…..............…................ 17

TABLE 8 RMZP24 LINE SIZE -20 F R22 ........................…..............................…........... 18

FIGURES

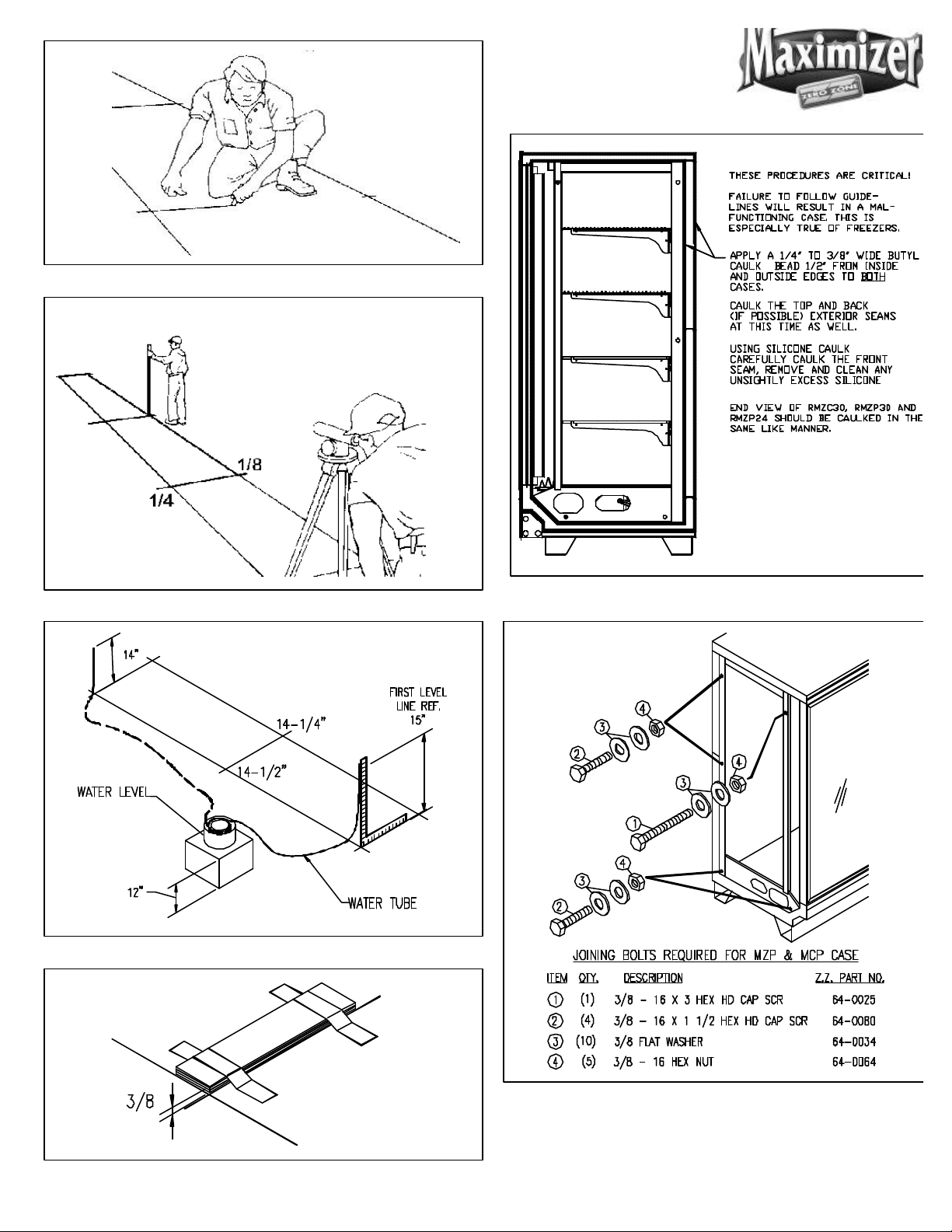

FIGURE 1 LEVELING CASES PRIOR TO JOINING .........................…..............……... 2

FIGURE 2 CAULKING CASES TO BE JOINED ....……....................…..............……... 2

FIGURE 3 JOINING 24” DOOR REACH-IN FREEZERS .........................….......……... 2

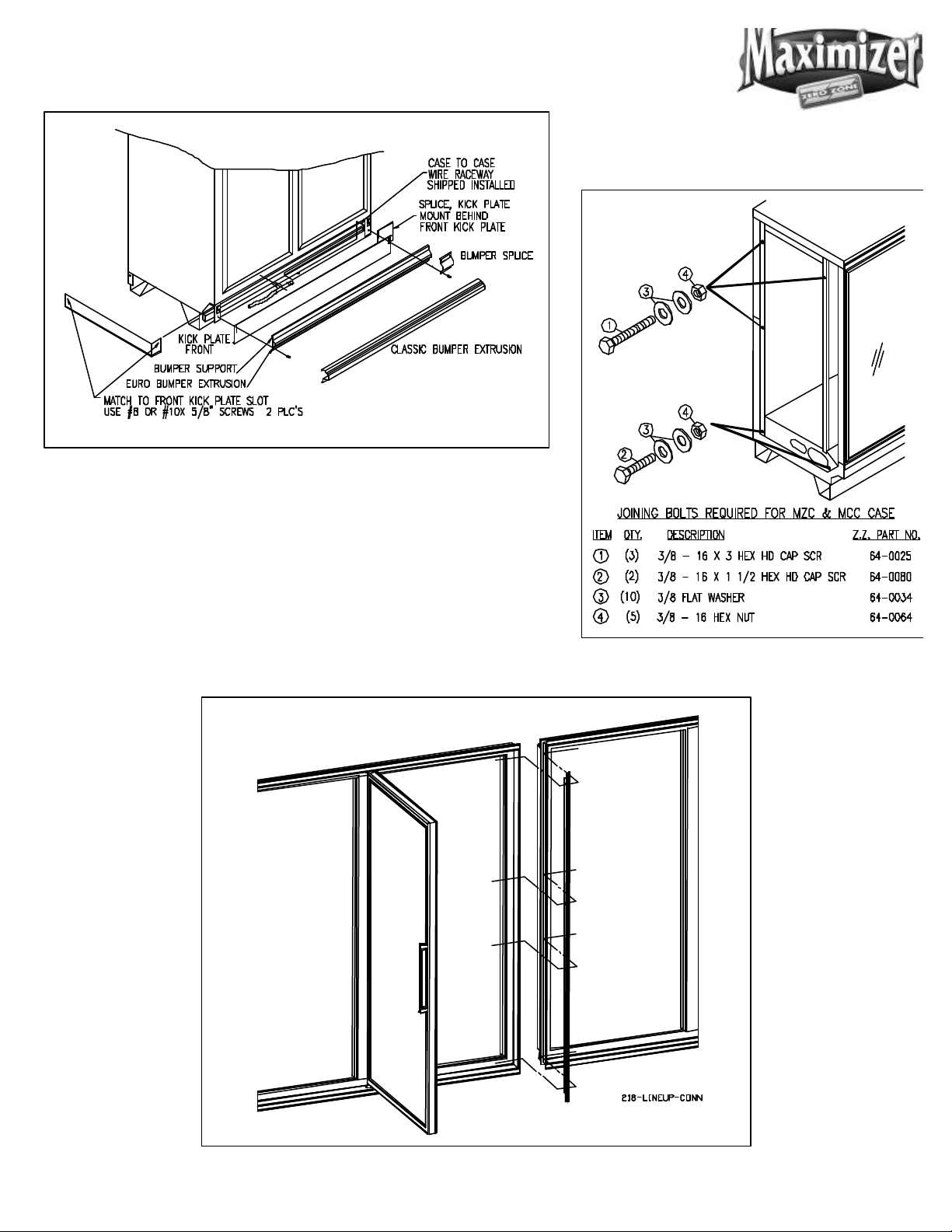

FIGURE 4 JOINING 30” DOOR REACH-IN FREEZERS ...............……..............……... 4

FIGURE 5 INSTALLING TEE STRIPS …………………........................…..............……... 4

FIGURE 6 INSTALLING THE CART BUMPER ………........................…..............……... 4

FIGURE 7 TEMPERATURE CONTROL SETTINGS ….........................…..............……... 5

FIGURE 8 TYPICAL TEMPERATURE CONTROLS ….........................…..............……... 6

FIGURE 9 DEFROST FREQUENCY AND TERMINATION ..................................……... 7

FIGURE 10 RMZC30 SPECIFICATION SHEET ...............................….......................... 19-20

FIGURE 11 RMZP30 SPECIFICATION SHEET ............................................................. 21-22

FIGURE 12 RMZP24 SPECIFICATION SHEET ............................................….............. 23-24

FIGURE 13 RMZC/P30/24 ELECTRIC DEFROST WIRING DIAGRAM .…................. 25

FIGURE 14 RMZC/P30/24 HOT GAS DEFROST WIRING DIAGRAM ...........…........ 26

FIGURE 15 RMZC/P30/24 WIRING DIAGRAM FOR TIME/TEMPERATURE DEFROST 27

FIGURE 16 RMZC/P30 ELECTRIC DEFROST ASSEMBLY ....................…................... 28

FIGURE 17 RMZC/P30 HOT GAS DEFROST ASSEMBLY ........................................... 29

FIGURE 18 RMZP24 ELECTRIC DEFROST ASSEMBLY .................……....................... 30

FIGURE 19 RMZP24 HOT GAS DEFROST ……...........…............................................ 31

WARRANTY ................................……………….............................................. 32

RMZC30, RMZP30, RMZP24

Page 4

GENERAL INFORMATION

1

Introduction

The information contained in this manual pertains to

the following Maximizer display freezers: RMZC30,

RMZP30 and RMZP24. These cases are used for

merchandising frozen food or ice cream. The RMZC30

and RMZP30 cases have 30-inch wide doors and

utilize the revolutionary new S-coil. The RMZP24 has

24” wide doors and utilizes our traditional oversized

coil. Zero Zone has made every effort to produce

refrigeration equipment of the highest quality using

state-of-the-art components.

These display freezers were designed to operate in an

air-conditioned store where the temperature is maintained at 75°F or lower and the relative humidity is

55% or lower.

Inspection

These display freezers were carefully factory-tested,

inspected and properly packed to ensure delivery in

the best possible condition. The equipment should be

uncrated and checked for damage immediately upon

delivery. ALL CLAIMS FOR DAMAGES MUST BE FILED

WITH THE TRANSPORTATION COMPANY - NOT WITH

ZERO ZONE. The carrier will supply necessary report

and claim forms.

Location

INSTALLATION

Leveling (See Figure 1)

Refrigeration equipment must be installed perfectly

level to allow efficient operation of the refrigeration

coils and complete drainage of defrost water. Since a

level area is seldom available, the following steps are

recommended to insure a level installation.

1. Measure off and mark on floor the exact dimensions of the case line-up. (Check blueprints).

2. Snap a chalk line at the locations for the front and

back positions of the base rails.

3. Mark locations of all joints (front and back).

4. Using a transit, find the highest point along both

base rail position lines. Using the high point as a

reference, mark the difference directly on the floor

to each joint (front and back).

5. If a transit is not available, a water level can be

used to mark reference elevation points. Water

levels can be purchased from a contractor supply

house for a minimal cost.

6. A string level can also be used to mark elevation

points. The string level should only be used on

short line-ups to avoid string sag.

These freezers must not be installed in the direct rays

of the sun or near a source of radiant heat.

Be certain that the floor under the installation is of

sufficient strength to prevent sagging. Out of level

conditions will result in reduced performance.

