Page 1

USE, CARE AND INSTALLATION GUIDE

Read all instructions before installing and operating this appliance

IMPORTANT SAFETY NOTICE

WARNING

Installation

The installation instruction in this manual is intended for qualified installers, service

technicians or persons with similar qualified background. DO NOT attempt to install this

appliance yourself. Injury could result from installing the unit due to lack of appropriate

electrical and technical background.

All electrical wiring should be properly installed, insulated, and grounded. Overly

accumulated grease on old duct work should be cleaned out or duct work should be

replaced if necessary to avoid the possibility of grease fire. Check all sections and joints

on duct work to insure proper connection and all joints should be properly taped.

Operations

Read all instructions in this manual before operating the appliance. Save these

instructions for future reference.

ALWAYS leave safety grills attached in place at all times. Operating blowers could catch

on to hair, fingers, and loose clothing.

Keep unit and residue containers clean from grease accumulation from time to time.

NEVER dispose foreign substances into the blowers. Do not dispose cigarette ashes or

ignitable substances into the blowers.

Cleaning

Use with extreme caution while performing the Self Cleaning Function and safety grills

are removed. Beware of fingers, hair, loose clothing from getting in the blowers and

NEVER leave children unattended.

NEVER disassemble parts to clean without proper instructions. Disassembly are

recommended to be performed by qualified personnel only. We are not responsible for

injury due to negligence and the warranty of the unit automatically expires due to

improper maintenance. Call our Service Center for removal instructions.

Page 2

1

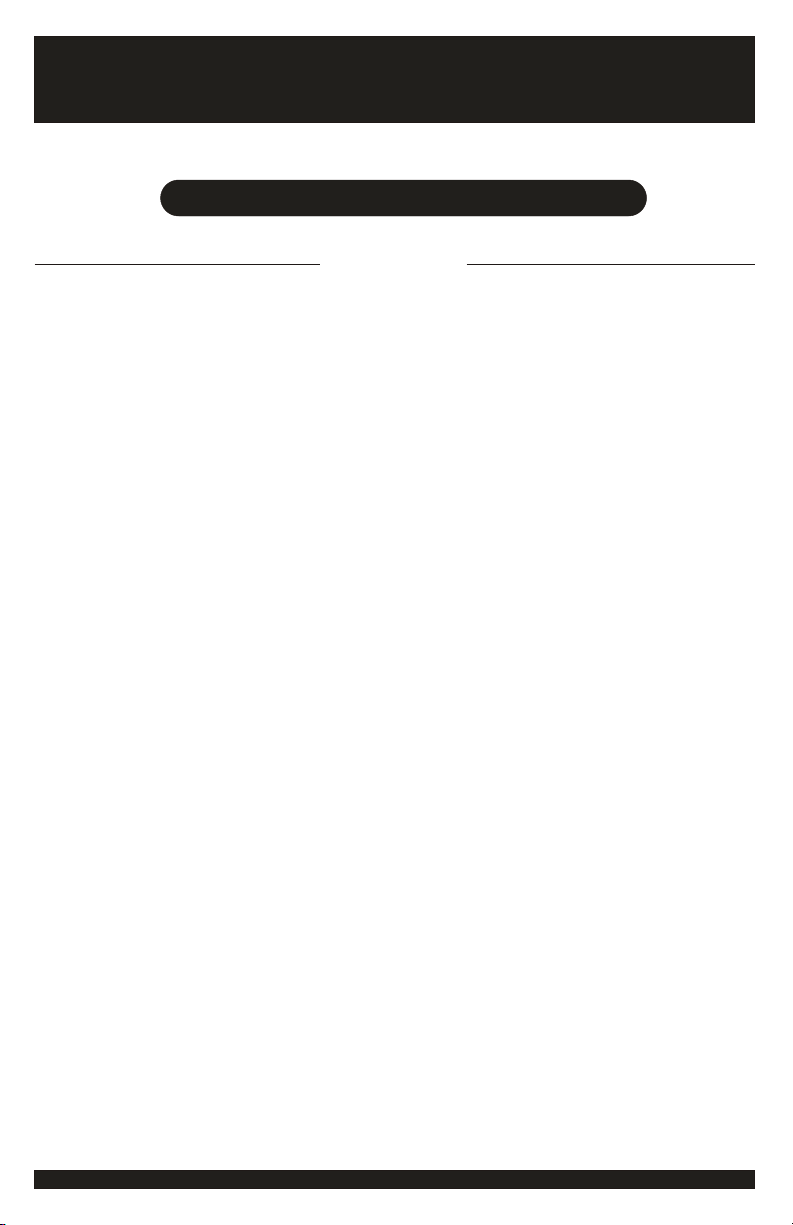

HURRICANE SERIES

CYCLONE SERIES

WHIRLWIND SERIES

PRODUCT OVERVIEW

Model number: AK2000, 2036

, QuattroVent Air Curtain

, Dual “Thrust-Fore" Self Clean Blowers

, Digital Touch Pad Controls

, Clock, Timer, 3 stage Delay Shutoff.

Model number: AK6000, 6036, 6042, 6048

, Dual “Thrust-Fore" Self Clean Blowers

, Independent Rocker Controls w/ High, Low

speed

, 3 Way convertible ducting option

Overview

1. QuattroVent Air Curtain

(Hurricane only)

