Zenoah GZ3500T User Manual

848CE093A0 (807)

OWNER’S MANUAL

GZ3500T

G

G

B

B

CHAIN SAW

GZ3500T

GB-1

GZ3500T

SAFETY FIRST

Instructions contained in warnings within this manual marked with a symbol concern critical points which must be

taken into consideration to prevent possible serious bodily injury, and for this reason you are requested to read all

such instructions carefully and follow them without fail.

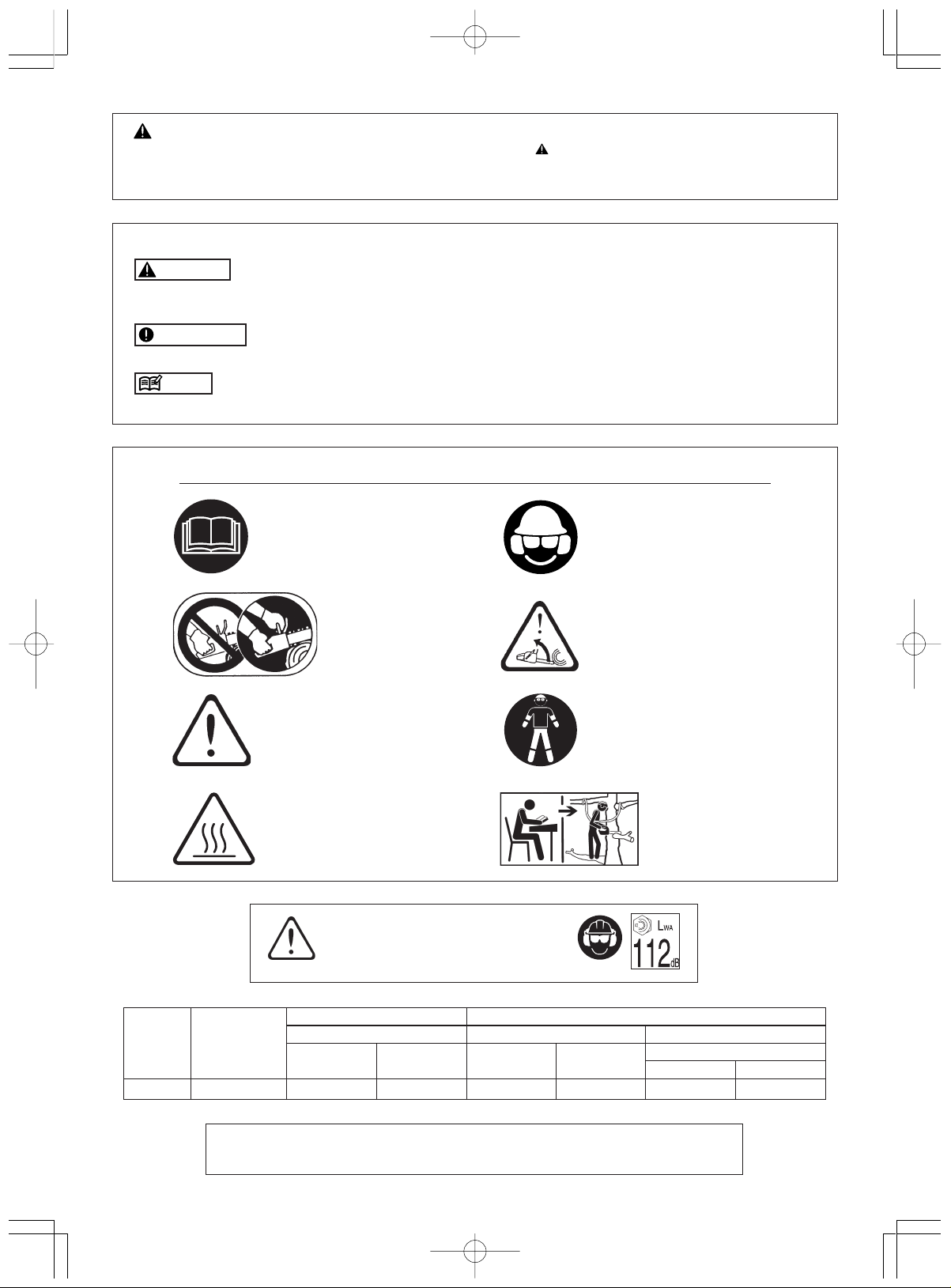

WARNINGS IN THE MANUAL

WARNING

This mark indicates instructions, which must be followed in order to prevent accidents, which could lead to serious

bodily injury or death.