Wall cases, and back to back cases, should be positioned to allow a minimum 2 - 4 inch space behind the

back of a unit. This will allow necessary air to circulate

behind the unit.

7. Place the required number of shims (supplied) at

each joint (front and back) to equal the highest

point. Tape all shims in place.

8. Place additional support shims at the center of four

and five door cases base rails (front and back).

9. Use a carpenter’s level to check installation as you

go. The case should be level from front to back

and side to side. Install the case at the highest

point first, if part of a line-up.

RMZC30, RMZP30, RMZP24

Page 5

Shim joints to equal highest points

Measure and mark exact case outline

2

Mark floor level differences

Water level elevation points

Figure 2: Caulking cases to be joined

Figure 3: Joining 24” Door Reach-In Freezers

RMZC30, RMZP30, RMZP24

Page 6

Joining Freezers

These reach-In freezers have been engineered for

continuous display. This means that any number of

cases can be joined together to create a display of any

desired length. Reach-In freezers are built on permanent steel skids to promote easy installation. The

cases can be moved on pipe rollers or with a Johnson

Bar. The ends of the case are protected with a removable steel plate.

To install Reach-Ins, perform the following steps:

Install a tee to the outlet pipe and a PVC drain trap to

the tee. Plug the open end of the tee using the cleanout plug supplied with the drain trap kit. The drain line

must be pitched away from the case a minimum of 1/4

inch per foot. The tee, drain trap, and plug are supplied standard with the case.

Cart Bumper

The cart bumper should be installed at the bottom

front of the case. (See Figure 6) The assembly is

adjustable to compensate for uneven floors.

1. Set the first Reach-In into the desired position and

level it. Run a 3/8-inch diameter bead of Butyl

caulk 1/2 inch in from both the inner and outer

surfaces of the case end. (See Figure 2)

2. Push the second Reach-In against the end of the

first. Level the second Reach-In. Remove the left

and right end coil covers and the rectangular

pocket hole covers, accessing the holes in the end

panels of each freezer as shown. (See Figure 3 for

24” door cases and Figure 4 for 30“ door cases).

Install tee strips between the doorframes at case

joints on 30” door cases. ( See Figure 5) Use

the special screws and nuts provided.

3. Start the joining bolts, but do not tighten them.

Begin tightening the bolts at the top rear, working

down the back of the case and up the front making

sure that the front seams are flush.

Drain Line

The drain is located at the center of the freezer in the

floor pan. On all 30” door cases, the drain can be

reached by removing the center coil covers. A plastic

access cover can then be removed from the fan

housing. On all 24” door cases, a small center cover

can be removed to access the drain. The 1-inch PVC

drain outlet is located at the center front of the freezer

behind the kick plate.

Center and hook the bumper assembly on the hangers provided.

In continuous line-ups, place a kick plate joint strip at

each joint. On case ends, lineup an end kick plate

with the front mounting holes. Fasten the rear of the

end kick plate to the case using TECH screws.

Slide the front kick plate behind the bumper assembly

and in front of the end kick plate or kick plate joint strip.

Install three screws (two screws on 2-door only) to hold

the kick plate and bumper in place. The screws attach

the kickplate to a bracket with a timmerman.

A bumper joint strip can be installed over the bumper

at the joints. This is standard on Euro Style Trim and

optional on Classic Style Trim.

REFRIGERATION

General

Unless otherwise specified, the liquid and suction

connections are made inside the case under the

evaporator fan/coil cover. Refrigerant piping may

enter the case through the front left bottom. (See

Figure 10, 11, and 12) Alternate locations are out the left

rear bottom of case or left rear top of case. After

connections have been made, the refrigeration access

hole in the freezer must be sealed completely with

aerosol-dispensed Urethane insulation or equivalent

(ie: great stuff).

RMZC30, RMZP30, RMZP24

Page 7

Figure 6: Installing The Cart Bumper

4

Figure 4: Joining 30” Door Reach-In Freezers

Figure 5: Installing Tee Strips

RMZC30, RMZP30, RMZP24

Page 8

Refrigerant Piping

R-502

TEMP.

TEMP.

5

Frozen Food

Correct refrigeration line sizing and installation is

essential for proper system operation. The following

tables (Tables 1 through 8) list R502, R404A, R507, and

R-22 line sizes for different combinations of frozen

food and ice cream freezers. A P-trap must be installed at the bottom of all vertical suction risers.

When two or more freezer sections are connected to

one compressor, the main liquid and suction line for

the group should be run through the freezers and

brought out through the refrigeration outlet of one

freezer only. A piping chase allows the refrigerant

lines to be run out of the right or left end frame.

The compressor should be installed as close as possible to the freezers to reduce pressure drop. If the

compressor is located above the freezer, check the

refrigerant line size tables (Tables 1 through 8) in the

back of this manual to determine the riser line size.

Install a shallow trap at the bottom of the riser. Use a

flexible connection (vibration eliminator) between the

suction line and compressor.

The suction and liquid lines may be taped together to

form an external heat exchanger. Insulate the tubing

for at least 20 feet from the freezer outlet.

The best location for the liquid line drier is inside the

freezing compartment. However, it may be installed

near the compressor for easy maintenance. Install

moisture indicating sight glass at the outlet end of the

drier.

Temperature Control

A low pressure or temperature control can be used to

control freezer temperature. The control should be

selected with adequate contact capacity for the

switching load. In rack systems, an evaporator pressure-regulating valve may be used to control the

evaporating temperature.

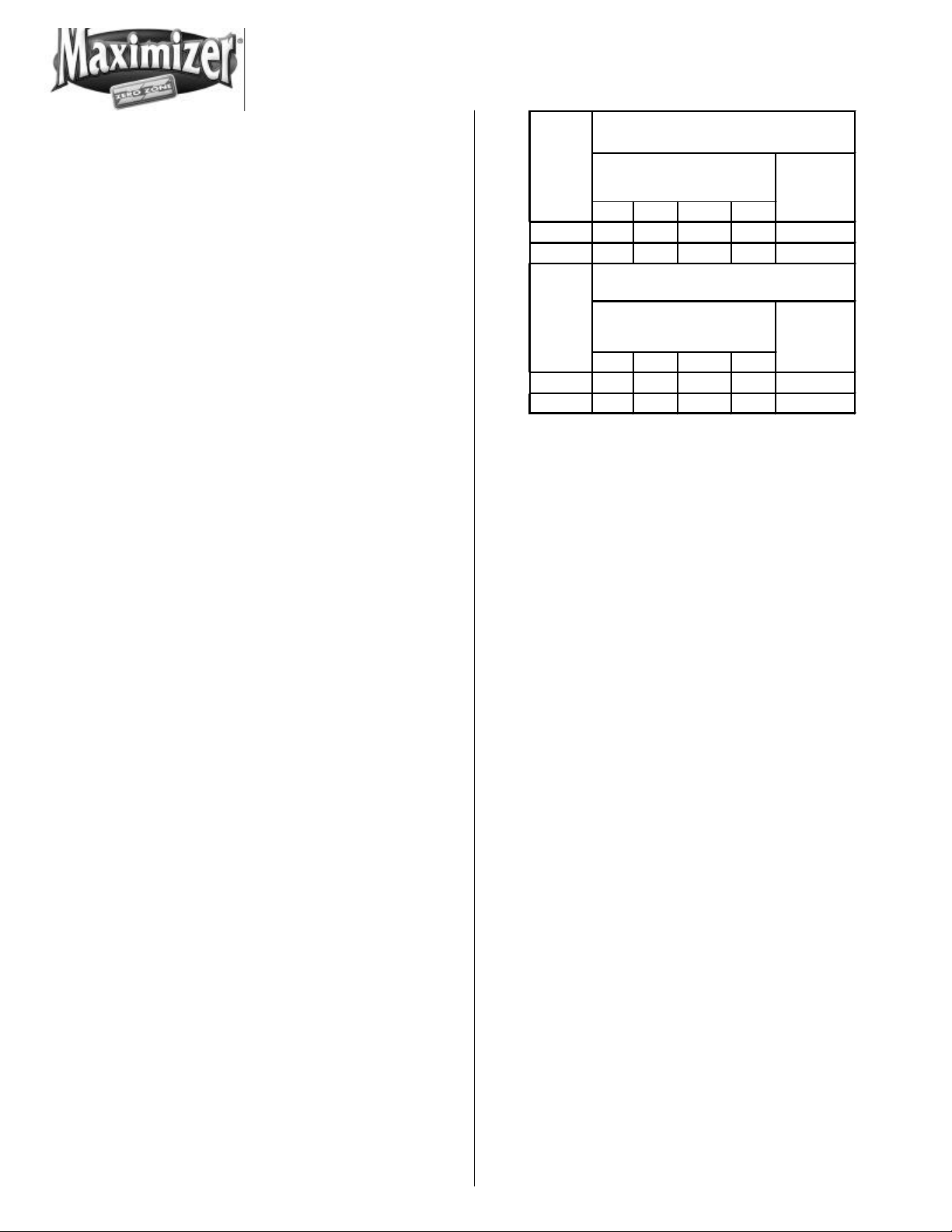

The settings (See Figure 7) are approximate due to

variations in gauge accuracy, differences in compressor efficiency, line pressure drop and super

Pressure

(psig)

R-22 R502 R404A R507

Cut In 24 31 33 35 +2°F

Cut Out 14 19 21 22 -4° F

Ice Cream

Pressure

(psig)

R-22

Cut In 19 25 26 28 -5°F

Cut Out 9 14 15 17 -11°F

Figure 7: Temperature Control Settings

R404A R507

RETURN

AIR

RETURN

AIR

heat settings. Before making adjustments for store or

stocking conditions, make sure the super heat is set

between 6°F and 10°F.