2. Self Clean Blowers

3. Controls

4. Light

5. Residue Cup

6. Underside splash guard

Model number: AK9200

, Dual Self Clean Blowers

, Independent Rocker Controls w/ High, Low

speed

, Slim Line Design

3

1

4

2

6

5

Page 3

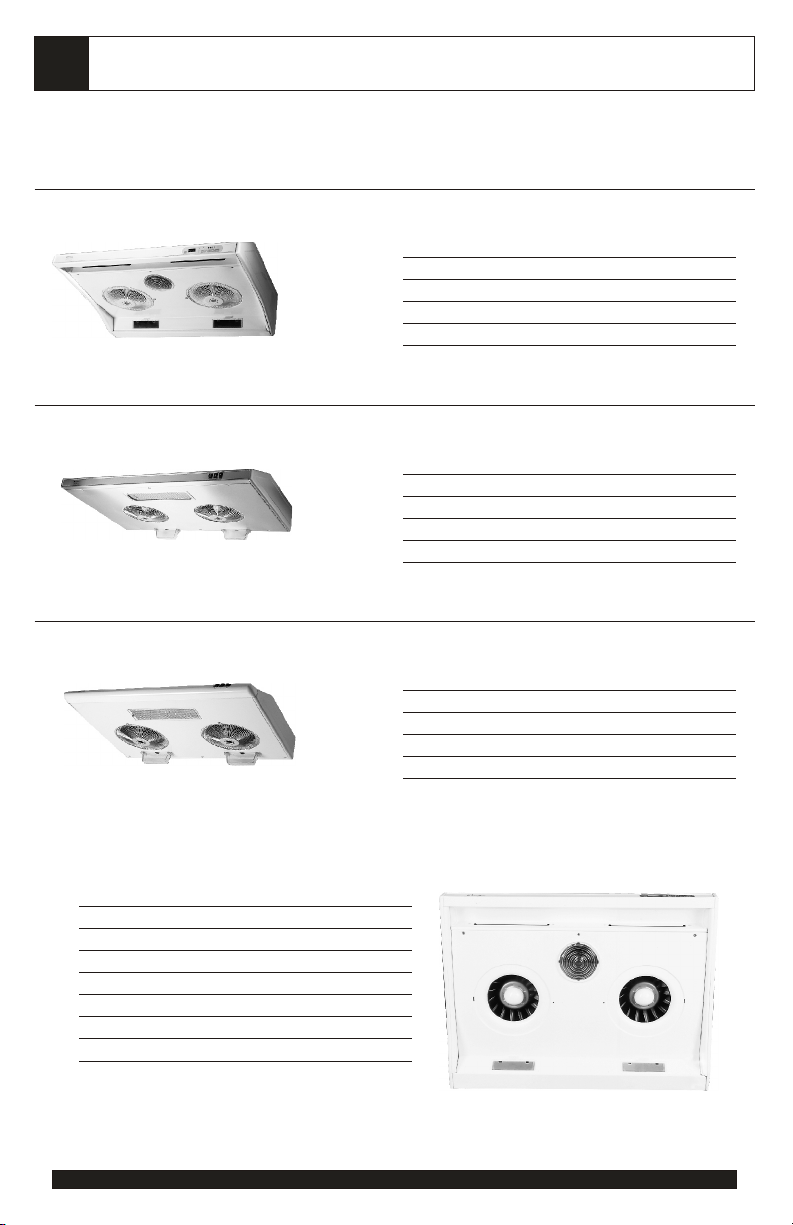

HURRICANE SERIES

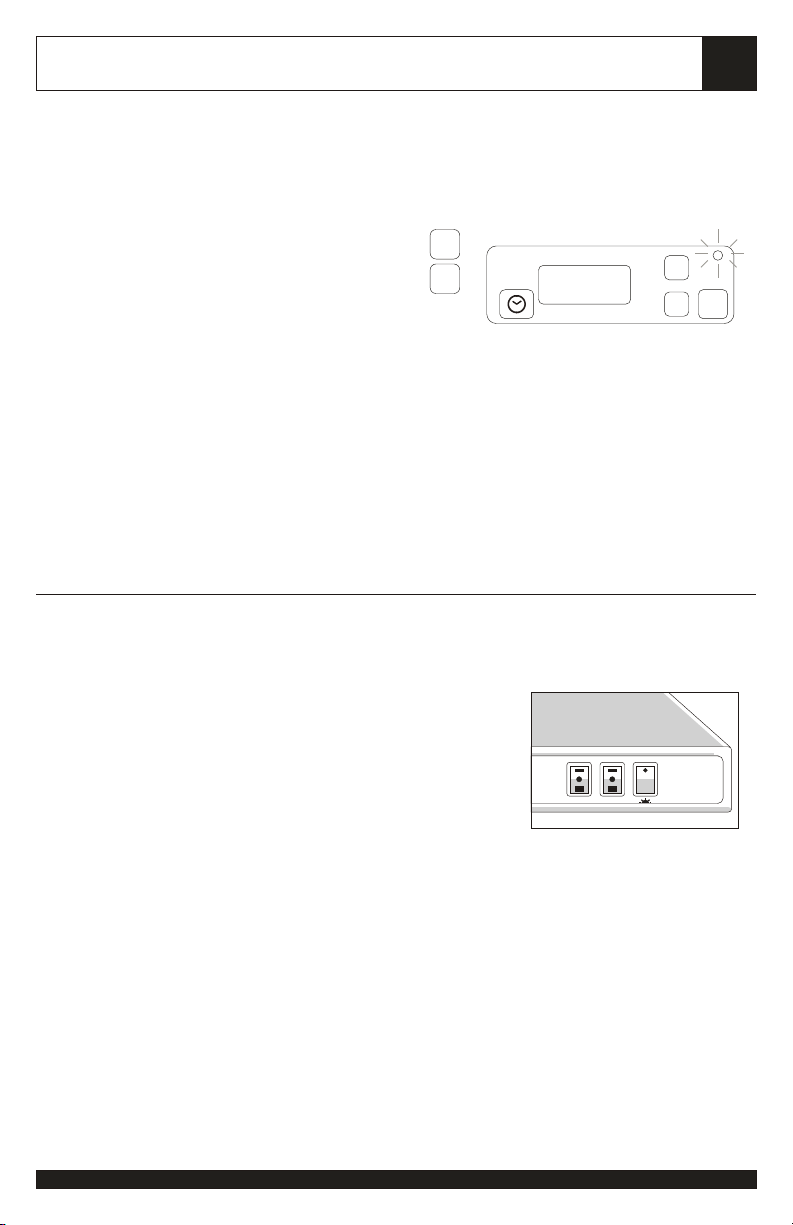

CONTROLS

2

2

1

12:01

Controls Overview

1. Set Time

2. Digital Display

3. Set Hours

4. Set Minutes

5. Set Timed Delay Shut Off

6. Light On-Off

7. Left Blower: On-High-Low-Off

Setting Clock

Press "clock".

Hour Indicator will flash indicating clock

setting function is ready.

Press "hr" to set hours (from 1-12).

Press "min" to set minutes (from 00-59).

14

3

hr hr

4

minmin

DELAY

OFF

5

LO LO

HI HI

FAN-L

6 7 8 9

8. Right Blower: On-High-Low-Off

9. Operations: On-Off

10. Right Blower Low Speed Indicator

11. Right Blower High Speed Indicator

12. Left Blower Low Speed Indicator

13. Left Blower High Speed Indicator

14. Delay Off Indicator

press:

12:01

hr hr

minmin

12:01

FAN-R

hr hr

DELAY

minmin

hr hr

DELAY

minmin

10111213

ON-OFF

LO LO

HI HI

FAN-R

ON-OFF

FAN-L

OFF

LO LO

HI HI

FAN-R

ON-OFF

FAN-L

OFF

Let clock flash for 7 seconds and your new

time input will automatically be stored.

Light On-Off

Press "light" button once to turn light on.