IMPORTANT

This mark indicates instructions, which must be followed, or it leads to mechanical failure, breakdown, or damage.

NOTE

This mark indicates hints or directions useful in the use of the product.

SYMBOLS IN THE OPERATOR’S MANUAL

Read operator's instruction

book before operating this

machine.

Use the chain saw

with two hands.

Read, understand and

follow all warnings.

Never touch hot surface.

WARNING!!!

RISK OF DAMAGING HEARING

Wear head, eye and ear protection.

Wear head, eye and ear

protection.

Warning! Danger of

kickback.

Use appropriate protections

for foot-leg and hand-arm.

This saw is for trained tree

service operators only.

MODEL

GZ3500T

GB-2

DISPLACEMENT

35.2 cm

3

SOUND LEVEL

ISO 22868

LpA

LwA

Front handle

98.3 dB(A) 112 dB(A) 6.7 m/s

ISO 22867

2

VIBRATION LEVEL

Rear handle

6.1 m/s

Front handle

2

3.7 m/s

APPROVAL NUMBER OF CE EXHAUST EMISSION REGULATION (2002/88/EC)

e13*97/68SH2G3*2002/88*0432*00

2002/44/EC

A(8)

Rear handle

2

3.3 m/s

2

DECLARATION OF CONFORMITY TO MACHINES DIRECTIVE

MANUFACTURER : Husqvarna Zenoah Co., Ltd.

DECLARES THAT THE DESIGN OF THE MACHINE DESCRIBED BELOW :

Model : GZ3500T

Serial no. : 800001 and up

Make : Husqvarna Zenoah

CONFORMS TO THE REQUIRMENTS OF THE MODIFIED MACHINES

DIRECTIVE (Directive 98/37/EC) AND TO THE NATIONAL REGULATIONS

GOVERNING ITS TRANSPOSITION ABROAD : AND

THAT IT HAS BEEN ISSUED WITH A “CE”CERTIFICATE, NO. U3 2892374 01 BY

TÜV Rheiniand Group - TÜV Rheinland InterCeret kft. Product Certification - H

1061 Budspest Pauley Eds u. 52 - HUNGARY

(Directive 98/37/EC, 89/336/EEC)

and to the regulations governing transposition

Internal control production

No. 9, 1-Chome

MINAMIDAI, KAWAGOE City

SAITAMA, JAPAN

GZ3500T

G

B

Signed in Saitama, Japan

Isamu NAKAZATO

General Manager, Quality Assurance Department

1st July 2008

Contents

1. For Safe Operation ................................................................... 4

2. Symbols on the Machine .......................................................... 8

3. Installing Guide Bar and Saw Chain ......................................... 9

4. Fuel and Chain Oil .................................................................. 10

5. Operating the Engine ............................................................. 11

6. Sawing .................................................................................... 12

7. Maintenance ........................................................................... 14

8. Maintenance of Saw Chain and Guide Bar ............................ 15

9. Troubleshooting Guide ........................................................... 16

10.

Disposal .............................................................................................. 16