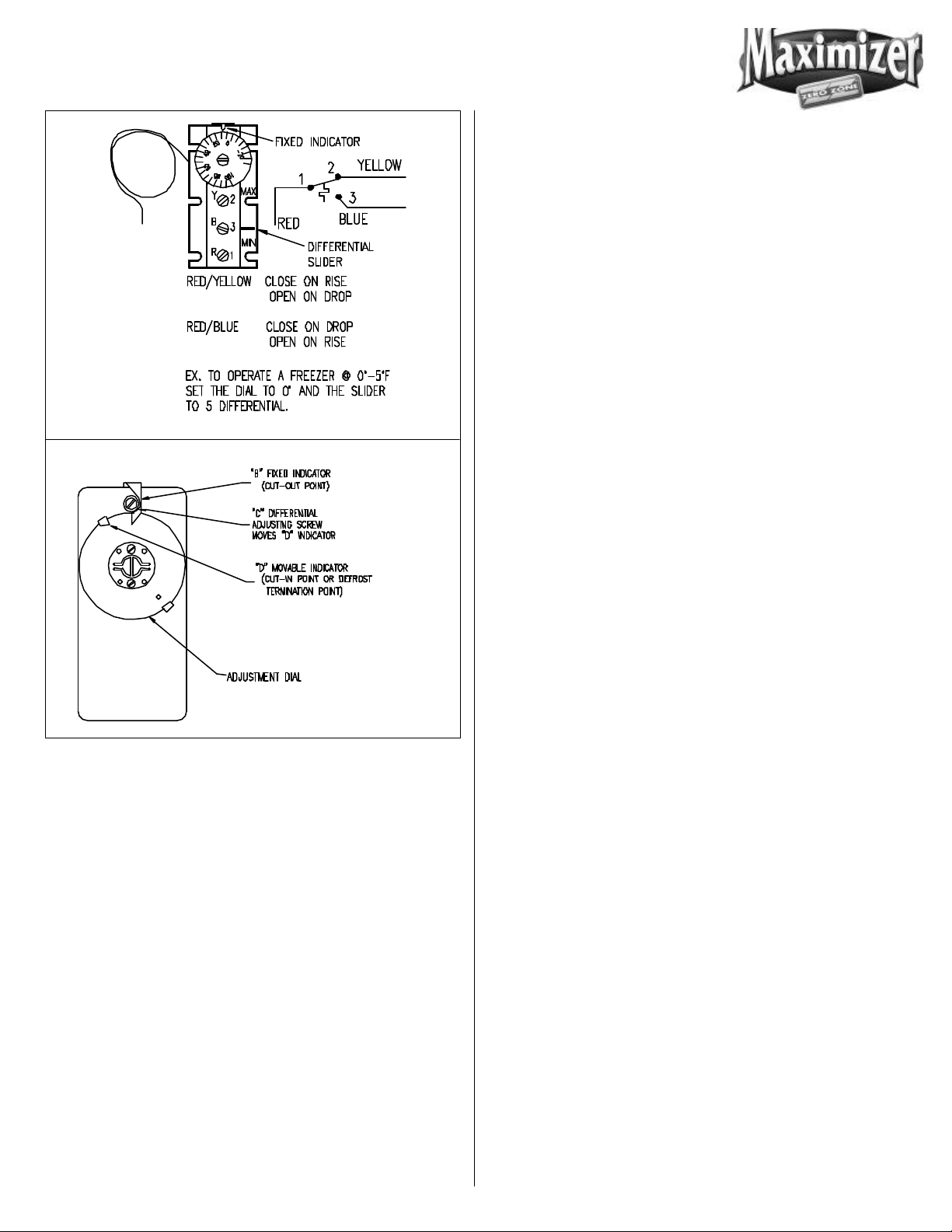

Temperature Control Adjustment

When factory installed, the temperature control is

located toward the right end of the freezer behind the

black kick plate. The sensing bulb is located under the

coil cover inside the cabinet. It should be wired in

series with the low-pressure (L.P.) control. The wiring

diagram (Figure 16) shows use of the thermostat in a

pump down system. (Figure 8) shows two types of

temperature controls.

Leak Check-Evacuation-Charging

After all of the refrigeration piping and system components have been assembled, the entire system must

be pressurized and checked for leaks. Use nitrogen

and refrigerant vapor to check for leaks. A Halide leak

detector or an electronic leak detector is recommended.

If the system is sealed, evacuate with a deep vacuum

pump. Triple evacuation to a minimum of 500 microns

and nitrogen sweep is recommended. After the

system has been thoroughly evacuated of all moisture

and non-condensable gas, charge the system with the

proper refrigerant, using “hi-side/low-side” charging

techniques.

RMZC30, RMZP30, RMZP24

Page 9

Figures 10, 11, and 12. All internal wiring has been

done at the factory. It has been terminated in the

electrical compartment located behind the kick rail at

the right end of the case. A terminal block has been

used to simplify field connections.

The line side of the contactor is energized with 115 volts

at all times. The 115-volt loads in the freezer are

energized at all times except during defrost and

during post-defrost pulldown. The 208/230 volt

defrost element is OFF at all times except during

defrost. The time clock is in operation at all times.

Note: All wiring must comply with the National Electrical Code and all local codes.

DEFROSTING

General

Figure 8: Typical Temperature Controls

Figure 14 shows the typical wiring diagram for a

freezer equipped with electric defrost. Figure 15 shows

the typical wiring diagram for a freezer equipped with

hot gas defrost. Each case is provided with a wiring

diagram located in the electric box that shows the

exact wiring of the case.

Figure 16 shows the typical wiring of one case with the

standard temperature terminating defrost control. The

defrost heaters will de-energize when the defrost

termination control has been satisfied.

Periodic defrosting to keep the coil free of frost is

accomplished automatically by a time clock used in

conjunction with an electric, hot gas, or reduced

temperature gas injection defrost system. The most

reliable and efficient defrost system for a single case

uses a time clock that incorporates a defrost termination device. Time clocks can be purchased that terminate on coil temperature or case coil pressure. These

clocks have the ability to match the defrost time to the

frost load on the coil. Coil temperature is sensed by

the defrost termination thermostat supplied as standard on all Zero Zone freezers. Pressure terminating

clocks generally have the pressure switch built into the

time clock. A time clock can be purchased from Zero

Zone or from a local refrigeration supply house.

There are many control options available for multiple

case defrost systems. Wiring diagrams and instructions can be obtained by calling Zero Zone’s Service

Department.

External wiring should be sized according to the

amperage rating stamped on the serial plate. The

RMZC30, RMZP30, RMZP24

Page 10

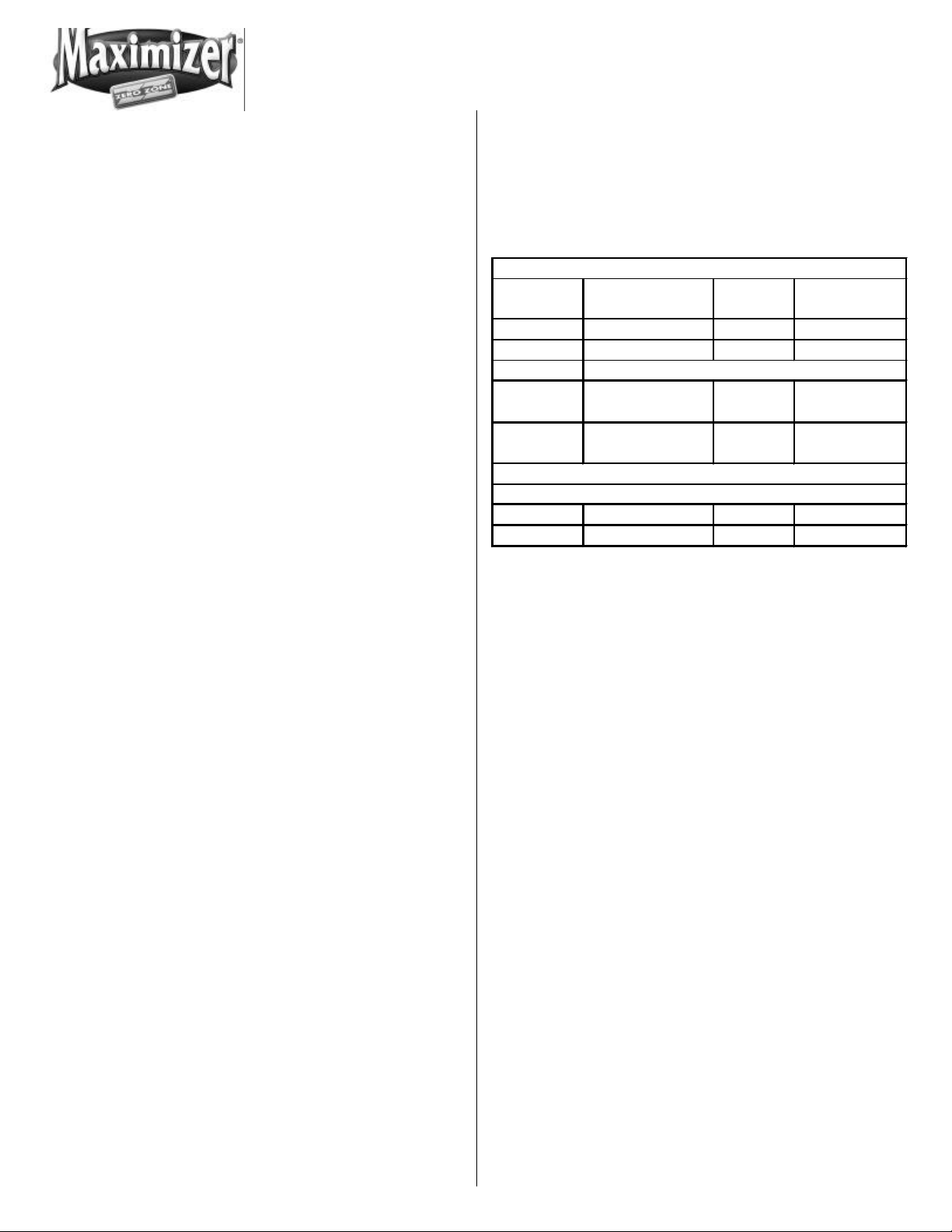

Electric Defrost

Saturated Suction Pressure Equal to 50 ° F.

Time (MIn.)

TIME ONLY TERMINATION

7

When the pin in the 24 hour dial reaches the TIME

arrow, the clock will trip and the defrost cycle will start.

At that time, the clock will stop the compressor, energize the 208/230 volt defrost heater, and energize the

normally closed 208/230 volt contactor. This deenergizes the 115-volt fans, lights, and anti-sweat

heaters.

After the defrost period, the compressor will operate.

When the coil temperature reaches +5°F, the fan, light

and anti-sweat heater limit thermostats will close,

starting the fans, lights and anti-sweat heaters.

Gas Defrost

Several types of gas defrost methods in conjunction

with time actuated, time or temperature terminated

defrost timers can be used to defrost the evaporator.

Liquid condensed in the serpentine passes through a

check valve into the liquid line. (See Figure 18 and 20)

Refer to the defrost frequency and termination recommendations that follow on Figure 9.

TEMPERATURE/PRESSURE TERMINATION

Reduced Temp.

Gas Defrost

Frequency

Temp.(°F)** 50 50 50

Pressure

Fail Safe

Time (Min.) 40 30 54

Drain

Time (Min.) 14-22 min. 12-20 min. 40-45 min.

Drain Time 0-3 0-3 0

1 1 1

0-3 0-3 0

Hot Gas Electric

The refrigeration system designer and installer are

responsible for correct line sizing for effective gas

defrost and liquid return from the freezers. Sizing and

component selection depend on the type of defrost,

size, and location of high side refrigeration system.

Zero Zone freezers equipped for gas defrost consist of

a side port, distributor and check valve for coil defrost,

and a check valve and serpentine coil attached to the

bottom of the pan to ensure pan and drain defrost.

Liquid and suction line connections are made inside

the case, through the refrigeration access hole located

in the floor pan on the left side of the freezer.

The timer starts the gas defrost cycle by energizing a

solenoid, reversing valve, or directional valve. The gas

is injected from the source into the suction line of the

evaporator to be defrosted. The gas flows into the

serpentine coil attached to the floor of the case and

into the evaporator. Condensed liquid leaves the

evaporator through the side port distributor, through a

check valve into the liquid line.

Figure 9: Defrost Frequency and Termination

Refrigeration technician should recheck coil condition after one

week of operation to be certain that the frequency and duration

of defrost is adequate for the particular store and locality. For

example, if defrost voltage is below 200 volts, additional failsafe time may be required.

Temp. termination thermostats should be wired in series for

multiple evaporator installations.

Limit Thermostat

Each freezer has factory set limit thermostats attached

to the return bends of the coil on the right end of the

freezer to regulate the operation of the evaporator

fans, freezer lights, and anti-sweat heaters.

OPERATION OF THE LIMIT THERMOSTATS CAUSES THE

EVAPORATOR FANS, FREEZER LIGHTS, AND ANTI-SWEAT

HEATERS TO REMAIN OFF UNTIL THE COMPRESSOR IS

OPERATING AND THE COIL TEMPERATURE IS BROUGHT

BELOW THE THERMOSTAT CUT-IN SETTING (+5°F ).

When the freezer first operates, the fans and lights

may cycle off and on a few times until coil temperature

is below +5 degrees F .