Press again to turn off.

press:

to turn light On/Off

Page 4

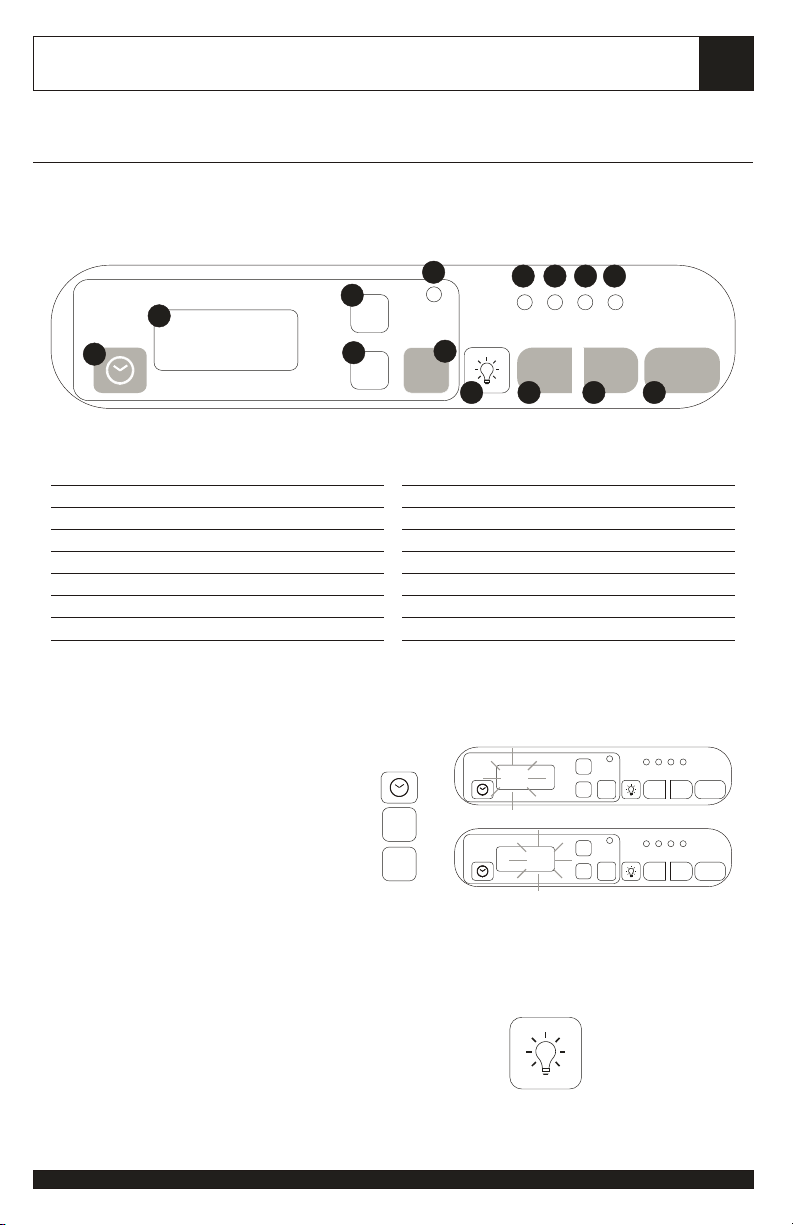

3

Blower Controls

CONTROLS

You can simultaneously turn On the light and

both blowers on Hi speed by simply pressing

"On/Off" once.

During this time, you can select blowers and

speed as indicated by pressing the "Fan-L"

and "Fan-R" button.

Note:

The third press on the "Fan-L" and "Fan-R"

button will turn blower Off the selected side (as

indicator light turns off).

You can also turn individual blowers On/Off

and select speed by simply pressing the

desired "Fan-L" or "Fan-R" button.

Press "On/Off" again and all operations will

stop.

Timed Delay Off

While blowers are in operation, pressing

"Delay Off" button once will set the unit to

turn off in 3 minutes. Press again for the

preset 5 minutes countdown and third

press for 10 minutes.

Once a desired time is selected,

countdown will start as the delay off

indicator light flashes. All operation will

cease as the countdown reaches zero.

Note: At any time when the delay function

is selected, the light will turn off

automatically and all blower will decelerate

to Lo speed.

press:

FAN-L

press:

indicator:

ON-OFF

FAN-R

ON-OFF

DELAY

OFF

to turn light and both

blowers on Hi

or turn individual blowers

On/Off and select Hi/Lo speed

press again to turn all

operations Off

once- countdown in 3 minutes

twice- in 5 minutes

3rd time- in 10 minutes

Light will turn off when pressed

and blowers will decelerate to

Lo speed.

hr hr

3

DELAY

minmin

OFF

Page 5

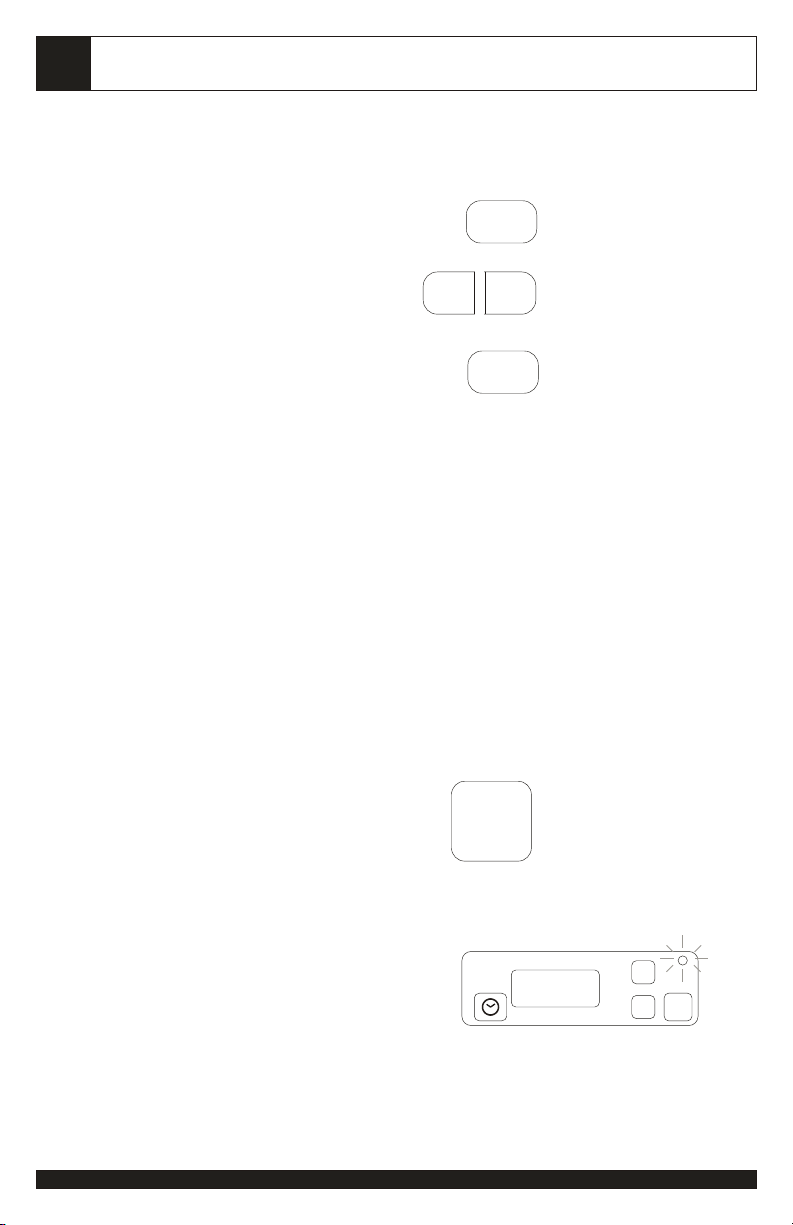

Setting Timer (Alarm)

CONTROLS

4

Press "hr" and "min" button to set desired timer

countdown.

