Zenoah G620PU, G620PU-1 Owner's Manual

OWNER’S MANUAL

848H5693A3 (208)

August 2012

• Do not modify any parts of the engine.

• This engine is designed to be used to Radio

controlled products.

• In case any modification by customer,

ZENOAH shall not bear any responsibility from

the damage caused by such modification.

• Keep ignition system well maintained.

WARNING

● この製品はラジオコントロール

飛行機用に設計されています。

●改造、組み替えされて使用され

た場合当社は一切の責任を負い

ません。

● 特に電装品は常に点検、整備し

てご使用ください。

警 告

MODEL:

G620PU

G620PU-1

• This manual describes the engine. For its mounting and control, see the instruction

manual for a model plane.

• This engine is designed for use on the model plane. If it is used for any other

purpose, we cannot be responsible for its reliability or safety.

•Use genuine parts for replacement.

• Check the propeller every time. If it is damaged replace it with a new one.

• If the propeller hits something while the engine is in operation, immediately stop

the engine and check it.

•Start the engine on flat surface without pebble stones.

• Never modify the flywheel.

• Check the flywheel. If it is damaged, replace it with a new one.

• When mixing the fuel, or operating the engine, carry it out in a well-ventilated place.

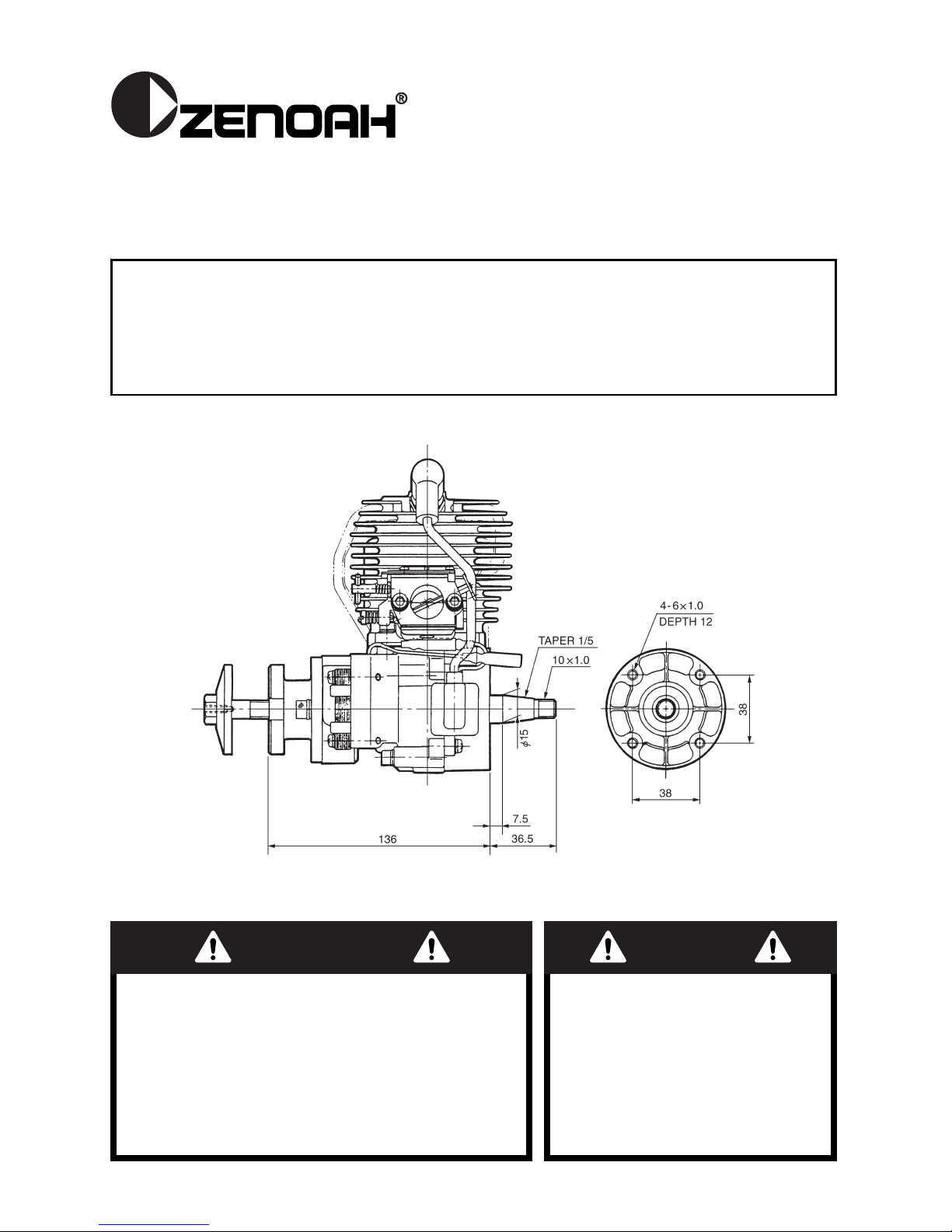

Make sure that the engine is mounted on the aircraft grade plywood with more than 10mm of

thickness or a mount of equivalent strength and is firmly fixed with 4 bolts.

[ NOTE ]

1. Be sure to set flat washers or metal plate on the reverse side of the mount to prevent

bolts from sinking into the mount. Before flying the air-plane, be sure to check for loose

bolts.

2. The mounting bolts should be screwed into the crankcase within 8 ~ 12 mm of depth.

3. Since this engine is equipped with a float-less carburetor with a diaphragm pump, the