11. Specifications ......................................................................... 17

12. Limited Warranty ..................................................................... 18

GB-3

GZ3500T

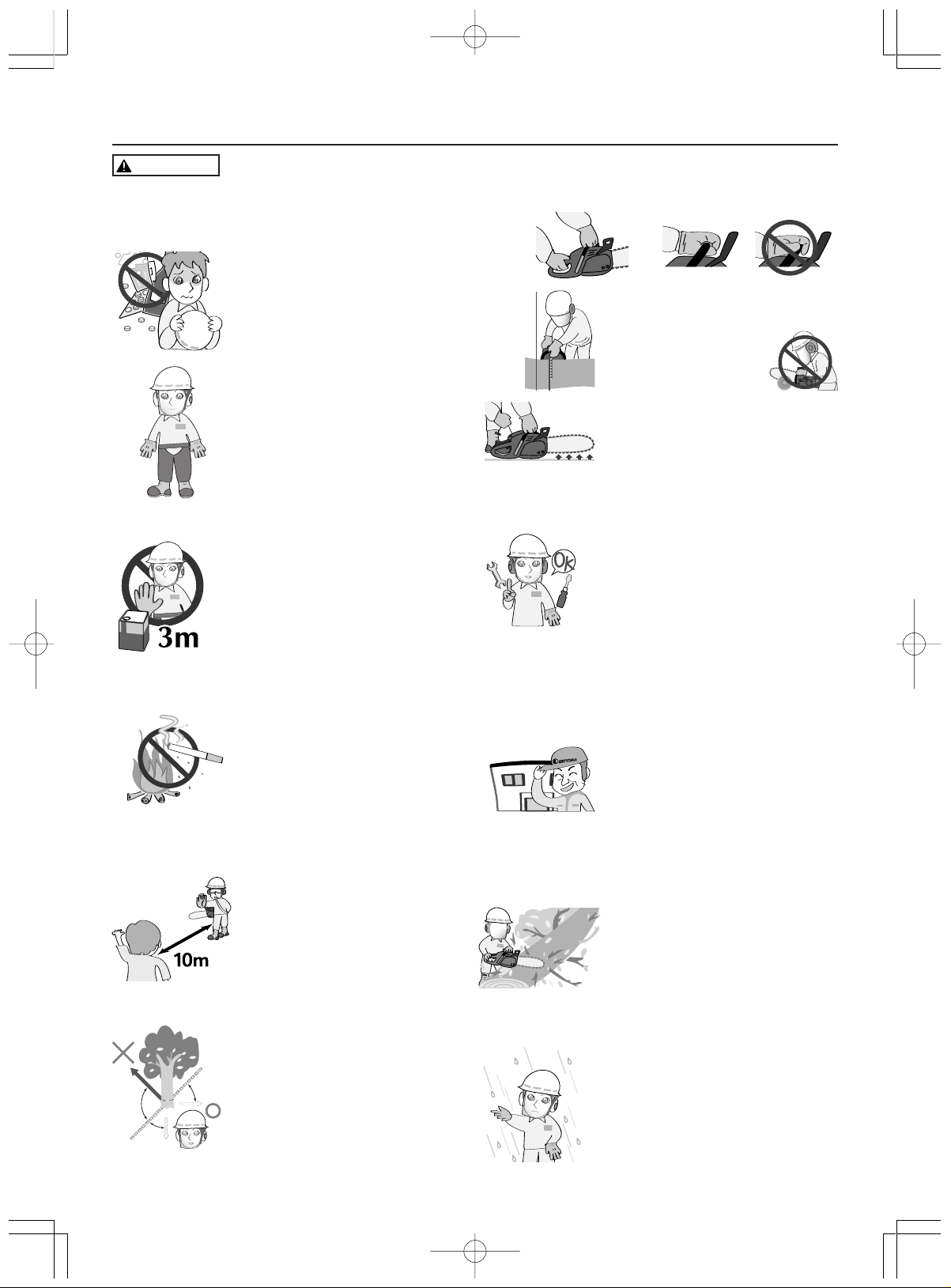

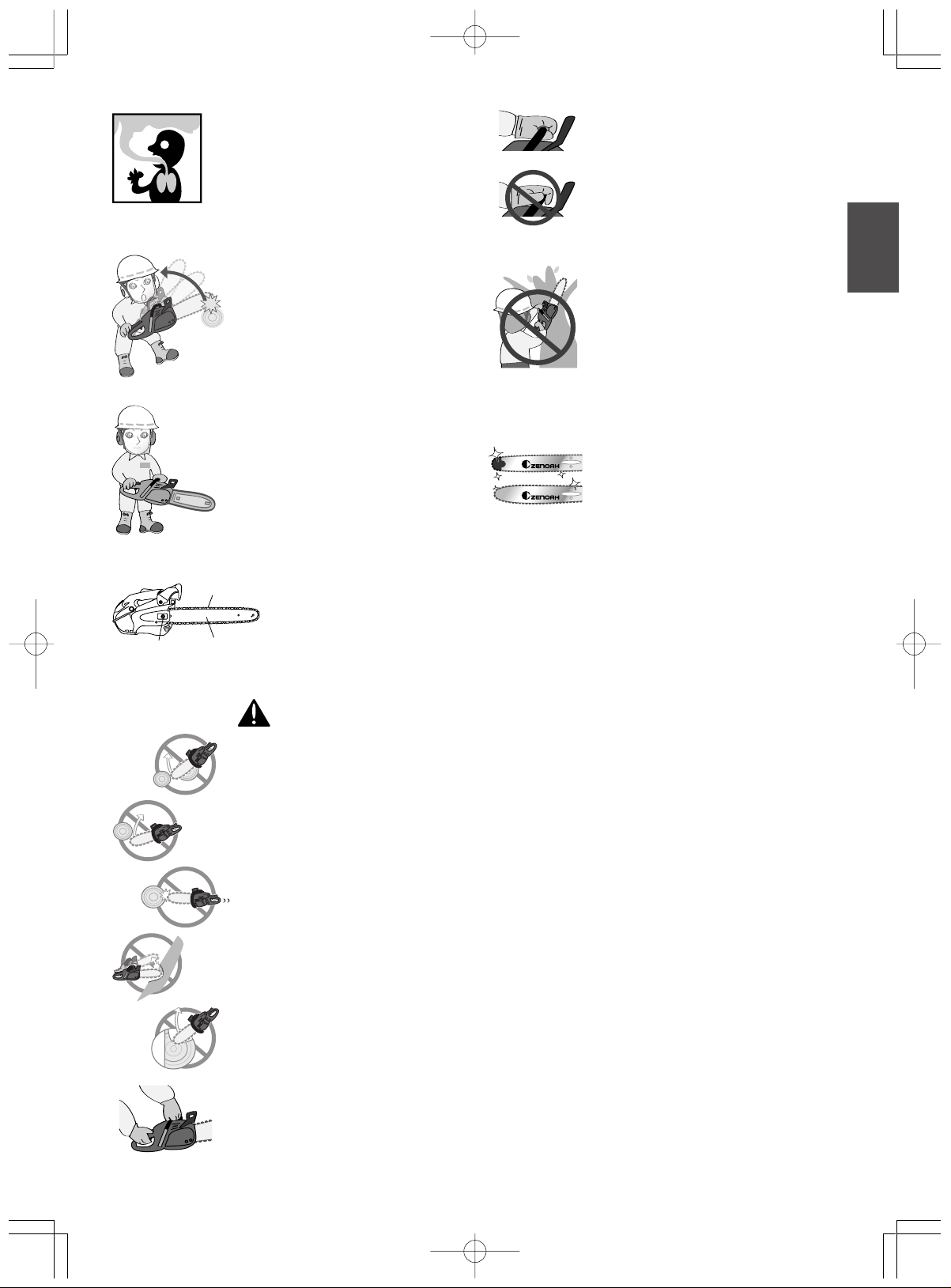

1. For safe operation

WARNING

This chainsaw has been especially designed for tree

maintenance and should therefore only be used by

trained operators when working on trees.

1. Never operate a chain saw when you

are fatigued, ill, or upset, or under the

influence of medication that may

make you drowsy, or if you are under

the influence of alcohol or drugs.

2. Use safety footwear, snug fitting

clothing and eye, hearing and head

protection devices.

Use the vibration-proof glove.

3. Keep the saw chain sharp and the

saw, including the AV system, well

maintained. A dull chain will increase

cutting time, and pressing a dull

chain through wood will increase the

vibrations transmitted to your hands.

A saw with loose components or with

damaged or worn AV buffers will also

tend to have higher vibration levels.

4. Always use caution when handling

fuel. Wipe up all spills and then move

the chain saw at least 3 m from the

fueling point before starting the engine.

5. Eliminate all sources of sparks or

flame (i.e. smoking, open flames, or

work that can cause sparks) in the

areas where fuel is mixed, poured,

or stored.