Once timer is set, countdown will start in 7

seconds as delay indicator light flashes.

When countdown reaches 0, 10 short beeps will

sound.

To cancel timer after setting, press "On/Off"

button to terminate all operations and restart.

Note: Timer function cannot be operated

simultaneously with the "Delay Off" function.

Nevertheless, setting the timer function will not

effect any other operations.

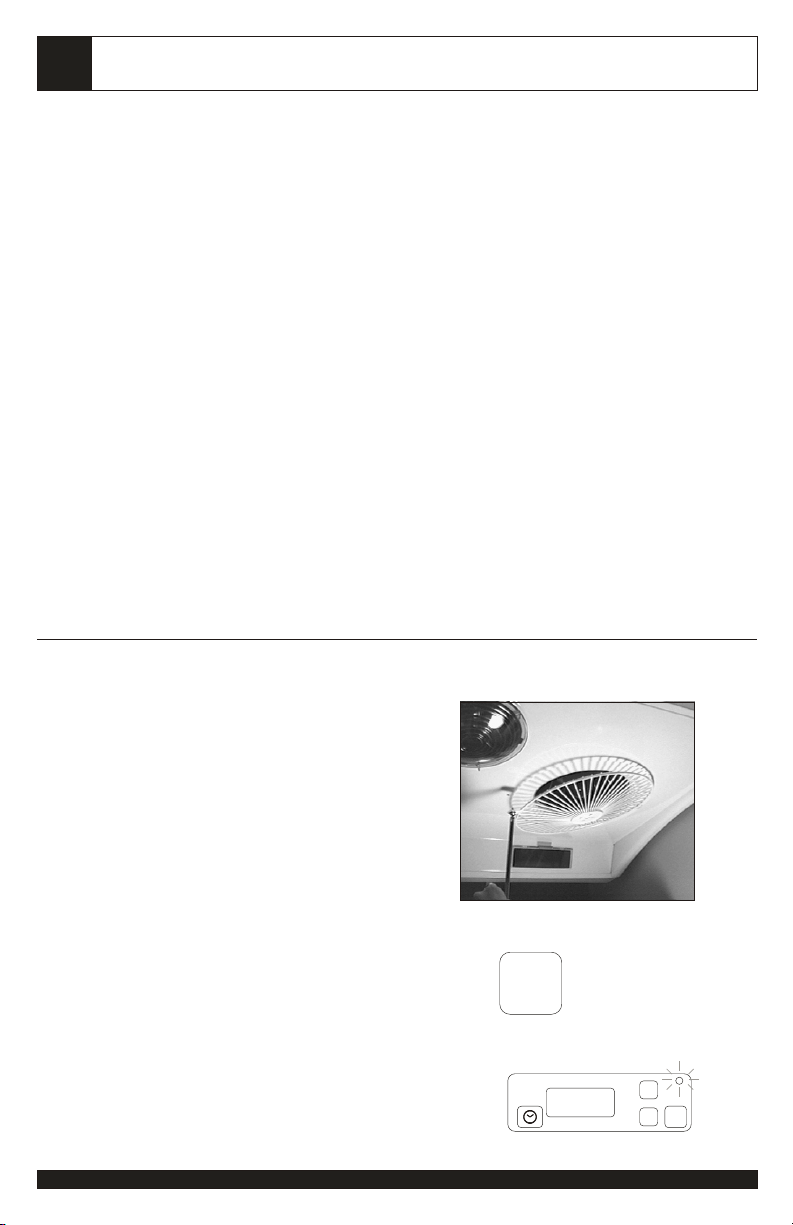

CYCLONE & WHIRLWIND

Rocker Controls

(1) Light- turns light On/Off

(2) (3) Blower Controls- Independently controls

Right and Left blowers. Rock switch up (I) for

Lo speed, (II) for Hi speed, and center (.) to

turn off.

press:

hr hr

minmin

set "hr" & "min" for timer countdown

alarm will sound at end of timer

(1) Light On/Off

(2) Right Blower

(Hi/Lo, Off)

(3) Left Blower

(Hi/Lo, Off)

1:04

R

L

hr hr

DELAY

minmin

OFF

123

Page 6

5

MAINTENANCE

Self Clean Feature

All Zephyr Range Hoods are filter-less and are designed with a self clean feature. The

centrifugal blower system automatically liquefies grease accumulated in its internal housing.

All systems are equipped with dishwasher safe grease containers for its self clean function.

Grease and residue from cooking are often automatically liquefied and can accumulate in the

containers from everyday use. Nevertheless, grease from cooking could also dry and

adhered in its internal housing. Running the self clean function periodically will flush out the

accumulated grease in the range hood’s internal housing.

Cleaning Frequency

Cleaning should be approximately once a month under normal use.

Detergent

Grease cutting detergent such as ‘409’ or its equivalent are recommended.