direction of cylinder and position of fuel tank can be freely selected.

1. Recommended prop size.

The recommended prop sizes are as shown in the table bellow.

This engine produces the maximum output when the engine is running at about

8,500rpm. Be sure to use a propeller which makes the engine speed approximately

7,000 ~ 9,000rpm while the airplane is flying. When using a propeller of small diameter, a

light weight propeller is not suitable.

2. There are two types of propeller mounting bolts; L=45 and L=50. Select the proper type

of bolt depending on the thickness of propeller used and the use of the spinner.

[ NOTE ]

1. When mounting a thin propeller, cut off the end of bolt or add a flat washer.

2. When mounting the spinner, set a pin on the hub with more than 3 mm of diameter, thus

preventing slipping.

• Mix gasoline (octane over 90) and high grade 2 cycle engine oil (mixing use type; F3C

grade or ISO-L-EGC grade) at mixing ratio 25~40:1.

• The mixing ratio is according to the oil recommendation.

4. Fuel

3. Propeller

2. Mounting

1. Safety Precautions

2

Diameter x Pitch (in.)

22 x 6 ~ 8, 20 x 7 ~ 10, 18 x 8 ~ 12

[ NOTE ]

1. Gasoline may contain maximum of 10% Ethanol (grain alcohol) or up to 15% MTBE

(Methyl tertiary-butyl ether).

Gasoline containing Methanol (Wood Alcohol) is NOT approved.

2. Gasoline is very flammable. Avoid smoking, bringing any fires near fuel.

3. To prevent all possible problems on fueling system, make sure to use the fuel filter which

has more than 300 mesh or equivalent and gasoline proof rubber pipe or equivalent.

Incorrect fuel filter use causes engine trouble like carburetor's fuel passage stuffing or

piston surface scratching etc.

Hand flip start

Since the engine is equipped with the ultra compact C.D.I. type flywheel magneto ignition

system, it should be started according to the following procedure;