6. Do not smoke while handling fuel or

while operating the chain saw.

7. Do not allow other persons to be near

the chain saw when starting or cutting. Keep bystanders and animals

out of the work area. Children, pets

and bystanders should be a minimum

of 10 m away when you start or operate the chain saw.

8. Never start cutting until you have a

clear work area, secure footing, and

a planned retreat path from the falling tree.

9. Always hold the chain saw firmly with

both hands when the engine is running. Use a firm grip with thumb and

fingers encircling the chain saw

handles.

GB-4

10. Keep all parts of your body away from

the saw chain when the engine is running.

11. Before you start the engine, make

sure the saw chain is not contacting

anything.

12. Always carry the chain saw with the

engine stopped, the guide bar and

saw chain to the rear, and the muffler

away from your body.

13. Always inspect the chain saw before

each use for worn, Ioose, or damaged parts. Never operate a chain

saw that is damaged, improperly adjusted, or is not completely and securely assembled. Be sure that the

saw chain stops moving when the

throttle control trigger is released.

14. All chain saw service, other than the

items listed in the Owner’s Manual,

should be performed by competent

chain saw service personnel. (E.g.,

if improper tools are used to remove

the flywheel, or if an improper tool is

used to hold the flywheel in order to

remove the clutch, structural damage

to the flywheel could occur which

could subsequently cause the flywheel to disintegrate.)

15. Always shut off the engine before

setting it down.

16. Use extreme caution when cutting

small size brush and saplings because slender material may catch the

saw chain and be whipped toward

you or pull you off balance.

17. When cutting a limb that is under tension, be alert for spring- back so that

you will not be struck when the tension in the wood fibers is released.

18. Never cut in high wind, bad weather,

when visibility is poor or in very high

or low temperatures. Always check

the tree for dead branches which

could fall during the felling operation.

19. Keep the handles dry, clean and free

of oil or fuel mixture.

GZ3500T

20. Operate the chain saw only in well

ventilated areas. Never start or run

the engine inside a closed room or

building and potentially explosive atmosphere. Exhaust fumes contain

dangerous carbon monoxide.

(2) Keep a good grip on the saw with

both hands, the right hand on the rear

handle, and the left hand on the front

handle, when the engine is running.

Use a firm grip with thumbs and fingers encircling the chain saw

handles. A firm grip will help you re-

21. Do not operate the chain saw in a tree

unless specially trained to do so.

duce kickback and maintain control

of the saw.

G

B

(3) Make certain that the area in which

22. Guard against kickback. Kickback is

the upward motion of the guide bar

which occurs when the saw chain at

the nose of the guide bar contacts

an object. Kickback can lead to dangerous loss of control of the chain

saw.

you are cutting is free from obstructions. Do not let the nose of the guide

bar contact a log, branch, or any

other obstruction which could be hit

while you are operating the saw.

(4) Cut at high engine speeds.

(5) Do not overreach or cut above shoul-

der height.

23. When transporting your chain saw,

make sure the appropriate guide bar

scabbard is in place.

(6) Follow the manufacturer’s sharpening

and maintenance instructions for the

saw chain.

(7) Only use replacement bars and

24. Never touch the cover, guide bar, saw

chain or nut with bare hands while

the engine is in operation or immediately after shutting down the engine.

Doing so could result in serious burns

because of high temperature.

(2)

(3)

(1)

(1) guide bar

(2) saw chain

(3) nut

KICKBACK SAFETY PRECAUTIONS

FOR CHAIN SAW USERS

WARNING

• Kickback may occur when the nose

or tip of the guide bar touches an

object, or when the wood closes in

and pinches the saw chain in the cut.

Tip contact in some cases may cause

a lightning fast reverse

reaction,kicking the guide bar up and

back towards the operator. Pinching

the saw chain along the top of the

guide bar may push the guide bar

rapidly back towards the operator.

Either of these reactions may cause

you to Iose control of the saw, which

could result in serious personal injury.

• Do not rely exclusively on the safety

devices built into your saw. As a chain

saw user you should take several

steps to keep cutting jobs free from

accident or injury.