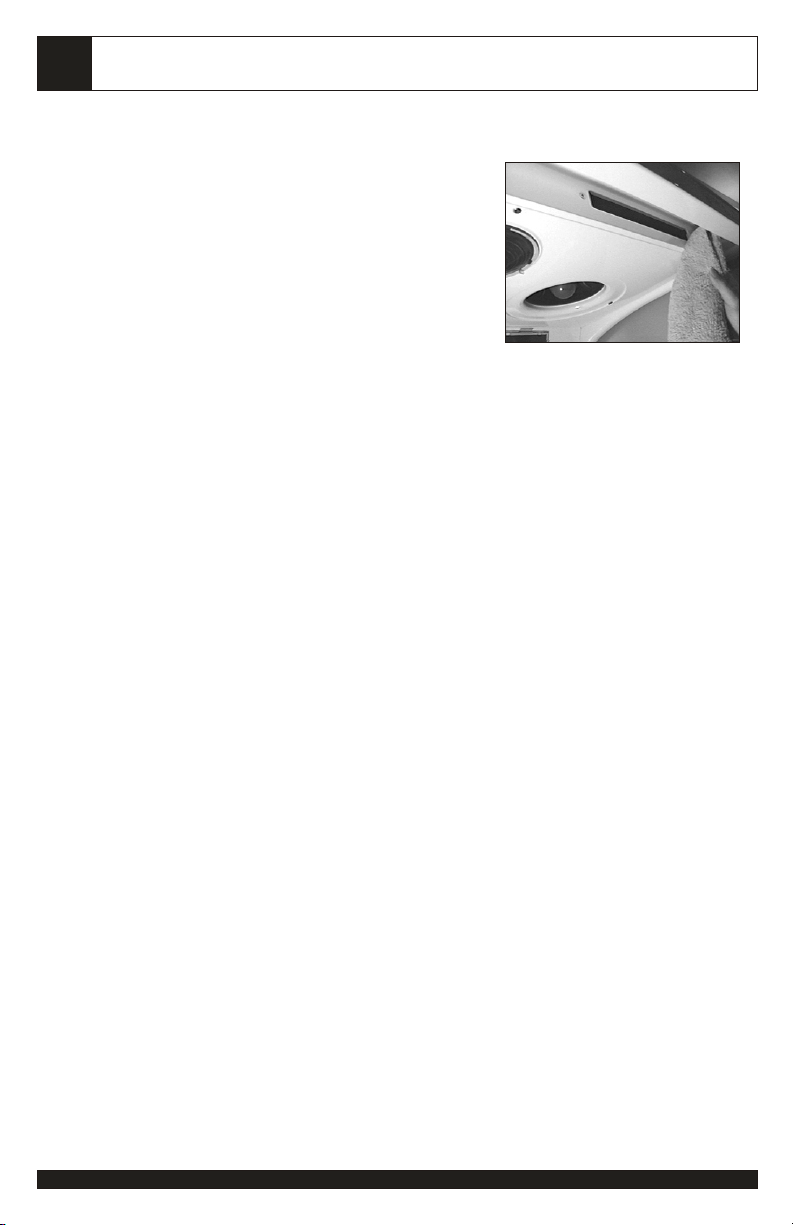

Cleaning

Safety Grill

Remove both safety grills for cleaning by

simply loosening Philips screws. Clean safety

grills in dishwasher under normal wash cycle.

WARNING: Use with extreme caution as both

safety grills are removed. Beware of blowers

catching on to hair, loose clothing, and fingers.

NEVER leave children unattended.

Self Clean

Turn both blowers on Low speed for cleaning.

For Hurricane series, simply set Timed Delay

Off to 5 minutes as indicated.

press:

indicator:

DELAY

OFF

twice- countdown in 5

minutes

hr hr

5

DELAY

minmin

OFF

Page 7

MAINTENANCE

With nozzle on ‘spray’, squirt ‘409’ detergent

directly onto blower blades 30-35 times.

Repeat with second blower. Allow self

cleaning to run for 5 minutes before switching

off. (If desired, spray water to rinse off detergent after

completion of the cleaning cycle and run for another few

minutes)

Remove residue containers by gently sliding

out with both hands. Clean in dishwasher

under normal wash cycle.

Hurricane Series:

Remove light shield by turning counterclockwise.

Clean in dishwasher under normal wash cycle.

6

Whirlwind Series:

Remove light shield by unscrewing Philips

screw.

Clean in dishwasher under normal wash cycle.

Cleaning Tip:

Fill residue containers ¼ full with water before cleaning or during regular use. This will

help to prevent grease from drying and tacking on cup surface.

Warning:

Edges on stainless steel surface are exposed once shield is removed. Clean around

edges with extreme care and we recommend the use of latex cleaning gloves.

Page 8

7

QuattroVent Channels

The QuattroVent Air-Curtain channels are

adjoined to its two main blowers and share the

same internal housing. No further cleaning is

required after the self clean is completed.

Clean residue around the channels surface

with ‘409’ and a cotton cloth regularly.

Surface Maintenance

Clean all surface residue with ‘409’ or mild detergent and wipe with a cotton cloth.

Stainless steel surface could further be polished with any stainless steel polish or glass

cleaners.

Replacing Lights

All light bulbs included are 40W appliance bulb. Replace with 60W bulbs if brighter

illumination are desired. Remove light shield according to instructions on page 6.

Warning: Edges on stainless steel surface are exposed once shield is removed. Replace

bulb through opening with extreme care. We recommend wearing of latex gloves.

MAINTENANCE

Page 9

INSTALLATION

WARNING

Installation of this product is intended for qualified installers, service technicians, or

persons with similar qualified background. DO NOT attempt to install this appliance

yourself. Injury could result form installing the unit due to lack of appropriate electrical

knowledge and technical background. Improper installation, adjustment, alteration,

service or maintenance can cause injury or property damage and the warranty on the

product automatically becomes void.

Installation of this product must conform with all local codes. All connections must be

electrically grounded and ducting must be properly vented outside in accordance to

codes. Never duct exhaust into attics, within walls, crawlspaces, garages, or anywhere

inside the house which might cause grease fire. All duct joints must be properly

inspected, taped and sealed.

Edges are exposed around the duct opening and once the bottom grease shield is

removed. Be careful when handling the sharp edges. Wearing protective gloves and

appropriate work clothing is recommended.

REQUIREMENTS

8

Duct Size

Hurricane- 6“ Vertical Duct Discharge

Whirlwind- 6“ Vertical Duct Discharge

Cyclone- 6“ Vertical Duct Discharge

3-1/4 x 10“ Vertical Duct Discharge

3-1/4 x 10“ Horizontal Rear

Discharge

ACCESSORIES

Hurricane & Whirlwind series

2 residue cups

2 ‘L’ brackets (for direct wall mount

only)

4 screws for ‘L’ brackets

1 6“ starting collar

3 electrical wire connectors & screws

Cyclone series

2 residue cups

2 ‘L’ brackets (for direct wall mount

only)

4 screws for ‘L’ brackets

Tools

Hand Drill with #2 philips

Flat head screwdriver to pry electrical knockout

3/4“ Wood Boring Bit

Jigsaw (if cabinet opening modification is

required)

Power Source

115W

1 6“ starting collar

3 electrical wire connectors & screws

1 Convertible transition collar

1 6“ collar cap

1 3-1/4 x 10“ starting collar (packaged

separately)

1 Back-splash

Check all accessories before installation, packaging also

includes 1) Care, Maintenance and installation manual

2) Owner’s Warranty Registration Card 3) Serial number

label adhered on top of box.

