Page 1

y

6200 Porter Road ● Sarasota, FL

y

www.st

By Commercial Refrigerator Door Compan

leline.com

HEAVY DUTY ENTRANCE DOOR

INSTALLATION GUIDE

FORM HDED080721IG

U

NPACK THE FRAME

1. Remove the cardboard from both sides of the frame crate.

2. Orders are sent with frame mounting screws, shims and Installation and Troubleshooting

Manual. Remove and save for later use. Note that hinge adjustment instructions and

adjustment tools are attached to the door in a separate package.

3. Remove the screws holding the frame into the crate.

4. Remove the frame from the crate.

5. Remove the packaging material holding lamps and/or lamp assembly to the frame (if

present) and store lamps and/or lamps flat in an appropriate, out of the way area. Be careful

not to damage any of the lamps or lamp assemblies.

BE CAREFUL NOT TO DAMAGE PINS

ON T-8 FLORESCENT LAMPS.

CAUTION

34240

UNPACK THE DOOR(S)

1. Remove the cardboard from both sides of the door crate.

2. Orders are sent with hinge adjustment instructions and adjustment tools attached to the

door. Remove and save for later use.

3. Remove the door(s) from the crate.

CAUTION

DO NOT LIFT THE DOOR

WITH THE PUSHBAR.