RMZC30, RMZP30, RMZP24

Page 11

USER INFORMATION

8

Light Switch

Cleaning

The freezer should be thoroughly cleaned before startup and routinely thereafter to maintain a clean appearance. Use mild detergent and warm water (never

an abrasive cleaner) to wipe out the inside of the

freezer. Wash down all glass doors with glass

cleaner. The freezer will remain bright and sparkling

with just a few minutes of cleaning each week. The

case drain should be regularly cleared of debris and

price tags.

Note: Do not use high-pressure water or steam to

clean the interior.

Shelf Location

The shelves are adjustable in 1-inch increments on

cantilever shelf cases and 1/2-inch increments on

pilaster cases and may be located in any position for

best display advantage.

Be sure shelf clips or brackets are completely

seated before installing the shelf.

Loading the Freezer

The freezer may be loaded with merchandise after it

has been operated for at least 24 hours with correct

case temperature and proper control operation. While

loading the shelves, leave at least 1 1/2 inch between

the top of the merchandise and the shelf above it so

the customer can remove the merchandise. The 1 1/2inch space allows an air curtain on the top of the

product.

The light switch is located on the mullion by the hinge

side right hand door. Turn the light switch off during

the initial freezer temperature pull-down to prevent the

freezer lights from cycling off and on. Always turn the

lights off when replacing lamps.

SERVICE

See Figures 17 and 18 for the typical component layout

of the 30” door case. See Figures 19 and 20 for the

typical component layout of the 24” door cases.

Cart Bumper

The cart bumper must be removed to gain access to

the drain clean out and electrical connection. Disassemble the bumper and black kick rail by removing

the 2 or 3 metal screws located in the kick rail. The

bumper assembly can be lifted up and removed from

the case. The kick plate can be removed, exposing

the electric tray cover and drain. (Figure 6 shows the

bumper assembly)

Evaporator

The evaporator coil, located at the rear bottom of the

freezer, is factory assembled with distributor, expansion valve, and heat exchanger. To inspect the 30”

door coil, remove the center or left of center coil cover.

A small inspection port is located at the rear of the

case. To inspect the entire 30” coil, remove the remaining coil covers and raise the evaporator cover.

The coil on the 24” door cases accessed by removing

the screws from the coil cover. Rotating it at the rear

integral hinge can raise the cover.

Expansion Valve

Unless otherwise specified, an externally equalized

thermostatic expansion valve with pressure limiting

charge adjustable super-heat and thermal bulb is

mounted to the evaporator coil. Adjust the super-

RMZC30, RMZP30, RMZP24

Page 12

heat setting for maximum coil effectiveness. Typical

9

super heat settings are between 6°F and 10°F. To

adjust the expansion valve, remove the right end coil

cover. Remove the cap from the bottom of the valve.

When looking at the valve stem end, turn the valve

stem counterclockwise to decrease super heat. Turn

the valve stem clockwise to increase super heat.

Measure the suction line temperature at the expansion valve sensing bulb and compare it to the suction

temperature corresponding to the saturated pressure.

Make sure that line pressure drop is taken into account.

metal clips holding the heater pan from both ends of

the coil end plates so they disengage the heater pan.

Then slide out the complete heater pan assembly from

under the coil and under the fan housing. Slowly lift

the heater pan assembly between coil and fan housing, turning it on edge while lifting.

Evaporator Fans

Air is circulated throughout the freezer with 115-volt low

temperature fan motors. These motors must be

operating at all times except during defrost.

Turn the valve stem only 1/4 turn at a time and allow

sufficient time (20 to 30 minutes) for the valve to settle

before making any further adjustments. Replace the

valve stem cap after the valve super-heat has been

adjusted. BE CERTAIN THE VALVE STEM CAP IS WIPED

DRY FIRST.

! CAUTION !

DISCONNECT POWER TO THE CASE BEFORE

SERVICING ELECTRICAL COMPONENTS

Defrost Heater Element

The heater element is located under the coil. The

electric wire leads are connected in the junction box

behind the front kick rail.

30” Door Heater Element Removal

30” Door Fan Removal

Turn off power to fans.

Remove coil cover.

Unplug fan from fan power supply plug located on the

front face of the fan housing.

Remove the two mounting bolts and remove the fan

assembly from the fan housing.

24” Door Fan Removal

Turn off power to fans.

Remove wire fan guard.

Remove fan motor mounting bracket screws.

Set motor fan assembly on floor of case.

To remove the defrost element, remove the coil covers.

Lift the inner coil cover upward and tip the fan housing

forward. This will expose the coil. Remove both fan

housing end brackets and center coil supports, then

slide out the complete heater pan assembly from

under the coil. Slowly lift the heater pan assembly

between the coil and fan housing, turning it on edge

while lifting.

24” Door Heater Element Removal

To remove the defrost element, remove the right, left,

and center coil covers. Next, remove the fan housing

legs and air baffle assembly fastened to the rear edge

of the fan housing with sheet metal screws. Turn the

Unplug power supply plug from fan.

Lift and rotate motor fan assembly from case.

Lights

High output 1500 milliamp T-10 lamps are standard

with 24” door and MZP freezers. These lamps are

optional on MZC freezers. To ensure maximum component life, always replace with 1500 milliamp lamps.

Use retainer clips and lamp shields.

RMZC30, RMZP30, RMZP24

Page 13

To change a lamp, turn off the light switch and remove

10

the retainer clip located between the top socket and

end cap. Carefully push the lamp up into the springloaded lamp socket to allow the lamp to be removed

from the bottom socket. (See Figure 10.) Remove the

end caps and shield. All

T-10 lamps must use end caps and shields.

must be installed over the lamp. Anthony’s lamp is

removed by sliding the end caps off of the lamp.

Detailed information is contained in the door instruction booklet.

Figure 10: Socket Detail

Ballasts

Zero Zone freezer ballasts are located either behind

the kick plate or in the door mullions.

Alternate Lighting -T8

T-8 lighting is standard on the 30” door case and

optional on the 24” door freezers. Many door manufacturers provide premium lighting systems. These

systems use a lens to direct light output evenly across

the shelves. The lens must be removed to access the

lamp. Ardco’s lamp may be removed by turning it 90

degrees and sliding the lamp pins out of the lamp

socket slot. The jacket

RMZC30, RMZP30, RMZP24

Page 14

EVAPORATOR FOR FROZEN FOOD

REMOTE REACH-IN FREEZER W/ 30" X 63" DOORS

BTU/HR

Table 1

11

MODEL RMZC30 & RMZP30

REFRIGERANT R-502, R-404a, R-507 @ -11° F

NO.

OF

DOOR

S

2 (1) 2-DR 5'-7 1/16" 3,141 3/8 3/8 3/8 5/8 5/8 7/8

3 (1) 3-DR 8'-1 1/2" 4,544 3/8 3/8 3/8 5/8 7/8 7/8

4 (1) 4-DR 10'-7 15/16" 5,892 3/8 3/8 3/8 7/8 7/8 7/8

5 (1) 5-DR 13'-2 3/8" 7,340 3/8 3/8 3/8 7/8 7/8 1 1/8

6 (2) 3-DR 15'-10" 8,808 3/8 3/8 3/8 7/8 7/8 1 1/8

7 (1) 3-DR & (1) 4-DR 18'-4 7/16" 10,276 3/8 3/8 3/8 7/8 1 1/8 1 1/8

8 (2) 4-DR 20'-10 7/8" 11,744 3/8 3/8 1/2 7/8 1 1/8 1 1/8

9 (1) 4-DR & (1) 5-DR 23'-5 5/16" 13,212 3/8 3/8 1/2 7/8 1 1/8 1 1/8

10 (2) 5-DR 25'-11 3/4" 14,680 3/8 1/2 1/2 1 1/8 1 1/8 1 1/8

11 (1) 3-DR & (2) 4-DR 28'-7 3/8" 16,148 3/8 1/2 1/2 1 1/8 1 1/8 1 3/8

12 (3) 4-DR 31'-1 13/16" 17,616 3/8 1/2 1/2 1 1/8 1 1/8 1 3/8

13 (2) 4-DR & (1) 5-DR 33'-8 1/4" 19,084 3/8 1/2 1/2 1 1/8 1 1/8 1 3/8

14 (1) 4-DR & (2) 5-DR 36'-2 11/16" 20,552 1/2 1/2 1/2 1 1/8 1 3/8 1 3/8

15 (3) 5-DR 38'-9 1/8" 22,020 1/2 1/2 5/8 1 1/8 1 3/8 1 3/8

16 (4) 4-DR 41'-4 3/4" 23,488 1/2 1/2 5/8 1 1/8 1 3/8 1 3/8

17 (3) 4-DR & (1) 5-DR 43'-11 3/16" 24,956 1/2 1/2 5/8 1 1/8 1 3/8 1 3/8

18 (2) 4-DR & (2) 5-DR 46'-5 5/8" 26,424 1/2 5/8 5/8 1 1/8 1 3/8 1 3/8

19 (1) 4-DR & (3) 5-DR 49'-1 1/16" 27,892 1/2 5/8 5/8 1 1/8 1 3/8 1 5/8

20 (4) 5-DR 51'-6 1/2" 29,360 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

21 (4) 4-DR & (1) 5-DR 54'-2 1/8" 30,828 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

22 (3) 4-DR & (2) 5-DR 56'-8 9/16" 32,296 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

23 (2) 4-DR & (3) 5-DR 59'-3" 33,764 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

24 (1) 4-DR & (4) 5-DR 61'-9 7/16" 35,232 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

25 (5) 5-DR 64'-3 7/8" 36,700 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

26 (4) 4-DR & (2) 5-DR 66'-11 1/2" 38,168 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

27 (3) 4-DR & (3) 5-DR 69'-5 15/16" 39,636 5/8 5/8 7/8 1 3/8 1 5/8 1 5/8

28 (2) 4-DR & (4) 5-DR 72'-3/8" 41,104 5/8 5/8 7/8 1 3/8 1 5/8 1 5/8

29 (1) 4-DR & (5) 5-DR 74'-6 13/16" 42,572 5/8 5/8 7/8 1 3/8 1 5/8 1 5/8

30 (6) 5-DR 77'-1 1/4" 44,040 5/8 7/8 7/8 1 3/8 1 5/8 2 1/8

FREEZER

COMBINATIONS

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

INDICATES VERTI

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

RMZC30, RMZP30, RMZP24

Page 15

REMOTE REACH-IN FREEZER W/ 30" X 63" DOORS

NO. OF

BTU/HR

Table 2

12

MODEL RMZC30 & RMZP30

REFRIGERANT R-502, R-404a, R-507 @ -18° F

EVAPORATOR FOR ICE CREAM

DOOR

S

2 (1) 2-DR 5'-7 1/16" 3,393 3/8 3/8 3/8 5/8 7/8 7/8

3 (1) 3-DR 8'-1 1/2" 4,922 3/8 3/8 3/8 7/8 7/8 7/8

4 (1) 4-DR 10'-7 15/16" 6,396 3/8 3/8 3/8 7/8 7/8 7/8

5 (1) 5-DR 13'-2 3/8" 7,970 3/8 3/8 3/8 7/8 7/8 1 1/8

6 (2) 3-DR 15'-10" 9,564 3/8 3/8 3/8 7/8 1 1/8 1 1/8

7 (1) 3-DR & (1) 4-DR 18'-4 7/16" 11,158 3/8 3/8 1/2 7/8 1 1/8 1 1/8

8 (2) 4-DR 20'-10 7/8" 12,752 3/8 3/8 1/2 1 1/8 1 1/8 1 1/8

9 (1) 4-DR & (1) 5-DR 23'-5 5/16" 14,346 3/8 1/2 1/2 1 1/8 1 1/8 1 3/8

10 (2) 5-DR 25'-11 3/4" 15,940 3/8 1/2 1/2 1 1/8 1 1/8 1 3/8

11 (1) 3-DR & (2) 4-DR 28'-7 3/8" 17,534 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