Page 10

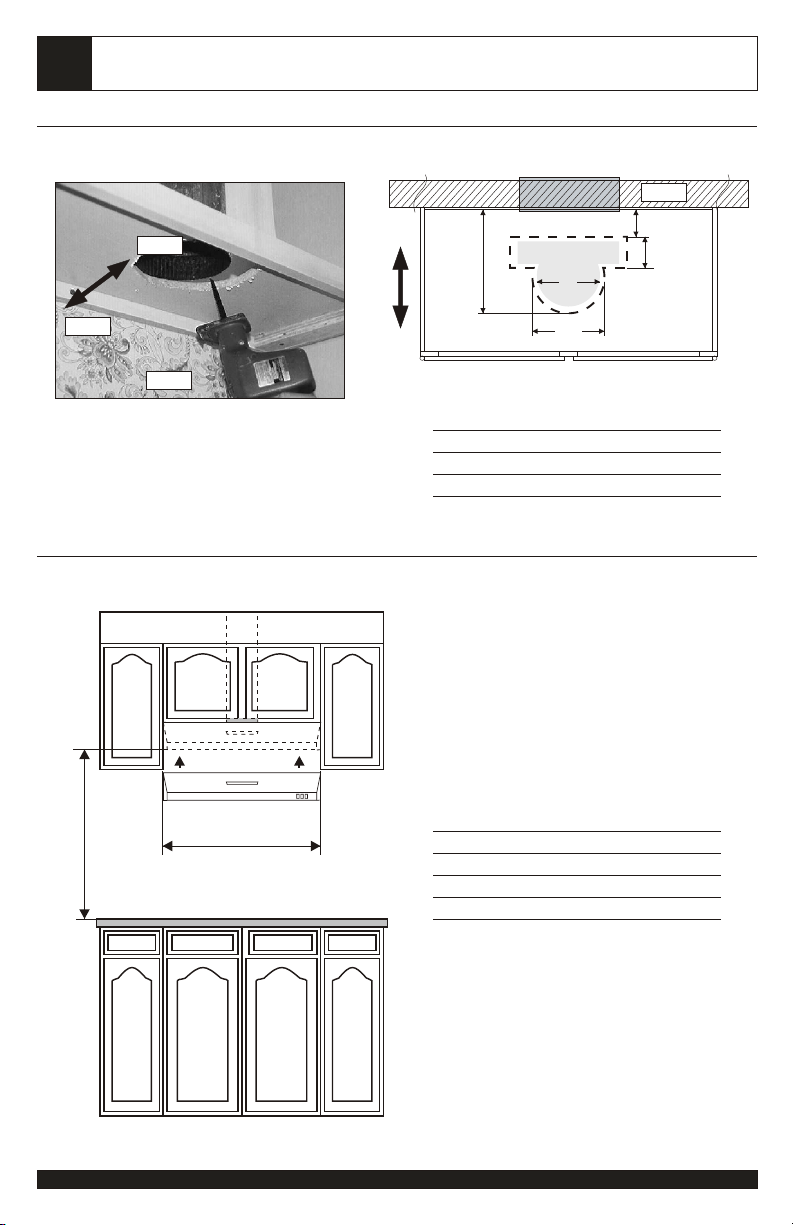

9

DUCT OPENING

Front

INSTALLATION

Rear

(A)

Wall

2-1/2”

4-1/2”3-1/4 x 10”

6”

Rear

Wall

CLEARANCES

MIN. 18” MAX 30”

net width

Front

7”

Cut Out Size (A):

Hurricane 10-1/2“

Cyclone 10-1/2”

Whirlwind 8-1/2”

Minimum clearance above range should be no

less than 18“ from the range surface to the

range hood’s base. Maximum height are

recommended not to exceed 30” for maximum

efficiency.

Net width on all models are call out width less

1/4”.

Call Out Size Net Width

30“ 29-3/4”

36“ 35-3/4”

42“ 41-3/4”

48“ 47-3/4”

Note: Refer Manufacturers’ height clearance

requirements on all high btu and professional

ranges.

Page 11

INSTALLATION

10

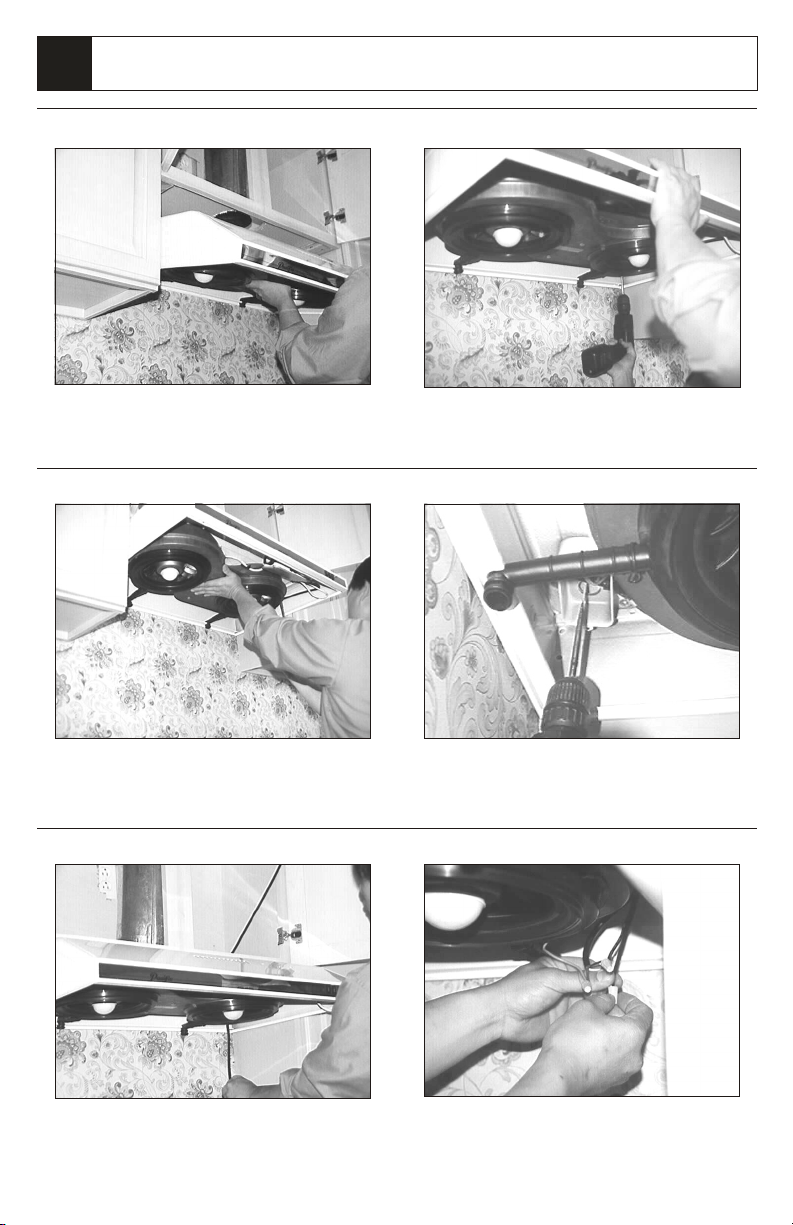

STEP 1

1. Remove all contents from box

2. Unscrew and remove bottom grease splash shield

STEP 3

STEP 2

1. Locate electrical connection box inside

2. Unscrew cover to reveal wiring

STEP 4

1. Locate electrical connection box knock out from left

rear of hood and pry open with screwdriver

STEP 5

1. Reinforce cabinet base with 1x2 wood strips if

additional strengthening is required.

2. Unscrew and remove bottom grease splash shield

1. Cut out cabinet base opening if necessary. Refer

cut out dimensions previous page.