Page 2

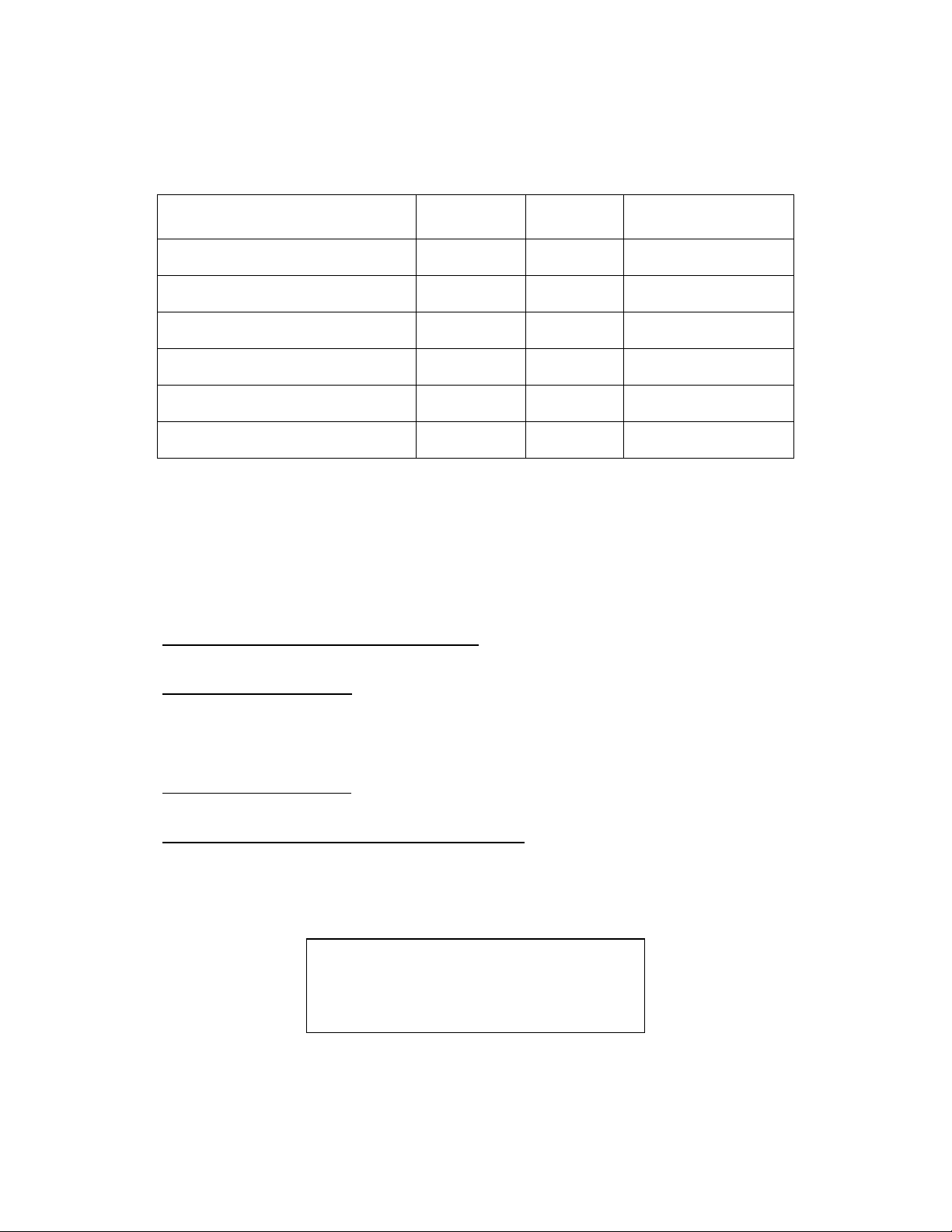

PREPARING FOR INSTALLATION

1. Check NCO (Net Cooler Opening) dimensions to insure that the rough opening is correct

(see chart below). The Model Number is available on serial plate.

Model Number

(First Six Characters)

01R1E1, 01R1E2 or 01R1S1

01D1E1, 01D1E2 or 01D1S1

02R1E1, 02R1E2 or 02R1S1

02D1E1, 02D1E2 or 02D1S1

01R2E1, 01R2E2 or 01R2S1

01D2E1, 01D2E2 or 01D2S1

02R2E1, 02R2E2 or 02R2S1

02D2E1, 02D2E2 or 02D2S1

01R3E1, 01R3E2 or 01R3S1

01D3E1, 01D3E2 or 01D3S1

02R3E1, 02R3E2 or 02R3S1

02D3E1, 02D3E2 or 02D3S1

Note not all RM or SD doors used as Beer Cave entrance doors are ADA compliant.

Door Size

(W x H)

26” x 80” 1 27-7/8” x 81-5/8”

26” x 80” 2 54-1/2” x 81-5/8”

30” x 80” 1 31-7/8” x 81-5/8”

30” x 80” 2 62-3/8” x 81-5/8”

36” x 80” 1 37-7/8” x 81-5/8”

36” x 80” 2 74-1/2” x 81-5/8”

Number

of Doors

NCO

(W x H)

To minimize the amount of caulking required, the NCO should not be more than ¼” larger

than the NCO specified above.

NCO shimming may be required to properly install the frame.

2. Additional items to check:

a. Is the floor in the threshold area level? If this area is not level, shimming is required

beneath the threshold to support the frame and keep the threshold from distorting.

b. Is the opening square? Check all corners with a framing square. Double-check by

comparing diagonal measurements. Excessively out-of-square openings will require

significant shimming in appropriate areas. Failure to correctly shim may result in door

operation problems.

c. Is the opening plumb?

If the opening is excessively out-of-plumb, door may bind on

floor and or fail to close correctly.

d. Are all the cooler panels in the same plane? The wall must be straight and in line

without any “warps” or “jogs”. Conditions of this sort may result in twisting of skewing

of the door frame, ultimately affecting operation. These types of conditions may also

result in aesthetic form and fit issues.

CORRECT INSTALLATION OF ANY ENTRANCE

DOOR IS CRITICAL TO CORRECT OPERATION.

NOTE

____________________________________________________________________________

Page 2 Heavy Duty Door Installation Guide

Page 3

I

NSTALLING THE FRAME

1. Entrance Doors directly adjacent to or near Reach-In Doors should be installed first. This

will allow for correct alignment of the top frames on the subsequent Reach-In frames.

Attempting to match this alignment with frames previously installed may result in the

threshold not setting on the floor, or “float” off the floor.