12 (3) 4-DR 31'-1 13/16" 19,128 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

13 (2) 4-DR & (1) 5-DR 33'-8 1/4" 20,722 1/2 1/2 1/2 1 1/8 1 3/8 1 3/8

14 (1) 4-DR & (2) 5-DR 36'-2 11/16" 22,316 1/2 1/2 5/8 1 1/8 1 3/8 1 3/8

15 (3) 5-DR 38'-9 1/8" 23,910 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

16 (4) 4-DR 41'-4 3/4" 25,504 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

17 (3) 4-DR & (1) 5-DR 43'-11 3/16" 27,098 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

18 (2) 4-DR & (2) 5-DR 46'-5 5/8" 28,692 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

19 (1) 4-DR & (3) 5-DR 49'-1 1/16" 30,286 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

20 (4) 5-DR 51'-6 1/2" 31,880 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

21 (4) 4-DR & (1) 5-DR 54'-2 1/8" 33,474 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

22 (3) 4-DR & (2) 5-DR 56'-8 9/16" 35,068 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

23 (2) 4-DR & (3) 5-DR 59'-3" 36,662 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

24 (1) 4-DR & (4) 5-DR 61'-9 7/16" 38,256 1/2 5/8 5/8 1 3/8 1 5/8 2 1/8

25 (5) 5-DR 64'-3 7/8" 39,850 5/8 5/8 7/8 1 3/8 1 5/8 2 1/8

26 (4) 4-DR & (2) 5-DR 66'-11 1/2" 41,444 5/8 5/8 7/8 1 3/8 1 5/8 2 1/8

27 (3) 4-DR & (3) 5-DR 69'-5 15/16" 43,038 5/8 5/8 7/8 1 5/8 1 5/8 2 1/8

28 (2) 4-DR & (4) 5-DR 72'-3/8" 44,632 5/8 5/8 7/8 1 5/8 1 5/8 2 1/8

29 (1) 4-DR & (5) 5-DR 74'-6 13/16" 46,226 5/8 5/8 7/8 1 5/8 2 1/8 2 1/8

30 (6) 5-DR 77'-1 1/4" 47,820 5/8 5/8 7/8 1 5/8 2 1/8 2 1/8

FREEZER

COMBINATIONS

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

INDICATES VERTIC

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

Page 16

INDICATES VERTIC

EVAPORATOR FOR FROZEN FOOD

BTU/HR

Table 3

13

REMOTE REACH-IN FREEZER W/ 30" X 63" DOORS

MODEL RMZC30 & RMZP30

REFRIGERANT R-22 @ -11° F

NO.

OF

DOOR

S

2 (1) 2-DR 5'-7 1/16" 3,141 3/8 3/8 3/8 5/8 5/8 5/8

3 (1) 3-DR 8'-1 1/2" 4,544 3/8 3/8 3/8 5/8 7/8 7/8

4 (1) 4-DR 10'-7 15/16" 5,892 3/8 3/8 3/8 5/8 7/8 7/8

5 (1) 5-DR 13'-2 3/8" 7,340 3/8 3/8 3/8 7/8 7/8 7/8

6 (2) 3-DR 15'-10" 8,808 3/8 3/8 3/8 7/8 7/8 7/8

7 (1) 3-DR & (1) 4-DR 18'-4 7/16" 10,276 3/8 3/8 3/8 7/8 7/8 1 1/8

8 (2) 4-DR 20'-10 7/8" 11,744 3/8 3/8 3/8 7/8 1 1/8 1 1/8

9 (1) 4-DR & (1) 5-DR 23'-5 5/16" 13,212 3/8 3/8 3/8 7/8 1 1/8 1 1/8

10 (2) 5-DR 25'-11 3/4" 14,680 3/8 3/8 3/8 7/8 1 1/8 1 1/8

11 (1) 3-DR & (2) 4-DR 28'-7 3/8" 16,148 3/8 3/8 3/8 7/8 1 1/8 1 1/8

12 (3) 4-DR 31'-1 13/16" 17,616 3/8 3/8 1/2 1 1/8 1 1/8 1 1/8

13 (2) 4-DR & (1) 5-DR 33'-8 1/4" 19,084 3/8 3/8 1/2 1 1/8 1 1/8 1 3/8

14 (1) 4-DR & (2) 5-DR 36'-2 11/16" 20,552 3/8 3/8 1/2 1 1/8 1 1/8 1 3/8

15 (3) 5-DR 38'-9 1/8" 22,020 3/8 1/2 1/2 1 1/8 1 1/8 1 3/8

16 (4) 4-DR 41'-4 3/4" 23,488 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

17 (3) 4-DR & (1) 5-DR 43'-11 3/16" 24,956 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

18 (2) 4-DR & (2) 5-DR 46'-5 5/8" 26,424 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

19 (1) 4-DR & (3) 5-DR 49'-1 1/16" 27,892 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

20 (4) 5-DR 51'-6 1/2" 29,360 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

21 (4) 4-DR & (1) 5-DR 54'-2 1/8" 30,828 1/2 1/2 1/2 1 1/8 1 3/8 1 3/8

22 (3) 4-DR & (2) 5-DR 56'-8 9/16" 32,296 1/2 1/2 5/8 1 1/8 1 3/8 1 3/8

23 (2) 4-DR & (3) 5-DR 59'-3" 33,764 1/2 1/2 5/8 1 1/8 1 3/8 1 5/8

24 (1) 4-DR & (4) 5-DR 61'-9 7/16" 35,232 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

25 (5) 5-DR 64'-3 7/8" 36,700 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

26 (4) 4-DR & (2) 5-DR 66'-11 1/2" 38,168 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

27 (3) 4-DR & (3) 5-DR 69'-5 15/16" 39,636 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

28 (2) 4-DR & (4) 5-DR 72'-3/8" 41,104 1/2 5/8 5/8 1 3/8 1 3/8 1 5/8

29 (1) 4-DR & (5) 5-DR 74'-6 13/16" 42,572 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

30 (6) 5-DR 77'-1 1/4" 44,040 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

FREEZER

COMBINATIONS

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

Page 17

NO. OF

EVAPORATOR FOR ICE CREAM

BTU/HR

Table 4

14

REMOTE REACH-IN FREEZER W/ 30" X 63" DOORS

MODEL RMZC30 & RMZP30

REFRIGERANT R-22 @ -18° F

FREEZER

DOORS

10 (2) 5-DR 25'-11 3/4" 15,940 3/8 3/8 3/8 1 1/8 1 1/8 1 3/8

11 (1) 3-DR & (2) 4-DR 28'-7 3/8" 17,534 3/8 3/8 1/2 1 1/8 1 1/8 1 3/8

12 (3) 4-DR 31'-1 13/16" 19,128 3/8 3/8 1/2 1 1/8 1 1/8 1 3/8

13 (2) 4-DR & (1) 5-DR 33'-8 1/4" 20,722 3/8 3/8 1/2 1 1/8 1 3/8 1 3/8

14 (1) 4-DR & (2) 5-DR 36'-2 11/16" 22,316 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

15 (3) 5-DR 38'-9 1/8" 23,910 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

16 (4) 4-DR 41'-4 3/4" 25,504 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

17 (3) 4-DR & (1) 5-DR 43'-11 3/16" 27,098 3/8 1/2 1/2 1 1/8 1 3/8 1 3/8

18 (2) 4-DR & (2) 5-DR 46'-5 5/8" 28,692 3/8 1/2 1/2 1 1/8 1 3/8 1 5/8

19 (1) 4-DR & (3) 5-DR 49'-1 1/16" 30,286 3/8 1/2 1/2 1 3/8 1 3/8 1 5/8

20 (4) 5-DR 51'-6 1/2" 31,880 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

21 (4) 4-DR & (1) 5-DR 54'-2 1/8" 33,474 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

22 (3) 4-DR & (2) 5-DR 56'-8 9/16" 35,068 1/2 1/2 5/8 1 3/8 1 3/8 1 5/8

23 (2) 4-DR & (3) 5-DR 59'-3" 36,662 1/2 1/2 5/8 1 3/8 1 5/8 1 5/8

24 (1) 4-DR & (4) 5-DR 61'-9 7/16" 38,256 1/2 1/2 5/8 1 3/8 1 5/8 1 5/8

25 (5) 5-DR 64'-3 7/8" 39,850 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

26 (4) 4-DR & (2) 5-DR 66'-11 1/2" 41,444 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

27 (3) 4-DR & (3) 5-DR 69'-5 15/16" 43,038 1/2 5/8 5/8 1 3/8 1 5/8 1 5/8

28 (2) 4-DR & (4) 5-DR 72'-3/8" 44,632 1/2 5/8 5/8 1 3/8 1 5/8 2 1/8

29 (1) 4-DR & (5) 5-DR 74'-6 13/16" 46,226 1/2 5/8 5/8 1 3/8 1 5/8 2 1/8

30 (6) 5-DR 77'-1 1/4" 47,820 1/2 5/8 5/8 1 3/8 1 5/8 2 1/8

COMBINATIONS

2 (1) 2-DR 5'-7 1/16" 3,393 3/8 3/8 3/8 5/8 5/8 7/8

3 (1) 3-DR 8'-1 1/2" 4,922 3/8 3/8 3/8 5/8 7/8 7/8

4 (1) 4-DR 10'-7 15/16" 6,396 3/8 3/8 3/8 7/8 7/8 7/8

5 (1) 5-DR 13'-2 3/8" 7,970 3/8 3/8 3/8 7/8 7/8 1 1/8

6 (2) 3-DR 15'-10" 9,564 3/8 3/8 3/8 7/8 7/8 1 1/8

7 (1) 3-DR & (1) 4-DR 18'-4 7/16" 11,158 3/8 3/8 3/8 7/8 1 1/8 1 1/8

8 (2) 4-DR 20'-10 7/8" 12,752 3/8 3/8 3/8 7/8 1 1/8 1 1/8

9 (1) 4-DR & (1) 5-DR 23'-5 5/16" 14,346 3/8 3/8 3/8 7/8 1 1/8 1 1/8

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

INDICATES VERTIC

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

Page 18

INDICATES VERTIC

EVAPORATOR FOR FROZEN FOOD

NO. OF

BTU/HR

Table 5

15

REMOTE REACH-IN FREEZER W/ 24" X 63" DOORS

MODEL RMZP24

REFRIGERANT R-502, R-404a, R-507 @ -14° F

FREEZER

DOORS

10 (2) 5-DR 20'-11 1/4" 13,250 3/8 1/2 1/2 7/8 1.1/8 1.1/8

11 (1) 3-DR & (2) 4-DR 22'-10 3/8" 14,575 3/8 1/2 1/2 7/8 1.1/8 1.1/8

12 (3) 4-DR 25'-3 1/4" 15,900 3/8 1/2 1/2 1.1/8 1.1/8 1.1/8

13 (2) 4-DR & (1) 5-DR 27'-2 7/8" 17,225 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

14 (1) 4-DR & (2) 5-DR 29'-2 5/8" 18,550 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

15 (3) 5-DR 31'-2 3/8" 19,875 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

16 (4) 4-DR 33'-6 1/2" 21,200 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