STEP 6 (also refer notes on pg. 16)

1. Install damper if required by local codes (not

provided), or install 6“ starting collar (green)**

Page 12

11

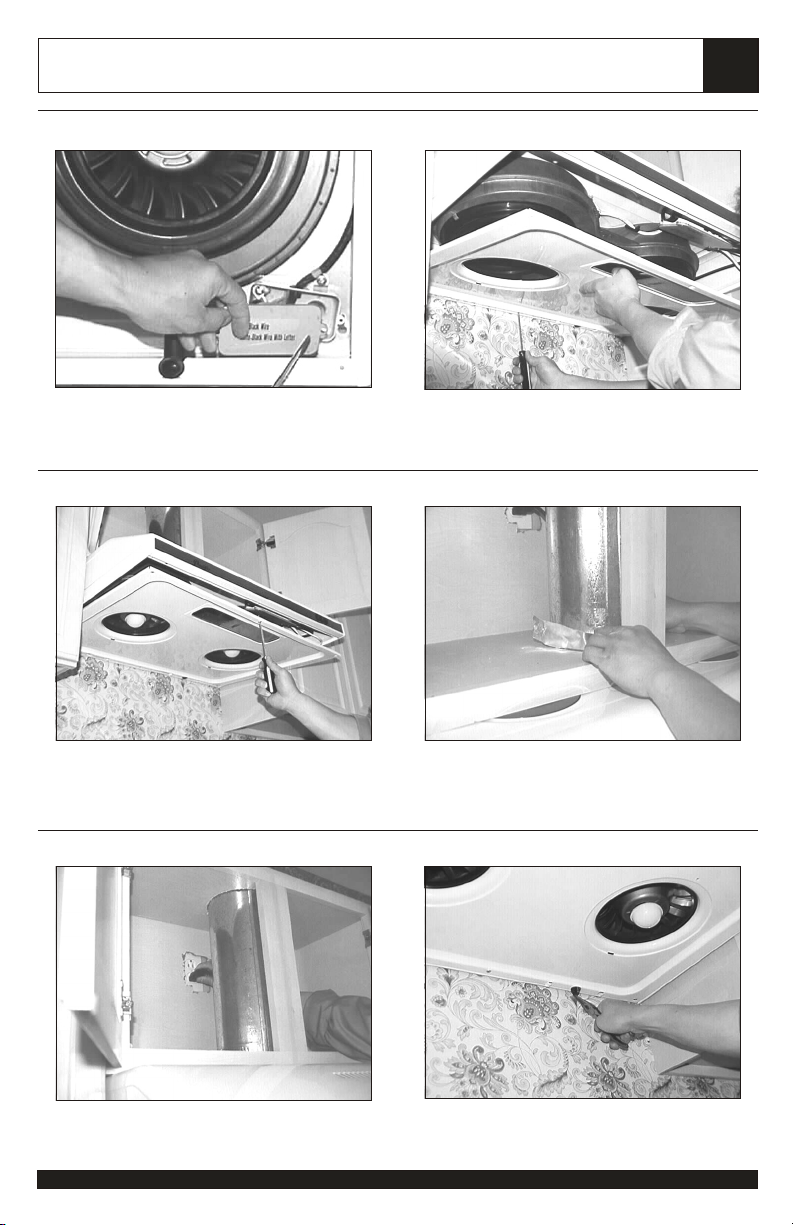

INSTALLATION

STEP 7

1. Lift hood to bottom of cabinet

STEP 9 (also refer notes on pg. 16)

STEP 8

1. Support hood to place, fasten both rear with screws

and washers provided.

STEP 10

1. Fasten front of hood. Level all sides and adjust

accordingly.**

STEP 11

1. Pull electrical supply wire through drill out or use

#14 grounded wire for receptacles (not supplied)

1. Drill out cabinet base through electrical box with

3/4" boring bit.

STEP 12 (also refer notes pg. 16)

1. Connect both wires (blk) on hood to either power

supply (blk or wht). Ground green wire.**

Page 13

INSTALLATION

12

STEP 13

1. Reinstall electrical box cover.

STEP 15

STEP 14

1. Reinstall bottom splash shield by first fastening 3

rear screws, (do not tighten all the way).

STEP 16

1. Next, fasten the 3 front screws and begin tightening

all screws from rear to front.

STEP 17

1. Turn on electrical supply or plug into receptacles.

1. Connect duct to opening, inspect and tape all joints

with approved aluminum or duct tape.

STEP 18

1. On Cyclone & Whirlwind models, be sure to pull

both grease tubes over its opening.

Page 14

13

INSTALLATION

CONVERTIBLE OPTIONS

Cyclone series: AK6000, 6036, 6042, 6048

Zephyr’s Cyclone series are equipped with the option of a 6“ vertical discharge, 3-1/4x10” vertical discharge, or 31/4x10” rear discharge. Additional accessories are provided to convert to either of the above discharge methods.

Convertible Options

Vertical discharge 6“ round

Vertical discharge 3-1/4 x 10“

Horizontal rear discharge 3-1/4 x 10”

Back Splash

Cyclone models also come with a standard back splash. If desired, install back splash to rear of range hood with

screws provided after all duct conversion steps below are completed.

Convertible Accessories

6“ round duct cap

Round to rectangular transition adaptor

Rectangular to round transition adaptor (pre-

mounted)

Gasket (pre-mounted)

Rectangular rear cap (pre-mounted)