2. Place the frame in the opening and temporarily secure with a clamp or similar devise.

3. Insure that the frame is pushed fully into the opening.

4. Adequately shim behind each of the hinge-side frame mounting holes insuring that the frame

is plumb and straight.

5. Once the hinge-side frame is plumb and in position, install the frame mounting screws. Do

not completely tighten.

6. Repeat on the handle-side frame. Insure that frame is fully shimmed behind each frame

mounting hole and the frame is plumb and straight prior to installing frame mounting screws.

Do not completely tighten screws.

7. Insure that the frame is square and fully shimmed before installing any frame mounting

screws in the top frame. This may require a slight loosening of one or more vertical screws

to allow for proper squaring of the frame. Do not completely tighten screws.

8. Prior to securing the threshold, insure that any required shimming is placed under the

threshold mounting holes and base of the vertical frame.

9. Reconfirm diagonal measurements. Tighten all mounting screws and secure threshold.

10. Trim off any exposed shim stock.

11. If frame is equipped with lighting, install the remote ballast box above the top of the frame at

this time.

12. Caulk the frame.

INSTALLING THE DOOR

1. Remove the hinge mounting screws that are placed in the hinge backer plate by the factory.

Set aside in a safe place.

2. Adequately shim behind each of the areas behind the hinge. The hinge mounting screws will

not penetrate the shimming, but it is important to provide structure behind the hinge. This

shimming will be held in place by subsequent caulking of the frame.

3. Holding the door in the open position, align the hinge holes with the holes in the backer

plate.

THIS MAY REQUIRE TWO INDIVIDUALS.

DO NOT SUPPORT THE DOOR

WITH THE PUSH BAR.

____________________________________________________________________________

Page 3 Heavy Duty Door Installation Guide

NOTE

CAUTION

Page 4

4. Install one hinge mounting screw in the top hinge and tighten.

5. Install one hinge mounting screw in each hinge.

6. Install and tighten all remaining hinge mounting screws.

7. Check for proper door opening and closing.

8. Attach the upper Door Stop to the Slide Pin and reinstall the “C” clip.

IF THE LOCATION IS IN UNDER CONTRUCTION,

DO NOT ATTACH THE DOOR STOP.

WHEN THE COOLER IS READIED FOR MERCHANDISING,

INSTALL THE DOOR STOP.

NOTE

.

9. Install all previously removed lamps and lamp assemblies.

ADJUSTING DOOR HINGE TENSION

1. Remove the Hinge Adjustment Instructions and adjustment tools from the bag attached to

the door.

2. Place the door in the open position.

3. Insert the Tension Lever (longer bar) in right hand hole in the hinge adjustment slot.

4. Rotate Tension Lever to the left and insert Tension Pin loosely in hole to the right of the

Tension Leveler.

5. Release Tension Lever until Tension Pin contacts the right hand side of adjustment slot.

6. Adjust all three hinges one notch and try the door for closing force.

7. If desired closing force is not achieved, repeat Steps 3 thru 6.

8. When hinges have been adjusted to close the door properly, drive the Tension Pins flush

with the hinge tube.

DO NOT EXCEED THREE (3) HOLES TENSION FOR

OR FOUR (4) HOLES TENSION FOR

CAUTION

180

°

DOOR OPENING,

90

°

DOOR OPENING.

CONNECT DOORS TO POWER

1. If the doors have power cords at the top of the door, plug the cord into the receptacle in the

frame and install the cord retainer screws.

2. Locate the power access at the upper left corner of the frame.

____________________________________________________________________________

Page 4 Heavy Duty Door Installation Guide

Page 5

3. Provide suitable power (voltage to match the name plate on the frame) and make

connections in a customer-supplied junction box in accordance with the NEC and any state

or local codes. Connections for heaters and lights should be separate circuits.

____________________________________________________________________________

Page 5 Heavy Duty Door Installation Guide

Loading...

Loading...