17 (3) 4-DR & (1) 5-DR 35'-6 1/4" 22,525 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

18 (2) 4-DR & (2) 5-DR 37'-6" 23,850 1/2 1/2 5/8 1.1/8 1.3/8 1.3/8

19 (1) 4-DR & (3) 5-DR 39'-5 3/4" 25,175 1/2 1/2 5/8 1.1/8 1.3/8 1.3/8

20 (4) 5-DR 41'-1/2" 26,500 1/2 1/2 5/8 1.1/8 1.3/8 1.3/8

21 (4) 4-DR & (1) 5-DR 43'-9 5/8" 27,825 1/2 1/2 5/8 1.1/8 1.3/8 1.3/8

22 (3) 4-DR & (2) 5-DR 45'-9 3/8" 29,150 1/2 5/8 5/8 1.3/8 1.3/8 1.5/8

23 (2) 4-DR & (3) 5-DR 47'-9 1/8" 30,475 1/2 5/8 5/8 1.3/8 1.3/8 1.5/8

24 (1) 4-DR & (4) 5-DR 49'-8 7/8" 31,800 1/2 5/8 5/8 1.3/8 1.3/8 1.5/8

25 (5) 5-DR 51'-8 5/8" 33,125 1/2 5/8 5/8 1.3/8 1.3/8 1.5/8

26 (4) 4-DR & (2) 5-DR 54'-3/4" 34,450 1/2 5/8 5/8 1.3/8 1.3/8 1.5/8

27 (3) 4-DR & (3) 5-DR 56'-1/2" 35,775 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

28 (2) 4-DR & (4) 5-DR 58'-1/4" 37,100 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

29 (1) 4-DR & (5) 5-DR 60'-0" 38,425 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

30 (6) 5-DR 61'-11 3/4" 39,750 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

COMBINATIONS

2 (1) 2-DR 4'-8 7/8" 3,375 3/8 3/8 3/8 5/8 5/8 7/8

3 (1) 3-DR 6'-8 5/8" 4,455 3/8 3/8 3/8 5/8 7/8 7/8

4 (1) 4-DR 8'-8 3/8" 5,530 3/8 3/8 3/8 7/8 7/8 7/8

5 (1) 5-DR 10'-8 1/8" 6,625 3/8 3/8 3/8 7/8 7/8 7/8

6 (2) 3-DR 13'-1/4" 7,950 3/8 3/8 3/8 7/8 7/8 7/8

7 (1) 3-DR & (1) 4-DR 15'-0" 9,275 3/8 3/8 3/8 7/8 7/8 1.1/8

8 (2) 4-DR 16'-11 3/4" 10,600 3/8 1/2 1/2 7/8 1.1/8 1.1/8

9 (1) 4-DR & (1) 5-DR 18'-11 1/2" 11,925 3/8 1/2 1/2 7/8 1.1/8 1.1/8

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

Page 19

INDICATES VERTIC

REMOTE REACH-IN FREEZER W/ 24" X 63" DOORS

EVAPORATOR FOR ICE CREAM

NO. OF

BTU/HR

Table 6

16

MODEL RMZP24

REFRIGERANT R-502, R-404a, R-507 @ -20° F

FREEZER

DOORS

COMBINATIONS

2 (1) 2-DR 4'-8 7/8" 3,620 3/8 3/8 3/8 5/8 7/8 7/8

3 (1) 3-DR 6'-8 5/8" 4,775 3/8 3/8 3/8 7/8 7/8 7/8

4 (1) 4-DR 8'-8 3/8" 5,930 3/8 3/8 3/8 7/8 7/8 7/8

5 (1) 5-DR 10'-8 1/8" 7,100 3/8 3/8 3/8 7/8 7/8 1.1/8

6 (2) 3-DR 13'-1/4" 8,520 3/8 3/8 3/8 7/8 1.1/8 1.1/8

7 (1) 3-DR & (1) 4-DR 15'-0" 9,940 3/8 1/2 1/2 7/8 1.1/8 1.1/8

8 (2) 4-DR 16'-11 3/4" 11,360 3/8 1/2 1/2 7/8 1.1/8 1.1/8

9 (1) 4-DR & (1) 5-DR 18'-11 1/2" 12,780 3/8 1/2 1/2 1.1/8 1.1/8 1.1/8

10 (2) 5-DR 20'-11 1/4" 14,200 3/8 1/2 1/2 1.1/8 1.1/8 1.3/8

11 (1) 3-DR & (2) 4-DR 22'-10 3/8" 15,620 3/8 1/2 1/2 1.1/8 1.1/8 1.3/8

12 (3) 4-DR 25'-3 1/4" 17,040 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

13 (2) 4-DR & (1) 5-DR 27'-2 7/8" 18,460 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

14 (1) 4-DR & (2) 5-DR 29'-2 5/8" 19,880 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

15 (3) 5-DR 31'-2 3/8" 21,300 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

16 (4) 4-DR 33'-6 1/2" 22,720 1/2 1/2 5/8 1.1/8 1.3/8 1.3/8

17 (3) 4-DR & (1) 5-DR 35'-6 1/4" 24,140 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

18 (2) 4-DR & (2) 5-DR 37'-6" 25,560 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

19 (1) 4-DR & (3) 5-DR 39'-5 3/4" 26,980 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

20 (4) 5-DR 41'-1/2" 28,400 1/2 5/8 5/8 1.3/8 1.3/8 1.5/8

21 (4) 4-DR & (1) 5-DR 43'-9 5/8" 29,820 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

22 (3) 4-DR & (2) 5-DR 45'-9 3/8" 31,240 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

23 (2) 4-DR & (3) 5-DR 47'-9 1/8" 32,660 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

24 (1) 4-DR & (4) 5-DR 49'-8 7/8" 34,080 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

25 (5) 5-DR 51'-8 5/8" 35,500 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

26 (4) 4-DR & (2) 5-DR 54'-3/4" 36,920 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

27 (3) 4-DR & (3) 5-DR 56'-1/2" 38,340 1/2 5/8 5/8 1.3/8 1.5/8 2.1/8

28 (2) 4-DR & (4) 5-DR 58'-1/4" 39,760 1/2 5/8 5/8 1.3/8 1.5/8 2.1/8

29 (1) 4-DR & (5) 5-DR 60'-0" 41,180 5/8 5/8 5/8 1.3/8 1.5/8 2.1/8

30 (6) 5-DR 61'-11 3/4" 42,600 5/8 5/8 7/8 1.5/8 1.5/8 2.1/8

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

Page 20

EVAPORATOR FOR FROZEN FOOD

REMOTE REACH-IN FREEZER W/ 24" X 63" DOORS

BTU/HR

Table 7

MODEL RMZP24

REFRIGERANT R-22 @ -14° F

NO. OF

DOORS

2 (1) 2-DR 4'-8 7/8" 3,375 3/8 3/8 3/8 5/8 5/8 5/8

3 (1) 3-DR 6'-8 5/8" 4,455 3/8 3/8 3/8 5/8 7/8 7/8

4 (1) 4-DR 8'-8 3/8" 5,530 3/8 3/8 3/8 5/8 7/8 7/8

5 (1) 5-DR 10'-8 1/8" 6,625 3/8 3/8 3/8 7/8 7/8 7/8

6 (2) 3-DR 13'-1/4" 7,950 3/8 3/8 3/8 7/8 7/8 7/8

7 (1) 3-DR & (1) 4-DR 15'-0" 9,275 3/8 3/8 3/8 7/8 7/8 7/8

8 (2) 4-DR 16'-11 3/4" 10,600 3/8 3/8 3/8 7/8 7/8 1.1/8

9 (1) 4-DR & (1) 5-DR 18'-11 1/2" 11,925 3/8 3/8 1/2 7/8 7/8 1.1/8

10 (2) 5-DR 20'-11 1/4" 13,250 3/8 3/8 1/2 7/8 1.1/8 1.1/8

11 (1) 3-DR & (2) 4-DR 22'-10 3/8" 14,575 3/8 1/2 1/2 7/8 1.1/8 1.1/8

12 (3) 4-DR 25'-3 1/4" 15,900 3/8 1/2 1/2 1.1/8 1.1/8 1.1/8

13 (2) 4-DR & (1) 5-DR 27'-2 7/8" 17,225 3/8 1/2 1/2 1.1/8 1.1/8 1.1/8

14 (1) 4-DR & (2) 5-DR 29'-2 5/8" 18,550 3/8 1/2 1/2 1.1/8 1.1/8 1.1/8

15 (3) 5-DR 31'-2 3/8" 19,875 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

16 (4) 4-DR 33'-6 1/2" 21,200 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

17 (3) 4-DR & (1) 5-DR 35'-6 1/4" 22,525 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

18 (2) 4-DR & (2) 5-DR 37'-6" 23,850 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

19 (1) 4-DR & (3) 5-DR 39'-5 3/4" 25,175 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

20 (4) 5-DR 41'-1/2" 26,500 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

21 (4) 4-DR & (1) 5-DR 43'-9 5/8" 27,825 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

22 (3) 4-DR & (2) 5-DR 45'-9 3/8" 29,150 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

23 (2) 4-DR & (3) 5-DR 47'-9 1/8" 30,475 1/2 1/2 1/2 1.3/8 1.3/8 1.3/8

24 (1) 4-DR & (4) 5-DR 49'-8 7/8" 31,800 1/2 1/2 1/2 1.3/8 1.3/8 1.3/8

25 (5) 5-DR 51'-8 5/8" 33,125 1/2 1/2 1/2 1.3/8 1.3/8 1.3/8

26 (4) 4-DR & (2) 5-DR 54'-3/4" 34,450 1/2 1/2 1/2 1.3/8 1.3/8 1.3/8

27 (3) 4-DR & (3) 5-DR 56'-1/2" 35,775 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

28 (2) 4-DR & (4) 5-DR 58'-1/4" 37,100 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

29 (1) 4-DR & (5) 5-DR 60'-0" 38,425 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

30 (6) 5-DR 61'-11 3/4" 39,750 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

FREEZER

COMBINATIONS

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

Page 21

EVAPORATOR FOR ICE CREAM

REMOTE REACH-IN FREEZER W/ 24" X 63" DOORS

NO. OF

BTU/HR

Table 8

18

MODEL RMZP24

REFRIGERANT R-22 @ -20° F

FREEZER

DOORS

COMBINATIONS

2 (1) 2-DR 4'-8 7/8" 3,620 3/8 3/8 3/8 5/8 7/8 7/8

3 (1) 3-DR 6'-8 5/8" 4,775 3/8 3/8 3/8 5/8 7/8 7/8

4 (1) 4-DR 8'-8 3/8" 5,930 3/8 3/8 3/8 7/8 7/8 7/8

5 (1) 5-DR 10'-8 1/8" 7,100 3/8 3/8 3/8 7/8 7/8 7/8

6 (2) 3-DR 13'-1/4" 8,520 3/8 3/8 3/8 7/8 7/8 1.1/8

7 (1) 3-DR & (1) 4-DR 15'-0" 9,940 3/8 3/8 1/2 7/8 1.1/8 1.1/8

8 (2) 4-DR 16'-11 3/4" 11,360 3/8 3/8 1/2 7/8 1.1/8 1.1/8

9 (1) 4-DR & (1) 5-DR 18'-11 1/2" 12,780 3/8 3/8 1/2 7/8 1.1/8 1.1/8

10 (2) 5-DR 20'-11 1/4" 14,200 3/8 1/2 1/2 7/8 1.1/8 1.1/8

11 (1) 3-DR & (2) 4-DR 22'-10 3/8" 15,620 3/8 1/2 1/2 1.1/8 1.1/8 1.1/8

12 (3) 4-DR 25'-3 1/4" 17,040 3/8 1/2 1/2 1.1/8 1.1/8 1.3/8

13 (2) 4-DR & (1) 5-DR 27'-2 7/8" 18,460 1/2 1/2 1/2 1.1/8 1.1/8 1.3/8

14 (1) 4-DR & (2) 5-DR 29'-2 5/8" 19,880 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