3-1/4 x 10“ starting collar

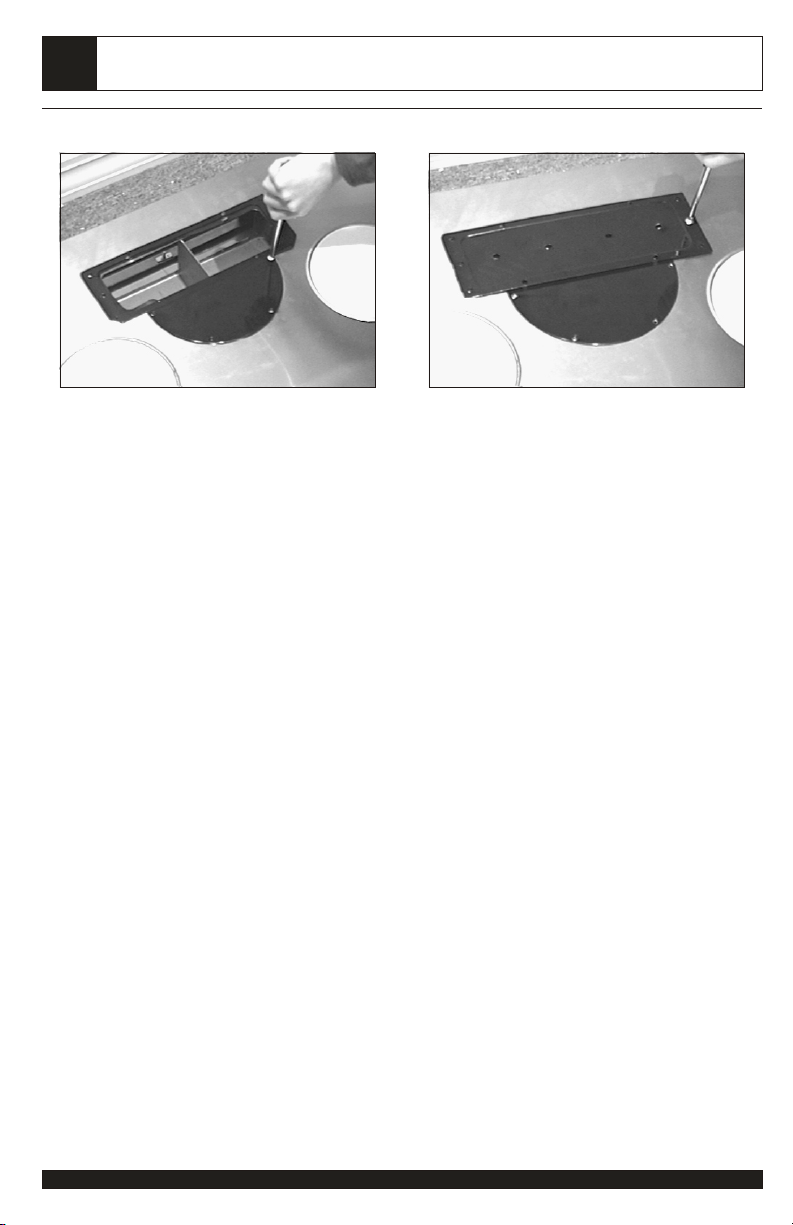

3-1/4 x 10“ Vertical Discharge

1. Remove pre-mounted 6“ transition adaptor on duct

opening. Leave attached gasket in its original place.

3. Mount the 3-1/4 x 10“ starting collar on top of

transition piece with remaining screws.

2. Place rectangular transition adaptor as shown over

gasket and by first installing 4 screws on half round

section.

Page 15

INSTALLATION

3-1/4 x 10“ Rear Discharge

14

4. At rear of range hood, remove all screws on premounted rear rectangular cap and remove cap with

gasket.

6. Remove 2 arch blocks through top opening.

5. Remove top pre-mounted transition piece. Leave

attached gasket in its original place.

7. Mount Starting Collar (provided) at rear discharge

opening with gasket previously removed.

Option 1: (for recessed cabinet base)

Re-install originally pre-mounted round transition

piece at opening with gasket.

Cap opening with 6“ cap provided OR, use option 2 if

cabinet base is not recessed.

Page 16

15

3-1/4 x 10“ Rear Discharge

INSTALLATION

Option 2: (for flush cabinet base)

Mount rectangular transition piece at opening with

gasket as shown.

Mount rectangular cap (previously removed) on top of

transition adaptor.

Page 17

INSTALLATION

INSTALLATION NOTES

Step 6:

A damper (not included) should be installed to prevent back-draft where needed. A damper might also be required

local codes in order to qualify for building inspections. You can purchase dampers from most hardware stores, or call

our service line to order.

When a damper is not installed, a starting collar is provided in order to increase and raise the duct opening clearance

above the cabinet's base. Snap the adaptor's smaller end to hood's duct opening and secure by drilling 2 pilot holes

and fasten with screws (as shown on step 6, page 10).

Step 9:

The hood should NEVER be installed so that the front is

tilting downward. This will cause grease to back flow to the

front instead of the rear. ALWAYS level the hood or slightly

tilt front of hood upward. Some models includes 2 preinstalled bumpers on the rear (or top) to aid the hood front

tilt upward when installed. Remove the bumpers simply by

peeling off if hood is preferred to be installed leveled. (refer

diagram)

16

Step 12:

A connector locking the electrical wiring on the electrical box is recommended and might be required by local codes.

Check with local inspectors, purchase and install the appropriate connector in order to meet all mandatory codes.

Call our service line to order connector.

Wall

Rear

Front

Page 18

17

TROUBLE SHOOTING

1. Upon completion of installation,

nothing works.

2. Light is on but blowers are not

turning at all or seems to be scraping on

something.

3. When blowers are on, something

seems to be loose and spinning

around inside.

4. Vibration when blowers are on

5. Blowers noise

6. Light is not working

7. No grease is collected in the residue

containers

Check if unit has been plugged in, make sure that all power

has been turned back on and all electrical wiring are

properly connected.

Blower blade unit might have been mounted too low and

scraping the bottom or jammed. Loosen hex screw on

blade unit and adjust to proper height.

There might have been foreign particles left within the

discharge opening or rocks, leaves, branches, etc. that

might have fell in from old duct work. Disconnect duct work

to inspect and remove any foreign particles.

Unit might not have been secured properly on cabinet. Or

cabinet might need to be further secured into studs on wall.

Our blowers are designed to perform up to 695 cfm. A

properly functioning motor itself should be relatively quiet.

Nevertheless, due to vacuum created by the suction, noise

level up to 5.5 sones will be generated when both blower

unit is turned on at its maximum speed. Employ both

blowers at maximum speed only when needed (heavy pan

frying, wok cooking etc.) Employing low speeds or a single

blower will suffice moderate cooking such as steaming,

broiling etc.

Light bulb might need to be replaced. On some instances,

the fragile bulb could have been damaged during the

shipping process. Simply replace with a 40 or 60W

appliance bulb.

Grease flow will vary by the amount, methods and types of

cooking. If pan-frying is frequent accompanied by

steaming, vapor from steam will liquefy accumulated

grease in its internal housing and flows in the containers.

No grease collected in the residue containers is normal

until the self clean function is completed. Clean blowers

approximately once a month as instructed to avoid

clogging.

8. No grease is collected in the residue

containers after self cleaning.

9. Safety grill are dirty

10. Blowers seemed weak

Tubes connected to the internal housing might have been

clogged due to lack of cleaning. Or hood might not have

been leveled when installed. Unclog tubes or re-install

hood (refer page 16).

The self clean feature cleans only the internal housing

within the range hood. Remove safety grill to clean in

dishwasher and clean all surface periodically as instructed.

Check duct size used, duct size should be at least 6“ or 31/4 x 10”. Range hood WILL NOT function properly with

the insufficient duct size.

Check if duct is clogged or if damper unit is not opening

properly. A tight mesh on a side wall cap unit might also

cause restriction to the air flow.

Page 19

TROUBLE SHOOTING

Use a damper type sidewall cap.

Reduce the number of elbows and length of duct work.

Check if all joints are properly connected, sealed and

taped.

18

11. Cooking fumes and smoke dissipates

before it reaches the blower.

Check if unit is installed at the recommended height

(page 9). The range hood should also be able to cover

the entire cooking area from left to right and most areas

from rear to front.

Open doors and windows might also distract air flow

before it reaches the blowers.

Make sure blowers are on high speed for heavy cooking.

For other questions and further assistance please call our service department with

the product’s registered serial number or write to:

ZEPHYR CORPORATION

Service Department

1.888.880.VENT (8368) 415.282.1211

1551 Minnesota St., San Francisco, CA 94107

Loading...

Loading...