(1) With a basic understanding of kick-

back you can reduce or eliminate the

element of surprise. Sudden surprise

contributes to accidents.

WORSE EFFECTS OF VIBRATION

If you continue to use high-vibration tools these

symptoms will probably get worse, for example:

• the numbness in your hands could become permanent and you won’t be able to feel things at all;

• you will have difficulty picking up small objects such

as screws or nails;

• the vibration white finger could happen more frequently and affect more of your fingers.

FOR PROTECTING YOUR BODY FROM VIBRATION

Please observe the following matter, in order to protect the health of your body.

1. Always use the right tool for each job (to do the job

more quickly and expose you to less hand-arm vibration).

2. Check tools before using them to make sure they

have been properly maintained and repaired to avoid

increased vibration caused by faults or general wear.

3. Make sure cutting tools are kept sharp so that they

remain efficient.

4. Reduce the amount of time you use a tool in one go,

by doing other jobs in between.

5. Avoid gripping or forcing a tool or workpiece more

than you have to.

6. Store tools so that they do not have very cold handles

when next used.

7. Encourage good blood circulation by:

• keeping warm and dry (when necessary, wear

gloves, a hat, waterproofs and use heating pads if

available);

•giving up or cutting down on smoking because

smoking reduces blood flow; and massaging and

exercising your fingers

DISPOSAL

When disposing your machine, fuel or oil for the ma-

chains specified by the manufacturer

or the equivalent.

chine, be sure to allow your local regulations.