15 (3) 5-DR 31'-2 3/8" 21,300 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

16 (4) 4-DR 33'-6 1/2" 22,720 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

17 (3) 4-DR & (1) 5-DR 35'-6 1/4" 24,140 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

18 (2) 4-DR & (2) 5-DR 37'-6" 25,560 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

19 (1) 4-DR & (3) 5-DR 39'-5 3/4" 26,980 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

20 (4) 5-DR 41'-1/2" 28,400 1/2 1/2 1/2 1.1/8 1.3/8 1.3/8

21 (4) 4-DR & (1) 5-DR 43'-9 5/8" 29,820 1/2 1/2 1/2 1.3/8 1.3/8 1.5/8

22 (3) 4-DR & (2) 5-DR 45'-9 3/8" 31,240 1/2 1/2 1/2 1.3/8 1.3/8 1.5/8

23 (2) 4-DR & (3) 5-DR 47'-9 1/8" 32,660 1/2 1/2 1/2 1.3/8 1.3/8 1.5/8

24 (1) 4-DR & (4) 5-DR 49'-8 7/8" 34,080 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

25 (5) 5-DR 51'-8 5/8" 35,500 1/2 1/2 5/8 1.3/8 1.3/8 1.5/8

26 (4) 4-DR & (2) 5-DR 54'-3/4" 36,920 1/2 1/2 5/8 1.3/8 1.5/8 1.5/8

27 (3) 4-DR & (3) 5-DR 56'-1/2" 38,340 1/2 1/2 5/8 1.3/8 1.5/8 1.5/8

28 (2) 4-DR & (4) 5-DR 58'-1/4" 39,760 1/2 1/2 5/8 1.3/8 1.5/8 1.5/8

29 (1) 4-DR & (5) 5-DR 60'-0" 41,180 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

30 (6) 5-DR 61'-11 3/4" 42,600 1/2 5/8 5/8 1.3/8 1.5/8 1.5/8

TOTAL

LENGTH

W/ENDS

RECOMMENDED

LIQUID LINE SIZES

EQUIVALENT LENGTH, FEET

50 100 150 50 100 150

RECOMMENDED

SUCTION LINE SIZES

EQUIVALENT LENGTH, FEET

NOTE: BTU RATINGS FOR T-8 ELECTRONIC LIGHTING SYSTEM. ADD 30 BTU/DOOR FOR T-10

LIGHTING. DEDUCT 57 BTU/HR PER DOOR FOR PSC FANS. CASES DESIGNED TO OPERATE IN AN

AMBIENT OF 75°F OR LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER. SHADED CELL

INDICATES VERTIC

AL SUCTION RISERS NEED TO BE ONE SIZE SMALLER THAN SIZE SHOWN

RMZC30, RMZP30, RMZP24

Page 22

19

Figure 10

RMZC30 SPECIFICATION SHEET

* NOTE: CASE DIMENSIONS SHOWN REFLECT STANDARD 4-1/2” HIGH BASES

DIMENSIONS SHOWN IN (PARENTHESIS) REFLECT 3-1/2” BASES.

Front View

Partial Side View

(Bottom)

Zero Zone, Inc. l 110 N. Oakridge Dr.

North Prairie, WI 53153-9792

1-800-247-4496 l FAX: 1-414-392-6450

www.zero-zone.com

Side View

All specifications are subject to change without notice.

RMZC30, RMZP30, RMZP24

Page 23

NUMBER

LINE O.D.

LINE O.D.

OUT TOP BACK

SIZES FOR ELECTRIC DEFROST

SIZES FOR HOT GAS DEFROST

1.5

2.25

5.52

6.73

7.83

10.09

9.84

13.46

12.05

16.83

ELECTRICAL SPECS. BY DOOR MANUFACTURER

VOLTAGE: 115 VOLTS 1 PHASE 60 HZ.

5RMZC30

1.70

BTU/HR ENERGY REQUIREMENTS: FROZEN FOOD -11°F EVAPORATOR (-5°F AVERAGE PRODUCT TEMPERATURE)

NUMBER

BTU/HR @

-11°F

-18°F

CASE DESIGNED TO OPERATE IN AN AMBIENT OF 75°F OR LOWER

DEDUCT 57 BTU/HR/DOOR FOR PSC FAN MOTORS

SYSTEM. MULTIPLY BY 1.04 FOR CONVENTIONAL SYSTEM.

*WEIGHT BASED ON UNCRATED CASES

SINGLE END WEIGHT: 54 POUNDS

WEIGHT IN

CASE

5RMZC30

2RMZC30

4RMZC30

125

68

5RMZC30

2RMZC30

3RMZC30

4RMZC30

Figure 10

RMZC30 SPECIFICATION SHEET

REFRIGERANT CONNECTIONS

SUCTION

LINE O.D. FOR

MODEL

SUCTION

LIQUID

REFRIGERATION

2RMZC30 7/8 3/8 5/8

3RMZC30 7/8 3/8 5/8

4RMZC30 7/8 3/8 7/8

5RMZC30 7/8 3/8 7/8

MODEL

NUMBER

FANS

AMPS

T-8

LIGHTS

AMPS

T-10

LIGHT

AMPS

ONE

END*

T-10

LIGHT

AMPS

BOTH

ENDS

ANTI-

SWEAT

HEATERS

DEFROST

HEATER

AMPS

208V/1/60HZ.

ANTHONY DOORS

2RMZC30 0.68 1.45 1.5 2.25 4.42 6.73

3RMZC30 1.02 1.94 2.25 3 6.44 10.09

4RMZC30 1.36 2.42 3 3.75 8.32 13.46

5RMZC30 1.70 2.91 3.75 4.5 10.16 16.83

ARDCO DOORS

2RMZC30 0.68

3RMZC30 1.02

4RMZC30 1.36

5RMZC30 1.70

SUBTRACT 0.19 AMPS PER DOOR FOR PSC FAN MOTORS

1.89

2.34 2.25 3

3.06 3 3.75

3.51 3.75 4.5

*STANDARD FOR CASE IN A LINE-UP

REFRIGERANT CONNECTIONS

SUCTION

LINE O.D. FOR

MODEL

NUMBER

SUCTION

LINE O.D.

LIQUID

LINE O.D.

REFRIGERATION

OUT TOP BACK

2RMZC30 7/8 1/2 5/8

3RMZC30 7/8 1/2 5/8

4RMZC30 7/8 1/2 7/8

5RMZC30 7/8 1/2 7/8

CAPACITY

SPECIFICATIONS

CAPACITIES

VERTICAL

SURFACE

CASE

SIZE

CUBIC FEET

SIZE

3RMZC30

USABLE

51 28

76 41

100 55

POUNDS*

SQUARE

FOOTAGE

788

1,096

1,468

1,870

WITHOUT ENDS, AND FULLY SHELVED.

ICE CREAM -18°F EVAPORATOR (-12°F AVERAGE PRODUCT TEMPERATURE)

MODEL

2RMZC30 3,141 3,393

3RMZC30 4,544 4,922

4RMZC30 5,892 6,396 AND RELATIVE HUMIDITY OF 55% OR LOWER.

5RMZC30

7,340 7,970

BTU/HR @

BTU/HR RATING BASED ON T-8 LIGHTING AND PARALLEL RACK

ADD 30 BTU/HR PER DOOR FOR T-10 LIGHTING

Zero Zone, Inc. l 110 N. Oakridge Dr.

North Prairie, WI 53153-9792

1-800-247-4496 l FAX: 1-414-392-6450

www.zero-zone.com

All specifications are subject to change without notice.

RMZC30, RMZP30, RMZP24

Page 24

Figure 11

21

RMZP30 SPECIFICATION SHEET

* NOTE: CASE DIMENSIONS SHOWN REFLECT STANDARD 4-1/2” HIGH BASES

DIMENSIONS SHOWN IN (PARENTHESIS) REFLECT 3-1/2” BASES.

Front View

Partial Side View

(Bottom)

Zero Zone, Inc. l 110 N. Oakridge Dr.

North Prairie, WI 53153-9792

1-800-247-4496 l FAX: 1-262-392-6450

www.zero-zone.com

Side View

All specifications are subject to change without notice.

RMZC30, RMZP30, RMZP24

Page 25

NUMBER

LINE O.D.

LINE O.D.

OUT TOP BACK

SIZES FOR ELECTRIC DEFROST

NUMBER

LINE O.D.

LINE O.D.

OUT TOP BACK

SIZES FOR HOT GAS DEFROST

1.5

2.25

5.52

6.73

7.83

10.09

9.84

13.46

12.05

16.83

ELECTRICAL SPECS. BY DOOR MANUFACTURER

VOLTAGE: 115 VOLTS 1 PHASE 60 HZ.

BTU/HR ENERGY REQUIREMENTS: FROZEN FOOD -11°F EVAPORATOR (-3°F AVERAGE PRODUCT TEMPERATURE)

ICE CREAM -18°F EVAPORATOR (-10°F AVERAGE PRODUCT TEMPERATURE)

NUMBER

BTU/HR @

-11°F

-18°F

CASE DESIGNED TO OPERATE IN AN AMBIENT OF 75°F OR LOWER

DEDUCT 57 BTU/HR/DOOR FOR PSC FAN MOTORS

SYSTEM. MULTIPLY BY 1.04 FOR CONVENTIONAL SYSTEM.

*WEIGHT BASED ON UNCRATED CASES

SINGLE END WEIGHT: 54 POUNDS

WEIGHT IN

CASE

5RMZP30

3RMZP30

4RMZP30

5RMZP30

2RMZP30

3RMZP30

4RMZP30

Figure 11

22

RMZP30 SPECIFICATION SHEET

REFRIGERANT CONNECTIONS

SUCTION

LINE O.D. FOR

MODEL

SUCTION

LIQUID

REFRIGERATION

2RMZP30 7/8 3/8 5/8

3RMZP30 7/8 3/8 5/8

4RMZP30 7/8 3/8 7/8

5RMZP30 7/8 3/8 7/8

MODEL

NUMBER

FANS

AMPS

T-8

LIGHTS

AMPS

T-10

LIGHT

AMPS

ONE

END*

T-10

LIGHT

AMPS

BOTH

ENDS

ANTI-

SWEAT

HEATERS

DEFROST

HEATER

AMPS

208V/1/60HZ.

ANTHONY DOORS

2RMZP30 0.68 1.45 1.5 2.25 4.42 6.73

3RMZP30 1.02 1.94 2.25 3 6.44 10.09

4RMZP30 1.36 2.42 3 3.75 8.32 13.46

5RMZP30 1.70 2.91 3.75 4.5 10.16 16.83

ARDCO DOORS

2RMZP30 0.68

3RMZP30 1.02

4RMZP30 1.36

5RMZP30 1.70

SUBTRACT 0.19 AMPS PER DOOR FOR PSC FAN MOTORS

1.89

2.34 2.25 3

3.06 3 3.75

3.51 3.75 4.5

*STANDARD FOR CASE IN A LINE-UP

REFRIGERANT CONNECTIONS

SUCTION

LINE O.D. FOR

MODEL

SUCTION

LIQUID

REFRIGERATION

2RMZP30 7/8 1/2 5/8

3RMZP30 7/8 1/2 5/8

4RMZP30 7/8 1/2 7/8

5RMZP30 7/8 1/2 7/8

CAPACITY

SPECIFICATIONS

CAPACITIES

VERTICAL

SURFACE

CASE

SIZE

CUBIC FEET

SIZE

2RMZP30

USABLE

54 28

81 41

107 55

134 68

POUNDS*

SQUARE

FOOTAGE

721

1,043

1,406

1,876

WITHOUT ENDS, AND FULLY SHELVED.