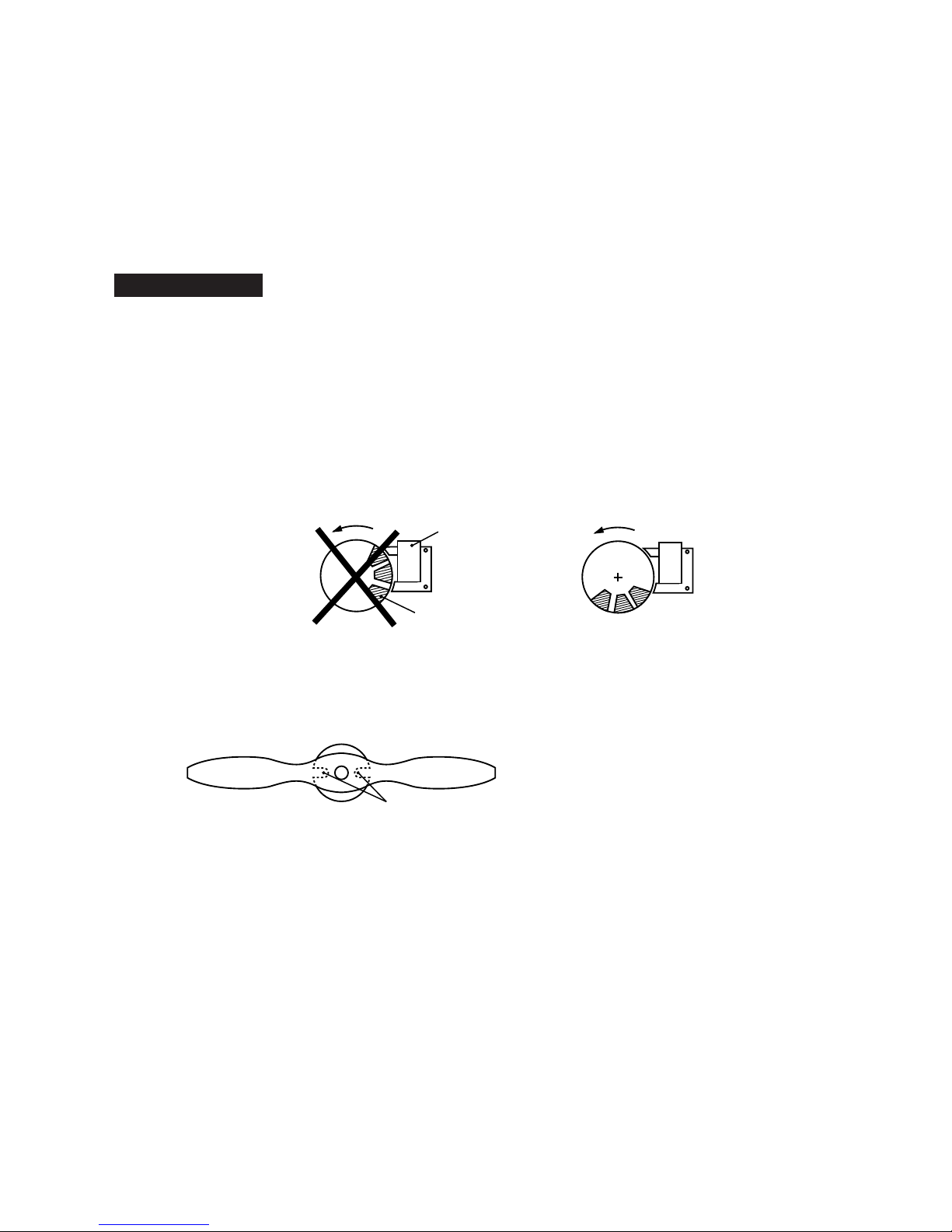

✽ The magneto system of the engine is designed in such a way that when the exhaust port

is closed by the piston, that is, when the compression stroke starts (Refer to Fig.1-A),

sparks are never produced on spark plug no matter how fast the propeller may be flipped.

Be sure to quickly flip the propeller when the edge of magnet on the rotor is approaching

the coil (Fig.1-B). It means that the propeller should be quickly flipped about 90 degrees

in crank angle before the compression is about to start.

✽ Because of the above conditions the propeller should be mounted to the hub as shown in

(Fig. 2) and quickly flipped within the range of about 180˚ from the horizontal position.

[ NOTE ]

When the engine is mounted so the cylinder is kept horizontal, the propeller should be set at

a different angle of 90˚.

How to Start the Engine

1. Fill the fuel tank with the fuel.

2. Close the choke valve and open the throttle valve approximately 1/3 ~ 1/2 of the full open

position.

3. Quickly flip the propeller in the counterclockwise direction according to the procedure

described above. When flipped several times, the sound (popping sound) of initial

explosion is heard.

4. When the initial explosion is heard, open the choke valve, set the throttle valve at the idle

position or at the position slightly open from the idle position and flip the propeller a few

more times. Then, the engine starts.

5. Operation

3

Magnet

Coil

A

Fig.1

B

Cut portion

Fig.2

The cut portions of propeller

mount and the propeller should

be set in the same direction.

Loading...

Loading...