GB-5

GZ3500T

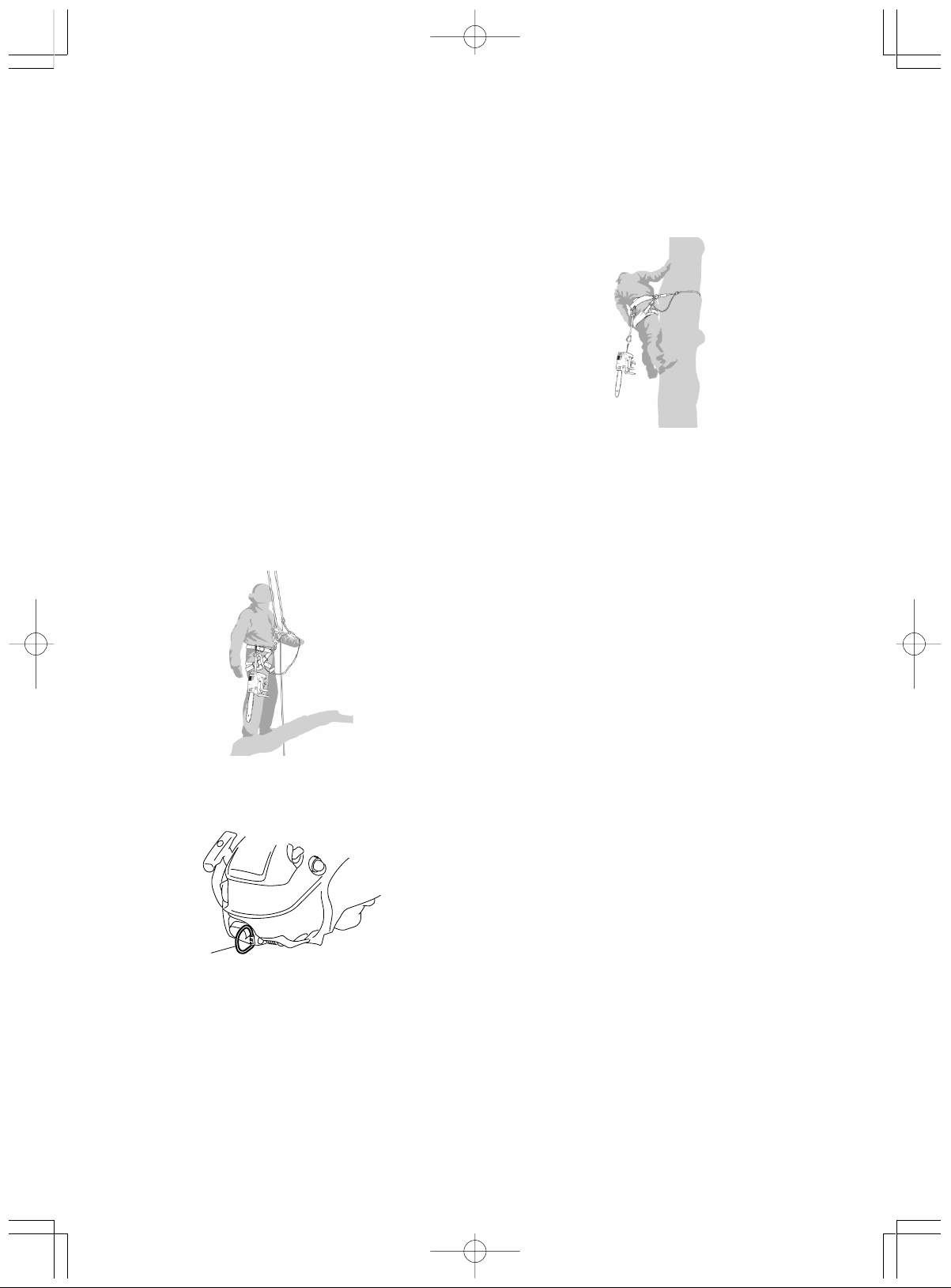

WORKING WITH TREE SERVICE CHAIN-SAWS

FROM A ROPE AND HARNESS

This chapter sets out working practices to reduce the

risk of injury from tree service chainsaws when working

at height from a rope and harness. While it may form

the basis of guidance and training literature, it should

not be regarded as a substitute for formal training.

General requirements working at height

Operators of tree service chainsaws working at height

from a rope and harness should never work alone. A

competent ground worker trained in appropriate emergency procedures should assist them.

Operators of tree service chainsaws for this work should

be trained in general safe climbing and work positioning techniques and shall properly equipped with harnesses, ropes, strops, karabiners and other equipment

for maintaining secure and safe working positions for

both themselves and the saw.

Preparing to use the saw in the tree

The chainsaw should checked, fuelled, started and

warmed up by the ground worker before it is sent up to

the operator in the tree. The chainsaw should be fitted

with a suitable strop for attaching to the operator’s harness:

a) choke the strop around the attachment point on the

rear of the saw (A);

The saw should only be attached to the recommended

attachment points on the harness. These may be at

mid-point (front or rear) or at the sides. Where possible

attaching the saw to centre rear mid-point will keep it

clear of climbing lines and support its weight centrally

down the operator’s spine.

When moving the saw from any attachment point to another, operators should ensure it is secured in the new

position before releasing it from the previous attachment

point.

Using the chainsaw in the tree

An analysis of accidents with these saws during tree

service operations shows the primary cause as being

inappropriate one-handed use of the saw. In the vast

majority of accidents, operators fail to adopt a secure

work position witch allows them to hold both handles of

the saw. This results in an increased risk of injury due

to:

• not having a firm grip on the saw if it kicks back;

•a lack of control of the saw such that it is more liable

to contact climbing lines and operators body (particularly the left hand and arm)

• losing control from insecure work position resulting

in contact with the saw (unexpected movement during operation of the saw)

Securing the work position for two-handed use

To allow the operator to hold the saw with both hands,

they should as general rule, aim for secure work position where they are operating the saw at:

• hip level when cutting horizontal sections;

• solar plexus level when cutting vertical sections.

(A)

b) provide suitable karabiners to allow indirect (i.e. via

the strop) and direct attachment (i.e. at the attachment point on the saw) of saw to the operators harness;

c) ensure the saw is securely attached when it is being

sent up to the operator;

d) ensure the saw it secured to the harness before it is

disconnected from the means of ascent.

GB-6

Where the operator is working close into vertical stems

with a low lateral forces on their work position, then a

good footing may be all that is needed to maintain a

secure work position. However as operators move away

from the stem, they will need to take steps to remove or

counteract the increasing lateral forces by, for example,

a re-direct of the main line via a supplementary anchor

point or using an adjustable strop direct from the harness to a supplementary anchor point.

Loading...

Loading...