MODEL

2RMZP30 3,141 3,393

3RMZP30 4,544 4,922

4RMZP30 5,892 6,396 AND RELATIVE HUMIDITY OF 55% OR LOWER.

5RMZP30 7,340 7,970

BTU/HR @

BTU/HR RATING BASED ON T-8 LIGHTING AND PARALLEL RACK

ADD 30 BTU/HR PER DOOR FOR T-10 LIGHTING

Zero Zone, Inc. l 110 N. Oakridge Dr.

North Prairie, WI 53153-9792

1-800-247-4496 l FAX: 1-262-392-6450

www.zero-zone.com

All specifications are subject to change without notice.

RMZC30, RMZP30, RMZP24

Page 26

Figure 12

RMZP24 SPECIFICATION SHEET

Front View

Top View

Shown in Section

5RMZP24

Zero Zone Inc. l 110 N. Oakridge Dr.

North Prairie, WI 53153-9792

1-800-247-4496 l FAX: 1-262-392-6450

www.zero-zone.com

Side View

All specifications are subject to change without notice.

RMZC30, RMZP30, RMZP24

Page 27

0.62

1.89

1.56

3.99

5.5

2.2531.94

2.22

1.24

2.25

2.34

5.71

8

2.42

1.86

2.65

3.12

7.47

10

2.91

2.48

3.1

3.9

9.28

12.5

1.65

2.4

1.12

1.9

1.7

4.72

5.5

1.68

2.4

2.55

6.63

8

3.3

4.05

3.06

3.4

2.24

2.7

3.4

8.34

10

2.8

3.1

4.25

10.15

12.5

* STANDARD FOR CASE IN A LINE-UP

DOORS

BTU/HR @

-14°F

BTU/HR @

-20°F

CONVENTIONAL SYSTEM

DEDUCT 57 BTU/HR FOR PSC FAN MOTORS

BTU/HR ENERGY REQUIREMENTS: FROZEN FOOD -14°F EVAP. & ICE CREAM -20°F EVAP.

CAPACITY

SQ. FT.

CUBIC FT.

42.9

567

62.5

820

101.7

1477

SINGLE END WEIGHT: 54#

RMZP24 SPECIFICATION SHEET

LINE O.D.

LINE O.D.

LINE O.D.

LINE O.D.

Figure 12

24

REFRIGERANT CONNECTIONS

HOT GAS DEFROST

TOP

MODEL

SUCTION

LINE O.D.

STANDARD

BOTTOM

SUCTION

BOTTOM

& TOP

LIQUID

RMZP24 CAPACITY

SPECIFICATIONS

SHELVING

CASE

SIZE

24 X 23 1/2"

NET

2 47.0

3 70.6

4 94.1 82.1 1073

5 117.6

WEIGHT BASED ON UNCRATED CASES

WITHOUT ENDS, AND FULLY SHELVED

ELECTRICAL SPECIFICATIONS FOR RMZP24 BY DOOR MANUFACTURER

CASE

MODEL

NUMBER

2RMZP24 0.68 1.5 2.25 1.45

3RMZP24 1.02

4RMZP24 1.36

5RMZP24 1.7

2RMZP24

3RMZP24 1.02

4RMZP24 1.36

5RMZP24 1.7

FANS

AMPS

0.68

CUBIC

FEET

NET

(T-10)

LIGHT

AMPS

ONE

END*

3.75 4.5

2.4 3.3 2.34 2.55

4.05 4.8 3.51 4.25

(T-10)

LIGHT

AMPS

BOTH

ENDS

3 3.75

SUBTRACT 0.19 AMPS PER DOOR FOR PSC FAN MOTORS

WEIGHT*

POUNDS

(T-8)

LIGHT

AMPS

1.89 1.7

2RMZP24 5/8 7/8 3/8

3RMZP24 7/8 7/8 3/8

4RMZP24 7/8 7/8 1/2

5RMZP24 1 1/8 1 1/8 1/2

2RMZP24 5/8 7/8 3/8

3RMZP24 7/8 7/8 3/8

4RMZP24 7/8 7/8 3/8

5RMZP24 1 1/8 1 1/8 3/8

STD.

DOOR

MULLION FRAME

ANTHONY DOORS

1.48

2.96

3.7

ARDCO DOORS

MODEL

REFRIGERANT CONNECTIONS

ELECTRIC DEFROST

TOP

SUCTION

LINE O.D.

FRAMELESS

DOOR

STANDARD

BOTTOM

SUCTION

TOTAL

FRAME

MULLION

STD.

DOOR

BOTTOM

DEFROST

HEATER

AMPS

220V/1/60Hz.

& TOP

LIQUID

VOLTAGE: 115 VOLTS 1 PHASE 60 HZ.

BTU/HR RATING BASED ON 1500 MA. T-10 LIGHTING AND

# OF

2 3375 3620

3 4455 4775

4 5530 5930

5 6625 7100

PARALLEL RACK SYSTEM. MULTIPLY BY 1.04 FOR

CASE DESIGNED TO OPERATE IN AN AMBIENT OF 75°F OR

LOWER AND RELATIVE HUMIDITY OF 55% OR LOWER.

Zero Zone Inc. l 110 N. Oakridge Dr.

North Prairie, WI 53153-9792

1-800-247-4496 l FAX: 1-262-392-6450

www.zero-zone.com

All specifications are subject to change without notice.

RMZC30, RMZP30, RMZP24

Page 28

Figure 14

25

RMZC30, RMZP30, RMZP24 ELECTRIC DEFROST WIRING DIAGRAM

RMZC30, RMZP30, RMZP24

Page 29

Figure 15

26

RMZC30, RMZP30, RMZP24 HOT GAS DEFROST WIRING DIAGRAM

RMZC30, RMZP30, RMZP24

Page 30

Figure 16

27

RMZC30, RMZP30, RMZP24 WIRING DIAGRAM FOR TIME/TEMPERATURE DEFROST

RMZC30, RMZP30, RMZP24

Page 31

1. Coil Cover

28

2. Fan

3. Liquid Line

4. Suction Line

5. Fan Housing

6. Drain Access Cover

7. Heat Exchanger

8. Expansion Valve

9. Heating Element

Fan, Lights, and Door

Heater Limit Thermostat

attached to return

bends

RMZC30, RMZP30 Electric Defrost

Figure 17

RMZC30, RMZP30, RMZP24

Page 32

1. Coil Cover

Fan, Lights, and Door

2. Fan Heater limit Thermostat

3.

Check Valve

4. liquid line

5.

Suction Line

6.

Fan Housing

7.

Drain Access Cover

attached to return

bends

8. Heat Exchanger

9.

Serpentine Coil

10. Expansion

Valve

/-

RMZC30, RMZP30, RMZC24 Hot Gas

Defrost

mure 18

Page 33

LIQUID LINE

29

SUCTION LINE

1. Left Coil Cover

2. Drain Access Cover

3. Center Coil Cover

4. Right Coil Cover

5. Hand Valve (Optional)

6. Expansion Valve

Fan, Lights, and Door

Heater Limit Thermostat

attached to return

bends

7. Heat Exchanger

8. Evaporator Coil

9. Fan Guard

10. Fan Housing Access Cover

11. Fan Blade - Fan Motor

12. Fan Housing

13. Heating Element

RMZP24 Electric Defrost

Figure 19

RMZC30, RMZP30, RMZP24

Page 34

LIQUID LINE

30

SUCTION LINE

1. Left Coil Cover

2. Drain Access Cover

3. Center Coil Cover

4. Right Coil Cover

5. Hand Valve (Optional)

6. Expansion Valve

Fan, Lights, and Door

Heater Limit Thermostat

attached to return

bends

7. Heat Exchanger

8. Evaporator Coil

9. Fan Guard

10. Fan Housing Access Cover

11. Fan Blade - Fan Motor

12. Fan Housing

13. Heating Element

RMZP24 Electric Defrost

Figure 19

RMZC30, RMZP30, RMZP24

Page 35

LIQUID LINE

31

SUCTION LINE

1. Left Coil Cover

2. Drain Access Cover

3. Center Coil Cover

4. Right Coil Cover

5. Hand Valve (Optional)

6. Expansion Valve

7. Check Valve (Hot Gas Defrost Only)

8. Heat Exchanger

9. Evaporator Coil

10. Fan Guard

11. Fan Blade - Fan Motor

12. Fan Housing

13. Serpentine Coil - Hot Gas Defrost

14. Fan Housing Access Cover

Fan, Lights, and Door

Heater Limit Thermostat

attached to return

bends

RMZP24 Hot Gas Defrost

Figure 20

RMZC30, RMZP30, RMZP24

Page 36

1. Limited Warranty. ZERO ZONE, INC. (“Seller”) hereby warrants that any products manufac-

32

tured by it and sold under this Warranty shall be free for a period of one year from the date

of shipment, from defects in material and workmanship which, under normal use and

service would render such products unusable or unserviceable. The obligation of Seller

under this Warranty shall be limited to the repair or replacement of any parts that the Seller

determines are defective. This Limited Warranty does not cover labor, freight, transportation

or other charges incidental to replacement or repair. Parts returned to Seller must be returned freight prepaid and replacements will be returned to the Buyer freight collect.

2. Motor Compressor Extended Warranty. Seller hereby warrants with respect to any motor

compressor sold under this Warranty, exclusive of any and all parts of the condensing unit

assembly thereof, that such motor compressor shall be free from defects in material and

workmanship for a period of four (4) years from the date of the expiration of the one year

Warranty provided by the manufacturer of such motor compressor, if the Buyer purchases

said Warranty at the time of equipment purchase. In the event the motor compressor is

not free from defects in material and/or workmanship during such four year period, Buyer

must purchase a replacement for the defective motor compressor and obtain whatever

salvage credit may be available from the manufacturer thereof. Upon receipt by Seller or

written notice from Buyer of compressor, Seller will issue a purchase or a refund, at Seller’s

option, for an amount of the salvage credit. All labor and shipping charges incurred in

connection with such replacement shall be the sole obligation of the Buyer.

3. Product Not Manufactured by Seller. The written Warranty, if any, provided by the manufacturer of any part of the refrigeration unit sold by Seller to Buyer, but not manufactured by

Seller, is hereby assigned to Buyer. However, Seller makes no representation or Warranty

regarding the existence, validity or enforceability of any such written Warranty.

4. LIMITATION AND EXCLUSION OF WARRANTIES. THE WARRANTIES SET FORTH HEREIN ARE

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES WHATSOEVER, INCLUDING BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR

A PARTICULAR PURPOSE.

5. Consequential Damages. Notwithstanding anything to the contrary set forth in this Warranty Certificate, Seller shall not be liable for any incidental or consequential damages

arising out of, or directly or indirectly caused by a defective part sold by Seller, including but

not limited to, costs arising from the replacement of the part, loss of gas or product, or any

damage to person or property, whether as a result of Seller’s negligence, breach of contract, breach of Warranty or otherwise.

Model No._________________________ Serial No.______________________

RMZC30, RMZP30, RMZP24

Loading...

Loading...